Page 1

NE-1022F

APH (USA)

ORDER NO.PAPMOSH1201014CE

E10

Microwave Oven

© Panasonic Appliances Microwave Oven

(Shanghai) Co., Ltd. 2012.

Page 2

NE-1022F

2

Page 3

NE-1022F

CONTENTS

Page Page

1 CONTROL PANEL 4

2 SCHEMATIC DIAGRAM

3 CAUTIONS TO BE OBSERVED WHEN TROUBLESHOOTING

3.1. Check the grounding

3.2. Warning about the electric charge in the high voltage

capacitor

3.3. Part replacement.

3.4. When the 18 Amp fuse is blown due to the malfunction of

the monitor interlock switch:

3.5. Avoid inserting nails, wire, etc. through any holes in the

unit during operation.

3.6. Verification after repair

4 DISASSEMBLY AND PARTS REPLACEMENT PROCEDURE

4.1. Magnetron

4.2. Fan motor

4.3. Stirrer motor

4.4. Door assembly

4.5. Floor shelf and/or moving antenna

5 COMPONENT TEST PROCEDURE

5.1. Primary, Secondary Interlock Switch

5.2. Monitor Interlock Switch

5.3. High voltage transformer

5.4. High voltage capacitor

5

6

6

6

6

6

6

6

7

7

7

7

8

8

9

9

9

9

9

5.5. Magnetron

5.6. Diode

5.7. Protector diode

6 MEASUREMENTS AND ADJUSTMENTS

6.1. Adjustment of primary interlock switch, secondary interlock

switch and monitor interlock switch.

6.2. Measurement of microwave output

7 PROCEDURE FOR MEASURING MICROWAVE ENERGY

LEAKAGE

7.1. Equipment

7.2. Procedure for measuring radiation leakage

7.3. Record keeping and notification after measuremen t

7.4. At least once a year, have the radiation monitor checked

for calibration by its manufacturer.

