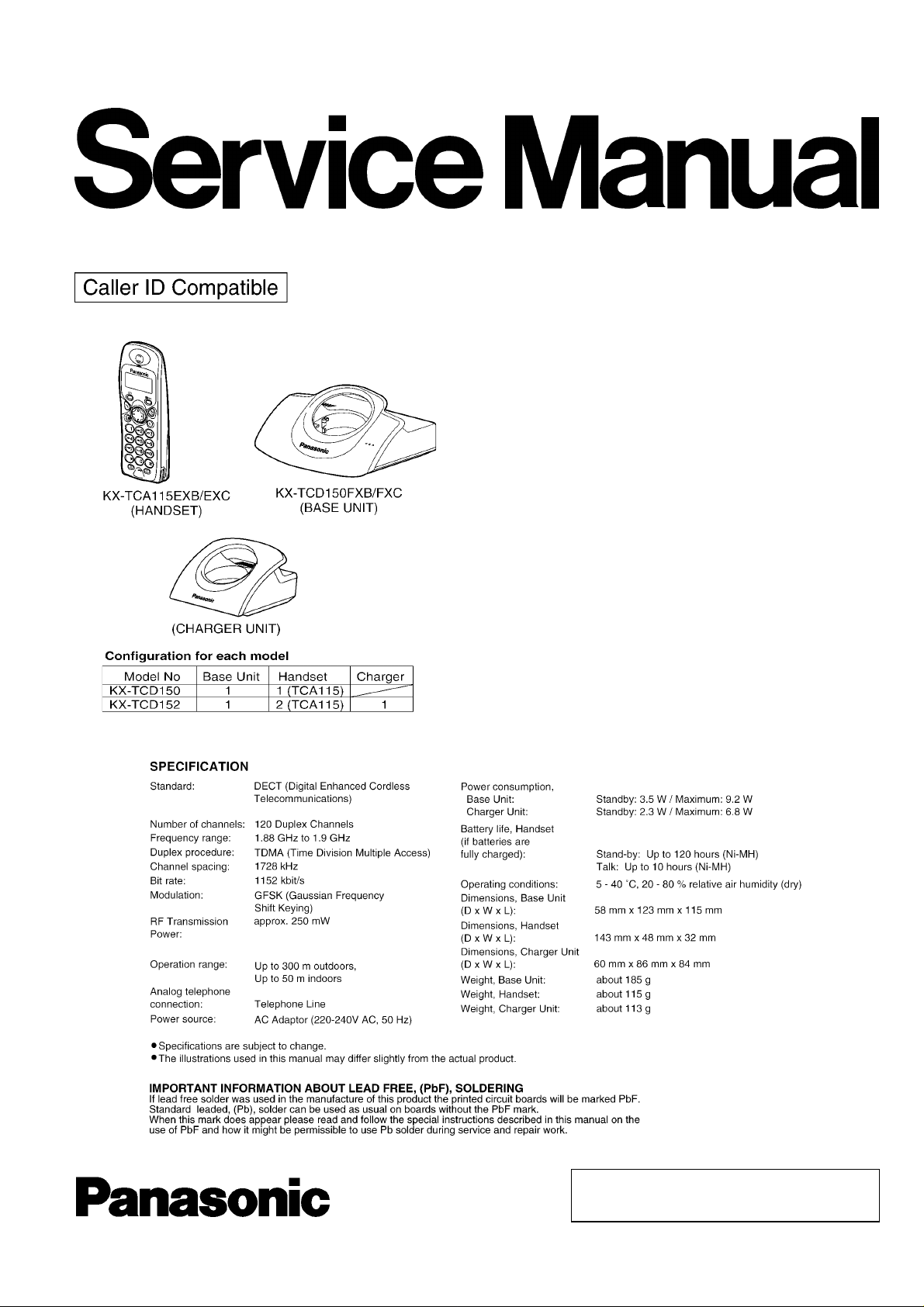

Panasonic KX-TCD150FXB, KX-TCD150FXC, KX-TCD152FXB, KX-TCA115EXB, KX-TCA115EXC Service Manual

ORDER NO. KM40507819CE

Telephone Equipment

KX-TCD150FXB

KX-TCD150FXC

KX-TCD152FXB

KX-TCA115EXB

KX-TCA115EXC

Digital Cordless Phone

Black Version

Dark Blue Version

(for Central Europe)

© 2005 Panasonic Communications Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

Note:

Because CONTENTS 4 is the extract from the Operating Instructions of this model, it is subject to change without notice. You can

download and refer to the original Operating Instructions on TSN Server for further information.

CONTENTS

Page Page

1 ABOUT LEAD FREE SOLDER (PbF: Pb free) 4

1.1. Suggested PbF Solder

1.2. How to recognize that Pb Free solder is used

2 FOR SERVICE TECHNICIANS

3 CAUTION

4 OPERATING INSTRUCTIONS

4.1. BATTERY

4.2. LOCATION OF CONTROLS

4.3. Connection

4.4. Guide to Settings

4.5. For Service Hint

5 DISASSEMBLY INSTRUCTIONS

5.1. Base Unit

5.2. Handset

5.3. Charger Unit

6 ASSEMBLY INSTRUCTIONS

6.1. Warning When Constructing the Base Unit

6.2. How to Replace the Handset LCD

7 TROUBLESHOOTING GUIDE

7.1. Check Power

7.2. Check Battery Charge

7.3. Check Link

7.4. Check Handset Transmission

7.5. Check Handset Reception

7.6. Check Caller ID

7.7. Bell Reception

8 TROUBLESHOOTING BY SYMPTOM (BASE UNIT AND

CHARGER UNIT)

