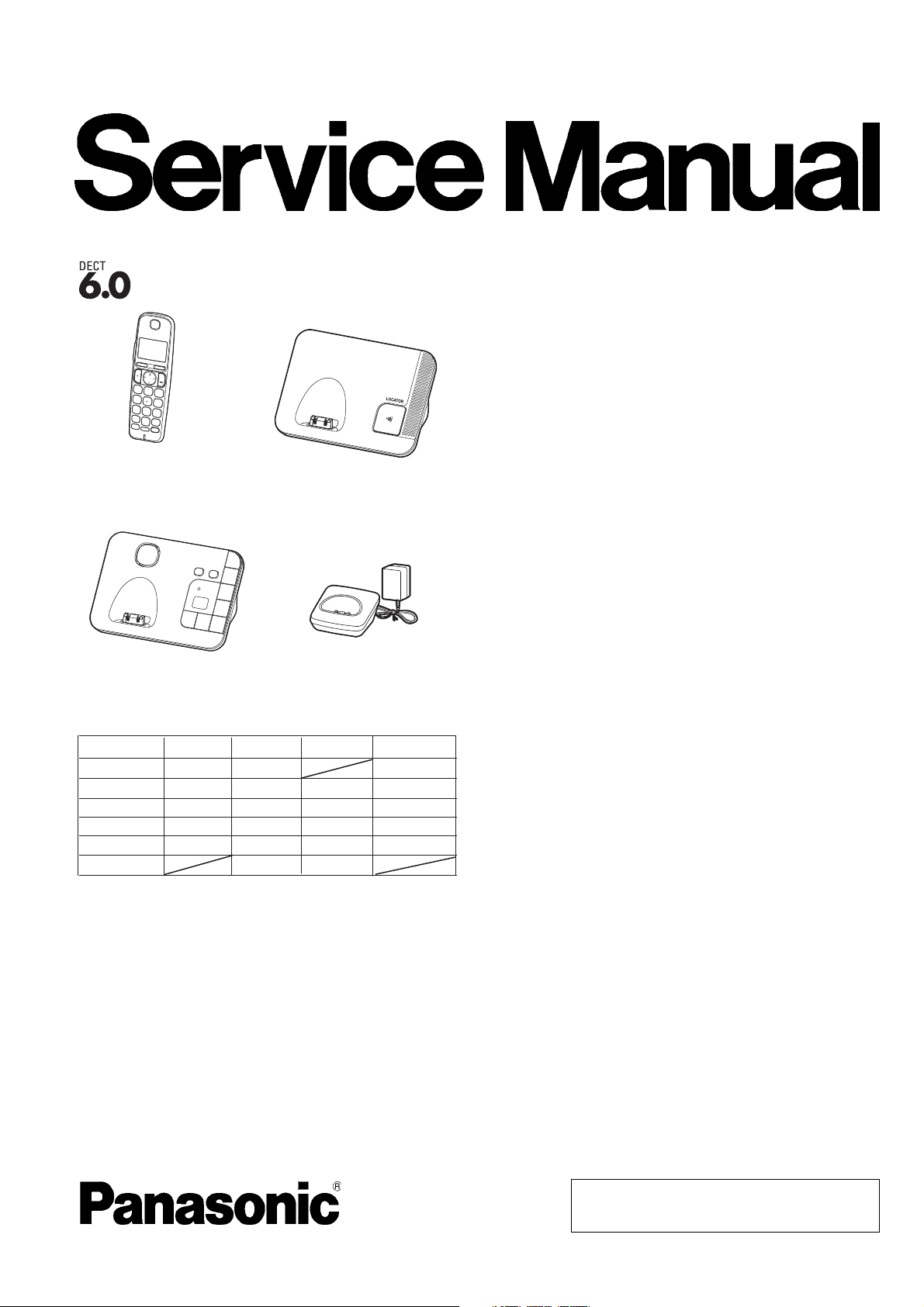

Page 1

ORDER NO. KM41401789CE

Telephone Equipment

Model No. KX-TGE210B

KX-TGE212B

KX-TGE232B

KX-TGE233B

KX-TGE234B

F13

KX-TGEA20

(Handset)

KX-TGE230

(Base Unit)

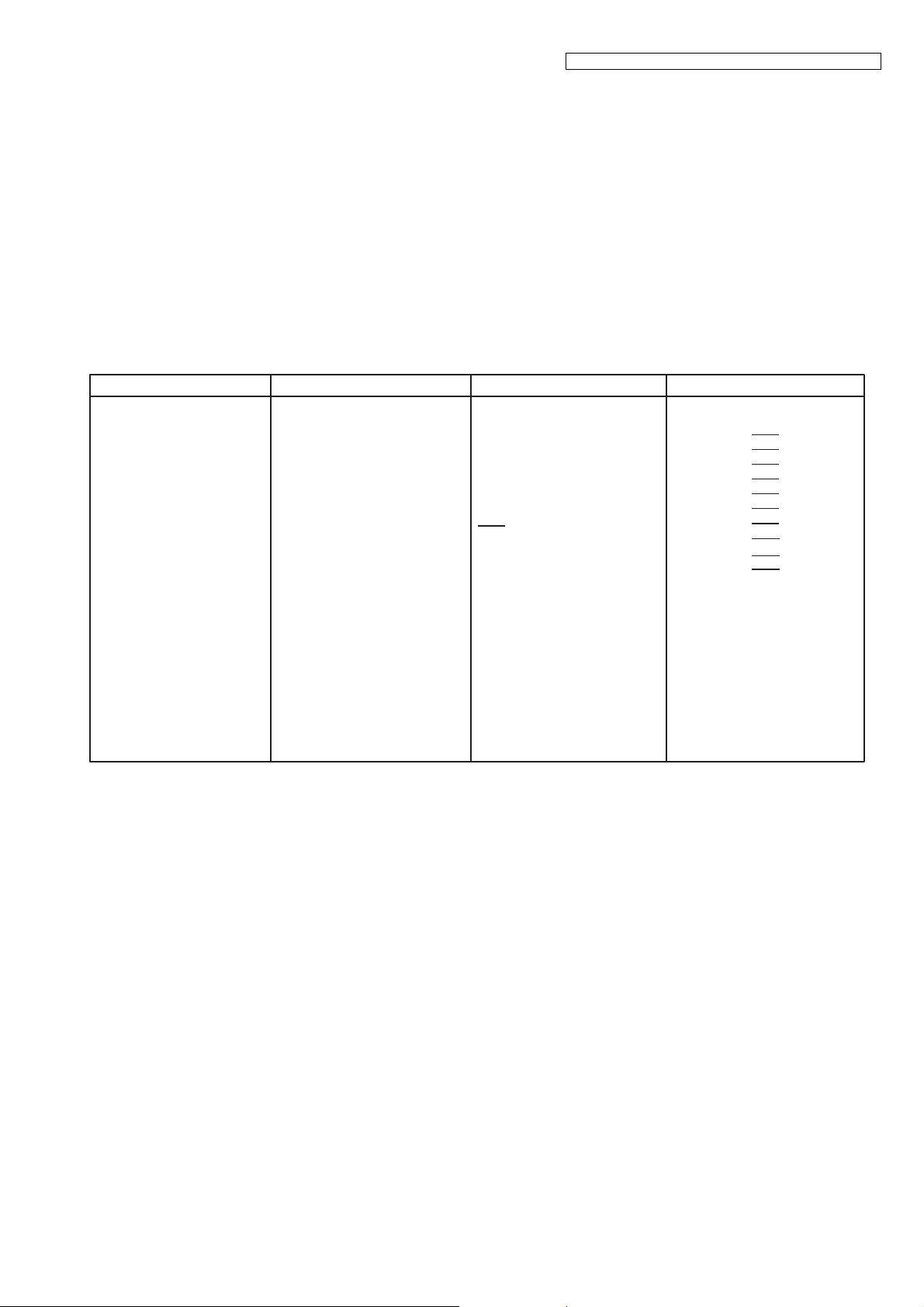

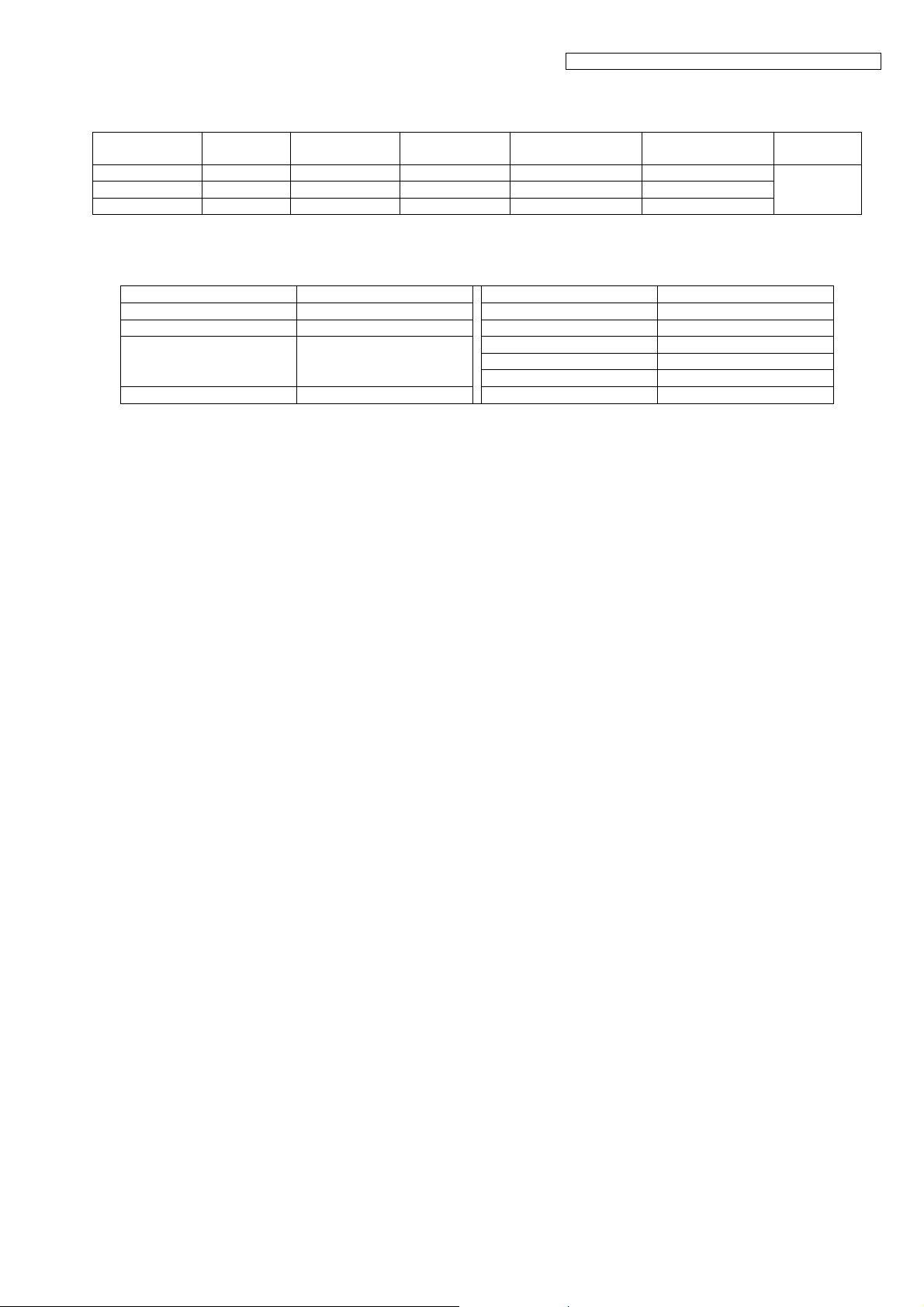

Configuration for each model

Model No

KX-TGE210

KX-TGE212

KX-TGE232

KX-TGE233

KX-TGE234

KX-TGEA20*

*KX-TGEA20 is also an optional accessory, which contains a

handset and a charger.

Base Unit Handset

1 (TGE210) 1 (TGEA20)

1 (TGE210) 2 (TGEA20) 1

1 (TGE230) 2 (TGEA20) 1

1 (TGE230) 3 (TGEA20) 2

1 (TGE230) 4 (TGEA20) 3

1 (TGEA20) 1

KX-TGE210

(Base Unit)

(Charger Unit)

Charger Unit Expandable

Up to 6

Up to 6

Up to 6

Up to 6

Up to 6

KX-TGEA20B

Digital Cordless Phone

Digital Cordless Answering System

B: Black Version

(for U.S.A.)

© Panasonic System Networks Co., Ltd. 2014

Unauthorized copying and distribution is a violation

of law.

Page 2

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general

public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting

to service a product. Products powered by electricity should be serviced or repaired only by experienced professional

technicians. Any attempt to service or repair the product or products dealt with in this service information by anyone

else could result in serious injury or death.

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Parts List. It is essential that

these critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT INFORMATION ABOUT LEAD FREE, (PbF), SOLDERING

If lead free solder was used in the manufacture of this product, the printed circuit boards will be marked PbF.

Standard leaded, (Pb), solder can be used as usual on boards without the PbF mark.

When this mark does appear, please read and follow the special instructions described in this manual on the

use of PbF and how it might be permissible to use Pb solder during service and repair work.

L When you note the serial number, write down all 11 digits. The serial number may be found on the bottom of the unit.

L The illustrations in this Service Manual may vary slightly from the actual product.

