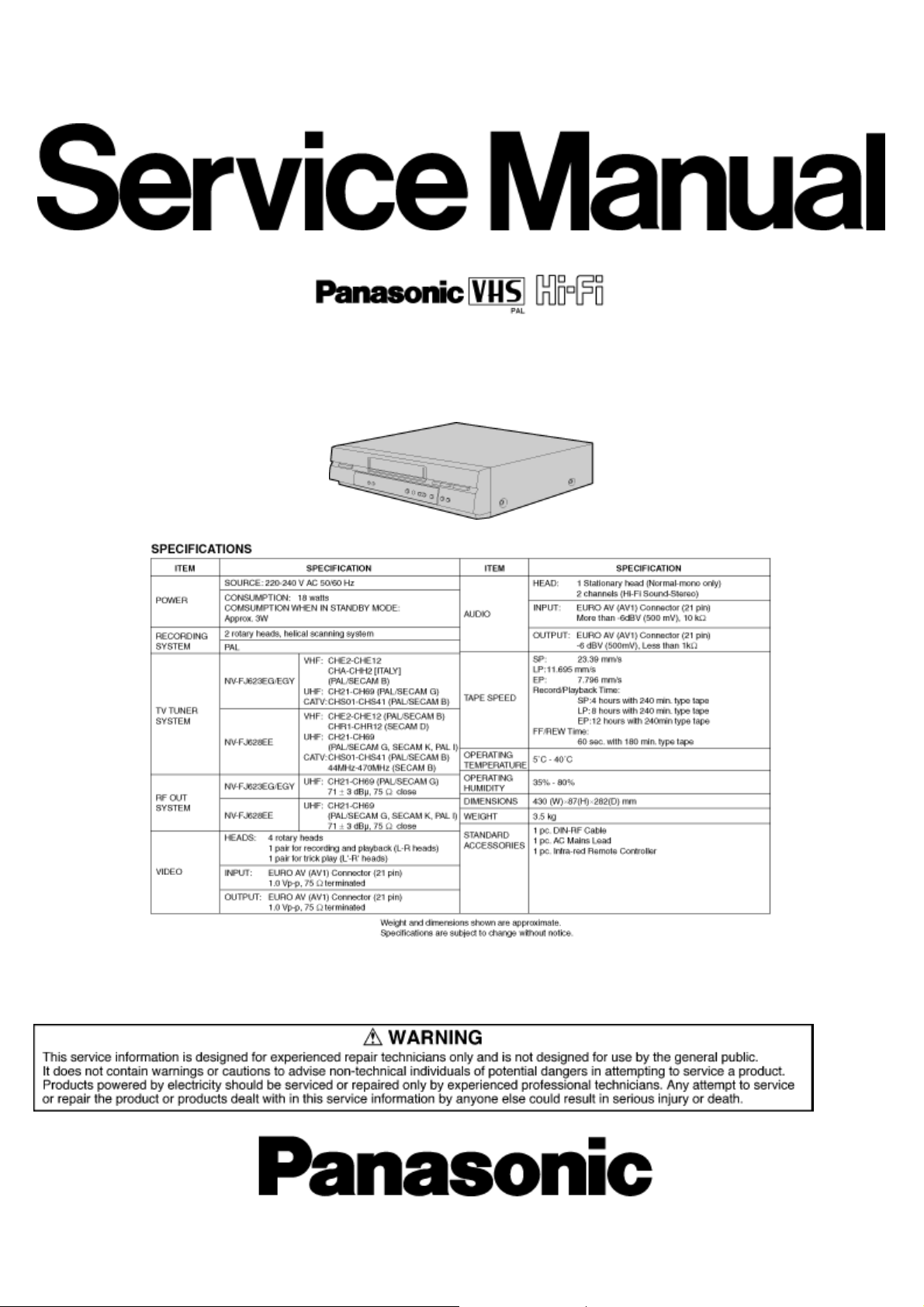

Panasonic NV-FJ623EG, NV-FJ623EGY, NV-FJ628EE Service Manual

Service Manual

ORDER NO. VRD0202004C2

Video Cassette Recorder

l NV-FJ623EG/NV-FJ623EGY/NV-FJ628EE

Z-MECHANISM

© 2002 Matsushita Electric Industrial Co., Ltd. All rights reserved. Unauthorized copying and distribution is a

violation of law.

1. INTRODUCTION

Note:

Procedures for Mechanism Chassis are separate volume from this service

The Model No. is indicated on the Schematic Diagram and Circuit Board

This service manual contains technical information which will allow service

personnel to understand and service this model.

If the circuit is changed or modified, this information will be followed by

supplementary service manual to be filed with original service manual.

1. Adjustment procedures, Disassembly Procedures and Assembly

manual./Please refer to the service manual for Z-Mechanism Chassis.

(Order No. VRD9802005C2)

2.

Diagrams as follows.

Model No. Indication Mark

NV-FJ623EG (EG)

NV-FJ623EGY

NV-FJ628EE (EE)

(EGY)

2.1.1 REPLACING IC7702/EEPROM

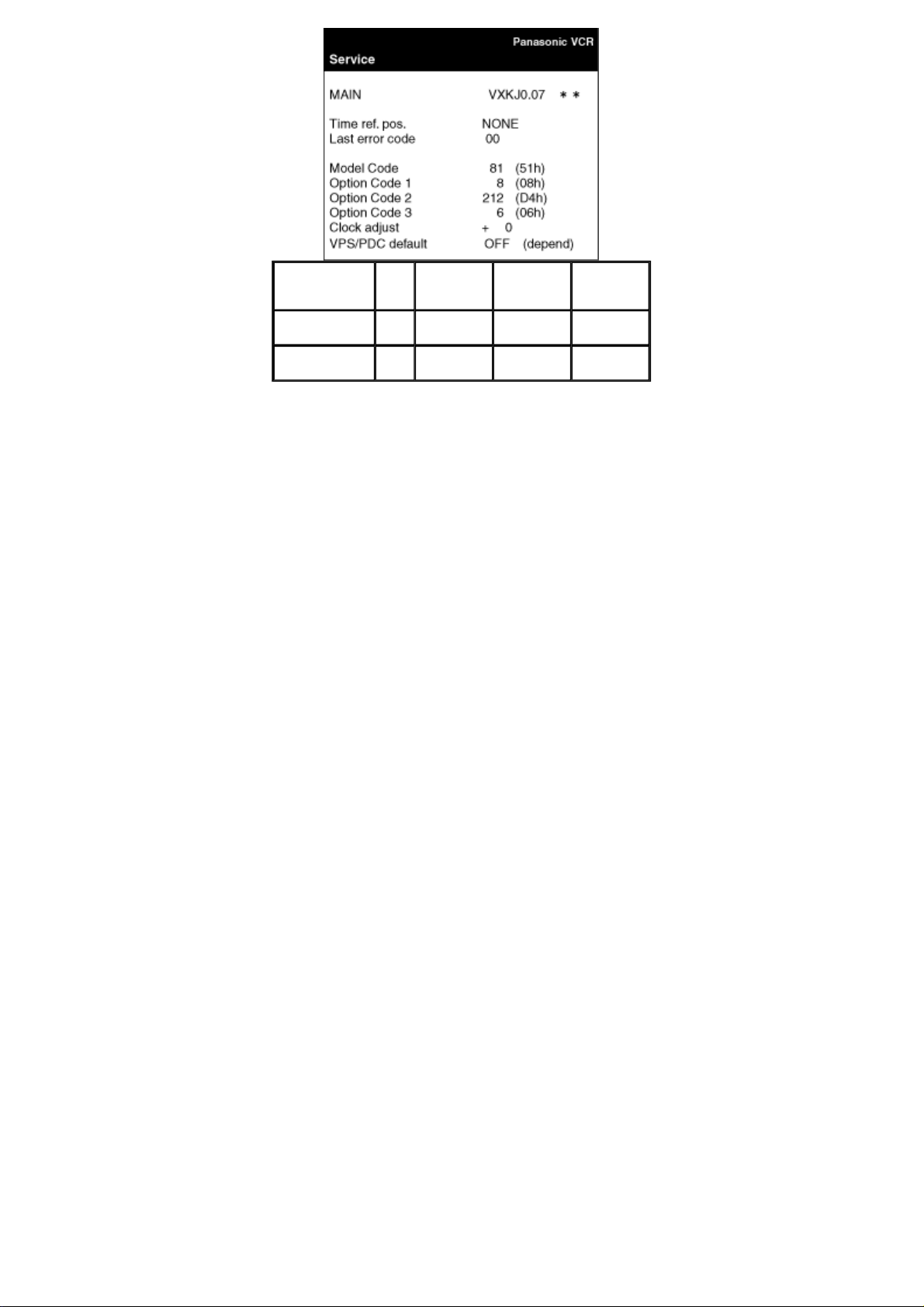

When the EEPROM: IC7702 is replaced, applicable model code, option code and electrical adjustment data will

not be available.

Therefore, enter and/or adjust the necessary data after replacing IC7702 by referring following procedure.

STEP1.REPLACE THE IC7702

1. Remove the C.B.A. with Mechanism unit by referring the Disassembly procedure.

2. Disconnect the AC plug and replace the IC7702.

STEP2.INPUT THE MODEL & OPTION CODE

1. Set up the applicable model code and option code by ordering the following table.

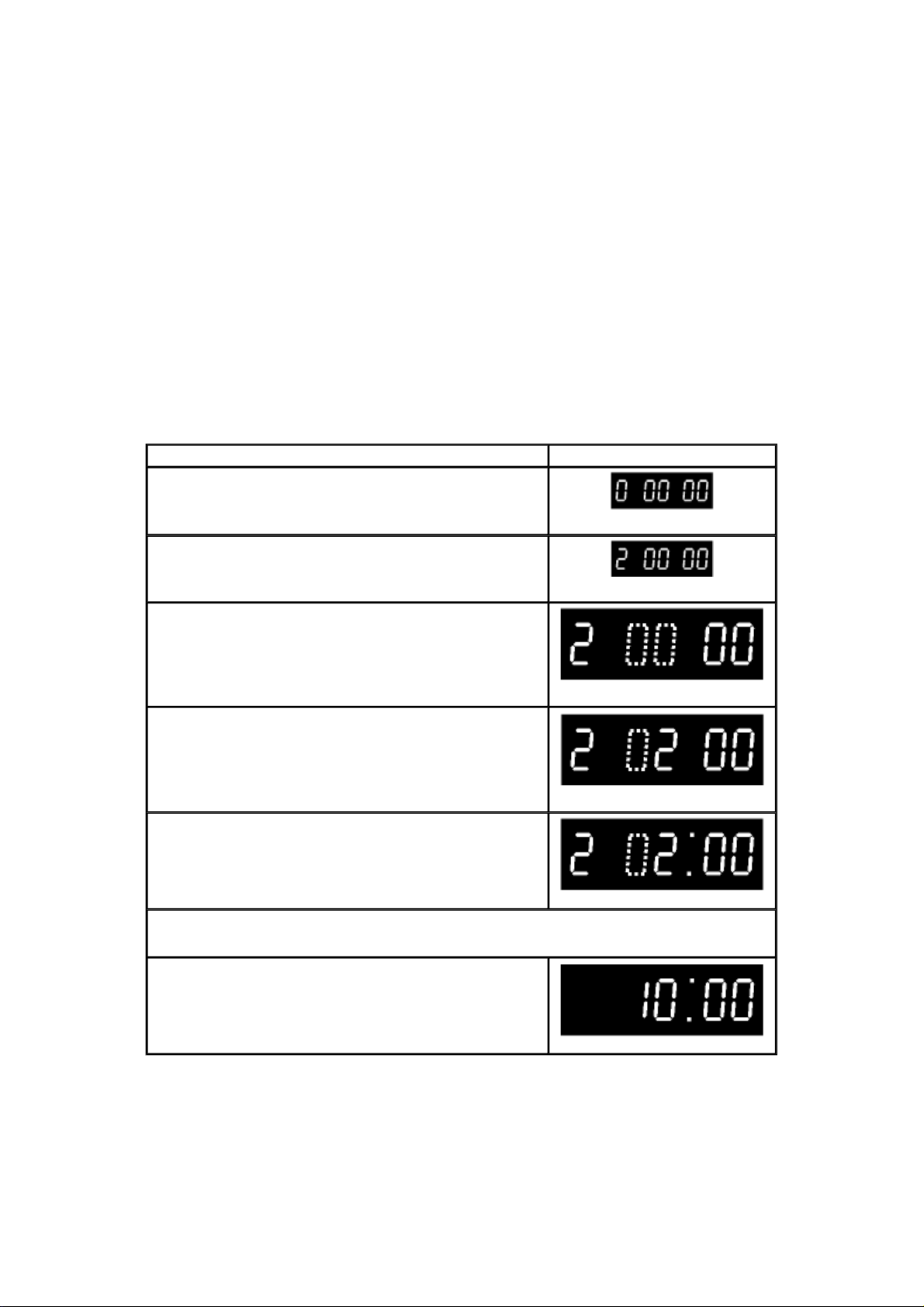

PROCEDURE F.I.P. DISPLAY

Turn on the Service Mode

1.Press the FF key and the EJECT key simultaneously for more than 3 seconds.

