Page 1

INSTRUCTION MANUAL

LED Beam Reflective Type Wafer Mapping Sensor

M-DW1

Thank you very much for using SUNX sensors.

Please read this Instruction Manual carefully

and thoroughly for the correct and optimum use

of this sensor. Kindly keep this manual in a

convenient place for quick reference.

䢇 Make sure to carry out the wiring in the power

supply off condition.

䢇

Take care that wrong wiring will damage the sensor.

䢇

Verify that the supply voltage variation is within the rating.

䢇

If power is supplied from a commercial switching

regulator, ensure that the frame ground (F.G.) terminal

of the power supply is connected to an actual ground.

䢇 In case noise generating equipment (switching

regulator, inverter motor, etc.) is used in the vicinity

of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

䢇 Do not use during the initial transient time (0.5 sec.)

after the power supply is switched on.

䢇 Extension up to total 10m is possible with 0.15mm

2

,

or more, cable. However, in order to reduce noise,

make the wiring as short as possible.

䢇

Do not run the wires together with high-voltage lines

or power lines or put them in the same raceway.

This can cause malfunction due to induction.

䢇 Take care that the sensor is not directly exposed to

fluorescent light from a rapid-starter lamp or a high

frequency lighting device, as it may affect the

sensing performance.

䢇 Avoid dust, dirt, and steam.

䢇 Take care that the sensor does not come in direct

contact with water, oil, grease, or organic solvents,

such as, thinner, etc.

䢇 Take care that dust, etc., does not collect on the

sensing surfaces, as it may result in malfunction.

Should it collect, clean the sensing surfaces by

blowing air or wiping them gently with a soft cloth.

䢇 Make sure to use an isolation transformer for the

DC power supply. If an auto-transformer (single

winding transformer) is used, this product or the

power supply may get damaged.

䢇 In case a surge is generated in the used power

supply, connect a surge absorber to the supply and

absorb the surge.

䢇

Set the distance between the sensor detection surface

and the wafer edge to be 45mm and mount the sensor

so that sensing is done at an angle of 12.5˚ with

respect to the wafer.

Mount using M4 (length 16mm) screws. The tightening

torque should be 1.2N•m or less. Further, although the

sensing distance may change due to variation in the

wafer position (wafer protrusion, orientation flat position,

etc.), if it is within

5

mm, stable sensing is possible.

䢇

This product is not a safety sensor. Its

use is not intended or designed to

protect life and prevent body injury or

property damage from dangerous

parts of machinery. It is a normal

object detection sensor.

䢇

In case the product may be subjected

to electrostatic discharge, make sure

to ground the stainless case.