8 TROUBLESHOOTING GUIDE

8.1. How to check the semiconductors using an OHM meter

9 EXPLODED VIEW AND PARTS LIST

9.1. EXPLODED VIEW

9.2. PARTS LIST

9.3. ESCUTCHEON BASE ASSEMBLY

9.4. DOOR ASSEMBLY

9.5. WIRING MATERIALS

9.6. PACKING AND ACCESSORIES

10

10

11

11

11

12

12

12

12

13

14

15

16

16

17

18

19

20

21

9

3

Page 4

NE-1022F

1 CONTROL PANEL

4

Page 5

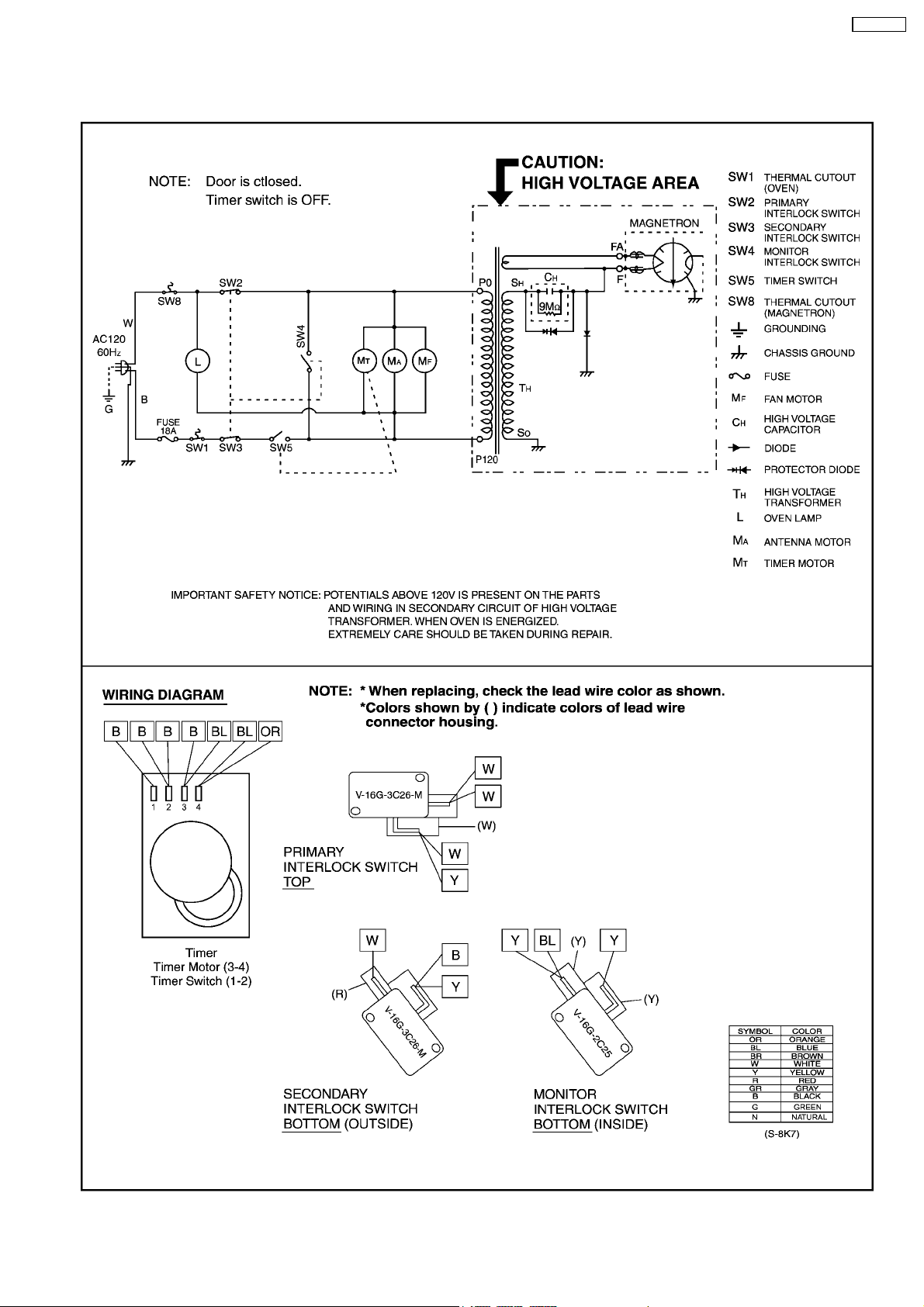

2 SCHEMATIC DIAGRAM

NE-1022F

5

Page 6

NE-1022F

3 CAUTIONS TO BE OBSERVED WHEN

TROUBLESHOOTING

Unlike many other appliances, the microwave oven is high

voltage, high current device. Though it is free from danger in

ordinary use, extreme care should be taken during repair.

CAUTION

Servicemen should remove their watches and rings whenever working

close to or replacing the magnetron.

3.1. Check the grounding

Do not operate on a 2-wire extension cord. The microwave

oven is designed to be grounded when used. It is imperative,

therefore, to make sure it is grounded properly before

beginning repair work.