Activate the Service Mode 2

2.While keep placing FF key, press the EJECT key in twice.

Activate the Entering Mode.

3.Press the EJECT key for more than 3 seconds.

Set the Mode 2.

4.Press the CH UP key in twice.

Display the Setting Code.

5.Press the POWER Button to turn the power on.

(Colon starts flashing)

Enter the Model and Option Code.

6.Service Screen is displayed on the monitor.

7.Set the applicable Model and Option code by using REW, PLAY, STOP and FF keys on theRemote Controller. (See Fig.S1 & S2)

Exit from Service Mode.

8.Press the POWER Button to turn the power off.

9. Press FF and EJECT keys simultaneously in 6 times.

(Normal Indication)

Fig.S1 Service Secreen (sample)

NOTE:

Model No. Model

NV-FJ623EG/EGY 65

NV-FJ628EE 70

Option Code 1 Option Code 2 Option Code 3

Code

(41h)

(46h)

Fig. S2 Model Code & Option Code

125

(7Dh)

121

(79h)

196

(C4h)

196

(C4h)

6

(6h)

6

(6h)

Since all electrical adjustments data is still not available, perform the Electrical Adjustment continuously.

2.1.2 CYLINDER UNIT REPLACEMENT

1. CYLINDER UNIT REPLACEMENT

A. Remove the mechanism unit from MAIN C.B.A./Chassis by referring “SECTION 2. Disassembly

Procedure”.

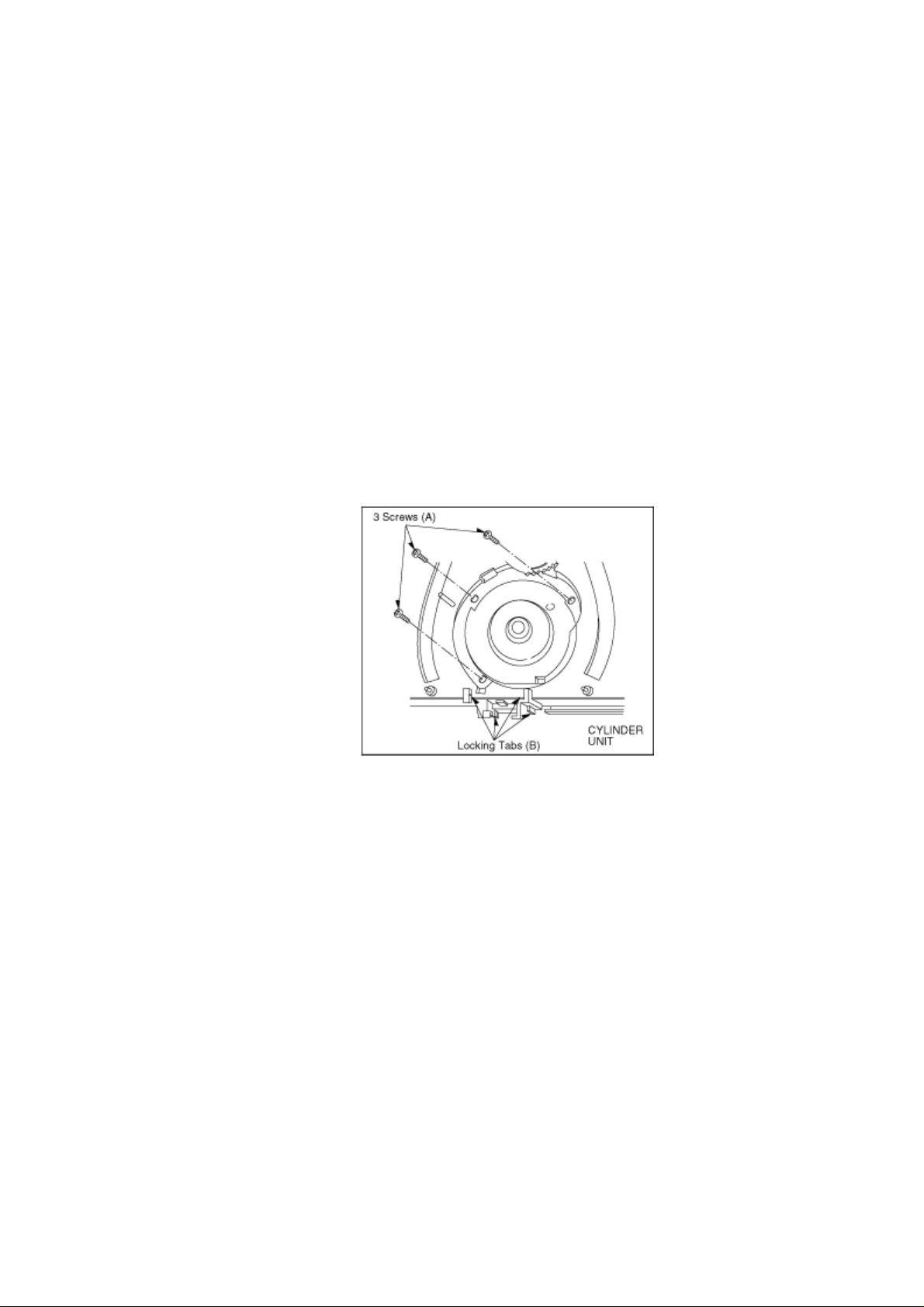

B. Remove the 3 screws (A) of the CYLINDER UNIT with a screw driver.

C. Unlock the 4 locking tabs (B) and disconnect the Cylinder flexible card from the FPC Holder.

D. Remove the CYLINDER UNIT.

CAUTION:

Handle the Cylinder flexible card with care. When it damaged, you should replace whole Cylinder

unit.

Fig. S3

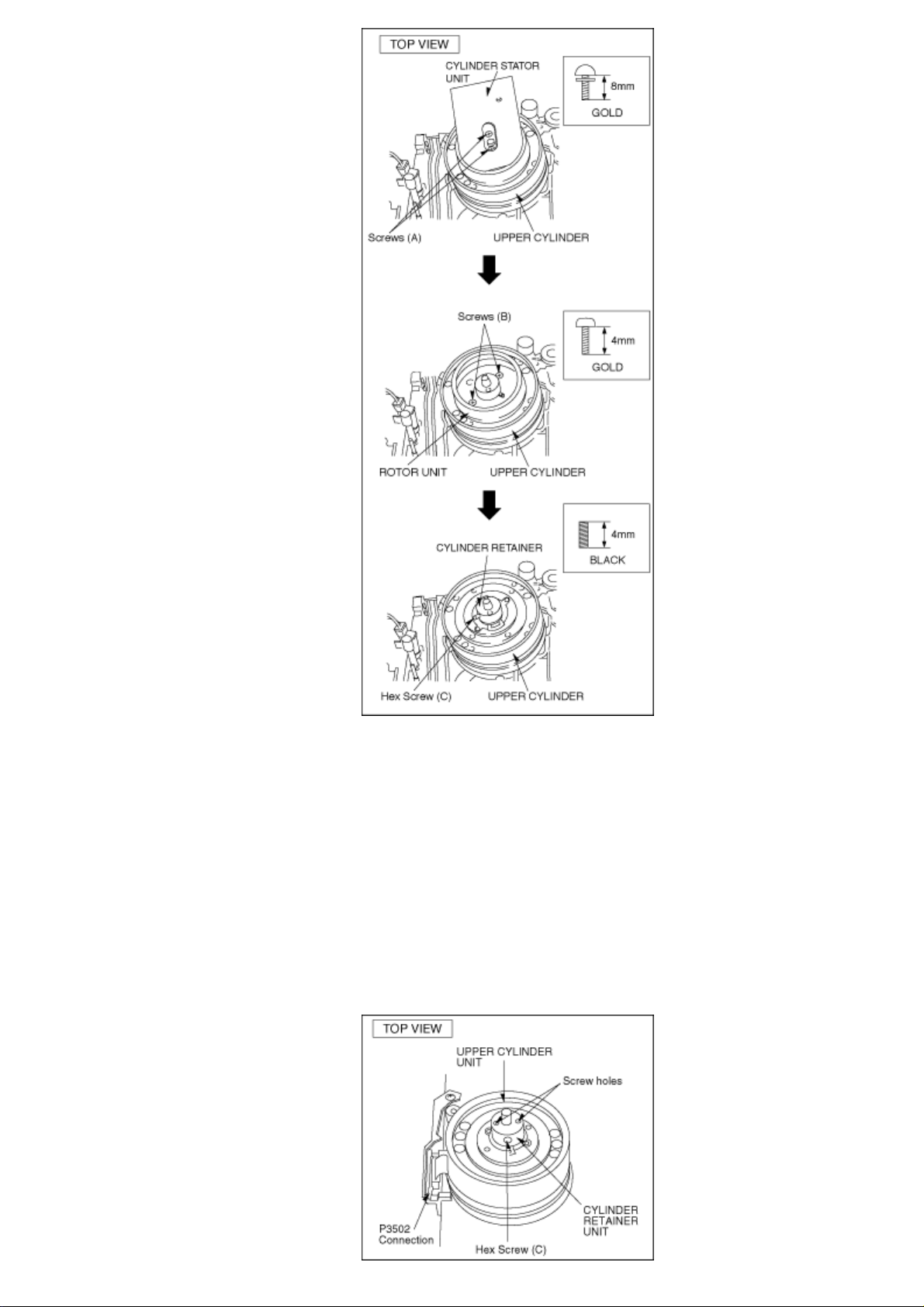

2. UPPER CYLINDER DISASSEMBLY

A. Remove 2 screws (A).

B. Remove the Cylinder Stator Unit.

C. Remove 2 screws (B).

D. Remove the Cylinder Rotor Unit.

E. Loose Hex screw (C) (1.5 mm) and remove the CYLINDER RETAINER.

F. Remove the Upper Cylinder.

Fig. S4

3. UPPER CYLINDER ASSEMBLY

When reassembling, perform the steps in the reverse order.

Notes:

A. Install the Cylinder Retainer so that the 2 holes on top of the Cylinder Retainer are at right angles

with the P3502 Connection.

B. Tighten the Hex screw (C) (1.5 mm) while pressing down on top of the Cylinder Retainer.

Fig. S5

C. Install the Cylinder Rotor Unit so that the inner hole of the Cylinder Rotor Unit fits to the small

projection (D) on top of the Upper Cylinder.

D. Tighten 2 screws (B).

Fig. S6

E. install the Cylinder Stator Unit.

F. Tighten 2 screws (A).

Fig. S7

G. Confirm the PG SHIFTER ADJUSTMENT with the alignment tape (PAL: VFJ8125H3F) and adjust

it if necessary.

