PANASONIC NV-FJ616 Service Manual

http://cxema.ru

ORDER NO. VRD0102005C2

Video Cassette Recorder

NV-FJ616EG

NV-FJ616EGY

NV-FJ616EC

NV-FJ616ECM

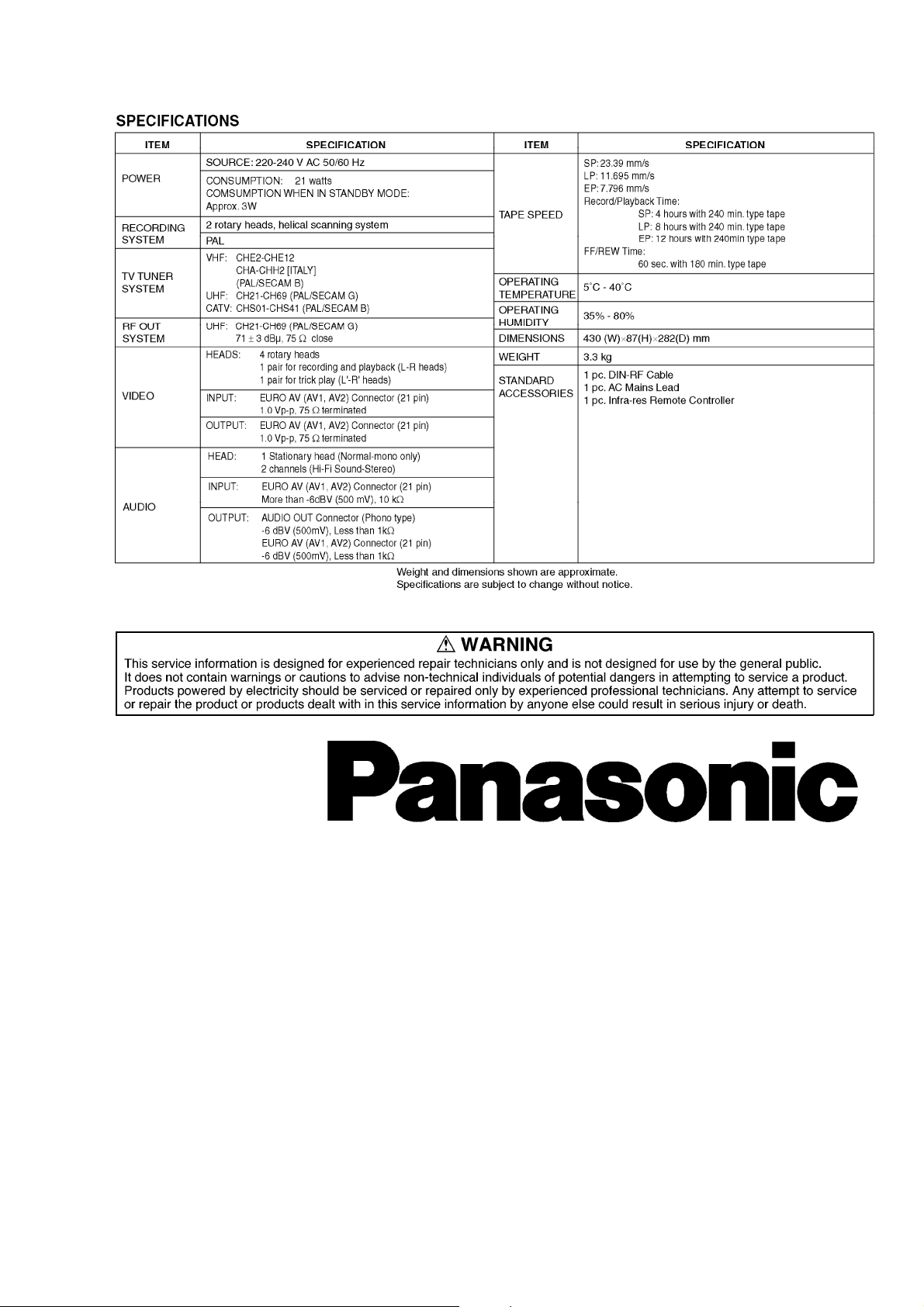

SPECIFICATIONS

NV-FJ616ECN

NV-FJ616ECY

Z-MECHANISM

http://cxema.ru

1

1. INTRODUCTION

This service manual contains technical information which will allow service

personnel to understand and service this model.

If the circuit is changed or modified, this information will be followed by

supplementary service manual to be filed with original service manual.

Note:

1. Adjustment procedures, Disassembly Procedures and Assembly Procedures for

Mechanism Chassis are separate volume from this service manual.

Please refer to the service manual for Z-Mechanism Chassis. (Order No.

VRD9802005C2)

2. The Model No. is indicated on the Schematic Diagram and Circuit Board Diagrams

http://cxema.ru

as follows.

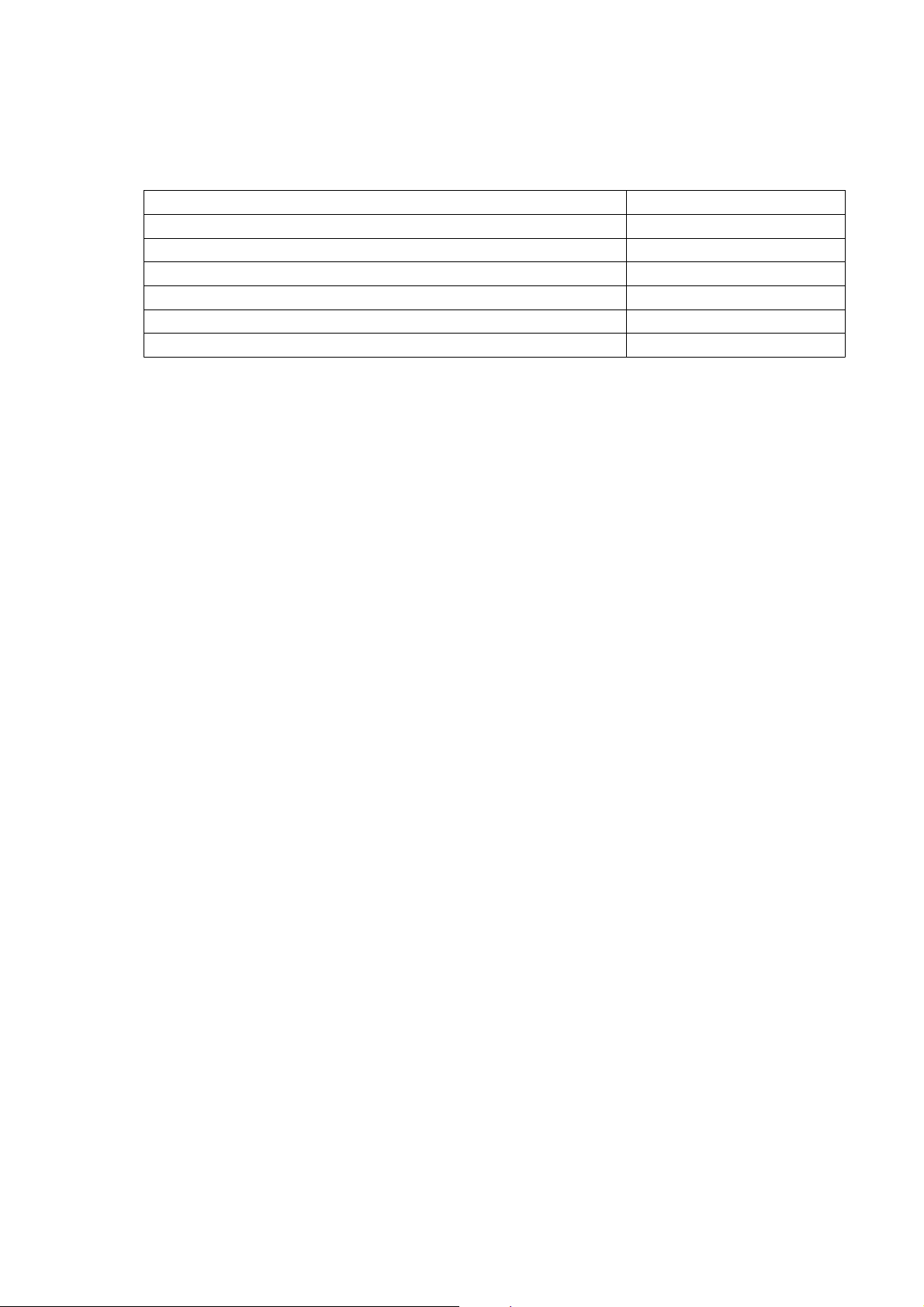

Model No. Indication Mark

NV-FJ616EG (A)

NV-FJ616EGY (B)

————— (C)

————— (D)

NV-FJ616EC/ECM/ECN (E)

NV-FJ616ECY (F)

2. GENERAL DESCRIPTIONS

2.1. SERVICE CAUTION

2.1.1. REPLACING IC7702/EEPROM

When the EEPROM: IC7702 is replaced, applicable model code, option code and

electrical adjustment data will not be available.

Therefore, enter and/or adjust the necessary data after replacing IC7702 by referring

following procedure.

