Panasonic LP-M200-S-CHN, LP-M200-S, LP-M500, LP-M200, LP-M500-CHN Serial Communication Manual

...

Laser Marker

Serial Communication Guide

LP-M series

LP-S series

LP-Z series

ME-LPMSZ-SR-9 No.9000-0063-59V

2019. 3

panasonic.net/id/pidsx/global

Preface

DANGER

WARNING

CAUTION

ME-LPMSZ-SR-9

Thank you for purchasing our product.

For full use of this product safely and properly, please read this document carefully.

This product has been strictly checked and tested prior to its delivery. However, please make sure that this product

operates properly before using it. In case that the product becomes damaged or does not operate as specied in this

document, contact the dealer you purchased from or our sales ofce.

General terms and conditions of this document

1. Before using this product, or before every starting operation, please conrm the correct functioning and performance

of this product.

2. Contents of this document could be changed without notice.

3. This document must not be partially or totally copied or revised.

4. All efforts have been made to ensure the accuracy of all information in this document. If there are any questions,

mistakes, or comments in this document, please notify us.

5. Please remind that we assume no liability for any results arising out of operations regardless of the above clauses.

Disclaimer

The applications described in this document are all intended for examples only. The purchase of our products described in

this document shall not be regarded as granting of a license to use our products in the described applications. We do NOT

warrant that we have obtained some intellectual properties, such as patent rights, with respect to such applications, or that

the described application may not infringe any intellectual property rights, such as patent rights, of a third party.

Trademark

• Windows is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

• QR Code is a registered trademarks of DENSO WAVE INCORPORATED.

• Adobe, the Adobe logo, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems

Incorporated in the United States and/or other countries.

• All other product names and companies provided in this document are trademarks or registered trademarks of their

respective companies.

ALWAYS FOLLOW THESE IMPORTANT

Cautions in Handling

To reduce the risk of injury, loss of life, electric shock, re, malfunction, and damage to equipment or property, always

observe the following safety precautions.

The following symbols are used to classify and describe the level of hazard, injury, and property damage caused when the

denotation is disregarded and improper use is performed.

Denotes a potential hazard that will result in serious injury or death.

Denotes a potential hazard that could result in serious injury or death.

Denotes a hazard that could result in minor injury.

The following symbols are used to classify and describe the type of instructions to be observed.

This symbol is used to alert users to a specic operating procedure that must not be performed.

This symbols is used to alert users to a specic operating procedure that must be followed in order to

operate the unit safely.

SAFETY PRECAUTIONS!

2

This symbols is used to alert users to a specic operating procedure that must be performed carefully.

This laser marker falls into Class 4 laser (marking laser) and Class 2 laser (guide laser) based on the classications of

DANGER

WARNING

ME-LPMSZ-SR-9

the Safety of laser products (JIS C 6802) / FDA standards 21 CFR 1040.10 and 1040.11/IEC60825-1. Perform the safety

protection measure before using the system. Refer to Safety / Setup / Maintenance Guide for details.

Never look at laser beam directly, through lens or through any other optical components.

Laser beam radiation into the eye causes blindness or serious damage to the eye.

Not only the direct beam of laser, but also diffused reected beam is harmful.

Never touch laser beam and avoid human skin, clothing and any other ammable object from laser beam

exposure directly.

Burning into deep skin might result and there is a risk of re.

Never disassemble the product.

Doing so may cause exposure to the laser beam or electric shock.

Take laser protection measures required to use Class 4 laser products subject to the local laws and

regulations of the country or region in which the laser marker is used.

Refer to Safety / Setup / Maintenance Guide for details.

To protect the operators’ eyes, make it mandatory to wear goggles against laser beam within the laser

controlled area. The protective goggles can momentarily protect the eyes against the scattered beam. Never

look at the direct beam or reected beam even when you are wearing the protective goggles.

In order to prevent unexpected exposures from object to be marked or its peripherals, set protective enclosure

with proper reectance, durability and thermal resistance to enclose the laser radiation area.

Construct an interlock systems such as a function to stop laser radiation for the maintenance door of the

protective enclosure.

Read all packaged guides and manuals thoroughly, and do not operate, install and connect the laser marker

with any other methods except the instructions provided in the manuals.

If the product is used in a manner not specied by the instruction, the safety protection and functions provided

by the device may be impaired and it may cause injury, electrical shock or exposure of laser beam.

Remove the dust and/or gas which may be generated during the laser radiation with dust collector or

exhauster. Use an appropriate dust collector or exhauster for dust or gas generated.

Depending on the material of the objects, harmful dust and/or gas to the human body and the laser marker

may be generated.

Prior to wiring, cable connecting and/or maintenance work, ensure that all the power switches are turned off.

Otherwise, electrical shock may result.

Connect ground wire before using.

A failure or leak that occurs when the unit is not properly grounded may result in electric shock.

3

How to Read this Document

ME-LPMSZ-SR-9

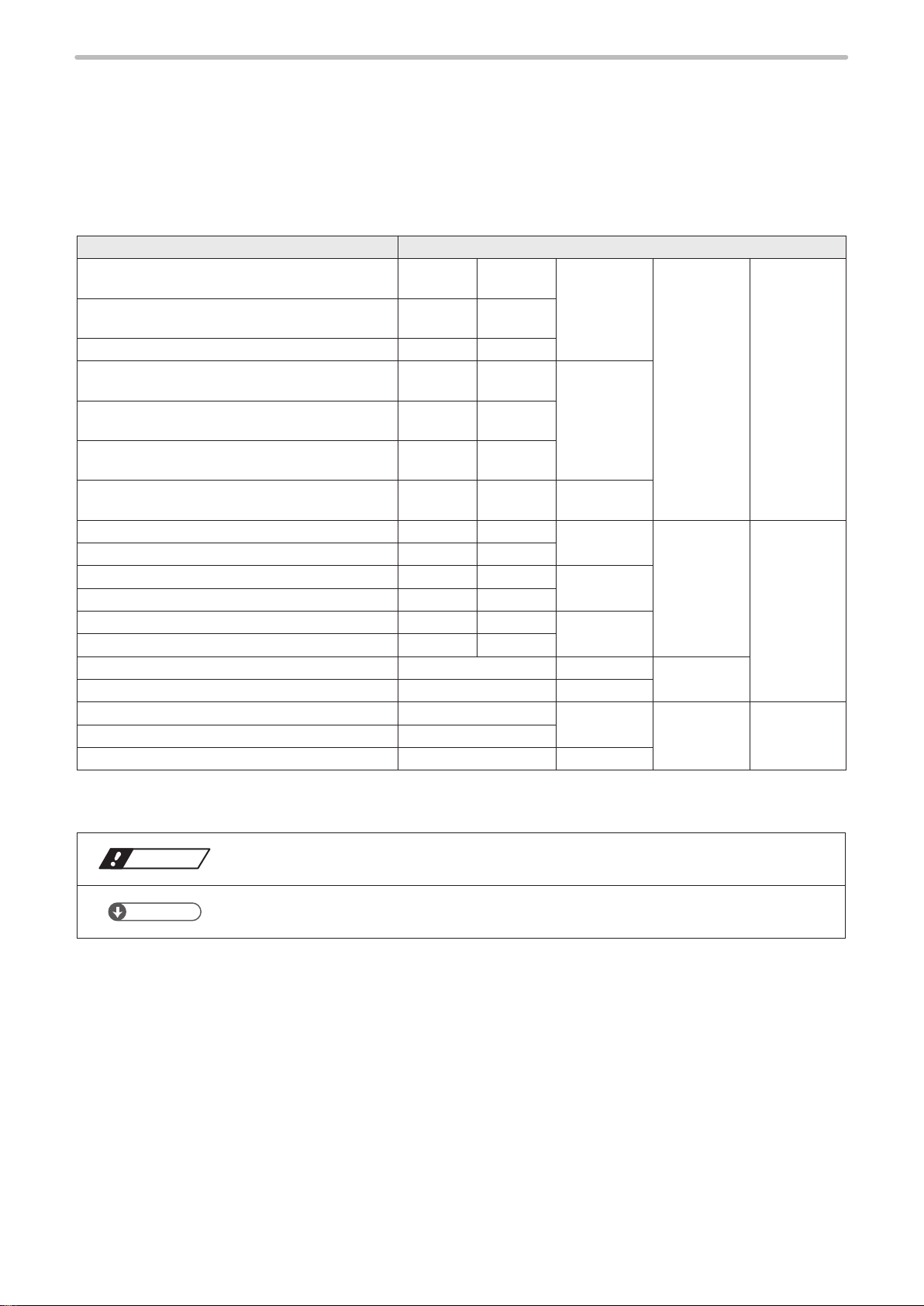

Target laser marker

This document is subject to the following Laser Marker models.

If the setting contents or specications vary by models, the target models are specied in the text.

In the text, multiple models may be described collectively, as shown in the table below.

Note that the illustration and screen image may vary with model.

Target model Description in the text

LP-M200, LP-M200-CHN, LP-M200-S,

LP-M200-S-CHN

LP-M500, LP-M500-CHN, LP-M500-S,

LP-M500-S-CHN

LP-MA00, LP-MA00-CHN LP-MA00 LP-MAxx

LP-M205, LP-M205-CHN, LP-M205-S,

LP-M205-S-CHN

LP-M505, LP-M505-CHN, LP-M505-S,

LP-M505-S-CHN

LP-MA05, LP-MA05 -CHN, LP-MA05 -S,

LP-MA05-S-CHN

LP-MA06, LP-MA06-CHN, LP-MA06-S,

LP-MA06-S-CHN

LP-S200, LP-S200-CHN, LP-S200-SF LP-S200 LP-S2xx LP-Sxx0 LP-Sxxx

LP-S500, LP-S500-CHN, LP-S500-SF LP-S500 LP-S5xx

LP-S202, LP-S202-CHN, LP-S202-SF LP-S202 LP-S2xx LP-Sxx2

LP-S502, LP-S502-CHN, LP-S502-SF LP-S502 LP-S5xx

LP-S205, LP-S205-CHN, LP-S205-SF LP-S205 LP-S2xx LP-Sxx5

LP-S505, LP-S505-CHN, LP-S505-SF LP-S505 LP-S5xx

LP-S500W, LP-S500W-CHN LP-S500W LP-Sxx0(W) LP-SxxxW

LP-S505W, LP-S505W-CHN LP-S505W LP-Sxx5(W)

LP-Z130, LP-Z130-CHN LP-Z130 LP-Zxx0 LP-Zxxx LP-Z Series

LP-Z250, LP-Z250-CHN LP-Z250

LP-Z256, LP-Z256-CHN LP-Z256 LP-Zxx6

LP-M200 LP-M2xx LP-Mxx0 LP-Mxxx

LP-Mxxx-S

LP-M500 LP-M5xx

LP-M205 LP-M2xx LP-Mxx5

LP-M505 LP-M5xx

LP-MA05 LP-MAxx

LP-MA06 LP-MAxx LP-Mxx6

LP-Sxxx-SF

LP-M Series

LP-S Sries

LP-Sxxx(W)

Symbol indications

Notice

Reference

• “Notice” denotes any instructions or precautions for using this product. To prevent the

damage or malfunction of the product, observe these precautions fully.

• “Reference” denotes any hints for operation, detail explanations, or references.

4

Type of manuals

ME-LPMSZ-SR-9

For this product, the following manuals are prepared. Read each manuals and operate this product correctly and safely.

Save the manuals for future use.

Safety / Setup / Maintenance Guide

This manual describes the safety precautions and the items required for the introduction, installation and maintenance of

the laser marker.

• Precautions and safety measures: All users shall be required for reading this part.

• Specications and outer dimensions

• Setup and connecting method

• I/O control method (signal layout, I/O rating, timing chart etc.)

• Maintenance

• Troubleshooting

Operation Manual

This manual describes how to operate the laser marker and set the marking data using touch panel console or monitor

and mouse.

Laser Marker NAVI plus Operation Manual

This manual describes how to operate the laser marker and set the marking data using PC setting software “Laser

Marker NAVI plus”.

Serial Communication Guide

This manual describes the communication commands to control the laser marker externally using the serial

communication (RS-232C/Ethernet). It describes the communication conditions, communication data formats,

communication commands, and the control samples.

Mainly the machine builder and system integrator shall be required for reading this manual.

Reference

• PDF data of each manual are included on an attached CD-ROM “Laser Marker Utility”.

• To read the PDF manual, Adobe Reader (Version X or later) of Adobe Systems Incorporated is required.