2

Page 3

TABLE OF CONTENTS

1 Safety Precautions ----------------------------------------------- 5

1.1. For Service Technicians --------------------------------- 5

2 Warning-------------------------------------------------------------- 5

2.1. Battery Caution--------------------------------------------- 5

2.2. About Lead Free Solder (PbF: Pb free)-------------- 5

2.2.1. Suggested PbF Solder ------------------------------ 6

2.3. Discarding of P. C. Board-------------------------------- 6

3 Specifications ----------------------------------------------------- 7

4 Technical Descriptions ----------------------------------------- 8

4.1. US-DECT Description ------------------------------------ 8

4.1.1. TDD Frame Format ---------------------------------- 8

4.1.2. TDMA system------------------------------------------ 8

4.1.3. Signal Flowchart in the Radio Parts-------------- 9

4.2. Block Diagram (Base Unit_Main)---------------------10

4.3. Tel Interface Circuit--------------------------------------- 11

4.4. Block Diagram (Base Unit_RF Part) -----------------12

4.5. Circuit Operation (Base Unit) --------------------------13

4.5.1. BBIC (Base Band IC: IC501) ---------------------13

4.5.2. Flash Memory (IC502)------------------------------13

4.5.3. Flash Memory (IC601)------------------------------13

4.5.4. EEPROM (IC611)------------------------------------13

4.5.5. Power Supply Circuit/Reset Circuit--------------14

4.5.6. Telephone Line Interface---------------------------16

4.5.7. Parallel Connection Detect Circuit/Auto

Disconnect Circuit -----------------------------------17

4.5.8. Calling Line Identification (Caller ID)/Call

Waiting Caller ID -------------------------------------18

4.6. Block Diagram (Handset)-------------------------------20

4.7. Block Diagram (Handset_RF Part)-------------------21

4.8. Circuit Operation (Handset)----------------------------22

4.8.1. Outline --------------------------------------------------22

4.8.2. Power Supply Circuit/Reset Circuit--------------22

4.8.3. Charge Circuit ----------------------------------------23

4.8.4. Battery Low/Power Down Detector--------------23

4.8.5. Speakerphone ----------------------------------------23

4.9. Behavior of Electric Power Failure -------------------24

4.10. Circuit Operation (Charger Unit) ----------------------24

5 Location of Controls and Components ------------------25

6 Installation Instructions ---------------------------------------25

7 Operating Instructions-----------------------------------------25

8 Test Mode ----------------------------------------------------------26

8.1. Engineering Mode ----------------------------------------26

8.1.1. Base Unit ----------------------------------------------26

8.1.2. Handset ------------------------------------------------28

9 Service Mode -----------------------------------------------------30

9.1. How to Clear User Setting (Handset Only)---------30

10 Troubleshooting Guide ----------------------------------------31

10.1. Troubleshooting Flowchart -----------------------------31

10.1.1. Check Power------------------------------------------32

10.1.2. Check Record ----------------------------------------33

10.1.3. Check Playback -------------------------------------36

10.1.4. Check Battery Charge ------------------------------36

10.1.5. Check Link---------------------------------------------37

10.1.6. Check the RF part -----------------------------------39

10.1.7. Registering a Handset to the Base Unit--------43

10.1.8. Deregistering a Handset ---------------------------43

10.1.9. Check Handset Transmission --------------------44

10.1.10. Check Handset Reception-------------------------44

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

PAG E PAG E

10.1.11. Check Caller ID ------------------------------------- 44

11 Disassembly and Assembly Instructions--------------- 45

11.1. Disassembly Instructions------------------------------- 45

11.1.1. Base Unit ---------------------------------------------- 45

11.1.2. Handset------------------------------------------------ 49

11.1.3. Charger Unit ------------------------------------------ 50

11.2. How to Replace the Handset LCD------------------- 51

12 Measurements and Adjustments -------------------------- 52

12.1. Equipment Required ------------------------------------ 52

12.2. The Setting Method of JIG----------------------------- 52

12.2.1. Connections (Base Unit) -------------------------- 52

12.2.2. Connections (Handset) ---------------------------- 53

12.2.3. How to install Batch file into P.C. ---------------- 54

12.2.4. Commands-------------------------------------------- 55

12.3. Adjustment Standard (Base Unit) -------------------- 56

12.3.1. Bottom View ------------------------------------------ 56

12.4. Adjustment Standard (Handset)---------------------- 57

12.4.1. Component View ------------------------------------ 57

12.5. Things to Do after Replacing IC or X'tal------------ 58

12.5.1. How to download the data ------------------------ 58

12.6. Frequency Table------------------------------------------ 59

13 Miscellaneous ---------------------------------------------------- 60

13.1. How to Replace the LLP (Leadless Leadframe

Package) IC ----------------------------------------------- 60

13.1.1. Preparation-------------------------------------------- 60

13.1.2. Caution------------------------------------------------- 60

13.1.3. How to Remove the IC ----------------------------- 60

13.1.4. How to Install the IC -------------------------------- 61

13.2. How to Replace the Flat Package IC --------------- 62

13.2.1. Preparation-------------------------------------------- 62

13.2.2. How to Remove the IC ----------------------------- 62

13.2.3. How to Install the IC -------------------------------- 63

13.2.4. How to Remove a Solder Bridge ---------------- 63

13.3. Terminal Guide of the ICs, Transistors and

Diodes ------------------------------------------------------ 64

13.3.1. Base Unit ---------------------------------------------- 64

13.3.2. Handset ------------------------------------------------ 64

14 Schematic Diagram -------------------------------------------- 66

14.1. For Schematic Diagram -------------------------------- 66

14.1.1. Base Unit (Schematic Diagram (Base

Unit_Main)) ------------------------------------------- 66

14.1.2. Handset (Schematic Diagram

(Handset_Main))------------------------------------- 66

14.2. Schematic Diagram (Base Unit_Main)-------------- 67

14.2.1. KX-TGE210 ------------------------------------------- 67

14.2.2. KX-TGE230 ------------------------------------------- 69

14.3. Schematic Diagram (Base Unit_Operation) ------- 71

14.3.1. KX-TGE230 ------------------------------------------- 71

14.4. Schematic Diagram (Handset_Main) --------------- 73

15 Printed Circuit Board ------------------------------------------ 76

15.1. Circuit Board (Base Unit_Main) ---------------------- 76

15.1.1. Component View ------------------------------------ 76

15.1.2. Bottom View ------------------------------------------ 77

15.2. Circuit Board (Base Unit_Operation)---------------- 78

15.2.1. KX-TGE230 ------------------------------------------- 78

15.3. Circuit Board (Handset_Main) ------------------------ 80

15.3.1. Component View ------------------------------------ 80

15.3.2. Bottom View ------------------------------------------ 81

3

Page 4

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

16 Exploded View and Replacement Parts List -----------82

16.1. Cabinet and Electrical Parts (Base Unit) ----------- 82

16.1.1. KX-TGE210 ------------------------------------------- 82

16.1.2. KX-TGE230 ------------------------------------------- 83

16.2. Cabinet and Electrical Parts (Handset) ------------- 84

16.3. Cabinet and Electrical Parts (Charger Unit) ------- 85

16.4. Accessories and Packing Materials ----------------- 86

16.4.1. KX-TGE210B ----------------------------------------- 86

16.4.2. KX-TGE212B ----------------------------------------- 87

16.4.3. KX-TGE232B ----------------------------------------- 88

16.4.4. KX-TGE233B ----------------------------------------- 89

16.4.5. KX-TGE234B ----------------------------------------- 90

16.5. Replacement Parts List --------------------------------- 91

16.5.1. Base Unit ----------------------------------------------91

16.5.2. Handset ------------------------------------------------ 94

16.5.3. Charger Unit ------------------------------------------95

16.5.4. Accessories and Packing Materials------------- 95

16.5.5. Screws ------------------------------------------------- 96

16.5.6. Fixtures and Tools ----------------------------------- 96

4

Page 5

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

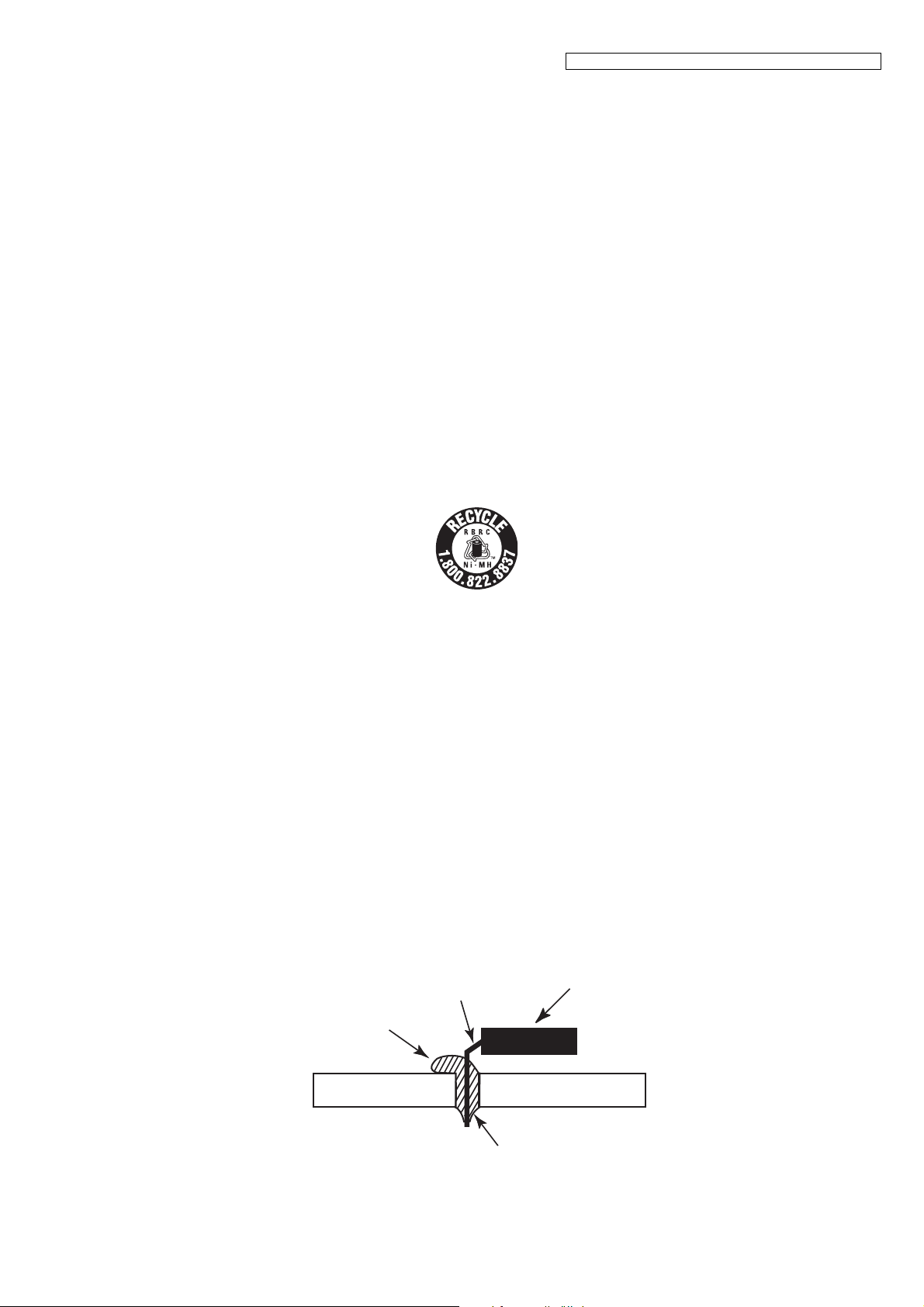

Component

Component

pin

Solder

Remove all of the

excess solder

(Slice View)

1 Safety Precautions

1.1. For Service Technicians

• Repair service shall be provided in accordance with repair technology information such as service manual so as to

prevent fires, injury or electric shock, which can be caused by improper repair work.

1. When repair services are provided, neither the products nor their parts or members shall be remodeled.

2. If a lead wire assembly is supplied as a repair part, the lead wire assembly shall be replaced.

3. FASTON terminals shall be plugged straight in and unplugged straight out.

• ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover plastic parts boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on worktable.

4. Do not grasp IC or LSI pins with bare fingers.

2Warning

2.1. Battery Caution

Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries according to the instructions.

Attention:

A nickel metal hydride battery that is recyclable powers the product you have purchased.

Please call 1-800-8-BATTERY (1-800-822-8837) for information on how to recycle this battery.

2.2. About Lead Free Solder (PbF: Pb free)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that

contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin (Sn),

Silver (Ag), and Copper (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder.

Caution

• PbF solder has a melting point that is 50 F ~ 70 F (30 C ~ 40 C) higher than Pb solder. Please use a soldering iron with

temperature control and adjust it to 700 F ± 20 F (370 C ± 10 C).

• Exercise care while using higher temperature soldering irons.:

Do not heat the PCB for too long time in order to prevent solder splash or damage to the PCB.

• PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100 F (600 C).

• When applying PbF solder to double layered boards, please check the component side for excess which may flow onto the

opposite side (See the figure below).

5

Page 6

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

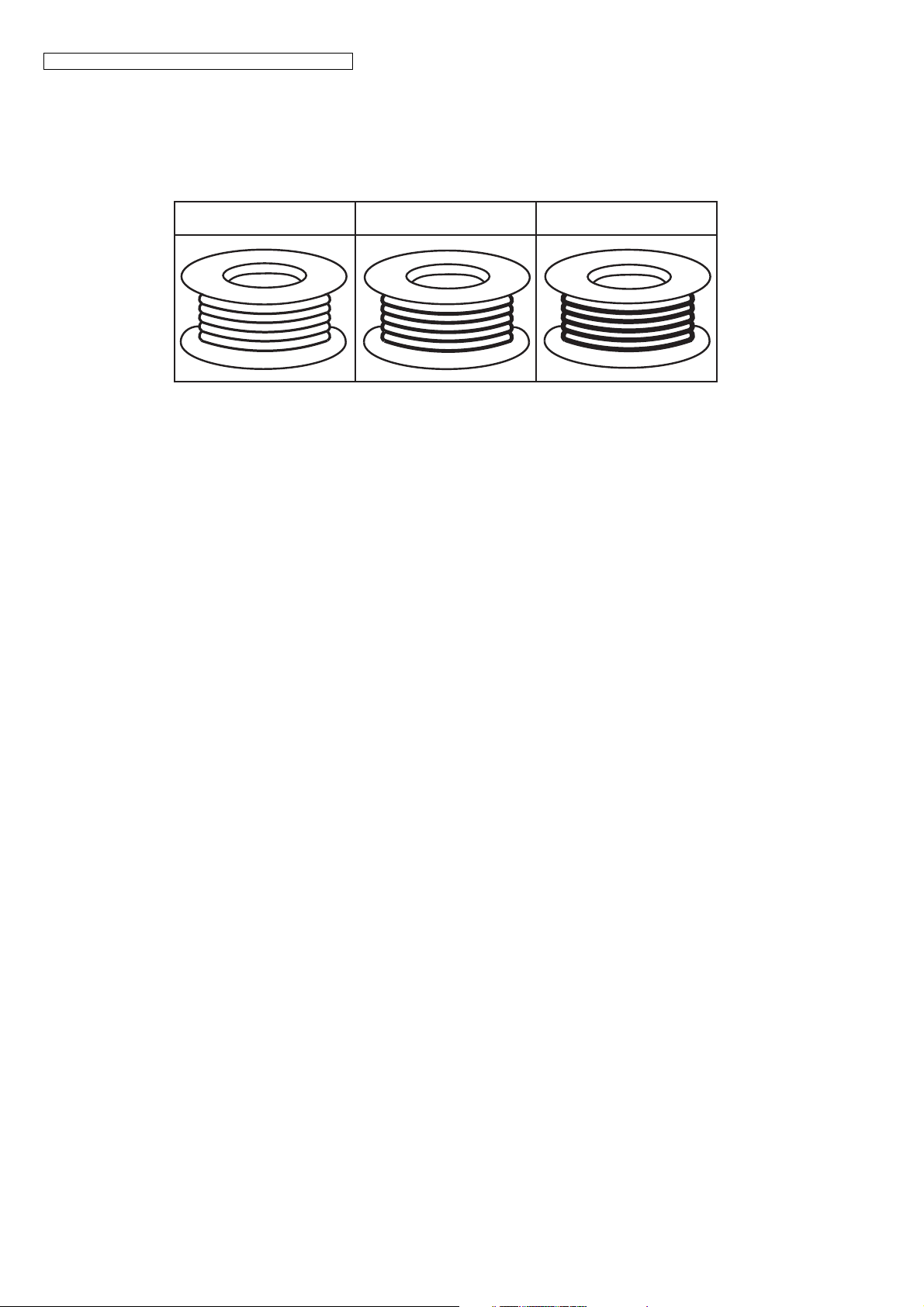

0.3 mm X 100 g

0.6 mm X 100 g 1.0 mm X 100 g

2.2.1. Suggested PbF Solder

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper

(Sn+Ag+Cu), you can also use Tin and Copper (Sn+Cu), or Tin, Zinc, and Bismuth (Sn+Zn+Bi). Please check the

manufacturer's specific instructions for the melting points of their products and any precautions for using their product with other

materials.

The following lead free (PbF) solder wire sizes are recommended for service of this product: 0.3 mm, 0.6 mm and 1.0 mm.

2.3. Discarding of P. C. Board

When discarding P. C. Board, delete all personal information such as telephone directory and caller list or scrap P. C. Board.

6

Page 7

3 Specifications

Rechargeable Ni-MH battery

AAA (R03) size (1.2 V 400 mAh)

Super Heterodyne

PLL synthesizer

Quadrature Discriminator

13.824 MHz ±100 Hz

Frequency Modulation

40 bit

Tone (DTMF)/Pulse

Up to 48 digits

Up to 24 digits

(Phonebook)

8 days at Standby,

10 hours at Talk

8 days at Standby,

10 hours at Talk

Approx. 130

0 °C - 40 °C (32 °F – 104 °F)

20 % – 80 % relative air humidity

(dry)

Approx. 54

mm x 31 mm x

171

mm

Approx. 130 g

Power source

Receiving Method

Oscillation Method

Detecting Method

Tolerance of OSC Frequency

Modulation Method

ID Code

Ringer Equivalence No. (REN)

Dialing Mode

Redial

Speed Dialer

Power Consumption

Operating Conditions

Dimensions (W x D x H)

Mass (Weight)

AC Adaptor

(PNLV226Z, 120 V AC, 60 Hz)

Super Heterodyne

PLL synthesizer

Quadrature Discriminator

10.368 MHz ±41 Hz

Frequency Modulation

40 bit

0.1B

Tone (DTMF)/Pulse

Up to 48 digits

Up to 24 digits (Phonebook)

Base Unit*1

Standby: Approx. 1.0 W

Maximum: Approx. 4.3 W

Base Unit*2

Standby: Approx. 1.0 W

Maximum: Approx. 4.3 W

0 °C - 40 °C (32 °F – 104 °F)

20 % – 80 % relative air humidity

(dry)

Approx. 197 mm x 88 mm x 83 mm

Approx. 270 g

Base Unit

Handset

Charger

AC Adaptor

(PNLV233AZ, 120 V AC, 60 Hz)

Standby: Approx 0.1 W

Maximum: Approx 1.8 W

Standby: Approx 0.1 W

Maximum: Approx 1.8 W

0 °C - 40 °C (32 °F – 104 °F)

20 % – 80 % relative air humidity

(dry)

Approx. 72 mm x 72 mm x 38 mm

Approx. 90 g

*1 KX-TGE210 series

*2 KX-TGE230 series

Duplex procedure:

TDMA (Time Division Multiple Access)

█ Channel spacing:

1.728MHz (DECT 6.0)

█ Bit rate:

1.152Mbit/s (DECT 6.0)

Modulation:

GFSK (Gaussian Frequency Shift Keying)

RF transmission power:

115 mW (max/DECT6.0)

Voice coding:

ADPCM 32 kbit/s (DECT 6.0)

█

█

█

█

█

█

█ Standard:

DECT 6.0 (Digital Enhanced Cordless

Telecommunications 6.0)

█ Number of channels:

60 Duplex Channels (DECT 6.0)

█ Frequency range:

1.92 GHz to 1.93 GHz (DECT 6.0)

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Note:

Design and specifications are subject to change without notice.

Note for Service:

• Operation range: Up to 300 m outdoors, Up to 50 m indoors, depending on the condition.

• Analog telephone connection: Telephone Line

• Optional headset: KX-TCA60, KX-TCA93, KX-TCA400, KX-TCA430

• Optional Range extender: KX-TGA405

• Optional Key detector: KX-TGA20

• T-adaptor: KX-J66

7

Page 8

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

4 Technical Descriptions

4.1. US-DECT Description

The frequency range of 1.92 GHz-1.93 GHz is used. Transmitting and receiving carrier between base unit and handset is same

frequency. Refer to Frequency Table (P.59).

