Page 1

For speed control of 3-phase induction motor

Low-Noise Inverter M1S Series

Operating Instructions

Be sure to provide the customer with a copy of this manual.

● Thank you for purchasing a Panasonic Inverter.

● Be sure to read the instructions thoroughly before attempting to operate the

inverter. After reading, be sure to keep in a safe place for future reference.

Industrial and Appliance Motor Division, Motor Company

Matsushita Electric Industrial Co., Ltd

Page 2

CONTENTS

Before use

Preparation and

adjustment

Safety Precautions

Introduction

● When unpacking・・・・・・・・・・・・・8

● Inverter model check ・・・・・・・・・8

・・・・・・・・・・・・8

System Configuratio n

・・・・・・4

・・

12

12

1212

and Wiring

●Wiring general view・・・・・・・・・ 12

●Applicable peripheral ・・・・・・・ 13

If necessary

Application and

equipment

●Wiring ・・・・・・・・・・・・・・・・・・・・・ 14

●Terminal function ・・・・・・・・・・・ 14

●Precautions when wiring ・・・・ 16

Protective Functions

●Protective functions・・・・・・・・・ 26

●Method of resetting trip・・・・・・ 28

Detalied Explanation

・・・26

・・・

31

of Parameters

Specifications

Specifications

‑2‑

・・・・・・・・・・・・

45

Page 3

CONTENTS

Parts Identification

●

Inverter

Precautions

●

Note the following

precautions in order to use

the inverter properly.

・・・・・・・・・・・・・・・・・・・・・9

・・・・・・・・・・・・・

・・・・・・・・・10

Parameter Setting

●

Parameter overview

●

Parameter configuration

and list of parameters

・・・・・・・・17 ●

・・・・・・9

10

・・・・・・

17

・・・・・17

Operation Method

Selection of operation

commands

●

How to change operation

Before use

・・・・・20

・・・・・・20

・・・・ 20

●

Setting

Test Operation

●

Pre-operation inspections

●

Test operation

Maintenance/

・・・・・・・・・・・・・・・・・・・17

・・・・・・・・・・

・・・・・・・・・・・・・19

・・・・・・・・・・・

Inspection

Troubleshooting

・・・・・・・・

Outer Dimensions

19

・・・19

29

30

・・・・46

command

●

Operation function

Servicing

・・・・・・・・

・・・・・・・・・・ 20

Backcover

If necessary Preparation and Adjustment

Parameter Setting

・・・・47

‑3‑

and Spec.

Application

Page 4

Safety Precautions

!

!!

!

!

!!

!

!

!!

!

!!!!

Precautions that must be heeded in order to protect the user and others from harm and

prevent property loss or damage are as follows:

■■■■

The extent of injury or damage that could be suffered by improper

use contrary to directions is ranked as follows:

DANGER

CAUTION

Items labeled as CAUTION could be connected with core serious consequences,

depending upon the circumstances. In any case, these instr uctions are ex tremely import ant

and should be observed in all cases.

■■■■

Installation

Situation involving danger which could result in death or serious

injury if equipment is handled incorrectly.

Situation involving danger which could result in medium to light

injury, or property damage if equipment is handled incorrectly.

CAUTION

● Install on non-combustible material such as metal.

Failure to do so could result in fire.

● Do not locate near combustibles.

Doing so could result in fire.

● Do not carry by the front case when moving the inverter.

Doing so is dangerous and could result in injury if dropped.

● Do not allow foreign material such as metal chips to get inside the inverter.

Doing so could result in fire.

● Be sure to install on a base capable of supporting the inverter’s weight in

accordance with the directions giving in the instruction manual.

Failure to do so could result in the inverter dropping or falling.

‑4‑

Page 5

■■■■

!

!!

!

!

!!

!

Wiring

DANGER

●

Make sure the power is cut off before handling wiring.

Failure to do so could result in electrical shock or fire.

● Be sure to install a no-fuse breaker (NFB).

Failure to do so could result in fire.

● Be sure to ground the GND terminal.

Failure to do so could result in electrical shock or fire.

● Have wiring work done a licensed electrician.

Failure to do so could result in electrical shock or fire.

● Be sure to install the inverter before wiring.

Failure to do so could result in electrical shock or fire.

CAUTION

● Do not ground the AC power source with the output terminals (U/T1, V/T2, W/T3).

Doing so could result in injury or fire.

● Make sure the voltage of the AC power source agrees with the rated voltage of the

inverter.

If not, it could result in injury or fire.

‑5‑

Page 6

Safety Precautions

!

!!

!

!

!!

!

■■■■

Operation

DANGER

● Be sure to mount the case and cover before turning the power on. Never remove

the case or cover while the inverter is receiving power.

Failure to mount or removing the case/cover could result in electric shock.

● The operator should secure the area before turning the power on or off.

Failure to do so could result in injury.

● Never operate the switches with wet hands.

Doing so could result in electric shock.

● Never touch the terminals of the inverter when it is charged with power, even when

it is not running. Doing so could result in electric shock.

● If the retry function is selected, the inverter could unexpectedly start operating

again if tripped. Do not approach the inverter in the condition.

Doing so could result in injury.

● If trip reset is carried out with the operate signal ON, the inverter could

unexpectedly start operating again. Do not approach the inverter in the condition.

Doing so could result in injury.

CAUTION

● The radiator and regenerative resistor become very hot.

Touching these parts could result in skin burning injury.

● The inverter can be easily set to operate at speeds ranging from low to high. Set

the operating speed so that it the motor and machine tolerance is not exceeded.

Failure to do so could result in injury.

‑6‑

Page 7

■■■■

!

!!

!

!

!!

!

Maintenance/inspection

DANGER

● Wait for at least 5 minutes after turning off the power to perform inspections.

Failure to do so could result in electric shock.

● Maintenance and inspection should not be performed by anyone except a qualified

repairman.

The repairman should remove all metallic objects (watch, rings, etc.) before

performing maintenance or inspection.

Use only insulated tools when performing maintenance or inspection.

Failure to do so could result in electric shock or injury.

■■■■

Other

DANGER

● Absolutely DO NOT modify the inverter in any way.

Doing so could result in electric shock, injury or fire.

GENERAL PRECAUTIONS

The diagrams given in this instruction manual may show the cases, covers or safety

breakers removed in order to show details.

When operating, be sure to return the cases, covers or safety breakers and operate

as specified in the manual.

When disposing of the inverte r, treat it as industrial waste.