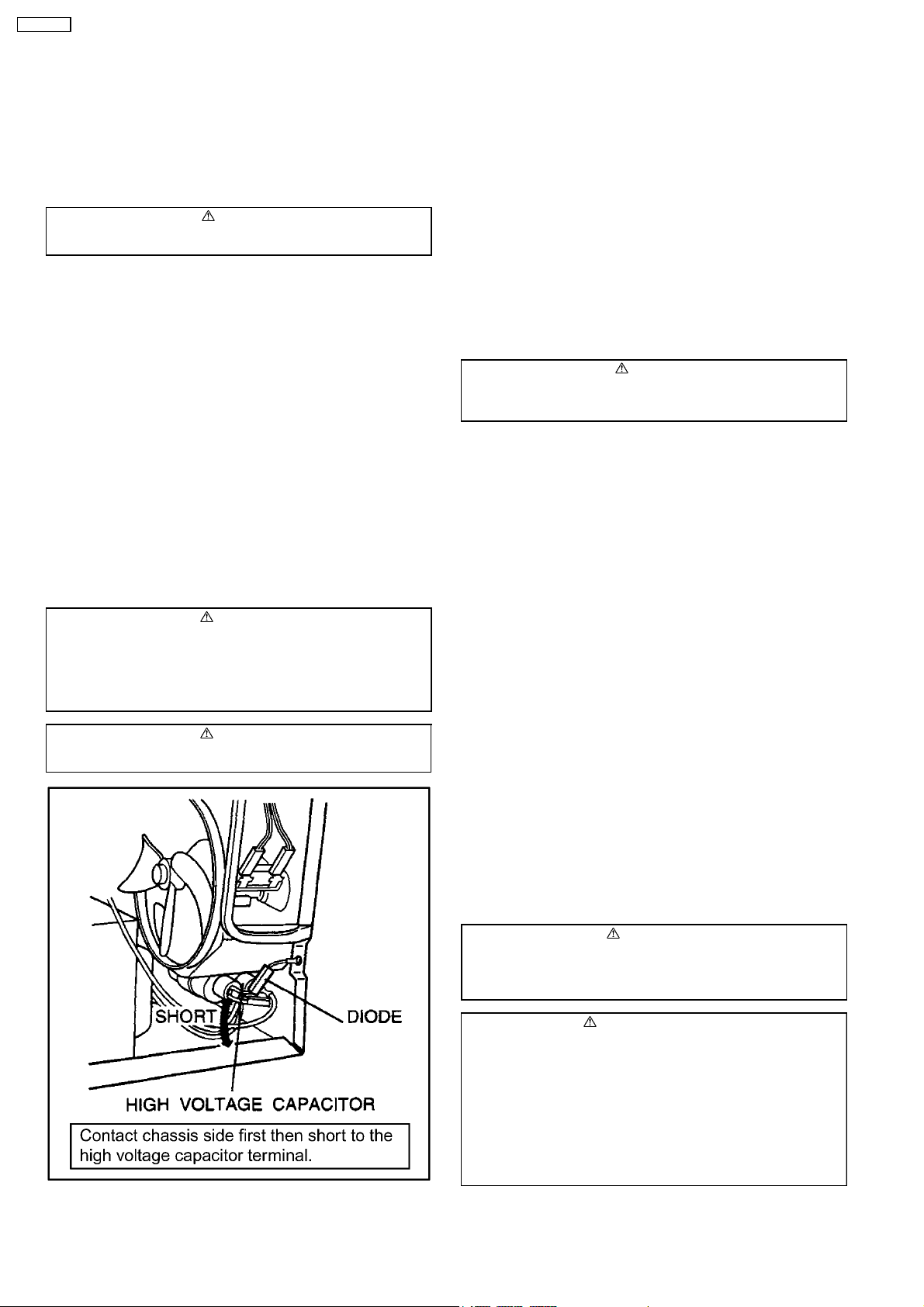

3.2. Warning about the electric

charge in the high voltage

capacitor

For about 30 seconds after the oven is turned off, an electric

charge remains in the high voltage capacitor.When replacing or

checking parts, remove the power plug from the outlet and

short the terminal of the high voltage capacitor (terminal of lead

wire from diode) to chassis ground with an insulated handle

screwdriver to discharge. Please be sure to contact the chassis

ground side first and then short to the output terminal.

WARNING

There is high voltage present with high current capabilities in the

circuits of the primary and secondary winding and filament winding of

the high voltage transformer. It is extremely dangerous to work on or

near these circuits with the oven energized.

DO NOT measure the voltage in the high voltage circuit including

filament voltage of the magnetron.

WARNING

Never touch any circuit wiring with your hand nor with an insulated

tool during operation.

3.3. Part replacement.

When troubleshootin g any part of component is to be replaced,

always ensure that the power cord is unplugged from the wall

outlet.

3.4. When the 18 Amp fuse is

blown due to the malfunction

of the monitor interlock

switch:

WARNING

When the 10 Amp fuse is blown due to malfunction of the short

switch, replace all of the components (Primary interlock switch,

Secondary interlock switch, Monitor interlock switch).

1. This is mandatory. Refer to “Measurements and

Adjustments” for the location of these switches.

2. When replacing the fuse, confirm that it has the appropriate

rating for these models.

3. When replacing faulty switches, be sure mounting tabs are

not bent, broken or deficient in their ability to hold the

switches.

3.5. Avoid inserting nails, wire, etc.

through any holes in the unit

during operation.

Never insert a wire, nail or any other metal object through the

lamp holes on the cavity or any holes or gaps, because such

objects may work as an antenna and cause microwave

leakage.

3.6. Verification after repair

1. After repair or replacement of parts, make sure that the

screws of the oven, etc. are neither loose nor missing.

Microwave energy might leak if screws are not properly

tightened.

2. Make sure that all electrical connections are tight before

inserting the plug into the wall outlet.

3. Check for microwave energy leakage.

MICROWAVE RADIATION OF LEAKAGE

USE CAUTION NOT TO BECOME EXPOSED TO RADIATION

FROM THE MICROWAVE MAGNETRON OR OTHER PARTS

CONDUCTING MICROWAVE ENERGY.

1.The following components have potentials above 2000V while the

appliance is operated.

* Magnetron

* High voltage transformer

* High voltage diode

* High voltage capacitor

Pay special attention to these areas.

2.When the appliance is operated with the door hinges or magnetron

installed incorrectly, the microwave leakage can exceed more than

5mW/cm

magnetron and the door hinges are is correctly installed.