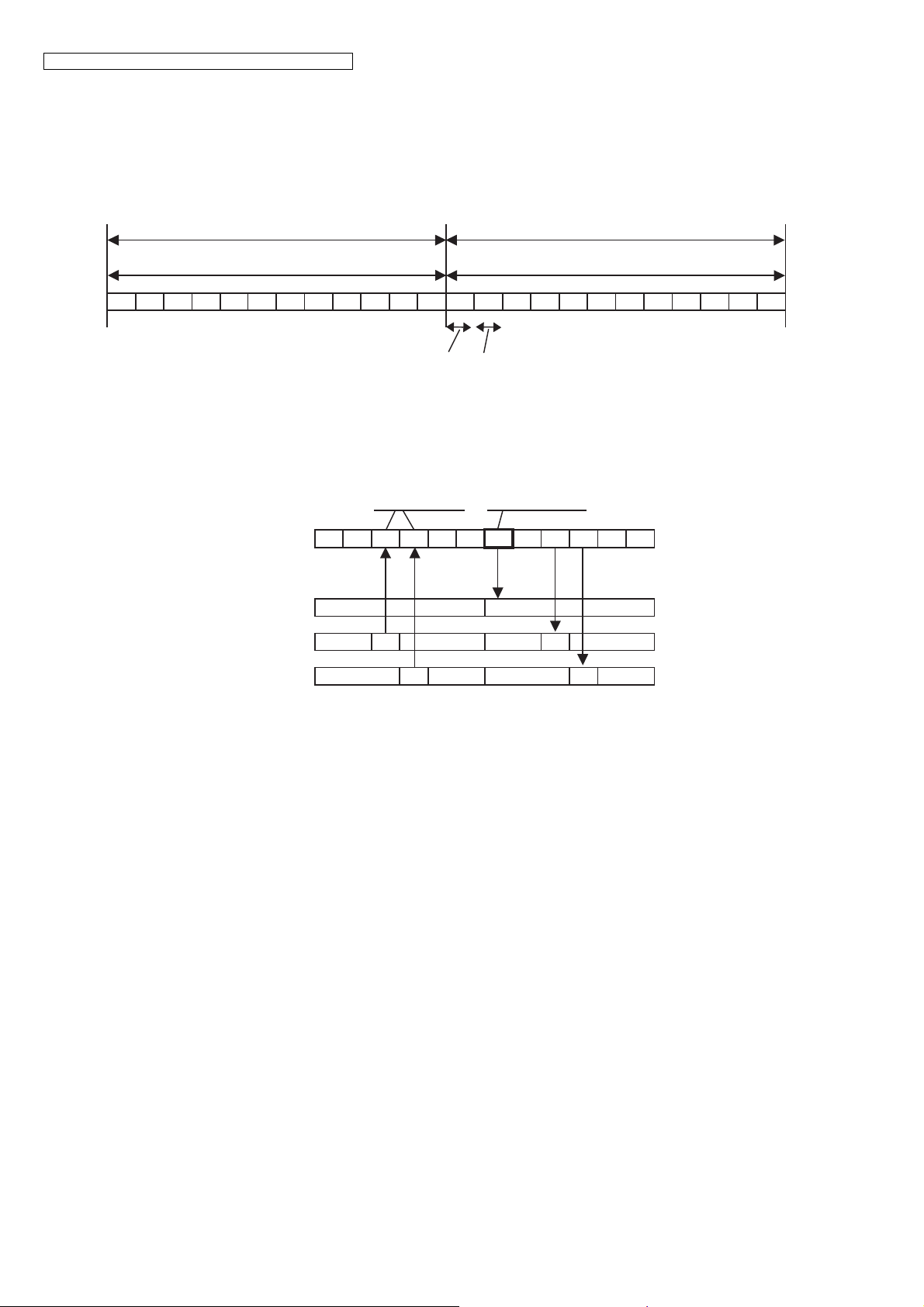

4.1.1. TDD Frame Format

5 ms 5 ms

Up Link ( Handset -> Base Unit ) Down Link ( Base Unit -> Handset )

RX1 RX2 RX3 RX4 RX5 RX6 TX1 TX2 TX3 TX4 TX5 TX6

DATA rate : 1.152 Mbps

417 μs (available) 417 μs (blind)

4.1.2. TDMA system

This system is the cycles of 10 ms, and has 6 duplex paths, but maximum duplex communication path is 5 because of dummy

bearer use.

In 1 slot 417 s, the 10 ms of voice data is transmitted.

• 2 - Handsets Link

Traffic Bearer Dummy bearer

Base unit

Handset 1

(Stand by)

Handset 2

(Link)

Handset 3

(Link)

Traffic Bearer

A link is established between base unit and handset.

The state where duplex communication is performed.

Handset doesn't make up duplex in no free RF channels because of interference. (*1)

Dummy Bearer

Base unit sends Dummy-data to the all stand-by state handsets.

Handsets receive that data for synchronization and monitoring request from the base unit.

Base unit doesn't send Dummy bearer in no free RF channels because of interference. (*1)

Note:

(*1) It is a feature under FCC 15 regulation and for interference avoidance.

In the case of checking RF parts, it is better in least interference condition.

RX1 RX2 RX3 RX4 RX5 RX6 TX1 TX2 TX3 TX4 TX5 TX6

TX RX

RXTX

8

Page 9

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

4.1.3. Signal Flowchart in the Radio Parts

Reception

Base unit:

A voice signal from TEL line is encoded to digital data and converted into a 1.9GHz modulated radio signal by BBIC(IC501).

The RF signal, after which is amplified in BBIC, is fed to selected antenna.

Handset:

As for a handset RF, RF signal is received in one antenna.

BBIC down-converts to 864 kHz IF signal from RX signal and demodulates it to digital data "RXDATA".

BBIC (IC1) converts RXDATA into a voice signal and outputs it to speaker.

Transmission

Handset:

A voice signal from microphone is encoded to digital data and converted into a 1.9GHz modulated radio signal by BBIC(IC1).

The RF signal, after which is amplified in BBIC, is fed to an antenna.

Base unit:

As for a base unit RF, RF signal is received in two antennas.

BBIC (IC501) compares RF signal levels and selects the antenna to be used. Then BBIC down-converts to 864 kHz IF signal

from RX signal in the selected antenna, and demodulates it to digital data "RXDATA".

BBIC (IC501) converts RXDATA into a voice signal and outputs it to TEL line.

9

Page 10

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

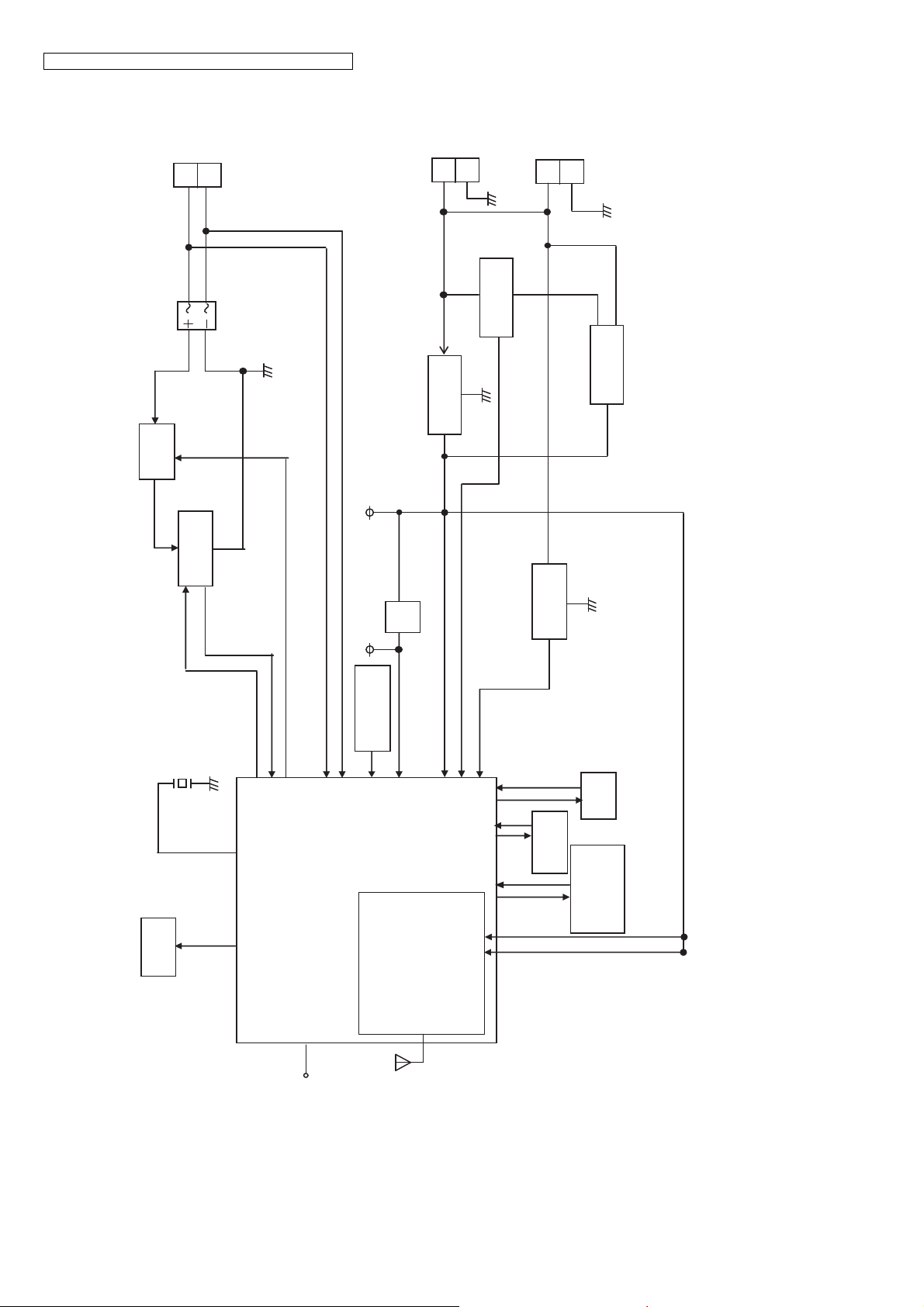

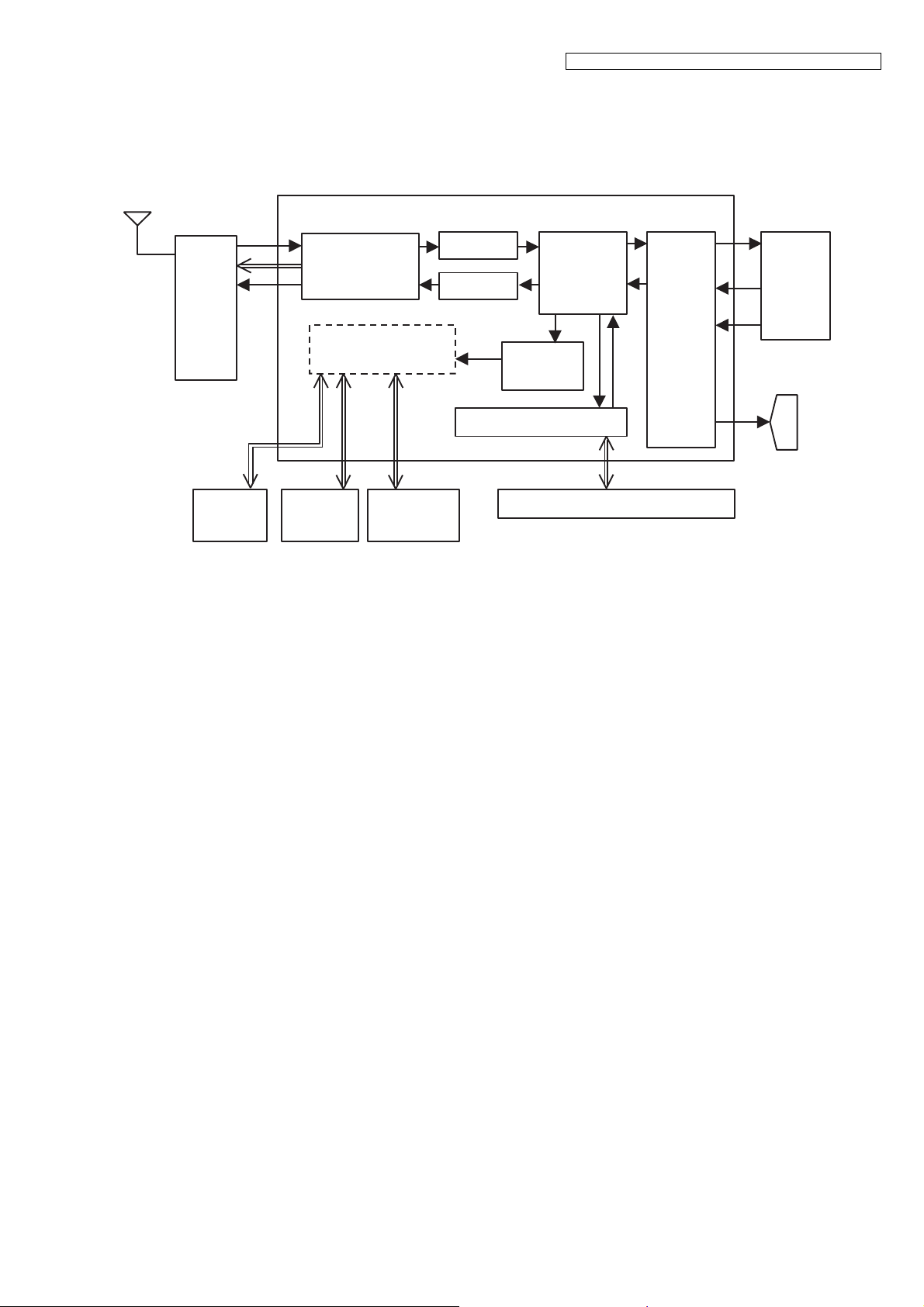

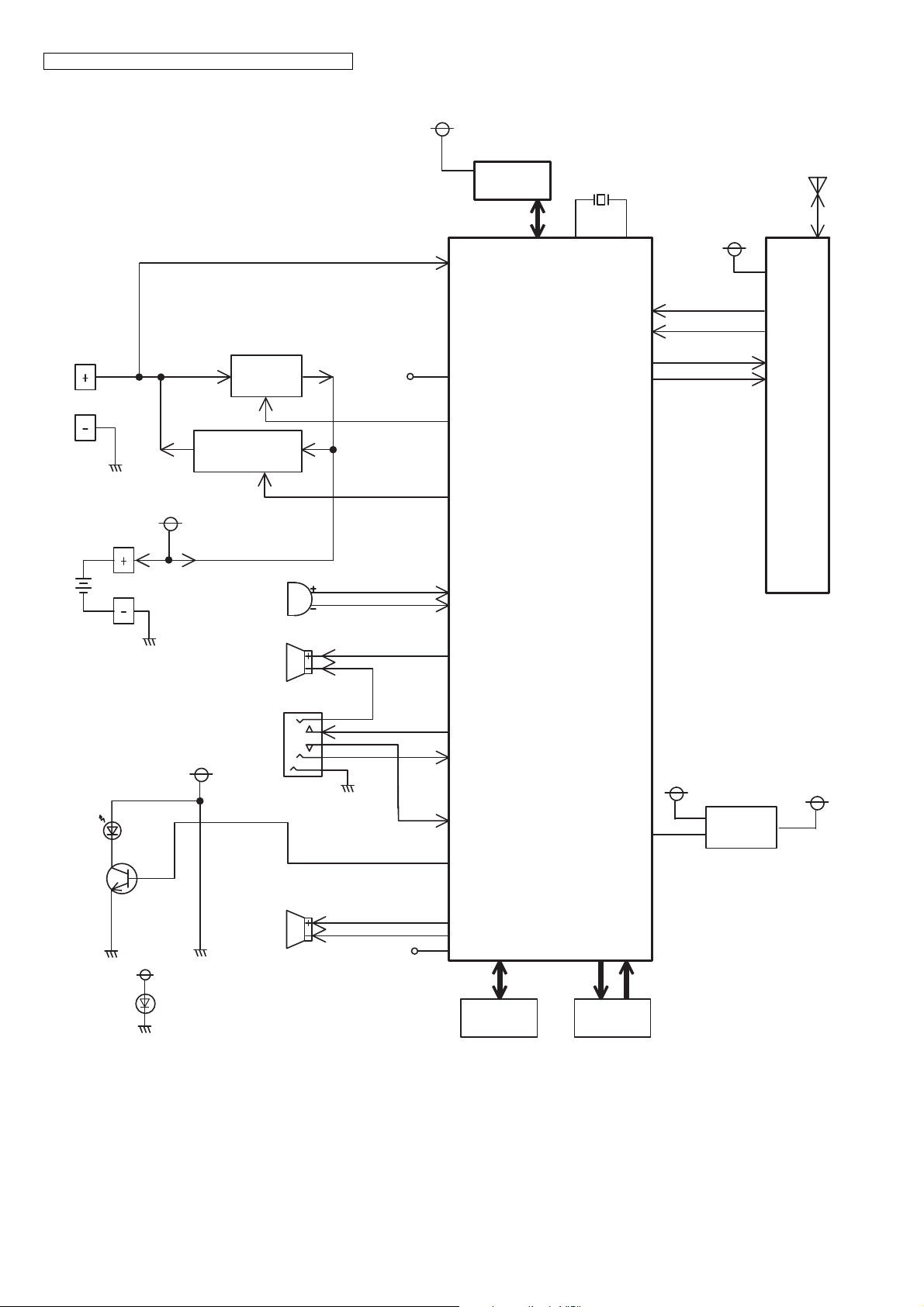

KX-TGE210/212/232/233/234 BLOCK DIAGRAM (Base Unit_Main)