‑7‑

Page 8

Introduction

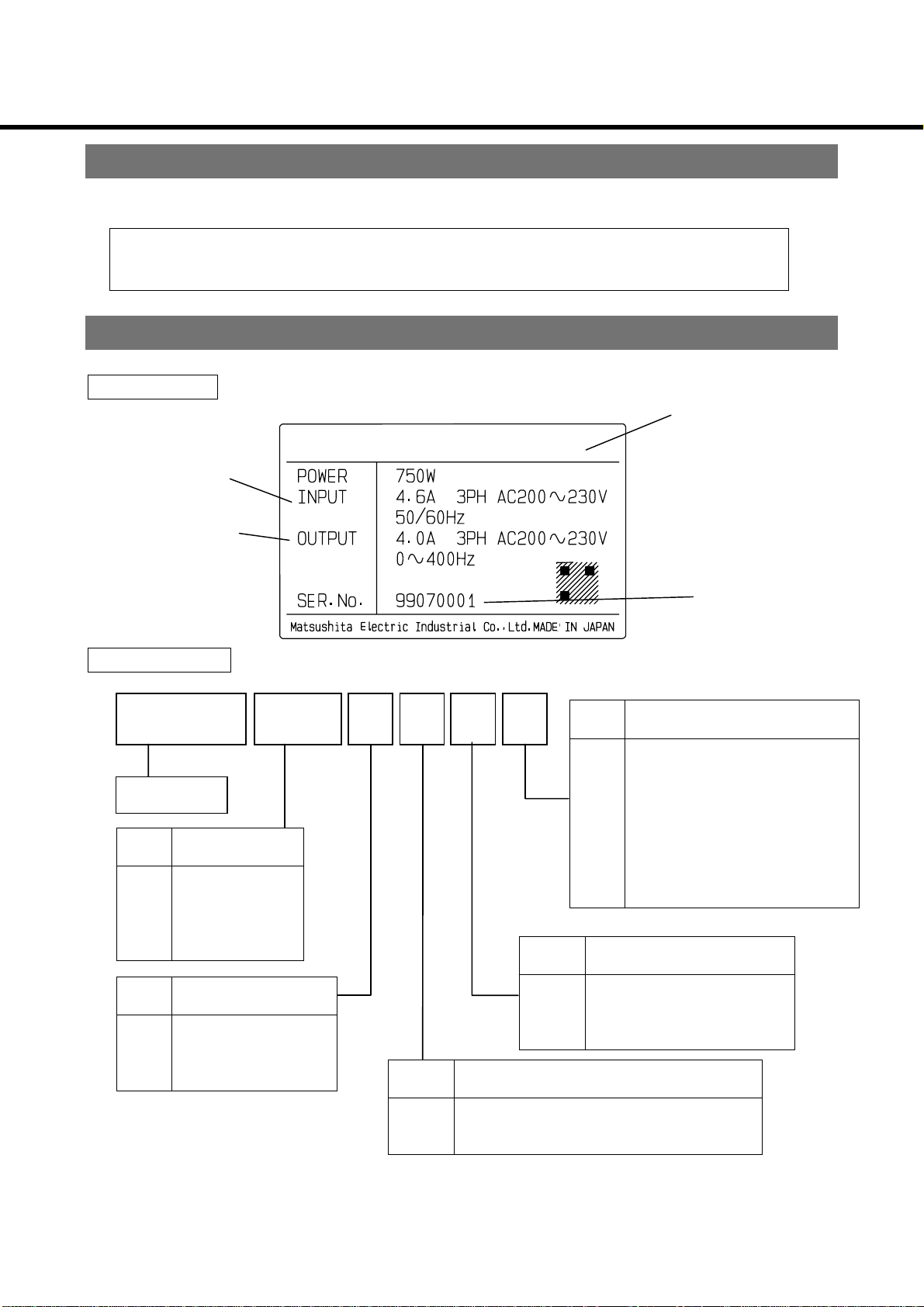

ModelNo

When unpacking

・Is the model correct?

・Was the equipment damaged in transport?

If there is anything wrong with the equipment, contact your Panasonic

dealer.

Inverter model check

Nameplate

Model number

Panasonic

Panasonic

PanasonicPanasonic

Rated input

Rated output

M1S083CSA

Product No.

Series name

Code Motor capacity

01

02

04

08

Code Volt age class

1

2

3

0.1 kW

0.2 kW

0.4 kW

0.75 kW

Single-phase 100 V

Single-phase 200 V

3-phase 200 V

Code Interface specs.

A

Without communicatio n functi on/

standard type (NPN logic)

B

Without communicatio n functi on/

standard type (PNP logic)

C

With communication fun ction/

standard type (NPN logic)

D

With communication fun ction/

standard type (NPN logic)

Code Operation panel specs.

S

V

N

Code Regenerative brake specs.

Without volume (standard)

Wit h volum e

Blank cover

Production number

(serial number)

A

Without regenerative brake circuit

C

With regenerative brake circuit (bui lt -in)

Consult your Panasonic de aler regarding products with communicat i on f unctions.

‑8‑

Page 9

Parts Identification

Outer appearance

・

You can remove the

operation panel using the

operation panel fixing

screws.

・ You can remove the case by

removing the case fixing

screw and pulling the lower

claw outward.

Panasonic

Panasonic

PanasonicPanasonic

GND terminal

Operation panel

・ Volume is mounted for

the products with volume.

Operation panel

fixing screws

Case

In case of M1S083CSA

GND terminal

With operation panel removed With case removed

DC reactor terminal Power terminals

Case fixing

screw

Charge

lamp

Operation panel

connector

Control terminals

Communication

connector

Factory-installed

option

Regenerative brake resistor t erminals Motor terminals

Be very careful of static electricity when wiring.

・・・・

After wiring, always replace the case and the operation panel to their

・・・・

original positions.

‑9‑

Page 10

Precautions

Note the following precautions in order to use the inverter properly.

1. Arrange for the power source capacity to be between 1.5 to 500kVA the inverter's

capacity. An excessively high peak current may flow to the power input circuit, and

damage the converter section if the wiring length between the power source and the

inverter is shorter than 100 m with a power source exceeding 500kVA, or the phaseadvancing capacitor is switched on the power source side. In this case, provide

individual power factor-enhancing AC reactors that match the inverter's capacity on

the inverter input side.

2. Do not connect the phase-advancing capacitor to the o utput sid e of th e inv erter. Doing

so could result in damage to the phase-advancing capacitor.

3. Do not provide a magnetic contactor between the inverter and motor. To turn the

motor on/off, use the RUN switch on the control panel or the control input terminal.

Avoid frequently turning the magnetic contactor, provided on the power source, on

and off.

4. Operating the motor by the inverter could increase leakage current and trip the earth

leakage breaker. In this case, use earth leakage breaker s desi gned for hig h freq uency

for this system and other systems.

5. Take the following precautions if using a built-in electronic thermal relay contained in

the inverter:

Check the rated current of your 3-phase ind ucti on m otor, and set the appropr i ate

・

electronic thermal value.

Use one motor for each inverter.

・

6. If operating the inverter w ith multi ple motors connected in parallel, selec t an inv erter of

a capacity that does not exceed the total rated current of the inverter. When

calculating by total output of the motor, the inverter’s rated current may be exceeded,

depending on the type of motor.

7. The total wiring length betw een inv ert er a nd mo tor sh ould not ex ceed 30 me ters. I f th e

wiring is to be longer than this, you should provide a reactor, etc., between inverter

and motor.

8. Install the inverter securely to avoid injuries in the case of an earthquake.

9. Before running the inverter following an earthquake, check installation of the inverter

and motor and make sure they are safe to operate.

‑10‑

Page 11

Installation

Install the inverter properly to prevent equipment failure or accidents.

Inverter

Installation location

Install the inverter indoors in a place not exposed to rain or direct sunlight. The inverter

①

is not waterproof.

Install in a place not ex posed to cor rosiv e/flammabl e gases, g ri nding fl ui d, oil mi st, metal

②

powder or chips.

Place with adequate ventilation, which i s not exposed to ex cessi v e hu mi di ty, dirt or dust.

③

Place not subject to vibration.

④

Environmental conditions

Item Conditions

10 〜 50℃ (Must not freeze)

Ambient temperature

Single-phase input specifications: −10 to 40

Ambient humidity

−

Max. 90%RH(Must be no condensation

)

℃

Storage temperature

Storage humidity

Max. 90 %RH(Must be no condensation

Protection structure IP40(Built-in the panel

Vibration Max. 5.9 m/s

Elevation Max. 1000 m

* Short-term temperature during transport

Mounting direction and clearance

Provide sufficient clearance for effective cooling.

・

30 mm

×

Min.

50 mm

Inverter

Inverter Inverter

Min.

10 mm

−20℃ 〜

Min.

10 mm

65℃ (Must not freeze)

)

2

10 〜 60Hz

(

Min. 100 mm

30 mm

Min.

50 mm

)

×

)

Min.

× 30 mm

50 mm

Make sure ambient tem per atur e d oesn’t exceed al low able te mperat ure at p ositi on in dicat ed

by X in the figure above.

‑11‑

Page 12

System Configuration and Wiring

A

Wiring general view

Main circuit

No-fuse breaker (NFB)

or Earth leakage breaker

Used to protect the power line.

Interrupts the circuit in the case of excessive

current.

* Use an anti-harmonic earth leakage

breaker for the inverter.

Noise filter (NF)

Blocks noise from the power line.

lso reduces effect of noise from the servomotor.

Magnetic contactor (MC)

Turn main power to servomotor on/off.

Used with surge absorber mounted.

Inverter

Motor

GND

AC reactor (AC-L)

Reduces harmonic current of the power source.

Refer to “Option.”

DC reactor (DC-L)

Reduces harmonic current of the power

source.

Refer to “Option.”

Regenerative resistor

Improves regenerative control capacity.

For the regenerative brake circuit built-in type only.

Refer to “Option.”

‑12‑

Page 13

Applicable peripheral equipment

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

Wiring apparatus selection

(1) Selection of no-fuse breaker, magnetic contactor, thermal relay, (Matsushita Electric

Works No.) and wiring

Inverter No.

MIS011*** 0.1

MIS021*** 0.2

MIS041*** 0.4

MIS01

MIS02

MIS04

MIS08

2

3

2

3

2

3

2

3

***

***

***

***

Applicabl

e motor

(kW)

0.1

0.2

0.4

0.75

No-fuse

breaker

(Rated current)

BBP25

(5A)

BBP35

(5A)

BBP310

(10A)

BBP35

(5A)

BBP35

(5A)

BBP35

(5A)

BBP310

(10A)

Magnetic

contactor

(Contact configuration)

BMFT61842N

(3P+1a)

BMFT61842N

(3P+1a)

BMFT61842N

(3P+1a)

BMFT61842N

(3P+1a)

BMFT61842N

(3P+1a)

BMFT61842N

(3P+1a)

BMFT61842N

(3P+1a)

Thermal

relay

(Current adjustment range)

BMF902E

(0.95〜1.45A)

BMF904E

(1.7〜2.6A)

BMF907E

(2.8〜4.2A)

BMF901E

(0.5〜0.75A)

BMF902E

(0.95〜1.45A)

BMF904E

(1.7〜2.6A)

BMF907E

(2.8〜4.2A)

Use the same size of wire for GND terminal ( ) as the wire for main circuit.