8.1. Check Point (Base Unit)

8.2. The Setting Method of JIG (Base Unit)

8.3. Adjustment Standard (Base Unit)

8.4. Check Point (Charger Unit)

8.5. Adjustment Standard (Charger Unit)

9 TROUBLESHOOTING BY SYMPTOM (HANDSET)

9.1. Check Point (Handset)

9.2. The Setting Method of JIG (Handset)

10

11

11

12

13

14

14

15

16

17

18

19

21

21

21

22

23

23

27

28

30

30

31

31

34

4

5

5

5

6

6

7

7

8

9.3. Adjustment Standard (Handset)

10 TH INGS TO DO AFTER REPLACING IC

10.1. Base Unit

10.2. Handset

11 RF SPECIFICAT ION

11.1. Base Unit

11.2. Handset

12 HOW TO CHECK THE HANDSET SPEAKER

13 FREQUENCY TABLE (MHz)

14 B LOCK DIAGRAM (BASE UNIT)

15 CIRCUIT OPERATION (BASE UNIT)

15.1. Outline

15.2. Power Supply Circuit

15.3. Telephone Line Interface

15.4. Transmitter/Receiver

15.5. Pulse Dialling

16 B LOCK DIAGRAM (HANDSET)

17 CIRCUIT OPERATION (HANDSET)

17.1. Outline

17.2. Power Supply Circuit/Reset Circuit

17.3. Charge Circuit

17.4. Battery Low/Power Down Detector

18 CIRCUIT OPERATION (CHARGER UNIT)

18.1. Power Supply Circuit

19 SIGNAL ROUTE

20 CPU DATA (BASE UNIT)

20.1. IC2 (BBIC)

21 CPU DATA (HANDSET)

21.1. IC1 (BBIC)

22 ENGINEERI N G MOD E

22.1. Base Unit

22.2. Handset

23 HOW TO REPLACE THE FLAT PACKAGE IC

23.1. PREPARATION

23.2. FLAT PACKAGE IC REMOVAL PROCEDURE

23.3. FLAT PACKAGE IC INSTALLATION PROCEDURE

35

36

36

36

37

37

37

37

38

39

40

40

41

42

42

42

43

44

44

44

44

44

45

45

46

47

47

48

48

50

50

52

54

54

54

55

2

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

23.4. BRIDGE MODIFICATION PROCEDURE 55

24 CABINET AND ELECTRICAL PARTS (BASE UNIT)

25 CABINET AND ELECTRICAL PARTS (HANDSET)

26 CABINET AND ELECTRICAL PARTS (CHARGER UNIT)

27 ACCESSORIES AND PACKING MATERIALS

27.1. KX-TCD150FXB/FXC

27.2. KX-TCD152FXB

28 TER MINAL GU IDE OF THE ICs, TR ANSISTO RS AND DIODES

28.1. Base Unit

28.2. Handset

28.3. Charger Unit

29 REPLACEMENT PARTS LIST

29.1. Base Unit

29.2. Handset

29.3. Charger Unit

29.4. Accessories and Packing Materials

29.5. Fixtures and Tools

30 FOR SCHEMATIC DIAGRAM

56

57

58

59

59

60

30.1. Base Unit (SCHEMATIC DIAGRAM (BASE UNIT))

30.2. Handset (SCHEMATIC DIAGRAM (HANDSET))

30.3. Charger Unit (SCHEMATIC DIAGRAM (CHARGER UNIT))

31 SCHEMATIC DIAGRAM (BASE UNIT)

32 SCHEMATIC DIAGRAM (HANDSET)

33 SCHEMATIC DIAGRAM (CHARGER UNIT)

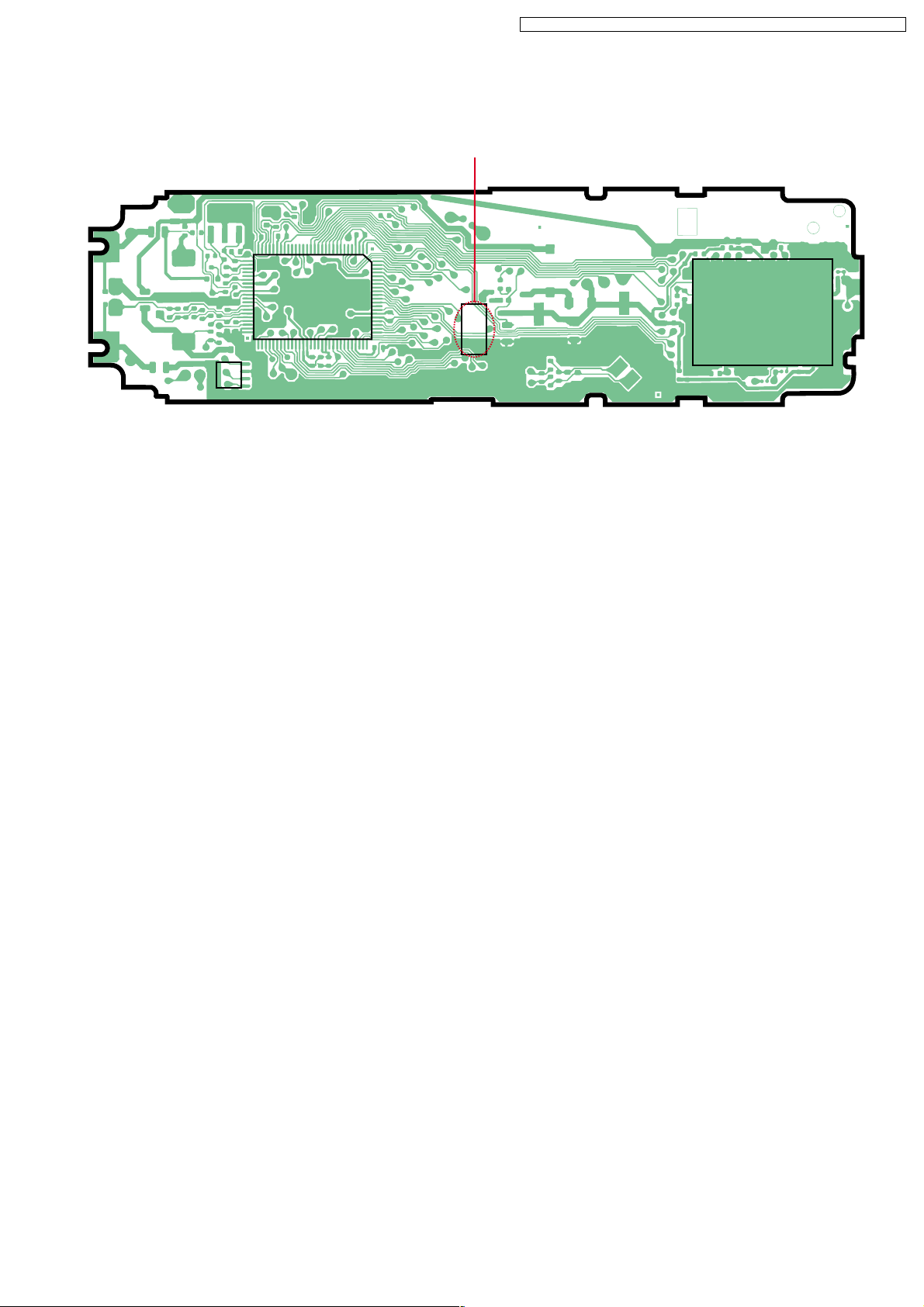