5

Contents

ME-LPMSZ-SR-9

Preface ……………………………………………………………………………… 2

Cautions in Handling

How to Read this Document

………………………………………………………………… 2

……………………………………………………… 4

1 Before External Control …………………………………………… 8

1-1 Operation by External Devices ……………………………………………… 9

1-1-1 Operation method using external control device …………………………… 9

1-1-2 Operation procedure with external control ………………………………… 10

1-2 Before External Control ………………………………………………………… 11

1-2-1 DIP switch setting …………………………………………………………… 12

1-2-2 Communication condition setting …………………………………………… 14

1-2-3 Shift to remote mode ………………………………………………………… 15

2 Basics of Serial Communication (RS-232/Ethernet) ……………16

2-1 Preparation of Command Control ……………………………………………17

2-1-1 RS-232C ……………………………………………………………………… 17

2-1-2 Ethernet ……………………………………………………………………… 20

2-2 Command Reception Condition ………………………………………………22

2-3 Connection Check ………………………………………………………………23

2-4 Control Sample …………………………………………………………………24

2-5 Communication Data Format …………………………………………………28

2-5-1 Command data ……………………………………………………………… 28

2-5-2 Response data ……………………………………………………………… 29

2-6 Communication Sequence ……………………………………………………32

3 Communication Command and Function ……………………… 34

3-1 Command at standard mode …………………………………………………35

3-1-1 Command list ………………………………………………………………… 35

3-1-2 Command description ……………………………………………………… 39

3-2 LP-F10/F10W Mode ………………………………………………………… 116

3-2-1 Selecting DIP switch ………………………………………………………… 116

3-2-2 LP-F10/F10W mode command list ………………………………………… 117

3-2-3 Each command description in LP-F10/F10W mode ……………………… 120

6

Troubleshooting ……………………………………………………… 165

Troubleshooting …………………………………………………………………… 166

Error Indication

Alarm ………………………………………………………………………………… 178

…………………………………………………………………… 178

Warning ……………………………………………………………………………… 181

ME-LPMSZ-SR-9

Character Code Table ……………………………………………… 186

ASCII Code ………………………………………………………………………… 187

Shift-JIS Code

…………………………………………………………………… 188

Index ………………………………………………………………… 199

Index ……………………………………………………………………………… 200

7

1 Before External Control

ME-LPMSZ-SR-9

1-1 Operation by External Devices

ME-LPMSZ-SR-9

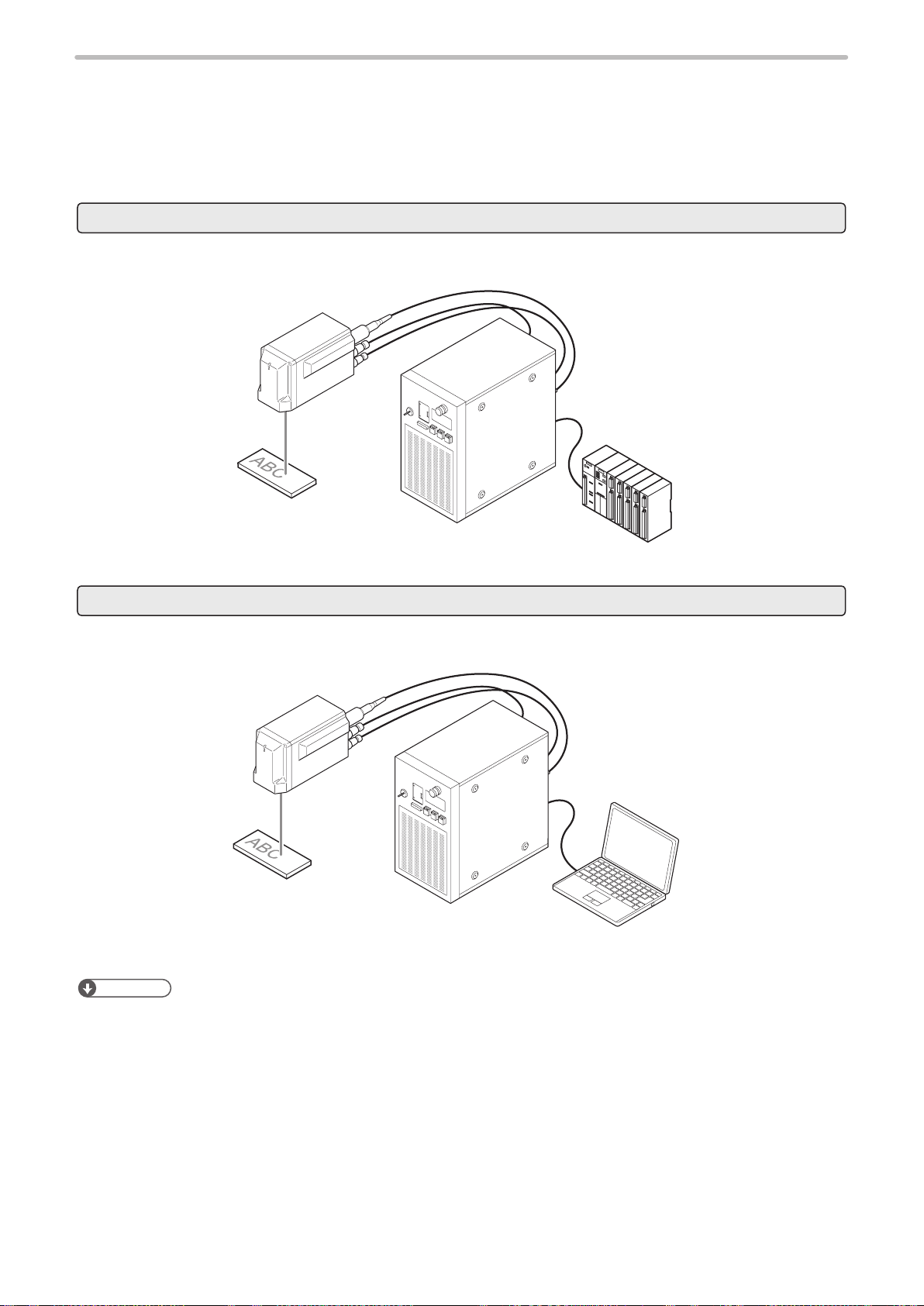

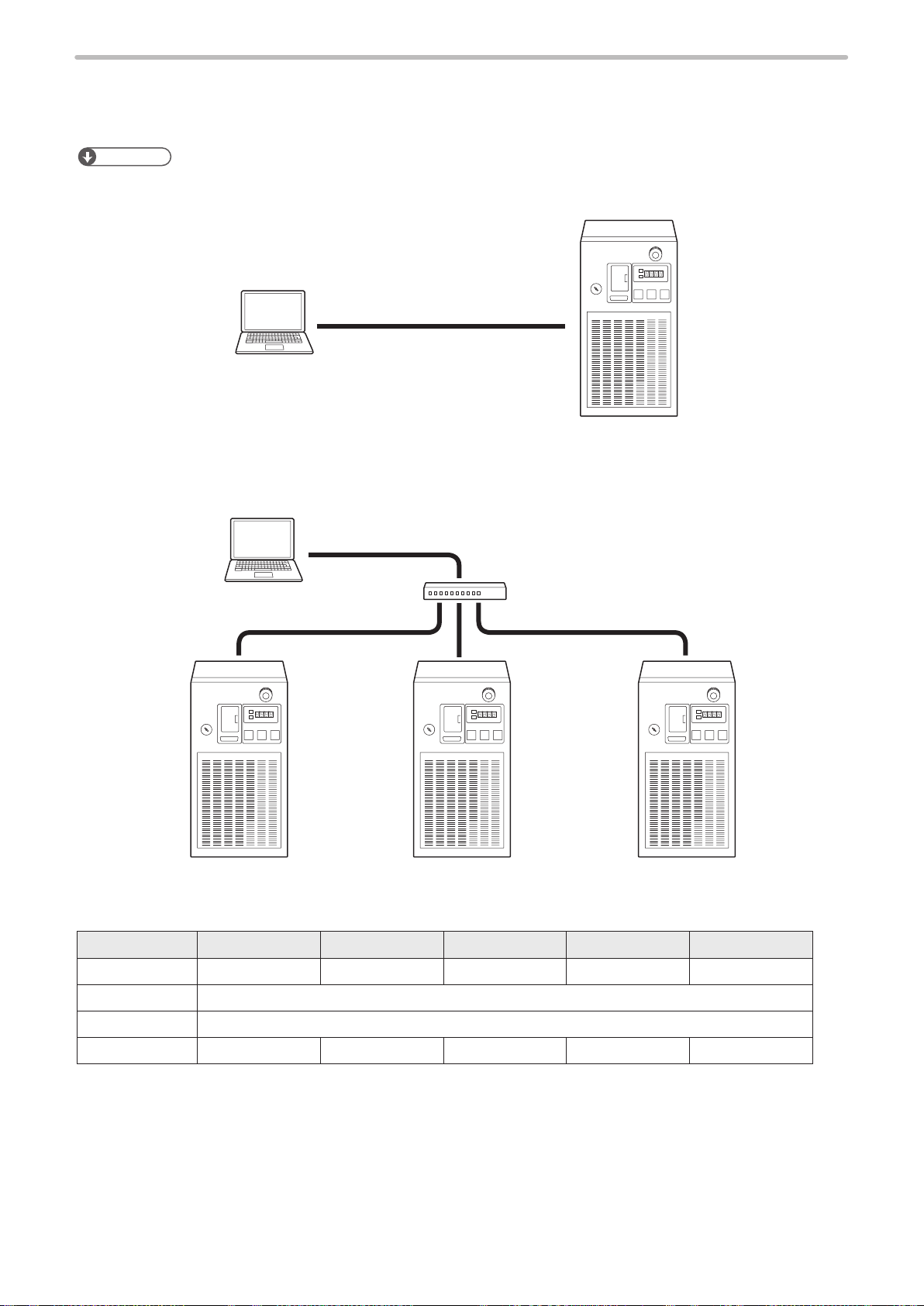

1-1-1 Operation method using external control device

To control the laser marker with the external control device, the following connecting methods are applicable:

External control using I/O : Remote mode operation

Controls the laser marker from external devices such as PLC using various I/O signals loaded into the laser marker.

For details, refer to “Safety / Setup / Maintenance Guide”.

I/O terminal block

I/O connector

PLC, etc.

External control by serial communication commands (RS-232C/Ethernet) : Remote mode operation

Controls the laser marker from external devices such as PLC using communication commands via RS-232C or Ethernet.

For details, refer to “2 Basics of Serial Communication (RS-232/Ethernet)” (P.16).

Ethernet or

RS-232C

External control device

Reference

• It is available to combine I/O and the serial communication for external control.

• To input marking trigger with I/O and congure other settings with a screen operation manually, use Run mode. For

details, refer to “Safety / Setup / Maintenance Guide”.