Wiring (mm2)

Main

circuit

2.0

AWG14

2.0

AWG14

2.0

AWG14

2.0

AWG14

2.0

AWG14

2.0

AWG14

2.0

AWG14

Control

circuit

0.75

AWG18

0.75

AWG18

0.75

AWG18

0.75

AWG18

0.75

AWG18

0.75

AWG18

0.75

AWG18

*1

(2) Relay selection

For relays used in control circuits such as the control input terminal, you should use a

small signal relay (min. guaranteed current of 1mA or less) in order to prevent poor

contact.

Examples

<

Matsushita Electric Works: DS type, NK type, HC type

>

Omron: G2A type

(3) Control circuit switch selection

If using a switch instead of a relay, use a switch for extremely small current in order to

prevent poor contact.

<Example> Nihon Kaiheiki: M-2012J-G

*1

Motor cable is used if the distance between inverter and motor is 20 meters or less. If more than 20 meters,

use a larger cable.

‑13‑

Page 14

System Configuration and Wiring

Wiring

Standard wiring diagram

Power source

●Connect to R/L1, S/L2 for single-phase

External frequency setting volume

1/4W, 5kΩ, B characteristic

Frequency meter*

1mA (full scale)

Forward/stop switch

Reverse/stop switch

Frequency setting selection (1)

Frequency setting selection (2)

Trip reset*

Be sure to provide proper treatment

for the shielded wire terminals.

R/L1

S/L2

T/L3

5V

FIN1

FOUT

12V

I1

I2

I3

I4

I5

G

Short (direct current reactor connection terminal)

P

PD

Main circuit

G

Control circuit

(Frame ground)

U/T1

V/T2

W/T3

Brake resistor

PB

connection terminal

(Collector)

O1

trip output*

C1

(Emitter)

max.=DC24V

V

CE

max.=50mA

I

C

NC

Trip signal

C2

Contact capacity

NO

DC30V 1A

Not built-in to

products without

regenerative

brake circuit.

Motor

GND terminal

Be sure to ground (max. 100Ω)

Asterisk (*) indicates factory-set function.

In case of M1S083CSA

Terminal functi on

(1) Main circuit terminal

Upper PD P R/L1 S/L2 T/L3 E◎ Lower P PB

Terminal

No.

R,S,T

L1,L2,L3

U,V,W

T1,T2,T3

Power source input terminal

Output terminal

E GND terminal

PD, P Reactor terminal DC reactor connection terminal

P, PB

Regenerative resistor

terminal

Terminal name Function description

Connects to 3-phase or singl ephase commercial power sourc e

Connects to 3-phase in duct i on

motor

Terminal for grounding inverter

base

Regenerative resistor conn ect i on

terminal

U/T1 V/T2 W/T3

Terminal

screw size

M3.5 0.8 ~ 1.0

M3.5 0.8 ~ 1.0

M4 1.0 ~ 0.2

M2.5 0.3 ~ 0.5

M2.5 0.3 ~ 0.5

E◎

Tightening

torque N·m

‑14‑

Page 15

(2) Control terminal

NO NC 01 FI FO I1 I3 I5

C2 C1 5V G 12V I2 I4 G

<Terminal screw size: M2, Tightening torque 0.25 ~ 0.3 N·m>

Terminal No. Terminal name Function description

Power source

5V

12V

terminal for frequency setting

Power source

terminal for

input terminal

+ 5VDC applied. I max. = 20 mA

+ 12VDC applied. I max. = 20 mA

FI

G

FOUT

I1

I2

I3

Input terminal

I4

I5

Input terminal

for frequency

setting

Ground for

control

Frequency

meter terminal

Forward/stop

command

terminal

Reverse /stop

command

terminal

Frequency

setting

selection

terminal

Frequency can be set when 0 ~ +5VDC (or 0 - +10VDC) is input

between “FIN1” and “G.”

If using these terminals, change “

−

or

−

.

frequency command” to

Common ground terminal for cont act i nput .

Outputs voltage proportional to output frequency between “FOUT” and

“G.” Connect full-scale 1 mA DC ammeter. You can output pulses

synchronized with output fr equency by altering “

FOUT switch”.

Forward by shorting between “I1” and “G”; stop by release

Reverse by shorting between “I2” and “G”; st op by release

You can change “I1” to run/stop command and “I2” t o forward/reverse

command by altering“

You can select the following functions by "

Operation mode I3 I4 I5

2-speed

operation mode

4-speed

operation mode

8-speed

operation mode

Forward

jogging

I1.12” function selection.

operation mode selection."

Reverse

jogging

G

Ground for

control

Contact input common ground terminal.

Open-collector output termina l. (Not maintained when power is OFF.)

output signal (1) selection.”

O1

C1

Output signal

terminal

You can select contents by “

Factory setting: “01” is trip signa l (transist or ON when tripped)

“O1” (collector) IC max. = 50mA

“C1” (emitter) VCE max. = 24VDC

NC

Output terminal

NO

Output signal

terminal

C2

Relay output termina l. 30VDC 1A (max.)

(Not maintained when power is O FF. )

You can select output contents by “

relay output polarity selection.”

Not built-in to products without regenerative brake circuit.

‑15‑

Page 16

System Configuration and Wiring

Precautions when wiring

The inner circuit is still energized with a high voltage after the input power is turned off. Do

not touch the inverter for at least 5 minutes after turning off the power.

Main circuit

(1) The inverter will be damaged if you invert the conn ections of the power input terminal

and motor output terminal (U/L1, V/L2, W/L3). Absolutely do not invert connections.

(2) Do not ground the main circuit terminal.

(3) Do not short motor output terminals (U/L1, V/L2, W/L3) together.

(4) The GND terminal (E) is the frame ground (FG) for the inverter.

(5) Be sure to use insulated crimp terminals for connecting to the main circuit terminals.

Control circuit

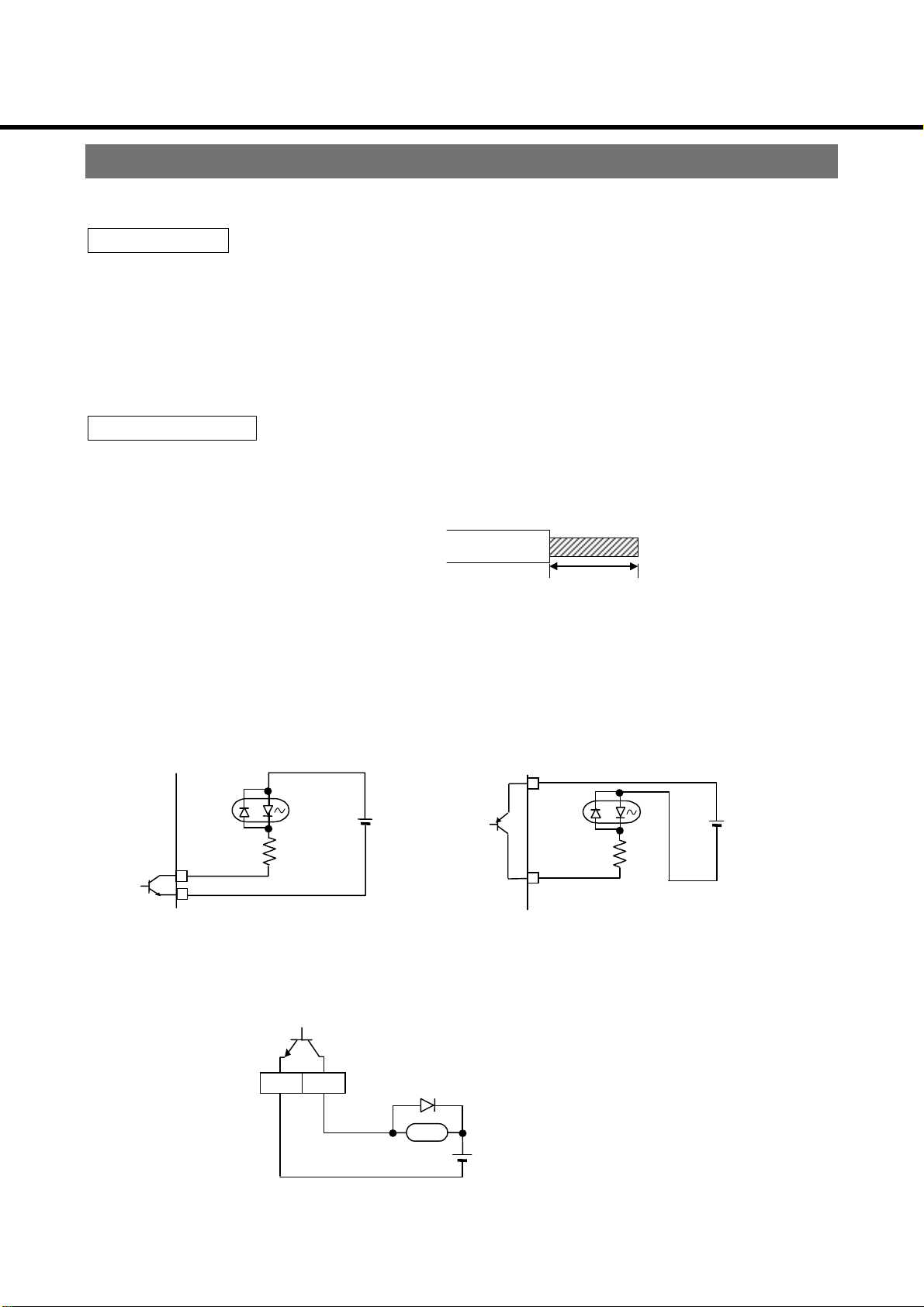

(1) Use the wires with the insulation removed, as shown below, to wire the control circuit.