34 CIRCUIT BOARD (BASE UNIT)

61

61

61

61

62

62

63

64

64

34.1. Component View

34.2. Flow Solder Side View

35 CIRCUIT BOARD (HANDSET)

35.1. Component View

35.2. Flow Solder Side View

36 CIRCUIT BOARD (CHARGER UNIT)

36.1. Component View

36.2. Flow Solder Side View

65

67

67

67

67

68

70

72

73

73

74

75

75

76

77

77

77

3

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

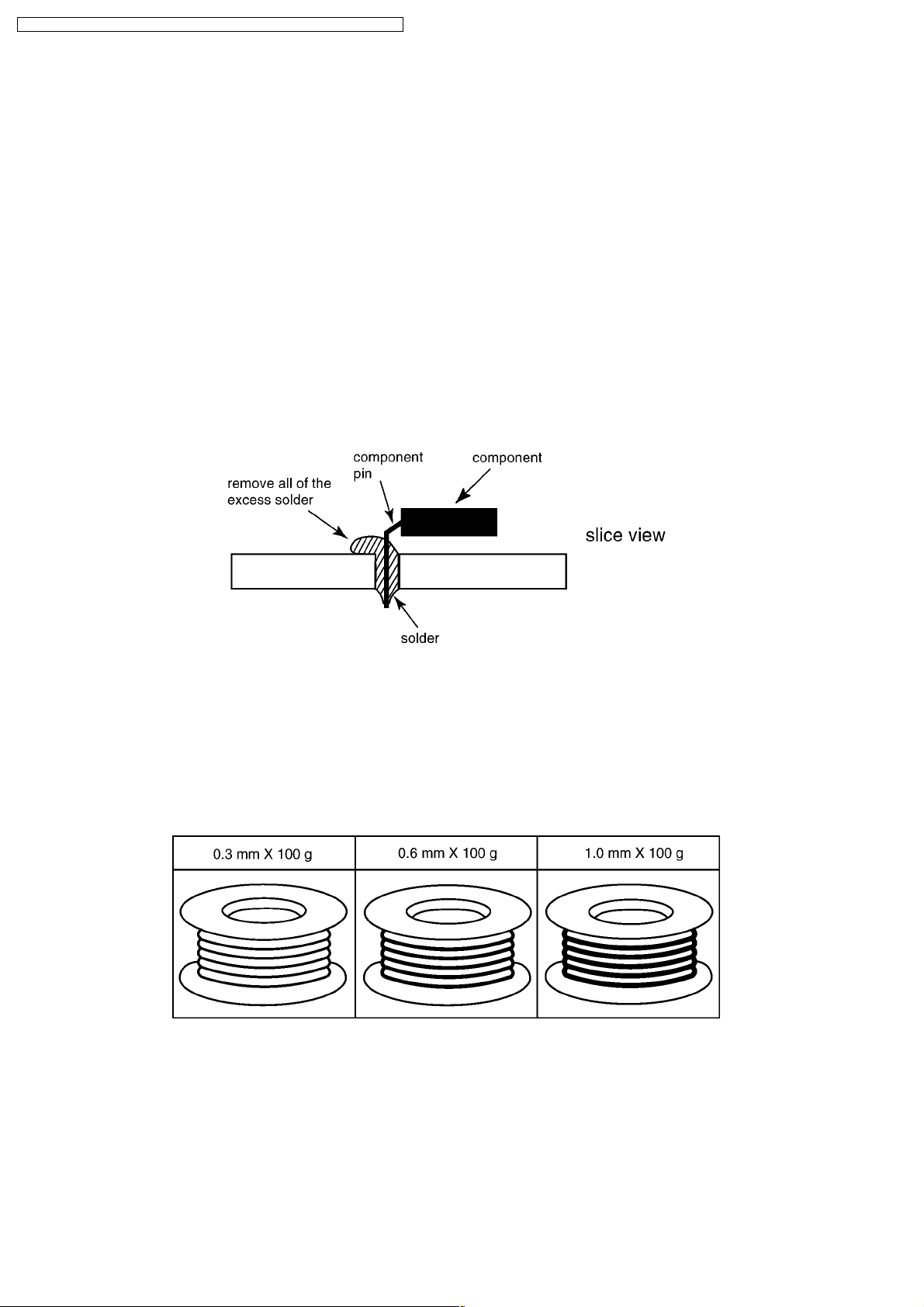

1 ABOUT LEAD FREE SOLDER (PbF: Pb free)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that

contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin (Sn),

Silver (Ag), and Copper (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder although, with some precautions, standard Pb solder can also be used.

Caution

· PbF solder has a melting point that is 50°F ~70°F (30°C ~ 40°C) higher than Pb solder. Please use a soldering iron with

temperature control and adjust it to 700°F ± 20°F (370°C ± 10°C). In case of using high temperature soldering iron, please

be careful not to heat too long.

· PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100°F (600°C).

· If you must use Pb solder on a PCB manufactured using PbF solder, remove as much of the original PbF solder as possible

and be sure that any remaining is melted prior to applying the Pb solder.

· When applying PbF solder to double layered boards, please check the component side for excess which may flow onto the

opposite side (See the figure below).

1.1. Suggested PbF Solder

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper

(Sn+Ag+Cu), you can also use Tin and Copper (Sn+Cu) or Tin, Zinc, and Bismuth (Sn+Zn+Bi). Please check the manufac

turer’s specific instructions for the melting points of their products and any precautions for using their product with other

materials. The following lead free (PbF) solder wire sizes are recommended for service of this product: 0.3 mm, 0.6 mm and

1.0 mm.

4

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

1.2. How to recognize that Pb Free solder is used

(Example: Handset P.C.B.)

Marked

30

31

IC1

50

51

8

1

IC2

4

5

1

100

PbF

81

80

(Component View)

Note:

The location of the “PbF” mark is subject to change without notice.

2 FOR SERVICE TECHNICIANS

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover the plastic parts boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on the worktable.