2

. After repair or exchange, it is very important to check if the

CAUTION OF

IMPORTANT NOTICE

6

Page 7

4 DISASSEMBLY AND PARTS REPLACEMENT

PROCEDURE

NE-1022F

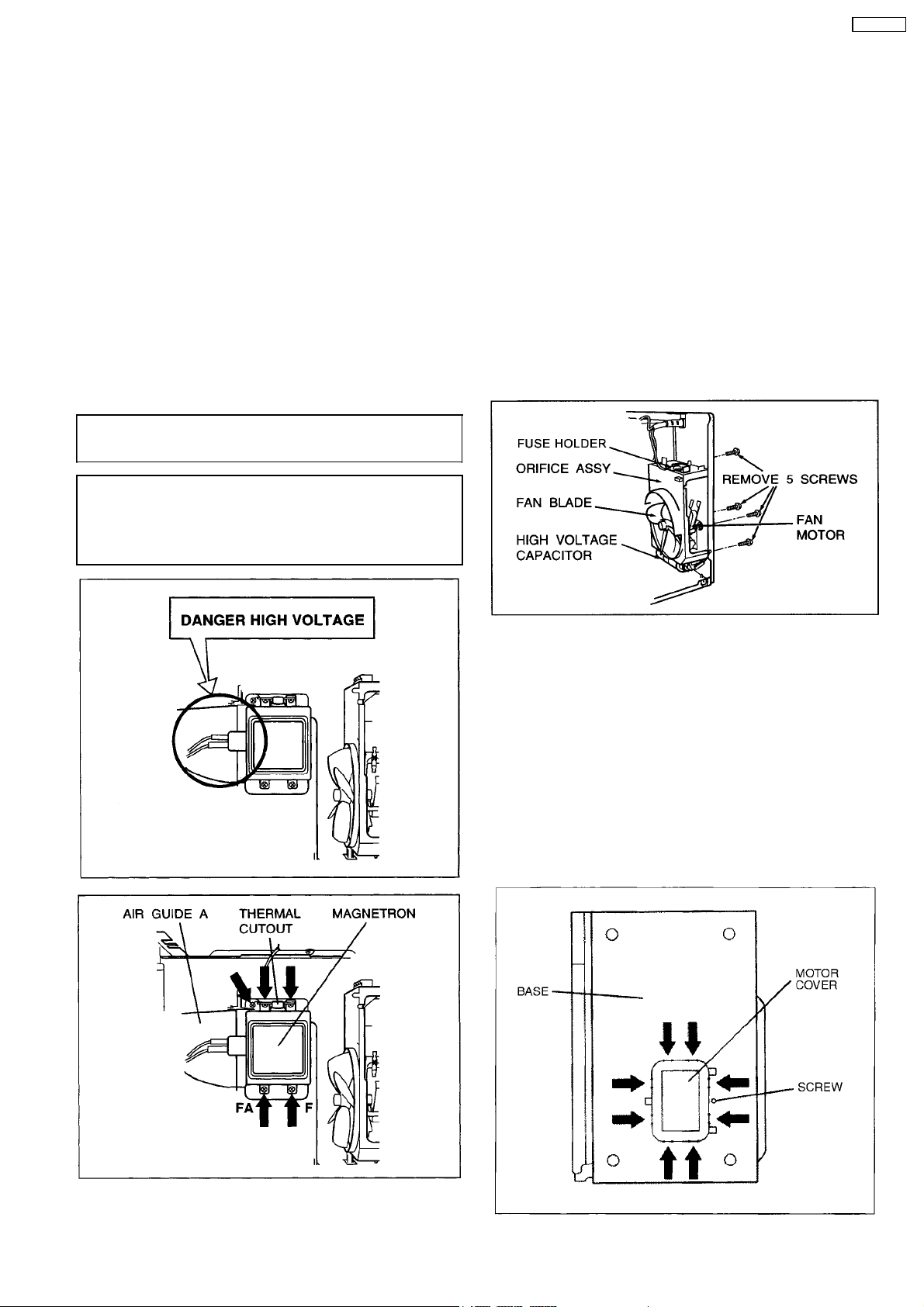

4.1. Magnetron

1. Discharge the high voltage capacitor.

2. Remove 2 screws holding magnetron thermal cutout.

3. Remove 1 screw holding air guide A.

4. Disconnect 2 high voltage lead wires from magnetron

filament terminals.

5. Remove 4 screws holding the magnetron.

NOTE:

After replacement of the magnetron, tighten mounting

screws properly making sure there is no gap between

the waveguide and the magnetron to prevent

microwave leakage.

CAUTION

When replacing the magnetron, be sure the antenna gasket is in

place.