SIDE_TONE

CIRCUIT

Crystal

10.368MHz

TR_RLY

TIP

RING

RF_Block

IC501

BBIC

DC5.5V+

GND

DC_JACK

+

-

CHARGE

3

4

2

D101

CHARGE

DETECT

Q701

REGULATOR

IC302

Power Down

DET

Power supply

at AC failure

KEY

PAD

LED

VBAT

PDN_DET

CHARGE_DET

IC611

Q301

+1.8V

+3.0V

AVD/VDD

QSPI

CIDINp

CIDINn

P3_6

MICh

LSRp

RF_VDD

VDD_PA

ANT1

IC502

Flash(Program)

IC601

Flash

(Voice prompt)

EEPROM

4.2. Block Diagram (Base Unit_Main)

10

Page 11

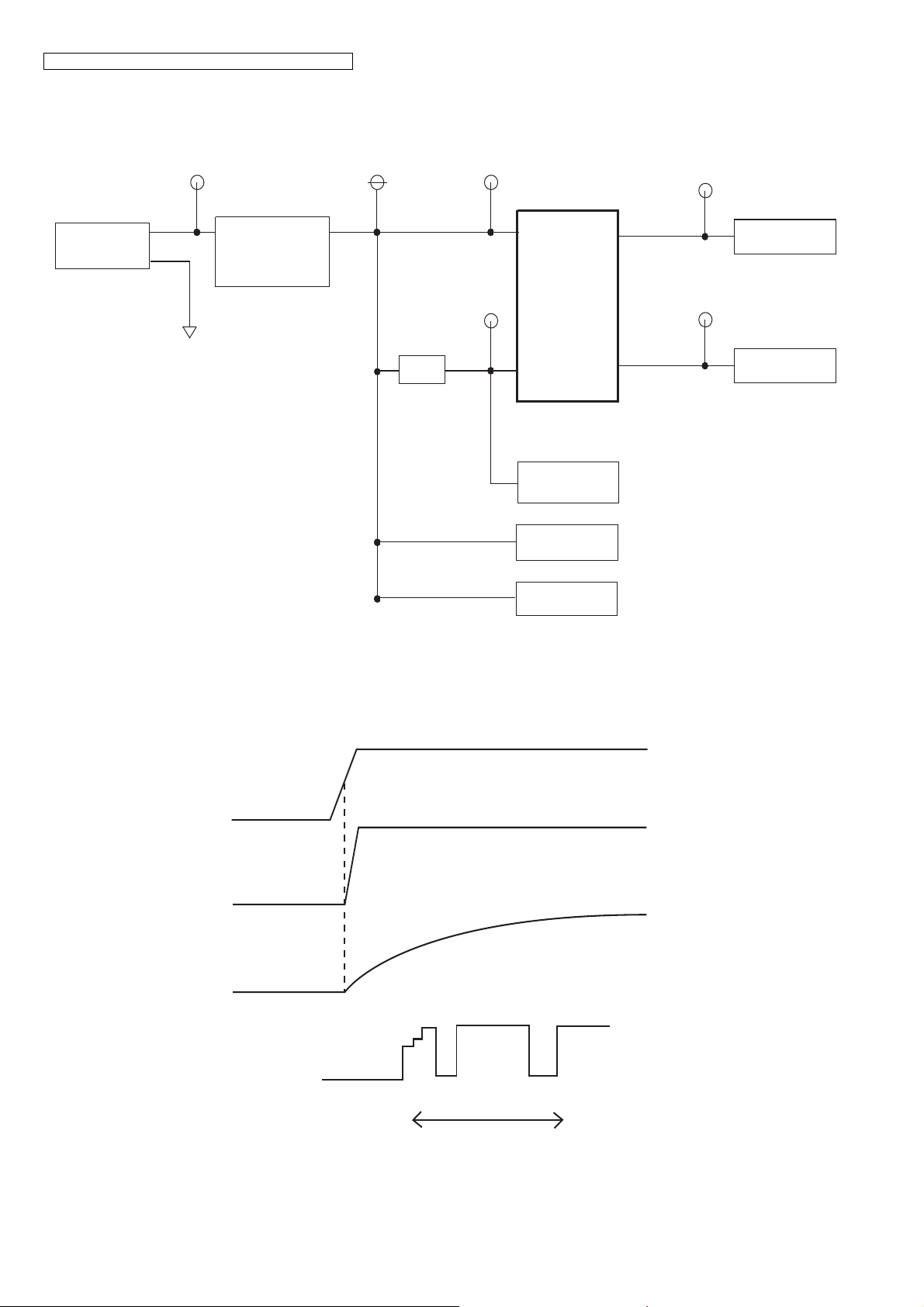

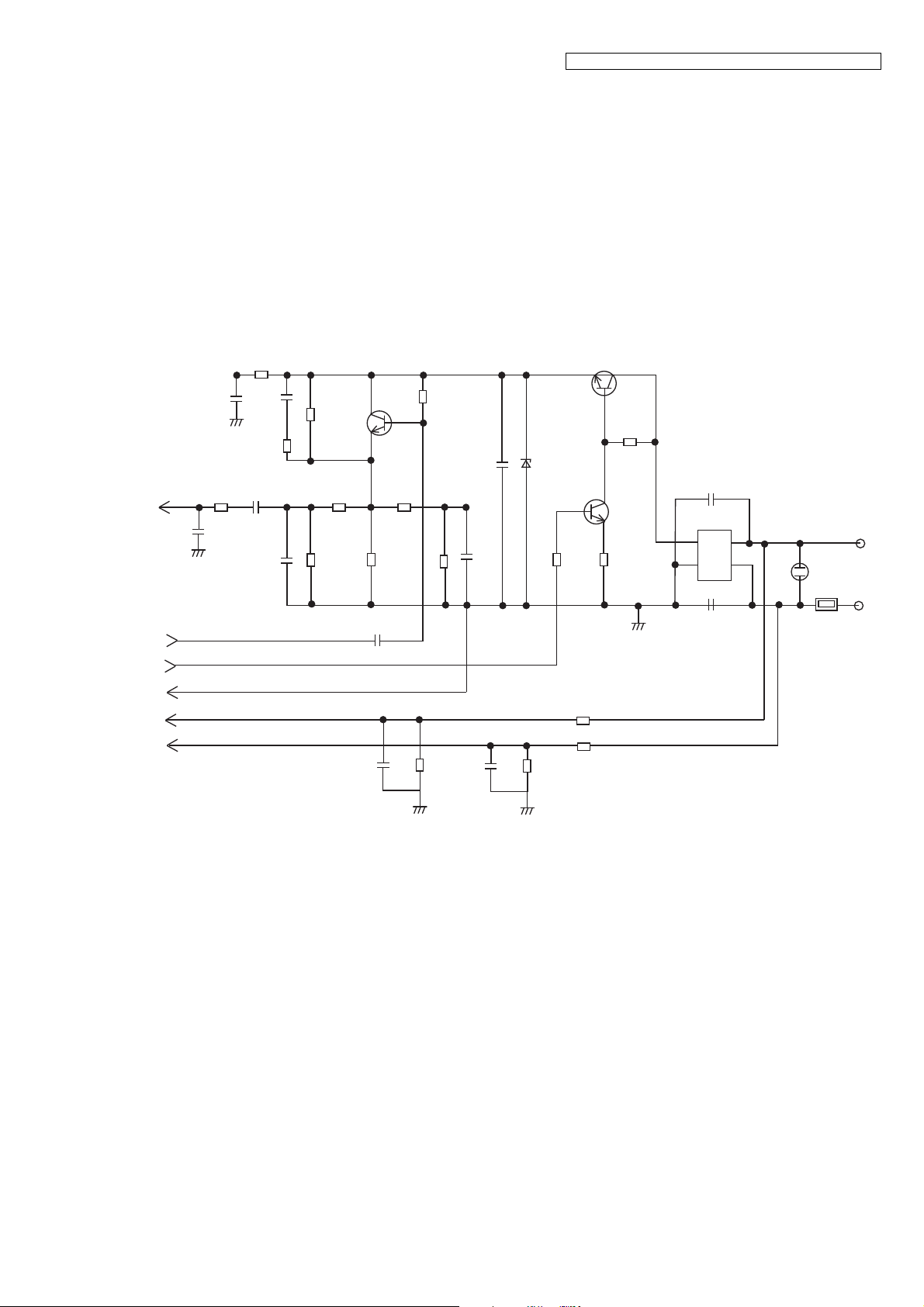

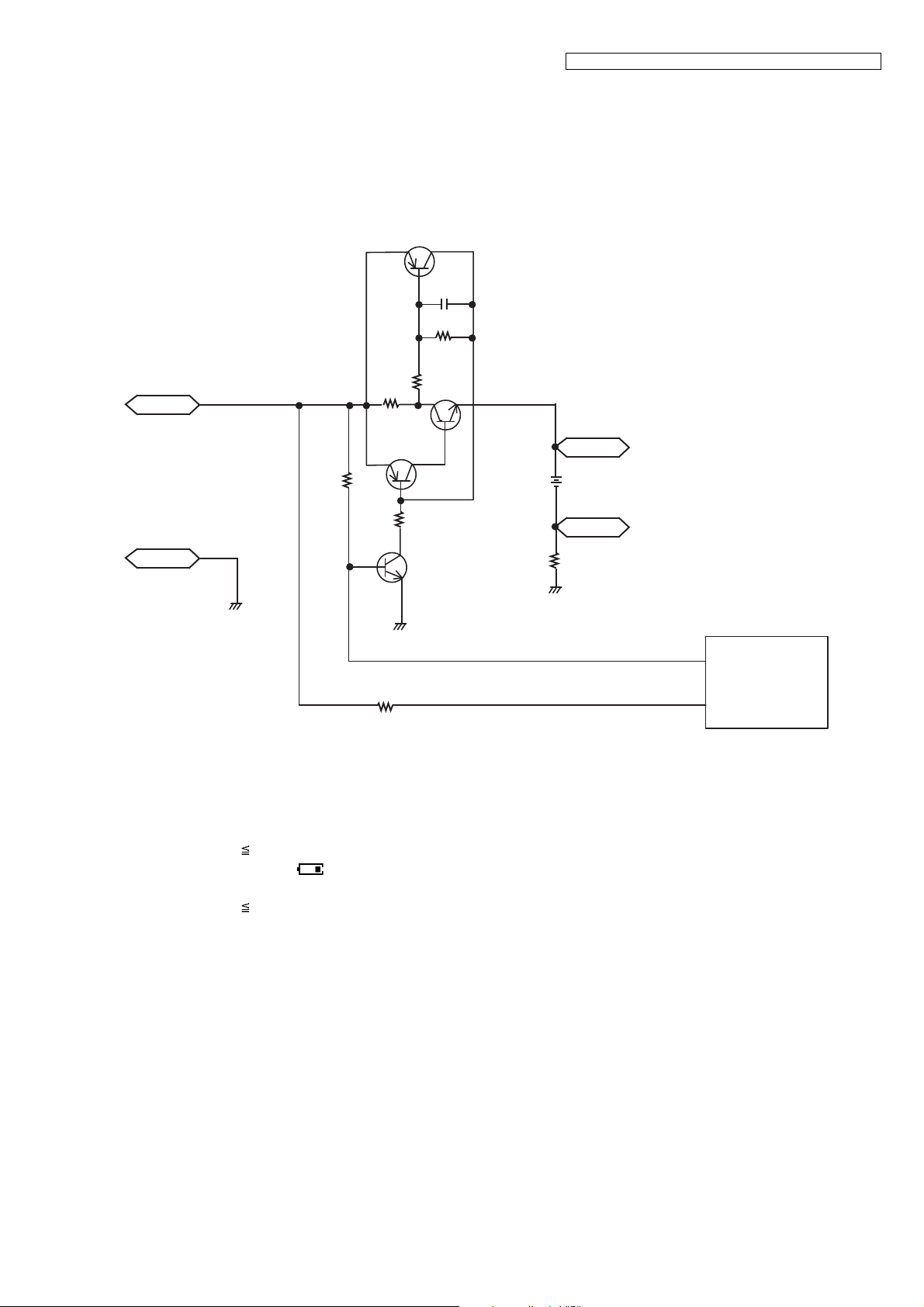

4.3. Tel Interface Circuit

TX AMP

SIDE TONE

RX AMP

CONTROL

CIRCUIT

CALLER ID

DETECT

BELL

DETECT

P101

R142

4

C101

Q141

C102

SA101

TIP

R141

REGULATOR

C104

R102

C106

R104

C103

R101

C105

R103

D101

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

11

Page 12

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

10.368

MHz

IC501 RF block

TXDATA

RF_TXp

RF_TXn

RF_RXp

RF_RXn

Control

Logic

RXDATA

Mixer

Demodulator

PLL

3856-3843MHz

/3859-3845MHz

Modulator

KX-TGE210/212/232/233/234 BLOCK DIAGRAM (Base Unit_RF Part)

4.4. Block Diagram (Base Unit_RF Part)

12

Page 13

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

4.5. Circuit Operation (Base Unit)

General Description:

(BBIC, Flash Memory, EERROM) is a digital speech/signal processing system that implements all the functions of speech

compression, record and playback, and memory management required in a digital telephone answering machine.

The BBIC system is fully controlled by a host processor. The host processor provides activation and control of all that functions

as follows.

ADPCM

ADPCM

Caller ID

Modem

Digital TAM System

Flash Memory IC601

Digital

Speech

Processor

Analog

Front

End

&

Multiplexer

TEL

Line

Interface

SP

RF part

EEPROM

IC611

TDD & TDMA

with FHSS

Processor

Keys/ LEDs

/ Charge

Host CPU

BBIC (IC501)

Flash Memory

(Program)

IC502

4.5.1. BBIC (Base Band IC: IC501)

• Voice Message Recording/Play back

The BBIC system uses a proprietary speech compression technique to record and store voice message in Flash Memory.

An error correction algorithm is used to enable playback of these messages from the Flash Memory.

• DTMF Generator

When the DTMF data from the handset is received, the DTMF signal is output.

• Synthesized Voice (Pre-recorded message)

The BBIC implements synthesized Voice, utilizing the built in speech detector and a Flash Memory, which stored the vocabulary.

• Caller ID demodulation

The BBIC implements monitor and demodulate the FSK/DTMF signals that provide CID information from the Central Office.

• Digital Switching

The voice signal from telephone line is transmitted to the handset or the voice signal from the handset is transmitted to the

Telephone line, etc. They are determined by the signal path route operation of voice signal.

• Block Interface Circuit

RF part, LED, Key scan, Speaker, Telephone line.

4.5.2. Flash Memory (IC502)

Main program data is stored.

4.5.3. Flash Memory (IC601)

Following information data is stored.

• Voice signal

ex: Pre-recorded Greeting message, Incoming message

4.5.4. EEPROM (IC611)

Following information data is stored.

• Settings

ex: message numbers, ID code, Flash Time, Tone/Pulse

13

Page 14

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

+5.5V

+5.5V +3.0V

+3.0V

+1.8V

+3.0V_CP

IC501

IC302

IC611

BBIC

AC Adaptor

3.0V

REGULATOR

EEPROM

VDD3

VDD1

VDD4

+3.0V_CP2

IC601

TAM FLASH

VDD5

RF Part

LEDs

Q301

QSPI FLASH

IC502

Startmonitor

(IC501 57pin)

VDD1 (1.8 V)

VBAT

Reset (RSTN)

(IC501_77pin)

BBIC chip initialize

(CKM/STM)

4.5.5. Power Supply Circuit/Reset Circuit

The power supply voltage from AC adaptor is converted to VBAT (3.0V) in IC302. And +3.0V for peripherals and analog part is

insulated from VBAT by Doubler of BBIC.

Circuit Operation:

14

Page 15

4.5.5.1. Charge Circuit

R372

D362

R371

CHARGE+

R373

C351

F301

DCP

CHARGE-

+5.5V

DCM

K A

The voltage from the AC adaptor is supplied to the charge circuits.

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

15

Page 16

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

OFF Hook

BELL signal detection

C174

C171

R166

R178

RX

Pin25 of IC501

TX

Pin27 of IC501

R160

+

C161

C167

R165

R162

C173

R151R164

C184

C103

C111

Q161

E

B

C

R163

R117

C115

R109

C109

Q141

Q142

C101

P101

L1T

L1R

D101

C102

1

2

3

+

~~

_

4

R145

C142

C152

R152

A

K

D142

R141

B

E

C

E

B

C

R142

SA101

R111

R101

HOOK

Pin19 of IC501

CIDOUT

Pin24 of IC501

LSRn

Pin28 of IC501

RINGING

Pin18 of IC501

CIDINn

Pin23 of IC501

CIDINp

Pin21 of IC501

R168

PARADET

Pin17 of IC501

ADC1

Pin33 of IC501

ADC0

Pin32 of IC501

R118

C116

R115

R116

R110

C110

R112

C113

C105

R103

C104

R102

C106

R104

4.5.6. Telephone Line Interface

Telephone Line Interface Circuit:

Function

• Bell signal detection

• ON/OFF hook and pulse dial circuit

• Side tone circuit

Bell (RINGING) signal detection and OFF HOOK circuit:

In the idle mode, Q141 is open to cut the DC loop current and decrease the ring load. When ring voltage appears at the Tip (T)

and Ring (R) leads (When the telephone rings), the AC ring voltage is transferred as follows:

L1T C105 R103 R110 R11 1 R112 BBIC pin18(RINGING)

When the CPU (BBIC) detects a ring signal, Q141 turns on, thus providing an off-hook condition (active DC current flow through

the circuit). Following signal flow is the DC current flow.