STEP1.REPLACE THE IC7702

1. Remove the C.B.A. with Mechanism unit by referring the Disassembly procedure.

2. Disconnect the AC plug and replace the IC7702.

STEP2.INPUT THE MODEL & OPTION CODE

1. Set up the applicable model code and option code by ordering the following table.

http://cxema.ru

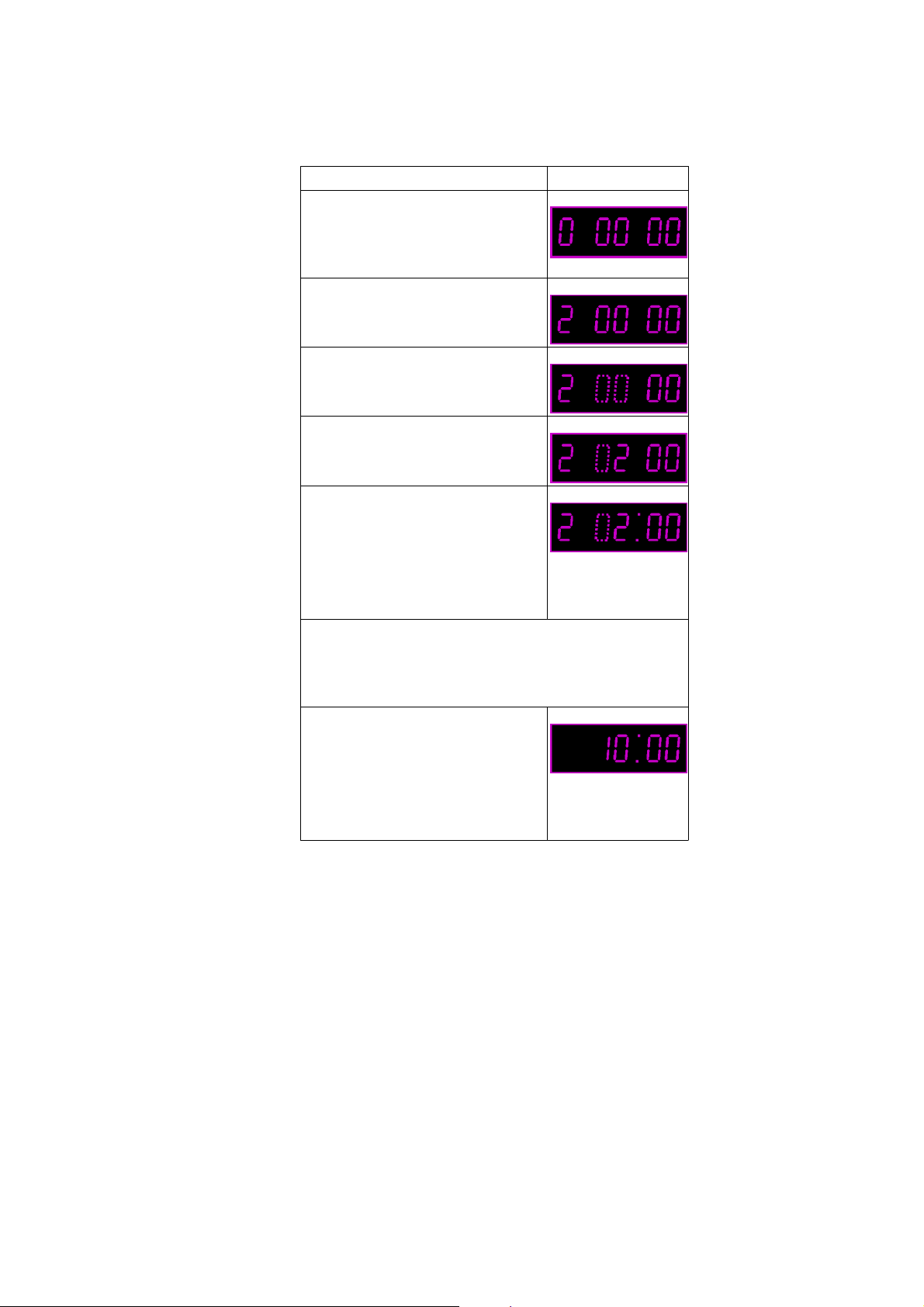

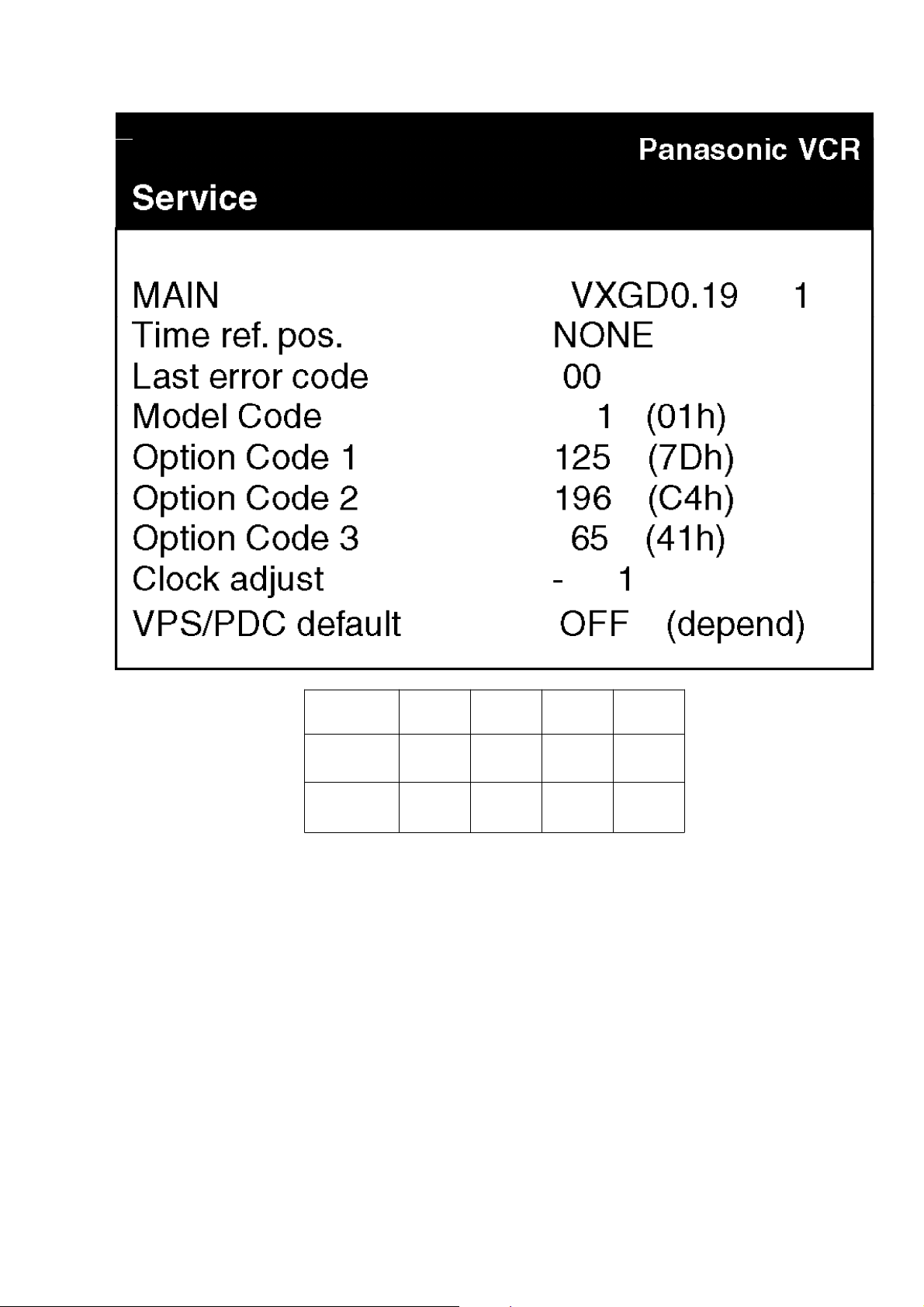

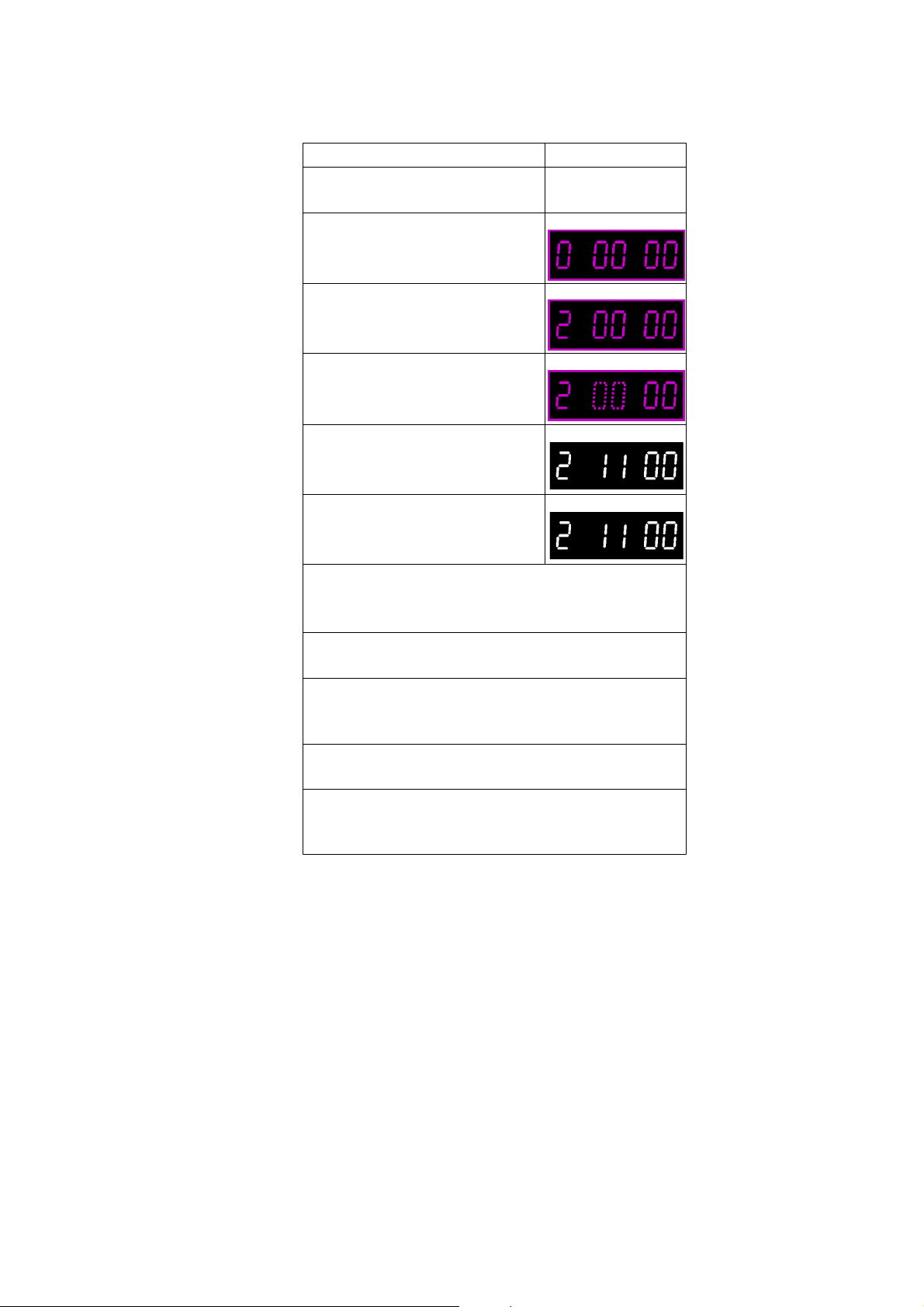

PROCEDURE F.I.P. DISPLAY

Turn on the Service Mode

1.Press the FF key and the

EJECT key simultaneously for

more than 3 seconds.

Activate the Service Mode 2

2.While keep placing FF key,

press the EJECT key in twice.

Activate the Entering Mode.

3.Press the EJECT key for more

than 3 seconds.

Set the Mode 2.

4.Press the CH UP key in twice.

Display the Setting Code.

5.Press the POWER Button to

turn the power on.

(Colon starts

flashing)

Enter the Model and Option Code.

6.Set the applicable Model and Option code by

using REW, PLAY, STOP and FF keys on the

Remote Controller. (See Fig.S1 & S2)

Exit from Service Mode.

7.Press the POWER Button to

turn the power off.

8. Press FF and EJECT keys

simultaneously in 6 times.

(Normal

Indication)

Fig.S1 Service Secreen (sample)

http://cxema.ru

Model No. Model

Code

NV-FJ616EG/

EGY

NV-FJ616EC/

ECM/ECN/ECY

Fig. S2 Model Code & Option Code

81

(51h)

82

(52h)

Option

Code 1

8

(08h)

8

(08h)

Option

Code 2

212

(D4h)

212

(D4h)

Option

Code 3

6

(06h)

6

(06h)

NOTE:

Since all electrical adjustments data is still not available, perform the Electrical

Adjustment continuously.