9

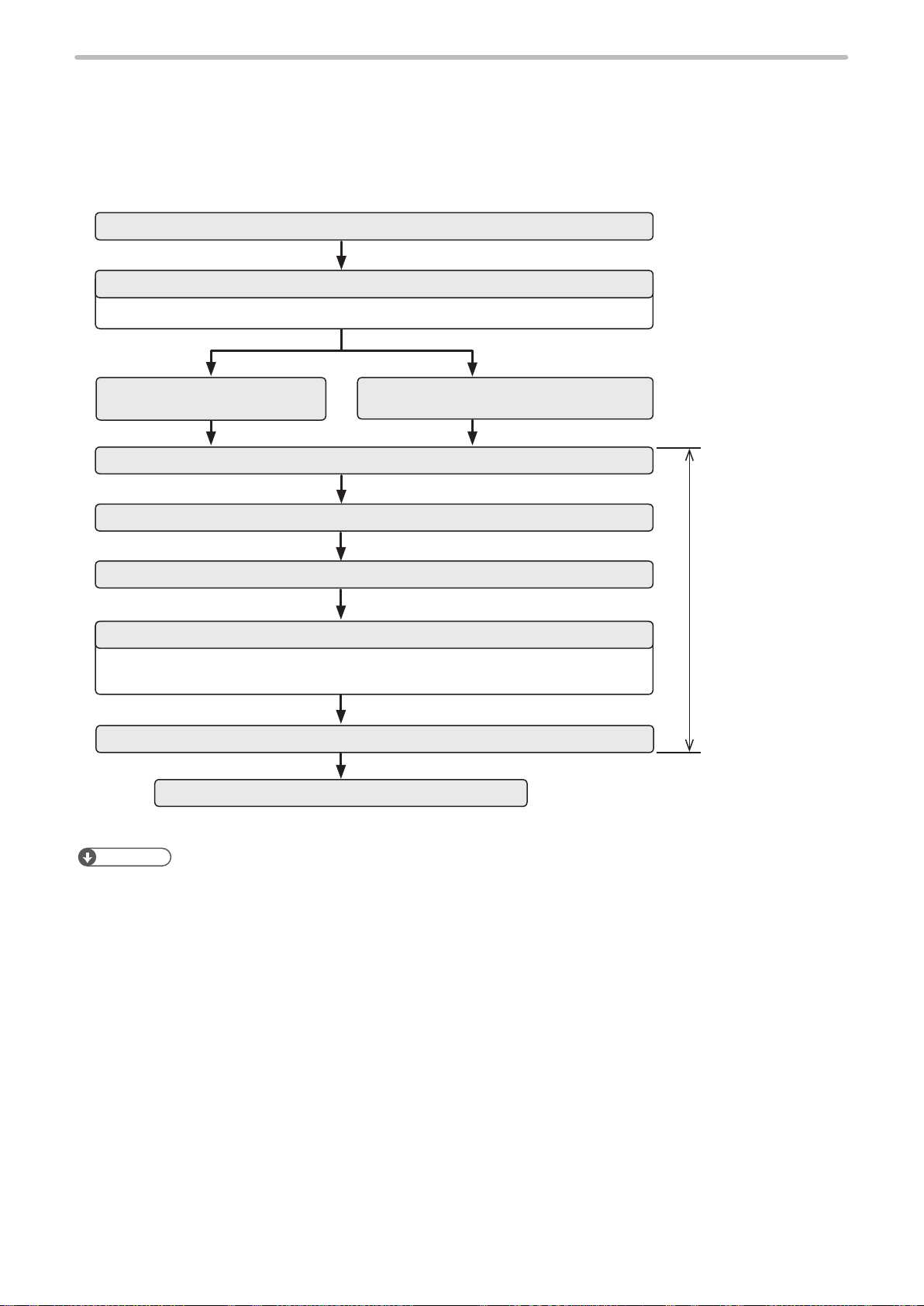

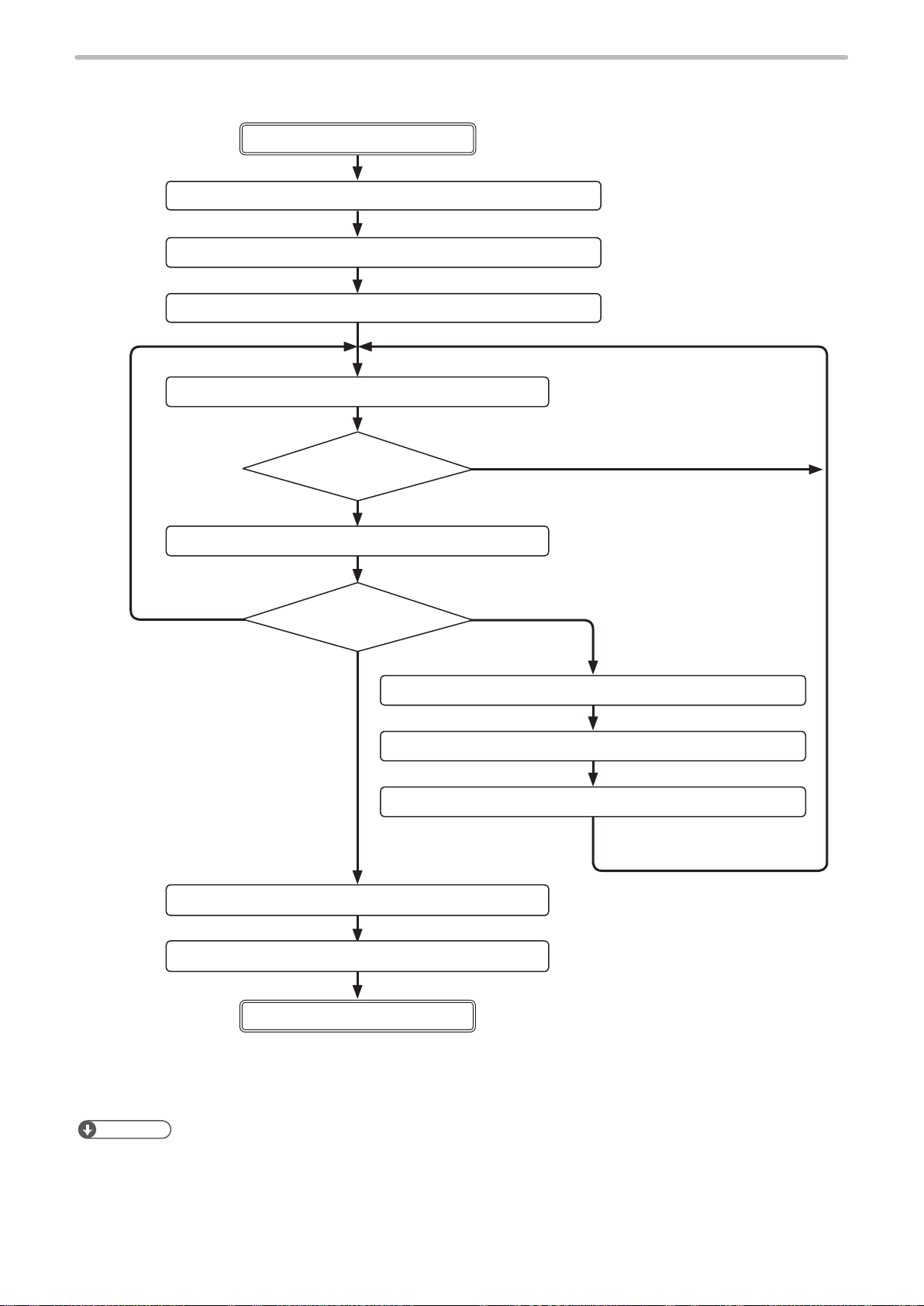

1-1-2 Operation procedure with external control

ME-LPMSZ-SR-9

■ Operation example when controlling the laser marker from external control

devices such as PLC

Turn ON key switch of laser marker controller

Remote mode ON

Refer to “1-2-3 Shift to remote mode” (P.15).

I/O control

Select le

Laser pumping ON

Open shutter

READY output ON

The device is ready for receiving the marking starting signal (trigger).

For LP-Mxxx-S type, open the laser gate to turn ON the ready signal.

Marking trigger input ON

Marking (Laser radiation)

Control by serial communication commands

about 15 to 20 seconds

Control by using I/O

or communication

commands

10

Reference

• It is available to combine I/O and the serial communication for external control.

• Congure the environment setting in advance before using external control. Refer to “1-2 Before External Control” (P.11).