CAUTION

When connecting 2 filament lead wires to the magnetron terminals,

be sure to connect the lead wires in the correct position. The lead wire

of high voltage transformer should be connected to "F terminal" and

the lead wire from high voltage capacitor should be connected to "FA

terminal".

4.2. Fan motor

1. Disconnect 2 lead wires from fan motor terminals.

2. Disconnect 2 lead wires from fuse holder terminals.

3. Disconnect 4 high voltage lead wires from high voltage

capacitor terminals.

4. Remove 5 screws holding fan motor and orifice assy,

detach the orifice assy with fan motor from oven assy.

5. Remove fan blade from the fan motor shaft by pulling it

straight Out.

6. Separate the fan motor from the orifice assy by freeing 2

catch hooks on the orifice assy.

4.3. Stirrer motor

1. Remove the motor cover by breaking off at the 8 spots

indicated by arrows with a cutter or the like. (See Figure)

Note:

After breaking off the motor cover, make sure the cut-off

portions are properly trimmed off or bend to inside so

that no sharp edge will expose to outside.

2. Disconnect 2 lead wires connected to the stirrer motor.

3. Remove the stirrer motor by removing 2 screws.

Note:

To reinstall the motor cover, use 4x6 screw.

7

Page 8

NE-1022F

4.4. Door assembly

1. Open the door and remove door C from door E by carefully

pulling outward starting from upper right hand corner.

2. Remove door key and door key spring.

3. Remove 2 screws holding side frame of door A.

4. Seperate the door A from the door E by freeing catch hooks

on the door A using a flat screwdriver.

To re-install components:

NOTE:

After replacement of the defective component parts

of the door, reassemble it properly and adjustment

so as to prevent an excessive microwave leakage.

Adjustment of the door assembly (Refer page 11).

5. When mounting the door to the oven, be sure to adjust the

door parallel to the bottom line of the oven face plate by

moving the upper hinge and lower hinge in the direction

necessary for proper alignment.

6. Adjust so that the door has no play between the inner door

surface and oven front surface. If the door assembly is not

mounted properly, microwave power may leak from the

clearance between the door and oven.

NOTE:

Door alignment is crucial. If door is misaligned, apply

pressure until alignment is achieved.

NOTE:

Adjust so that the upper portion of the door will touch

firmly to the oven cavity front plate, without pushing the

door. If the door assembly is not mounted properly,

microwave power may leak from the clearance between

the door and oven.

NOTE:

Always perform the microwave leakage measurement

test after installation and adjustment of door assembly.

4.5. Floor shelf and/or moving

antenna

1. Insert a phillips type screwdriver or equivalent approx. 2"

(5 cm) in shaft length in the access hole in the left side oven

wall as shown in Figure.

2. Carefully lift up the floor shelf by prying up with the

screwdriver until the floor shelf is lifted up over the level of

oven front opening.

3. Remove the floor shelf by lifting it out through the oven

front.

To replace moving antenna.

4. Remove the moving antenna by simply lifting it up off the

stirrer motor shaft.

NOTE:

When replacing the moving antenna, make sure the

plastic stirrer spacers are correctly in place. They

are necessary to stabilize the antenna by gliding

around the oven bottom as the antenna turns.

Be sure the gap between door E and cavity front plate will be

0.3~0.8mm.

8

Page 9

5 COMPONENT TEST PROCEDURE

NE-1022F

WARNING

1. High voltage is present at the high voltage terminal of the high

voltage transformer during any cook cycle.

2. It is neither necessary nor advisable to attempt measurement of the

high voltage.

3. Before touching any oven components, or wiring, always unplug

the power cord and discharge the high voltage capacitor (see page 6).

5.1. Primary, Secondary Interlock

Switch

1. Unplug lead connectors to Primary Interlock Switch and

Secondary Interlock Switch.

2. Test the continuity of switches at door opened and closed

positions with ohm meter (low scale).

Normal continuity readings should be as follows.

5.2. Monitor Interlock Switch

1. Unplug lead wires from H.V.transformer primary terminals.

2. Connect test probes of ohm meter to the disconnected

leads of the H.V. Transformer.

3. Test the continuity of Monitor Interlock Switch with door

opened and closed positions using lowest scale of the ohm

meter.

Normal continuity readings should be as follows.

5.3. High voltage transformer

1. Remove connectors from the transformer terminals and

check continuity.

2. Normal (cold) resistance readings should be as follows:

Secondary winding......................... Approx. 60 Ω~120 Ω

Filament winding........... ................... Approx. 0 Ω

Primary winding................................. Approx. 0 Ω ~2 Ω

5.4. High voltage capacitor

1. Check continuity of capacitor with meter on highest OHM

scale.

