Panasonic LH-CD6 Installation Manual

INSTRUCTION MANUAL

LED Type Optical Displacement Sensor

High-functionality Controller

1-Head Type

LH-CS6, LH-CS6P

High-functionality Controller

2-Head Type

LH-CD6, LH-CD6P

Thank you very much for using SUNX sensors. Please read this Instruction Manual

carefully and thoroughly for the correct and

optimum use of this sensor. Kindly keep

this manual in a convenient place f or quick

reference.

This product is not a safety

sensor. Its use is not

intended or designed to

protect life and prevent body

injury or property damage

from dangerous parts of

machinery. It is a normal

object detection sensor.

For details, please refer to the User’s

Manual.

— CONTENTS —

z SPECIFICATIONS ....................... 1

x CAUTIONS .................................. 3

c MOUNTING ................................. 3

v CONNECTION ............................. 4

b

n FUNCTIONAL DESCRIPTION .... 8

m SETTING ..................................... 9

, DIMENSIONS ............................ 19

Page

䢇 Connection of sensor

head to controller ...................4

䢇 I/O circuit diagrams ................5

䢇 RS-232C modular connector

pin position ............................7

ANALOG OUTPUT DIAGRAMS

... 7

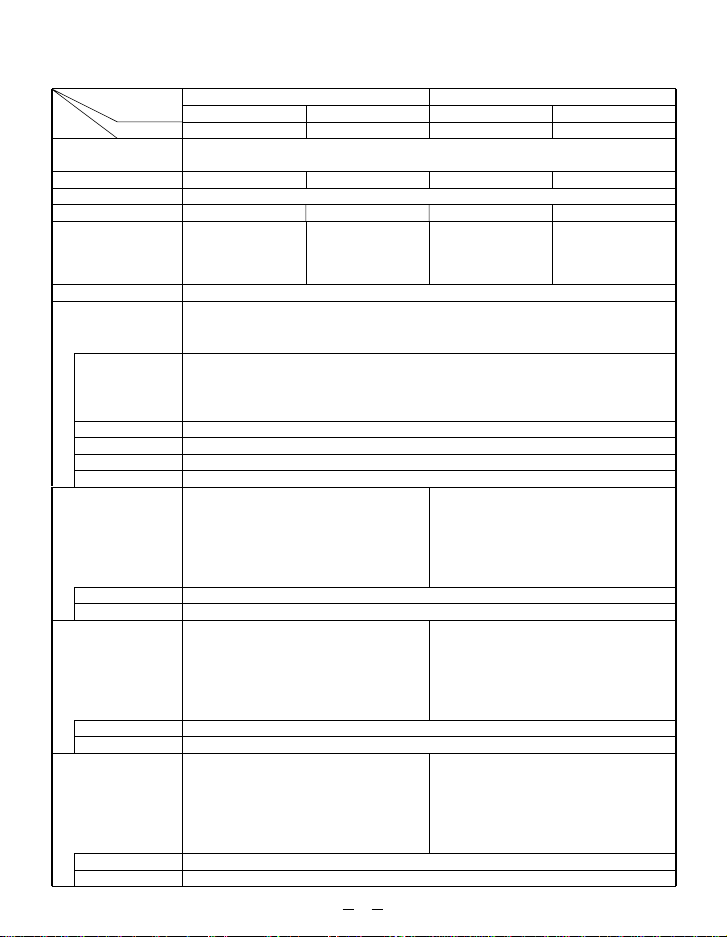

z SPECIFICATIONS

Type

Applicable sensor

head (Note 2)

Connectable sensor heads (Max.)

Supply voltage

Current consumption (Note 3)

Sampling frequency

Gain setting

Analog output

()

Comparative output

(HI, GO, LO)

Strobe output

Alarm output

Model No.Item

Analog voltage output

Analog current output

Response time

(Note 5)

Linearity (Note 6)

Temp. characteristics

Span adjustment

Shift adjustment

Output operation

Short-circuit protection

Output operation

Short-circuit protection

Output operation

Short-circuit protection

NPN open-collector transistor

• Maximum sink current: 30mA

• Applied voltage: 30V DC or less

• Residual voltage:

NPN open-collector transistor

• Maximum sink current: 30mA

• Applied voltage: 30V DC or less

• Residual voltage:

NPN open-collector transistor

• Maximum sink current: 30mA

• Applied voltage: 30V DC or less

• Residual voltage:

NPN output type

1-head type

LH-CS6

1 No.

3.3kHz approx.

