Page 1

MCO-20AIC

Large Capacity

Cell Culture

CO2 Incubator

Features:

• The industry’s most complete cell culture

solution for highly regulated applications or

conventional incubation.

• Patented SafeCell UV system decontaminates

the chamber air without downtime

Panasonic… the new name for SANYO

www.panasonic.com/biomedical

Page 2

Key Features & Benefits

The Panasonic Large Capacity Cell Culture CO2 incubator has the capacity and flexibility to grow with your culturing needs while providing a

precise and repeatable environment.

SafeCell UV

Decontamination

(U.S. Patent 6255103)

The patented SafeCell UV system scrubs

interior airflow to destroy airborne and

humidity pan contaminants.

CO2 Control

Panasonic proprietary single-beam (IR)

CO

sensor delivers precise CO2 control,

2

quick recovery following door openings,

and auto sampling with no moving

parts. Ceramic-based infrared system is

maintenance free, and continuous zero

calibration is standard.

InCu-saFe® Copper

Stainless Steel Alloy

InCu-saFe® copper-enriched stainless

steel alloy combines the corrosion

resistance and durability of stainless

steel with the germicidal properties

of copper. The inCu-saFe

®

walls and

shelves significantly reduce the risk of

contamination developing on internal

surfaces.

SafeCell UV

Active Background

Contamination Control

(5 min. door openings)

PREP: 15 min.

Before sterilization by UV lamp, remove all attachments

SafeCell UV 24hr

Decontamination Protocol

(24 Hours, total)

(trays, tray supports, side supports, top duct, rear duct,

humidifying pan, and pan cover with fan) in the chamber.

Ideal for Highly Regulated or

Sensitive Applications

The combination of Panasonic’s CO2

incubator performance functions permit

use with confidence in high-value cell

protocols among hard-to-grow cell lines,

cells highly sensitive to contamination,

ultra-sensitive media and reagents, or

protocols that require a strict isolation and

sterilization between processes.

Active Background

Contamination Control

At the base of the plenum, an isolated

beam of high intensity, ozone-free UV

light destroys contaminants in the air and

in the water pan, away from cell cultures,

not simply collected in a HEPA filter. Even

small particles, which can easily pass

through a HEPA filter, are destroyed.

Plenum components isolate UV light

to protect cell cultures, while the UV

process continues in the background as

programmed without downtime.

Airborne contaminants are eliminated

by an automatic 5 minute UV cycle

(programmable 0 - 30 minutes). Trace

contaminants which attach to walls,

shelves and plenum components are

destroyed by the germicidal properties of

the inCu-SaFe

®

copper-enriched stainless

steel surfaces.

Other design factors which help mitigate

contamination include condensation

control, inner door gasket design and

triple 0.3 micron filters for vent air and

CO

sensor sampling.

2

• The SafeCell UV air flow plenum

promotes temperature uniformity

through the chamber, shaped by

natural and mechanical convection

through and around the perforated

shelves with gentle circulation through

the plenum for UV sterilization and

warm water humidification.

• Contaminants contained within the

distilled water in the humidity pan are

destroyed by UV.

• Sterile, humidified air is released from

the lower plenum for vertical convection through and around the perforated

shelves

• Interior air motion stops when the door is

opened, minimizing movement of room

air into the chamber.

Start Incubation

Start Cycle: 24 hours

Follow keypad function code.

UV lamp is on for 24 hours.

SafeCell UV on:

5 min. after door

opening

Scrubs interior air

flow to destroy

airborne and

humidity pan

contaminants.

SafeCell UV on:

5 min. after door

opening

SafeCell UV on:

5 min. after door

opening

Elapsed Time:

Conventional High Heat

Decontamination

(24 Hours, total)

15 min. 30 min. 45 min. 1 2

PREP: 15 min.

Remove interior components

sensitive to high heat.

Start Cycle: 90 min.

Interior chamber elevates to high heat.

2 Large Capacity Cell Culture CO2 Incubator www.panasonic.com/biomedical

3

Sterilize: 14 hours

Interior chamber remains at high heat.

