)

ABA

M18-L…-A… (axial)

INSTRUCTION MANUAL

This product is not a safety sensor. It is not intended to be used to

protect life or prevent bodily injury or damage from dangerous machine

parts. It is a normal object detection sensor.

CONTROLS

OUTPUT LED

The yellow LED ON i ndicates that the N.O. (normal ly open)

output status is closed.

POWER ON LED

The green LED indicates that the sensor is operating.

TRIMMER

The trim mer can be used to adjust s ensitivity; the operating

distance increases turning the trimmer clockwise.

WARNING

: The trimmer rotation is limited to 270° by a

mechanical stop.

Do not apply excessive torque when adjusting (max 40 N•m).

INSTALLATION

M18-L (plastic): The sensor can be fixed by means of the

M18x1 threaded body through a ∅ 18 mm hole, using the

specific washer and the two C H.24 nuts enclosed (1.5 N•m

maximum tightening torque).

Alternatively, the sensor can be mounted through the two

housing’s holes using two screws (M3x22 or longer) and

washer.

Amongst the various poss ibl e s oluti ons , we suggest to choose

the combination that offers the best visibility of the signalling

LEDs and the easiest access to the trimmer.

22 mm nuts, h=8 m m, (2 N•m maximum tightening torque) are

available to guarantee an improved torque.

M18-L (metal): The s ensor can be fi xed by means of the M18x1

threaded body through a ∅ 18 mm hol e, using the specific

washer and the two CH .24 nuts enclosed ( 22 N•m maximum

tightening torque).

For both plastic version and metallic

version are available various orientable

fixing brackets to ease the sensor

positioning.

The operating di stance i s measur ed from

the front surface of the sensor lens.

In case of lateral translation, the object

must move as indicated in the figure.

CONNECTIONS

The connections are compliant to the EN 60947-5-2 standard.

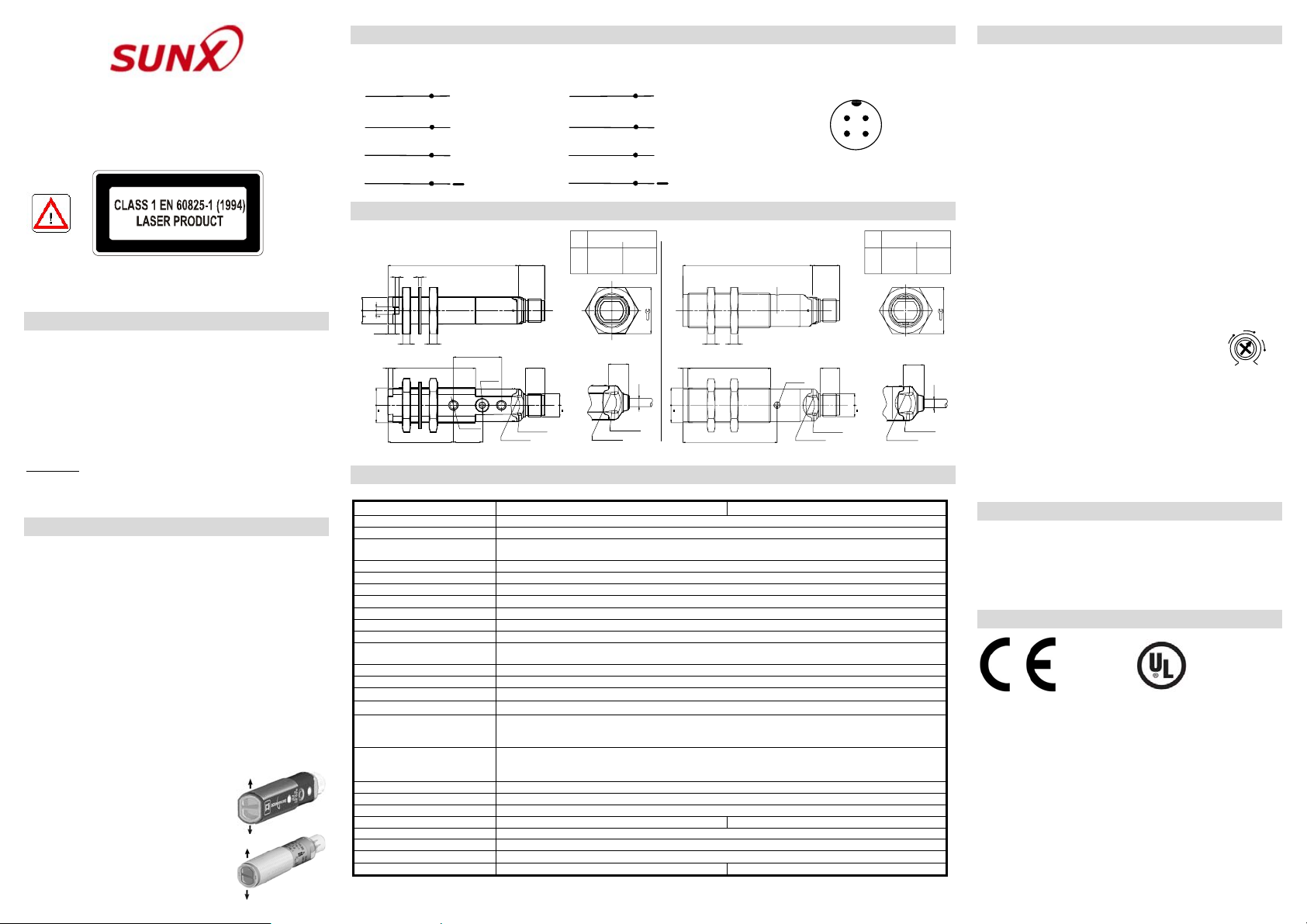

M18-LP/LD/LT

BROWN 1

WHITE 2

BLACK

BLUE

4

3

10 … 30 VDC

+

N.C. OUTPUT

N.O. OU T PUT

0 V

M18-LT (emitter)