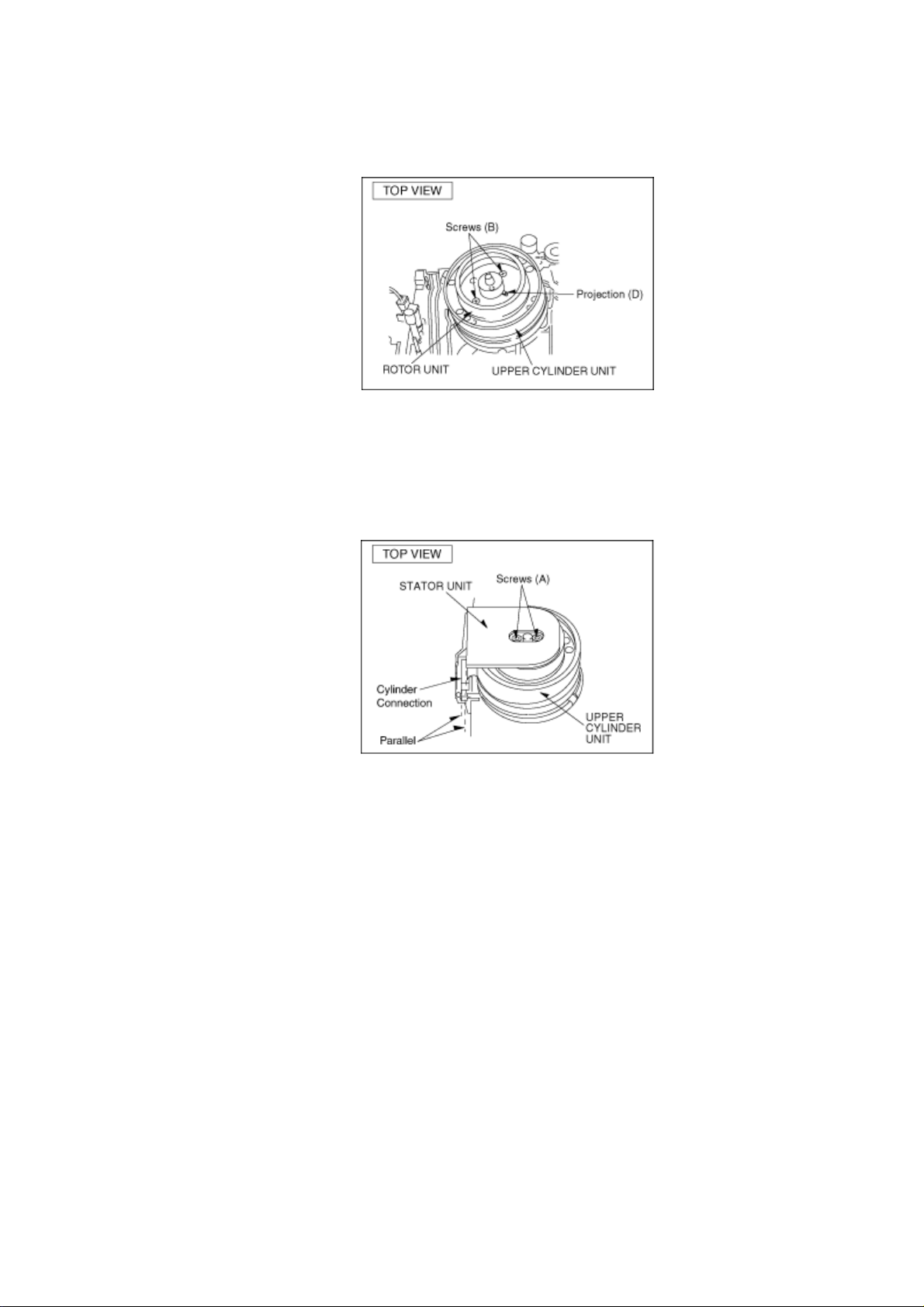

2.1.3 CHECKING OF MAIN C.B.A.

When servicing the MAIN C.B.A., take out the MAIN C.B.A. and mechanism from the frame and turn over.

Fig. S8

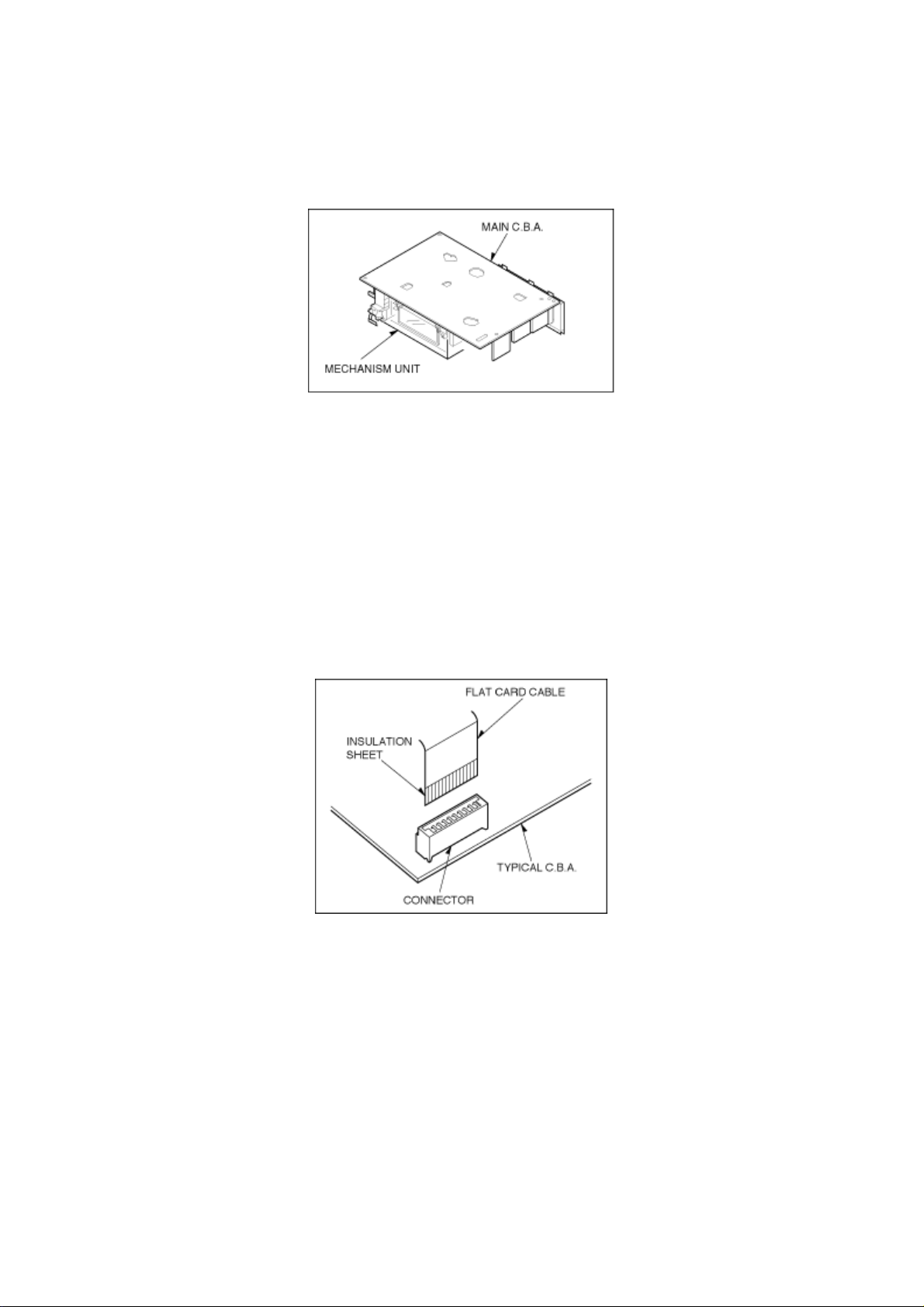

2.1.4 FLAT CARD CABLE INSTALLATION

When installing the Flat Card Cable on the connector, install the Flat Card Cable with the cable contacts facing

the connector contacts.

Fig. S9

2.2 REMOVAL OF CASSETTE TAPE

There are 2 ways to remove a cassette tape.

1. Service Information Display Operation

A. Press the FF and EJECT keys simultaneously for 3 seconds and set the Service Mode 7.

B. Press STOP key in order to rotate the Loading Motor for unloading operation. (Pay an attention of

tape slack)

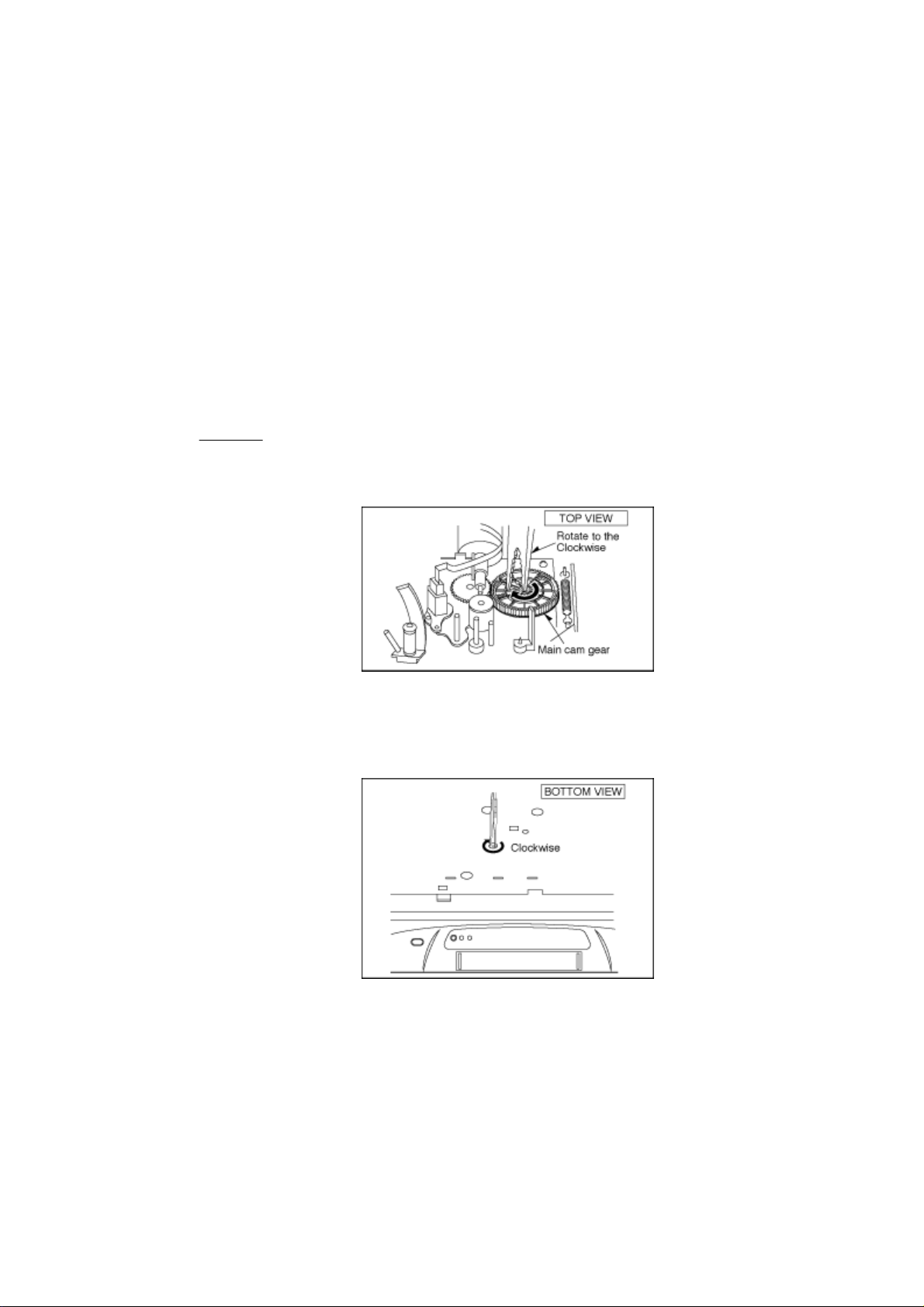

2. Manual Operation

A. Disconnect the AC Mains Lead and remove the Top Panel.

B. Rotate the Main Cam Gear clockwise until the Loading Posts move to fully unloaded position as

shown in Fig. S10 . (Tape is remaining)

