Panasonic LN189S Datasheet

Infrared Light Emitting Diodes

,

LN189S

GaAlAs Infrared Light Emitting Diode

Light source for distance measuring systems

Features

High-power output, high-efficiency : PO = 5.5 mW (typ.)

Fast response and high-speed modulation capability :

Infrared light emission close to monochromatic light :

Narrow direcivity using spherical lenses; works well with optical

systems in auto focus systems

Mini hollow mold resin package

Absolute Maximum Ratings (Ta = 25˚C)

Parameter Symbol Ratings Unit

Power dissipation P

Forward current (DC) I

Pulse forward current I

Reverse voltage (DC) V

Operating ambient temperature

Storage temperature T

*

f = 10 kHz, Duty cycle = 25 %

D

F

*

FP

R

T

opr

stg

160 mW

0.15 A

–25 to +85 ˚C

– 40 to +100 ˚C

tr, tf =20 ns (typ.)

λP = 880 nm(typ.)

80 mA

3V

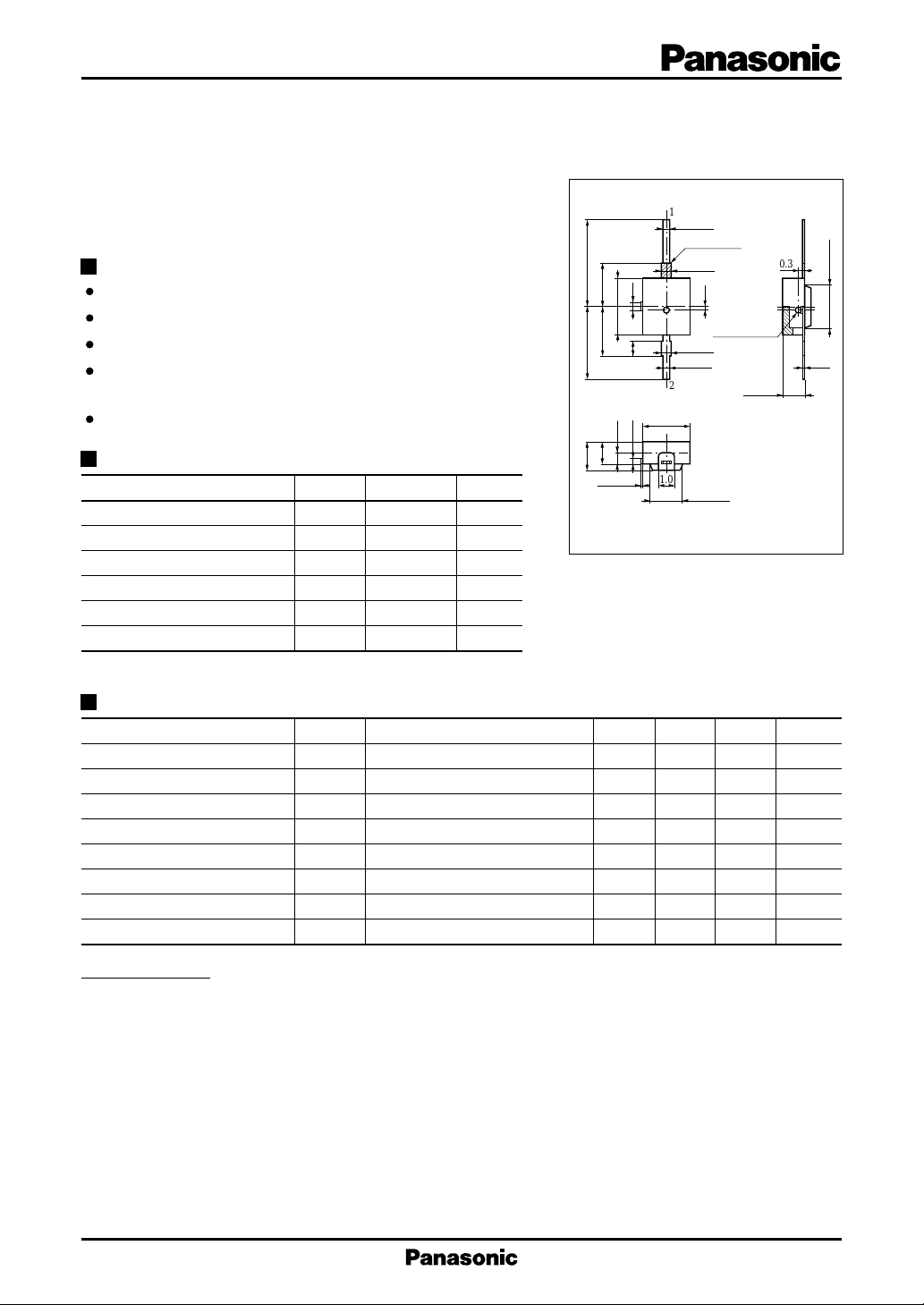

6.0±0.35.0±0.3

2.0±0.2

3.0±0.2

4.0± 0.15

3.4±0.2

0.75

1.5

0.1 max.

0.60.35

1.0

3.2±0.15

1.0

1

0.4±0.1

Mark (Blue)

0.6±0.1

0.6±0.1

0.5±0.1

2

0.2

2.2±0.15

Spherical lens

ø0.4±0.03

1.5±0.2

Unit : mm

0.3

0.15

1: Anode

2: Cathode

3.0±0.15

Electro-Optical Characteristics (Ta = 25˚C)

Parameter Symbol Conditions min typ max Unit

Radiant power P

Peak emission wavelength λ

Spectral half band width ∆λ IF = 100mA 50 nm