4. Do not touch IC or LSI pins with bare fingers.

3 CAUTION

10

IC3

17

1

26

1. Danger of explosion if battery is incorrectly replaced.

2. Replace only with the same or equivalent type recommended by the manufacturer.

3. Dispose of used batteries according to the manufacture’s Instructions.

5

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

4 OPERATING INSTRUCTIONS

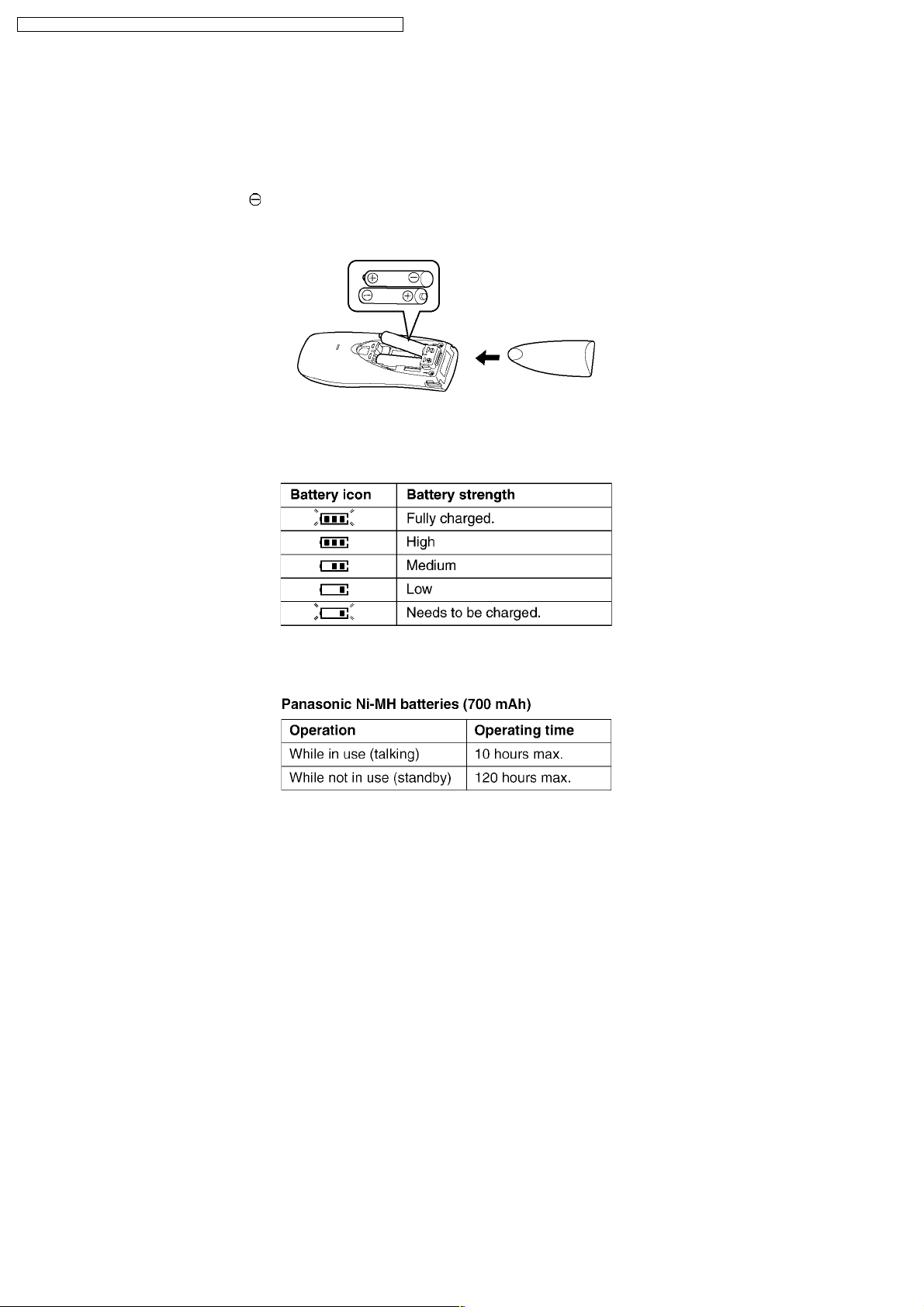

4.1. BATTERY

4.1.1. Battery Installation

Insert the batteries negative ( ) terminal first. Close the handset cover.

Note:

· Use only rechargeable P03P (HHR-4EPT) batteries.

4.1.2. Battery Charge

Place the handset on the base unit for about 7 hours before initial use.