Fig. S10

C. Rotate the Capstan Motor clockwise from the bottom side to take up the tape.

Fig. S11

D. Rotate the Main Cam Gear clockwise until the cassette tape is ejected.

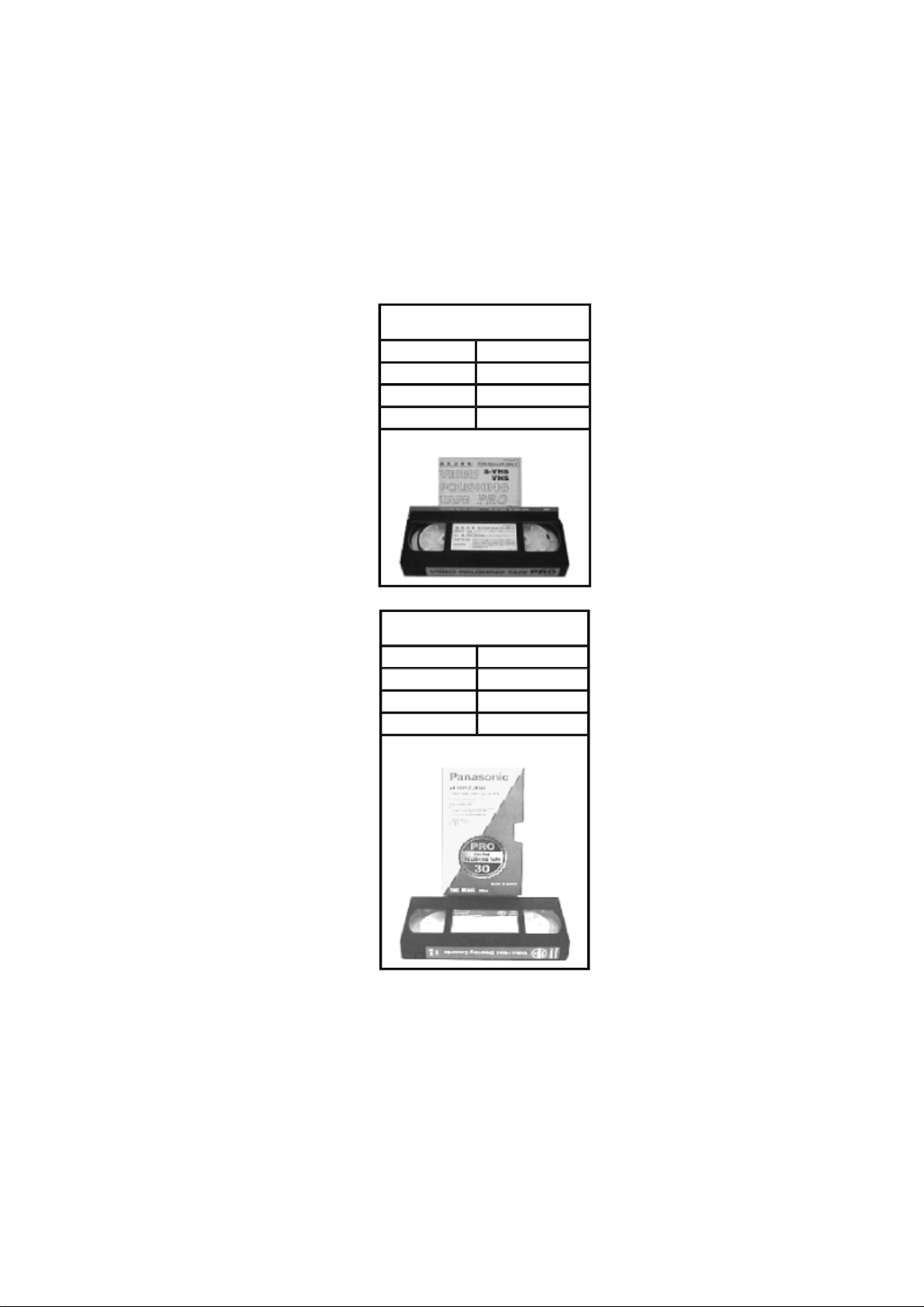

2.3 INTRODUCTION OF VIDEO HEAD CLEANING CASSETTE/

(POLISHING TYPE)

1. We are pleased to introduce Panasonic Video Head Cleaning Cassette, VFK0923FT [for service purposes]

and VFK0923FSE [ for end users] for all VHS/SVHS VCP and VCR.

2. These cleaning cassettes are exclusive removing the hard and sticky clogging on video heads.

3. These improve the efficiency of video head cleaning service and shortening cleaning time for end users.

VFK0923FT

(For Service usage)

Type of Cassette Full VHS Cassette

Cleaning Time 10 Seconds/Time

Tape Length 20 m

Usability in a Path 180 Times

Note:

VFK0823FSE

(For end users)

Type of Cassette Full VHS Cassette

Cleaning Time 10 Seconds/Time

Tape Length 3.34 m

Usability in a Path 30 Times

The tape material itself is the same in both types.

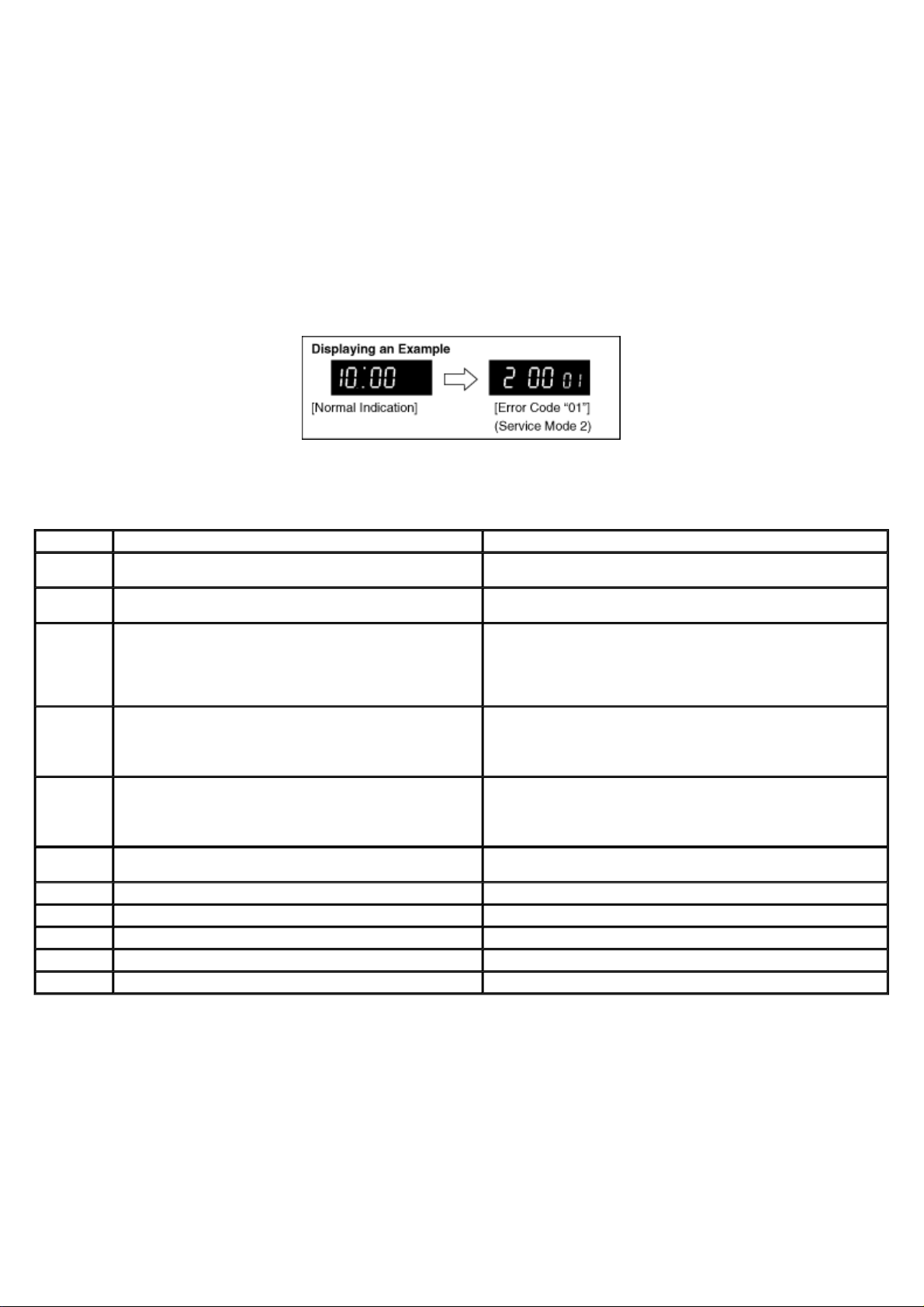

2.4 SELF-DIAGNOSIS RESULT DISPLAY

The "SELF-DIAGNOSIS RESULT DISPLAY & MEMORY function is built in this VTR.

It means that when the VCR detects undesirable condition, it can be displayed a “Error code (Two numbers from

the right)” with Service Mode 2.

Since the "Error code" is stored in the EEPROM, it can be displayed although after disconnected the AC leads. It

can be displayed with Service Mode 2.

(If a second error had been detected, only the most recent error is displayed. )

For more details, refer to the Service Manual for Z-Mechanism Chassis Order number VRD9802005C2.

Fig. T1 Self-Test indication Display

INDICATION

01 After cylinder lock is detected, the cylinder does not start rotating again

even after tape unloading.

02 Cassette tape is not wound up during the tape unloading except EJECT

mode.

03 Mechanism locks during mode transition except EJECT mode. 1. Check the loading motor drive circuit.

04 Mechanism locks during tape unloading. 1. Check the loading motor drive circuit.

06 Mechanism locks after tape unloading in EJECT mode. 1. Check the loading motor drive circuit.

07 During recording mode, recording signal is less than the normal condition. Protection of the over-current flowing in transistor which produces the power

08 Recording circuit works except recording mode. Check the recording circuit.

16 Cylinder lock detection. Check the cylinder unit and the cylinder motor drive circuit.

17 Supply reel mechanism lock detection Check the supply reel mechanism and the supply reel circuit.

18 Take-up reel mechanism lock detection Check the Take-up reel mechanism and the Take-up reel circuit.

2* PG shifter automatic adjustment error. Check the servo/system control circuit and the cylinder unit.

CAUSE REMEDY/CHECK

Check the cylinder motor drive circuit.

Check the capstan motor drive circuit.

2. Check the mechanism phase alignment.

3. Check the mode switch.

2. Check the mechanism phase alignment.

2. Check the mechanism phase alignment for cassette holder unit.

supply for recording mode.