T D101 Q141 Q161 R163 D101 P101 R

ON HOOK Circuit:

Q141 is open, Q141 is connected as to cut the DC loop current and to cut the voice signal. The unit is consequently in an onhook condition.

Pulse Dial Circuit:

Pin 19 of BBIC turns Q141 ON/OFF to make the pulse dialing.

Side Tone Circuit:

Basically this circuit prevents the TX signal from feeding back to RX signal. As for this unit, TX signal feed back from Q161 is

canceled by the canceller circuit of BBIC.

16

Page 17

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

C174

C171

R166

R178

RX

Pin25 of IC501

TX

Pin27 of IC501

R160

+

C161

C167

R165

R162

C173

R151R164

C184

Q161

E

B

C

R163

R117

C115

Q141

Q142

C101

P101

L1T

L1R

D101

C102

1

2

3

+

~~

_

4

R145

C142

C152

R152

A

K

D142

R141

B

E

C

E

B

C

R142

SA101

HOOK

Pin19 of IC501

R168

PARADET

Pin17 of IC501

ADC1

Pin33 of IC501

ADC0

Pin32 of IC501

R118

C116

R115

R116

4.5.7. Parallel Connection Detect Circuit/Auto Disconnect Circuit

Function:

In order to disable call waiting and stutter tone functions when using telephones connected in parallel, it is necessary to have a

circuit that judges whether a telephone connected in parallel is in use or not. This circuit determines whether the telephone

connected in parallel is on hook or off hook by detecting changes in the T/R voltage.

Circuit Operation:

Parallel connection detection when on hook:

When on hook, the voltage is monitored at pin 32 of IC501. There is no parallel connection if the voltage is

0.54 V or higher, while a parallel connection is deemed to exist if the voltage is lower.

Parallel connection detection when off hook:

When off hook, the voltage is monitored at pin 17 of IC501; the presence/absence of a parallel connection is determined by

detecting the voltage changes.

If the Auto disconnect function is ON and statuses are Hold, receiving ICM, OGM transmitting, BBIC disconnects the line after

detecting parallel connection is off hook.

17

Page 18

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

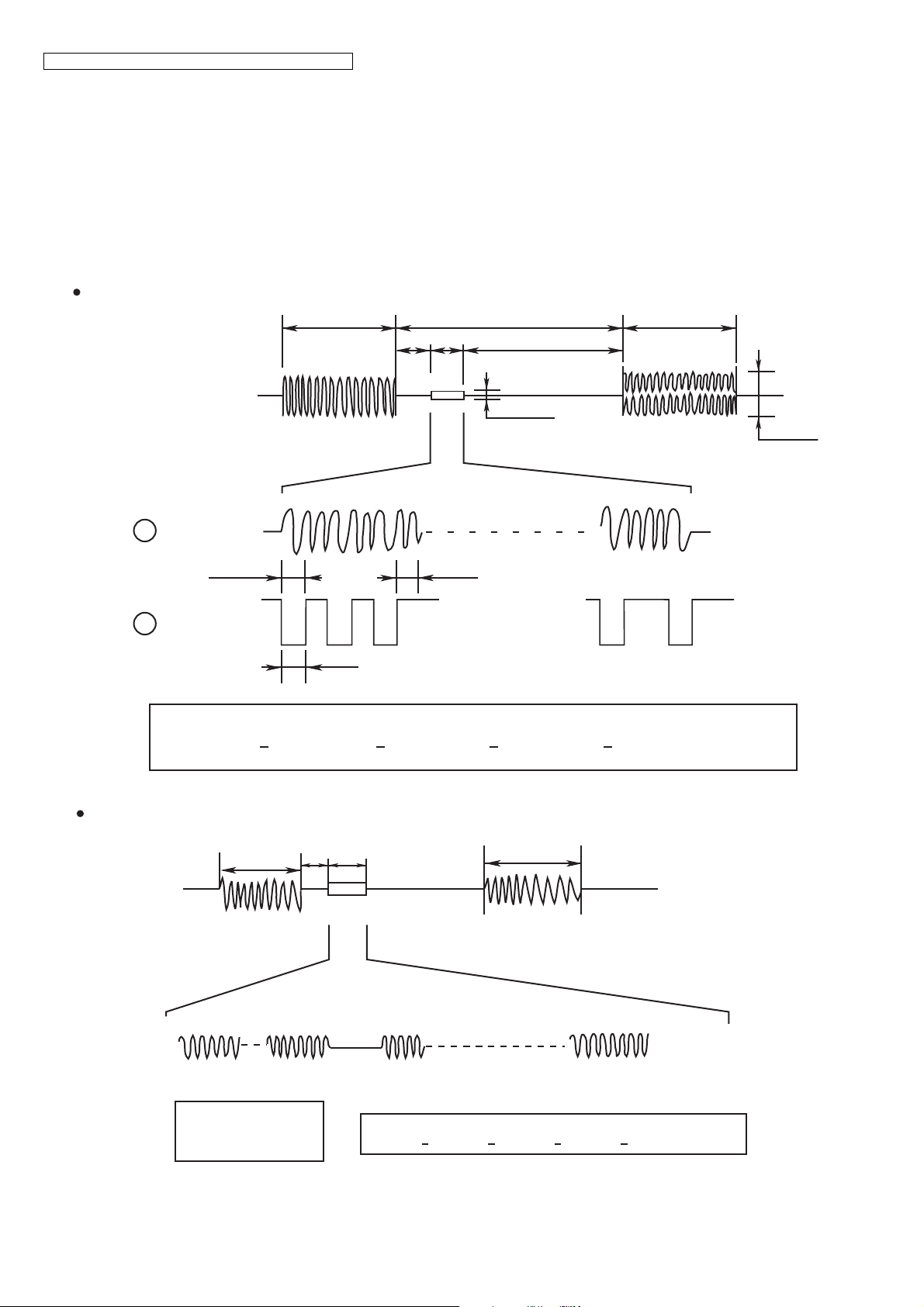

4.5.8. Calling Line Identification (Caller ID)/Call Waiting Caller ID

Function:

Caller ID

The caller ID is a chargeable ID which the user of a telephone circuit obtains by entering a contract with the telephone company

to utilize a caller ID service. For this reason, the operation of this circuit assumes that a caller ID service contract has been

entered for the circuit being used. The data for the caller ID from the telephone exchange is sent during the interval between the

first and second rings of the bell signal. The data from the telephone exchange is a modem signal which is modulated in an FSK

(Frequency Shift Keying) * format. Data

the message format which can be received: i.e. the single message format and plural message format. The plural message

format allows to transmit the name and data code information in addition to the time and telephone number data.

*: Also the telephone exchange service provides other formats.

Single message format

"1" is a 1200 Hz sine wave, and data "0" is a 2200 Hz sine wave. There are two types of

1st Ring

2 sec

0.5 s 575 ms

Silent interval 4 sec

min 0.5 s

2nd Ring

2 sec

STD Ring / 20 Hz

Tip-Ring

DATA in

A

1200 Hz

=DATA "1"

DATA out

B

month day hour minute number

Plural message format

DATA

0.1 Vrms

70 Vrms

2200 Hz

=DATA "0 "

1 bit=833 µs

201348700035161504

1st Ring

2 sec

0.5 s

DATA CODE NAME

201 John Smith

718 ms

DATA

month

04

18

day

2nd Ring

hour

16

minute

number

20134870003516

Page 19

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

CAS

CAS: CPE Alerting Signal

Dual Tone of 2130 Hz, 2750 Hz

-15 dBm (900 ohm load)

80 5 ms

MARK

DATA

0~500 ms

58~75 ms about 300 ms

(be changed by

Information Volume)

Continuance Signal

of 1200 Hz (Data "1")

"FSK"

ACK: Acknowledged Signal

DTMF

"D"

ACK

0~100 ms

60 5 ms

Telephone Exchange

Cordless phone

Cordless phone

Signal Flow

Signal Flow

Telephone Exchange

Call Waiting Format

Call Waiting Caller ID

Calling Identity Delivery on Call Waiting (CIDCW) is a CLASS service that allows a customer, while off-hook on an existing call,

to receive information about a calling party on a waited call. The transmission of the calling information takes place almost

immediately after the customer is alerted to the new call so he/she can use this information to decide whether to take the new

call.

Function:

The telephone exchange transmits or receives CAS and ACK signals through each voice RX/TX route. Then FSK data and

MARK data pass the following route.

Telephone Line P101 C105, C104 R103, R104 RA101 IC501(23, 21).

If the unit deems that a telephone connected in parallel is in use, ACK is not returned even if CAS is received, and the

information for the second and subsequent callers is not displayed on the portable handset display.

IC501

CIDOUT

Pin 24

CIDINn

Pin 23

CIDINp

Pin 21

LSRn

Pin 28

C110

C109

R110

R109

R101

R103

R102

R104

C103

C105

C104

C106

SA101

P101

L1T

L1R

19

Page 20

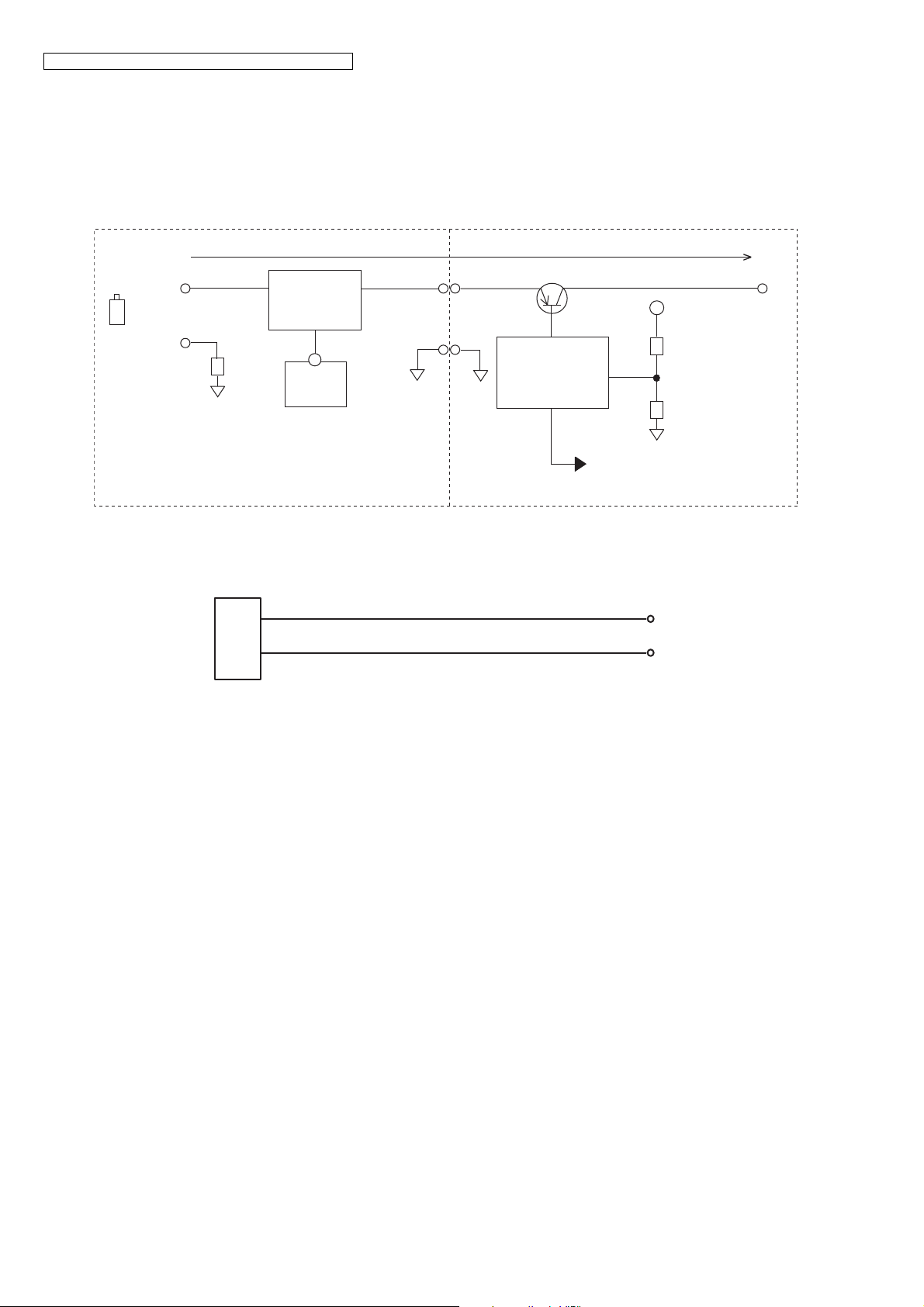

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

IC1

IC3

MIP

MIN

HSSPOUTP

LOUT

HSMIP

HEADSET_DET

SPOUTP

SPOUTN

CKM//STM

CKM/STM

BBIC

RESET

CHG_CTL

BATTERY_ON

CHG_DET

WP, CLK, DATA

KEYSTOROBE_A~E

KEYIN_1~5

CHARGE

MIC

Receiver

Headset Jack

CN4

Monitor SP

LCD

CHARGE

PUMP

IC4

KEYS

RF part

ANT1

X1

13.824 MHz

EEPROM

3V

BATTERY

LED

(LCD)

RSTN

VBAT

VBAT

3V

4.0V

VBAT

RXn

RXp

TXp

TXn

KX-TGEA20 BLOCK DIAGRAM (Handset)

KEY_LED

CP_OFF

Q6

LED

(KEY)

4V

CHARGE

CONTROL

POWER SUPPLY

CONTROL

4.6. Block Diagram (Handset)

20

Page 21

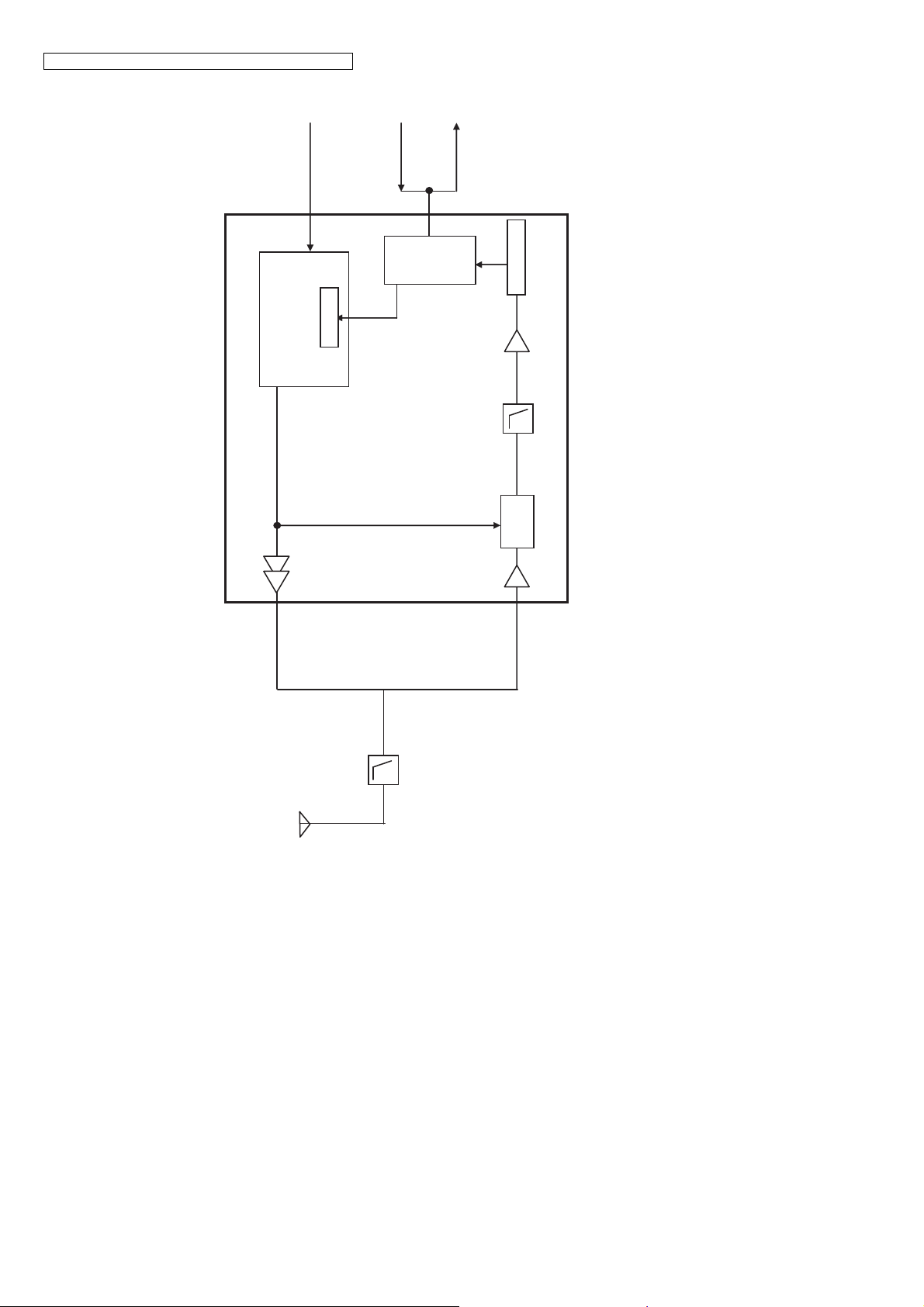

4.7. Block Diagram (Handset_RF Part)

ANT

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

TXp

TXn

RXp

RXn

KX-TGEA20 BLOCK DIAGRAM (Handset_RF Part)

21

Page 22

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

4.8. Circuit Operation (Handset)

4.8.1. Outline

Handset consists of the following ICs as shown in Block Diagram (Handset) (P.20).