4.1.3. Battery Life

6

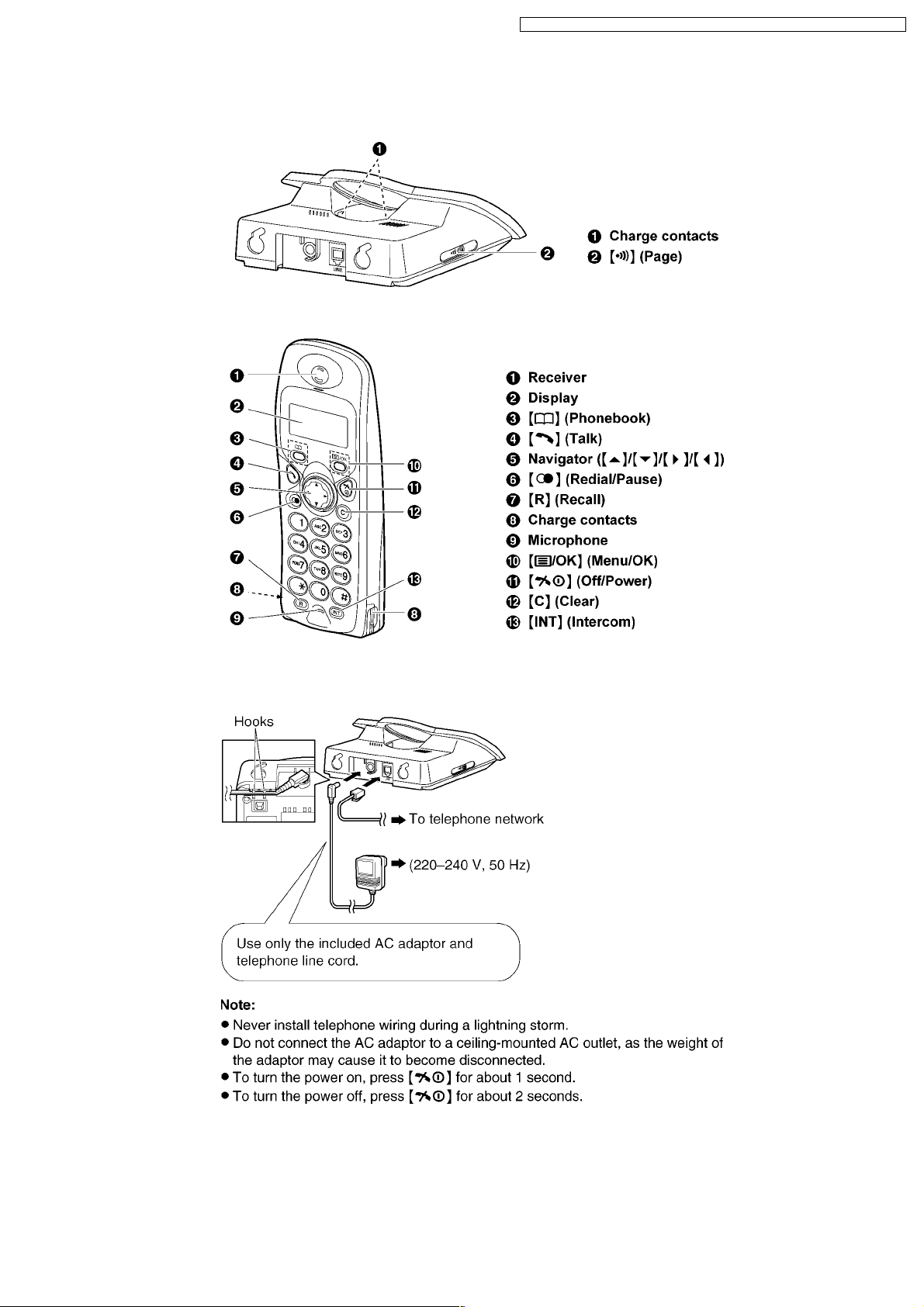

4.2. LOCATION OF CONTROLS

4.2.1. Base Unit

4.2.2. Handset

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

4.3. Connection

7

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

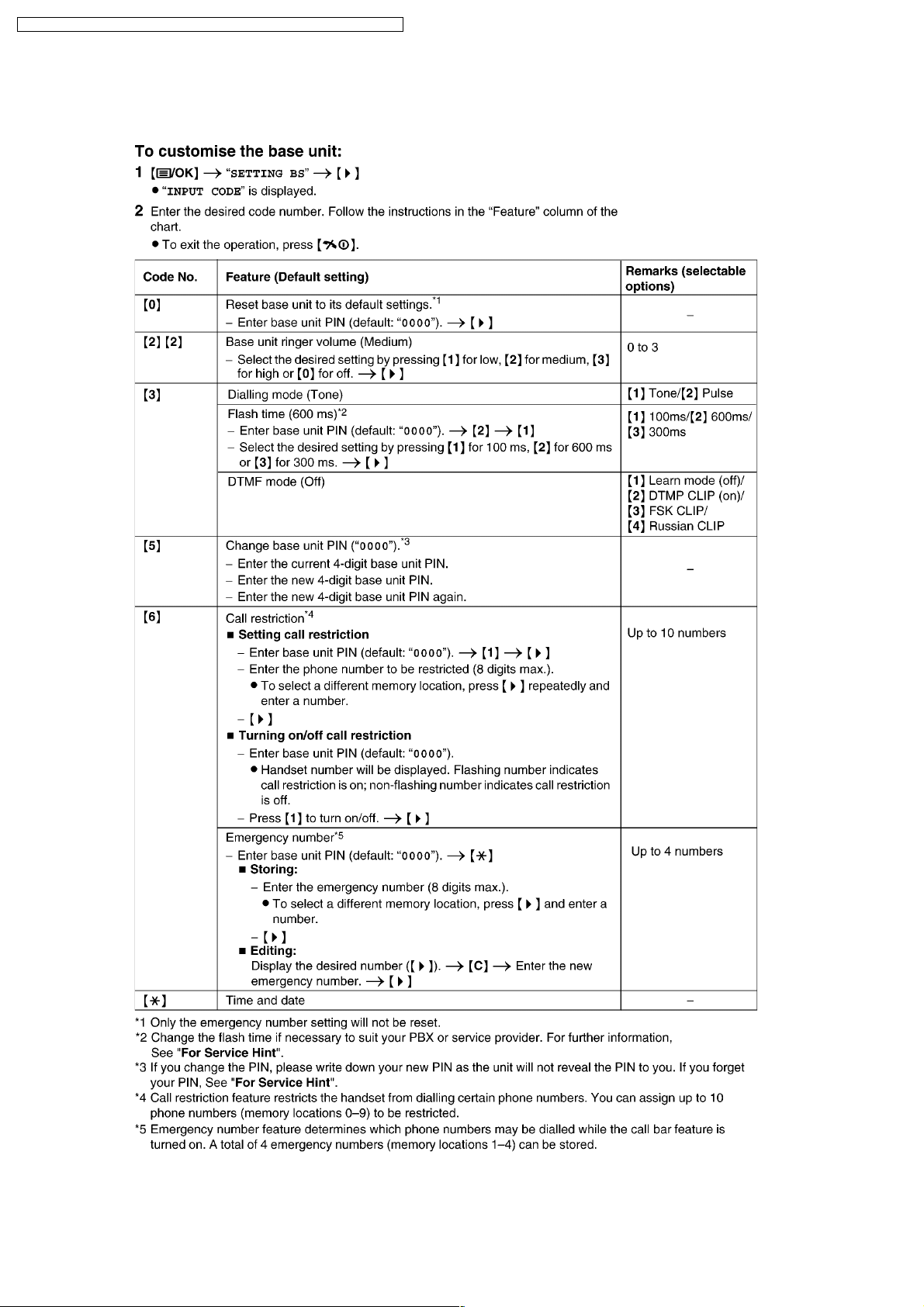

4.4. Guide to Settings

4.4.1. Base Unit

Cross Reference:

For Service Hint (P.10)

8

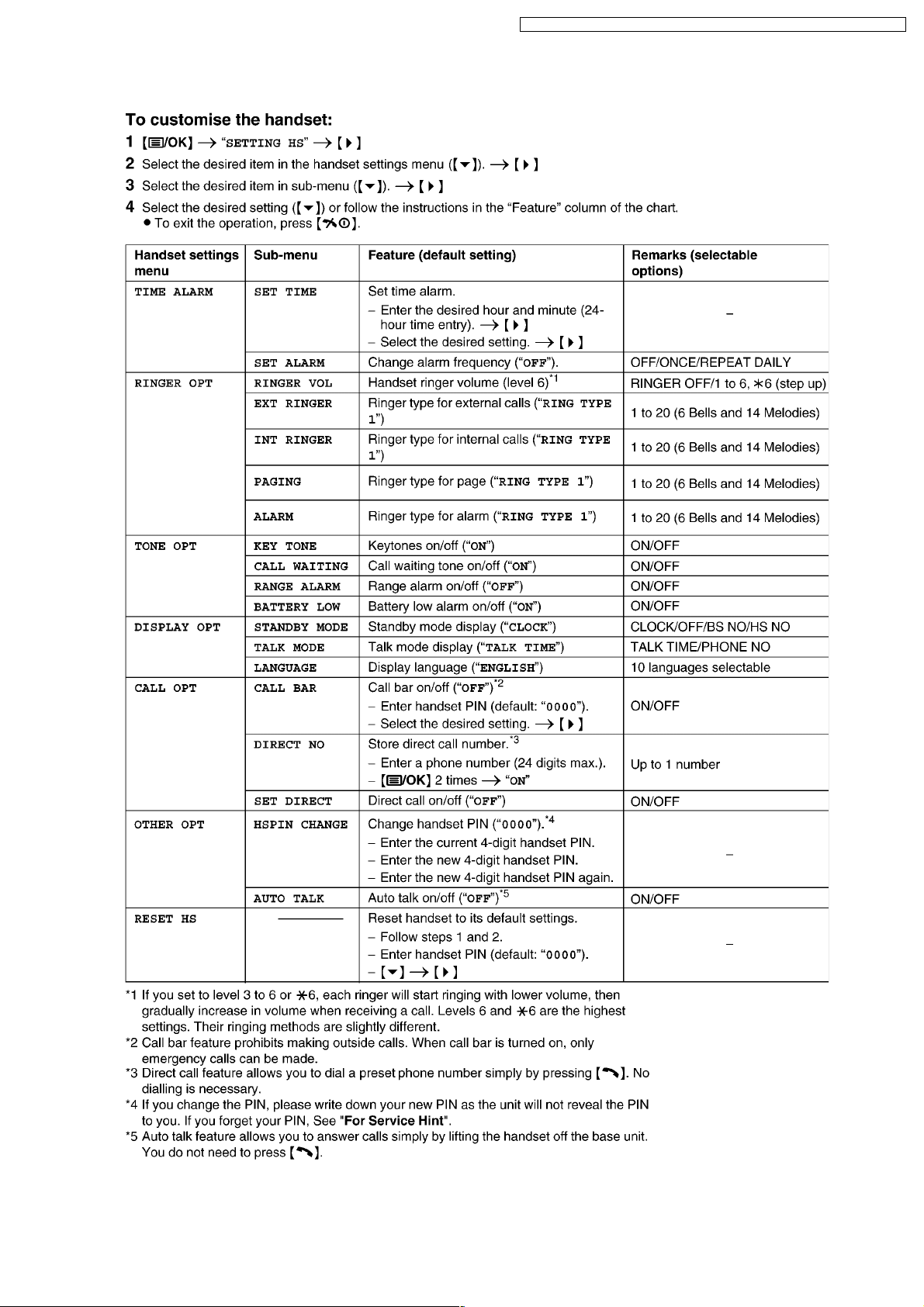

4.4.2. Handset

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

Cross Reference:

For Service Hint (P.10)

9

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

4.5. For Service Hint

10

5 DISASSEMBLY INSTRUCTIONS

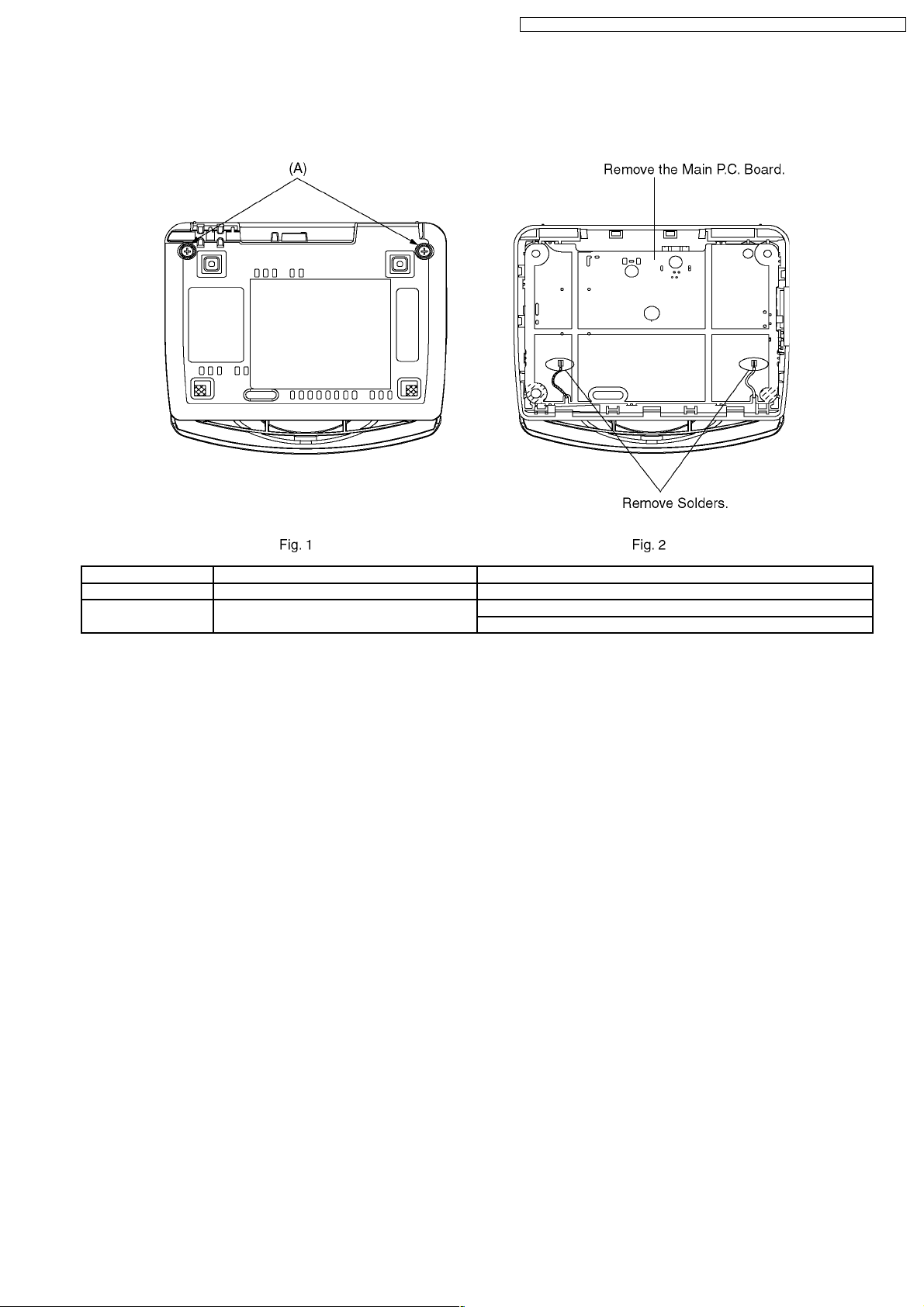

5.1. Base Unit

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

Shown in Fig.- To Remove Remove

1 Lower Cabinet Screws (2.6 × 12)..........(A) × 2

2 Main P.C. Board Solders

Main P.C. Board

11

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

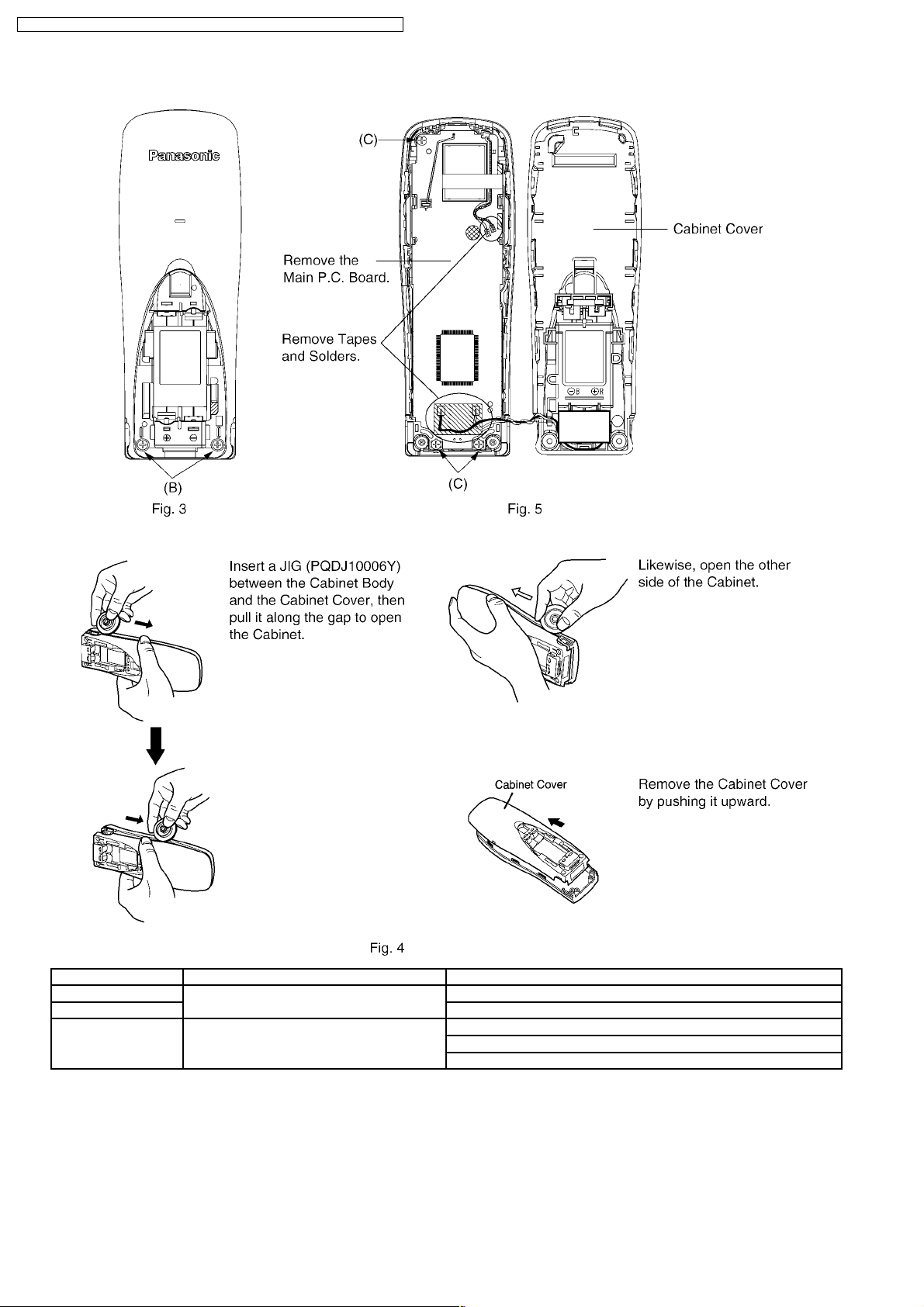

5.2. Handset

Shown in Fig.- To Remove Remove