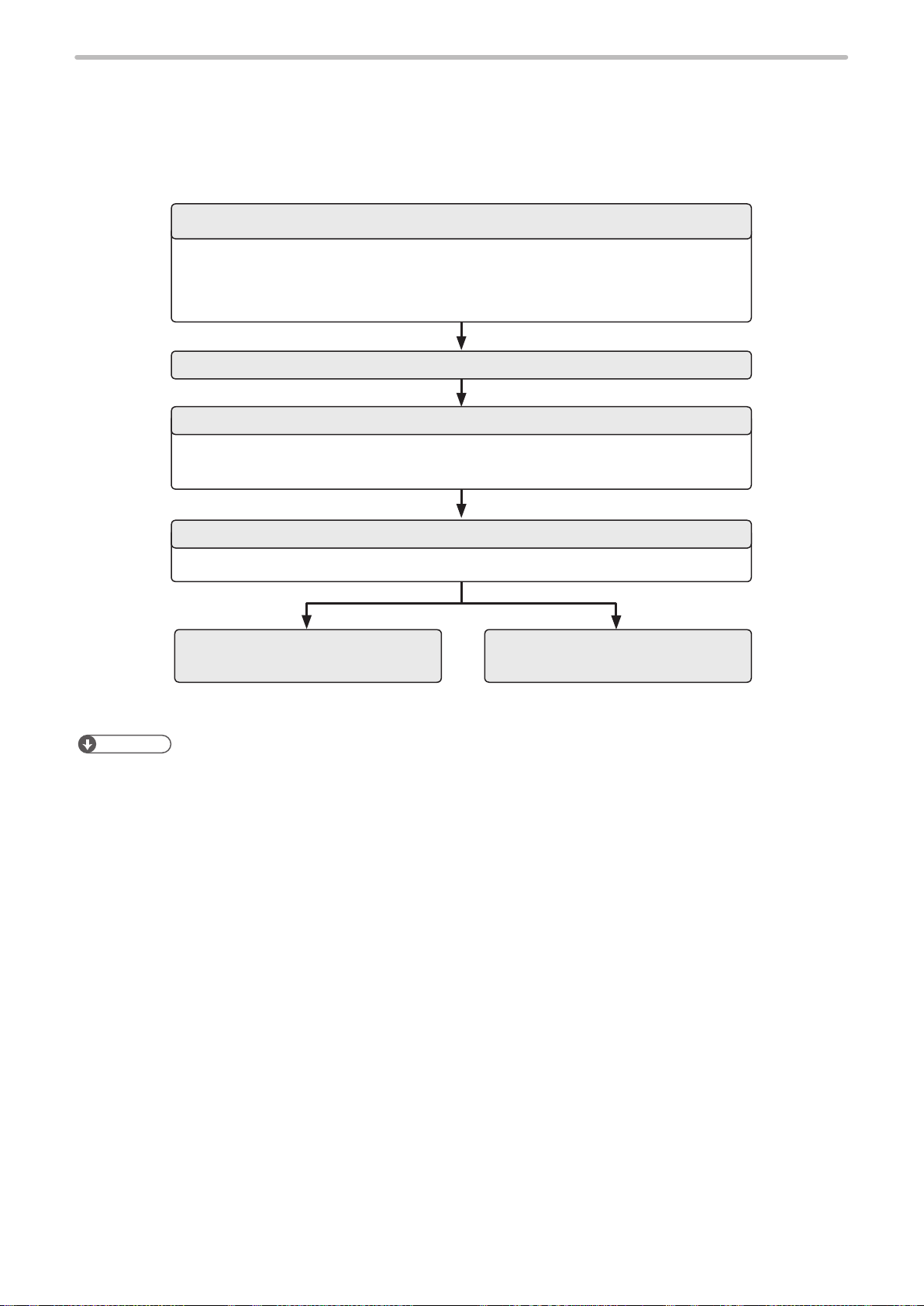

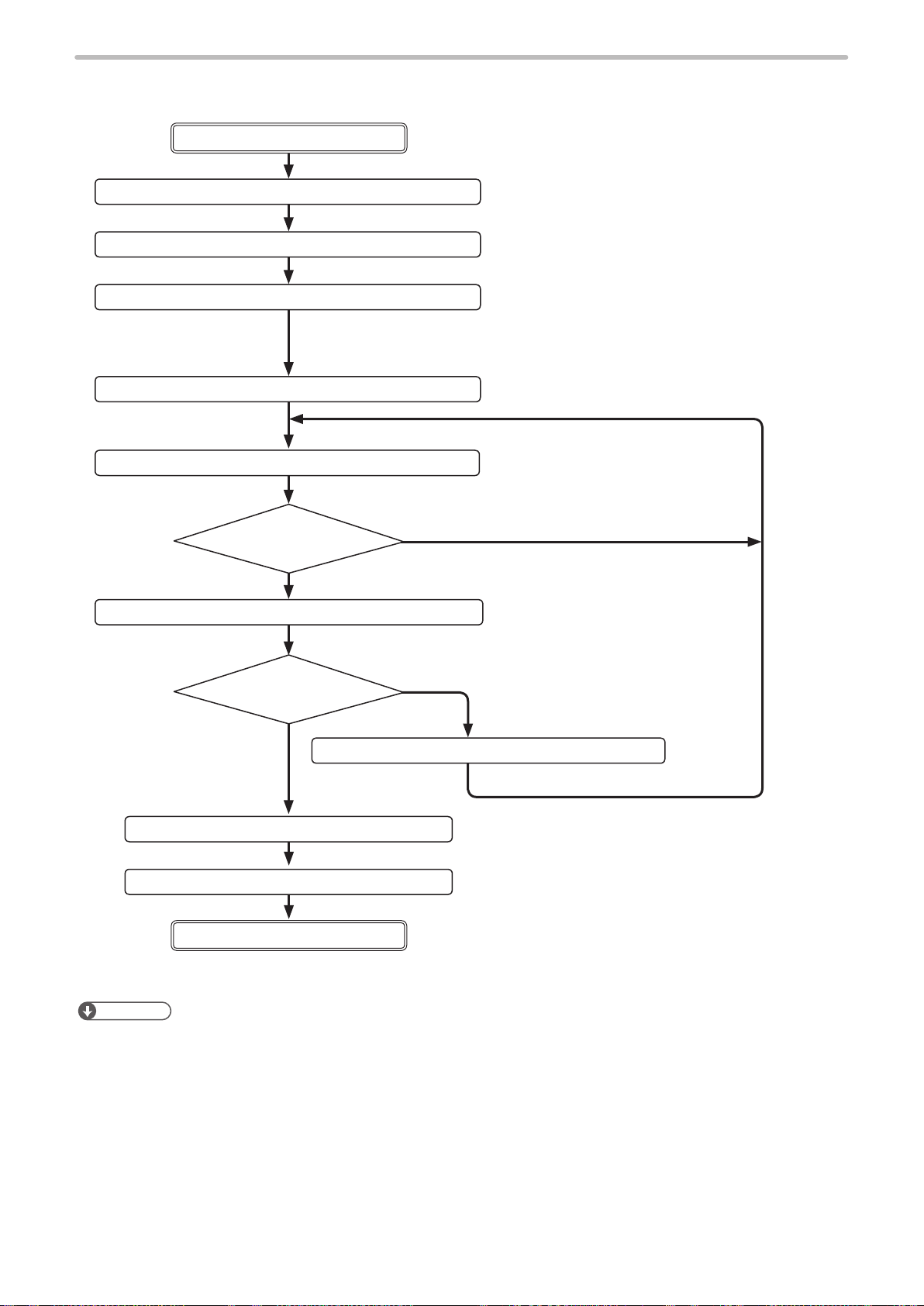

1-2 Before External Control

ME-LPMSZ-SR-9

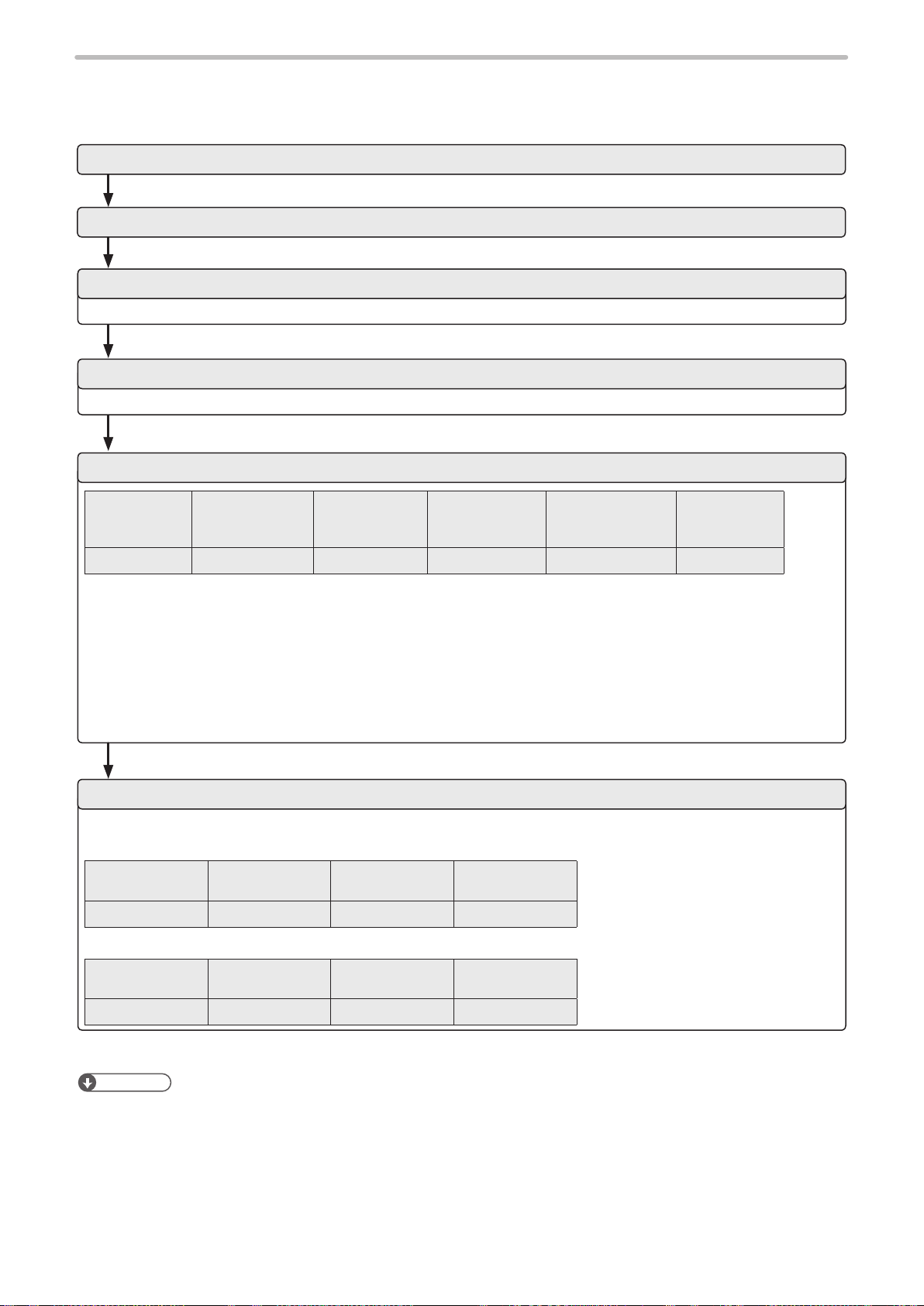

The following settings are required before the external control by using I/O or communication commands.

■ Setting ow to start external control

DIP switch setting

• DIP switch No. 2: Select control method, I/O or command for some specic operations.

• DIP switch No. 5 and No. 6: Select setting method of remote mode.

• DIP switch No. 7 and No. 8: Select compatible mode for the previous models.

Refer to “1-2-1 DIP switch setting” (P.12).

Turn ON laser marker

Communication environment setting

Set I/O and communication conditions in the environment setting screen.

Refer to “1-2-2 Communication condition setting” (P.14).

Remote mode ON

Refer to “1-2-3 Shift to remote mode” (P.15).

I/O control

Reference

• For the installation and the setup of the laser marker, refer to “Safety / Setup / Maintenance Guide”.

Control by serial communication

commands

11

1-2-1 DIP switch setting

ME-LPMSZ-SR-9

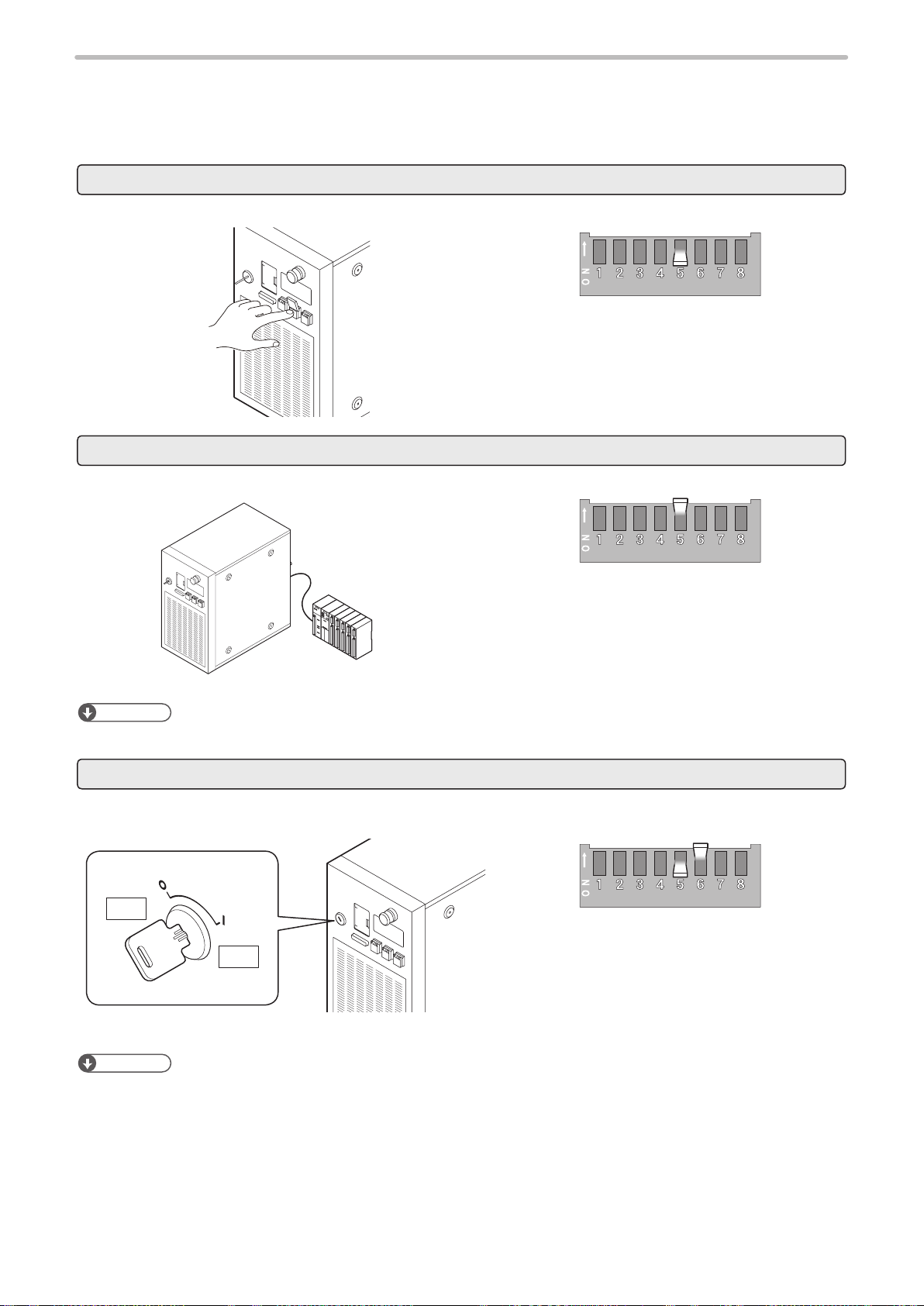

Set the operational options for the external control with the DIP switch equipped on the controller rear side.

Reference

• The initial setting of all DIP switches is OFF.

• Turn OFF the power at DIP switch setting.

• For the details on DIP switch, refer to “Safety / Setup / Maintenance Guide”.

Turn OFF the power of laser marker.

1.

Remove the DIP switch cover on the rear of the controller.

2.

ON

OFF

DIP switch

Rear of controller

With DIP switch No. 2, select the control method, I/O or command

3.

for some specic operations.

DIP switch No. 2 Control method for specic operations

ON Control by serial communication commands for the

following operations

• Laser pumping (LSR)

• Shutter control (SHT)

• Guide laser (GID)

• Laser check radiation (SPT)

• Laser power measurement (PWM)

• Power check (PWR)

• Test marking (TST)

OFF (initial setting) Control by I/O for the following operations

• Laser pumping

• Shutter control

• Guide laser

Reference

• “Laser check radiation”, “Laser power measurement”, “Power check” and “Test marking” cannot be controlled by I/O.

They can be controlled only by using serial communication in the remote mode.

12

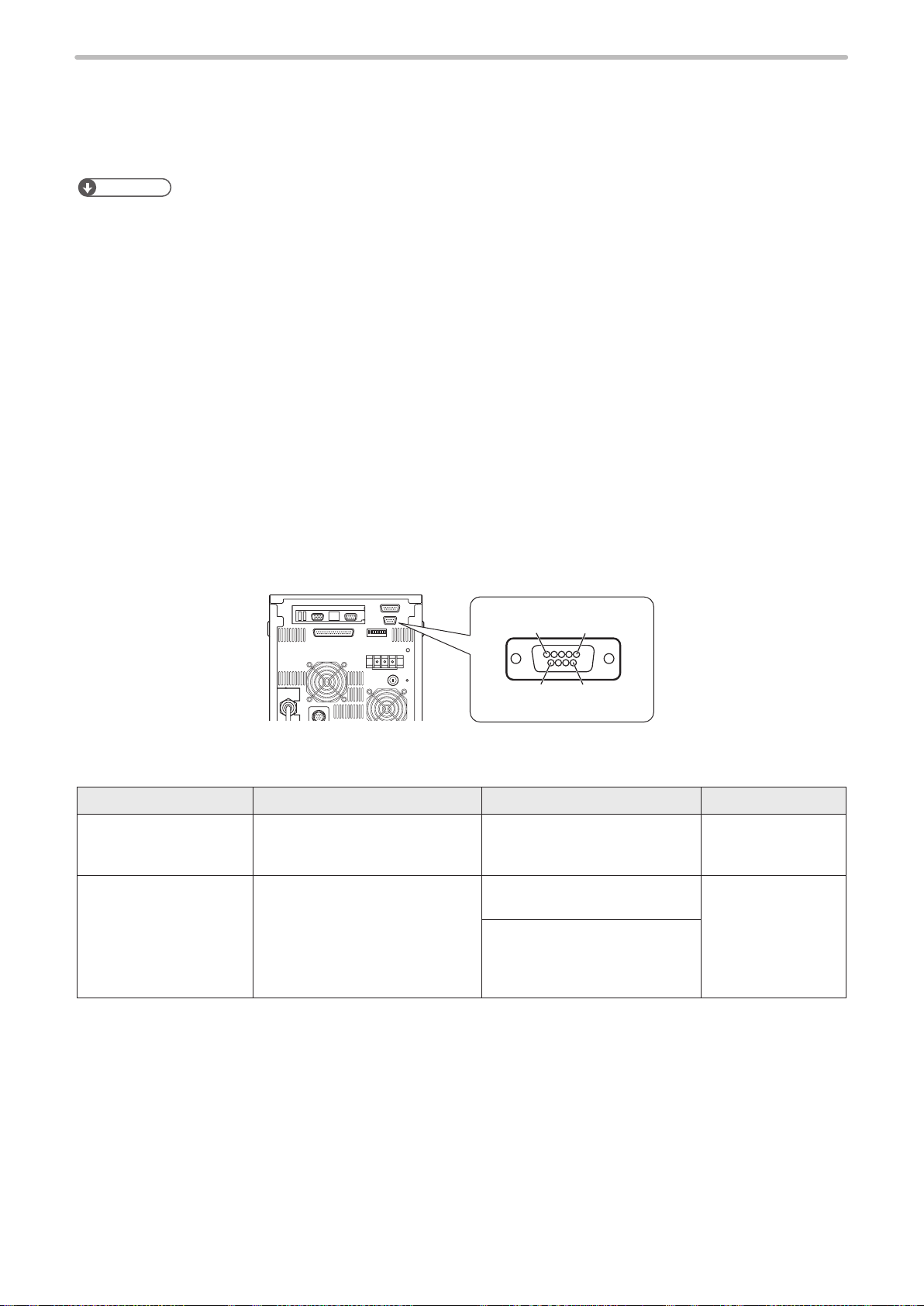

With DIP switch No. 5, select the setting method of the remote

CAUTION

ME-LPMSZ-SR-9

4.

mode.