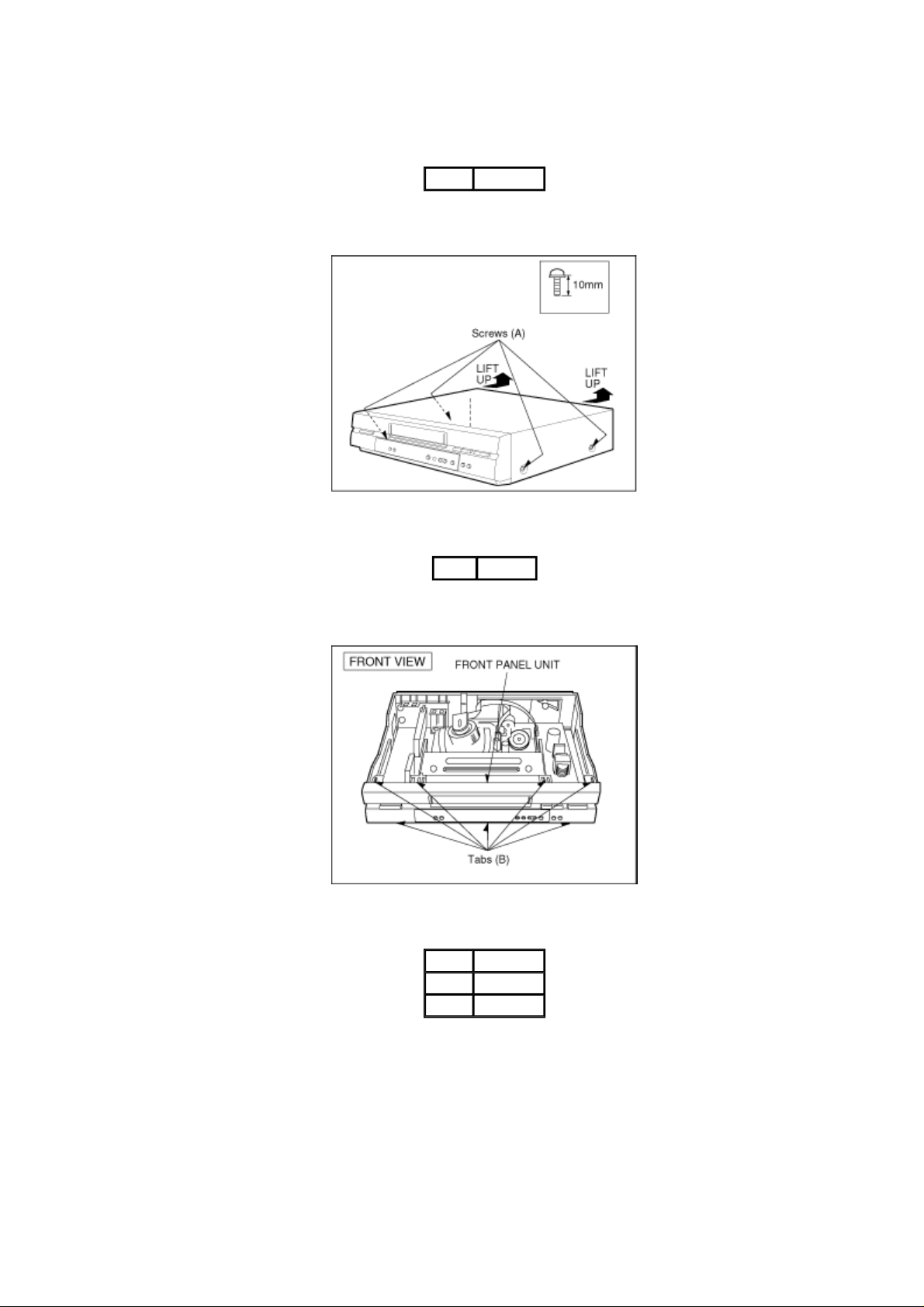

3.1.1 DISASSEMBLY FLOW CHART

This flow chart indicates disassembly steps of the cabinet parts and the circuit boards in order to find the

necessary items for servicing.

When reassembling, perform the steps in the reverse order.

Fig. D1

3.1.2 DETAIL OF DISASSEMBLY METHOD

1. REMOVAL OF THE TOP PANEL

Remove 4 Screws (A)

Fig.D2

2. REMOVAL OF THE FRONT PANEL UNIT

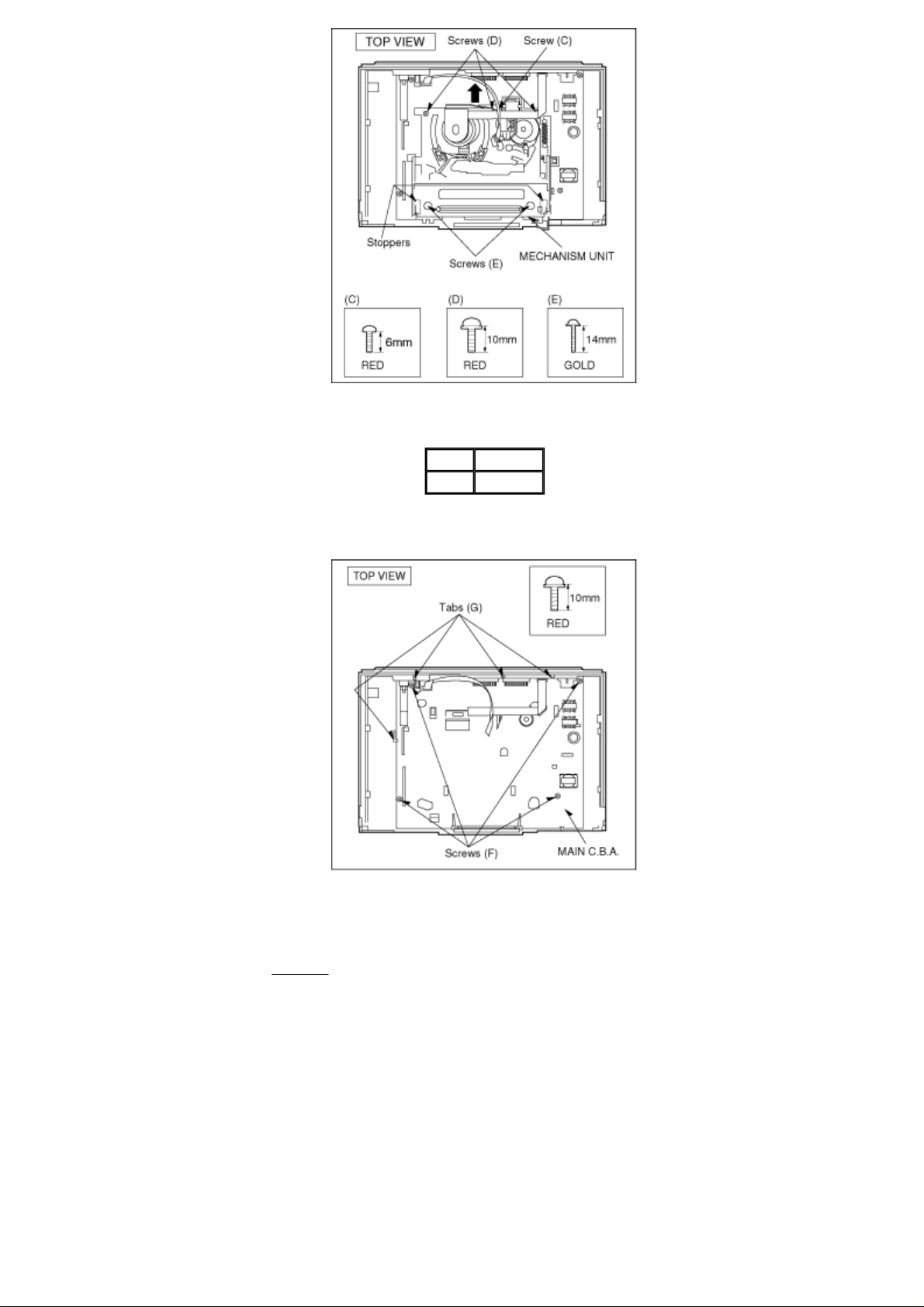

3. REMOVAL OF THE MECHANISM UNIT

Unlock 7 Tabs (B)

Fig. D3

Remove Screw (C)

Remove 3 Screws (D)

Remove 2 Screws (E)

Note:

A. Keep pressing 2 stoppers on Cassette Holder Plate and Press Cassette Holder Plate to the rear.

B. Remove the Mechanism Unit after bend the Cylinder Shield in the direction of the arrow.

Fig. D4

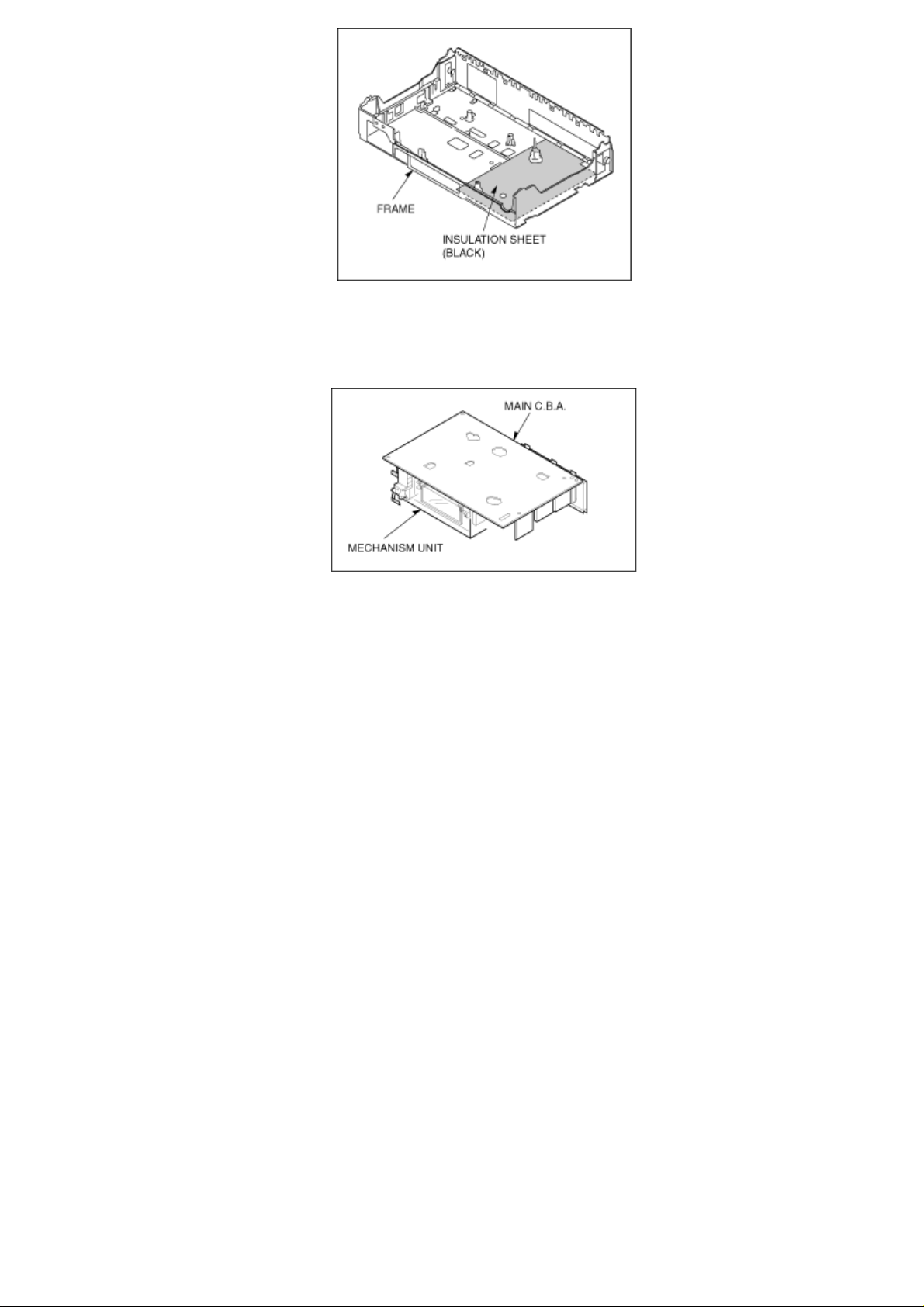

4. REMOVAL OF THE MAIN C.B.A.

Fig. D6

Remove 4 Screws (F)

Unlock 4 Tabs (G)

Fig. D5

NOTE:

Before mounting the MAIN C.B.A. onto the frame, be sure to confirm that the insulation sheet is mounted

on the frame as shown in Fig. D6 .

5. SERVICING POSITION

Fig. D7

3.2 MECHANICAL ADJUSTMENT PROCEDURES

Refer to the Service Manual for Z-Mechanism Chassis./(Order No. VRD9802005C2)

3.3.1 TEST EQUIPMENT

(Set to signal input terminal number)

The following equipments are required for Electrical Adjustments.