3 Cabinet Cover Screws (2 × 8)..........(B) × 2

4 Follow the procedure.

5 Main P.C. Board Screw (2 × 8)..............(C) × 3

Tapes and Solders

Main P.C. Board

12

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

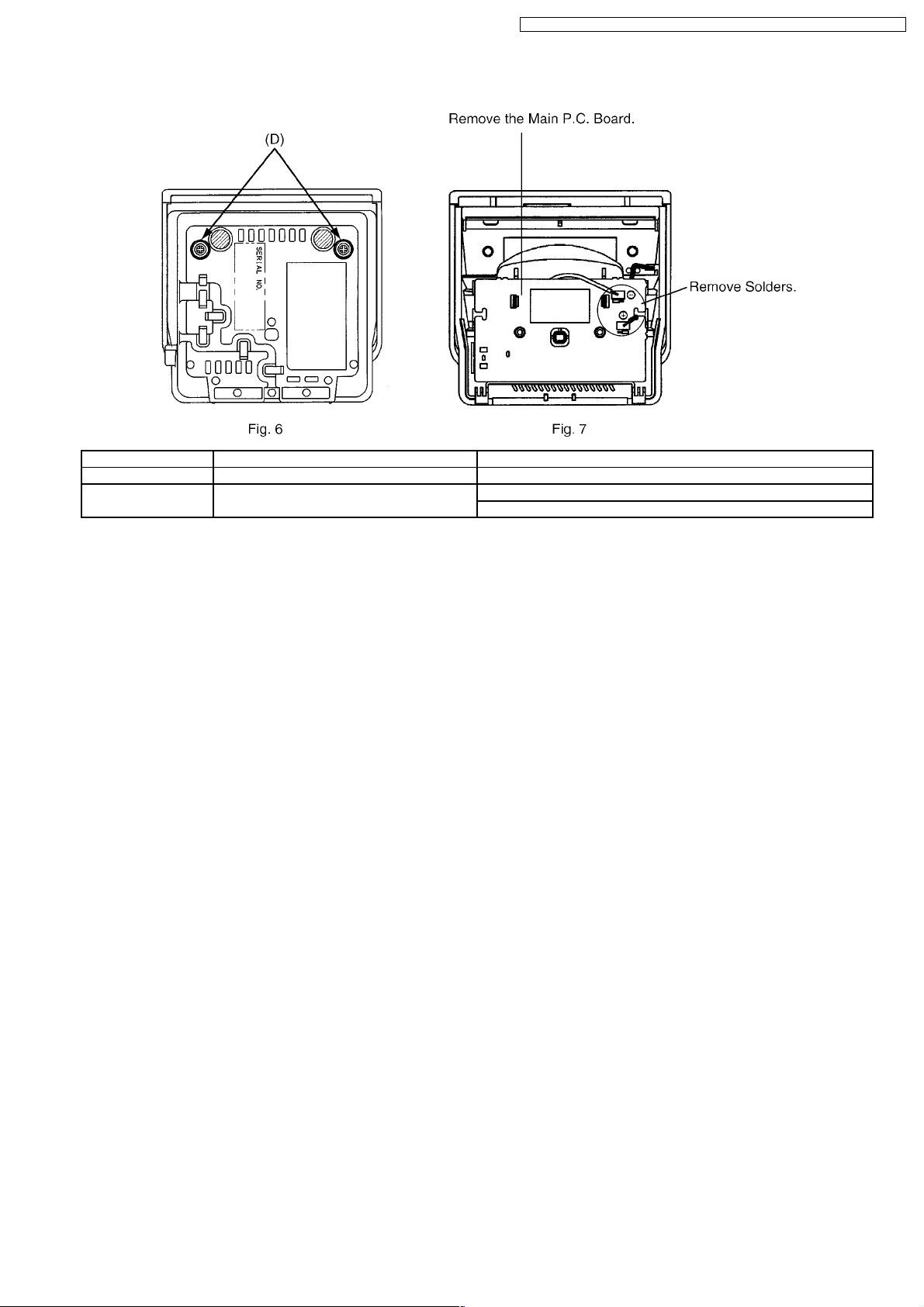

5.3. Charger Unit

Shown in Fig.- To Remove Remove

6 Lower Cabinet Screws (2.6 × 14)..........(D) × 2

7 Main P.C. Board Solders

Main P.C. Board

13

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

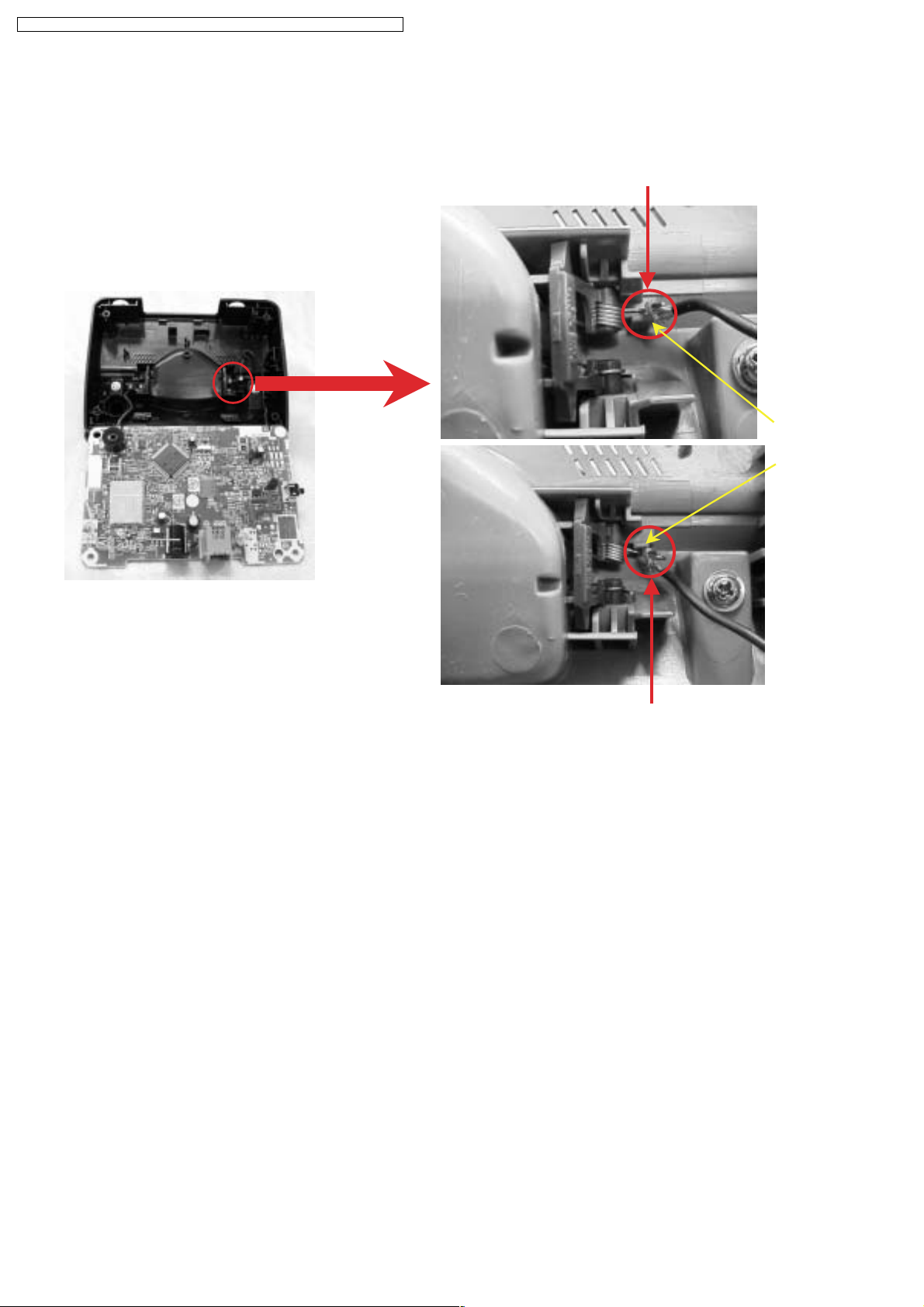

6 ASSEMBLY INSTRUCTIONS