Forward voltage (DC) V

Reverse current (DC) I

Rise time t

Fall time t

Half-power angle θ

Precautions for Use

[Airtightness] This product is not structured to provide a complete air seal. Therefore it cannot be immersed in solutions for

purposes such as boiling tests or ultrasonic cleaning.

[Ability to withstand soldering heat]

The package of this product contains thermoplastic resin which has a limited ability to withstand heat. Therefore

this product cannot be put through automated soldering operations in which the ambient temperature exceeds

the specified temperature. The recommended soldering conditions are as follows.

· Temperature of soldering iron tip : 260˚C or less

· Soldering time : 5 seconds or less : 1 second or less

· Soldering position : At least 2 mm away from lead base

[Ability to withstand chemicals]

If the transparent case requires cleaning, wipe it lightly using ethyl alcohol, methyl alcohol, or isopropyl alcohol.

If you plan to use other solvents, carefully check to make sure there are no problems such as a misshapen case or

a change in the condition of the case material.

IF = 100mA 3 5.5 mW

O

IF = 100mA 880 nm

P

IF = 100mA 1.60 2.0 V

F

VR = 3V 10 µA

R

I

r

f

= 100mA 20 ns

FP

I

= 100mA 20 ns

FP

The angle in which radiant intencity is 50%

or

]

: 300˚C or less

15 deg.