If the exposed area is too long, there is the possibility of a short occurring with the

adjacent wire. If it is too short, the wire could be pulled. Twist the bare wires when

wiring, so that they will not get loose.

5.5 mm ± 1 mm

(2) Use a wire which diameter is less than 0.9 mm when wiring using a bar terminal or single

wire. If it is larger than 0.9 mm, the screw thread may be damaged when tightened.

(3) Do not apply more than 24VDC, 50mA to the output terminals (O1, C1), or apply

voltage to terminal in reverse.

(4) Input terminal configuration is internally pulled up from approx. +12V by approx. 3.3kΩ.

You can control by contact or by open collector output. Do not apply external voltage.

Internal circuits of I1 – I5 are as follows:

Photo coupler

G

I

1 ~ I5

+12V

power

source

Internal circuits of I1 – I5 are as follows:

+12V

I

1 ~ I5

+12V

power

source

NPN logic PNP logic

(5) Do not short the frequency setting power source terminal (5V) and ground for control

terminal (G).

(6) To directly drive the relay by the output terminals ( O1, C 1), mount a fly w heel di ode (F D ) .

C1 O1

FD(100V 1A)

Y

R

<Examples> Fuji Electric ERA15-01

ERB12-01

Pay attention to polarity of diode.

(7) Use shielded wires for the cable to be connected to the control circuit.

‑16‑

Page 17

Parameter Setting

Setting

Operation Panel

r/min

Hz

STOP

DATA

SET

RUN

MODE

2-digit LED

Frequency Hz is displayed when in the normal monito r mode.

You can display synchronized rotations for the parameter "

A

V

^

^

5-digit LED

display power."

5-digit LED

2-digit LED

MODE

switch

DATA SET

switch

Displays output freque ncy, set frequency or display power , cause of error , or

parameter.

Displays parameter No. Direction of rotation is displayed in the monitor mode.

Switch for changing monitor mo de. Pressing the switch change s t he mode in the

cycle of:

Output frequency

Switch for selecting parameter No. mode and parameter value mode, setting

parameter value.

●

Mode description

Monitor

mode

Parameter

No. mode

Displays output frequency, converter voltage or motor current.

Mode when the power is turned on.

When in the parameter No. mode or parameter value mode,

pressing the MODE

Displays parameter No.

When in the monitor mode, pressing the DATA SET

changes to the parameter No. mode.

Converter voltage

switch changes to the monitor mode.

(

〜

Motor current

)

by flashing.

switch

△ ▽

switch

RUN switch

STOP

switch

Parameter

value mode

Enable you to select parameters, and set/change contents.

Commands the inverter to run.

Commands the inverter to stop.

Displays parameter content s (set t ing value) by flashing.

You can change the setting value with the △ ▽ switches.

After changing the setting, press the DATA SET

enter the setting in the memory.

‑17‑

switch to

Page 18

Power ON Monitor mode Hz

y

Output frequency

↓

MODE

↓

Current

A MODE

↓

MODE

↓

Converter voltage

V

△

▽

Can set directly No. 0

speed setting with UP and

DOWN ke

s.

MODE

MODE

Storage Storage

DATA SET

DATA SET

Parameter No.

mode

DATA SET

Parameter

value mode

frequency command

.

Note) Available when "

selection" is set to

●

Parameter No. display LED will flash.

△

▽

Change (select) parameter numbers

with UP and DOWN keys.

●

Parameter value display LED will flash.

△

▽

Data will be stored every time UP key or

DATA SET key is pressed in the parameter

value mode.

‑18‑

△

▽

Change (select) parameter values with UP

and DOWN keys.

△

▽

Page 19

Test Operation

Pre-operation inspections

After installing and wiring, inspect the following before running the inverter.

(1) Is the wiring connected correctly? (Especially power input terminals R/L1, S/L2 and

T/L3, output terminals U/T1, V/T2 and W/T3, load side short or ground)

(2) Does input power comply with the rating?

(3) Are there any places that could be shorted by wire cuttings, etc?

(4) Are any screws or terminals loose?

Test operation

(1) Conduct the following for safe operation.

Set the motor so that the motor can be operated independently.

①

Set all of the input of the control terminal base to "OFF" (Open)

②

(2) Turn ON the power and run a test operation by following the procedures shown below.

Operation

①

Turn on the

power

Switch LED display

Operation panel

Remarks

・

Turn ON the power in t he monitor

mode. (Output frequency is

displayed.)

When setting with the volume on the operation panel, set " frequency command selection" to

Volume. (See page 21.)

Operation

② Frequency

setting

③ Return to the

monitor mo d e

④ Run command

(forward

rotation)

⑤ Stop

command

Switch LED display

△

Press

△

Press

frequency.

Press MODE

Press RUN

Press STOP

Operation panel

.

to set

.

.

.

Remarks

・

No. 0 speed frequency is

displayed. (Output set tin g: 0.0 Hz )

・

Set No. 0 speed frequency to 60

Hz.

・

Frequency is gradually changed.

・

Rotating direction is displ ayed.

・

Frequency is gradually changed.

<Points to check when running a test operation>

(1) Is the motor running smoothly? Are there any abnormal sounds or vibrations?

(2) Are acceleration and deceleration smooth?

(3) Is the direction of rotating of the motor correct?

‑19‑

Page 20

Operation Method

Selection of operation commands

You can perform the following six kinds of operation using the frequency command and run

command on the operation panel or using the terminal block with the MIS series inverters.

Frequency command Run command Parameter setting

Operation

panel or

volume

1

2 ○○

3 ○○

4 ○○

5 ○○

6 ○○

" frequency command selection " and " run command selection " are

factory-set values.

○○

How to change operation command

Terminal

block

"FIN1"

Operation

panel

*1

*1

Terminal

block

*1

○

*1

○

Frequency command

selection

or (both)

or (both)

or (panel)

or (panel)

or (terminal block)

or (terminal block)

Run command

selection

(Ex.) Change " frequency command selection" to " " from " ".

Operation

① Turn on the

power

② Parameter No.

mode

③ Parameter value

mode

Switch LED display

Press DATA SET

Press △

the parameter No.

Press DATA SET

Store the setting with

MODE

DATA SET

or

Operation panel

.

, and select

.

.

Press △, and select the parameter No.

Press △, and select the parameter No.

*1

When the operation command is set for the operation panel and you are using the terminal block, the

terminal block has priority.

RUN switch on the operation panel is valid only when both the forward/stop switch "I1" and the

reverse/stop switch "12" on the terminal block are "OFF." When either or both of "I1" and "I2" on the

terminal block is turned "ON," the previously set of the RUN switch will be cancelled.

‑20‑

Page 21

Operation Function

Inverters of this series provide the following operation functions. You can issue

commands using the switches on the operation panel or on the terminal block.

Operation function Explanation

Normal operation

JOG (Jogging)

operation

Free-run stop

DC brake

Positioning DC brake

Sudden stop

(all regions) DC brake

■

Operation function with acceleration/deceleration time setting.

You can set acceleration time and deceleration time individually

within the range of 0 to 3600 seconds.

■ Operation function with z ero acceleration/decelerat ion t ime. This function

is useful for positioning.

When the "operation mode" is set t o JO G (jogging) mode, the JOG

(jogging) operation beco mes valid.

When a forward or reverse operation command is given after making the

control terminals between "I 3" and "G " short , it becomes available to

change to normal operation from JOG (jogging) operation.

JOG (jogging) frequency can be set within the range of 0 to 30 Hz .

However, please note that w hen it is too high, a trip caused by an overcurrent may occur.

■ This function trips the app lied voltage to the motor, and sets the motor to a

free-run.