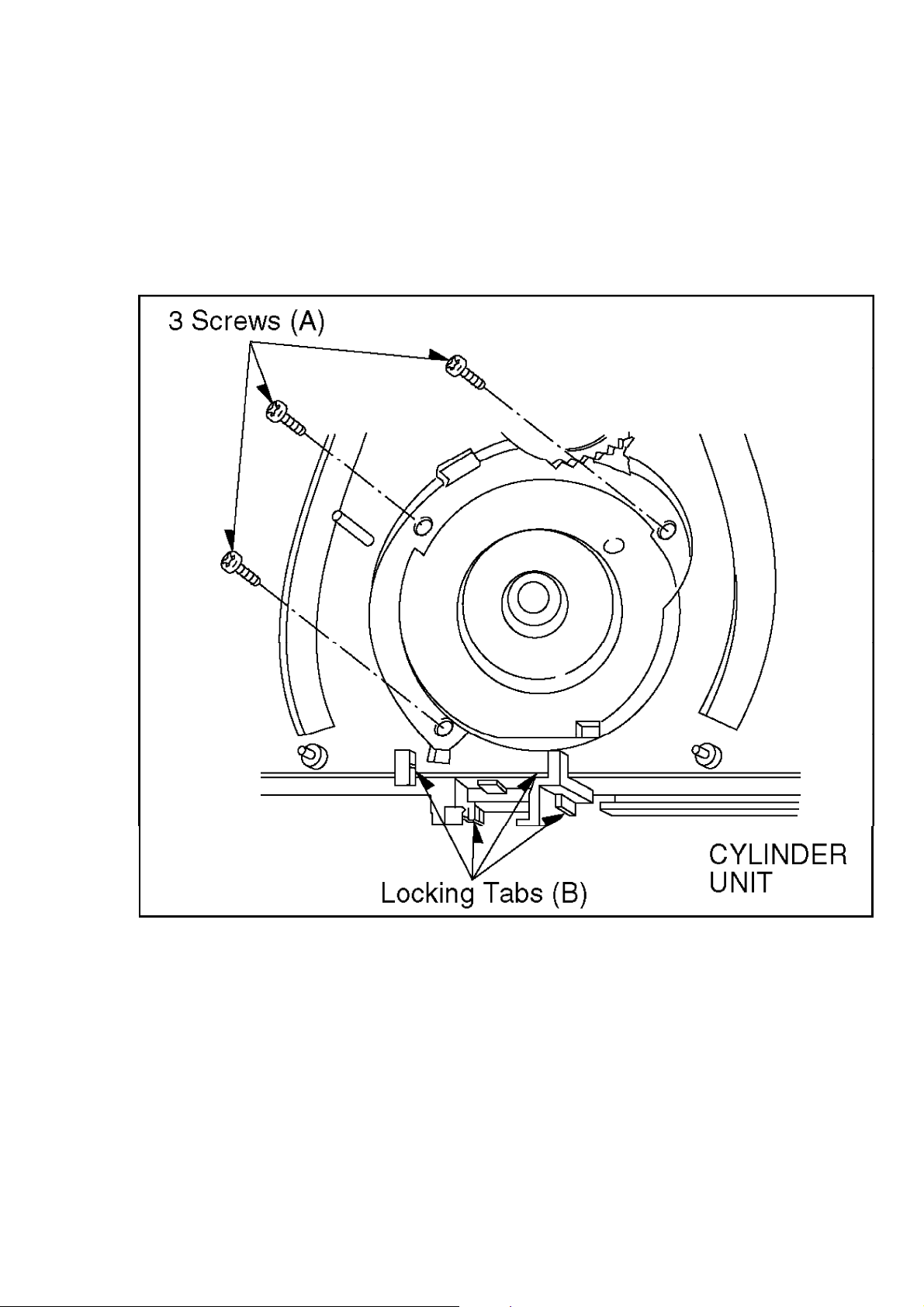

2.1.2. CYLINDER UNIT REPLACEMENT

1. CYLINDER UNIT REPLACEMENT

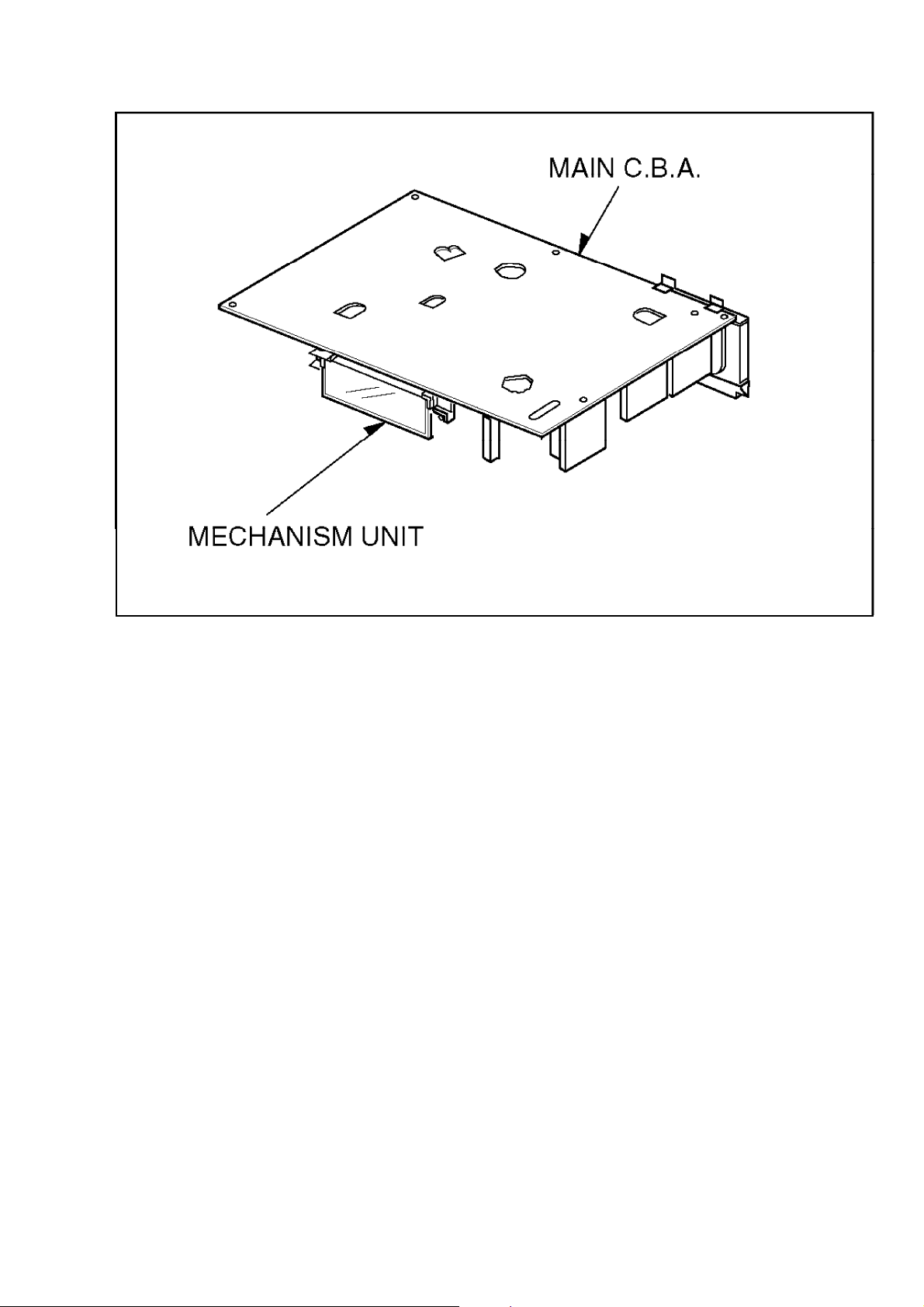

A. Remove the mechanism unit from MAIN C.B.A./Chassis by referring “SECTION

2. Disassembly Procedure”.

B. Remove the 3 screws (A) of the CYLINDER UNIT with a screw driver.

http://cxema.ru

C. Unlock the 4 locking tabs (B) and disconnect the Cylinder fiexible card from the

FPC Holder.

D. Remove the CYLINDER UNIT.

CAUTION:

Handle the Cylinder fiexible card with care. When it damaged, you should replace

whole Cylinder unit.