1. Dual-Trace Oscilloscope

¡

Voltage Range: 0.005-5V/div

¡

Frequency Range: DC-35MHz

¡

Probes: 10:1 / 1:1

2. Frequency Counter

¡ Frequency Range: 0-10MHz

¡

Probes: 1:1

3. Universal Counter

4. Digital Volt Meter (D.V.M.)

5. Video Sweep Generator

6. Sinewave Generator

7. Video Pattern Generator

8. Monitor TV

9. DC Power Supply

10. VHS Blank Tape

11. VHS Alignment Tape

¡

Parts No.: VFJ8125H3F(PAL)

3.3.2 VCR SETTING

When no indication in the procedure, set each selector as follows:

1. TAPE SPEED: SP

2. CHANNEL: AV1

3.3.3 ADJUSTMENTS

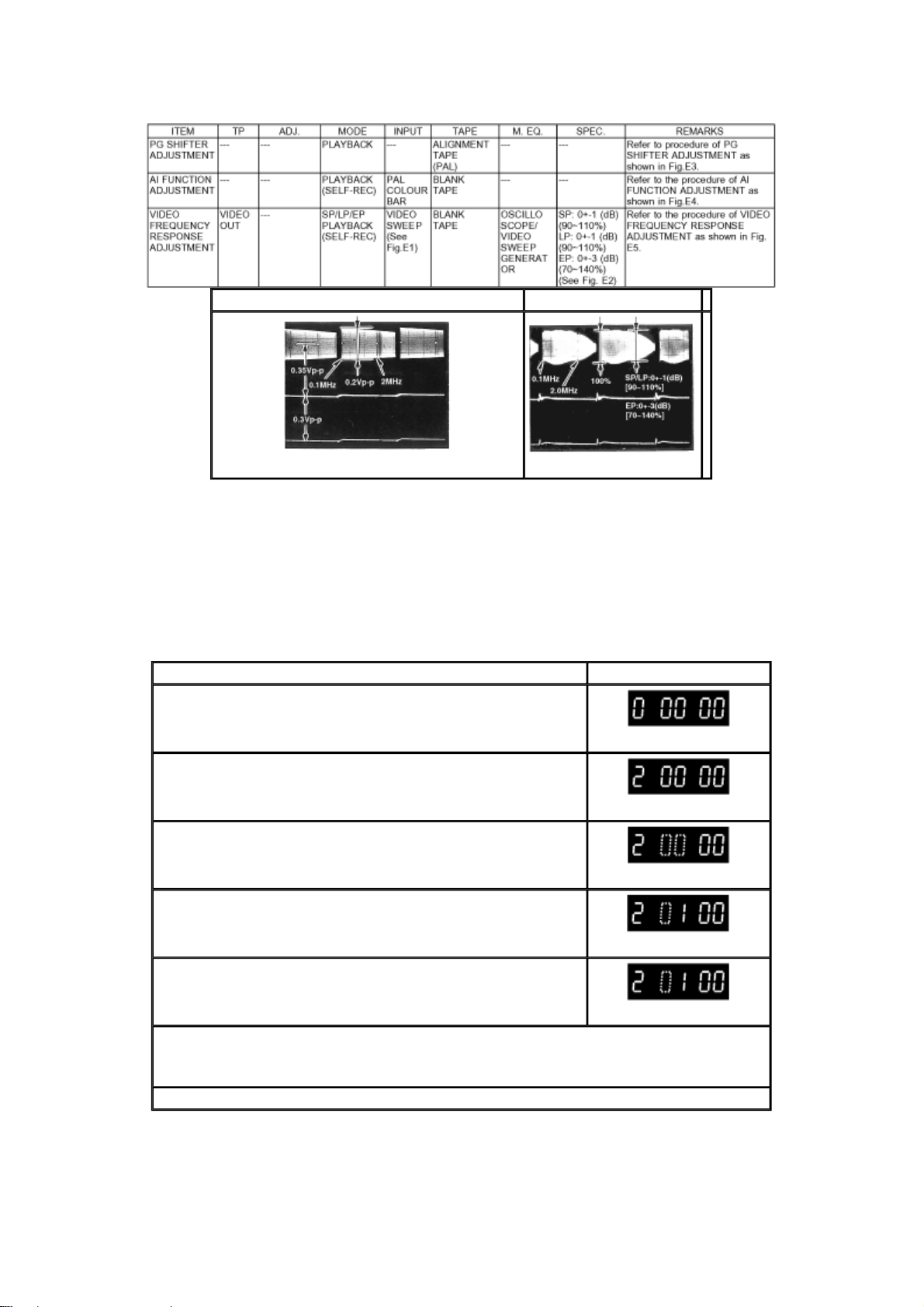

Fig.E1 Fig.E2

CONDITION: BURST SIGNAL OFF / 75 ohm TERMINATED

3.3.4 PG SHIFTER ADJUSTMENT/(AUTOMATIC)

PROCEDURES FIP DISPLAY

Press the FF and EJECT Keys

simultaneously for 3 seconds.

Press the FF and EJECT Keys

simultaneously twice.

Press the EJECT key for 3 seconds.

Press the CH UP key once.

Insert the Alignment cassette tape. (PAL:VFJ8125H3F)

When the sequence of the automatical adjustment has been terminated, the following action has been made.

*SUCCEED: The cassette tape is ejected.

*ERROR : The "F2"is displayed on the FIP.

(Check the Servo/Syscon circuit and Cylinder unit.)

Release the Service mode by pressing the EJECT and FF keys simultaneously in 6 times until the FIP becomes normal indication.

Fig. E3

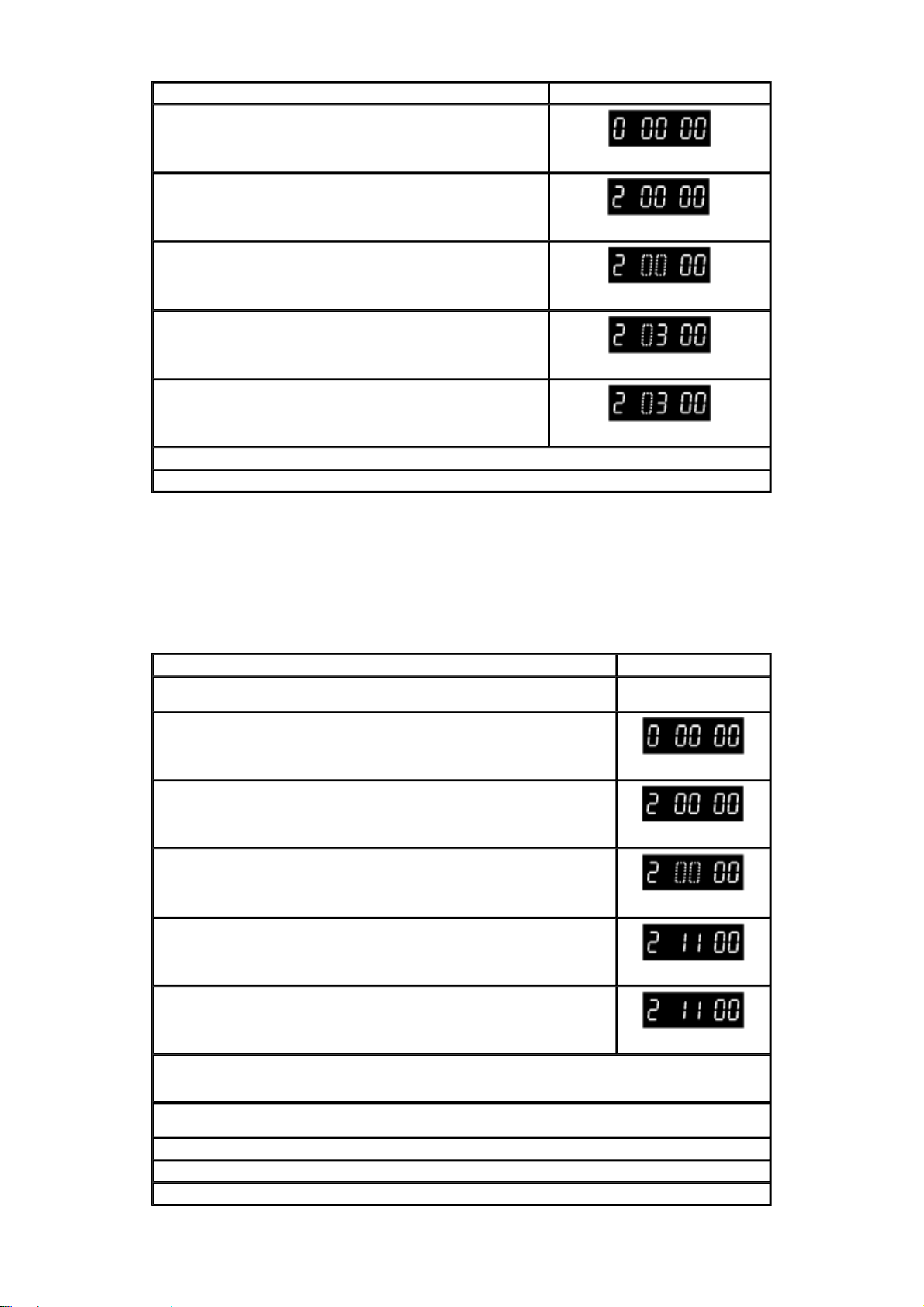

3.3.5 AI FUNCTION ADJUSTMENT (AUTOMATIC)

PROCEDURES FIP DISPLAY

Press the FF and EJECT Keys

simultaneously for 3 seconds.

Press the FF and EJECT Keys

simultaneously twice.

Press the EJECT key for 3 seconds.

Press the CH UP key in 3 times.

Insert the blank cassette tape.

(The adjustment is automatically started.)

When the sequence of the automatical adjustment has been terminated successfully, the VCR goes to STOP mode.

Release the Service mode by pressing the EJECT and FF keys simultaneously in 6 times until the FIP becomes normal indication.

Fig. E4

3.3.6 VIDEO FREQUENCY RESPONSE ADJUSTMENT

PROCEDURES FIP DISPLAY

Input the Video sweep signal.

(See Fig.E1)

Press the FF and EJECT Keys

simultaneously for 3 seconds.

Press the FF and EJECT Keys

simultaneously twice.

Press the EJECT key for 3 seconds.

Press the CH UP and/or CH DOWN key until "11" is displayed on FIP.

Insert the Self-recorded tape and playback it. (SP/LP/EP mode)

Connect the Oscilloscope to:

*CH1....Video Out (TW3002).

*CH2....V.FREQ.(TW6002)

Press the "4" key on the remote controller.

(Confirm that TW6002 becomes high(5V)).

Adjust the Frequency response by pressing the "2"(increase) and/or "8"(decrease) key on the Remote Controller. (See Fig.E2)

Store the Adjusted value by pressing the "5" key on the Remote Controller.

Release the Service mode by pressing the EJECT and FF keys simultaneously in 6 times until the FIP becomes normal indication.