4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Page 3

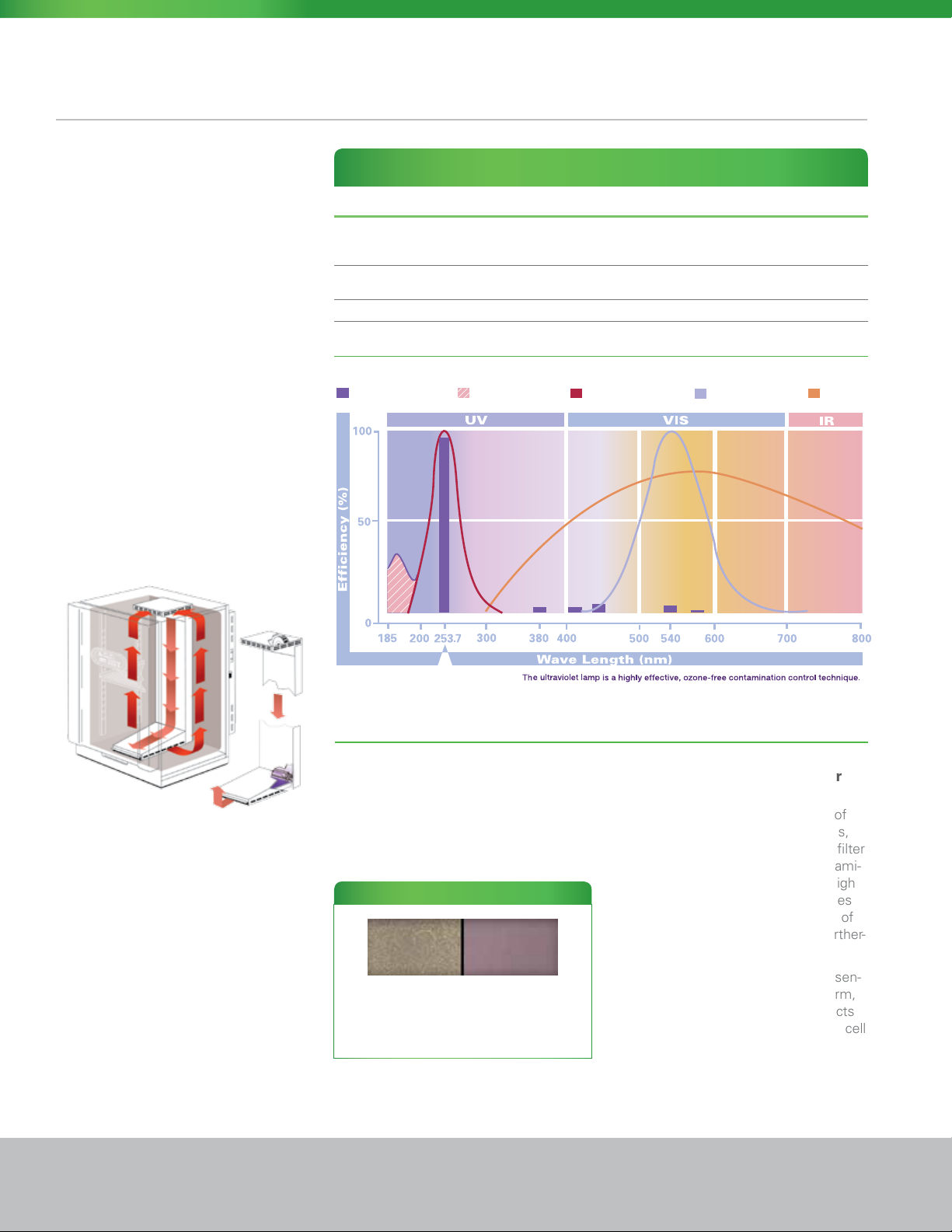

Contamination Control

UV Decontamination vs.

High Heat Decontamination

Independent testing1 confirms that the

UV decontamination technique employed

by the Panasonic incubator is equally

effective against contamination as

conventional high heat decontamination

over a range of +90°C to +140°C.

Whenever overnight or event

decontamination of the Panasonic

incubator chamber is desired, all interior

components are removed for autoclaving,

exposing all interior surfaces to ultraviolet

light.

During normal operation when cells are

being incubated within the chamber,

the UV lamp is visibly isolated from the

cell culture chamber by a plenum cover

over the humidity pan, permitting UV

decontamination of circulated, humidified

air and humidity pan surface water to

remain in process without damaging the

cells.

1

A Comparative Analysis of Ultraviolet Light Decontamination vs.