Fig. S3

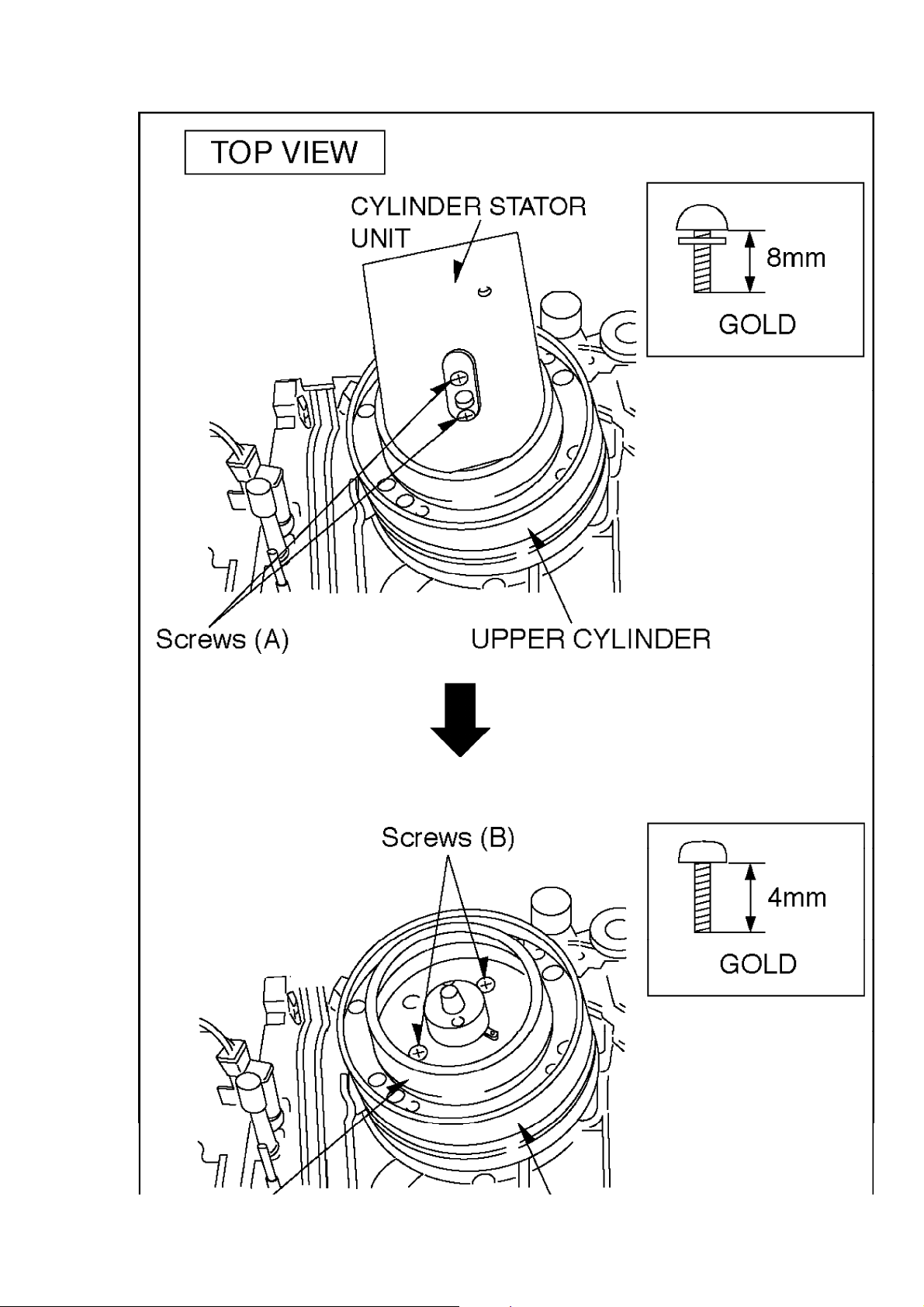

2. UPPER CYLINDER DISASSEMBLY

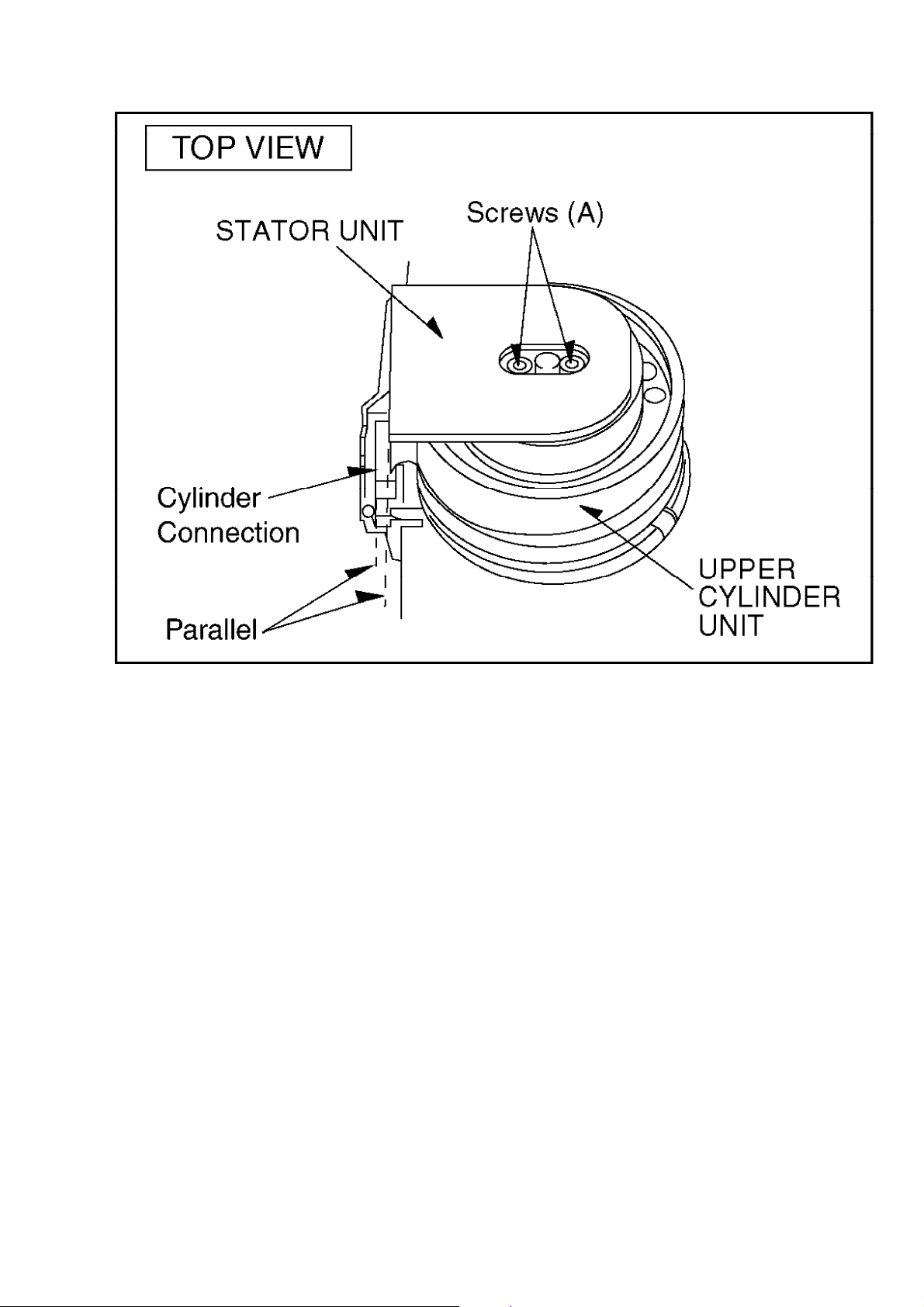

A. Remove 2 screws (A).

B. Remove the Cylinder Stator Unit.

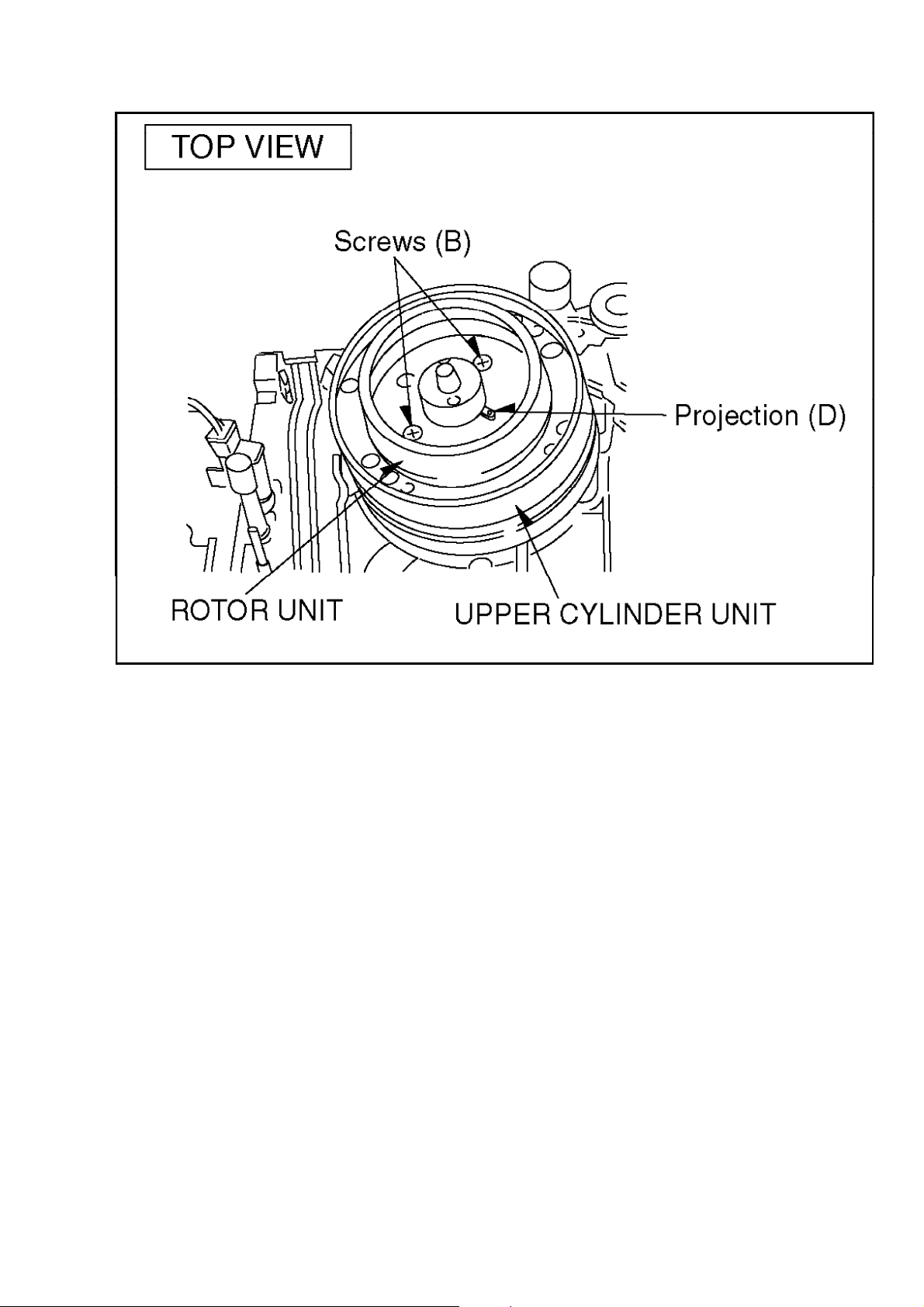

C. Remove 2 screws (B).

D. Remove the Cylinder Rotor Unit.

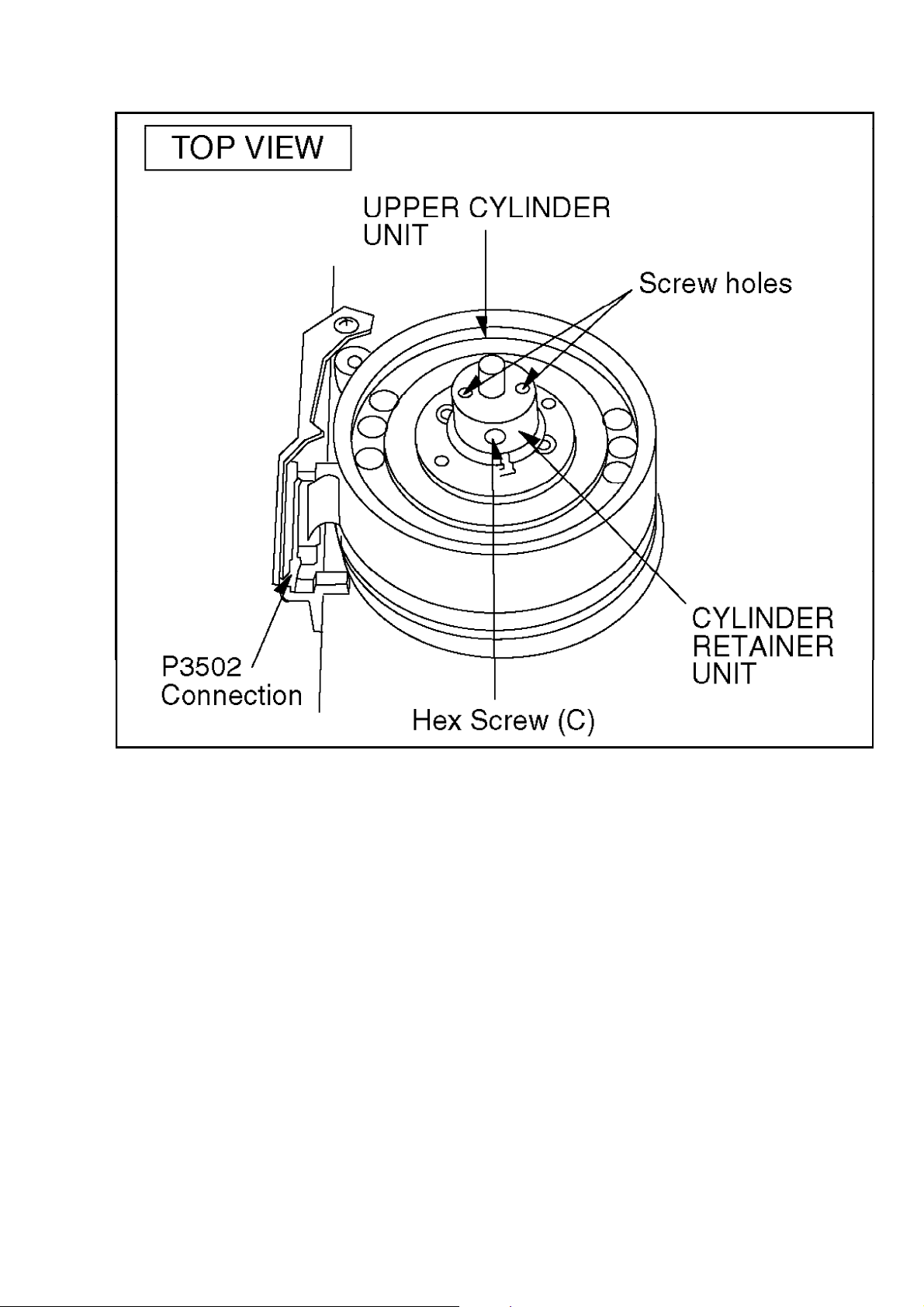

E. Loose Hex screw (C) (1.5 mm) and remove the CYLINDER RETAINER.

F. Remove the Upper Cylinder.

Fig. S4

http://cxema.ru

http://cxema.ru

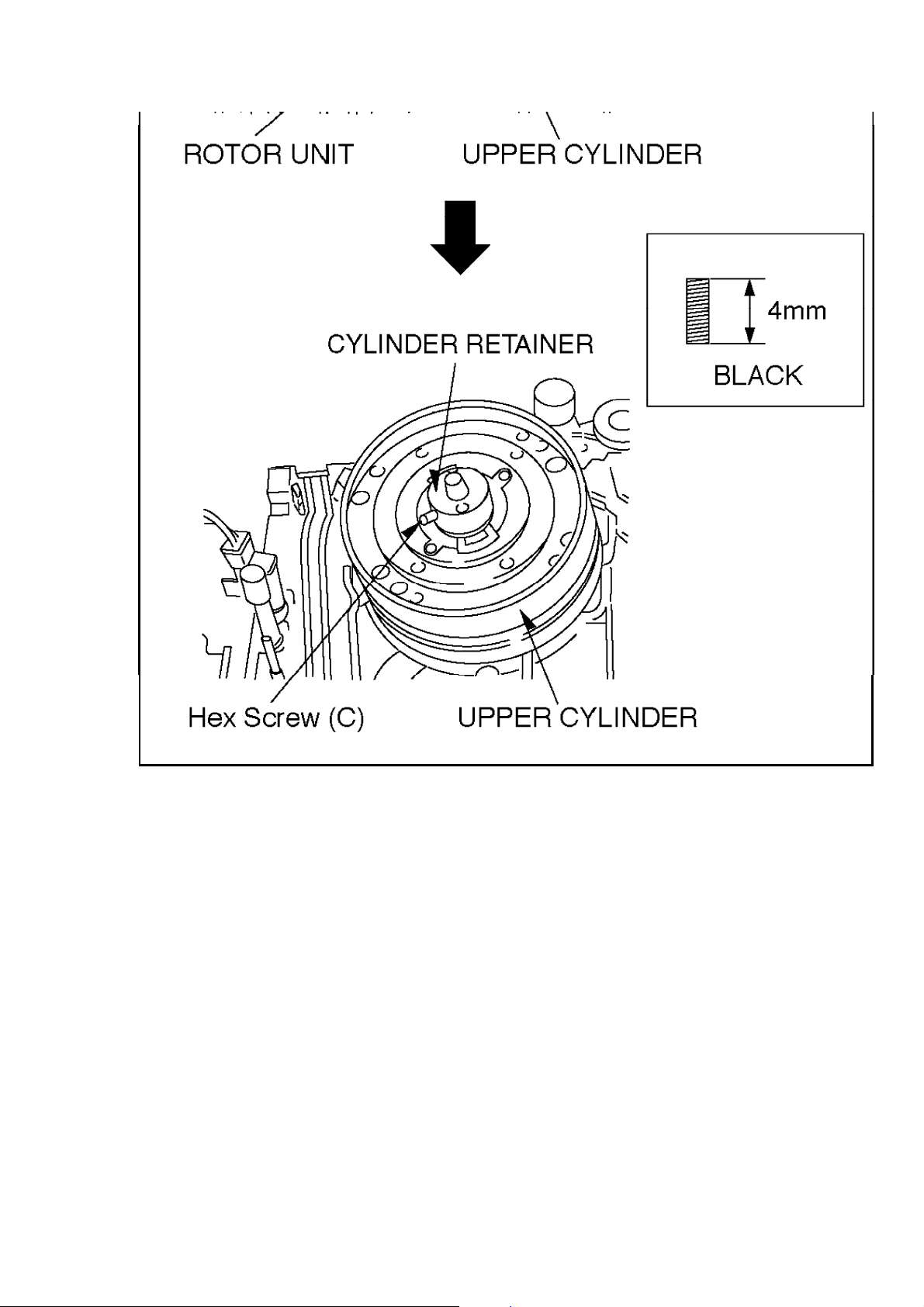

3. UPPER CYLINDER ASSEMBLY

When reassembling, perform the steps in the reverse order.

Notes:

1. Install the Cylinder Retainer so that the 2 holes on top of the Cylinder Retainer are

at right angles with the P3502 Connection.

2. Tighten the Hex screw (C) (1.5 mm) while pressing down on top of the Cylinder

Retainer.

Fig. S5

http://cxema.ru

3. Install the Cylinder Rotor Unit so that the inner hole of the Cylinder Rotor Unit fits

to the small projection (D) on top of the Upper Cylinder.

4. Tighten 2 screws (B).

Fig. S6

http://cxema.ru

5. install the Cylinder Stator Unit.

6. Tighten 2 screws (A).

Fig. S7

http://cxema.ru

7. Confirm the PG SHIFTER ADJUSTMENT with the alignment tape (PAL:

VFJ8125H3F) and adjust it if necessary.

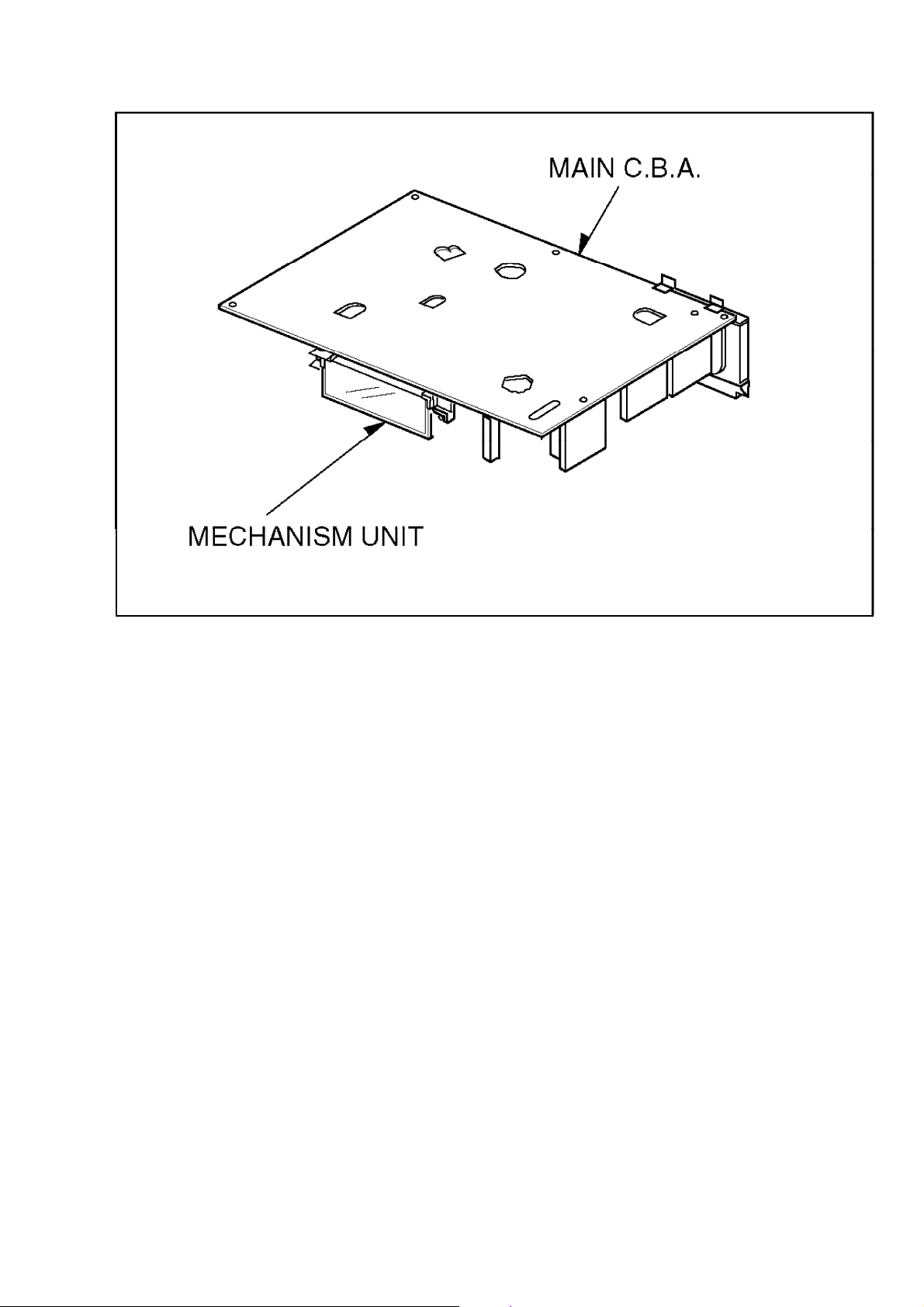

2.1.3. CHECKING OF MAIN C.B.A.

When servicing the MAIN C.B.A., take out the MAIN C.B.A. and mechanism from the

frame and turn over.