DIP switch No. 5 Setting method of remote mode

ON Use the input signal of REMOTE IN (X5) on I/O terminal.

OFF(initial setting) Use the remote switch on the front of the controller.

Reference

• When DIP switch No. 5 is ON, the remote switch on the controller is not available.

When DIP switch No. 5 is OFF, select the remote mode state at

5.

powered ON with DIP switch No. 6.

DIP switch No. 6 Remote mode state at powered ON

ON Starts up with remote mode ON

OFF (initial setting) Starts up with remote mode OFF

Reference

• When DIP switch No. 5 is ON, keep DIP switch No. 6 OFF.

• When DIP switch No. 6 is ON, “X5: REMOTE IN” signal on I/O terminal is not available.

• If the DIP switch No. 5 or No. 6 are used while turned on, construct a system

for re-pumping the laser manually as safety protection measures after the stop

of the laser radiation due to an emergency stop or an interlock.

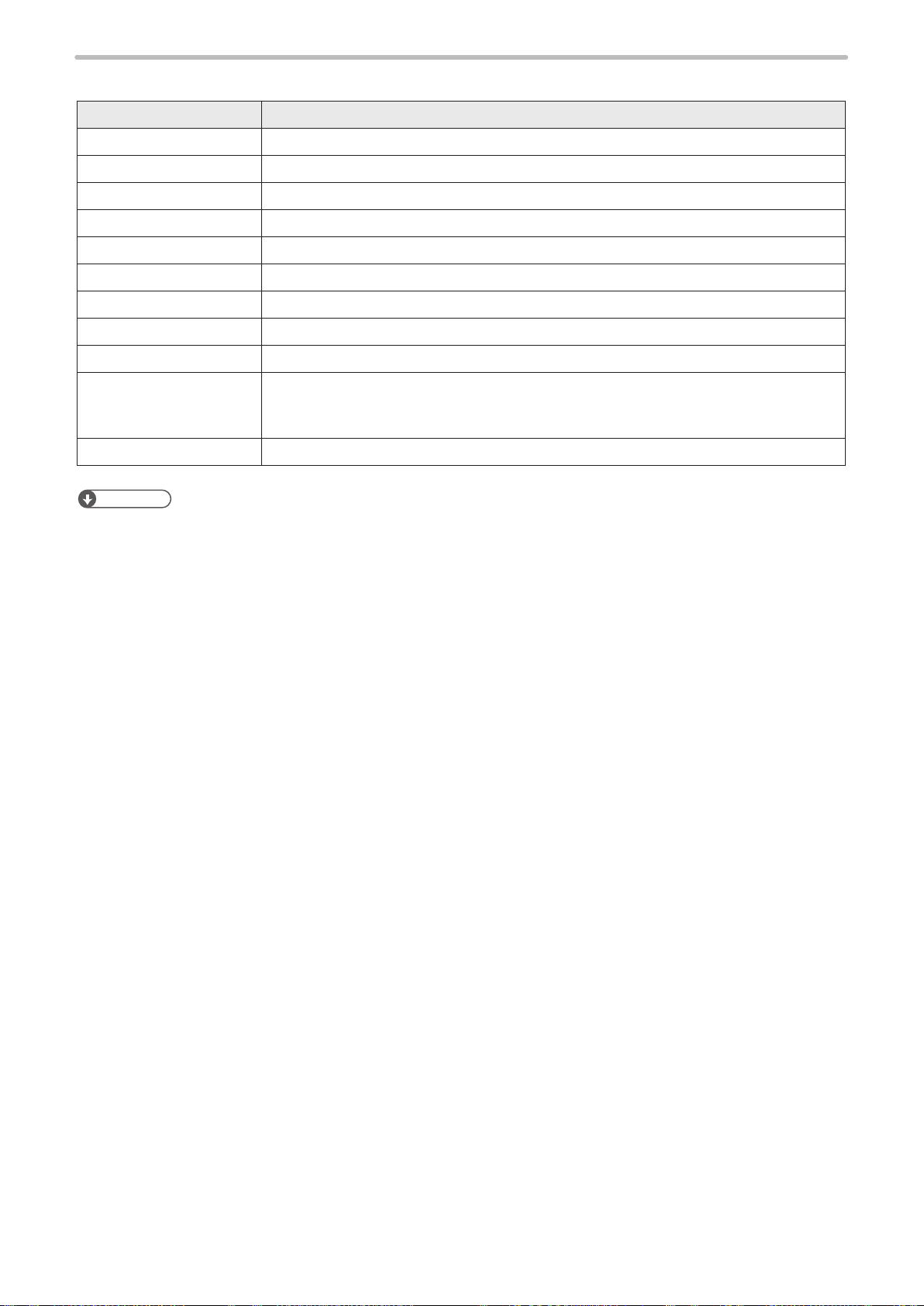

If you want to use the command format compatible with the former models of LP-F10/LP-F10W

6.

series, select the command mode using DIP switch No. 7 and No. 8.

Standard Mode LP-F10 Mode LP-F10W Mode

No. 7: OFF

No. 8: OFF

Notice

• Even with the use of LP-F10/F10W mode, there is a difference in communication processing time and I/O operation

timing between older model of LP-F10/LP-F10W and LP-M/LP-S/LP-Z series.

Install the DIP switch cover to the controller.

7.

Notice

• A plastic cover is installed on the DIP switch. Install this cover always to avoid the dust penetration to the controller.

Turn ON the power of laser marker.

8.

No. 7: ON

No. 8: OFF

No. 7: OFF

No. 8: ON

13

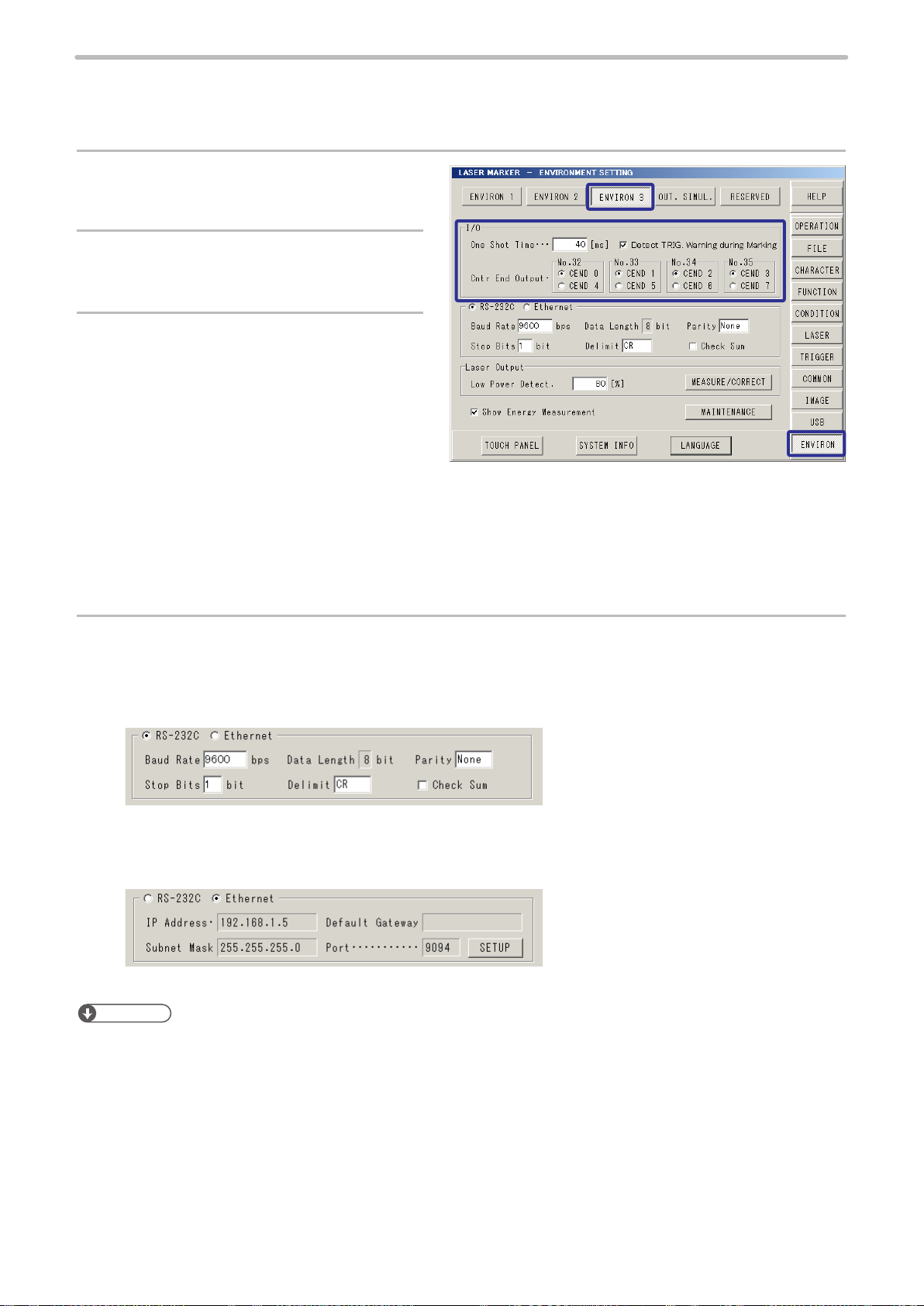

1-2-2 Communication condition setting

ME-LPMSZ-SR-9

To control the laser marker by using I/O or communication commands, congure the following items in advance on the

environment setting screen.

Select “ENVIRON” on the right menu.

1.

Select “ENVIRON 3”.

2.

To use I/O signals, congure the following

3.

output conditions:

• One-shot time:

Sets the output duration for some signals such

as MARK END OUT and SET OK OUT.

Setting range: 2 ms to 510 ms (initial value is 40

ms)

• Detect TRIG. Warning during Marking

Congure if you will output (ON) or will not output (OFF) the warning for the invalid trigger. With enabling this setting,

the warning is output when the marking trigger that cannot be accepted was input while the shutter is opened.

• Counter end output

Assign the counter No. from 0 to 7 to the counter end output signals in I/O connector pin No. 32 to 35 respectively.

To use the serial communication commands, set communication conditions for Ethernet or RS-

4.

232C.

• For RS-232C:

Congure the communication conditions of the laser marker corresponding to the external control device.

Default settings are as follows:

• Baud Rate: 9600 bps

• Parity: None

• Stop Bits: 1 bit

• Delimit: CR

• Check sum: None

• For Ethernet:

Congure the communication conditions according to the network environment.

Default settings are as follows:

• IP Address: 192.168.1.5

• Subnet Mask: 255.255.255.0

• Default Gateway: None

• Port: 9094

14

Reference

• The laser marker can be controlled by I/O and communication commands combined.

• RS-232C and Ethernet cannot be used at the same time.

• The parameters on the environment setting screen are applied to the laser marker directly without saving.

• When using RS-232C, specify the “Flow control” to “None” at the communication port settings of the external control

device.

1-2-3 Shift to remote mode

ME-LPMSZ-SR-9

To control the laser marker externally using I/O or serial communication commands, set the operation mode to the remote

mode in one of the following methods.

Select the method to switch to the remote mode by setting the DIP switch on the rear side of the controller.

Use the remote switch on the front of the controller.

Turn ON the remote mode switch on the front of the controller.

Turn OFF the DIP switch No. 5.

Refer to “1-2-1 DIP switch setting” (P.12).

Use input signal of X5 “REMOTE IN” on I/O terminal.

Turn ON the remote mode input (X5) of the I/O terminal on the rear of the controller.

X5: REMOTE IN

Turn ON the DIP switch No. 5.