2. A normal capacitor will show continuity for a short time, and

then indicate 9MΩ once the capacitor is charged.

3. A shorted capacitor will show continuous continuity.

4. An open capacitor will show constant 9MΩ.

5. Resistance between each terminal and chassis should be

infinite.

5.5. Magnetron

Continuity checks can only indicate an open filament or a

shorted magnetron. To diagnose for an open filament or

shorted magnetron:

1. Isolate magnetron from the circuit by disconnecting the

leads.

2. A continuity check across magnetron filament terminals

should indicate one ohm or less.

3. A continuity check between each filament terminal and

magnetron case should read open.

9

Page 10

NE-1022F

5.6. Diode

1. Isolate the diode from the circuit by disconnecting the leads.

2. With the ohmmeter set on the highest resistance scale,

measure the resistance across the diode terminals.

Reverse the meter leads and again observe the resistance

reading. Meter with 6V, 9V or higher voltage batteries

should be used to check the front-to-back resistance of the

diode, otherwise an infinite resistance may be read in both

directions.

A normal diode´s resistance will be infinite in one direction

and several hundred kΩ in the other direction.

5.7. Protector diode

1. Isolate the protector diode assembly from the circuit by

disconnecting its leads.

2. With the ohmmeter set on the highest resistance scale,

measure the resistance across the protector diode

terminals.

Reverse the meter leads and again observe the resistance

reading. A normal protector diode´s resistance will be

infinite in both directions.

It is faulty if it shows continuity in one or both directions.

10

Page 11

6 MEASUREMENTS AND ADJUSTMENTS

6.1. Adjustment of primary

interlock switch, secondary

interlock switch and monitor

interlock switch.

NE-1022F

1. Mount the Primary interlock switch, the Secondary interlock

switch and the Monitor Interlock switch to the door hook

assembly as shown in illustration.

NOTE:

No specific individual adjustments during

installation of the Primary interlock switch,

Secondary interlock switch or Monitor interlock

switch to the door hook are required.

2. When mounting the door hook assembly to the oven

assembly, adjust the door hook assembly by moving it in

the direction of the arrows in the illustration so that the oven

door will not have any play in it. Check for play in the door

by pulling the door assembly. Make sure that the latch keys

move smoothly after adjustment is completed. Completely

tighten the screws holding the door hook assembly to the

oven assembly.

3. Reconnect the monitor interlock switch and check the

continuity of the monitor circuit and all interlock switches

again by following the component test procedures.

6.2. Measurement of microwave

output

The output power of the magnetron can be determined by

performing IEC standard test procedures. However, due to the

complexity of IEC test procedures, it is recommended to test

the magnetron using the simple method outlined below.

Necessary Equipment:

*1 liter beaker *Glass thermometer

*Wrist watch or stopwatch

NOTE:

Check the line voltage under load. Low voltage will

lower the magnetron output. Take the temperature

readings and heating time as accurately as possible.

1. Fill the beaker with exactly one liter of tap water. Stir the

water using the thermometer and record the water’s

temperature. (recorded as T1).

2. Place the beaker on the center of glass tray.

Set the oven for High power and heat it for exactly one

minute.

3. Stir the water again and read the temperature of the water.

(recorded as T2).

4. The normal temperature rise at High power level for each

model is as shown in table.

TABLE (1L-1min. test)

RATED OUTPUT TEMPERATURE RISE

1000W Min. 15.4°F(8.6°C )

11

Page 12

NE-1022F

7 PROCEDURE FOR MEASURING MICROWAVE ENERGY

LEAKAGE

7.2.1. Measurement with the outer panel

removed.

Whenever you replace the magnetron, measure for radiation

leakage before the outer panel is installed and after all

necessary components are replaced or adjusted. Special care

should be taken in measuring around the magnetron.

NOTE:

The U.S. Government standard is 5 mW/cm

customer’s home. 2mW/cm

voluntary standard. (1mW/cm

2

stated here is our own

2

for Canada)

2

while in the

7.1. Equipment

• Electromagnatic radiation monitor

• Glass thermometer 212°F or 100°C

• 600cc glass beaker

7.2. Procedure for measuring

radiation leakage

Note before measuring:

• Do not exceed meter full scale deflection. Leakage monitor

should initially be set to the highest scale.

• To prevent false readings, the test probe should be held by

the grip portion of the handle only and moved along the

shaded area in Figure no faster than 1 inch/sec

(2.5cm/sec).