• DECT BBIC (Base Band IC): IC1

- All data signals (forming/analyzing ACK or CMD signal)

- All interfaces (ex: Key, Detector Circuit, Charge, EEPROM, LCD)

• EEPROM: IC3

- Setting data is stored. (e.g. ID, user setting)

4.8.2. Power Supply Circuit/Reset Circuit

Circuit Operation:

When powering on the Handset, the voltage is as follows;

BATTERY(2.2 V ~ 2.6 V: BATT+) F1 BBC1 (IC1) 10 pin

The Reset signal generates IC1 (54 pin) and 1.8 V.

VBAT

VDDC (1.2 V)

GND

VBAT

External Charge Pump

Circuit or IC

Reset (RSTN)

(IC1_54 pin)

Start monitor

(IC1 57pin)

(CKM/STM)

BATTERY

2CELL

VDDC (1.2V)

VBAT

4.0V

BBIC

BBIC chip initialize

3.0V

3.0V

DOUBLER OUT (Charge Pump)

For all peripherals

3.0V3.0V

EEPROM

3.0V3.0V

LCD

4.0 output

LCD BACKLIT LED

3.0V

KEY LED

GND

22

Page 23

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

CHG +

Q4

R45

R4

47K

R6

10K

Q9

GND

R7 CHG DET (34)

CHG CTRL (32)

100K

CHG -

GND

BATT +

BATTERY

2CELL

BATT -

GND

BBIC

IC1

Q2

R8

Q3

C27

R2

R9

4.8.3. Charge Circuit

Circuit Operation:

When charging the handset on the Base Unit, the charge current is as follows;

DCP(5.5V) F301 R371 R372 D362 CHARGE+(Base) CHARGE+(Handset) R8 Q3 F1 BATTERY+...

Battery...

BATTERY- R45 GND CHARGE-(Handset) CHARGE-(Base) GND DC-(GND)

In this way, the BBIC on Handset detects the fact that the battery is charged.

The charge current is controlled by switching Q9 of Handset.

Refer to Fig.101 in Power Supply Circuit/Reset Circuit (P.14).

4.8.4. Battery Low/Power Down Detector

Circuit Operation:

“Battery Low” and “Power Down” are detected by BBIC which check the voltage from battery.

The detected voltage is as follows;

• Battery Low

Battery voltage: V(Batt) 2.35 V ± 50 mV

The BBIC detects this level and " " starts flashing.

• Power Down

Battery voltage: V(Batt) 2.1 V ± 50 mV

The BBIC detects this level and power down.

4.8.5. Speakerphone

The hands-free loudspeaker at SP+ and SP- is used to generate the ring alarm.

23

Page 24

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

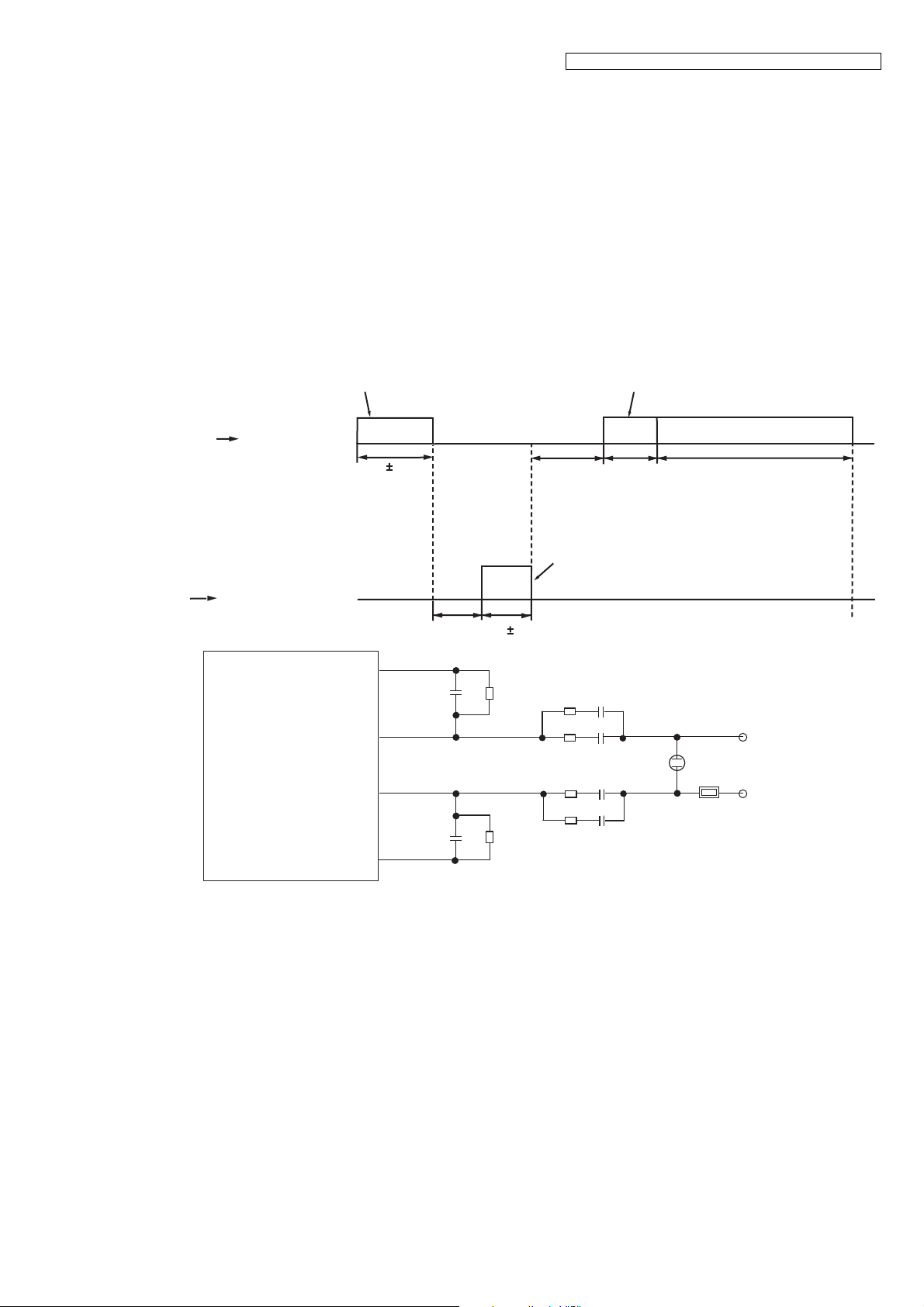

4.9. Behavior of Electric Power Failure

In case that the power from AC adaptor is lost and lose radio waves, BBIC (IC1) turns Q11 ON since handset presumes that

base unit's power is falied.

Base unit detects that power voltage of AC adaptor +5.5V is OFF, then turns Q351 ON.

It's possible to use the units during the power failure, supplying power to VBAT of base unit from battery of handset through

Q10, CHG terminal and Q351.

Handset

Base Unit

BATT+

BATT_

R45

CHG+

Power Supply

at AC failure

(Q10,Q11,Q12)

CHG-

3

BBIC

IC1

Q351

Power Down

DET

(Q352,Q353,Q354)

(pin101-IC501)

+5.5V

R351

R352

PDN_DET

4.10. Circuit Operation (Charger Unit)

Charge control is executed at handset side so that the operation when using charger is also controlled by handset.

Refer to Circuit Operation (Handset) (P.22)

TP1

J1

TP2

AC Adaptor

VBAT

The route for this is as follows: DC+pin of J1(+) CHARGE+pad Handset CHARGE-pad DC-pin of J1(-)

24

Page 25

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

5 Location of Controls and Components

Refer to the Operating Instructions.

Note:

You can download and refer to the Operating Instructions (Instruction book) on TSN Server.

6 Installation Instructions

Refer to the Operating Instructions.

Note:

You can download and refer to the Operating Instructions (Instruction book) on TSN Server.

7 Operating Instructions

Refer to the Operating Instructions.

Note:

You can download and refer to the Operating Instructions (Instruction book) on TSN Server.

25

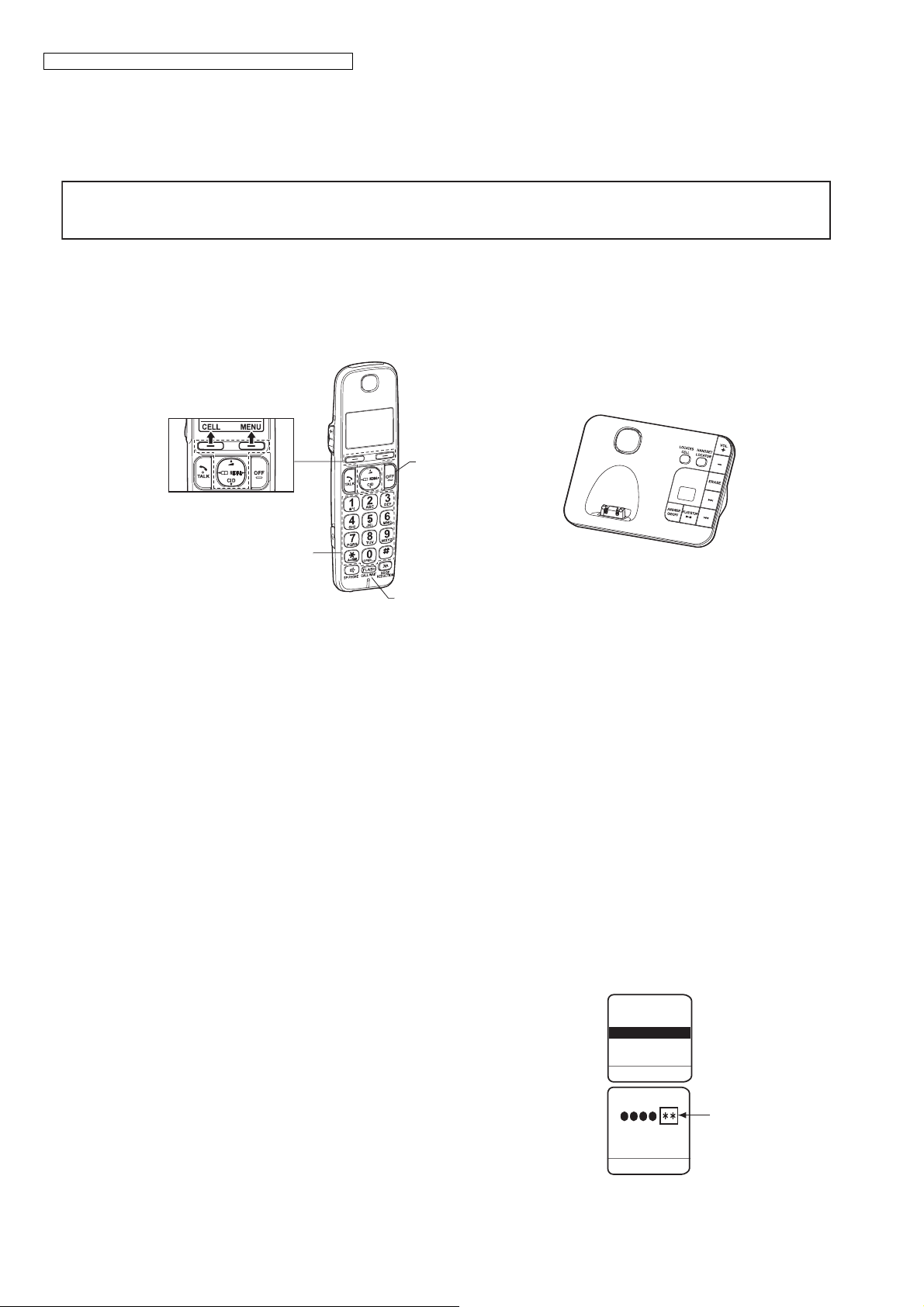

Page 26

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

8 Test Mode

8.1. Engineering Mode

8.1.1. Base Unit

Important:

Make sure the address on LCD is correct when entering new data. Otherwise, you may ruin the unit.

Make sure the link between Base and Handset before that. Then in case using not original Handset,

you need to deregister Handset.

Note: Refer to Registering a Handset to a Base Unit in the Operating Instructions.

{OFF}

Dial keypad

{FLASH}

H/S key operation

{CALL WAIT}

1). Press {MENU}.

{^}

2). Select "Settings" using or

then press

{SELECT} or {>}.

Select "Set tel line" using or

then press

{SELECT} or {>}.

{V}

{^} {V}

3). Enter "7", "2", "6", "2", "7", "6", "6", "4".

Note: 7262 7664 = PANA SONI

(see letters printed on dial keys)

4). Select "Write EEP" using or

then press

{SELECT} or {>}.

{^} {V}

This pictured model is KX-TGE230.

H/S LCD

Service Mode

Read EEP

Write EEP

5). Enter "

6). Enter "

ە

", "ە", "ە", "ە" (Address). (*1)

㸨

", "㸨" (New Data). (*1)

26

BACK

Set Addr.:

CLEAR

SELECT

Default Data

OK

Page 27

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

7). Press {OK} , a long confirmation beep

will be heard.

8).

Press to return to standby mode.

After that, turn the base unit power off and then power on.

Note:

New Data

_ _ _ _ _ _

Set Addr.:

Set Addr.:

{OFF}

CLEAR

OK

BACK

* "Set tel line" isn't displayed in Cell line only mode.

To return to normal mode, execute the following procedure:

1 {MENU} i {#}{1}{5}{7}

2 {V}/{^}: Select "off "i {SELECT}

3 {OFF}

Frequently Used Items (Base Unit)

ex.)

Items Address Default Data New Data Remarks

C-ID (FSK) sensitivity 06 0B 00 01 (6dB UP) 02 (12dB UP) When hex changes from"00" to "01" or "02"

gain increases by 6dB or 12dB.

Frequency 00 07 / 00 08 70/02 - - Use these items in a READ-ONLY mode to

ID 00 02 ~ 00 06 Given value - -

confirm the contents. Careless rewriting may

cause serious damage to the computer system.

Note:

(*1) When you enter the address or New Data, please refer to the table below.

Desired Number (hex) Input Keys Desired Number (hex) Input Keys

0 0 A [Flash] + 0

1 1 B [Flash] + 1

. . C [Flash] + 2

. . D [Flash] + 3

. . E [Flash] + 4

9 9 F [Flash] + 5

27

Page 28

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

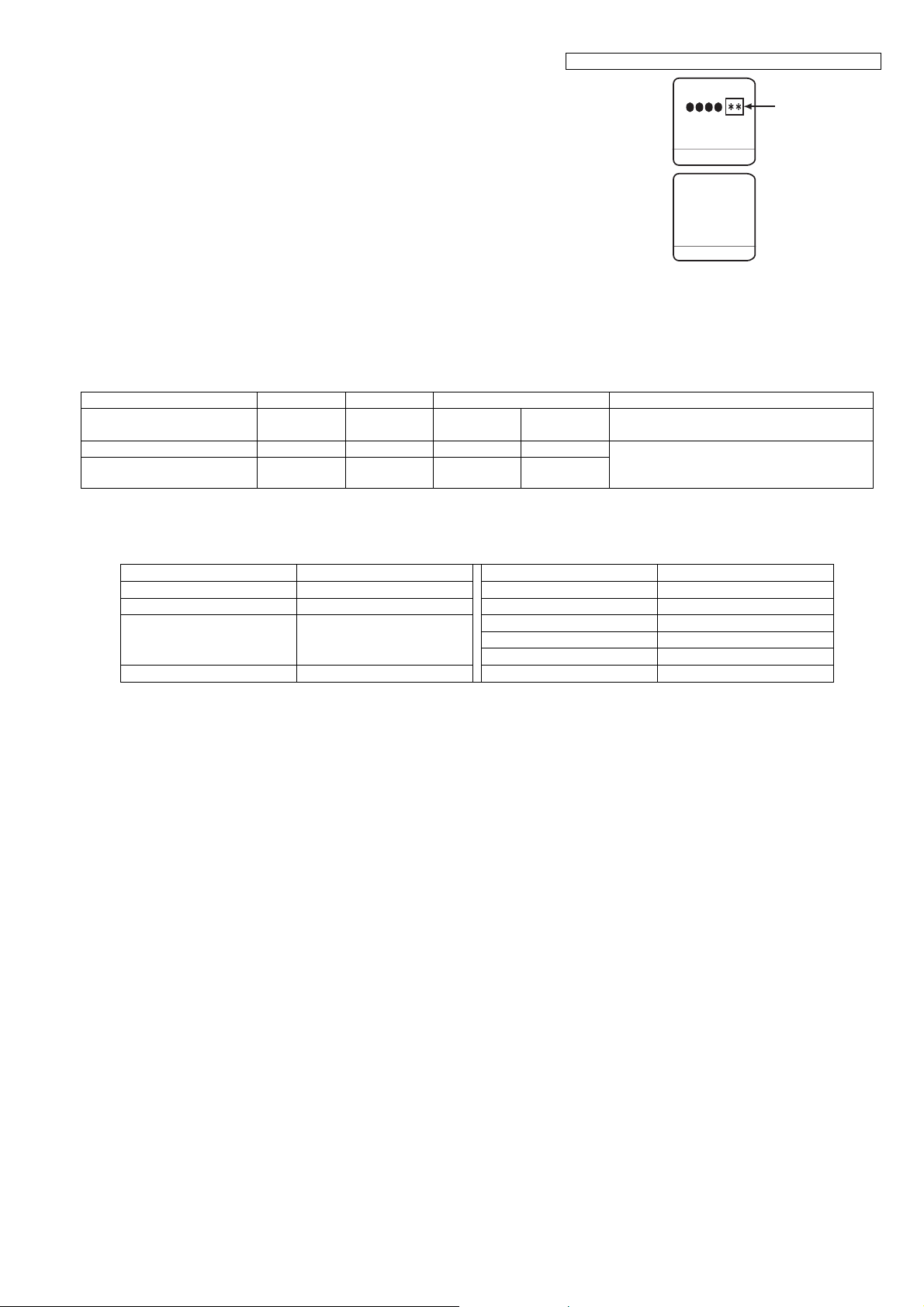

8.1.2. Handset

Important:

Make sure the address on LCD is correct when entering new data. Otherwise, you may ruin the unit.