Refer to “1-2-1 DIP switch setting” (P.12).

Reference

• When DIP switch No. 5 is ON, the remote switch on the controller is not available.

Start the laser marker in the remote mode

The laser marker starts up always in the remote mode state. Use the remote mode switch button of the controller for

releasing and resetting the remote mode.

ヱヰヸユン

OFF

ON

Turn OFF the DIP switch No. 5 and turn ON the DIP

switch No. 6.

Refer to “1-2-1 DIP switch setting” (P.12).

Reference

• When DIP switch No. 6 is ON, “X5: REMOTE IN” signal on I/O terminal is not available.

• The remote switch on the controller is available when DIP switch No. 6 is ON.

15

2 Basics of Serial Communication

ME-LPMSZ-SR-9

(RS-232/Ethernet)

2-1 Preparation of Command Control

ME-LPMSZ-SR-9

This product has RS-232C port and Ethernet port as the serial communication interfaces on the rear side of the controller.

Before using serial communication control, congure the DIP switch and the environment settings. Refer to “1-2 Before

External Control” (P.11).

Reference

• For communication with external devices, select either RS-232C or Ethernet port. (They cannot be used at the same

time, or switched.) The port selected in the environment setting screen indicates the valid communication port. For

details of the environment setting screen, please refer to the Operation Manual.

• If Ethernet is not used for the external control, connect nothing to the Ethernet port.

■ Combined control by serial communication and I/O

• The control method for “Laser Control”, “Shutter Control”, and “Guide Laser Control” should be selected from either the

serial communication or I/O. Turn the No. 2 DIP switch on the back surface of controller before turning on the power to

select the control (serial communication or I/O).

• Those commands can be used only when the DIP switch No. 2 is set to ON:

Laser pumping (LSR), Shutter (SHT), Guide LD indication (GID), Laser check radiation (SPT), Test marking (TST), Laser

power measurement (PWM), Power check (PWR)

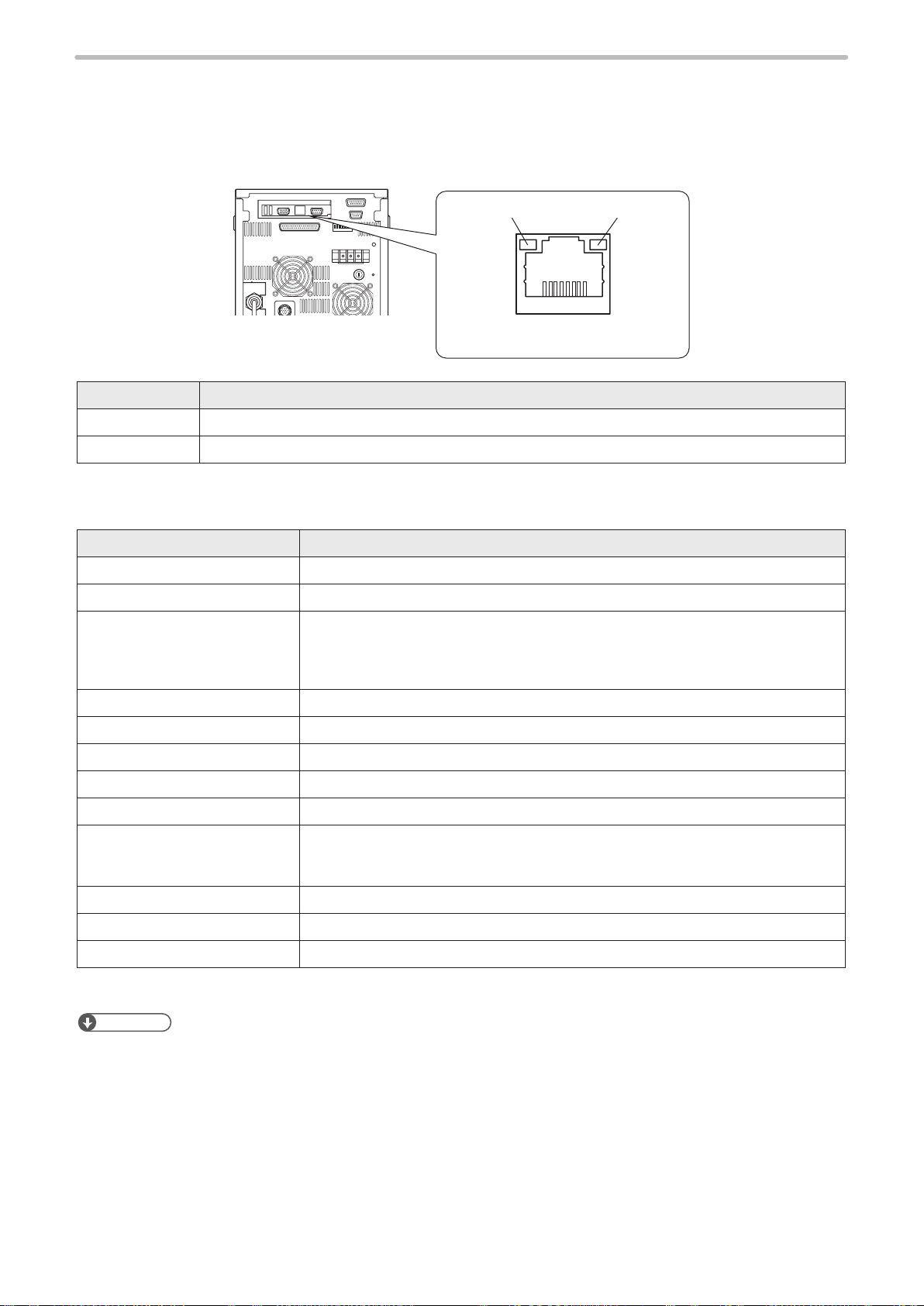

2-1-1 RS-232C

■ Interface specications and connection

To control laser marker by communication command with RS-232C, connect the RS-232C port on the rear of the controller

to the external control device.

51

6

Rear of controller

Connector position Connector specications Model Manufacturer name

On the laser marker side D-sub 9-pin, male

Screw type: No. 4-40UNC inch

screw, female

User side D-sub 9 -pin, female

Screw type: No. 4-40UNC inch

screw, male

Laser marker controller side

RS-232C por t (male)

- -

Recommended connector

17JE-13090-02(D1)A

Recommended connector cover

17JE-09H-1C4-CF

or

17JE-09H-1C-CF

9

DDK Ltd.

17

■ Signals of RS-232C connector

ME-LPMSZ-SR-9

Terminal No. Signal Function

1 Reserve Do not use this terminal.

2 RxD (RD) Receiving data: Connect TxD (SD) of the external control device.

3 TxD (SD) Transmission data: Connect RxD (RD) of the external control device.

4 Reserve Do not use this terminal.

5 GND (SG) Signal ground: Connect GND (SG) of the external control device.

6 Reserve Do not use this terminal.

7

8

9

■ Connecting to external control devices

• To connect the laser marker to the PC for control, use a commercially available RS-232C cross cable (9-pin).

• In case of connecting to PLC, a type of the cable (straight or cross) differs depending on a manufacturer or a model.

Please follow the PLC manual.

• To connect RS-232C terminal without using a commercially available RS-232C cable, connect only 3 signals of RxD,

TxD and GND and do not use other signals on the laser marker side.

• The external controller may need a signal line connection (loop back line) other than RxD, TxD, or GND on the external

control device side depending on the specications of the external control device. Read the instruction manual of the

external control device and connect it to the laser marker appropriately.

Connection example

RS-232C connector

(Laser marker)

Terminal No.

2

3

5

Signal

RxD

TxD

GND

Cross cable

*

* The loop back wiring on the external control device side shown in the above gure is just an example. The wiring

method varies depending on the specications of each external control device. Read the instruction manual of the

external control device and connect it to the laser marker appropriately.

External controller

RxD

TxD

DTR

RTS

CTS

Terminal No.

2

3

5

1

4

6

7

8

Signal

GND

DCD

DSR

18

■ RS-232C communication conditions

ME-LPMSZ-SR-9

Item RS-232C communication conditions

Synchro system Start-stop method

Communication Full-duplex transmission

Baud Rate 1200 / 2400 / 4800 / 9600 / 19200 / 38400 bps (initial setting: 9600 bps)

Data length 8-bit xed

Parity None / Even / Odd (initial setting: None)

Stop Bits 1-bit / 2-bit (initial setting: 1-bit)

Flow control None

Check sum OFF / ON (initial setting: OFF)

Delimiter CR / CR + LF (initial setting: CR)

Start Code

Reception timer Timeout monitoring ON (10 sec.)

Reference

• For the details of the setting method of communication conditions, refer to “1-2-2 Communication condition setting” (P.14).

• Setting request, Reading request, Reading response: STX

• Normal response: ACK

• Abnormal response: NAK

19

2-1-2 Ethernet

ME-LPMSZ-SR-9

■ Port specications

When Ethernet perform communication control of the laser marker, use an Ethernet port.

Green LED

Rear of controller

Light color Description

Green Lights up while 1000 BASE-T Management port is in link-up state.

Orange Blinks while there is activity on this port.

RJ-45 8-pole connector

Orange LED

■ Ethernet communication conditions

Item Ethernet communication conditions

Communication protocol TCP/IP

Standards IEEE802.3ab (1000BASE-T) / IEEE802.3u (100BASE-TX) / IEEE802.3 (10BASE-T)

Applicable cable Category 5e or higher

• To connect an external device and one laser marker: Cross cable

• To connect an external device and two or more laser markers through a HUB or a

router: Straight cable

Applicable HUB (or rooter) 1000BASE-T / 100BASE-TX / 10BASE-T compatible

IP Address 1.0.0.0 to 223.255.255.255 *1 / Initial value : 192.168.1.5

Subnet Mask 128.0.0.0 to 255.255.255.254 / Initial value : 255.255.255.0

Default Gateway 1.0.0.0 to 223.255.255.255 *1 / Initial value : Unspecied (0.0.0.0)

Port 5001 to 65534, except 9090 and 9091 / Initial value: 9094

Start Code

Check sum OFF

Delimiter CR xed

Reception timer Timeout monitoring ON (10 sec.)

*1 : Do not use “127” in the rst octet.

Reference

• Although the cable length between the devices is specied as 100 m at maximum in the Ethernet standard, use of cable

length below 10 m is recommended to avoid communication failure caused by noise and device malfunction.

• The communication control of the laser marker through the Ethernet should be performed in a secure network

environment.

• Depending on the combination, there are cases where IP Address and Subnet Mask values cannot be set even if they

are within the setting range.

• Make sure that the IP address for the laser marker on the network is not overlapping the IP address for the PC.

• If Ethernet is not used for the external control, connect nothing to the Ethernet port.

• For the details of the setting method of communication conditions, refer to “1-2-2 Communication condition setting” (P.14).

• Setting request, Reading request, Reading response: STX

• Normal response: ACK

• Abnormal response: NAK

20

■ Connecting to external control devices

ME-LPMSZ-SR-9

• To connect an external device and the laser marker directly one to one:

Use a Category 5e or higher cross cable for connection.

Reference

• If the external control device has the AutoMDI/MDI-X function, either a straight cable or a crossed cable can be

connected to the laser marker.

Cross cable

External control device

(PC, etc.)

Laser marker controller

• To connect an external device and the laser marker one to many through a HUB or a router:

Use a HUB (or a router) that supports 1000BASE-T/100BASE-TX/10BASE-T and Category 5e or higher straight cables

for connection.

External control device

(PC, etc.)

Straight cable

Laser marker controllers

Example of communication environment setting:

Make sure that the IP address for the laser marker on the network is not overlapping the IP address for the PC.

PC Laser Marker A Laser Marker B Laser Marker C Laser Marker D

IP Address

Subnet Mask

Default Gateway

Port

192.168.1.10 192.168.1.5 192.168.1.6 192.168.1.7 192.168.1.8

255.255.255.0

- 9094 9094 9094 9094

HUB (or router)

None

21

2-2 Command Reception Condition

ME-LPMSZ-SR-9

■ Command reception permission

When transmitting the communication command including an action to update the laser marker data, commands are

refused in the marking ready ON status or the shutter open. If “reception mode ON” is set for “command reception

permission (MKM command)” before transmitting a command, marking ready is set to OFF and commands get acceptable.

Set “reception mode OFF” for “command reception permission (MKM command)” to set marking ready ON before marking.

Reference

• Commands are acceptable by closing the shutter instead of “command reception permission (MKM command)”.

However, it is recommended to use the “command reception permission (MKM command)” when the number of open

and close of the shutter is a lot.

• The command reception permission (MKM command) does not include actual opening/closing operation of the shutter.

■ Commands acceptable only with shutter closed

(Unacceptable commands when “reception mode ON” is set for command reception permission (MKM command))

• Laser power measurement (PWM)

• Power check (PWR)

• Test marking (TST)

■ Commands that do not need the command reception permission (MKM command)

The following commands can be transmitted while the shutter is opened.