High Heat Sterilization in the Cell Culture CO2 Incubator, with the Use

of Copper-Enriched Stainless Steel Construction to Achieve Active

Background Contamination Control" H. Busujima; D. Mistry 2007

UV vs. High Heat Comparison

High Heat

Method Panasonic UV

Test Results, Maximum Log Reductions

Bacteria > 4.5 > 4.5 > 4.5

Yeast > 2.9 > 2.9 > 2.9

Mold > 2.7 > 2.7 > 2.7

Decontamination Options

Overnight

Active Background

Contamination Control

+140°C +90°C

Mycoplasma Survival Results

Mycoplasma

Strain

Mycoplasma

fermentans PG18

Mycoplasma

orale CH19299

Mycoplasma

arginini G230

Mycoplasma

hominis PG21

Positive

Control

survival no survival no survival survival

survival no survival no survival survival

survival no survival no survival survival

survival no survival no survival survival

Conventional Type

304 Stainless Steel

Panasonic

InCu-saFe

®

Conventional

Copper C1100

SafeCell UV on:

5 min. after door

opening

Chart summarizes test results with four strains of mycoplasma. Results demonstrate how Panasonic inCu-saFe

®

copper enriched stainless steel alloy offers germicidal properties of conventional C1100 copper while maintaining

both corrosion-proof and discoloration-resistant properties of conventional Type 304 stainless steel.

Detailed test results are available from Panasonic.

SafeCell UV on: 5 min.

(every 12 hours)

Finish.

Shelves, humidity pan and plenum

are returned to operating position.

Finish.

Incubator must cool from high heat temperatures to near ambient.

3

Page 4

Contamination Control

Ozone ReleasePanasonic Lamp Germicidal Effect Eye Sensitivity Sunlight

SafeCell UV System

MCO-20AIC includes SafeCell UV

contamination control technology based

on an integrated combination of narrow

bandwidth, ozone-free ultraviolet light,

ceramic infrared CO

copper-enriched stainless steel alloy

interiors and Direct Heat and Air Jacket

heating managed by a microprocessor

controller.

These incubators offer the industry’s

most stable cell culture environment

and are useful for the most critical

applications where continuous

contamination control is essential to

cell viability.

Panasonic SafeCell UV Series CO

incubators offer significant economic

benefits by minimizing interruptions

for decontamination, by improving cell

culture growth and expression under

stable, repeatable conditions, and by

minimizing the potential for product loss.

control, inCu-SaFe®

2

2

SafeCell UV Lamp Program Cycles

Mode Function

After H2O

Vaporization

After Door

Opening

OFF If UV protection is not desired.

24 Hour

Continuous ON

The UV lamp automatically cycles ON for up to 90 minutes following the ten -minute H

2

vapor cycle, reducing the H

onto a naturally cooler section of the interior oor for easy wipe-up.

UV lamp automatically ON for ve minutes af ter door is closed decontaminates

incoming room air.

Useful for overnight decontamination prior to rst use, clinical decontamination protocols

between patients, or following total chamber wipe -out after maintenance or ser vice.

to water droplets. These droplets automatically condense

2O2

2O2

• SafeCell UV includes a programmable

ultraviolet lamp, isolated from cell

cultures, that sterilizes conditioned air

and humidity reservoir water to prevent

contamination without affecting cell

cultures in vitro.

• SafeCell UV inhibits the growth of mycoplasma, bacteria, molds, spores, yeasts

and fungi without costly HEPA filter air

scrubbers which accumulate contaminants in the chamber air.

The SafeCell UV lamp cycle is factory set for normal use, and can be re-programmed as desired by entering parameters

through the central microprocessor control panel.

• High temperature decontamination systems, which can actually encourage in vitro growth of heat resistant thermophilic

and hyperthermophilic microorganisms,

are avoided.

Eliminates Need for HEPA Filter

and Heat Cycle

The MCO-20AIC inhibits the growth of

mycoplasmas, bacteria, molds, spores,

yeast and fungi without costly HEPA filter

air scrubbers which accumulate contami-

Humidifying Water Comparison

nants in the chamber, or disruptive, high

temperature decontamination schemes

which can actually encourage growth of

heat resistant thermophilic and hyperther-

mophilic microorganisms in vitro.

No exposure to UV

Test results after three months confirm the

efficacy of Panasonic SafeCell UV protection

on humidifying water after three months.

Five-minute exposure to

SafeCell UV

As a result, the MCO-20AIC offers a sen-

sitive yet robust platform for short term,

high-throughput drug discovery projects

as well as intermediate and long-term cell

culture investigations.

4 Large Capacity Cell Culture CO2 Incubator www.panasonic.com/biomedical

Page 5

Control System

Control and Monitoring

• Control and information center includes

central mounted touchpad and digital

display.

• Precise PID logic controls adjust to

all temperature setpoints and alarm

parameters.