This is useful when braking mechanically. However, be very careful not to

touch the output terminals of the motor (U, V, W) even if the motor is freerunning, because you can receive a serious electric shock.

■ This brakes the motor by applying direct current to the motor when the

inverter stops from the operating status. When a forward, reverse, or JOG

(jogging) operation command is given while the D C bra ke is activated, the

DC brake is stopped, and the spe ci fied operation is started.

■ If a stop command is given durin g normal operation, soft-stop and braking

are activated when output frequ ency reaches 3 Hz (can be changed by t he

parameter setting.)

■ If the setting frequency is set to zero, braking is activated when output

frequency becomes 1 Hz or low er.

■ Braking strength (torque) and time can be set by the parameters.

■ If a stop command is given durin g normal operation, braking is activated

immediately without soft-stop.

■ Braking strength (torque) and time can be set by the parameters.

■ Braking time will be twic e t he t ime of "positioning DC brake mode".

*1

*1

Time that changes in 50 Hz

‑21‑

Page 22

Operation Function

q

<DC brake operation pattern example>

Positioning DC brake

RUN command

Setting deceleration time

Time set in " DC brake time"

Output frequency

Time determined by load GD2, loaded

tor

ue and " DC brake volume"

Motor speed

and brake

RUN command

Output frequency

Regenerative brake DC brake

Sudden stop DC brake

Time set in "

DC brake time"

Time determined by load GD2, loaded

torque and "

DC brake volume"

Motor speed

and brake

DC brake

‑22‑

Page 23

Inverters of this series provide the following kinds of operation mode.

Select an operation mode in the parameter " operation mode selection".

Function of terminal block

"Value on

Operation

mode

I1

I2 I3 I4 I5

*1

operation

mode

selection"

2-speed

operation

mode

4-speed

operation

mode

Forward Reverse

Forward Reverse

Forward

jogging

Reverse

jogging

Frequency setting

selection

Free-run

External forced trip

No. 2 acceleration/deceleration time

Trip reset

Free-run

External forced trip

No. 2 acceleration/deceleration time

Trip reset

[Factory setting]

8-speed

operation

Forward Reverse

Frequency setting selection

mode

You can perform multi-speed operation shown on the next page by conducting

"Short"/"Open" settings in frequency setting selection terminals for operation modes with 4speed or higher. No. 0 speed frequency is selected and the s etting by the param eter "

setting frequency (0 speed)" or by the exter nal fr eq uency setting dial is possible when all o f

the terminals are set to "Open."

(In " frequency command selection", select whether 0 speed frequency is set by the

parameter setting or by the external setting.)

■ Explanation of input terminal function

(1) Priority for the function of input terminals is as follows:

DC brake < Normal operation < Jogging operation < Free-run stop < External forced trip

Ex.) ① The inverter goes into the operation immediately when a run command is

given while the DC brake is activated.

② Free-run stop is performed when a free-run stop command is given during

jogging operation.

③ The operation does not start even if a run command is given while free-run

stop is performed.

A stop command is activated if a contradicting command is given (for example,

command of forward and reverse operations are given at the same time).

(2) The trip status can be released when forward and reverse operation commands are

both given while tripping. Release the trip after removing the causes of the trip.

*1

Select using “14 Function Selection”

‑23‑

Page 24

Operation Function

■ Selection method of the type of frequency setting for multi-speed operation

(1) When " Multi-speed input selection" is set to

You can select 1 type of multi-speed frequency for 1 terminal of the "Frequency

setting selection terminals" using this setting. This runs the inverter in 3 speeds in

4-speed operation mode and 4 speeds in 8-speed operation mode.

Ex.) With 8-speed mode oper a t ion

Input terminals

I3 I4 I5

OFF OFF OFF No. 0 speed frequency

ON × × No. 1 speed frequency

OFF ON × No. 2 speed frequency

OFF OFF ON No. 3 speed frequency

・

"ON" and "OFF" are related to "G" terminal

・

"×" means that either of "ON" or "OFF" is selectable.

(2) When " multi-speed input selection" is set to

You can select the frequency by setting "Frequency setting selection terminals" in

binary using this setting.

Frequency setting

(1 bit): 1 bit input

(Binary): Binary input

<With 4-speed operation mode>

“I3” “I4” Frequency setting

OFF OFF No. 0 speed frequency

ON OFF No. 1 speed frequency

OFF ON No. 2 speed frequency

ON ON No. 3 speed frequency

<With 8-speed operation mode>

“I3” “I4” “I5” Frequency setting

OFF OFF OFF No. 0 speed frequency

ON OFF OFF No. 1 speed frequency

OFF ON OFF No. 2 speed frequency

ON ON OFF No. 3 speed frequency

OFF OFF ON No. 4 speed frequency

ON OFF ON No. 5 speed frequency

OFF ON ON No. 6 speed frequency

ON ON ON No. 7 speed frequency

‑24‑

Page 25

■ Operation pattern example in the 2-speed operation mode

(I3)

(I4)

(I3)

(I4)

When " I5 function selection" is set to −

acceleration/deceleration time

No. 1 acceleration time

Jogging frequency

Positioning DC brake

Forward

Reverse

Forward/stop switch

(I1)

Reverse/stop switch

(I2)

Forward jogging

Reverse jogging

No. 2

acceleration/deceleration time

(I5)

0-speed

No. 1

deceleration time

Positioning DC brake

0-speed

No. 2

deceleration time

■ Operation pattern example in the 4-speed operation mode (factory setting)

No. 0 speed frequency

Forward

Reverse

Deceleration time

Forward/stop switch

(I1)

Reverse/stop switch

(I2)

Frequency setting selection (1)

Acceleration time

No. 1 speed

No. 2 speed

No. 3 speed

Positioning DC brake

No. 3 speed

: 2-speed

Frequency setting selection (2)

‑25‑

Page 26

Protective Function

Protective functions

The protective functions classified as shown below are built-in the inverters of this series.

① Functions that display a warning.

② Functions that do not display a warning, but act to avoid a tripping of the system.

③ Functions that display a warning and shut off inverter output.

④ Functions that trip the inverter. (Trip signal cannot be retained when the power is

turned off.)

Classification

①

②

5-digit LED display Description of protection Countermeasures, etc.

Electronic thermal

relay operation

Monitor display flashes when output

current reaches the electronic thermal

relay level and the timer operat es.

Electronic thermal relay trip.

Be careful of the size of the

load when using.

(Monitor)

(Flashes)

Acceleration/

deceleration stall

prevention

Prevents tripping when acceleration/

deceleration time becomes too long in

the following situ ations:

Increase acceleration/

deceleration time or

decrease inertia load.

(no display)

・

DC voltage of the converter

exceeds approx. 375V.

・

Motor current exceeds inverter’s

current limit operation po int.

Insufficient voltage

warning

If DC voltage of the converter drops

below approx. 170V, it is regarded as

Investigate the wiring and

power source informatio n.

“instantaneous power failure,” and

Instantaneous

power failure

protection

inverter output is shut off.

below approx. 100V, the control circuit

is reset. If voltage is restored by the

*1

If it drops

time the control circuit is reset,

operation can be restarted

automatically.

*2

③

Reverse prevention

*3

Selecting the reverse prevention

function prevents reverse operation if

Check if the reverse

command has been given.

the inverter receives a reverse sign al.

Restart prevention

when power is

restored

*2

Prevents the inverter from restarting

automatically if already given the run

command when power is turned,

After commanding the

inverter to stop, command it

to run again.

restored following power failure or

reset.

*1

The inverter will operate correctly if power failure does not exceed approx. 15ms.

*2

Prevents the inverter from restarting automatically if “ restart prevention when power is restored” is selected for

.

*3

Effective only when “ reverse prev ent ion” is se lecte d fo r .

‑26‑

Page 27

Protective Function

Classification

5-digit LED display Description of protection Countermeasures, etc.

Over-current trip

Regenerative overvoltage trip

Trips if inverter output current

exceeds the rated current approx.

by 200%.

Trips if DC voltage of the

converter rises above approx.

400V.

Possible causes in cl ude drop in

power source voltage, excessive

2

load, acceleratio n/

GD

deceleration time is set too short ,

load short, or grounding. Take the

proper measures to determine

the cause.

If it trips while the inverter is

running, deceleration time could

be too short. Try setting

deceleration time longer. If it trips

when the power is turned on, the

inductance of the power-boosting

AC reactor provided on the input

side of the inverter may be too

high. Select an AC reactor that

matches the inverter capacit y.

④

Over-voltage trip

retry when power is

turned on

Over-load trip

(Electronic thermal

relay)

CPU

error

If over-voltage trip occurs when

the power is turned on because

the inductance of the powerboosting AC reactor provided on

the input side of the invert er is t oo

high, etc.,

and output is shut off.