Analog voltage Analog current

• Output voltage:

• Output impedance: 100 Ω • Load resistance: 300 Ω or less

When set to SELECT: 0.5ms/1ms/10ms/20ms/30ms/40ms/100ms/300ms

When set to AUTO: 0.5ms/1ms/10ms/20ms/30ms/40ms/100ms/300ms

(between comparative output and 0V)

1.0V or less (at 30mA sink current)

0.4V or less (at 16mA sink current)

(between strobe output and 0V)

1.0V or less (at 30mA sink current)

0.4V or less (at 16mA sink current)

(between alarm output and 0V)

1.0V or less (at 30mA sink current)

0.4V or less (at 16mA sink current)

OFF when DARK, BRIGHT, NEAR, FAR, or other error is displayed.

2-head type

LH-CD6

LH-54, LH-58, LH-512

2 Nos.

24V DC

±

10% Ripple P-P 10% or less

350mA or less 350mA or less300mA or less 300mA or less

When set to CH 1 or CH 2:

•

3.3kHz approx.

•

When set to Calculation:

825Hz approx.

AUTO (Note 4) / SELECT (settable in 11 steps)

–5 to +5V • Output current: 4 to 20mA

selectable by key

automatically selected depending on the measured object

Within

Within

±

Within

Within

±

ON when threshold level is reached

ON when comparative output is effective

Incorporated

Incorporated

1-head type

LH-CS6P

3.3kHz approx.

±

0.2% F.S.

±

0.04% F.S./˚C

30% F.S. (Note 7)

30% F.S. (Note 7)

PNP open-collector transistor

• Maximum source current: 30mA

• Applied voltage: 30V DC or less

(between comparative output and

• Residual voltage:

1.0V or less (at 30mA source current)

0.4V or less (at 16mA source current)

PNP open-collector transistor

• Maximum source current: 30mA

• Applied voltage: 30V DC or less

• Residual voltage:

1.0V or less (at 30mA source current)

0.4V or less (at 16mA source current)

PNP open-collector transistor

• Maximum source current: 30mA

• Applied voltage: 30V DC or less

• Residual voltage:

1.0V or less (at 30mA source current)

0.4V or less (at 16mA source current)

—

1

PNP output type

1 No.

(between strobe output and

(between alarm output and

2-head type

•

When set to CH 1 or CH 2:

•

When set to Calculation:

LH-CD6P

2 Nos.

3.3kHz approx.

825Hz approx.

+V)

+V)

+V)