Microprocessor Based Controller

Panasonic expertise in electronic

innovations applies to the Panasonic

MCO-20AIC microprocessor control

system. All incubator functions are

managed by a fully integrated controller

which acquires and processes information

from data entry, setpoints and alarm

parameters.

• P.I.D. Proportional, integral and derivative controls supervise temperature, and

other features for accurate, repeatable

performance.

• A range of setpoint, alarm and programmable inputs are established through the

use of function keys.

• Standard parameters are factory-set for

quick start-up, and all parameters may be

changed as required.

• A remote alarm terminal mounted at the

rear of the cabinet can be connected to

an external alarm system.

The MCO-20AIC control panel is center

mounted in the outer door for easy access, even when incubators are stacked.

Microprocessor based controls manage

all incubator functions including setpoints,

alarm parameters, UV lamp periods, programming, calibration and diagnostics.

Extra-large digital displays are easy to

read. Tactile feedback touchpad data shift

and entry keys simplify operation. When

stacked, door mounted controls remain

easily accessible at eye level.

Cabinet Design

• High volume, low profile cabinets are

stackable with field-reversible doors.

• Interior components and adjustable

shelves are configured for easy access.

• Digital Temperature Display

• Heat ON Lamp

MCO-20AIC

Interior components and adjustable shelves

are configured for easy access, in situ sterilization and flexible arrangement for a variety

of applications.

Model MCO-20AIC is designed for use with

a variety of standard cell culture vessels

and protocols. Four adjustable shelves are

included, standard; maximum shelf capacity

is 15 shelves.

• UV Lamp

• Door Open Lamp

• Low Water Lamp

• Overtemperature

Warning Lamp

• Overtemperature Setpoint Adjustment

• CO

Inject Lamp

2

• Digital CO

Display Multi-function

2

• Gas Cylinder Switch Key (optional)

• Audible Alarm

Silence Key

• Gas Cylinder Supply

Indicator (optional)

5

Page 6

Design & Technology

Direct Heat and Air Jacket Heating System

Zone Location Function Energy Microprocessor Controller

Main

(Red)

Base

(Yel lo w)

Side, top and rear walls Dominant heat source Variable

Floor

Base heater elevates the humidity reservoir

to achieve 95% RH at 37 °C

Variable

Energizes any, all or

in combination of heating

elements as required.

Front

(Green)

Air Jacket

(White)

Insulation

(Gray)

Outer door

Side, top and rear walls

Side, top and rear walls, door

Direct Heat and Air Jacket

Heating System

The patented Direct Heat and Air Jacket

heating system surrounds the inner walls

with a natural convection airow that

converts to radiant wall heat through

thermal conduction to achieve accurate,

uniform and highly responsive temperature control within the chamber.

• The microprocessor controller directs

proportional distribution of power to

independent heating sources surrounding the chamber.

• Arranged in three zones, these sources

include the side, top and rear walls, the

chamber base and the outer door.

• Each zone is controlled by the microprocessor which manages continuous

feedback from the chamber sensors.

Warms the inner glass in response to ambient conditions;

eliminates condensation on glass and around the opening

and promotes temperature uniformity

Sealed. Surrounds interior chamber with natural

air convection and promotes chamber wall uniformity

Promotes energy efciency, mitigates effect of

ambient temperature uctuations on air jacket

The patented Direct Heat and Air Jacket heating system distributes proportional energy to the interior chamber

through a natural convection air jacket surrounded by a high density insulation to protect against ambient temperature

fluctuations

Infrared CO2 Control System

The Panasonic MCO-20AIC uses a

unique ceramic based infrared sensor

system to maintain precise CO

regardless of temperature and relative

humidity changes within the incubator

chamber. Sensor stability is especially

useful following door openings while

temperature and humidity return

to equilibrium.

The ceramic based sensor is maintenance

free with no moving parts and eliminates

control

2

Variable

– –

– –

Ergonomic Cabinet Design

With reversible inner and outer doors, a

single Panasonic incubator offers the industry’s most exible installation options

available.

• Low prole cabinet with door-mounted

control panel permits easy access and

viewing.

• The outer door latch and door heater

cable is easily switched if a reverse

opening is required.

filament bulbs or electro-mechanical

“chopping” devices.

• The CO

every four hours.

• The system allows CO

sensor automatically calibrates

2

control over

2

MCO-20AIC

a range from 0-20% in 0.1% setpoint

increments.