The trip is automatically reset

when DC voltage of the converter

drops below approx. 400V,

enabling normal operat ion.

If motor current continues to

exceed the electronic thermal

relay setting value, load is

regarded as being to high

causing the function to t r ip.

Trips if a control microcomputer

error is detected.

is displayed

*1

The capacity of the powerboosting AC reactor provided on

the input side of the inverter may

be too large. Select a reactor that

matches the inverter capacit y.

Try reducing load, modifying

operating pattern, or raising

capacity of inverter.

A malfunction caused by outside

noise could have occurred.

Check the area for noise and

remove the source of noise.

*1

Effective only when “ over-voltage trip retry when power is turned on” is selected for .

‑27‑

Page 28

Classification

④

5-digit LED display Description of protection Countermeasures, etc.

Self-diagno sis t rip

External forced trip

Trips if parameter such as “

operation mode selection” is

changed.

Trips when “ I5 function

selection” is set by external

forced trip and I5 – G becomes

open.

Cancel by trip after shorting.

There is nothing wrong with the

equipment. The results of the

change become effective when

the trip is reset.

Investigate the cause of overlo ad.

Try reducing the load, changing

the operation pattern, or raising

the capacity of the inverter and

motor.

Method of resetting trip

In the event of a trip, remove the cause and cancel by one of the following methods.

[1] Turn off the inverter’s power. When the trip display disappears, turn the power

back on.

[2] Short between both I1 – G and I2 – G for at least 0.1 seconds while the cause of

the current trip is being displayed.

*1

[3] Press both △ ▽ switches on the operation panel simultaneously for at

least 1 second while the cause of the current trip is being displayed.

[4] Input the trip reset command while the cause of the current trip is being

displayed.

*2

※ A CPU error cannot be reset by methods 2, 3 or 4. Reset by method 1

given above.

*1

Cannot be reset if “ I1.I2 function selection” is set to I1: Run/stop or I2: Forward/reverse.

*2

Effective only when “ I5 function selection” is selected for .

‑28‑

Page 29

Maintenance/Inspection

You should perform maintenance/inspection on a regular basis in order to ensure safety

and keep the inverter in good running order.

Precautions when performing maintenance/inspections

(1) The power should be turned on/off only by the person performing the task.

(2) The internal circuits of the inverter remain charged with high voltage for a short while

after power is turned off. To perform inspection, first turn off the power and then wait for

the LED display on the front panel to go off (min. 5 minutes).

(3) Do not perform insulation resistance measurement on the inverter. Doing so will

damage the inverter.

Inspection items and environment

● Ordinary/normal usag e condi tions

Ambient conditions: Annual mean temperature 30°C, min. 20 hrs/day at max. load rate 80%

● Perform daily and periodic inspections in accordance with the following items:

Classification Inspection cycle Inspection items

・

Ambient temperatur e, humidit y , dirt, dust, foreign o bjects, etc.

・

Is there abnormal vibration/noise?

・

Is main circuit volt age normal?

・

Daily

inspection

Periodic

inspections

Daily

1 year

Is there strange odor?

・

Is there lint in the air holes?

・

Cleanliness of control unit

・

Is wiring damaged?

・

Are equipment connections loose or off cent er?

・

Are foreign objects lodged in at the load side?

・

Are fastened sections loose?

・

Is there evidence of overhe ating?

・

Are terminal blocks da ma ged?

<Caution>

Inspection cycle for periodic inspections may vary if usage conditions differ from those

given above.

Approximate period for part replacement

Period for part replacement varies according to how the inverter is used. Parts must be

replaced or repaired when something is wrong with them. Under the ordinary/normal

usage conditions.

Product

name

Inverter

Smoothing capacitor Approx. 5 years

Cooling fan

Aluminum electrolytic

capacitor of PC board

Part name Standard replacement

period (hrs)

2〜3 years

(1〜30,000 hrs)

Approx. 5 years

Remarks

Standard replacement period gives

a number of years for reference

only. If a part becomes fault y it must

be replaced even if the standard

replacement period has not yet

been reached.

‑29‑

Page 30

Troubleshooting

Inspection to determine cause of problem

When a prob lem occurs , perform th e inspe ctions and t ake the m easures pre scribed in the

following table. If you cannot determine the cause of the problem, if you suspect that the

inverter is not working properly, if a part is damaged, or there are any other problems you

cannot solve, contact your Panasonic dealer.

Problem Description of inspection Corrective measures, etc.

Motor doesn’t work.

Motor turns in

reverse.

Is there anything wrong with the

wiring?

Is power being supplied to the power

input terminals?

Is the LED on the operation panel lit? Recheck the above.

Is the voltage of the power in put

terminals normal?

Is an error being displayed? See “protective function”.

Has free-run been commanded? Cancel free-run.

Are both the forward AND reverse

switches on?

Is there anything wrong with the

frequency setting?

Is the motor locked? (Is the load too

heavy?)

Is phase interruption operation being

carried out?

Is there a mistake in the phase order

of the output terminals (U/T1, V/T2,

W/T3)?

Wire correctly.

Turn on the power.

Turn off the power once, and then turn

back on.

Check power source voltag e.

Turn either the forward OR reverse

switch on, and the other off.

Check the frequency sett ing.

Cancel the motor lock. (Reduce the

load.)

Recheck the wiring between the

inverter and motor.

Match the phase order of the output

terminals (U/T1, V/T2, W /T3) with the

motor.

The motor runs but

speed doesn’t change.

Motor speed is not

correct.

Motor speed is

unsteady.

Is the load too heavy? Reduce the load.

Are the number of poles and volt age

of the motor correct?

Is voltage of the power input

terminals (R/L1, S/L2, T/L3) c orrect ?

Is the frequency setting range

normal?

Has motor terminal voltage dropped

excessively?

Is the load too heavy? Reduce the load.

Is load variation too large? Reduce load variation. Raise the

Check the specificat ion manual and

name plate.

Check power source voltag e.

“

lower limit frequency”

upper limit frequency”

“

“

base frequency”

max. output voltage adjustment”

“

V/F reduction characteristics”

“

capacity of the inverter and motor.

‑30‑

Page 31

Detailed Explanation of Parameters

Parameter functions

No. Parameter name

Setting frequency

(0 speed)

1st speed frequency

nd

speed frequency

2

rd

speed frequency

3

th

speed frequency

4

th

speed frequency

5

th

speed frequency

6

th

speed frequency

7

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Run command

selection

Explanation

Sets the frequency with which you want to run the machine.

Valid when “

This sets the frequency when running in multi-speed mode.

Valid when “

Allows you to set 4

running mode for “

Operation Mode

8 Speed Operation Mode Frequency Setting Selections

This selects the run command from the following.

●

frequency command se lect” is

Running mode select” is higher than 4th speed operation.

th

speed frequency to 7th speed frequency when you select 8 speed

Running Mode Select.”

Input Terminal

I 3 I 4 I 5

(PANEL) :

RUN

switch on the operation panel.

.

(TERMINAL) : Input terminals “I1” and “I2”

(BOTH): Both operation panel and input terminals are

valid.

is selected, you cannot use the input terminal as the run

setting frequency

" setting frequency (0 speed)"

Analog Command “F1”

(Voltage Command) DC 0 to 5 V

Analog Command “F1”

(Voltage Command) DC 0 to 10 V

Volume on Main Unit *

Frequency command

selection

■

V alues set at ex-factory.

●

■

When

※

command.

This selects whether to set the 0 speed frequency using “

(0 speed), ” the input terminal for Frequency Setting Selections “F1” or the switch on

the main unit.

■

●

●

●

* You cannot operate inverters without volume under the 0 speed frequency when

selected.

is

‑31‑

Page 32

Detailed Explanation of Parameters

No. Parameter name

Operation mode

selection

Torque control

Explanation

These are the parameters that select the operation mode.

●

■

●

●

This adjusts the voltage output of the inverter at a low frequency region.

Be aware that as the settings are

※

increased, excessive current will

flow which will cause a trip.

●

●

2nd Speed mode

4th Speed mode

8th Speed mode

〜

: Auto-boost Controls for the optimum auto-torque for the

inverter and motor with the same capacity.

: Controls slip frequency compensation.

Controls compensation of the slip frequency for the motor

selected by “

Manual torque boost

:

Maximum output voltage

Large

Output voltage

0

Small

motor selection.”

Base frequency

Output frequency

<Precautions regarding the selection of Auto-boost and slip frequency compensation>

Select parameters when the motor is stopped.

・

Do not use when running in serial.

・

There are cases in which the system will be unstable depend ing on th e c ond itions of

・

the load. If that should occur, set the manual torque boost.

When running at a high power supply voltage, adjust to lower the output voltage of

・

the inverter using “

adjustment.”

Jogging frequency This sets the frequency for operating in the jogging mode.