Fig. S8

http://cxema.ru

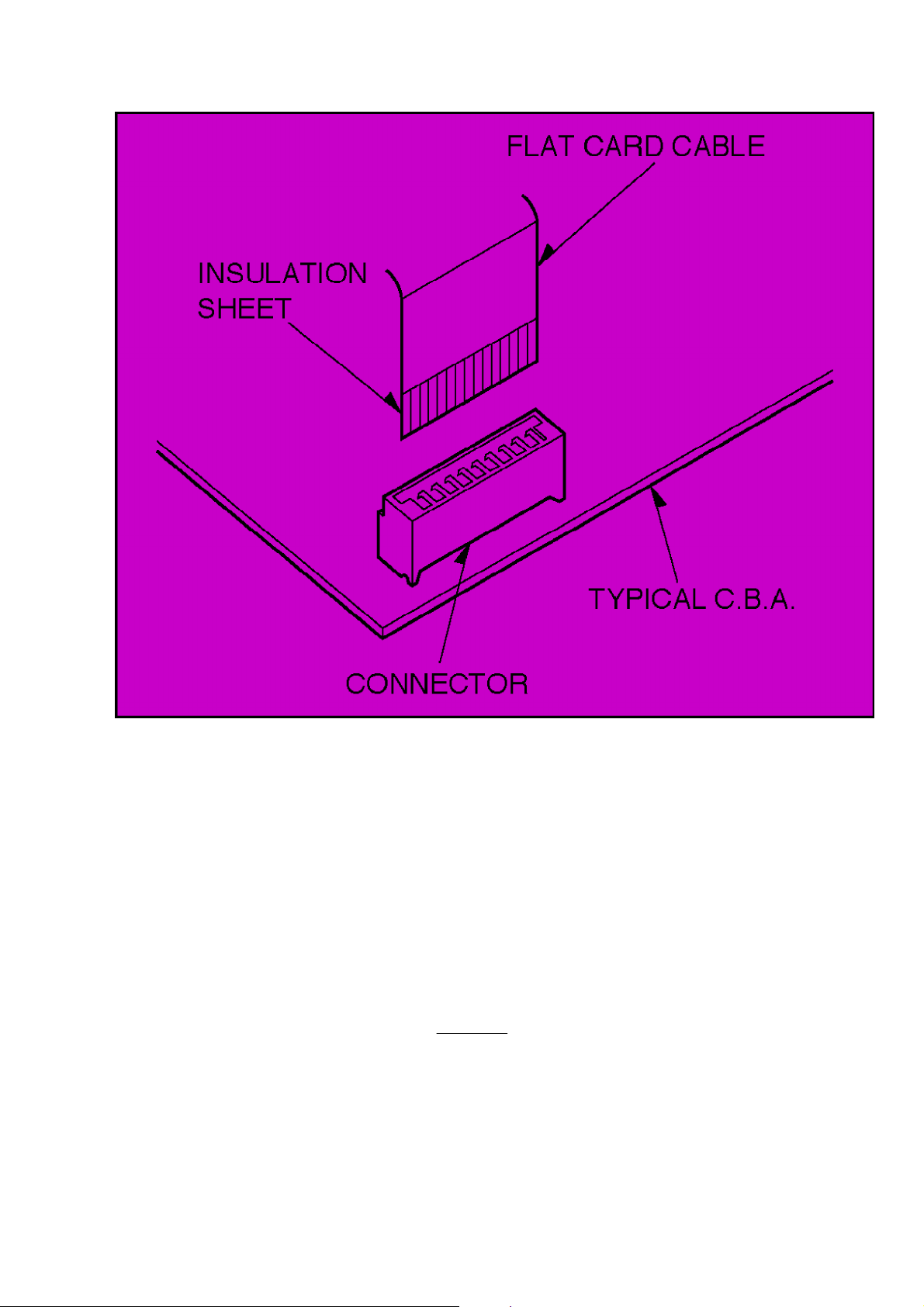

2.1.4. FLAT CARD CABLE INSTALLATION

When installing the Flat Card Cable on the connector, install the Flat Card Cable with

the cable contacts facing the connector contacts.

Fig. S9

http://cxema.ru

2.2. REMOVAL OF CASSETTE TAPE

There are 2 ways to remove a cassette tape.

1. Service Information Display Operation

A. Press the FF and EJECT keys simultaneosly for 3 seconds and set the Service

Mode 7.

B. Press STOP key in order to rotate the Loading Motor for unloading operation.

(Pay an attention of tape slack)

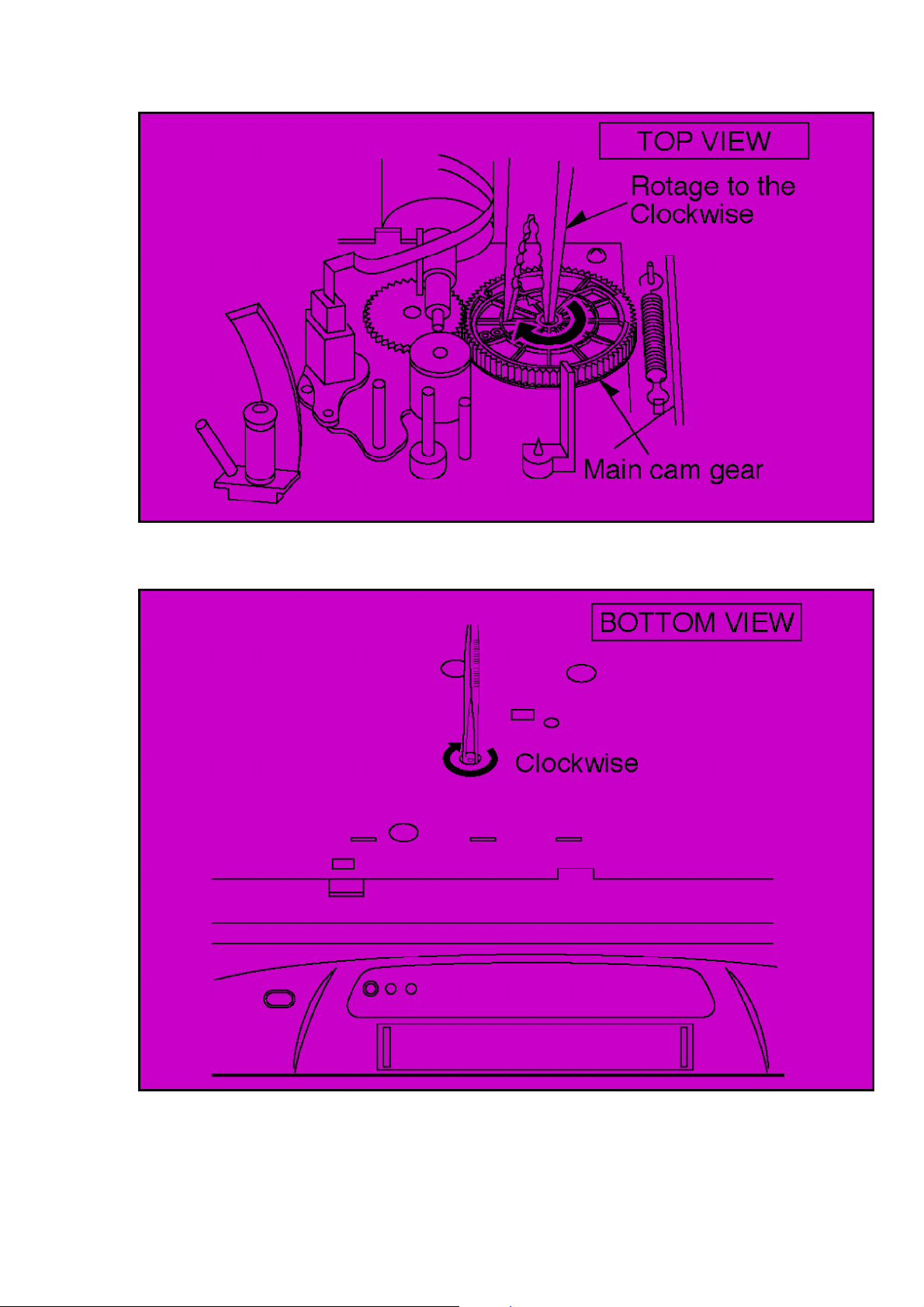

2. Manual Operation

A. Disconnect the AC Mains Lead and remove the Top Panel.

B. Rotate the Main Cam Gear clockwise until the Loading Posts move to fully

unloaded position as shown in

Fig. S10 . (Tape is remaining)

Fig. S10

http://cxema.ru

C. Rotate the Capstan Motor clockwise from the bottom side to take up the tape.

Fig. S11

D. Rotate the Main Cam Gear clockwise until the cassette tape is ejected.

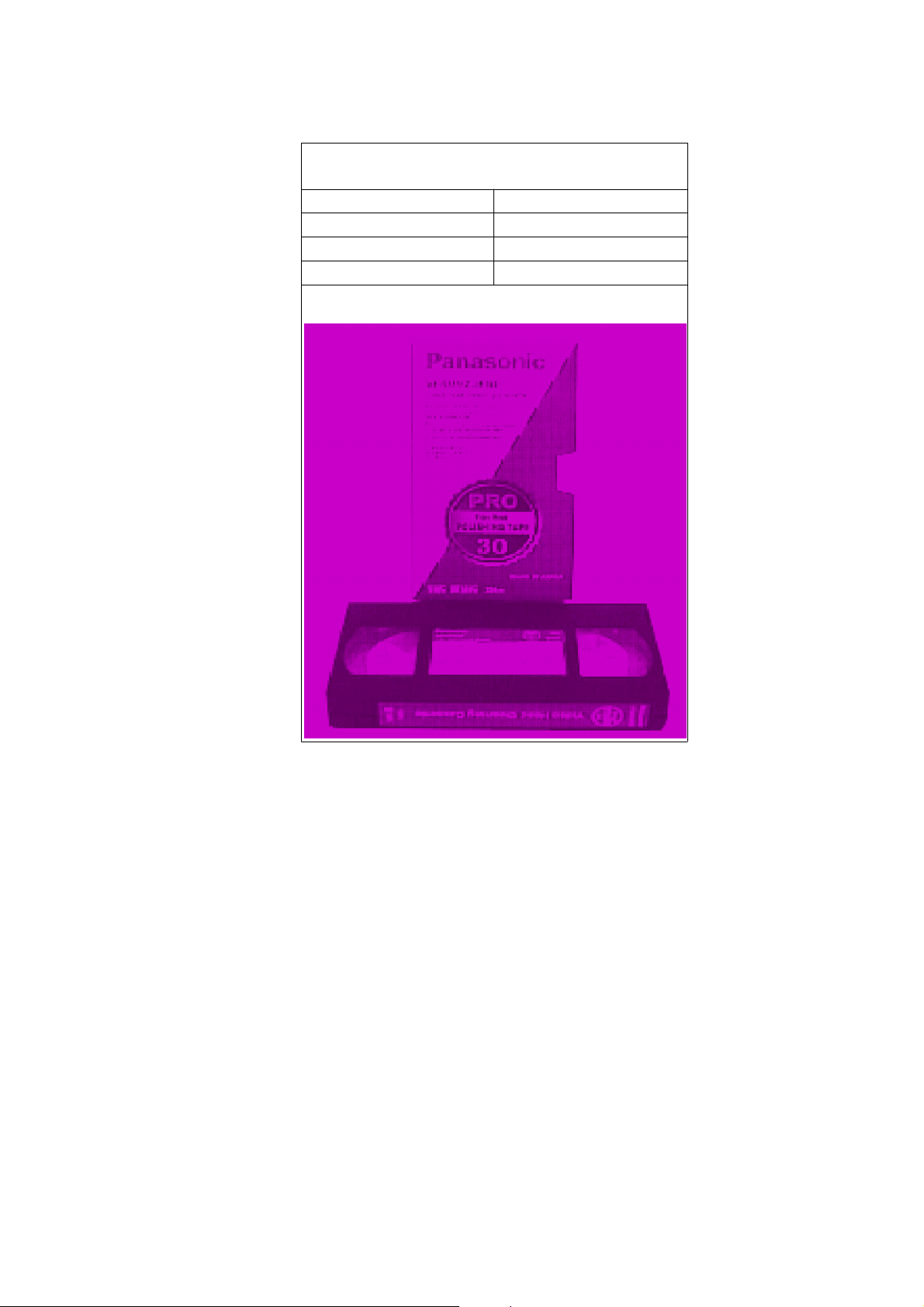

2.3. INTRODUCTION OF VIDEO HEAD CLEANING CASSETTE

http://cxema.ru

(POLISHING TYPE)

1. We are pleased to introduce Panasonic Video Head Cleaning Cassette, VFK0923FT

[for service purposes] and VFK0923FSE [ for end users] for all VHS/SVHS VCP and

VCR.