{OFF}

Dial keypad

{FLASH}

H/S key operation H/S LCD

1). Press {MENU}.

{CALL WAIT}

2). Select "Settings" using or

then press

{SELECT} or {>}.

{^} {V}

3). Enter "7", "2", "6", "2", "7", "6", "6", "4".

Note: 7262 7664 = PANA SONI

(see letters printed on dial keys)

4). Select "Write EEP" using or

then press

5). Enter "

6). Enter "

7). Press

{SELECT} or {>}.

ە

", "ە", "ە", "ە" (Address). (*1)

㸨

", "㸨" (New Data). (*1)

{OK} , a long confirmation beep

{^} {V}

will be heard.

Service Mode

Read EEP

Write EEP

BACK

SELECT

Set Addr.:

CLEAR

Set Addr.:

CLEAR

Set Addr.:

_ _ _ _ _ _

Default Data

OK

New Data

OK

8).

{OFF}

Press to return to standby mode.

BACK

After that, remove and reinsert the batteries. Press the Power button for

about 1 second if the power is not turned on.

28

Page 29

Frequently Used Items (Handset)

ex.)

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Items Address Default Data New Data Possible Adjusted

Value MA X (hex)

Battery Low 00 12/00 13 00 / 00 - - -

Frequency 00 07 / 00 08 00 / 01 - - -

ID 00 02 ~ 00 06 Given value - - -

Possible Adjusted

Value MIN (hex)

Remarks

(*2)

Note:

(*1) When you enter the address or New Data, please refer to the table below.

Desired Number (hex.) Input Keys Desired Number (hex.) Input Keys

0 0 A [Flash] + 0

1 1 B [Flash] + 1

. . C [Flash] + 2

. . D [Flash] + 3

. . E [Flash] + 4

9 9 F [Flash] + 5

(*2) Use these items in a READ-ONLY mode to confirm the contents. Careless rewriting may cause serious damage to the

handset.

29

Page 30

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

9 Service Mode

9.1. How to Clear User Setting (Handset Only)

Handset

Press ,,, simultaneously until a beep sound is heard. Then single handset is initialized.

(The contents of user setting are reset to factory default)

*Usage time is not cleared.

30

Page 31

10 Troubleshooting Guide

10.1. Troubleshooting Flowchart

FLOW CHART

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Power ON Base Unit

OK

Record

OK

Playback Pre-Message Check Playback

OK

Link

No link

Battery Charge

OK

Range Check the RF part

Handset Voice Transmission Check Handset Transmission

Handset Voice Reception

Caller ID function Check Caller ID

OK

OK

OK

OK

Not working

Not recording (*1)

No playback

Not charged

NG

No voice

No voice

Caller ID Error

Check Power

Check Record

Check Battery Charge

Check Link

Check Handset Reception

Cross Reference:

Check Power (P.32)

Check Record (P.33)

Check Playback (P.36)

Check Battery Charge (P.36)

Check Link (P.37)

Check the RF part (P.39)

Check Handset Transmission (P.44)

Check Handset Reception (P.44)

Check Caller ID (P.44)

Note:

(*1) When a user claims that the unit disconnects a call right

after the greeting message and no incoming messages can

be recorded, this symptom can not reappear with TEL

simulator in the service center. In this case, try to change

the Auto disconnect activation time and Vox level.

<How to change the Auto Disconnect activation time

and VOX level> (P.34) item (A) and (B).

31

Page 32

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

10.1.1. Check Power

10.1.1.1. Base Unit

Is the AC Adaptor inserted into AC outlet? (*1)

Is output voltage of AC adaptor 5.5 V?

YES

Check VDD1(1.8V) :Test point (VDD1)

OK

RSTN: Reset = "High"?

YES

Check Xtal CLK=10.368MHz?

YES

Check BBIC.

Cross Reference:

Power Supply Circuit/Reset Circuit (P.14)

10.1.1.2. Handset

Is the battery inserted to BATT+ and BATT-?

YES

Is the voltage of TP-VBAT 2.3 V more?

YES

Is the voltage of TP 3.0 V about 3.0 V?

NO

NO

NO

NO

NO

NO

Check AC Adaptor.

Check Power Supply Circuit.

Check Reset Circuit.

Check X501.

Note:

BBIC is IC501.

(*1) Refer to Specifications (P.7) for part number and

supply voltage of AC adaptor.

(*2) Refer to Circuit Board (Base Unit_Main) (P.76).

Check the battery and around BATT+ and

BATT- are not shorted.

YES

Is the voltage of TP VDDC about 1.2 V?

YES

Does BBIC (IC1: 36) oscillate at 13.824 MHz?

YES

Check BBIC (IC1).

Cross Reference:

Power Supply Circuit/Reset Circuit (P.22)

Check Power Supply Circuit/Reset Circuit.

NO

NO

Check X1, C52, C53.

32

Page 33

10.1.2. Check Record

10.1.2.1. Base Unit

Not record Incoming Message

Check Bell signal.

Does the unit catch line?

Check Line In: Pin 25 of BBIC. Check ICM Recording in Signal Route.

Check Auto Disconnect Circuit.

Check Parallel Connection Detection

Circuit.

Check BBIC and Flash Memory.

OK

YES

OK

OK

OK

NO

NO

NO

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Check Telephone Line Interface

[Bell].

Check Telephone Line Interface

[OFF HOOK].

Cross Reference:

Telephone Line Interface (P.16)

Parallel Connection Detect Circuit/Auto Disconnect

Circuit (P.17)

Note:

Flash Memory is IC601.

BBIC is IC501.

33

Page 34

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

1) Press "MENU " key at standby Mode and "#" key.

Note: The set must power on and be linked.

2) Press "9", "0", "0", "0"," " .

3) Press "7","3","1".

4) Then enter the below last digit;

5) Back to "standby" mode automatically after step 4).

You can hear beep sound which is a confirmation tone.

Service ready

:731

Service ready

:

LCD (H/S)

last digit

"0"

Auto disconnect & CPC

: enable

㨇default㨉

(*1)

(*1)

Auto disconnect & CPC

: disable

(*2)

"1"

"2"

Auto disconnect : enable

CPC : disable

Note:

(*1) Both Auto Disconnect and CPC don't detect for the first 2 seconds.

(*2) If the "Disable" is selected, even if the parallel-connected telephone is OFF HOOK,

the line isn't disconnected.

CLEAR

BACK

<How to change the Auto Disconnect activation time and VOX level>

A) Auto Disconnect activation time:

Some Telephone Company lines (fiber or cable) ON Hook and OFF Hook voltages are lower than conventional lines, which may

cause a malfunction of Auto Disconnect detection. To solve this problem, try changing the Auto Disconnect activation through

the procedures below.

34

Page 35

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

B) Vox level:

It makes easier to detect a small voice (caller) by raising the sensitivity of VOX level. Therefore, the recording of TAM is not

turned off during detection.

1) ~ 2) are same as (A).

3) Press "5","1","1".

Service ready

:511

CLEAR

4) Then enter the below last digit;

last digit

default setting

"0"

: normal

6dB up

"1"

5) Back to "standby" mode automatically after step 4.

You can hear beep sound which is a confirmation tone.

35

Page 36

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Check Charge Circuit of Base Unit.

Check Handset.

Plug in the AC Power source.

Charge Handset on Base Unit.

Is the voltage of two charge contacts about

3 V or more?

OK

NO

Check Charge Contacts at

Base Unit from mechanical point of view.

YES

Is BBIC (IC1: 34) high at charge state?

Check Charge Circuit.

Check Power of Handset.

Is Check Power OK?

NO

NO

YES

Check Charge Circuit of Charger Unit.

Check Handset.

Plug in the AC Power source.

Charge Handset on Charger Unit.

Is the voltage of two charge contacts about

5.5 V or more?

OK

NO

Check Charge Contacts at Charger Unit

from mechanical point of view.

YES

10.1.3. Check Playback

10.1.3.1. Base Unit

Check VDD1(1.8V) :Test point (VDD1)

OK

Check output of BBIC (Pin 41,43).

OK

Check Speaker and its surroundings.

NO

NO

Check Power Supply Circuit.

Check BBIC and Flash Memory.

Cross Reference:

Power Supply Circuit/Reset Circuit (P.14)

Note:

Flash Memory is IC601.

10.1.4. Check Battery Charge

10.1.4.1. Base Unit

Cross Reference:

Charge Circuit (P.15)

10.1.4.2. Handset

BBIC is IC1.

(*1) Refer to Circuit Board (Base Unit_Main) (P.76).

Cross Reference:

Check Power (P.32)

Charge Circuit (P.23)

10.1.4.3. Charger Unit

Cross Reference:

Charge Circuit (P.23)

36

Page 37

10.1.5. Check Link

Check around Power Supply Circuit.

Does Base Unit connect to the properly working

Handset?

Check around X501 and RF module and adjust

clock frequency.

NO

NO

NO

NO

YES

YES

Is the voltage of VDD3 about 3.0V?

Check the RF part

Does the RF clock (CLK) oscillate at 10.368 MHz in

Base Unit Test Mode?

YES

Is the voltage of VDD1 about 1.8V?

YES

Base Unit is OK. Check Handset.

*1

10.1.5.1. Base Unit

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Cross Reference:

Power Supply Circuit/Reset Circuit (P.14)

Check the RF part (P.39)

Note:

Refer to Things to Do after Replacing IC or X'tal (P.52)(P.58) for Base Unit.

*1 How to adjust the frequency of X501.

37

Page 38

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Check around Power Supply Circuit/Reset Circuit.

Does Handset link with Base Unit?

(Properly working unit)

Check around X1 and RF module and adjust

clock frequency.

NO

NO

NO

NO

Is the voltage of TP VBAT about 2.2~2.8 V?

Is the voltage of TP VDDC about 1.2 V?

YES

YES

YES

YES

Is the voltage of TP 3.0 V about 3.0 V?

Does the RF clock (CLK) oscillate: 13.824 MHz

in Handset Test Mode?

Handset is OK. Check Base Unit.

YES

Check the RF part

Check the batteries.

*1

10.1.5.2. Handset

Cross Reference:

Power Supply Circuit/Reset Circuit (P.22)

Check the RF part (P.39)

Note:

Refer to Things to Do after Replacing IC or X'tal (P.53)(P.58) for Handset.

*1 How to adjust the frequency of X1.

38

Page 39

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

1. Prepare Regular HS(*1) and Regular BU(*2).

2. a. Re-register regular HS (Normal mode) to base unit (to be checked).

If this operation fails in some ways, the base unit is defective.

b. Re-register handset (to be checked) to regular BU (Normal mode).

If this operation fails in some ways, the handset is defective.

Base unit is defective Handset is defective

START

Registration of

Regular HS to

base unit

Registration of

handset to

Regular BU

(other checkings)

Registration of handset to base unit

(checked ones)

Registration of Regular HS to Regular BU

Yes

No No

Yes

10.1.6. Check the RF part

10.1.6.1. Finding out the Defective part

After All the Checkings or Repairing

1. Re-register the checked handset to the checked base unit, and Regular HS to Regular BU.

Note:

(*1) HS: Handset

(*2) BU: Base Unit

39

Page 40

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

10.1.6.2. RF Check Flowchart

Each item (1 ~ 5) of RF Check Flowchart corresponds to Check Table for RF part (P.41).

Please refer to the each item.

Start

1

confirmation

Normal

OK

Link

NG

2

Control

signal

confirmation

OK

3

X'tal

Frequency

confirmation

OK

4

TX confirmation

OK

NG

NG

NG

Check BBIC interface parts.

(RF Block <->BBIC on BU/HS P.C.B)

Adjust X'tal Frequency. (*1)

Check TX Block.

5

Range

confirmation

Normal

OK

GOOD

Note:

(*1) Refer to Check Link (P.37).

NG

TEST RANGE Check.

40

Page 41

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

10.1.6.3. Check Table for RF part

No. Item BU (Base Unit) Check HS (Handset) Check

1 Link Confirmation Normal

HS, BU Mode [Normal Mode]

2

X

'tal Frequency confirmation

HS, BU Mode: [Adjustment]

3 TX confirmation

HS Mode:

HS_Burst Mode] (*1)

BS Mode:

BS_Burst Mode] (*1)

4 Range Confirmation Normal

HS, BU Mode: [Normal Mode]

Note:

(*1) Refer to Commands (P.55)

(*2) Adjustment Standard (Base Unit) (P.56)

(*3) Adjustment Standard (Handset) (P.57)

1. Register Regular HS to BU (to be

checked).

2. Press [Talk] key of the Regular HS to

establish link.

Check X'tal Frequency.

(10.368 MHz ± 41Hz)

1. Remove wire antenna 2 and connect

spectrum analyzer to TP. (*2)

2. Confirm TX power whether spec. is

satisfied.

Power >=13.5dBm

1. Register Regular HS to BU (to be

checked).

2. Press [Talk] key of the Regular HS to

establish link.

3. Compare the range of the BU (being

checked) with that of the Regular BU.

1. Register HS (to be checked) to Regular

BU.

2. Press [Talk] key of the HS to establish link.

Check X'tal Frequency.

(13.824 MHz ±100 Hz)

1. Connect spectrum analyzer to TP. (*3)

2. Confirm TX power whether satisfied spec.

Power >=16.0dBm

1. Register HS (to be checked) to Regular

BU.

2. Press [Talk] key of the HS to establish link.

3. Compare the range of the HS (being

checked) with that of the Regular HS.

41

Page 42

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

10.1.6.4. TEST RANGE Check

Circuit block which range is defective can be found by the following check.

Item BU (Base Unit) Check HS (Handset) Check

Range Confirmation TX TEST

(TX Power check)

HS, BU setting

Checked unit: Low TX power (*1)

Regular unit: High TX power (*1)

Range Confirmation RX TEST

(RX sensitivity check)

HS, BU setting

Checked unit: High TX power (*1)

Regular unit: Low TX power (*1)

1. Register Regular HS to BU (to be checked).

2. Set TX Power of the BU and the Regular HS

according to CHART1.

3. At distance of about 20m between HS and BU,

Link OK = TX Power of the BU is OK.

No Link = TX Power of the BU is NG.

1. Register Regular HS to BU (to be checked).

2. Set TX Power of the BU and the Regular HS

according to CHART1.

3. At distance of about 20m between HS and BU,

Link OK= RX Sensitivity of the BU is OK.

No Link = RX Sensitivity of the BU is NG.

CHART1: Setting of TX Power and RX Sensitivity in Range Confirmation TX TEST, RX TEST

BU (to be checked) Regular_HS

TX Power TX Power

BU (Base Unit) TX Power Check Low Hig h

BU (Base Unit) RX Sensitivity Check High Low

1. Register HS (to be checked) to Regular BU.

2. Set TX Power of the HS and the Regular BU

according to CHART1.

3. At distance of about 20m between HS and BU,

Link OK = TX Power of the HS is OK.

No Link = TX Power of the HS is NG.

1. Register HS (to be checked) to Regular BU.

2. Set TX Power of the Checking HS and the Regular BU according to CHART1.

3. At distance of about 20m between HS and BU,

Link OK= RX Sensitivity of the HS is OK.

No Link = RX Sensitivity of the HS is NG

HS (Handset) TX Power Check Low High

HS (Handset) RX Sensitivity Check High Low

Note:

(*1) Refer to Commands (P.55).

HS (to be checked) Regular_BU

TX Power TX Power

42

Page 43

10.1.7. Registering a Handset to the Base Unit

L

{OFF}

{ }

A handset can cancel its own registration to the base unit, or other handsets

registered to the same base unit. This allows the handset to end its wireless

connection with the system.

1

All handsets registered to the base unit are displayed.

2 : Select the handset you want to cancel. i {SELECT}

3 : “Yes” i {SELECT}

4

{MENU} i # 1 3 1

{ }

The supplied handset and base unit are pre-registered. If for some reason the

handset is not registered to the base unit, re-register the handset.

1 Handset:

{MENU} i # 1 3 0

2 Base unit:

Press and hold {LOCATOR} for about 5 seconds until the registration tone

sounds.

If all registered handsets start ringing, press {LOCATOR} again to stop, then

L

repeat this step.

The next step must be completed within 90 seconds.

L

3 Handset:

Press {OK}, then wait until a long beep sounds.

Note:

While registering, “Base in registering” is displayed on all registered

L

handsets.

When you purchase an additional handset, refer to the additional handset’s

L

installation manual for registration.