3

MOUNTING

5

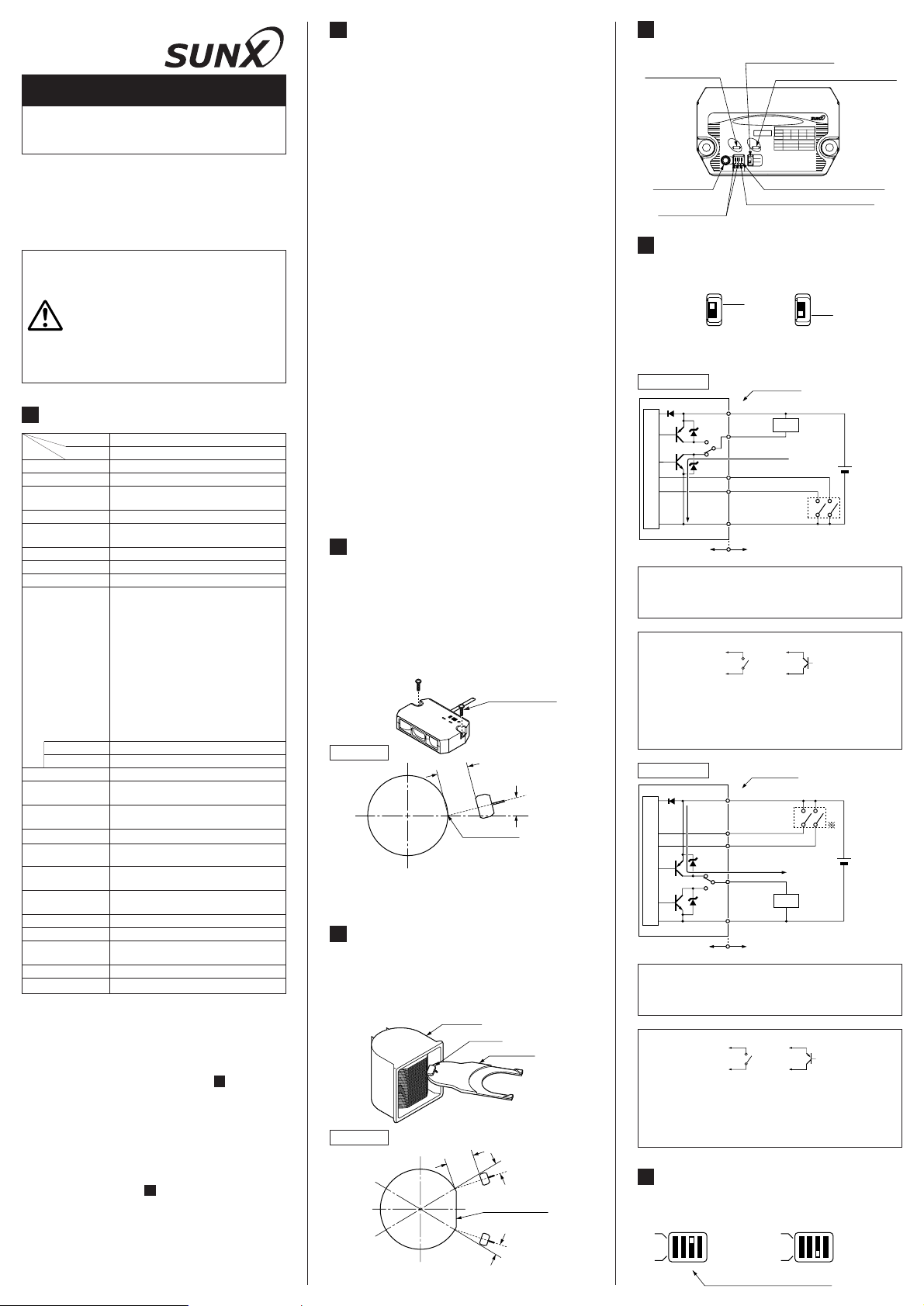

PART DESCRIPTION

1

SPECIFICATIONS

2

CAUTIONS

Notes: 1) In case of 8 inch or less wafers, the wafer pitch,

orientation flat or the surface condition may affect the

sensing.

Notes: 2) Polished wafers, etc., which have a sharp edge

cannot be detected since they do not reflect the light

in the light receiving direction.

Notes: 3) Since the position of the orientation flat may vary by

Ⳳ20˚ due to its rotation, refer to DETECTING

WAFER HAVING ORIENTATION FLAT for detection

of a wafer having an orientation flat.

Notes: 4) This is the pitch of an 8 inch wafer near its center

region when it is inserted in an inclined fashion. When

detecting a wafer having an orientation flat, the wafer

pitch becomes still smaller when sensing at positions

which avoid the orientation flat. In this case, the

sensing signal cannot be resolved and it becomes a

continuous, broad signal.

For details, refer to SENSING SIGNAL.

13

4

M4 screw

(Length 16mm)

Cassette

Sensor

Robot arm

45mm

Mounting angle

12.5˚

Sensor axis

Spot position

Wafer

center axis

Orientation flat

Detection

2

Detection

1

4

5

m

m

12.5

ⴗ

12.5

ⴗ

Note: If the wafer center axis and the sensor axis lie along a

straight line, detection is not possible. Always mount the

sensor at an angle to the wafer.

䢇

When detecting a wafer having an orientation flat,

mount the sensor so that a portion other than the

orientation flat is detected. Further, arrange to detect

the wafer from two different angles by moving the

robot arm, etc., and OR the signal so obtained.