Fig. E5

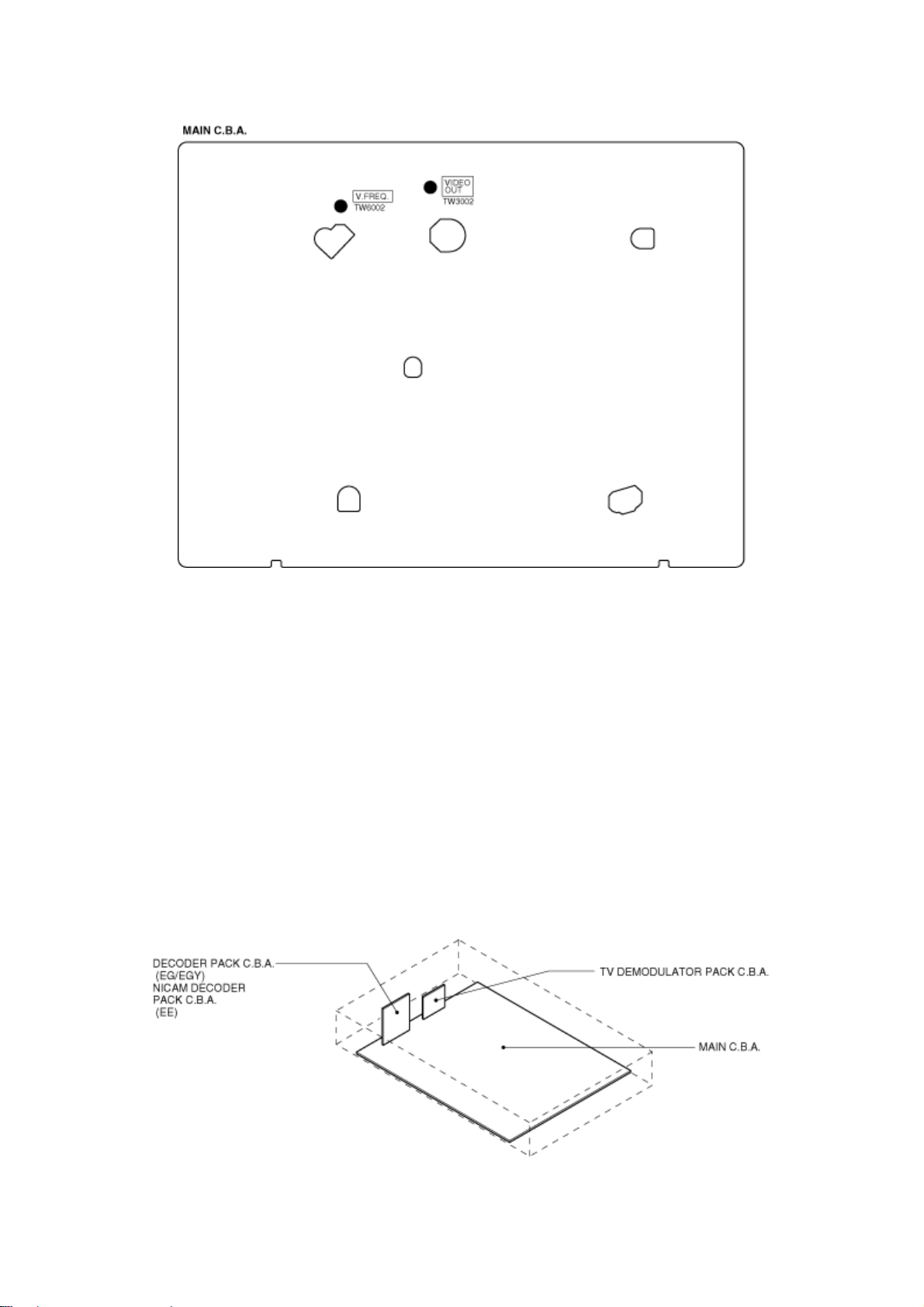

3.3.7 LOCATION OF TEST POINTS& CONTROLS

3.3.8 CIRCUIT BOARD LAYOUT

443NT [L]

A. COMP

A. COMPO

A. D.P [L]

A. D/L [L]

A. DEF [S]

A. DEF [S] [L]

A. DUB P [L]

A. DUB [H]

A. ERASE

A. H. SW

A. HEAD [R]

A. HEAD [W]

A. IN [L]

A. IN [R]

A. MUT [H]

A. MUTE [H]

A. OUT [L]

A. OUT [R]

A. RF OUT

A/VS/S. DATA

AC ONLINE

AC. O/EE. H

AFC S C

AFC [S]

AFC. DEF

ARFC OUT

ART. V

ART. V. MM

ART. V/H/N

AT. V/H/N

ATSW/TEST/NOR/SE

AUDIO IN [L]

AUDIO IN [R]

AUDIO OUT [L]

AUDIO OUT [R]

AUDIO SELECT [H]

AUDIO. L

AUDIO. R

AV CNT

AV CTL

AV CTL/S. CLK

AV. C.M.

AVCNT/METER. R

AVSW/METER. L

B MODE. H

B.G.P

BACKUP 5V

BAND. U.E.

BANDVL. D

BI/MI [L]

4.43 NTSC

AUDIO COMPONENT SIGNAL

AUDIO COMPONENT SIGNAL

AUDIO DUBBING PAUSE

AUDIO DUBBING PAUSE L

AUDIO DEFEAT

AUDIO DEFEAT

AUDIO DUBBING PAUSE

AUDIO DUBBING H

AUDIO ERASE

AUDIO HEAD SWITCHING PULSE

AUDIO HEAD (REC)

AUDIO HEAD (PLAY)

AUDIO INPUT (L)

AUDIO INPUT (R)

AUDIO MUTE

AUDIO MUTE H

AUDIO OUTPUT (L)

AUDIO OUTPUT (R)

AUDIO RF SIGNAL OUTPUT

AV SW/SERIAL DATA

AC ONLINE

AC ONLINE/EE

AFC S CURVE

AFC S CURVE

AFC DEFEAT

AUDIO RF SIGNAL OUTPUT

ARTIFICIAL VERTICAL SYNC SIGNAL

ARTIFICIAL VERTICAL SYNC

SIGNAL MONO MULTI

ARTIFICIAL VERTICAL SYNC

SIGNAL

ARTIFICIAL VERTICAL SYNC SIGNAL

TEST/NORMAL/SERVICE

AUDIO INPUT (L)

AUDIO INPUT (R)

AUDIO OUTPUT (L)

AUDIO OUTPUT (R)

AUDIO SELECT

AUDIO (L)

AUDIO (R)

AV CONTROL

AV CONTROL

AV CONTROL/SERIAL CLOCK

AV CONTROL MODE

AV CONTROL/LEVEL METER (R)

AV SW/LEVEL METER (L)

B MODE

BURST GATE PULSE

BACK UP 5V

BAND U

BAND VL

BILINGUAL/MIX

L

L

L

H

H

H/NORMAL

H

H

L

BIL

BIL [L]

BIL. [H]

BIL/M1 [L]

BS CLOCK

BS DATA

BS LCH IN

BS MIX [H]

BS MON [H]

BS MONI [H]

BS RCH IN

BS VIDEO

BS VIDEO/BS1

BS [H]

BS. LEVEL

BS. M [H]

BS/VTR [H]

BUS CLK

BUS LSN

BUS TLK

BUZZER

CAP EC

CAP M GND

CAP. ET

CAP. FG1

CAP. FG2

CAS. SW

CCN

CCP

CHM

CHP

CINEM [L]

CINEMA [L]

CINEMA/MIX

CKL

CKS

CL

CLK

CLK (C.G)

CLOCK. IN

CLP

COL/B/W/NOR

COLOR [H]

CONV

CS

CTL GND

CTL HEAD [

CTL HEAD [

CTL [

CTL [

CUE BIAS

CURRENT LIM

CYL ET

+

−

]

+

]

−

BILINGUAL

BILINGUAL

BILINGUAL H

BILINGUAL L

BS CLOCK

BS DATA

BS L CHANNEL INPUT

BS MIX

BS MONITOR H

BS MONITOR H

BS R CHANNEL INPUT

BS VIDEO SIGNAL

BS VIDEO SIGNAL

BS

H

BS LEVEL

BS MONITOR

BS/VTR H

BUS CLOCK

BUS LISTEN

BUS TALK

BUZZER

CAPSTAN TORQUE CONTROL

CAPSTAN MOTOR GND

CAPSTAN TORQUE CONTROL

CAPSTAN FG1 PULSE

CAPSTAN FG2 PULSE

CASSETTE SW

PLAYBACK CONTROL SIGNAL (−)

PLAYBACK CONTROL SIGNAL (

CONTROL SIGNAL (+)

CONTROL SIGNAL (

CINEMA

CINEMA L

CINEMA/MIX

RATCH LOCK

SHIFT LOCK

CLOCK

CLOCK

CLOCK

CLOCK INPUT

CLAMP

COLOUR/BLACK & WHITE/NORMAL

COLOUR H

CONVERTOR

CHIP SELECT

CONTROL GND

]

]

CONTROL HEAD (

CONTROL HEAD (

CONTROL HEAD (

CONTROL HEAD (

CUE BIAS

CURRENT LIMMITER

CYLINDER TORQUE CONTROL

H

L

L

H

+

)

−

)

+

)

−

)

+

)

−

)

CYL GND

D.F.M. REC [H]

D. FM REC [L]

D. GND

D. REC [H]

D4/S. LED

D4/STILLED

DAC [CLK]

DAC/FSCS

DAREC [H]

DATA

DECODER [L]

DECODER [R]

DEW

DEW SNS

DFMRE [H]

E. REC 5V

EC

ECR

EDT TRIG [L]

EDIT [H]

EE [H]

EE [H]/INS [M]

EE. VV. TR

EJECT. PO

EJECT/VDET

ENV. SEL

ENVE. OUT

ENVE. SEL

ENV SELECT

EP [H]

EP/LP [H]

EP/LP/SP

EP/SS [H]

EPROMCS

EX. REC 5V

FF/REW [L]

FG1 IN

FG2 IN

FILTER ADJUSTMENT

FLY ERASE [H]

FLY ON [H]

FLY. E [H]

FM MUT [H]

FM MUTE [H]

FM OUT [L]

FM OUT [R]

FM PACK OUT [L]

FM PACK OUT [R]

FM/BS SEL [L]

FM/BS SEL [R]

FS. CLK

FUL. E [H]

FULL. E [H]

CYLINDER GND

DELAIED FM RECORDING

DELAIED FM RECORDING L

DIGITAL GND

DELAYED RECORDING

D4/STILL LED

D4/STILL LED

TUNER DAC (CLOCK)

TUNER DAC/FS CHIP SELECT

DELAYED AUDIO RECORDING

DATA

DECODER (L)

DECODER (R)

DEW

DEW SENSOR

DELAYED FM AUDIO RECORDING

EXCEPT RECORDING 5V

ERROR TORQUE CONTROL

ERROR TORQUE CONTROL

REFERENCE VOLTAGE

EDIT TRIGGER

EDIT H

EE H

EE H/INSERT M

EE/VV/TRICK PLAY

EJECT POSITION

EJECT/REVERSE SLOW LOCK

ENVELOPE SELECT

ENVELOPE OUTPUT

ENVELOPE SELECT

ENVELOPE SELECT

LP

H

LP H

LP/SP

LP/SLOW/STILL/STOP

EPROM CHIP SELECT

EXCEPT RECORDING 5V

FIRST FORWARD/REWIND

FG1 PULSE INPUT

FG2 PULSE INPUT

FILTER ADJUSTMENT

FLYING ERASE HEAD ON

FLYING ERASE HEAD ON H

FLYING ERASE HEAD ON H

FM AUDIO MUTE H

FM AUDIO MUTE H

FM OUTPUT (L)

FM OUTPUT (R)

FM PACK OUTPUT (L)

FM PACK OUTPUT (R)

FM/BS SELECT (L)

FM/BS SELECT (R)

FS CLOCK

FULL ERASE HEAD ON

FULL ERASE HEAD ON H

L

H

H

H

H

H

L

H

H

FULL. E. 12V

GND [A]

GND [TU]

GND/N. SW. 12V

H. SYNC

H. AMP. SW

H. P <R>

H. P <L>

H. P GND

H. P OUT [L]

H. P OUT [R]

H. SW

HEAD PHONE [L]

HEAD PHONE [R]

HEAD SW

HEATER [

HEATER [

HSS

HTR [

HTR [

I RFE

ICL

IF

IN SELA1

IN SELA2

IN SELA3

INS L/R [L]

INS. [H]

INSEL A1

INSEL A2

INSERT

INSERT [H]

IO CS

JOG1

JOG S3 LED/FOWRD

JOG/F. LED

JSB [H]

JST. CLCK

JST. CLK

JST. CLOCK

L. OUT

L. CH [H]

L. CH [L]

LED (MAIN)

LED (STEREO)

LED (SUB)

LED CKL

LED CKS

LED DATA

LINE IN 1 [L]

LINE IN 1 [R]

LINE IN 2 [L]

LINE IN 2 [R]

LINE IN V

LINE IN [L]

+

]

−

]

+

]

−

]

FULL ERASE 12V

GND (ANALOG)

GND (TUNER)

GND/NON SW 12V

HORIZONTAL SYNC

HEAD AMP SW PULSE

HEAD PHONE (R)

HEAD PHONE (L)