(There is no need to set “reception mode ON” for “command reception permission (MKM command)”.

• File change (specied with a number) (FNO)

• File change (specied with a comment) (FNN)

• Shutter (close only) (SHT)

• Command reception permission (MKM)

• Laser pumping (LSR)

• Counter reset (CTR)

• Status request (STS)

• Marking trigger (MRK)

• Serial offset (SEO)

• Serial data input (SIN)

• Error code (ECR)

■ Commands acceptable during warning/alarm occurrence

The laser marker accepts only the following commands while an alarm or warning occurs.

Alarm

• Status request (STS)

• Error code (ECR)

Warning

• Status request (STS)

• Error code (ECR)

• Shutter (close only) (SHT)

• Command reception permission (MKM) (reception mode ON and reception mode readout)

Reference

• The laser marker should be in the remote status when controlling it by serial communication.

• The Shutter (SHT) command is not acceptable when the No. 2 DIP switch on the back surface of controller is turned to

OFF.

• To release the warning (except error codes E800 to E811) by serial communication control, close the internal shutter

by Shutter (SHT) command or set the “command reception mode ON” by Command reception permission (MKM)

command, and remove the cause of warning.

• An alarm can not be released by serial communication control.

22

2-3 Connection Check

ME-LPMSZ-SR-9

Check the connection between laser marker and external control device if they are correctly connected.

1. Turn ON the power of the external control device

2. Turn ON the key switch of laser marker.

3. Coordinate the communication conditions between laser marker and external control device

Refer to “1-2-2 Communication condition setting” (P.14).

4. Set the laser marker to the remote mode

Refer to “1-2-3 Shift to remote mode” (P.15).

5. Change the le number of the laser marker (transmit the FNO command)

Start code

STX

02 46 4E 4F 53 32 30 34 37 30 35 0D (HEX)

The transmission data above is just a sample. Check sum ON/OFF and delimiter content vary depending on the

communication environment settings.

*1 : For the command above, calculate the check sum value as follows:

Convert the data from the start code to those before the check sum into the hexadecimal values according to the

ASCII code table and add them all together. Check sum is the value calculated by converting the lower two digits of

the total value into two characters in the ASCII code.

• 02(HEX) + 46(HEX) + 4E(HEX) + 4F(HEX) + 53(HEX) + 32(HEX) + 30(HEX) + 34(HEX) + 37(HEX) = 205(HEX)

• 30 35 (HEX) is the value converted the lower two digits character (lower one-byte) 05 (HEX) into two characters

in the ASCII code

6. Check the response from the laser marker

When the connection and communication condition settings are appropriate, the laser marker returns response data.

Example of response data for normal communication

Start code

ACK

06 30 30 36 36 0D (HEX)

Example of response data for abnormal communication

Command

“FNO”

“00” Check sum Delimiter

Sub command

“S”

Data:

File No.

“2047”

Check sum*1

Delimiter

CR

Start code

NAK

15 30 36 37 42 0D (HEX)

Reference

• To use Ethernet, the delimiter is [CR] xed. To use RS-232C, select either [CR] or [CR] [LF].

• Check sum cannot be added with Ethernet communication.

“06” Check sum Delimiter

23

2-4 Control Sample

ME-LPMSZ-SR-9

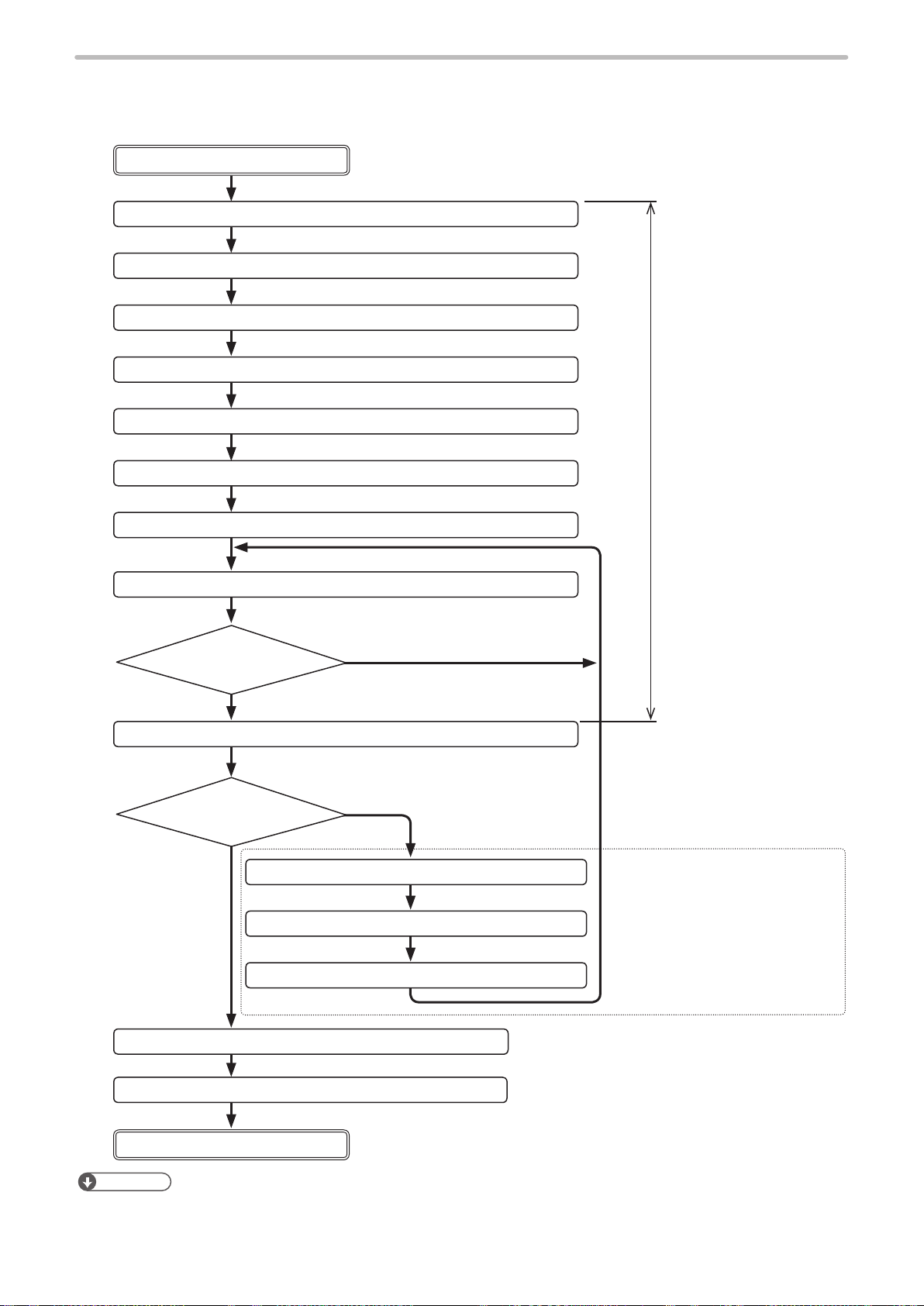

This paragraph gives the sample of ow chart for control of laser marker by serial communication.

Remote mode ON

1. Laser pumping (ON) LSR command

2. Marking character string setting

3. General condition setting ALC command

4. Character condition setting STC command

5. Laser power setting LPW command

6. Scan speed setting SSP command

7. Shutter (open) setting SHT command

8. Status request STS command

“READY”: ON

Yes

MCS command or STR command

Send STS command

No.

again after a while.

The interval between “1

Laser pumping ON” and

“9 Marking trigger” should

be about 20 seconds or

more with the LP-Mxxx /

LP-Sxxx / LP-Zxxx type,

and about 15 seconds or

more with the LP-SxxxW

type.

9. Marking trigger MRM command

Change setting contents

To nish the marking

13. Shutter setting (close) SHT command

14. Laser pumping (OFF) LSR command

Remote mode OFF

Reference

10.

Command reception mode ON

11. Various conditions setting LSR command

12.

Command reception mode OFF

To change the settings

MKM command

MRK command

When “10. Command reception

mode ON” is transmitted, the

commands unacceptable during

shutter open become settable

and various conditions can be set.

After setting various conditions,

set marking ready ON by “12.

Command reception mode OFF”.

24

• For LP-Mxxx-S type, open the laser gate to turn ON the ready signal.

Laser gate can be controlled with any timing regardless of the command sequence by the external signal input.

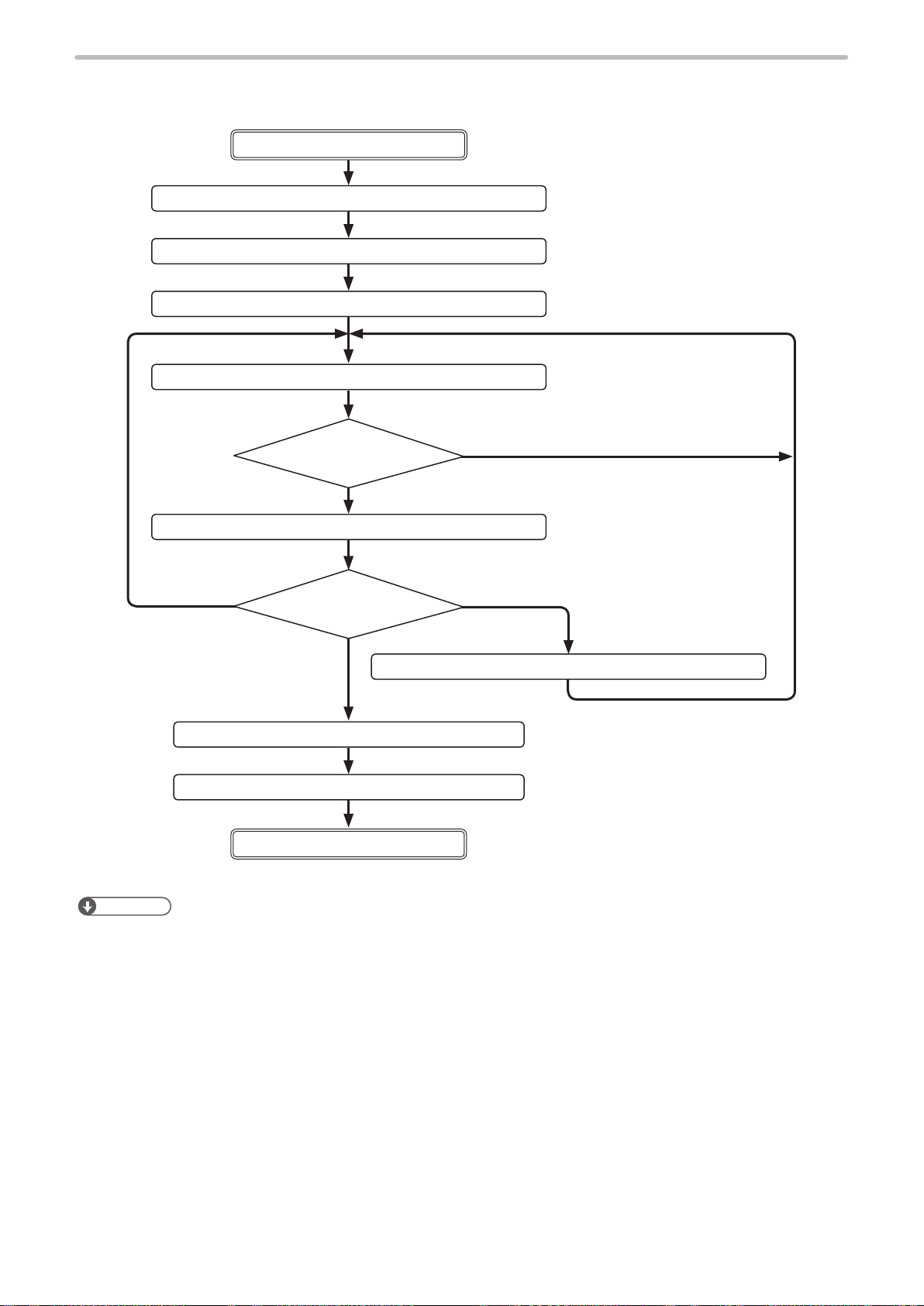

■ Control sample 1-1 : Changing the marking characters

ME-LPMSZ-SR-9

Remote mode ON

1. Laser pumping (ON) LSR command

2. Marking character string setting MCS command or STR command

3. Shutter setting (open)

4. Status request STS command

5. Marking trigger

Mark the same

character.

SHT command

“READY”: ON

Yes

MRK command

Change the character

to be marked

To nish the

marking

6. Command reception mode ON

Send the character

to be marked.

No.

Send STS command

again after a while.

Change the character.

MKM command

7. Marking character string setting MCS command or STR command

8. Command reception mode OFF

9. Shutter setting (close) SHT command

10. Laser pumping (OFF) LSR command

Remote mode OFF

Reference

• Other than STR and MCS command, SIN command can be used for changing character of marking command. SIN

command is recommended to use in case faster processing is required.