BROWN

WHITE 2

BLACK

BLUE

M12 CONNECTO R

1

10 … 30 VDC

+

TEST +

4

NOT USED

3

0 V

2

3

1

4

DIMENSIONS

S50-PL VERSIONS S50-ML VERSIONS

M18-L (plastic

2

=4=

14

3.8

3.5

2.5

=

M18x1

L

1.5

4

25

X

N°.2 Ø 3.8

X1

15

TRIMMER

OUTPUT LED

14.5

10

POWER ON LED

M O D E L S

B/C/F version

L

67

X

43

X1

34

CABLE VERSION

=

M12

OUTPUT LED

10

POWER ON LED

*Models: A = M18-LP/LD/LT, B = M18-LT (emitter)

G version

Ø4

57

42

24

24

mm

M18-L (metal)

2.5

=

M18x1

44

X

49

L

TRIMMER

OUTPUT LED

14.5

10

POWER ON LED

M O D E L S

B/C/F version

LX67

43

CABLE VERSION

=

M12

OUTPU T LE D

10

POWER ON LE D

G version

B

57

38

24

Ø4

TECHNICAL DAT A

M18-L PLASTIC VERSIONS M18-L METALLIC VERSIONS

Power supply: 10 … 30 VDC (limit values)

Ripple: 2 Vpp max.

Current consumption

(output current excluded):

Outputs: N.O. and N.C.; PNP or NPN (short-circuit protection)

Output current: 100 mA max.

Output saturation voltage: 2 V max.

Response time:

Switching frequency: 1.5 kHz

Indicators: OUTPUT LED (YELLOW) / POWER ON LED (GREEN)

Setting: Sensitivity trimmer

Operating mode: LIGHT mode on N.O. output / DARK mode on N.C. output (M18-LT…)

Operating temperature: -10 … 50 °C

Storage temperature: -25 … 70 °C

Insulating strength: 500 VAC 1 min., between electronics and housing

DARK mode on N.O. output / LIGHT mode on N.C. output (M18-LP/LD)

Insulating resistance: >20 MΩ 500 VDC, between electronics and housing

Operating distance (typical

values):

Emission type: RED LASER: Class 1 EN 60825-1 (1994)

Ambient light rejec tion: According to EN 60947-5-2

Vibrations: 0.5 mm amplitude, 10 … 55 Hz frequency, for every axis (EN60068-2-6)

Shock resistance: 11 ms (30 G) 6 shock for every axis (EN60068-2-27)

Housing material: PBT Nickel plated brass

Lens material: PMMA

Mechanical protection: IP67

Connections:

Weight: 75 g. max. cable vers./25 g. max. connector vers. 110 g. max. cable vers./60 g. max. connector vers.

Max. power ≤ 1 mW; P ulse = 4.5 μs; λ = 630…680nm; Frequency =25 kHz

35 mA max. (M18-LP/LD/LT (receiver))

30 mA max. (M18-LT (emitter))

333 μs

M18-LP…: 0.1 ... 16 m on M18-RF48

M18-LD…: 0 ... 35 cm

M18-LT: 0 ... 60 m

Class II CDRH 21 CFR PART 1040.10

2 m cable ∅ 4 mm / M12 - 4 pole connector

SETTING

Setting of M18-LP…

Position the sensor and reflector on opposite sides.

Turn the sensitivity trimmer to the maximum position.

Moving the sensor both vertically and horizontally, determine

the power O N and O FF points of the OUT PUT LED and then

mount the sensor in the middle of the points defined.

If necessary reduce sensitivity in order to detect very small

targets.

In order to improve alignment, repeat the pr ocedure detailed

above whilst progressively reducing the sensitivity.

Setting of M18-LT…

Position the sensors on opposite sides.

Turn the sens itivity trimmer to maximum: moving the sensor

both vertically and horizontally, determi ne the power ON and

OFF points of the OUTPUT LED and then mount the sensor in

the middle of the points defined.

If necessary, reduce sensi tivity using the trimmer, in order to

detect very small targets. In order to improve alignment, repeat

the procedure detail ed above whilst pr ogres s ively reducing the

sensitivity.

Setting of M18-LD…

Turn the sensitivity trimmer to minimum: the

OUTPUT LED is OFF.

Position the target to detect in front of the

sensor.

A

C

B

MAX

Turn the sens itivity trimm er cl ockwis e until the O UTPUT LED

turns ON (Target detected state, pos.A).

Remove the target, the OUTPUT LED turns OFF.

Turn the sens itivity trimm er cl ockwis e until the O UTPUT LED

turns ON (Background detected state, pos.B).

The trimmer reaches maximum if the background is not

detected.

Turn the trim mer to the interm ediate positi on C, between the

two positions A and B.

TEST FUNCTION (M18-LT)

The T EST input can be used to inhi bit the emitter and verify

that the system is correctly operating.

The r eceiver output should switch when the test i s activated

while the beam is uninterrupted.

The input activating voltage range is 10…30 VDC.

CONFORMITY

Panasonic Electric Works Europe AG

83607 Holzkirchen, Germany

Fax: +49(0)8024-648-111

www.panasonic-electric-works.com

Order number: M18LALeafV10EN

COPYRIGHT © 2007 All Right Reserved

Rudolf-Diesel-Ring 2

Tel.: +49(0)8024-648-0

Loading...

Loading...