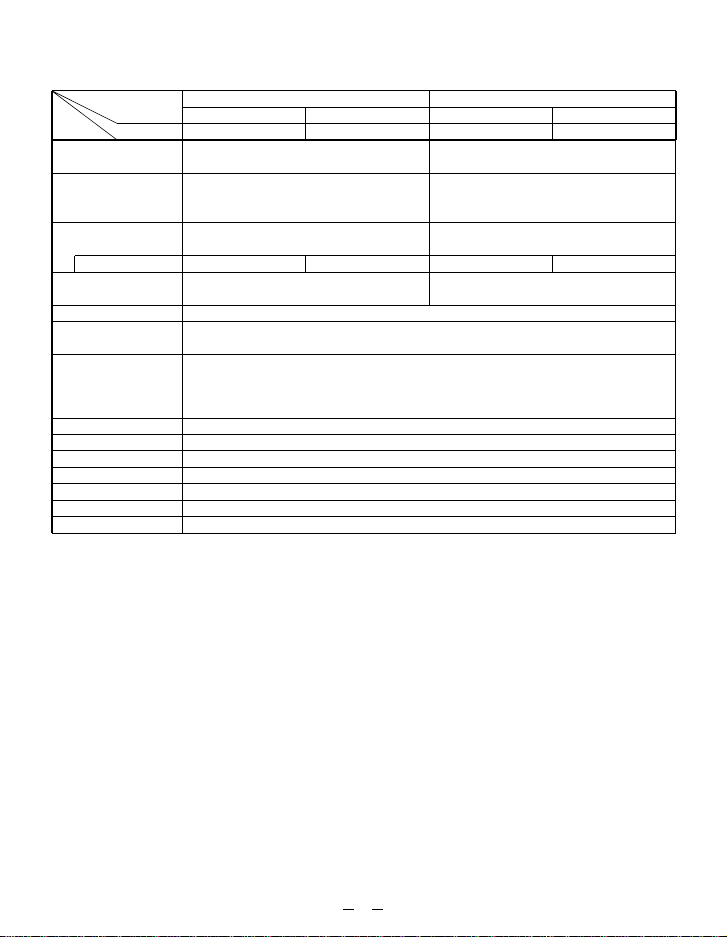

Type

Model No.Item

0-ADJ input

Remote interlock input

BUSY input

No. of inputs

Calculation hold reset

input

Timer function

Interference prevention

function (Note 8)

Serial communication

Display

Ambient temperature

Ambient humidity

Material

Connection method

Weight

Accessory

NPN output type

1-head type

LH-CS6

Low (0 to 1V): 0-ADJ operation

• Applied voltage: 30V DC or less

Low (0 to 1V): Emission

High (

+

V or open): Emission stopped

• Applied voltage: 30V DC or less

Low (0 to 1V): Measurement stopped

• Applied voltage: 30V DC or less

1 ch.

Low (0 to 1V): Calculation result reset

• Applied voltage: 30V DC or less

Incorporated (operates on comparative output and alarm output)

Standard: RS-232C (RD/SD/SG)

Connector: 6 pin modular jack

Operation: user setting external switching, function detail external setting,

0 to

2-head type

LH-CD6

High (

Low (0 to 1V, or open): Emission stopped

• Applied voltage: 30V DC or less

2 ch.

Incorporated (up to two units)

measurement data transmission, etc.

+

50˚C (No dew condensation), Storage: –20 to +60˚C

5 digit red LED display

35 to 85% RH, Storage: 35 to 85% RH

Enclosure: Polycarbonate

Terminal block connection

120g approx.

ATA4811 (Controller mounting frame): 1 set

PNP output type

1-head type

LH-CS6P

High (

+

V): 0-ADJ operation

• Applied voltage: 30V DC or less

+

V): Emission

High (

+

V): Measurement stopped

• Applied voltage: 30V DC or less

1 ch.

+

V): Calculation result reset

High (

• Applied voltage: 30V DC or less

2-head type

LH-CD6P

2 ch.

Notes:

1) Conditions which have not been specified are to be taken as: 24V DC supply voltage,

+20˚C

ambient temperature, SELECT gain setting, 300ms response time setting, center measuring

distance, interference prevention function not used, and white ceramic board object.

2) For details of the applicable sensor head, please refer to the instruction manual of the sensor

head.

3) Including the sensor head.

4) Take care that when the gain is set to AUTO, the linearity and the resolution may deteriorate.

5) For LH-CD6(P), this is the response time for CH 1 or CH 2 setting. The response time for Calculation setting is four times this value. Also, take care that when the response time is set to AUTO,

the linearity, resolution and the response time will vary.

6) This is the value for white ceramic board object. The linearity may differ depending on the measured object. Further, in case of LH-CD6(P), this is the value for CH 1 or CH 2 setting. For

calculation setting, the linearity is approx. twice the value given in the above table.

7) The linearity of the sensor head and the controller has been adjusted at the time of shipment.

Carry out the shift adjustment and the span adjustment to suit the operating conditions.

8) Take care that the linearity, resolution and the response time may deteriorate when the interference prevention function is used.

2

x CAUTIONS

This controller has been designed to meet the specifications when used along with the optional

exclusive sensor heads. In case it is used in a combination that does not use the optional

exclusive sensor heads, not onl y the specifications ma y not be met, b ut it ma y also cause an

accident, etc. Hence, always use this controller along with the exc lusive sensor heads.

䢇 Use this product 30 min. after the power is supplied. Immediately on supply of power,

the electrical circuit is yet to stabilize, which may cause variation in measured values.