2. These cleaning cassettes are exclusive removing the hard and sticky clogging on

video heads.

3. These improve the efficiency of video head cleaning service and shortening

cleaning time for end users.

VFK0923FT

(For Service usage)

Type of Cassette Full VHS Cassette

Cleaning Time 10 Seconds/Time

Tape Length 20 m

Usability in a Path 180 Times

http://cxema.ru

VFK0823FSE

(For end users)

Type of Cassette Full VHS Cassette

Cleaning Time 10 Seconds/Time

Tape Length 3.34 m

Usability in a Path 30 Times

Note:

The tape material itself is the same in both types.

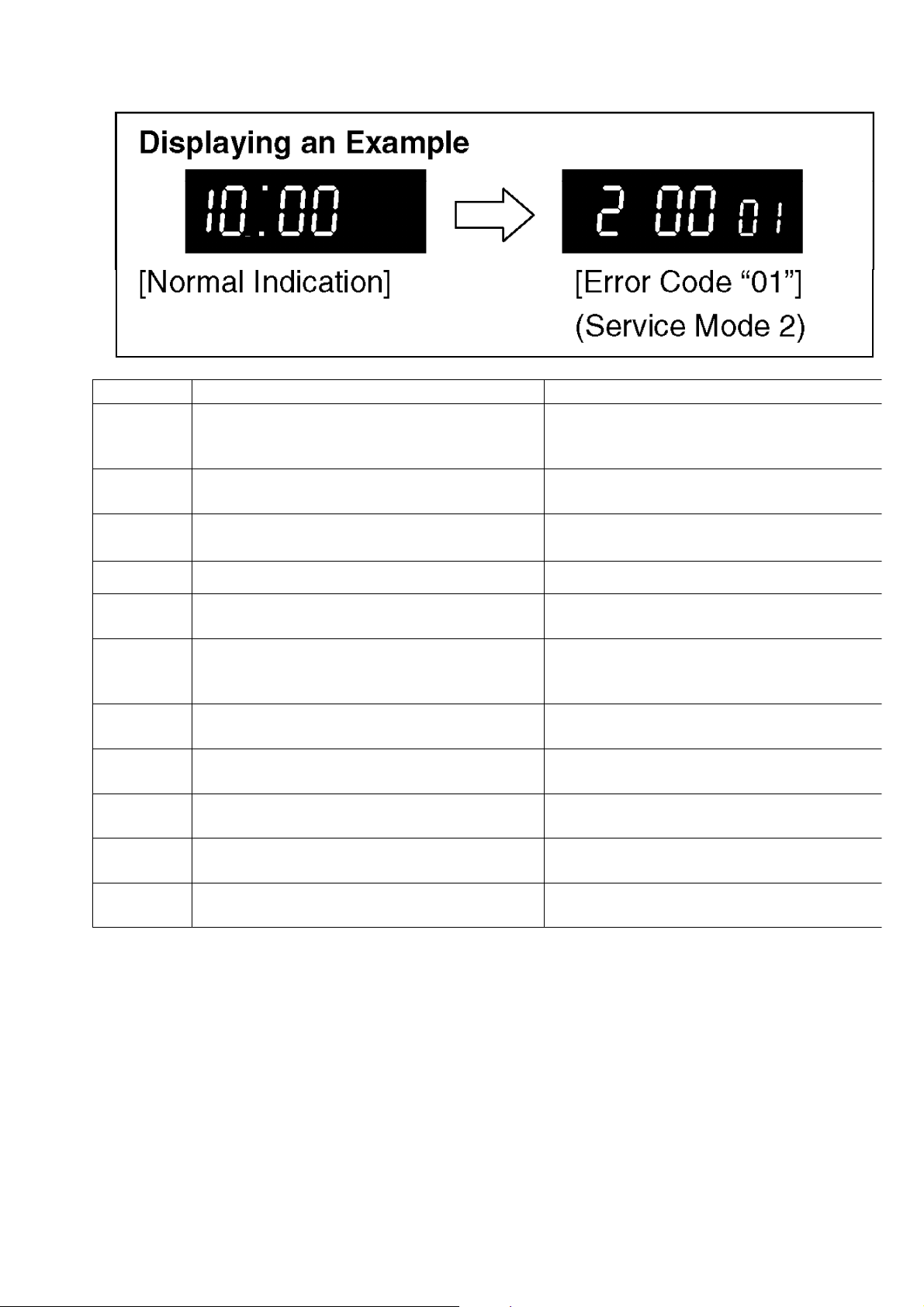

2.4. SELF-DIAGNOSIS RESULT DISPLAY

The "SELF-DIAGNOSIS RESULT DISPLAY & MEMORY function is built in this VTR.

It means that when the VCR detects undesirable condition, it can be displayed a

“Error code (Two numbers from the left)” with Service Mode 2.

Since the "Error code" is stored in the EEPROM, it can be displayed although after

disconnected the AC leads. It can be displayed with Service Mode 2.

(If a second error had been detected, only the most recent error is displayed. )

For more details, refer to the Service Manual for Z-Mechanism Chassis Order number

VRD9612M129.

http://cxema.ru

INDICATION CAUSE REMEDY/CHECK

i

01 After cylinder lock is detected, the cylinder

Check the cylinder motor drive circuit.

does not start rotating again even after tape

unloading.

02 Cassette tape is not wound up during the tape

Check the capstan motor drive circuit.

unloading except EJECT mode.

03 Mechanism locks during mode transition

except EJECT mode.

04 Mechanism locks during tape unloading.

06 Mechanism locks after tape unloading in

EJECT mode.

07 During recording mode, recording signal is

less than the normal condition.

1. Check the loading motor drive circuit.

2. Check the mechanism phase alignment.

3. Check the mode switch.

1. Check the loading motor drive circuit.

2. Check the mechanism phase alignment.

1. Check the loading motor drive circuit.

2. Check the mechanism phase alignment for cassette holder un

Protection of the over-current flowing in

transistor which produces the power supply

for recording mode.

08 Recording circuit works except recording

Check the recording circuit.

mode.

16 Cylinder lock detection. Check the cylinder unit and the cylinder moto

drive circuit.

17 Supply reel mechanism lock detection Check the supply reel mechanism and the

supply reel circuit.

18 Take-up reel mechanism lock detection Check the Take-up reel mechanism and the

Take-up reel circuit.

2* PG shifter automatic adjustment error. Check the servo/system control circuit and

the cylinder unit.

3. ADJUSTMENT PROCEDURES

3.1. DISASSEMBLY METHOD

3.1.1. DISASSEMBLY FLOW CHART

Fig. T1 Self-Test indication Display

http://cxema.ru

This flow chart indicates disassembly steps of the cabinet parts and the circuit

boards in order to find the necessary items for servicing.

When reassembling, perform the steps in the reverse order.

Fig. D1

3.1.2. DETAIL OF DISASSEMBLY METHOD

http://cxema.ru

1. REMOVAL OF THE TOP PANEL

Remove 4 Screws (A)

Fig.D2

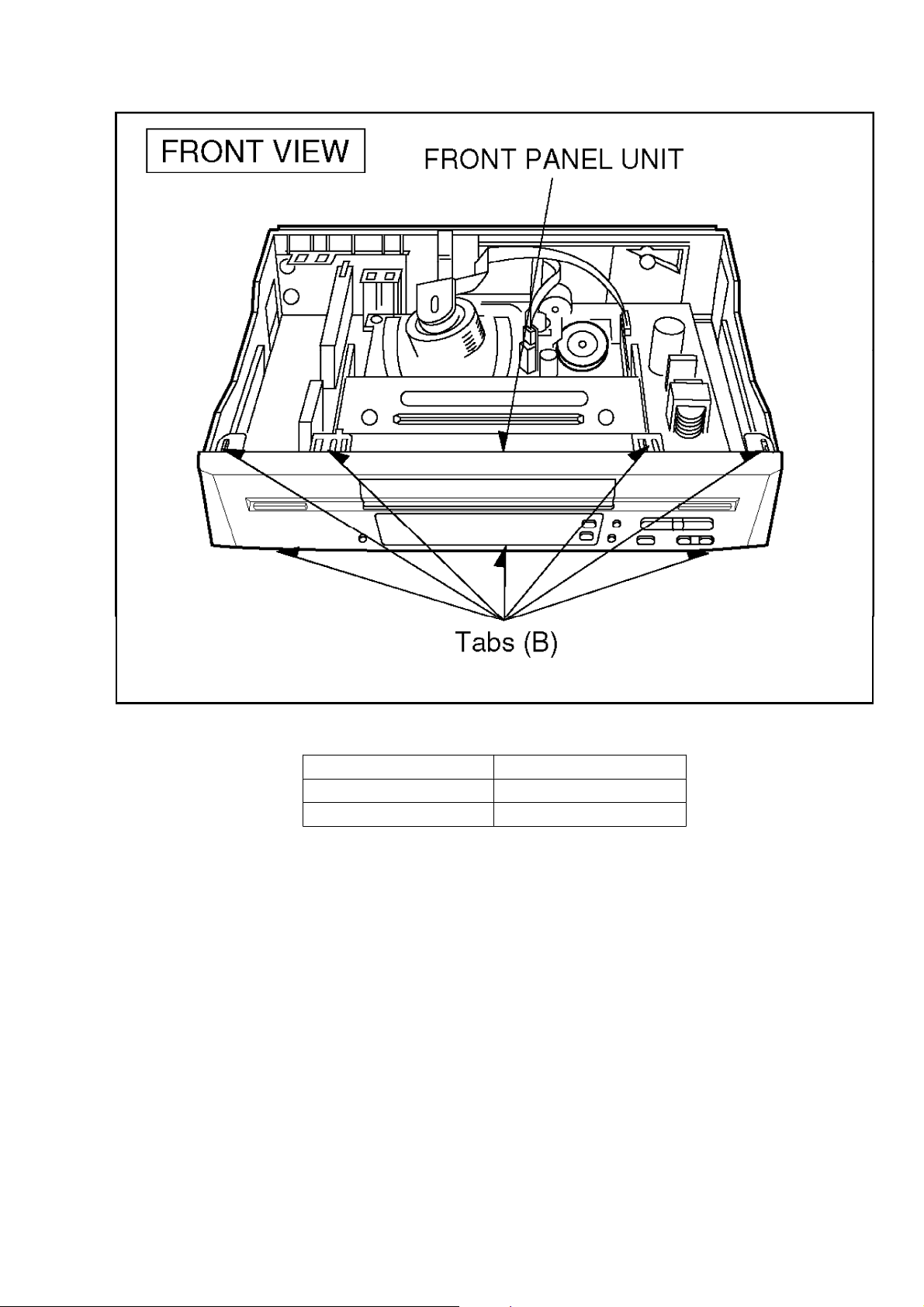

2. REMOVAL OF THE FRONT PANEL UNIT

Unlock 7 Tabs (B)

Fig. D3

http://cxema.ru

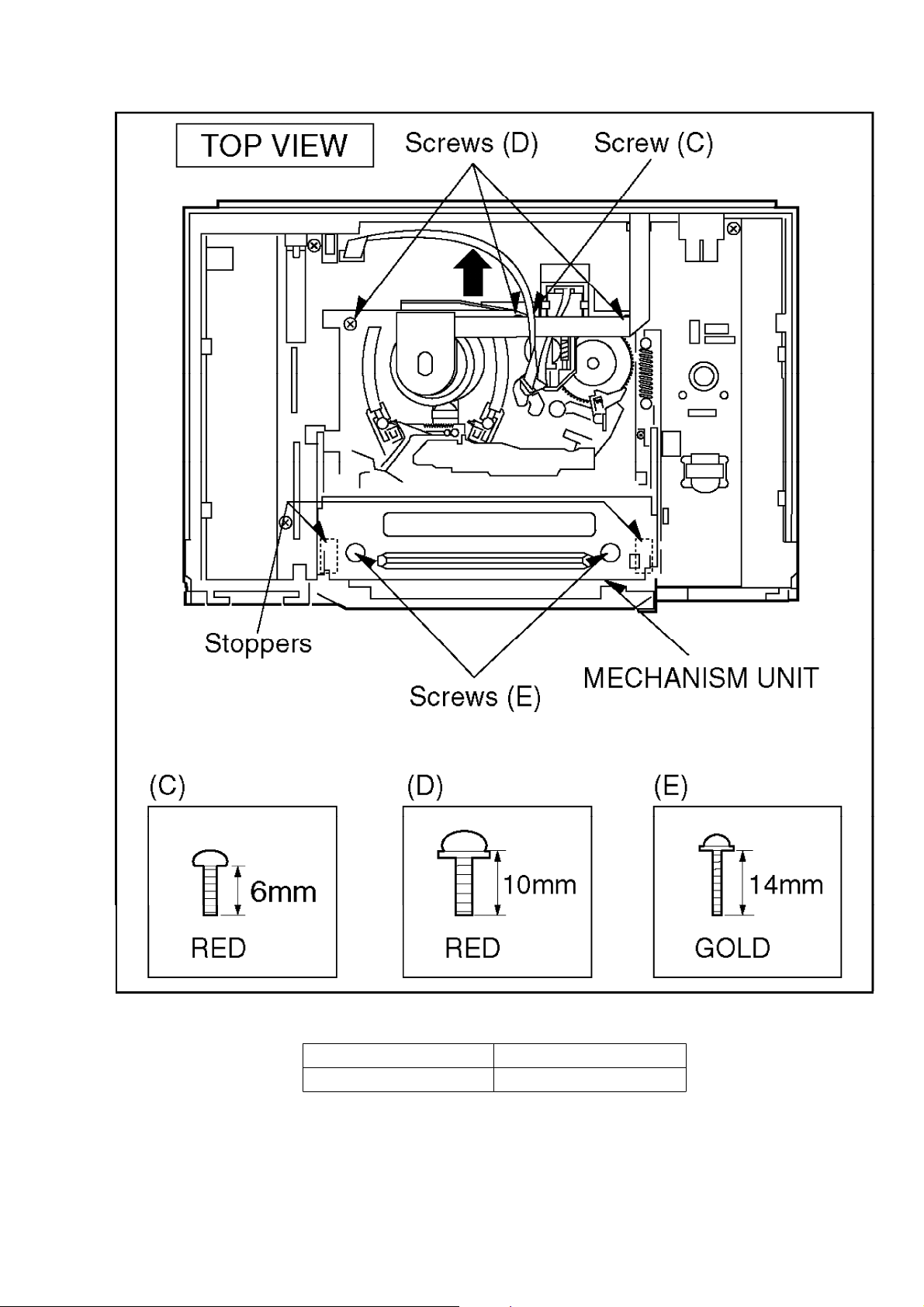

3. REMOVAL OF THE MECHANISM UNIT

Remove Screw (C)

Remove 3 Screws (D)

Remove 2 screw (E)

Note:

1. Keep pressing 2 stoppers on Cassette Holder Plate and Press Cassette Holder

Plate to the rear.