6

I/O CIRCUIT DIAGRAMS

Brown : 12 to 24V DC

Blue : 0V

Black : Out

Pink : Light emission control

Violet : Ext. sensitivity selection

LowMidHighMaxSW

LLLLHHH

H

SW

PNP

NPN

OFDNON

D-ONL-ON

Sensitivity SW

LH

4

3

2

1

M-DW1

Wafer Mapping Sensor

STB OUT

SET 1 2 3 4

L

H

MADE IN JAPAN

Timer operation mode switch

Output operation mode switch

Output setting switch

Operation indicator (Orange)

Sensitivity

selection switch

Sensitivity

setting button

Stability indicator

(Green)

PNP

NPN

Users' circuitInternal circuit

Color code

(Brown)

ⳭV

(Black) Output

100mA max.

12 to 24V DC

Ⳳ10%

(Pink) Ext. light

emission control input

(Violet) Ext. sensitivity selection input

(Blue) 0V

ZD2

D

Tr2

ZD1

Tr1

Sensor circuit

Load

1

Ⳮ

ⳮ

Symbols...D: Reverse supply polarity protection diode

Z

D1, ZD2: Surge absorption zener diode

Tr

1: NPN output transistor

Tr

2: PNP output transistor

Non-voltage contact or PNP open-collector transistor

• External emission control input

0 to 3V, or 9V to

ⳭV (26.4V max.): Emission halted

Open, or 4 to 8V: Emission

• External sensitivity selection input

0 to 3V, or 9V to

ⳭV (26.4V max.): Input ON

Open, or 4 to 8V: Input OFF

Non-voltage contact or NPN open-collector transistor

• External emission control input

0 to 3V, or 9V to

ⳭV (26.4V max.): Emission halted

Open, or 4 to 8V: Emission

• External sensitivity selection input

0 to 3V, or 9V to

ⳭV (26.4V max.): Input ON

Open, or 4 to 8V: Input OFF

Symbols...D: Reverse supply polarity protection diode

Z

D1, ZD2: Surge absorption zener diode

Tr

1: NPN output transistor

Tr

2: PNP output transistor

䢇 The output can be selected as NPN output or PNP

output by the output setting switch.

4

DETECTING WAFER HAVING ORIENTATION FLAT

m1

m1

Top-view

Top-view

NPN output

PNP output

7

OUTPUT OPERATION

䢇 The output operation can be set either Light-ON or

Dark-ON by the output operation mode switch.

: Light-ON : Dark-ON

Output operation mode switch

L

H

L

H

1 2 3 4 1 2 3 4

Designation

Item

Model No.

Center measuring distance

Sensing object

Detectable surface

Sensing angle

Wafer pitch

Suitable cassette

Supply voltage

Current consumption

Output

Output operation

Short-circuit protection

Response time

External light

emission control input

External sensitivity

selection input

Operation indicator

Stability indicator

Timer function

Ambient

temperature

Ambient humidity

Emitting element

Material

Cable

Weight

LED beam reflective type wafer mapping sensor

M-DW1

45mm

3 inch or larger semiconductor wafer (Note 1)

Surface having a side edge which reflects

light in the light receiving direction (Note 2)

12.5˚Ⳳ5˚ (Note 3)

Separate sensing is possible at normal

sensitivity for 3mm pitch or more (Note 4)

SEMI standard FOUP cassette / open cassette

12 to 24V DCⳲ10% Ripple P-P 10% or less

65mA or less

NPN output / PNP output, selectable with

output selection switch

<NPN output>

NPN open-collector transistor

• Maximum sink current: 100mA

•

Applied voltage: 30V DC or less (between output and 0V)

•

Residual voltage: 1V or less (at 100mA sink current)

0.4V or less (at 16mA sink current)

<PNP output>

PNP open-collector transistor

• Maximum source current: 100mA

•

Applied voltage: 30V DC or less (between output and +V)

•

Residual voltage: 1V or less (at 100mA source current)

0.4V or less (at 16mA source current)

Light-ON / Dark-ON, selectable by switch

Incorporated (restored automatically)

500!s or less

0 to 3V, or 9V toⳭV (26.4V max.): Emission halted

Open, or 4 to 8V: Emission

0 to 3V, or 9V toⳭV (26.4V max.): Input ON

Open, or 4 to 8V: Input OFF

Orange LED (lights up when the output is ON)

Green LED (lights up under stable light

received condition or stable dark condition)

Approx. 2ms fixed OFF-delay timer,

switchable either effective or ineffective

0 to

Ⳮ55˚C (No dew condensation)

Storage:

ⳮ10 toⳭ70˚C

35 to 85% RH, Storage: 35 to 85% RH

LED (modulated)

Enclosure: ABS / SUS301

Lens: Acrylic

0.15 mm25-core cabtyre cable, 300mm long

75g approx.