䢇 Take care that after switching on the power supply, there is a muting time of 5 sec.

䢇

Make sure to carry out the wiring in the power supply off condition.

䢇 Take care that wrong wiring will damage the sensor.

䢇 Verify that the supply voltage variation is within the rating.

䢇 If power is supplied from a commercial switching regulator,

ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

䢇

In case noise generating equipment (switching regulator, inverter

motor, etc.) is used in the vicinity of this product, connect the

frame ground (F .G.) terminal of the equipment to an actual ground.

䢇 Do not r un the wires together with high-voltage lines or power lines or put them in

the same raceway. This can cause malfunction due to induction.

䢇 The analog output and the alarm output are not incorporated with a short-circuit pro-

tection circuit. Do not connect them directly to a power supply or a capacitive load.

䢇 Avoid dust, dirt, and steam.

䢇 Take care that the sensor does not come in direct contact with water, oil, grease, or

organic solvents, such as, thinner, etc.

䢇 Mount the controller such that the ventilation holes are not blocked.

䢇 If the controller is used for a long time, although it becomes hot, this does not indi-

cate any abnormality. However, if the controller is used by being enclosed in a control box, make sure to provide for enough heat radiation or cooling by fan, etc.

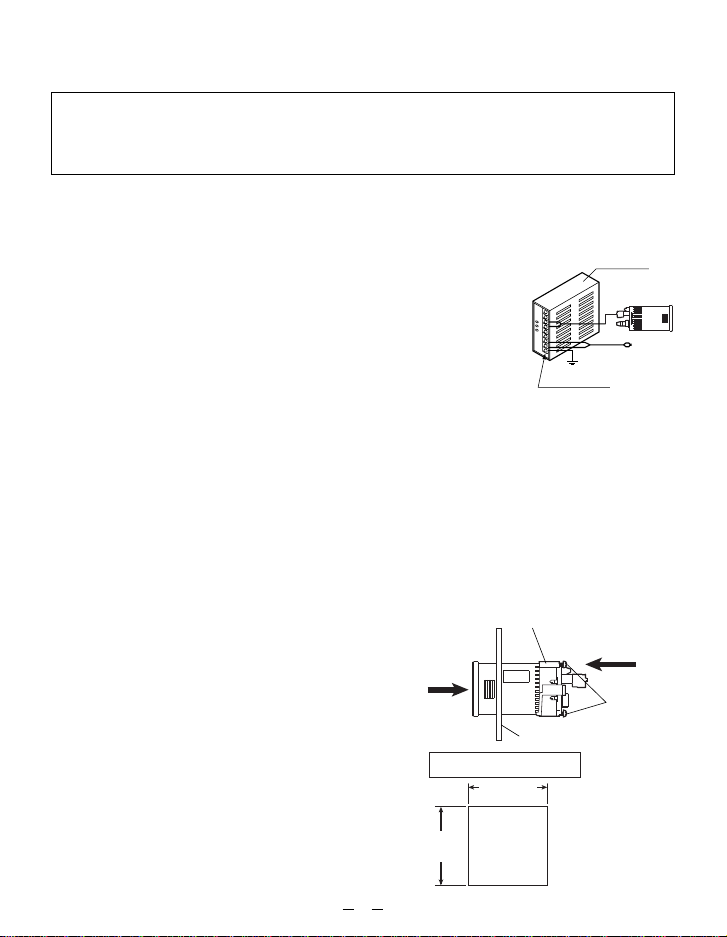

c MOUNTING

Controller mounting frame (ATA4811) (Accessory)

q Insert the controller, from its rear portion, into

the cut-out of the panel.

q

w Insert the enclosed controller mounting frame

(ATA4811) from the rear side of the controller

and push it till the end.

e Tighten the controller mounting frame uniformly ,

using the mounting screws (2 Nos.) enclosed

with it. After mounting on the panel, make sure

to confirm that the controller is firmly mounted

Panel cut-out dimensions

45±

0.6

0

Panel thickness:

1 to 5mm

mm

and that it does not shake.