2. Remove the Mechanism Unit after bend the Cylinder Shield in the direction of the

arrow.

Fig. D4

http://cxema.ru

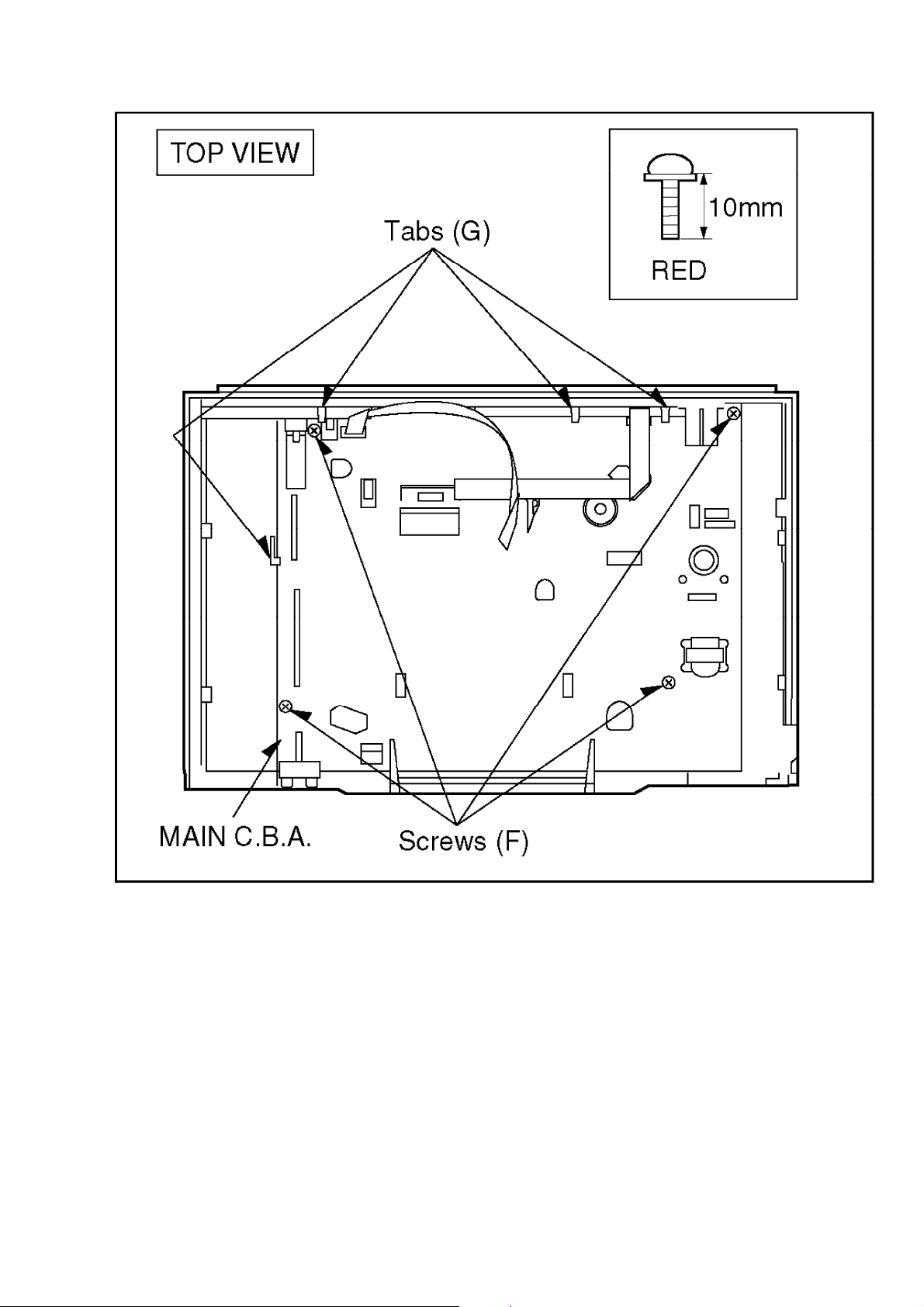

4. REMOVAL OF THE MAIN C.B.A.

Remove 4 screws (F)

Unlock 4 Tabs (G)

Fig. D5

http://cxema.ru

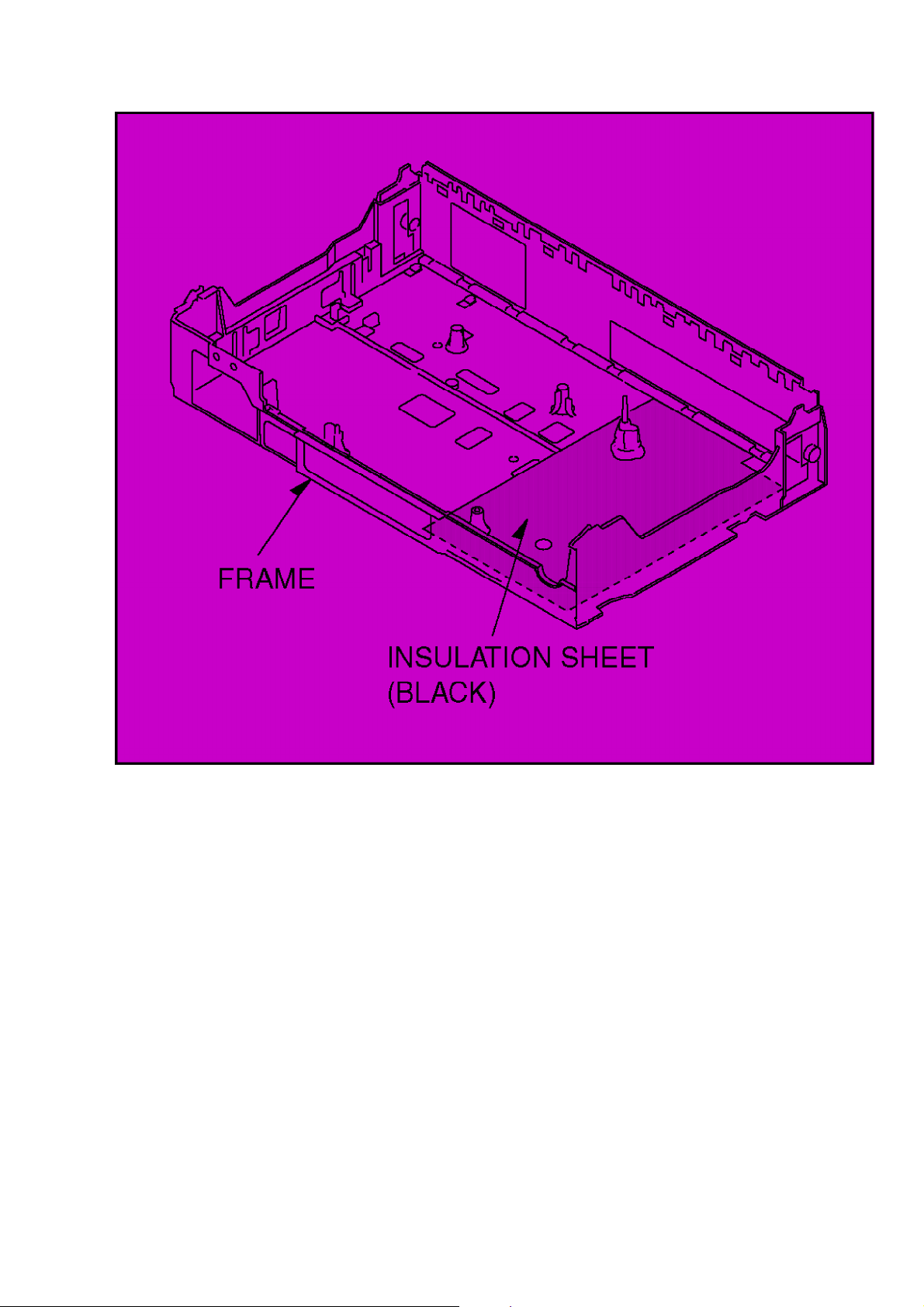

NOTE:

Before mounting the MAIN C.B.A. onto the frame, be sure to confirm that the

insulation sheet is mounted on the frame as shown in Fig. D6.

Fig. D6

http://cxema.ru

5. SERVICING POSITION

Fig. D7

http://cxema.ru

3.2. MECHANICAL ADJUSTMENT PROCEDURES

Refer to the Service Manual for Z-Mechanism Chassis.

(Order No. VRD9802005C2)

3.3. ELECTRICAL ADJUSTMENT PROCEDURES

3.3.1. TEST EQUIPMENT

The following equipments are required for Electrical Adjustments.

1. Dual-Trace Oscilloscope

- Voltage Range: 0.005-5V/div

- Frequency Range: DC-35MHz

- Probes: 10:1 / 1:1

2. Frequency Counter

- Frequency Range: 0-10MHz

- Probes: 1:1

3. Universal Counter

4. Digital Volt Meter (D.V.M.)

5. Video Sweep Generator

http://cxema.ru

6. Sinewave Generator

n

n

n

7. Video Pattern Generator

8. Monitor TV

9. DC Power Supply

10. VHS Blank Tape

11. VHS Alignment Tape

- Parts No.: VFJ8125H3F(PAL)

3.3.2. VCR SETTING

When no indication in the procedure, set each selector as follows.

1. TAPE SPEED: SP

2. CHANNEL: AV1/AV2

(Set to signal input terminal number)