Note: Make sure to operate the output setting switch in the

power supply off condition. If it is operated with power on,

it may get damaged.

D

ZD2

Tr2

ZD1

Tr1

Sensor circuit

Color code

(Brown)ⳭV

Load

(Black) Output

100mA max.

(Pink) Ext. light emission control input

(Violet) Ext. sensitivity selection input

(Blue) 0V

Users' circuitInternal circuit

or

Ⳮ

ⳮ

m1

12 to 24V DC

Ⳳ10%

or

Page 2

䢇 Sensing signal width

• The sensing signal which is output from the sensor

is as follows

1

The sensing signal has a width larger than the

thickness of the wafer.

2

The signal width also varies with the reflectivity of

the sensing edge.

High reflectivity (polish, aluminum film, etc.): Large signal width

Example:

Low reflectivity (nitride or oxide film processed): Small signal width

Example:

3

The signal width also changes with the sensing

distance or the sensing angle.

Maximum

sensitivity

(MAX)

Medium

sensitivity

(MID)

High

sensitivity

(HIGH)

Low

sensitivity

(LOW)

ON

OFF

ON

OFF

14

DIMENSIONS (Unit: mm)

13

SENSING SIGNAL

12

LIGHT EMISSION CONTROL FUNCTION

11

TIMER FUNCTION

9

External sensitivity selection input

8

SENSITIVITY SELECTION SETTING

10

SENSITIVITY SETTING

䢇

Although this sensor has an optical system whitch makes

it difficult for the background to affect the detection, the

background may have an effect when detecting small

diameter wafers. Hence, if the background gets detected,

or the stability indicator (green) lights off when the

cassette has no wafers, sensitivity setting should be

done so that the background does not have an effect.

However, the sensitivity reduces when sensitivity

setting is done.

䢇 Sensitivity setting is done when the background

affects the detection.

Press the sensitivity setting button in the actual

environment where the sensor is to be used (place

at which the background has an effect), but without

any wafers being present.

䢇

The sensitivity is set at the time the sensitivity setting

button is released. After the sensitivity setting, the

output once turns into the detection state. If the

sensitivity setting has been successfully done, the

output turns to the non-detection state after 25ms

approx. and the sensitivity is set so that the

background does not have an effect.

In case the output remains in the detection state,

since this is a condition in which detection cannot be

done, readjust the sensitivity selection switch. In this

case, set the sensitivity selection switch to one level

higher sensitivity than the present sensitivity level.

However, if the sensitivity selection switch is already

at maximum sensitivity (MAX), move the background

further away.

䢇

If sensitivity setting is done with nothing in the

background, the sensitivity returns to the initial value.

䢇

Since the sensitivity is stored in an EEPROM when the

sensitivity setting button is pressed, the setting need

not be repeated when the power is switched on again.

However, note that the EEPROM has a lifetime and its

guaranteed life is 100,000 write operation cycles.

䢇

Sensitivity can be selected from four levels by appropriate setting of the sensitivity selection switch (2 bit).

䢇 The external sensitivity selection input (violet)

becomes ON when it is connected to 0 to 3V, or 9V

to

ⳭV (26.4V max.), and becomes OFF when it is

kept open or connected to 4 to 8V.

䢇 If the sensitivity is selected with the external

sensitivity selection input, set the sensitivity

selection switch as shown in the table below.

䢇 Using the timer operation mode switch, it is possi-

ble to select an approx. 2ms fixed OFF-delay timer.

Since the output is extended by a fixed period, it is

useful when the connected device has a slow

response time.

䢇 Light emission is halted when the external light

emission control input (pink) is connected to 0 to

3V, or 9V to

ⳭV (26.4V max.).

In this case, the output turns to the dark state.

Setting method

Time Chart

Time Chart

• From the above, for determining the position of the

wafer from the sensing signal, calculate the center

position of the signal's ON region, while taking into

consideration the response time.