10.1.8. Deregistering a Handset

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

43

Page 44

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Check MIC of handset.

Check handset Tx in Signal Route.

Check speaker of handset.

Check handset Rx in Signal Route.

YES

Did bell ring?

(Message indicator

blinks)

Check Calling Line Identification (Caller ID)/

Call Waiting Caller ID.

Check bell signal detection in

Telephone Line Interface.

BASE UNIT

NO

10.1.9. Check Handset Transmission

10.1.10. Check Handset Reception

Note:

When checking the RF part, Refer to Check the RF part

(P.39).

10.1.11. Check Caller ID

Cross Reference:

Telephone Line Interface (P.16)

Calling Line Identification (Caller ID)/Call Waiting Caller

ID (P.18)

Note:

• Make sure the format of the Caller ID service of the

Telephone company that the customer subscribes to.

• It is also recommended to confirm that the customer is really

a subscriber of the service.

44

Page 45

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

11 Disassembly and Assembly Instructions

11.1. Disassembly Instructions

11.1.1. Base Unit

11.1.1.1. KX-TGE210

Remove the 2 screws to remove

ձ

the cabinet cover.

Cabinet

cover

ձ

2 screws

ղ

Remove the solders.

ղ

Solders

45

Page 46

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

ճ

Screw

Main P.C.Board

Jack holder

Remove the screw to remove the Jack Holder and

Main P.C.Board.

ճ

46

Page 47

11.1.1.2. KX-TGE230

Remove the 5 screws to remove

ձ

the cabinet cover.

Remove the solders.

ղ

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

4 screws

Cabinet cover

Solders

Main P.C. board

Remove the screw to remove the

ճ

Jack Holder.

screws

Jack holder

47

Page 48

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Remove the pararell wire to remove the

main P.C. board.

Main P.C. board

Remove the 5 screws to remove

յ

the operational P.C.B board.

Pararell wire

2 screws

Operational P.C.B board

48

Page 49

11.1.2. Handset

Remove the 2 screws.

Insert a plastic card.

(Ex. Used SIM card etc.)

between the cabinet body

and the cabinet cover, then

pull it along the gap to open

the cabinet.

Likewise, open the other

side of the cabinet.

Remove the cabinet cover

by pushing it upward.

Remove the solders.

Remove the solders to remove

the 2 charge terminals.

Remove the screw to remove

the main P. C. board.

Cabinet body

Cabinet cover

2 screws

Cabinet cover

Screw

Solders

Main P.C. board

2 charge terminals

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

49

Page 50

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

11.1.3. Charger Unit

Unhook the click of one side.

ձ

Then unhook the other one.

ղ

2 charge terminals

50

Page 51

11.2. How to Replace the Handset LCD

Peel off the FFC (Flexible Flat Cable) from

the LCD, in the direction of the arrow. Take

care to ensure that the foil on the P.C. board

is not damaged.

Fit the heatseal of a new LCD.

Heatweld with the tip of the soldering

iron about 5 to 8 seconds

(in case of 60W soldering iron).

0.2 mm

0.2 mm

P. C . board

New LCD

Tip of Soldering Iron

(Part No. PQZZ430PIR)

Rubber of Soldering Iron

(Part No. PQZZ430PRB)

If interval tolerance between center lines

is less than 0.2 mm, it is o.k.

Horizontal Interval

Tolerance

Vertical Interval

Tolerance

OK

NG

NG

NG

(Horizontal interval tolerance is

more than 0.2 mm.)

(Vertical interval tolerance is

more than 0.2 mm.)

(Inclined)

Note:

The illustrations are simplified in this page.

They may differ from the actual product.

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

51

Page 52

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Base unit P. C. board

AC adaptor

1

DC JACK

UTX (yellow)

3

2

3

GND (black)

URX (red)

To Serial Port

(COM port 1*)

JIG Cable

PC

GND

UTX

URX

12 Measurements and Adjustments

This chapter explains the measuring equipment, the JIG connection, and the PC setting method necessary for the measurement in

Troubleshooting Guide (P.31)

12.1. Equipment Required

• Digital multi-meter (DMM): it must be able to measure voltage and current.

• Oscilloscope.

• Frequency counter: It must be precise enough to measure intervals of 1 Hz (precision; ±4 ppm)

Hewlett Packard, 53131A is recommended.

• DECT tester: Rohde & Schwarz, CMD 60 is recommended.

This equipment may be useful in order to precisely adjust like a mass production.

12.2. The Setting Method of JIG

<Preparation>

• Serial JIG cable: PQZZ1CD300E*

• PC which runs in DOS mode

• Batch file CD-ROM for setting: PNZZTGE230M

12.2.1. Connections (Base Unit)

Connect the AC adaptor.

Connect the JIG Cable GND (black).

Connect the JIG Cable RX (red) and TX (yellow).

Note:

*: If you have the JIG Cable for TCD500 series

(PQZZ1CD505E), change the following values of

resistance. Then you can use it as a JIG Cable for both

TCD300 and TCD500 series. (It is an upper compatible JIG

Cable.)

Resistor Old value (k) New value (k)

R2 22 3.3

R3 22 3.3

R4 22 4.7

R7 4.7 10

Note:

*: COM port names may vary depending on what your PC calls it.

52

Page 53

12.2.2. Connections (Handset)

DC Power

or Battery

2

GND

(black)

3

To Serial Port

(com port 1*)

JIG Cable

PC

URX (red)

3

UTX (yellow)

Handset P. C. board

1

BATT-BATT+

GND

UTX

URX

Connect the DC Power or Battery to BATT+ and BATT-.

Connect the JIG cable GND (black) to GND.

Connect the JIG cable UTX (yellow) to UTX and URX (red) to URX.

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Note:

*: COM port names may vary depending on what your PC calls it.

53

Page 54

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

1. Insert the Batch file CD-ROM into CD-ROM drive and

copy PNZZTG**** folder to your PC (example: D drive).

2. Open an MS-DOS mode window.

3. At the DOS prompt, type "D:" (for example) to select the

drive, then press the Enter key.

4. Type "CD 㪳PNZZTG****", then press the Enter key.

5. Type "SET_COM=X", then press the Enter key

(X: COM port number used for the serial connection on your PC).

6. Type "READID", then press the Enter key.

䊶If any error messages appear, change the port number or

䇭check the cable connection.

䊶If any value appear, go to next step.

7. Type "DOSKEY", then press the Enter key.

<Example>

C: >Documents and Settings>D:

D: >>CD >PNZZTG****

D: >PNZZTG**** >SET_COM=X

D: >PNZZTG****>READID

00 52 4F A8 A8

D: >PNZZTG****>DOSKEY

D: >PNZZTG****>

<Example: error happens>

C: >Documents and Settings>D:

D: >>CD >PNZZTG****

D: >PNZZTG**** >SET_COM=X

D: >PNZZTG****>READID

ޓCreateFile error

ERROR 10: Can't open serial port

D: >PNZZTG ****>

<Example for Windows>

On your computer, click [Start], select Programs

(All Programs for Windows XP/Windows Server 2003),

then click

MS-DOS Prompt. (for Windows 95/Windows 98)

Or

Accessories-MS-DOS Prompt. (for Windows Me)

Or

Command Prompt. (for Windows NT 4.0)

Or

Accessories-Command Prompt.

(for Windows 2000/Windows XP/Windows Server 2003)

12.2.3. How to install Batch file into P.C.

Note:

• “*****” varies depending on the country or models.

54

Page 55

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

12.2.4. Commands

See the table below for frequently used commands.

Command name Function Example

rdeeprom Read the data of EEPROM Type “rdeeprom 00 00 FF”, and the data from address

“00 00” to “FF” is read out.

readid Read ID (RFPI) Type “readid”, and the registered ID is read out.

writeid Write ID (RFPI) Type “writeid 00 18 E0 0E 98”, and the ID “0018 E0 0E

hookoff Off-hook mode on Base Type “hookoff”.

hookon On-hook mode on Base Type “hookon”.

getchk (Base unit) Read checksum Type “getchk”.

How to use of

"getchk"

in Handset

wreeprom Write the data of EEPROM Type “wreeprom 01 23 45”. “01 23” is address and “45”

bursttx Burst TX mode Type “bursttx”

testrx Burst RX mode Type “testrx”

tph Keep TX power high Type"tph"

tpl Keep TX power low Type"tpl"

1.rdeeprom Read EEPROM Type “RdEeprom 03 7D 04”, and the data from address

2.sendchar epw Write EEPROM Type “sendchar epw 03 7D 04 FF FF FF FF”

3.sendchar RST Reset baseset Type “sendchar RST”

4.getchk Read checksum Type “getchk”.

5.sendchar epw Write EEPROM Type “sendchar epw 03 7D 04 WW XX YY ZZ”

98” is written.

"03 7D" to "03 80" is read out

*This command gets 4 byte "WW", "XX", "YY", "ZZ".

*Please NEVER forget these 4 byte data!

*"WW", "XX", "YY", "ZZ" is 4 byte data that already read

from same address.

is data to be written.

55

Page 56

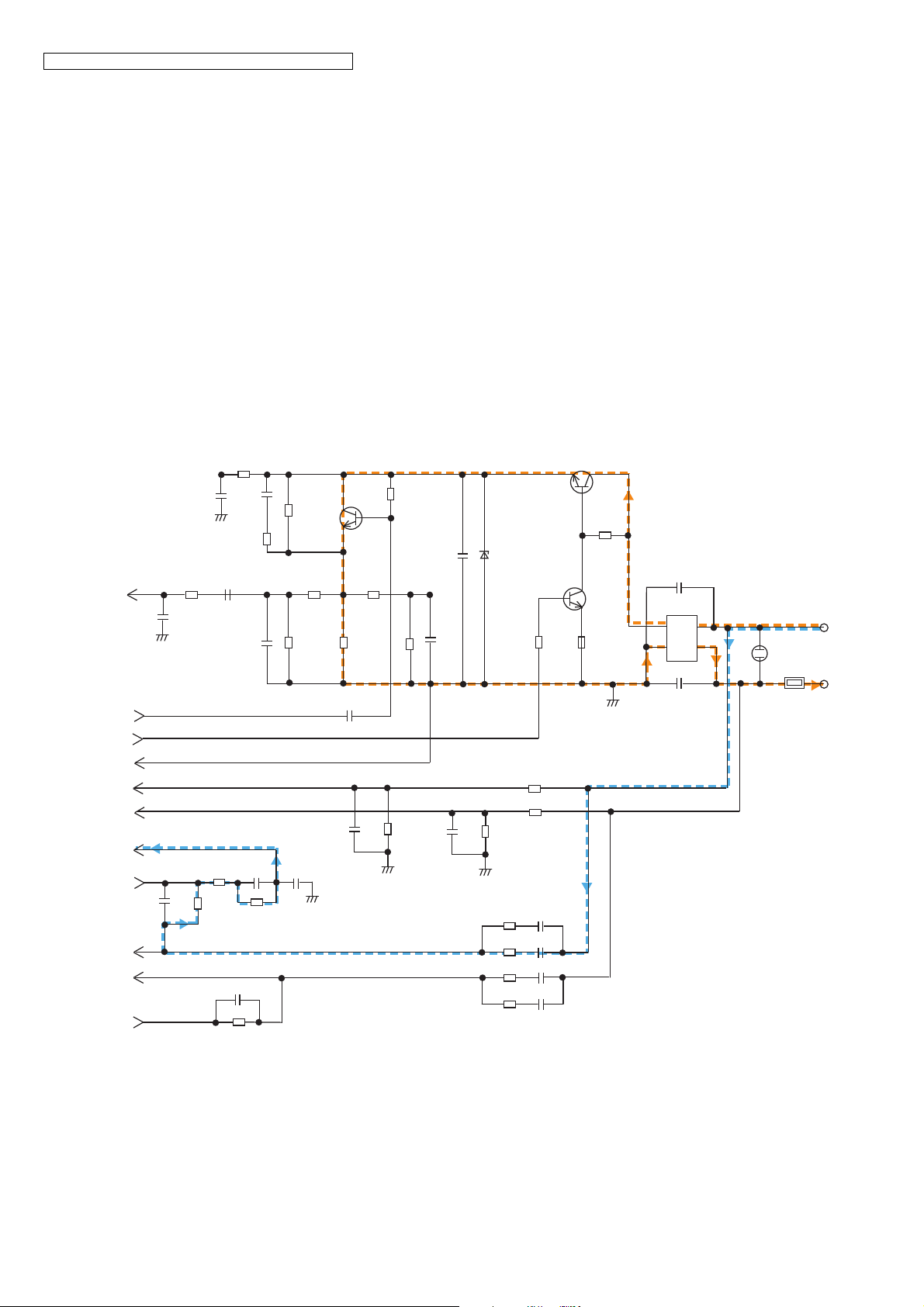

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

+

-

+

-

GRY

PUR

BRN/RED

BLU

ORG

+

-

YLW/BLK

PNLB2278ZP N L B 2 2 7 8 Z

PC

URX

UTX

GND

UART

JIG

A

PbF

RSTN

DCM

DCP

STM/P15

C611

CHARGE+

CHARGE-

F301

SPN

SPP

R477

ANT1-S-GND

URX

R891

C661

C662

C857

C663

C664

C477

ANT1_TP

C478

Q901

Q902

Q903

Q904

Q905

Q906

Q907

UTX

Q909

Q910

Q913

Q914

Q144

IC611

JTAG

Q351

Q352

Q353

R115R116

R117

Vcap

R125

D472

ANT2_TP

R901

R902

R903

R904

R906

R907

GAP

R143

VDD1

R146

VDD3

R917

R147

R918

VDD4

R148

R919

VDD5

R920

R151

C115

R152

C116

R924

R925

R926

L1R

L1T

R351

R352

R354

R355

R163

R167

C518

C519

+5.5V

RA611

R178

ANT1-Short

R371

R372

R373

R951

R952

R953

R954

R956

R957

R958

C152

R960

R961

R965

R966

C351

C174

CKM

C962

D132

C963

D133

C964

IC502

IC901

GND

D362

C901

C870

C511

R478

D473

R923

R118

Frequency Counter (*1)

Oscilloscope (*2)

Send command "SFR", then

the frequency output on this TP.

STM/CKM/P15

DC

5.5V

ANT_1

Spectrum

Analyzer

12.3. Adjustment Standard (Base Unit)

When connecting the simulator equipment for checking, please refer to below.

12.3.1. Bottom View

Note:

(*1) refers to No.2 of Check Table for RF part (P.41)

(*2) refers to Power Supply Circuit/Reset Circuit (P.14)

56

Page 57

12.4. Adjustment Standard (Handset)

When connecting the simulator equipment for checking, please refer to below.

12.4.1. Component View

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

Oscilloscope (*2)

* Start Monitor

ANT

Spectrum Analyzer

PNLB2282Z

PbF

TDI

GND_J

CKM/STM

3.0V

TMS

TCK

O

TD

the frequency output on this TP.

* Send command "SFR", then

Frequency Counter (*1)

IC3

RA5

C3

C2

C1

ANT1

ANT-Short

CKM/STM

RA1

C69

C40

R18

C19

ANT-Short-GND

C44

C807

C46

D30

RA2

RA3

RSTN

RTCK

C41

Q6

CS

RESET

ATSTP

ATSTN

C79

CD

SCL

C4

5

C51

C32

CHG_CUR

R72

R33

C92

SID

L801

C43

IC1

C30

C29

L3

R31

C36

VBAT_MON

21DEL11DEL

Q5

R70

R51

R50

C81

RECEIVER

C71

Blue

R16

R73

Q7

C42

C70

U_LOV

P

D13

D14

V

O

WD_L

X1

C16

R81

R55

R56

Q13

C93

C91

S

P

P

H

NO

E

S_

AEP

EK

R

Orange

C72

C73

C802

C801

C80

6

C22

C25

C24

C26

C52

C99

C68

C98

C97

C96

C53

C17

C89

C88

C39

R24

C20

C21

C31

C18

R22

R26

RA4

C14

C13

C11

C34

C80

Oscilloscope

VOLT METER

40

Oscilloscope

VOLT METER

8

VBG/CHG_MON

R21

R10

R20

Q12

Q11

CHG+

Q10

Q9

CHG_CTRL

C35

R4

Q2

R8

Q4

Q3

C56

IC4

C58

BAT+

Note:

(*1) refers to No.2 of Check Check Table for RF part (P.41)

(*2) refers to Power Supply Circuit/Reset Circuit (P.22)

R7

R6

R2

C27

R9

C57

F1

C33

R11

R13

R12

C90

CHG_DET

C6

R71

47

MIC+

MIC-

GND

VBAT

+

+

47

SPM

MIC+

SPP

MIC-

C85

R80

C84

C12

R32

R34

R23

R28

C83

R27

C37

R25

C78

R54

Q8

CN4

C82

C86

C15

R45

C10

URX

UTX

VBAT

GND

CHG-

BAT-

MIC Load

1.1 kHz

OSC

DC POWER SUPPLY

2.6 V 2.34 V

DC VOLT METER

R3

C5

A

57

Page 58

KX-TGE210/KX-TGE212/KX-TGE232/KX-TGE233/KX-TGE234/TGEA20

12.5. Things to Do after Replacing IC or X'tal

If repairing or replacing EEPROM and X'tal, it is necessary to download the required data such as Programming data or adjustment

data, etc. in memory.

The set doesn't operate if it is not executed.

12.5.1. How to download the data

12.5.1.1. Base Unit

First, operate the PC setting according to The Setting Method of JIG (P.52).