Note: If the mounting screws are tightened excessiv ely, the control-

ler mounting frame gets displaced. In case this happens,

loosen the screws once, push in the controller mounting

frame and then tighten the mounting screws.

45±

mm

0.6

0

3

Ground

F.G. terminal

Switching

regulator

w

e

v CONNECTION

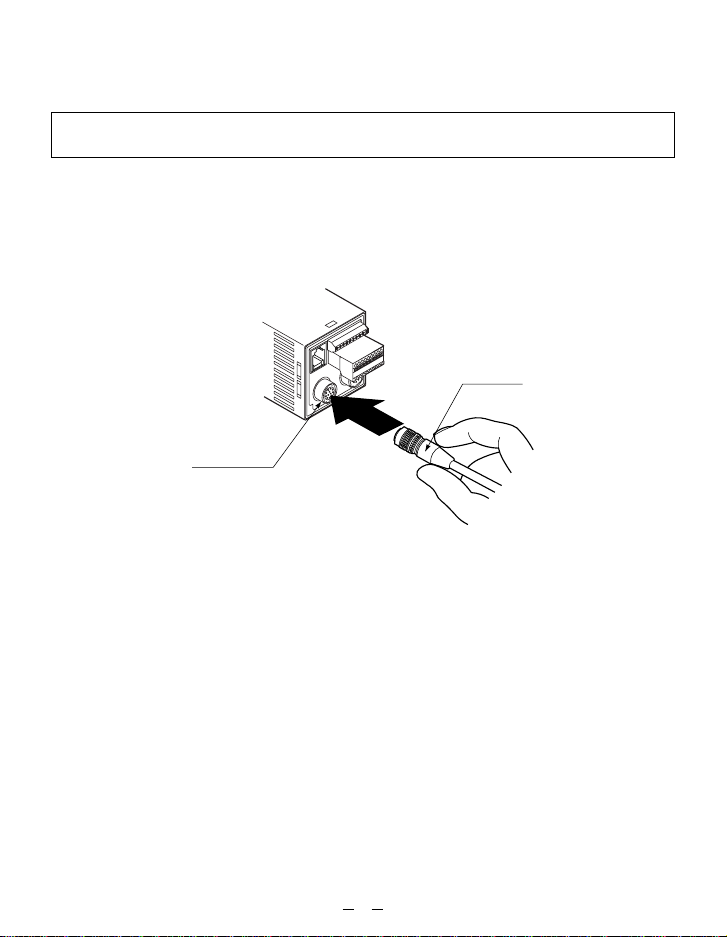

䢇 Connection of sensor head to controller

Make sure to connect or disconnect the connector to the controller in the power

supply off condition.

• One sensor head can be connected to LH-CS6(P), whereas, up to two sensor heads

can be connected to LH-CD6(P).

Hold the sensor head’s connector and insert it into the connector provided on the

controller for sensor head connection. Insert till it locks.

Connector

Connector for

sensor head

※ To remove the sensor head, hold its connector by the outer ring and pull it straight

out. While removing the connector from the controller, take care not to touch the

terminals inside the connector.

(Do not pull by holding the cable, as this can result in cable disconnection.)