• Actual CO

is displayed on the main

2

control panel.

• A CO

sample port mounted on the incu-

2

bator front permits convenient confirmation of chamber CO

density.

2

MCO-20IC shown with double stack option.

6 Large Capacity Cell Culture CO2 Incubator www.panasonic.com/biomedical

Page 7

Product Specifications

MCO-20AIC Specifications

Description

Model Number MCO-20AIC- PA

Dimensions

Interior

w x f-b x h

Exterior

w x f-b x h

Volume

Shelves

Net Weight

Major Operating Systems

SafeCell UV System Standard

Sensor Standard

IR CO

2

InCu-SaFe

®

Copper Enriched Stainless Steel Interior Standard

Controller/Display, Door Mounted Standard

Direct Heat, Air (DHA) Air Jacket Standard

24.4” x 20.6” x 26.2”

620 x 523 x 6 65 mm

30.3” x 27.9” x 35.4”

770 x 709 x 899 mm

7.6 cu.ft.

215 L

205 lbs

93 kg

Decontamination

Interior UV Lamp, Programmable, Ozone Free Standard

Copper Enriched Stainless Steel Interior

with Germicidal Protection

Standard

Energy, Elecrical & Utilities

Maximum Power Consumption 310W

Maximum Heat Discharge 1062 BTU

Electrical 115V,60Hz with NEM A 5-15 plug provided; requires NEMA 5 -15R grounded receptacle

CO

Gas Connection 4 to 6mm inner diameter tubing

2

CO

Gas Pressure Nominal 4.3 PSI from two- stage CO2 regulator

2

CO

Gas Cylinder Swichover System Optional

2

Environmental Performance

Temperature Control Range +5ºC above ambient to 50°C (in a 5ºC to 35º C ambient )

Temperature Control Uniformity Deviation ±0.25º C (in 25º C ambient, setting 37 ºC, 5% CO2, no load)

CO

Control Range and Deviation 0% to 20%, ±0.15% in 25ºC ambient, setting 37ºC, 5% CO2, no load

2

CO

Sensor Platform

2

Calibration Single point zero automatic

CO

2

Ceramic based, single beam, dual wavelength measurement

of actual vs. contrast, with continuous auto-zero calibration.

Airow Gentle vertic al airow, continuous with inner door closed.

7

Page 8

Product Specifications & Accessories

628

34

44469

20

880

665

80

523

“dŒ¹ƒR?[ƒh?oŒûˆÊ’u

125

125

15

15

620

730

770

MCO-20AIC Specifications

Control, Monitoring, Alarm

Temperature and CO2 Control P.I.D., setpoint resolution 0.1% and 0.1°C

Display LED digital display messaging

Data Acquisition Data Acquisition Automatic log function of temperature and CO

Communications

Catalo g #MCO -420MA, remote alarm contacts standard. Optional 4-20 mA connection.

Optional PC interface, Catalog No. MTR -480 with RS232/RS485 data ports available.

Cabinet Design and Construction

Superstructure, Exterior Cabinet and Door Galvanized steel exterior, baked-on enamel nish

Interior and Shelves Copper-enriched stainless steel

Inner Door Tempered glass

Insulation Rigid foam polyurethane

Outer Door Reversible, heated

Access Port Single opening with interior and exterior 30mm non-VOC silicone stoppers

Leveling Feet 4, adjustable

Optional Accessories

Automatic CO

CO

Cylinder Regulator, CGA tting 320 MCO-10 0L

2

Cylinder Switchover System MCO- 21GC- PW

2

Roller Base. For use in single or stacked installations MCO-20RB-PW

InCu-SaFe

Includes two shelf brackets, Full shelf

Communications Por t. Located at rear of chamber

Connector, cable and software not supplied

Communications Por t. Located at rear of chamber,

analog 4 -20mA.

SafeCell UV System Kit Narrow- bandwidth

253.7nm lamp and assembly

®

Shelf and Brackets

MCO -58S T-P W

MTR-480-PW

MCO-420MA-PW

Built-In

.

2

Panasonic Biomedical products include a broad range of accessories to meet specific applications requirements.

For accessory requirements or options not listed herein, contact Panasonic or your authorized Panasonic sales representative.

Panasonic Healthcare Company of North America

1300 Michael Drive, Suite A, Wood Dale, IL 60191

Toll Free USA (800) 858-8442, Fax (630) 238-0074

www.panasonic.com/biomedical

© Panasonic Printed in USA 2012.03 JK

JB201205V2

Loading...

Loading...