• For LP-Mxxx-S type, open the laser gate to turn ON the ready signal.

Laser gate can be controlled with any timing regardless of the command sequence by the external signal input.

MKM command

* To memorize the last marked

character into the laser marker,

save it with “File Overwriting

Registration (FOR)”.

25

■ Control sample 1-2: Changing the marking characters for each marking

ME-LPMSZ-SR-9

Remote mode ON

1. Laser pumping (ON) LSR command

2. Select le No. FNO command

3. Shutter setting (open) SHT command

* Before sending SIN data, keep 20 sec. (LP-Mxxx / LP-Sxxx / LP-Zxxx) or 15 sec. (LP-SxxxW)

after turning ON the laser pumping, and 1 sec. after the opening shutter.

4. Serial data input SIN command

5. Status request STS command

“READY”: ON

* “READY” will turn ON after the SIN command reception.

Yes

6. Marking trigger MRK command

Change the character.

“READY”: OFF

No.

Select the le set “Command (SIN)

specied character”

Send the character data to be marked.

Send STS command

again after a while.

To nish the

marking

8. Shutter setting (close) SHT command

9. Laser pumping (OFF) LSR command

Remote mode OFF

Reference

• For using this command, set “serial data” of function characters at setting screen beforehand.

• When using this function (serial data), transmit this command by every marking. Otherwise it does not become marking

ready condition, and marking is not available.

• Only when the internal shutter is opened during the remote mode, the serial data can be transmitted to the laser marker.

• When transmit this command without any data, marking ready become ON, then nothing to be marked with serial data

input.

• For resetting the data, set the “reception mode ON” for command reception permission (MKM command) or close the

shutter.

• For LP-Mxxx-S type, open the laser gate to turn ON the ready signal.

Laser gate can be controlled with any timing regardless of the command sequence by the external signal input.

7. Serial data input SIN command

26

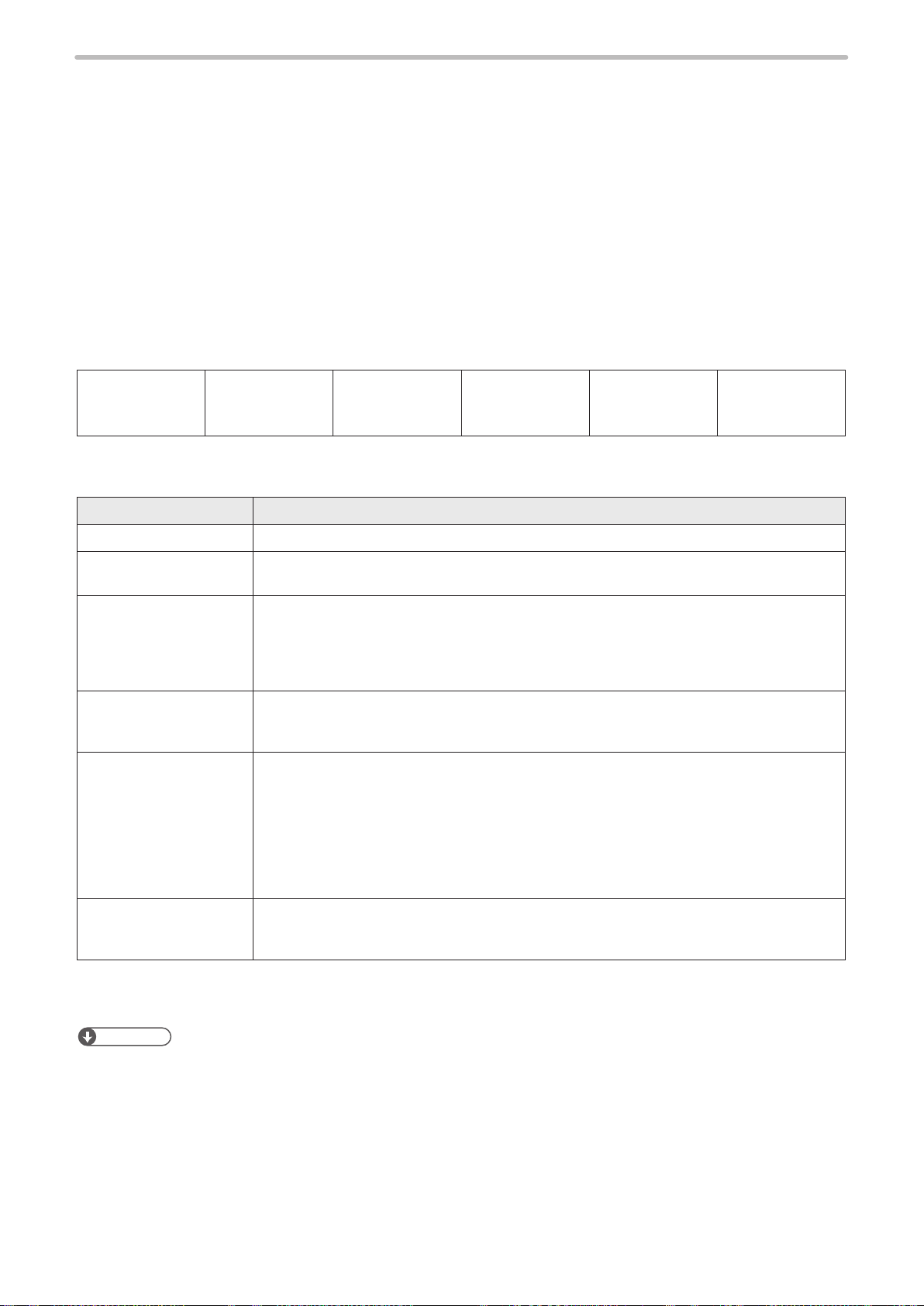

■ Control sample 2 : Changing the marking les

ME-LPMSZ-SR-9

Remote mode ON

1. Laser pumping (ON) LSR command

2. File switching (File No. specied) FNO

3. Shutter setting (open) SHT command

4. Status request STS command

“READY”: ON

Yes

5. Marking trigger

Change the le

Mark the same le.

to be marked

To nish the

marking

6. Change File No. FNO command

command

No.

MRK

command

Change the le.

Send STS command

again after a while.

7. Shutter setting (close) SHT command

8. Laser pumping (OFF) LSR command

Remote mode OFF

Reference

• For LP-Mxxx-S type, open the laser gate to turn ON the ready signal.

Laser gate can be controlled with any timing regardless of the command sequence by the external signal input.

27

2-5 Communication Data Format

ME-LPMSZ-SR-9

Use the ASCII code basically and the shift-JIS code partially as characters for communication when controlling the laser

marker by external device.

The characters (or character strings) enclosed with double quotation marks (“ ”) in the description below indicates that

they uses the ASCII code.

When using the shift-JIS code, it is described in each case.

2-5-1 Command data

The word “command” means the instruction which is sent to the laser marker from external device. Command data is

created with the specied format. Remote control of laser marker or execution of specied procedures are possible by

sending the command data to laser marker.

■ Command data format

Start code

Single character

Head End

Code Description

Start code A start code is a code to identify the data head. STX: 02 (HEX) xed.

Command A command is specied with three characters. Refer to “3 Communication Command and

Sub command A sub command is an instruction of setting/readout complementary added to a command.

Data Data specied per command

Check sum

*1

Command

Three characters

Function” (P.34)

Species one of the characters below.

“S”: Data setting or operation (Set)

“R”: Readout of setting data (Read)

(Note) “S” or “R” cannot be selected for some commands.

The content to be specied varies per command. Refer to “3 Communication Command and

Function” (P.34)

Check sum indicates the lower 1-byte of adding result of value (binary) from the start code

to the last data by converting it to two characters by ASCII code.

Where the command is “ABC”, sub command is “S” and data is “000”

02(HEX)+41(HEX)+42(HEX)+43(HEX)+53(HEX)+30(HEX)+30(HEX)+30(HEX)=1AB(HEX)

AB(HEX), the lower 1-byte of 1AB(HEX) is converted to 41(HEX)+42(HEX) to two

characters by ASCII code.

ON/OFF of check sum can be selected on the environment setting of laser marker.

Refer to Operation Manual for the details.

Sub command

Single character

Data

Variable length

Check sum

Two characters

Delimiter

Two characters/

Single character

28

Delimiter

*1 : A check sum can be added in case of RS-232C.

*2 : You can select [CR] or [CR+LF] for a delimiter in case of RS-232C. [CR] is xed in case of Ethernet.

Reference

• The laser marker recognizes the data from the start code (STX) to the delimiter (CR or CR+LF) as one command data.

If there exists an unnecessary character string before the start code or after the delimiter, it is ignored (neither an

abnormal response data is returned).

• When using the external device set by 2-byte, NUL (00 (HEX)) can be used.

• Add to NUL before STX or after delimiter.

*2

Delimiter is a code to identify the end of data.

CR+LF (0D (HEX) 0A (HEX)) or CR(0D (HEX)).

Selects CR+LF or CR on the console. Refer to Operation Manual for the details.

2-5-2 Response data

ME-LPMSZ-SR-9

Response data is data which is returned from the laser marker for the command sent by an external device and consists of

the following three types.

1. Response data for normal receiving

The data starts with the start code “ACK”. It returns when the command transmitted is normal or the command

processing has been completed normally.

2. Response data for abnormal receiving

The data starts with the start code “NAK”. It returns when the command transmitted is abnormal or the command

processing has been completed abnormally.

3. Readout data

The data starts with the start code “STX”. It returns when the command transmitted is normal and the sub command

is specied to “R”.

■ Response data format for normal receiving

Start code

Single character

Head End

Code Description

Start code ACK: 06 (HEX) xed. A start code is a code to identify the data head and to indicate that the

Response code Two characters “00” is returned if the start code is ACK.

Check sum

Delimiter

*1 : A check sum can be added in case of RS-232C.

*2 : You can select [CR] or [CR+LF] for a delimiter in case of RS-232C. [CR] is xed in case of Ethernet.

*1

*2

Response code

Two characters

data is a response data for normal receiving.

Check sum indicates the lower 1-byte of adding result of value (binary) from the start code

to the response code by converting it to two characters by ASCII code.

(ex): 06 (HEX)+30 (HEX)+30 (HEX)=66 (HEX)

66 (HEX) is converted to 36 (HEX)+36 (HEX), to two characters by ASCII code.

ON/OFF of check sum can be selected on the environment setting of laser marker.

Refer to Operation Manual for the details.

Delimiter is a code to identify the end of data.

CR+LF (0D (HEX) 0A (HEX)) or CR(0D (HEX)).

Selects CR+LF or CR on the console. Refer to Operation Manual for the details.

Check sum

Two characters

Delimiter

Two characters/

Single character

29

■ Response data format for abnormal receiving

ME-LPMSZ-SR-9

Start code

Single character

Head End

Code Description

Start code NAK: 15 (HEX) xed. A start code is a code to identify the data head and to indicate that the

Response code Two characters is returned if the start code is NAK.

Response code

Two characters

data is a response data for abnormal receiving.

“01”: Inappropriate STX has been received.

“02”: Inappropriate delimiter has been received.

“03”: Unacceptable command because the shutter is opened or “command reception mode

ON” is not set for the MKM command

“04”: No applicable command

“05”: Incorrect check sum

“06”: Incorrect length of receiving data

“07”: Unacceptable command due to priority of input terminal

“08”: Incorrect sub command

“09”: Incorrect receiving data

“10”: Alarm or warning occurs

“11”: SIN or SEO command is not acceptable because of following conditions.

• Internal shutter status is closed.

• No setting of Serial data input on character string (When SIN command is used)

• No setting of Serial data on external offset condition (When SEO command is used)

“12”: The le cannot be saved due to lack of capacity in the ash disk

“14”: This command is not supported with the LP-F10/LP-F10W mode.

“15”: This function or setting value is not supported with the LP-F10/LP-F10W mode.

“99”: Others

Check sum

Two characters

Delimiter

Two characters/

Single character

Check sum *1 Check sum indicates the lower 1-byte of adding result of value (binary) from the start code

to the response code by converting it to two characters by ASCII code.

(ex): where the response code is “20”,

15 (HEX)+32 (HEX)+30 (HEX)=77 (HEX)

77 (HEX) is converted to 37 (HEX)+37 (HEX), to two characters by ASCII code.

ON/OFF of check sum can be selected on the environment setting of laser marker.

Refer to Operation Manual for the details.

Delimiter *2 Delimiter is a code to identify the end of data.

CR+LF (0D (HEX) 0A (HEX)) or CR(0D (HEX)).

Selects CR+LF or CR on the console. Refer to Operation Manual for the details.

*1 : A check sum can be added in case of RS-232C.

*2 : You can select [CR] or [CR+LF] for a delimiter in case of RS-232C. [CR] is xed in case of Ethernet.

30

Loading...

Loading...