Acceleration time

No. 2 Acceleration

time

This determines the rate of change of the output frequency during acceleration.

Sets the time that changes in 50 Hz.

・

When set to 0 seconds, ac celerati on is at its op timum sp eed and deceler ation w ill b e

・

0.01 second.

When less than 3 seconds set to 0.01 sec intervals; When 3 to 9 seconds set to 0.1

・

sec intervals; When 10 seconds or more set t o 1 sec interv als.

This sets the acceleration time of the No. 2 Acceleration.

This is valid when you select “

No. 2 Acceleration.

Base frequency” or “ Maximum output voltage

I5 Function Selection” in the

■ Values set at ex-factory.

‑32‑

Page 33

No. Parameter name

Not used

Not used

DC brake volume

DC brake time

DC braking time This selects the type of DC brake.

Starting brake time This runs the inverter after applying the DC brake to the motor for the amount of time

Brake start frequency This adjusts the frequency for starting to apply the positioning DC brake.

This adjusts the DC brake time and the DC brake volume when shifting from inverter

drive to a stopped state.

- The machine will enter a free-run when either or both the time and volume are set to

0 (zero).

※ The DC brake time when you select a sudden brake (all regions) will be twice the

time of the positioning brake.

■

set when you are starting up. This does not function when you set to 0 (zero).

・ The strength (torque) of the DC brake (torque) is the “

but be careful because it does not operate when set to 0.

・ The DC brake will be applied when the output frequency is lower than “Brake start

frequency” when you cause a soft-stop using the stop command and stop from

normal operation.

: Position

Explanation

●

: Sudden stop (all regions)

DC brake volume”

Carrier frequency

variable

■ Values set at ex-factory.

・ The DC brake will be applied when lower than 1 Hz regardless of the settings of

“Brake start frequency” when it stops because the frequency settings are low while

in normal operation.

This is the parameter that selects the carrier frequency. This selects the following 8.

Change the carrier frequency when the motor is stopped.Do not change while it is

operating.

Setting value Carrier frequency Setting value Carrier frequency

0 1.2kHz 4 8.0kHz

1 2.6kHz 5 10.1kHz

■

2 3.9kHz 6 12.0kHz

3 6.0kHz 7 14.9kHz

‑33‑

Page 34

Detailed Explanation of Parameters

A

e

(

)

No. Parameter name

Explanation

Deceleration time This determines the rate of change of the output frequency when decelerating.

・ Sets the time that changes in 50 Hz.

・ When set to 0 seconds, acceleration is at its optimum speed and deceleration will

be 0.01 second.

・ When less than 3 seco nds set to 0.01 sec intervals; When 3 to 9 se conds set to 0.1

sec intervals; When 10 or more seconds set t o 1 sec interv als.

No. 2 deceleration

time

This sets the deceleration time of the No. 2 Deceleration.

This is valid when you selec t “

I5 Function Selectio n” in the

Acceleration.

Not used

Not used

Base frequency

This sets the base frequency (maximum

Maximum output voltage

frequency of the torque region) to any

frequency within the range of 30 to 400 Hz

that matches the motor rating.

Output voltage

0

Output frequency

Adjustment range

(30 ~ 400Hz)

Base frequency

No. 2

Max. Output voltage

adjustment

V/F reduction

characteristics

■: Values set at ex-factory.

This adjusts the maximum output voltage

(base frequency voltage). The range of

adjustment is 0 to 100%.

Maximum output voltage

100 :

Power supply

voltage

Output voltage

0

Output frequency

djustment rang

0 ~ 100%

Base frequency

This adjusts the V/F characteristics to match

the load characteristics.

●

Rated torque load

●

Reduction torque load

1.0

Output voltage

0

Large

Base frequency

Output frequency

You can make fine adjustments between 1.0

and 2.0.

Note: This is valid only when you have selected “torque control” in the manual boost.

‑34‑

Page 35

0

No. Parameter name

No. 2 V/F selection

No. 2 V/F base

frequency

No. 2 V/F boost

Explanation

This sets the special V/F pattern using “No. 2 V/F selection.”

This selects the No. 2 V/F upper pattern

set using the normal V/F and “No. 2 V/F base frequency” and “No. 2 V/F boost.”

■

●

●

Normal pattern

Upper pattern

Lower pattern

Note: This is valid only when you have selected “torque control” in the manual boost

or the lower pattern

No. 2 V/F

Output voltage

Normal V/F

0

Output frequency

Upper selection

Output voltage

0

Output frequency

Lower selection

Output voltage

0

Output frequency

.

Jump frequency width

Jump frequency 1

Jump frequency 2

Jump frequency 3

Jump frequency 4

This creates areas that cannot set the

frequency in a range set by “

Jump

frequency width” above and below as the

center of the frequency set by “

frequency 1” to “

Jump frequency 4”

Jump

Set frequency

Frequency Frequency Frequency

1 2 3

Frequency command (Between F IN and G)

in order to avoid mechanical resonance.

・

Acceleration time outputs the frequency even in the jump region.

・ If jump frequency ranges are overlapped, it jumps all overlapping ranges.

I1/I2 function selection This switches the input terminals “I1” and “I2” in the following manner.

Input terminal

■

(

:

Fwd-Stop/Rev-Stop

Between “I1” and “G” Between “I2” and “G”

Short Open Short Open

Forward

Operation

Stop

Operation Stop

Reverse

Operation

Reverse Forward

:

Run-Stop/Fwd-Rev)

Jump frequency width

Stop

■: Values set at ex-factory.

‑35‑

Page 36

Detailed Explanation of Parameters

No. Parameter name

I5 function selection

Not used

Multi-speed input

selection

Explanation

This selects the input terminals “I5” functions in the following manner.

●

:

“Terminal” – “G” Short

●

:

“Terminal” – “G”

●

:

selection

“Terminal” – “G” short

■

※

This selects the type of frequency setting for multi-speed operation.

●

“Terminal” – “G” short

Set the status of the short “Terminal” – “G” before selecting “

When open, a trip occurs.

(FREE)

(THeRmal)

→

(UpーDown)

(ReSeT)

(1bit):1 bit input

→

Free-run Stop

External forced trip command

No. 2 acceleration and deceleration time

→

→

Trip reset command

.”

Not used

■: Values set at ex-factory.

This selects 1 type of multi-speed frequency for 1 terminal of the “Frequency setting

selection terminals.” This runs the inverter in 3 speeds in 4 speed operation mode

and 4 speeds in 8 speed operation mode.

Ex.) With 8 speed mode operation

Input terminals

I3 I4 I5

Open Open Open

Short

Open Short

Open Open Short

■

This selects the frequency by setting “Frequency setting selection terminals” in

binary.

××

×

(Binary):Binary input

Frequency setting

No. 0 speed

frequency

No. 1 speed

frequency

No. 2 speed

frequency

No. 3 speed

frequency

・ Open and short

are related to “G”

and terminals.

・× means there

is no relationship

between short

and open.

‑36‑

Page 37

No. Parameter name

Output signal 1

selection

Not used

Explanation

This selects the output signal between output terminals “O1” to “O2” in the following

manner.

■

:

●

:

Trip output signal (When trip: ON*)

Arrival signal (When arrival: ON*)

●

:

●

:

Run/Stop signal (When run: ON*)

Free-run singnal (While Free-run: ON*)

●

:

Forward operation signal (While forward operation: ON*)

●

:

●

:

→

Reverse operation signal (While reverse operation: ON*)

Output frequency detection signal

Refer to:

(TRIP)

(STaBLe)

(RUN)

(FREE)

(Fwd)

(Rev)

(CheckーF)

Compare frequency A” and “

Compare frequency B”

●

:

→

●

:

●

:

Motor current detection signal

Refer to “

DC brake signal (While DC brake: ON*)

Trip cause detection signal

(CheckーC)

Motor current detection level”*

(DC-Brake)

(CAUS)

The following signals are output when a trip occurs.*

Trip contents

Normal over-current

Acceleration over-current

Deceleration over-current

Over-voltage

External forced trip

Electronic thermal

CPU error

ON time

Continuous

3 seconds

1 second

1 second

0.25 second 0.25 second

0.9 second

0.1 second

OFF time

1 second

3 seconds

1 second

0.1 second

0.4 second

■: Values set at ex-factory.

* “

selection.”