• Leakage with the outer panel removed: less than 5mW/c m

• Leakage for a fully assembled oven with door normally

closed: less than 2mW/cm

• Leakage for a fully assembled oven [Before the latch switch

(primary) is interrupted] while pulling the door: less than

2mW/cm

1. Pour 275 ± 15cc (9ozs

water in a beaker which is graduated to 600cc, and place in

the center of the oven.

2. Set the radiation monitor to 2450MHz and use it following

the manufacturer´s recommended test procedure to assure

correct results.

3. When measuring the leakage, always use the 2 inch (5cm)

spacer supplied with the probe.

4. Tap the [Start] button or set the timer and with the

magnetron oscillating, measure the leakage by holding the

probe perpendicular to the surface being measured.

2

.

2

(1mW/cm2for Canada).

s

± 1/2oz) of 20°C ± 5°C (68° ± 9°F)

7.2.2. Measurements with a fully

assembled oven.

After all components, including outer panel are fully assembled,

measure for radiation leakage around the door periphery, the

door viewing window, the exhaust opening, control panel and

air inlet openings.

7.3. Record keeping and

notification after measurement

• After any adjustment or repair to a microwave oven, a

leakage reading must be taken. Record this leakage

reading on the repair ticket even if it is zero.

A copy of this repair ticket and the microwave leakage

reading should be kept by repair facility.

• Should the radiation leakage be more than 2 mW/cm

(1mW/cm2for Canada) after determining that all parts are in

good condition, function ing properly, and genuine

replacement parts as listed in this manual have been used,

2

.

immediately notify PSTC, PPR or PCI.

2

12

Page 13

7.4. At least once a year, have the

radiation monitor checked for

calibration by its

manufacturer.

NE-1022F

13

Page 14

NE-1022F

8 TROUBLESHOOTING GUIDE

DANGER: HIGH VOLTAGES

1. Ensure proper grounding before troubleshoot ing.

2. Be careful of high voltage circuit.

3. Discharge high voltage capacitor.

4. When checking the continuity of the switches or the high voltage transformer, disconnect one lead wire from these parts and then check

continuity with the AC plug removed. To do otherwise may result in a false reading or damage to your meter.

When disconnecting a plastic connector from a terminal, you must hold the plastic connector instead of the lead wire and then disconnect it,

otherwise lead wire may be damaged or the connector cannot be removed.

Before troubleshooting, operate the microwave oven following the correct operating procedures in the instruction manual in order

to find the exact cause of any trouble, since operator error may be mistaken for the oven’s malfunction.

14

Page 15

8.1. How to check the semiconductors using an OHM meter

NE-1022F

15

Page 16

NE-1022F

9 EXPLODED VIEW AND PARTS LIST

9.1. EXPLODED VIEW

16

Page 17

9.2. PARTS LIST

NOTE:

1. When ordering replacement part(s), please use part number(s) shown in this part list.

Do not use description of the part.

2. Important safety notice:

Components identified by

When replacing any of these components, use only manufa cture’s specified parts.

Ref. No. Part No. Part Name & Description Pcs/Set Remarks

1 F00069660AP CAUTION LABEL 1

2 F00338K00AP FUSE LABEL 1

3 A010T8K10AP CERAMIC TRAY 1

4 F0903000AG CUSHION RUBBER A 2

5 F0904000BB CUSHION RUBBER A 2

7 F100A3700AP BASE 1

8 A1008-1180S RUBBER FOOT 4

9 F10098K10AP CABINET BODY (U) 1

10 F11406V00HP STOPPER A 1

11 F10613130AP REAR COVER 1

12 F200A8K10AP OVEN CAVITY 1

13 F20194210AQ ANTENNA SPACER 2

14 F202K3700BP MOVING ANTENNA 1

15 F20553130AP CEILING COVER 1

mark have special characteristics important for safety.