1st cross pitch

(small)

Orientation flat length

Normal sensing

position

2nd cross pitch

(large)

Cross-condition

wafer

Normal wafer

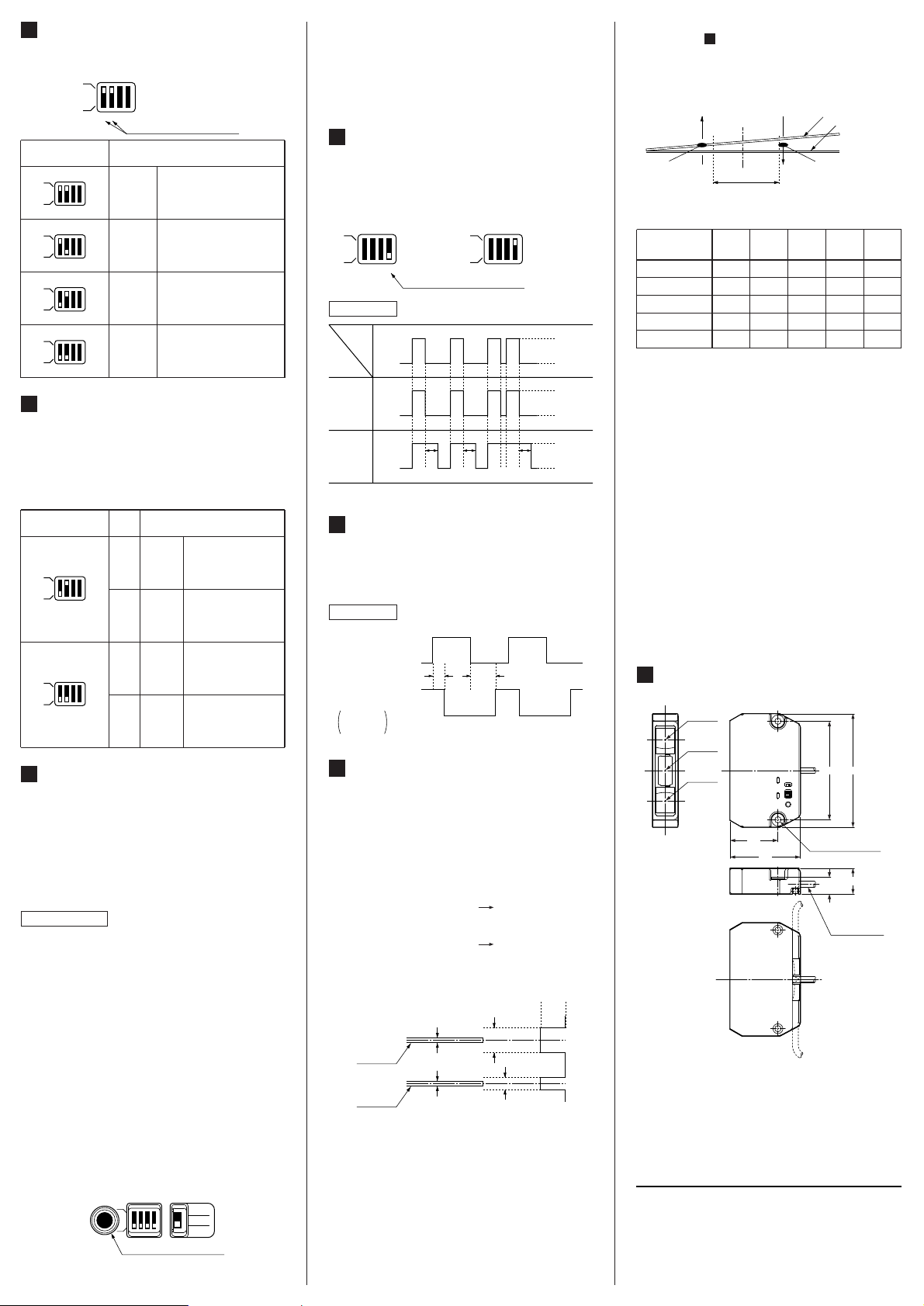

• The calculated pitch based on the wafer size is

given in the table below.

• From the above, it is seen that, since the pitch of

the cross-condition wafer reduces, the pitch

resolution required for high reflectivity wafers

becomes more stringent than the specified

resolution of 3mm. Hence, the sensing signal from

two wafers may not be resolved and may become a

continuous signal.