Self-diagnosis

output signal 1 selection” can invert “

‑37‑

0.5 second

output signal 1 polarity

0.5 second

Page 38

Detailed Explanation of Parameters

No. Parameter name Explanation

Relay output selection

This selects the output signal when the relay output between “NC,” “C2” and “NO” is

used. Trip output signal

●

●

●

●

●

●

(TRIP):Trip output signal

(When trip: Between “NC” and “C2”: Open, Between “NO”

and “C2”:Closed)

(STaBLe):Arrival signal

(When arrival: Between “NC” and “C2”: Open, Between “NO”

and “C2”: Closed)

(RUN):Run/stop signal

(When run: Between “NC” and “C2”: Open Between “NO”

and “C2”: Closed)

(FREE):Free-run signal

(When free-run: Between “NC” and “C2”: Open, Between

“NO” and “C2”: Closed)

(Fwd):Forward operation signal

(When forward operation: Between “NC” and “C2”: Open,

Between “NO” and “C2”: Closed)

(Rev):Reverse operation signal

(When reverse operation: Between “NC” and “C2”: Open,

Between “NO” and “C2”: Closed)

Motor current

detection level

Output signal 1

polarity selection

Current limit operating

point

■ Values set at ex-factory.

●

●

Set the current level you want to detect using a percentage for the rated current of the

inverter when you selected “

selection” in

exceeds the detection level you set and it will turn “OFF” when it is below.

This function inverts the polarity of the output signal between output terminals “O1” and

“C1.”

■

●

This limits the operating point for the motor current that was set.

Numbers are percentages for the inverter rated current.

(NORmal): When operation: transistor “ON”

(REVerse): When operation: transistor “OFF

(Check-F):Output frequency detection signal

→"

Refer to “

(Check ー C):Motor current detection signal

→Refer to “

. The output terminal will operate when the motor current

Compare frequency A,” and

Compare frequency B."

Motor current detection level.”

Output signal 1 selection” and “

Relay output

‑38‑

Page 39

No. Parameter name Explanation

Stall deceleration

magnification

Acceleration mode

switch

Deceleration mode

switch

This adjusts the decelerat ion tim e when the stall prevention function of the decelerati on

is operating.

・Set in percentages for the deceleration time of the normal setting.

This selects the straight line acceleration/deceleration or curved line (S) acceleration/

deceleration independently.

■

Output frequency

0

This is a general

acceleration mode to

accelerate and decelerate

on a straight line up to the

set frequency.

Straight line ● S Shape 1 ● S Shape 2

Time

utput frequency

Base frequency

0

Time

With large output of the

motor torque, the incline is

steep and when the output

torque is small, the incline

is gentle.

Output frequency

f2

f1

0

Time

This shows an S

characteristic between

running frequencies f1 t o f2.

This is a smooth acceleration and deceleration

characteristic.

* This changes using the acceleration and deceleration time set when under the base

frequency if you select

S shape 1, but when over the base frequency,

the incline is gentler than the set time.

Monitor mode switch This selects the content that displays in the 4 digit LED.

Display magnification This sets the magnification of the value that displays in the 4 digit LED. This displays

■ Values set at ex-factory.

The value to which the “

display magnification” was applied is displayed with the

frequency display.

■

●

Output frequency ●

Set frequency ● Converter unit DC voltage

Output current

the motor synchronized rotation or the line speed.

* The parameters related to frequency (below) display the value to which the display

magnification was applied when you change the display magnification.

〜〜〜〜 0 to 8th speed frequency” " 〜〜〜〜 Compare frequency"

"

Jogging frequency" "Matching detection width"

"

Brake start frequency" " Instantaneous drop frequency"

"

" 〜〜〜〜 Jump frequency" "Lower limit frequency"

Frequency meter full scale indication" " Upper limit frequency"

"

‑39‑

Page 40

Detailed Explanation of Parameters

No. Parameter name Explanation

Frequency meter

adjustment

Frequency meter full

scale indication

This calibrates the frequency meter. Adjust using the △ ▽ switches so that

the needle on the frequency meter points at the full scale.

This indicates the frequency when using the frequency meter full scale. This is set to

60 Hz full scale at ex-factory so adjust to be used higher than 60 Hz.

“FOUT” switch This selects the frequency signal to output to the frequency output terminal “FOUT.”

■

●

Frequency analog output

Frequency digital output

● Current analog output

Compare frequency A

Compare frequency B

This sets the frequency to detect when you selected “ output signal 1 selection”

and “

relay output selection” in the output frequency detection signal

.

- The output signal is ON when the outp ut fre que ncy exceeds*1 “compare frequency A”

and is OFF when it is less

Output frequency

0

ON

Between “01” and “COM”

*1

than “compare frequency B.”

Output frequency

A

B

0

ON

ON ON

Between “01” and “COM”

A

B

Match detection width

■ Values set at ex-factory.

When A ≧ B

When A < B

* It does not turn ON or OFF if the difference of the output frequency and compare

frequency does not exceed 1 Hz.

This adjusts the timing to output the arrival signal during acceleration and deceleration

when you selected “ output signal 1 selection” and “ relay output selection” in

the

arrival signal.

- The arrival signal is output when the difference of the output frequency and the set

frequency is smaller than “match detection width.”

- The arrival signal is not output when 0 is set.

- The arrival signal is not output when forward/reverse are switched when stopped

or during DC brake.

- The arrival signal is output until immediately before stopping when “ brake

start frequency” < “match detection width.”

‑40‑

Page 41

No. Parameter name Explanation

Instantaneous drop

frequency

Instantaneous freerun time

Restart prevention

when power is

restored

Retry selection

Retry start time

This adjusts the output frequency after instantaneous stop or after the power is

restored.

- This starts the output from the value that subtracted “Instantaneous drop

frequency” from the output frequency of the instantaneous detection when power

was restored.

- It starts running from 0.5 Hz in the same way as when turning on the power under

normal conditions even though power is restored and the control circuit was reset

when the power cut was long.

This adjusts the free-run time after instantaneous stop or restoring power.

This prevents restarting after an instantaneous stop or after power was restored by

setting

.

You can try to continue running by automatically canceling the trip after “Retry start

time” even when a trip occurs. This will retry (re-execute) the set number of times but

if a trip does not occur in over approximately 120 minutes, the retry count will be

initialized.

■

(NO): Does not retry

● 〜 :Retries the set number of times

・Outputs a trip signal and stops when the set number of retries is reached but does

not output the trip signal (when trip is “ output signal 1 selection” and “

relay output selection”) during a retry.

* The retry function is invalid when Restart prevention when power is restored is set

.

Set frequency

Frequency setting

bias

to

This sets the “0 V input frequency” of

the frequency setting input terminal

“FI.”

0V

0 V input frequency Frequency setting voltage

Lower limit frequency This sets the lower limit of the inverter output frequency.

Upper limit frequency This sets the upper limit of the inverter output frequency.

Constant for input

filter

This sets the constant for input filter of the voltage or the current’s frequency setting

signal from an external source.

* Increase the constant of the filter if you cannot attain stable operation because of

the effects of noise. As you increase the setting value, response will worsen.

5 V input fr e que nc y

5V

(Between “FIN” and “G”)

■ Values set at ex-factory.

‑41‑

Page 42

Detailed Explanation of Parameters

No. Parameter name Explanation

Over-voltage trip retry

when power is turned

on

Reverse prevention

Electronic thermal

relay

This displays the

on the power when you set to

Also, the trip is automatically canceled at the point the DC voltage falls below

approximately 400 V on the converter.

※ The display will change from to and it will consider the

normal over-voltage trip when you continue the over-voltage beyond a prescribed

amount of time after turning on the power supply.

This prevents the trouble caused by reversing when you set to

This adjusts the amount that the electronic

thermal relay functions.

・ Set the percentage for the inverter’s rated

current.

・ The operation panel display unit will flash

when the motor current exceeds the set

value.

※ It is necessary to check the ambient

temperature when the setting is higher

than the ex-factory setting.

and trips when an over-voltage trip occurs when turning

.

.

1 min.

50 100 150

Operating time

0

100% 150%

Parameter value

200%

Motor current

Trip cause clear This clears the cause of the trip.

<How to clear>

Trip cause 1

Trip cause 2

Trip cause 3

Trip cause 4

Trip cause 5

Parameter

initialization

①

Use the △

is.

② After the display extinguishes, it will be cleared when the power is turned back on.

③ Switch the power supply again if the inverter does not operate in this state and use

after turning on the power again.

This remembers the latest 5 trips.

Refer to “Monitor” for details regarding the content of the display.

This initializes and returns all parameters to our standard ex-factory settings.

<How to initialize>

① Use the △

is.

② After the display extinguishes, it will be init ializ ed w hen the power i s turned bac k on.

switch to switch the power supply with the setting

will be displayed in the 4 digit LED.

switch to switch the power supply with the setting as it

will be displayed in the 5 digit LED.

as it

③ Switch the power supply again if the inverter does not operate in this state and use

after turning on the power again.

‑42‑

Page 43

No. Parameter name Explanation

Motor selection

Start-up starting

frequency

Automatic voltage

regulation reference

voltage

Automatic voltage

regulation selection

Parameter extraction This extracts the parameter. Refer to “How to Extract Parameters” for details.

Parameter lock This locks the parameters that you set.