4

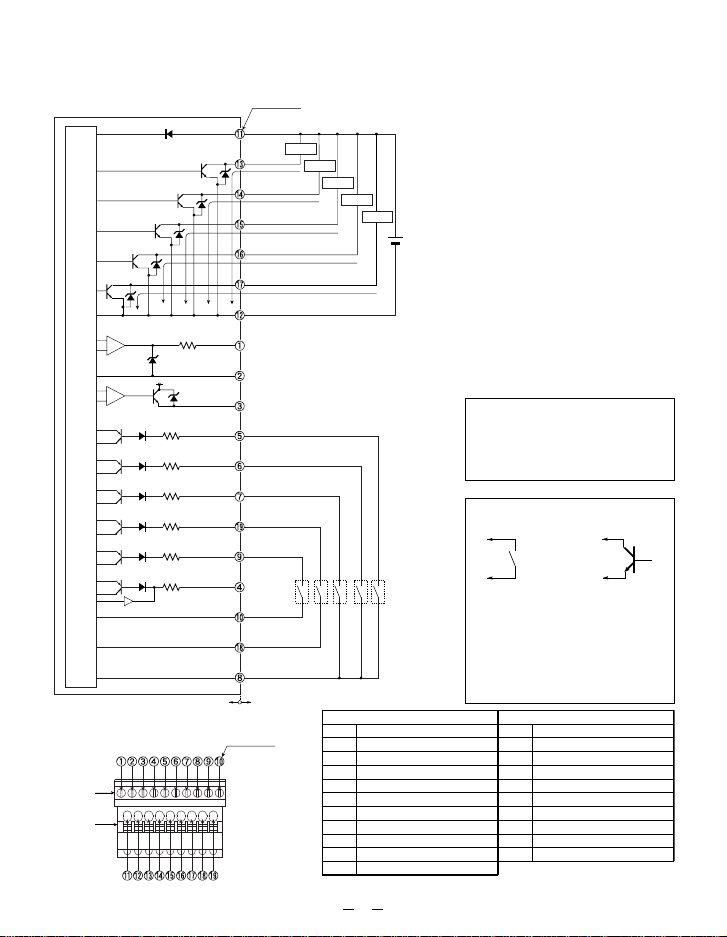

䢇 I/O circuit diagrams

• LH-CS6, LH-CD6/NPN output type

Terminal No.

1

D

T

T

r

2

D3

Z

T

r

3

D4

Z

T

r

4

Z

D5

T

r

5

+

−

+

−

Main circuit

• Terminal arrangement

Upper

terminal

block

Lower

terminal

block

100 Ω

D6

Z

+

12V

Z

D7

4.7kΩ

2

D

4.7kΩ

D

3

4.7kΩ

4

D

4.7kΩ

D

5

4.7kΩ

D

6

4.7kΩ

D

7

Internal circuit

+

V

Comparative

D1

Z

output HI

r

1

Z

30mA max.

D2

Comparative output GO

30mA max.

Comparative output LO

Strobe output

Alarm output

0V

Analog voltage output –5 to

GND for analog output

Analog current output 4 to 20mA (Note 2)

BUSY input HEAD 1

BUSY input HEAD 2 (Note 3)

Calculation hold reset input

0-ADJ input

Remote interlock input

Interference

prevention

I/O (Note 4)

Input COM

Input COM

Input COM

Users’ circuit

Terminal No.

Load

Load

30mA max.

※1

Load

Load

Load

+

24V DC

±

10%

30mA max.

※1

Terminal No.

–

30mA max.

+

5V (Note 1)

※1

※1

※1

Upper terminal block

Description

Analog voltage output

q

GND for analog output

w

Analog current output

e

Interference prevention I/O

r

BUSY input HEAD 1

t

BUSY input HEAD 2 (Note)

y

Calculation hold reset input

u

Input COM

i

Remote interlock input

o

Input COM

!0

Note: Not used in LH-CS6.

5

Notes:

1) The device connected to ‘q

Analog voltage output’ should

have an input impedance of

1MΩ or more.

2) The device connected to ‘e

Analog current output’ should

have a load resistance of

300Ω or less.

3) In case of LH-CS6, terminal

No. y is not used.

4) Do not wire an interference

prevention I/O other than that

of LH-CS6(P) or LH-CD6(P) to

the interference prevention

I/O. Further, do not connect

together two controllers which

have both been set as masters

during interference prevention

setting, as this will cause a

fault.

Symbols

D1:

Reverse supply polarity protection diode

D2 to D7: Input protection diode

ZD1 to ZD7:

Surge absorption zener diode

Tr1 to Tr5: NPN output transistor

※ 1

Non-voltage contact or

NPN open-collector transistor

or

• 0-ADJ input, BUSY input,

Calculation hold reset input

Low (0 to 1V): Effective

High (+V or open): Ineffective

• Remote interlock input

Low (0 to 1V): Emission

High (+V or open): Emission stopped

Lower terminal block

Terminal No.

!1

!2

!3

!4

!5

!6

!7

!8

!9

Description

+

V

0V

Comparative Output HI

Comparative Output GO

Comparative Output LO

Strobe output

Alarm output

Input COM

0-ADJ input

Loading...

Loading...