3.3.3. ADJUSTMENTS

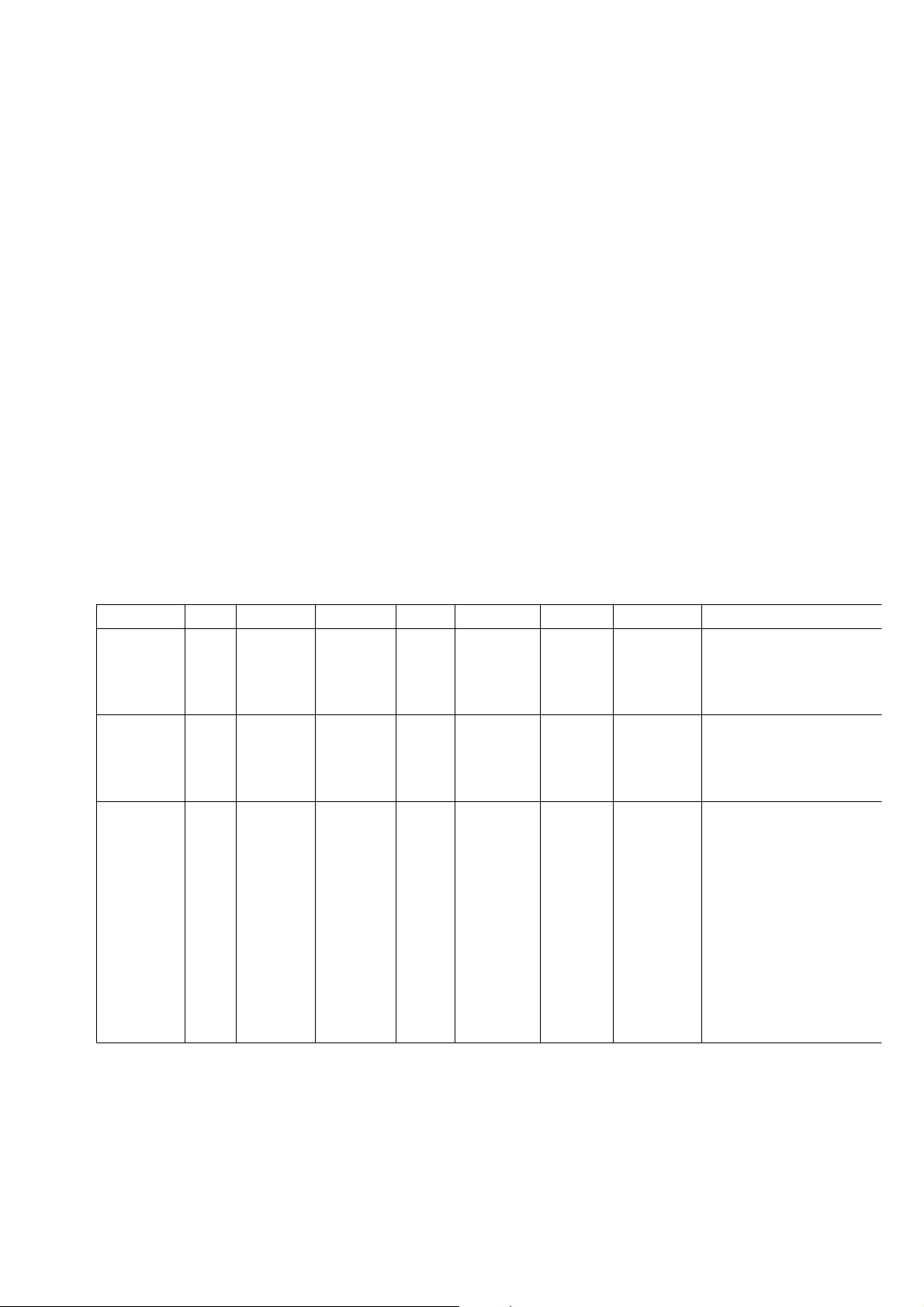

ITEM TP ADJ. MODE INPUT TAPE M. EQ. SPEC. REMARKS

PG

SHIFTER

ADJUSTMENT

AI

FUNCTION

ADJUSTMENT

VIDEO

FREQUENCY

RESPONSE

ADJUSTMENT

--- ---

--- ---

VIDEO

OUT

--- SP/LP/EP

PLAYBACK

PLAYBACK

(SELF-REC)

PLAYBACK

(SELF-REC)

---

PAL

COLOUR

BAR

VIDEO

SWEEP

(See

Fig.E1)

ALIGNMENT

TAPE

(PAL)

BLANK

TAPE

BLANK

TAPE

--- --- Refer to procedure of

PG SHIFTER

ADJUSTMENT as show

in Fig.E3.

--- --- Refer to the procedure

of AI FUNCTION

ADJUSTMENT as show

in Fig.E4.

OSCILLO

SCOPE/

VIDEO

SWEEP

GENERATOR

SP: 0+-1

(dB)

(90~110%)

LP: 0+-1

(dB)

(90~110%)

EP: 0+-3

(dB)

(70~140%)

(See Fig.

E2)

Refer to the procedure

of VIDEO FREQUENCY

RESPONSE

ADJUSTMENT as show

in Fig. E5.

http://cxema.ru

Fig.E1 Fig.E2

CONDITION: BURST SIGNAL OFF /

75 ohm TERMINATED

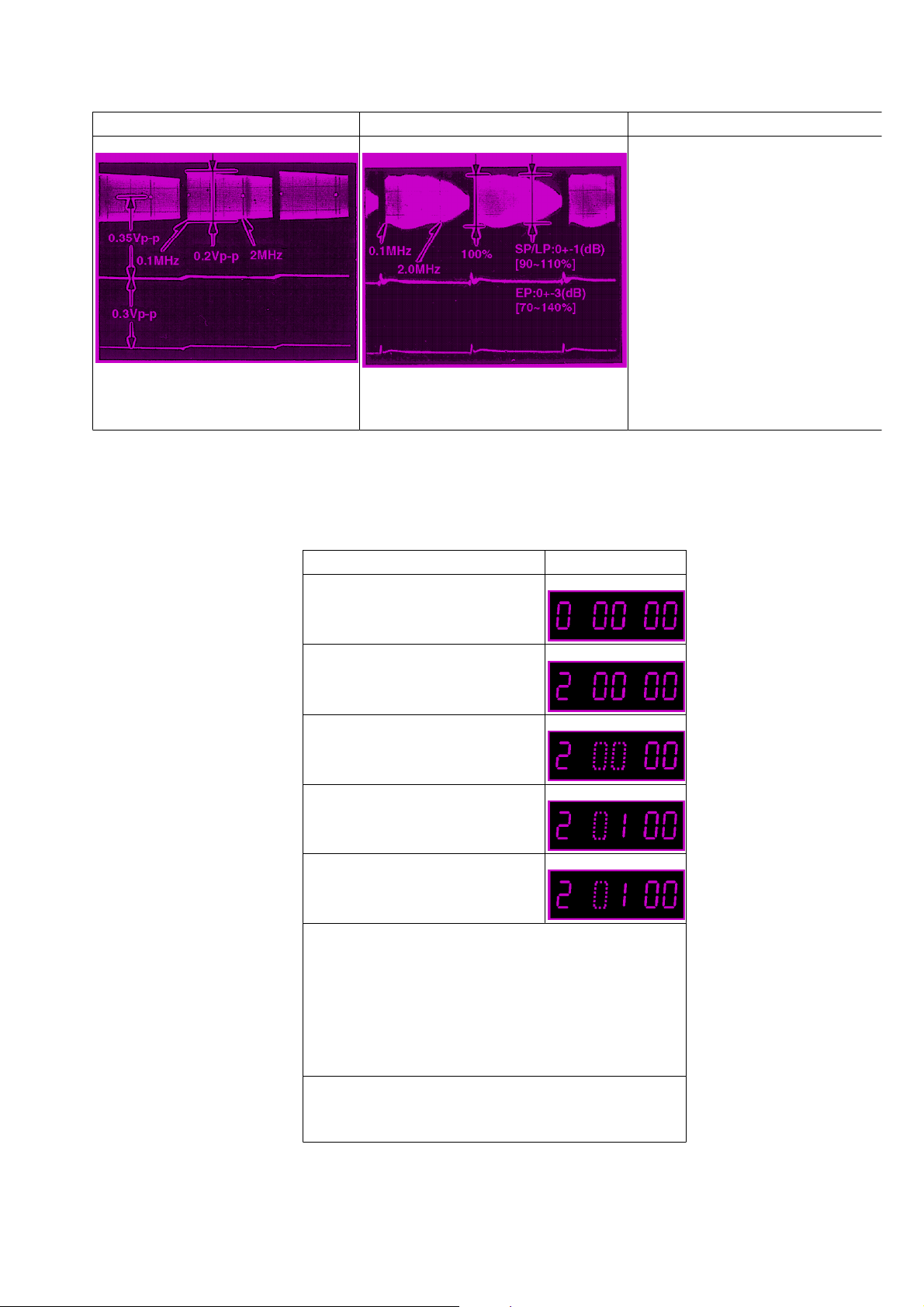

3.3.4. PG SHIFTER ADJUSTMENT

(AUTOMATIC)

PROCEDURES FIP DISPLAY

Press the FF and EJECT Keys

simultaneously for 3 seconds.

Press the FF and EJECT Keys

simultaneously twice.

Press the EJECT key for 3

seconds.

Press the CH UP key once.

Insert the Alignment cassette

tape. (PAL:VFJ8125H3F)

When the sequence of the automatical adjustment

has been terminated, the following action has

been made.

*SUCCEED: The cassette tape is ejected.

*ERROR : The "F2"is displayed on the FIP.

(Check the Servo/Syscon circuit and

Cylinder unit.)

Release the Service mode by pressing the EJECT

and FF keys simultaneously in 6 times until the FIP

becomes normal indication.

http://cxema.ru

Fig. E3

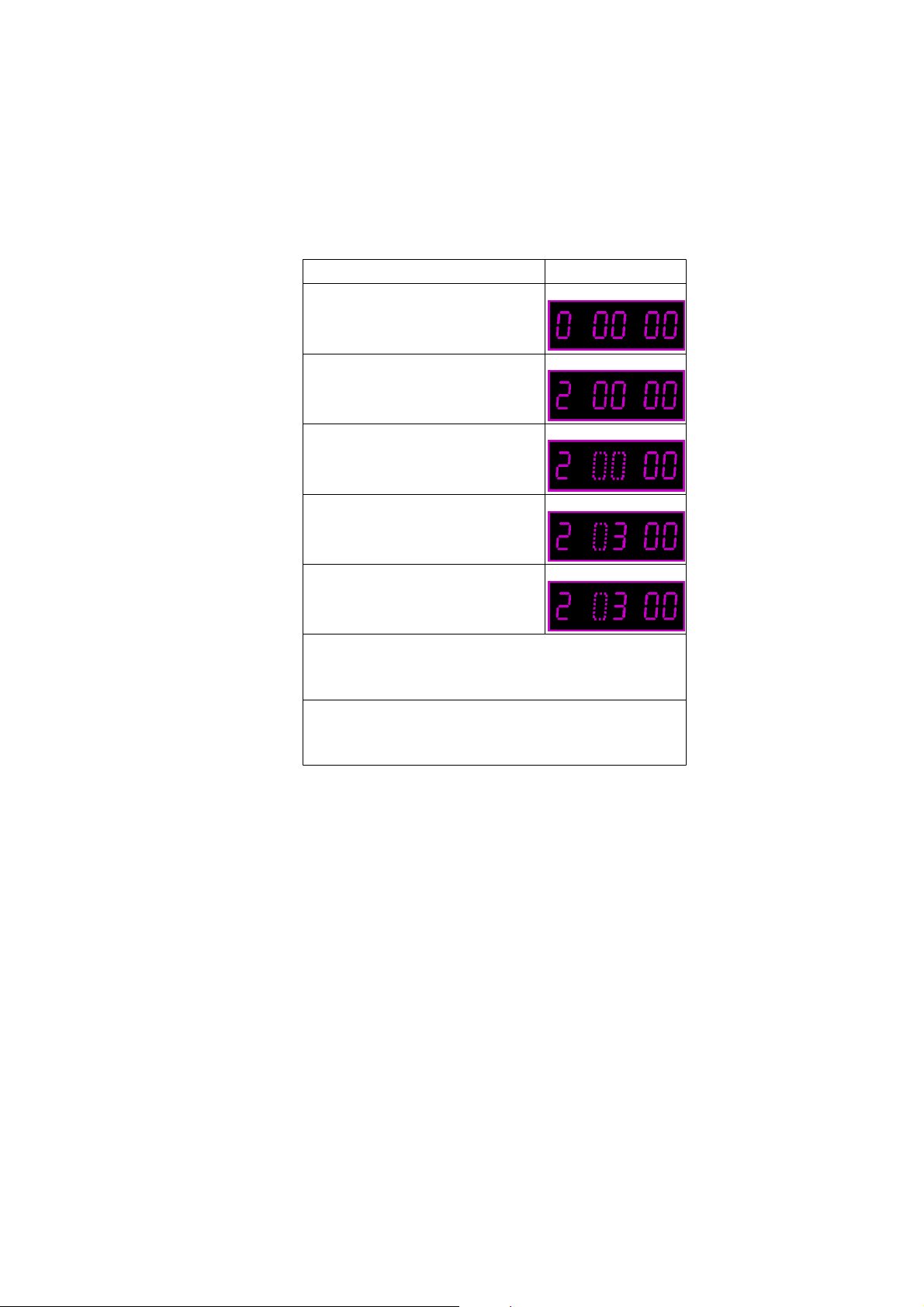

3.3.5. AI FUNCTION ADJUSTMENT (AUTOMATIC)

PROCEDURES FIP DISPLAY

Press the FF and EJECT Keys

simultaneously for 3 seconds.

Press the FF and EJECT Keys

simultaneously twice.

Press the EJECT key for 3

seconds.

Press the CH UP key in 3 times.

Insert the blank cassette tape.

(The adjustment is

automatically started.)

When the sequence of the automatical adjustment

has been terminated successfully, the VCR goes

to STOP mode.

Release the Service mode by pressing the EJECT

and FF keys simultaneously in 6 times until the FIP

becomes normal indication.

Fig. E4

3.3.6. VIDEO FREQUENCY RESPONSE ADJUSTMENT

http://cxema.ru

PROCEDURES FIP DISPLAY

Input the Video sweep signal.

(See Fig.E1)

Press the FF and EJECT Keys

simultaneously for 3 seconds.

Press the FF and EJECT Keys

simultaneously twice.

Press the EJECT key for 3

seconds.

Press the CH UP and/or CH

DOWN key until "11" is

displayed on FIP.

Insert the Self-recorded tape

and playback it. (SP/LP/EP

mode)

Connect the Oscilloscope to:

*CH1....Video Out (TW3002).

*CH2....V.FREQ.(TW6002)

Press the "4" key on the remote controller.

(Confirm that TW6002 becomes high(5V)).

Adjust the Frequency response by pressing the

"2"(increase) and/or "8"(decrease) key on the

Remote Controller. (See Fig.E2)

Store the Adjusted value by pressing the "5" key

on the Remote Controller.

Release the Service mode by pressing the EJECT

and FF keys simultaneously in 6 times until the FIP

becomes normal indication.

3.3.7. LOCATION OF TEST POINTS & CONTROLS

Fig. E5

http://cxema.ru

3.3.8. CIRCUIT BOARD LAYOUT

4. ABBREVIATIONS

Loading...

Loading...