Further, the sensing signal may also change due to

the sensitivity setting, the reflectivity of the wafer,

and the sensing conditions (sensing distance or

sensing angle).

For the above reasons, in case of wafers which

have been cross-inserted, since the small crosspitch side is similar to overlapping wafers, the

sensing signal of two wafers may become a

continuous signal or may get resolved.

• If the orientation flat happens to get in the position

of sensing, sensing is not possible in one of the two

sensing positions. Therefore, if the wafer is crossinserted, a resolved signal may not be output, and

in this case, the information on the wafer position

calculated from the sensing signal will be

erroneous.

"4.2 cable,

300mm long

2-"4.5 mounting

holes

Beamreceiving

part

Beamreceiving

part

Beam

emitting

part

18.3

12

50

34

80.670

PRINTED IN JAPAN

http://www.sunx.co.jp/

Head Office

SUNX Limited

Phone: ⴐ81-(0)568-33-7861 FAX: ⴐ81-(0)568-33-8591

Overseas Sales Dept.

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: ⴐ81-(0)568-33-7211 FAX: ⴐ81-(0)568-33-2631

Sensitivity selection

switch

Sensitivity

Maximum

sensitivity

(MAX)

High

sensitivity

(HIGH)

Medium

sensitivity

(MID)

Low

sensitivity

(LOW)

Used for low reflectivity

wafers with nitride or oxide

film processing, or for thin

wafers (0.3 to 0.4mm)

Sensitivity between maximum

sensitivity and medium

sensitivity

Used for high reflectivity

polished wafers, etc., or for

3mm wafer pitch

Lowest possible sensitivity

setting

L

H

1 2 3 4

L

H

1 2 3 4

3 inch (75mm)

4 inch (100mm)

5 inch (125mm)

6 inch (150mm)

8 inch (200mm)

4.75mm

4.75mm

4.75mm

4.75mm

6.35mm

22.2mm

32.5mm

42.5mm

57.5mm

59.3mm

0.380mm

0.625mm

0.625mm

0.675mm

0.725mm

1.58mm

1.54mm

1.52mm

1.43mm

2.19mm

3.17mm

3.21mm

3.23mm

3.33mm

4.16mm

Wafer size

Normal

pitch

Orientation

flat length

Wafer

thickness

Cross pitch

(small)

Cross pitch

(large)

Sensitivity selection

switch

Ext.sensitivity

selection input

Sensitivity

Used for low reflectivity

wafers with nitride or oxide

film processing, or for thin

wafers (0.3 to 0.4mm)

Used for high reflectivity polished wafers,

etc., or for 3mm wafer

pitch

Sensitivity between

maximum sensitivity

and medium sensitivity

Lowest possible sensitivity setting

L

H

1 2 3 4

L

H

1 2 3 4

L

H

1 2 3 4

L

H

1 2 3 4

m The cable

direction can be

changed.

Wafer thickness

t=0.6mm

Signal width

1.5mm approx.

Wafer thickness

t=0.6mm

Signal width

1.1mm approx.

䢇 Narrow pitch sensing signal width

• In case of

4

DETECTING WAFER HAVING ORI-

ENTATION FLAT, when the sensor is mounted at

positions which avoid the wafer orientation flat, the

pitch of a cross-condition wafer changes as shown

in the figure below.

H

L

1 2 3 4

Sensitivity selection switch

H

L

: Approx. 2ms

OFF-delay

timer

1 2 3 4 1 2 3 4

Timer operation mode switch

H

L

: Without

timer

Sensing

condition

Operation

Normal

With

timer

T T T

Timer period: T= 2ms approx.

Sensing

Not

sensing

ON

OFF

ON

OFF

External light

emission

control input

Output

In case of

Light-ON

ON

OFF

T1 T2

ON

OFF

T1=5ms, T2=20ms max.

H

L

Sensitivity setting button

NPN

PNP

High

reflectivity

wafer

Low

reflectivity

wafer

Wafer

thickness

t=0.6mm

Wafer

thickness

t=0.6mm

Sensing signal

width 1.5mm

approx. (Example)

Sensing signal

width 1.1mm

approx. (Example)

ON OFF

Loading...

Loading...