1

LN189S Infrared Light Emitting Diodes

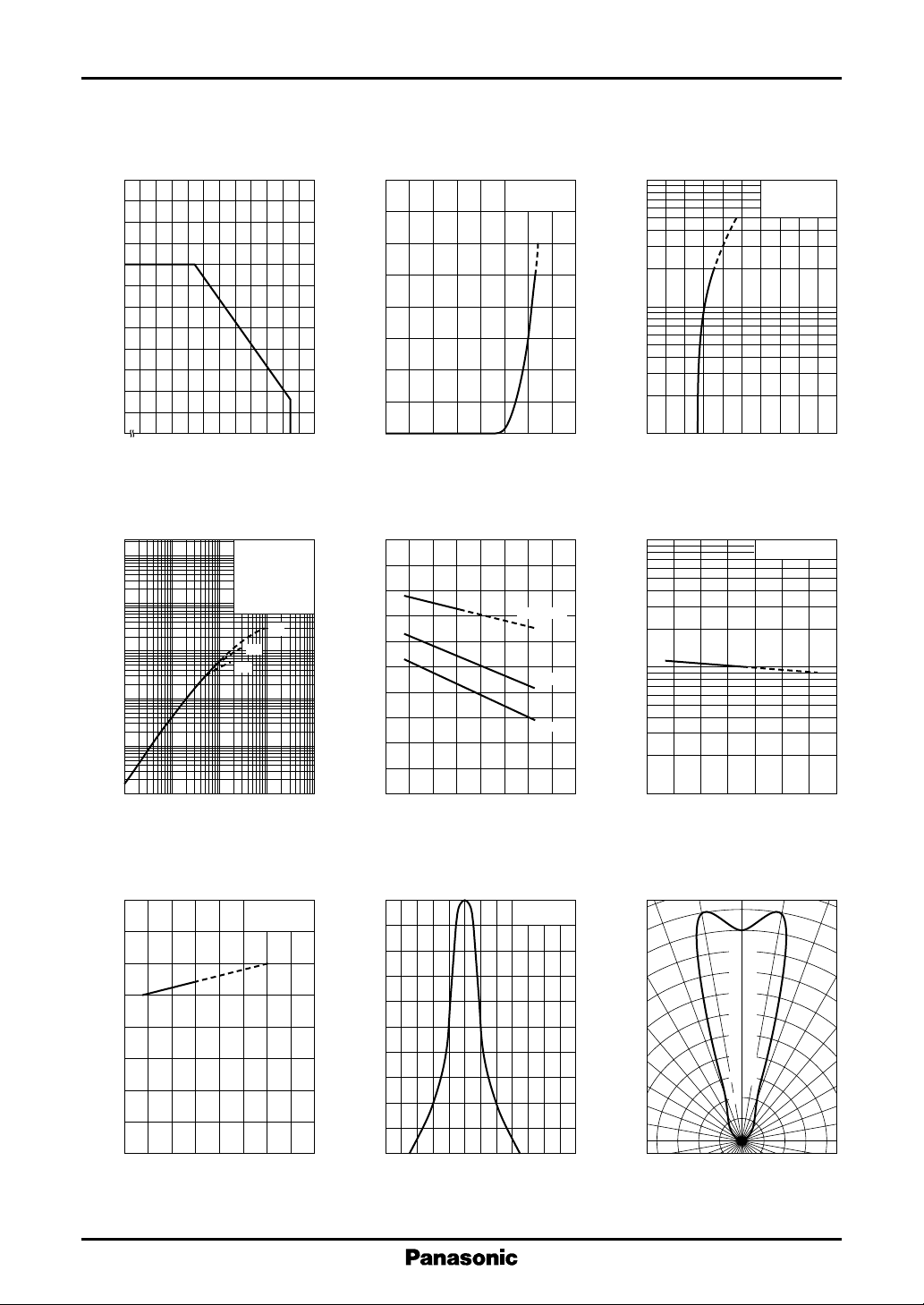

I

120

100

80

(mA)

F

60

40

F

Forward current I

20

0

0 20406080100

– 25

Ambient temperature Ta (˚C )

∆P

3

10

O

2

10

10

1

— Ta

— I

O

F

(1) tw = 10µs

Duty = 0.1%

(2) tw = 50µs

Duty = 50%

(3) DC

Ta = 25˚C

(1)

(2)

(3)

I

— V

F

160

140

120

(mA)

F

100

80

60

40

Forward current I

20

0

0 0.5 1.0 1.5 2.0

F

Forward voltage VF (V)

V

— Ta

F

(V)

F

1.8

1.6

1.4

1.2

Ta = 25˚C

IF = 80mA

10mA

I

FP

(A)

FP

10

1

–1

Pulse forward current I

–2

10

0

13524

Forward voltage VF (V)

∆P

10

O

1

O

— V

— Ta

F

t

= 10µs

w

f = 100Hz

Ta = 25˚C

IF = 80mA

Relative radiant power ∆P

–1

10

–2

10

–3

–2

10

10

–1

10

1

Forward current IF (A)

λ

— Ta

1000

(nm)

900

P

800

700

P

IF = 100mA

Peak emission wavelength λ

600

– 40 0 40 80 120

Ambient temperature Ta (˚C )

Forward voltage V

1.0

10

0.8

– 40 0 40 80 120

Ambient temperature Ta (˚C )

Spectral characteristics

100

80

60

40

Relative radiant intensity (%)

20

0

780

1mA

I

= 50mA

F

Ta = 25˚C

820 860 900 940 980 1020

Wavelength λ (nm)

Relative radiant power ∆P

–1

10

– 40 0 40 80

Ambient temperature Ta (˚C )

Directivity characteristics

0˚ 10˚ 20˚

100

90

80

70

60

50

40

30

Relative radiant intensity (%)

20

30˚

40˚

50˚

60˚

70˚

80˚

90˚

2

Loading...

Loading...