NE-1022F

16 F30073700BP LOWER HINGE (B) 1

17 J3020-1480 DOOR HOOK 1

18 J3137-1480 HOOK SPACER B 1

19 J3138-1480 HOOK SPACER C 1

20 F4008-1480 FAN BLADE 1

21 F40253700BP AIR GUIDE A 1

22 F41445540AP ORIFICE 1

23 F621B6P10AP H.V.TRANSFORMER 1

25 F612E5Y30AP INCANDESCENT LAMP (U) 1

26 J6142-1450 MICRO SWITCH 1 (V-16G-3C26-M) PRIMARY INTERLOCK SWITCH

27 J6142-1450 MICRO SWITCH 1 (V-16G-3C26-M) SECONDARY INTERLOCK SWITCH

28 F61448K00AP ANTENNA MOTOR 1

29 F61456N00AP THERMAL CUTOUT 1 FOR OVEN CAVITY

30 F61458K10AP THERMAL CUTOUT 1 FOR MAGNETRON

32 ANE6161-3X0 MICRO SWITCH 1 (V-16G-2C25) MONITOR INTERLOCK SWITCH

33 F60374760GP CAPACITOR HOLDER 1

34 F62025G10XN DIODE,SI 1

35 F62308F20AP FUSE 1 18A

36 F62315G10XN FUSE HOLDER 1

37 XTTBFE4T12AS SCREW 5 FOR CABINET BODY

38 F60908K00AP H.V.CAPACITOR 1

40 F900C8K00AP AC CORD W/PLUG 1

41 A90823960AP CLIP 2 FOR COVER

42 XTWFL4+12T SCREW 4 FOR MAGNETRON

43 2M244-M1J1P MAGNETRON 1

44 J400A8K00AP FAN MOTOR 1 120V,AC SINGLE PHASE

45 J3136-1480 HOOK SPACER A 1

46 J3097-1480 LATCH SPRING 1

47 F0903000CD CUSHION RUBBER A 1

48 F10498K00AP SPACER CUSHION 1

49 XTWFA4+12LR SCREW 2

50 XYFBFE4+AF8 SCREW 2

51 XTC4+12BC SCREW 2 FOR CABINET BODY SIDE

52 F60708K30BP INSULATION SHEET 1

61 F606V8K00CP PROTECTOR DIODE (U) 1

65 J393C3710BP DOOR HOOK (U) 1

17

Page 18

NE-1022F

9.3. ESCUTCHEON BASE ASSEMBLY

Ref. No. Part No. Part Name & Description Pcs/Set Remarks

E1 F00078K70AP NAME PLATE 1

E2 F60018K20AP TIMER SWITCH 1

E5 F80206P00AP TIMER KNOB 1

E6 F80346P00AP ESCUTCHEON BASE 1

E10 F80356P00AP ESCUT FACIA 1

E12 XTWEFNE3+8Q SCREW 1

E14 F800L8K20SAP ESCUTCHEON BASE (BU) 1

18

Page 19

9.4. DOOR ASSEMBLY

NE-1022F

Ref. No. Part No. Part Name & Description Pcs/Set Remarks

D1 F02459660AP DHHS LABEL 1

D2 F30063700BP UPPER HINGE (A) 1

D3 F3018-1480 DOOR KEY A 1

D4 F30214000AP DOOR KEY SPRING 1

D5 XTN3+8BJ SCREW 2

D6 F30858960HN DOOR C 1

D7 F302K3700BP DOOR E (U) 1

D8 F31454J50XN DOOR SCREEN A 1

D9 F30016P00AP DOOR A 1

D10 F30026P00AP DOOR B (U) 1

D11 F31466P00AP DOOR SCREEN B 1

D12 F32863700AP HANDLE BRACKET 1

D13 F30706P00AP HANDLE PIECE A 1

D14 F31466P00AP HANDLE PIECE B 1

D15 F90096P00AP EARTH PLATE 1

D16 XTN4+16Q SCREW 2

D17 XTN4+8C SCREW 4

D18 XTCAFL4+12AFS SCREW 2

D19 F301F6P10AP HANDLE (U) 2

D20 F302A8K10SAP DOOR A (U) 1

D25 F390L8K10SAP DOOR (U) 1

19

Page 20

NE-1022F

9.5. WIRING MATERIALS

Ref. No. Part No. Part Name & Description Pcs/Set Remarks

W1 F030A8K20AP LEAD WIRE HARNESS 1

61 F606V8K00CP PROTECTOR DIODE (U) 1

20

Page 21

9.6. PACKING AND ACCESSORIES

NE-1022F

Ref. No. Part No. Part Name & Description Pcs/Set Remarks

P1 F00036P00AP OPERATING INSTRUCTION 1

P2 F01028K70SAP PACKING CASE, PAPER 1

P3 F01048K00AP UPPER FILLER 1

P4 F01058K00AP LOWER FILLER 1

P5 F01068K00AP P.E.BAG 1

P6 F01074W00AP DOOR SHEET 1

P8 F01924T00AP SHEET 1

P9 F01088K00AP TRAY PACKING 1

P10 F04243130AP SECURITY BOLT INSTALLATION

INSTRUCTION

1

21

01/12

S-8K7

Printed in China

Loading...

Loading...