HEAD PHONE GND

HEAD PHONE OUTPUT (L)

HEAD PHONE OUTPUT (R)

HEAD SW PULSE

HEAD PHONE (L)

HEAD PHONE (R)

HEAD SW

H

H

H

+

)

−

)

+

)

−

)

L

HEATER (

HEATER (

HORIZONTAL SYNC SIGNAL

HEATER (

HEATER (

REFERENCE CURRENT

CONTROL AGC CIRCUIT

INTERMEDIATE FREQUENCY

INPUT SELECT A1 POSITION

INPUT SELECT A2 POSITION

INPUT SELECT A3 POSITION

INSERT Lch/Rch

INSERT H

INPUT SELECT A1 POSITION

INPUT SELECT A2 POSITION

INSERT

INSERT

INPUT/OUTPUT CHIP SELECT

JOG1

JOG LED/FORWARD LED

JOG LED/FORWARD LED

JSB

JUST CLOCK

JUST CLOCK

JUST CLOCK

Lch OUTPUT

Lch

Lch L

LED (MAIN)

LED (STEREO)

LED (SUB)

LED SERIAL CLOCK

LED SERIAL CLOCK

LED SERIAL DATA

LINE INPUT 1 (L)

LINE INPUT 1 (R)

LINE INPUT 2 (L)

LINE INPUT 2 (R)

LINE INPUT VIDEO

LINE INPUT (L)

LINE IN [R]

LINE OUT [L]

LINE OUT [R]

LP [H]

LPTRI [L]

Lch/A. DUB

M GND

M REG

MAIN OUT

MAIN [L]

MAIN/MONO

MAX IN

MES [H]

MESE [H]

MESE [L]

METER 5V

METER [L]

METER [R]

METER. L/AVS

METER. R/AVC

MI/BI [L]

MIC GND

MIC IN

MIC IN [L]

MIC IN [R]

MIC [H]

MIX [H]

MIX [H]/CINEMA [L]

MIX/CINE

MIX/CINEMA [L]

MN. H/M. L

MN. H/MAI. L

MN2/MES. L

MODE SEL

MODE SW

MODE. S. IN

MODE. S. OUT

MONO [H]

MONO [H]/MAIN [L]

MONO2 [L]

MONO2/MESE [FM(L)]

MOTOR GND

MUTE

N. A. REC [L]

N. SW 12V

N. SW. 5. DET

NICAM

NICAM [L]

NOL [H]

NOR/SOFT [H]

NORMAL [H]

NR BIAS

NTSC [L]

OCH

OUT

LINE INPUT (R)

LINE OUTPUT (L)

LINE OUTPUT (R)

LP

H

LP TRICK PLAY L

Lch/AUDIO DUBBING

MOTOR GND

MOTOR REGULATOR

MAIN OUTPUT

MAIN

L

MAIN/MONAURAL

MAXIMAM INPUT

MESECAM

MESECAM H

MESECAM L

LEVEL METER 5V

LEVEL METER (L)

LEVEL METER (R)

LEVEL METER (L)

LEVEL METER (R)

MIX

MIC GND

MIC INPUT

MIC INPUT (L)

MIC INPUT (R)

MIC

MIX H

MIX H/CINEMA SOUND L

MIX H/CINEMA SOUND L

MIX H/CINEMA SOUND L

MONAURAL H/MAIN L

MONAURAL H/MAIN L

MONAURAL 2/MESECAM L

AUDIO MODE SELECT

AUDIO MODE SW

AUDIO MODE SELECT INPUT

AUDIO MODE SELECT OUTPUT

MONAURAL

MONAURAL H/MAIN L

MONAURAL 2

MONAURAL 2/MESECAM (FM

MOTOR GND

MUTE

NORMAL AUDIO RECORDING

NON SW 12V

NON SW 5V DETECT

NICAM

NICAM

PAL H/4.43 NTSC M/3.58 NTSC

NORMAL/SOFT TAPE PLAY H

NORMAL H

NR BIAS

NTSC

CONTROL AGC CIRCUIT

OUTPUT

H

H/BILIGUAL

H

H

L

L

P-OFF [H]

P-OFF [L]

P. FAIL

P. OFF [H]

P. OFF [L]

PAL [H]

PAL [L]/NTSC [H]

PB ADJ OUT

PB OUT

PB. H

PFG

PHOTSN +B

PICT. CNT

PLAY LED/RVS LED

PLAY. PO

PLAY/R. LED

PLY/DEW

POWER OFF [L]

PREROLL [H]

PWRFAIL

R. CH [H]

R. CH [L]

R. ST

R/S/F

RCH [H]

REC 12V

REC CHROMA

REC H

REC IN

REC OUT [L]

REC START

REC VR [C]

REC VR [L]

REC VR [R]

REC Y

REC [H]

REC. C

REC. Y

REC/EE CTL

REEL-T

REEL-S

L)

REGULATOR FILTER

RESET

REV M F/R

REV M V1

REV M V2

REV MOTOR F/R

L

REV MOTOR V1

REV MOTOR V2

REV MOTOR [

REV MOTOR [

REV. M. GND

RF. CHROMA

POWER OFF

POWER OFF L

POWER FAILURE DETECT

POWER OFF

POWER OFF L

PAL H

PAL L/NTSC H

PLAYBACK ADJUST OUTPUT

PLAYBACK OUTPUT

PLAYBACK

PG/FG

PHOTO SENSOR +B

PICTURE CONTROL

PLAY LED/REVERSE LED

PLAY POSITION

PLAY LED/REVERSE LED

PLAY/DEW

POWER OFF L

PREROLL H

POWER FAILURE DETECT

Rch

H

Rch L

RESET

REVERSE H/STOP M/FORWARD

Rch H

RECORDING 12V

RECORDING CHROMINANCE SIGNAL

RECORDING H

RECORDING INPUT

RECORDING OUTPUT

RECORDING START

RECORDING VOLUME (COMMON)

RECORDING VOLUME (L)

RECORDING VOLUME (R)

RECORDING LUMINANCE SIGNAL

RECORDING H

RECORDING CHROMINANCE SIGNAL

RECORDING LUMINANCE SIGNAL

RECORDING/EE CONTROL

REEL PULSE (TAKE-UP)

REEL PULSE (SUPPLY)

REGULATOR FILTER

RESET

REVIEW MOTOR

FORWARD/REVERSE

REVIEW MOTOR V1

REVIEW MOTOR V2

REVIEW MOTOR

FORWARD/REVERSE

REVIEW MOTOR V1

REVIEW MOTOR V2

+

]

−

]

REVIEW MOTOR (

REVIEW MOTOR (

REVIEW MOTOR GND

RF CHROMINANCE SIGNAL

H

H

H

H

L

L

+

)

+

)

RF OUT

RF Y

RF. Y. IN

RF. Y. OUT

ROTAR. SW

ROTARY

RST

RST [L]

Rch/INST

S IN

S OUT

S-PHOTO

S-RL. PLS

S. CLK

S. CLK/AV

S. DATA

S. DATA/A

S. PHOTO

S. TAB [L]

S/P/N

SC IN

SC OUT

SCK SELECT

SEL OUT [L]

SEL OUT [R]

SHUTTLE 1

SIF

SLMUT [H]

SLNID [

SLNID [

SLW TR. MM

SLW TR. REF

SNS. GND

SOFT [H]

SOFT [H]/NORMAL

SOLENOID ON [L]

SP [H]

SP/L/SLP

SSS [L]

STEREO LED

STEREO [H]

STEREO [L]

STOP. PO

STOP/5V

STOP1/TAPE SEL

STOP1/PAL:ST

STOP2. PO

STOP2/S-TAB

STREO [H]

SUB BIAS

SUB. SW

SVHS CAS [L]

SW. 5. DET

SYNC [L]

+

]

−

]

RF OUTPUT

RF LUMINANCE SIGNAL

RF LUMINANCE SIGNAL INPUT

RF LUMINANCE SIGNAL OUTPUT

ROTARY SW

ROTARY SW

RESET

RESET

Rch/INSERT

SERIAL DATA INPUT

SERIAL DATA OUTPUT

SUPPLY PHOTO TRANSISTOR

SUPPLY REEL PULSE

SERIAL CLOCK

SERIAL CLOCK/AV

SERIAL DATA

SERIAL DATA

SUPPLY PHOTO TRANSISTOR

SAFETY TAB SW ON

SECAM/PAL/NTSC

SERIAL CLOCK INPUT

SERIAL CLOCK OUTPUT

SERIAL CLOCK SELECT

SELECT OUTPUT (L)

SELECT OUTPUT (R)

SHUTTLE 1

SOUND INTERMEDIATE FREQUENCY

INPUT SELECT MUTE H

SOLENOID (+)

SOLENOID (

SLOW TRACKING MONO MULTI

SLOW TRACKING REFERENCE

VOLTAGE

SENSOR GND

SOFT TAPE PLAY

SOFT TAPE PLAY H/NORMAL H

SOLENOID ON L

SP H

SP/LP

SLOW/STILL/STOP

STEREO LED

STEREO

STEREO L

STOP POSITION

STOP POSITION/5V

STOP1 POSITION/TAPE SELECT

STOP1 POSITION/PAL

STOP 2 POSITION

STOP 2 POSITION/SAFETY TAB SW

STEREO H

SUB BIAS

SUB SW

S-VHS CASSETTE

SW 5V DETECT

SYNC

L

L

H

L

−

)

H

L

SYSCON 5V

SYSTEM

T-PHOTO

T-RL. PLS

T. BUSCLK

T. BUSLSN

T. BUSTLK

T. END [L]

T. PHOTO

TAPE END [L]

TAPE END [L]/CAM

TEST

TPZ

TRIC [L]

TRICK [L]

TRK. ENV

TU. AUDIO

TU. GND

TU. V. IN

TU. VIDEO

TUN NOR IN

TUN R

TUN. AUDIO IN

TUNER 12V

TUNER L

TUNER V IN

TUNER [L]

TUNER [N]

TUNER [R]

TUNER. 12

TUOFF [H]

TV. AUDIO

TV/VTR

TXTON [L]

U. REG45V

UNREG

UNREG19V

V. REF

V. EE [H]

V. EE [L]

VCO REF

VD. IN

VD. OUT

VIDEO EE [L]

VIDEO IN

VIDEO OUT

VM

VM DOWN [L]

VSS

VTR [H]

VTR. 12V

X IN

X OUT

SYSTEM CONTROL 5V

SYSTEM SW

TAKE-UP PHOTO TRANSISTOR

TAKE-UP REEL PULSE

TIMER BUS CLOCK

TIMER BUS LISTEN

TIMER BUS TALK

TAPE END

TAKE-UP PHOTO TRANSISTOR

TAPE END

TAPE END L/CAMERA PAUSE

TEST MODE

TRAPEZOIDAL WAVE CIRCUIT

TRIC PLAY

TRIC PLAY L

AUTO TRACKING ENVELOPE DETECT

TUNER AUDIO

TUNER GND

TUNER VIDEO SIGNAL INPUT

TUNER VIDEO

TUNER NORMAL INPUT

TUNER AUDIO (R)

TUNER AUDIO INPUT

TUNER 12V

TUNER AUDIO (L)

TUNER VIDEO SIGNAL INPUT

TUNER AUDIO (L)

TUNER AUDIO (NORMAL)

TUNER AUDIO (R)

TUNER 12V

TUNER OFF

TV AUDIO

TV/VTR

TEXT ON

UNREGULATOR 45V

UNREGULATOR

UNREGULATOR 19V

REFERENCE VOLTAGE

VIDEO EE

VIDEO EE L

REFERENCE OSCILLATER

VIDEO SIGNAL INPUT

VIDEO SIGNAL OUTPUT

VIDEO EE

VIDEO SIGNAL INPUT

VIDEO SIGNAL OUTPUT

MOTOR VOLTAGE

MOTOR VOLTAGE DOWN

VERTICAL SYNC SIGNAL

VTR

VTR 12V

OSCILLATOR INPUT

OSCILLATOR OUTPUT

L

L

L

H

L

H

L

L

H

Loading...

Loading...