6.1. Warning When Constructing the Base Unit

OK

NG

CHG terminal is properly fit in the cabinet.

Rib

CHG terminal comes out of rib by pulling black lead wire when opening the cabinet and turning

the PCB over. The terminal cannot have enough elastic force, cannot have good contact with

handset, and it will result in charge problem.

14

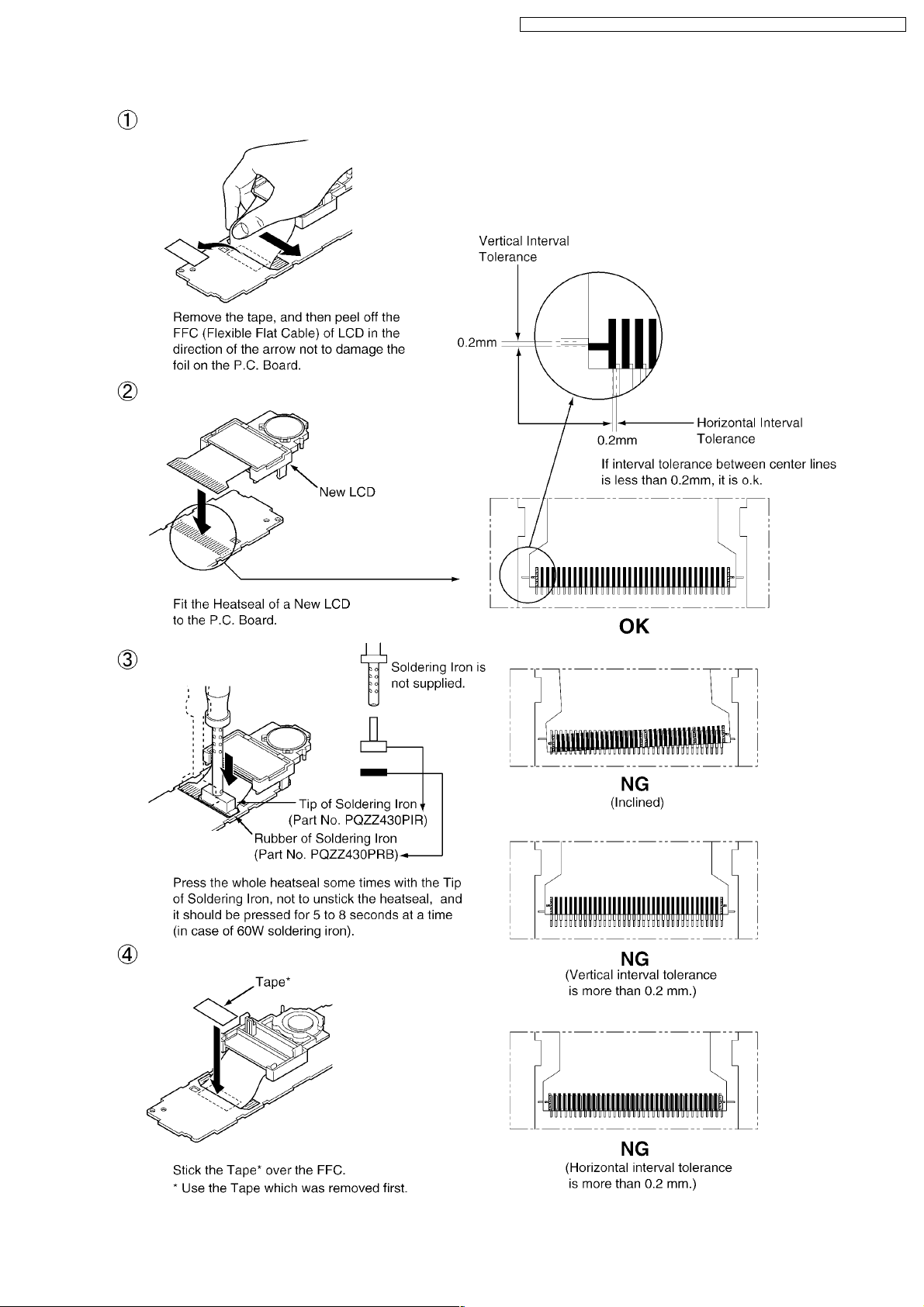

6.2. How to Replace the Handset LCD

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

15

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

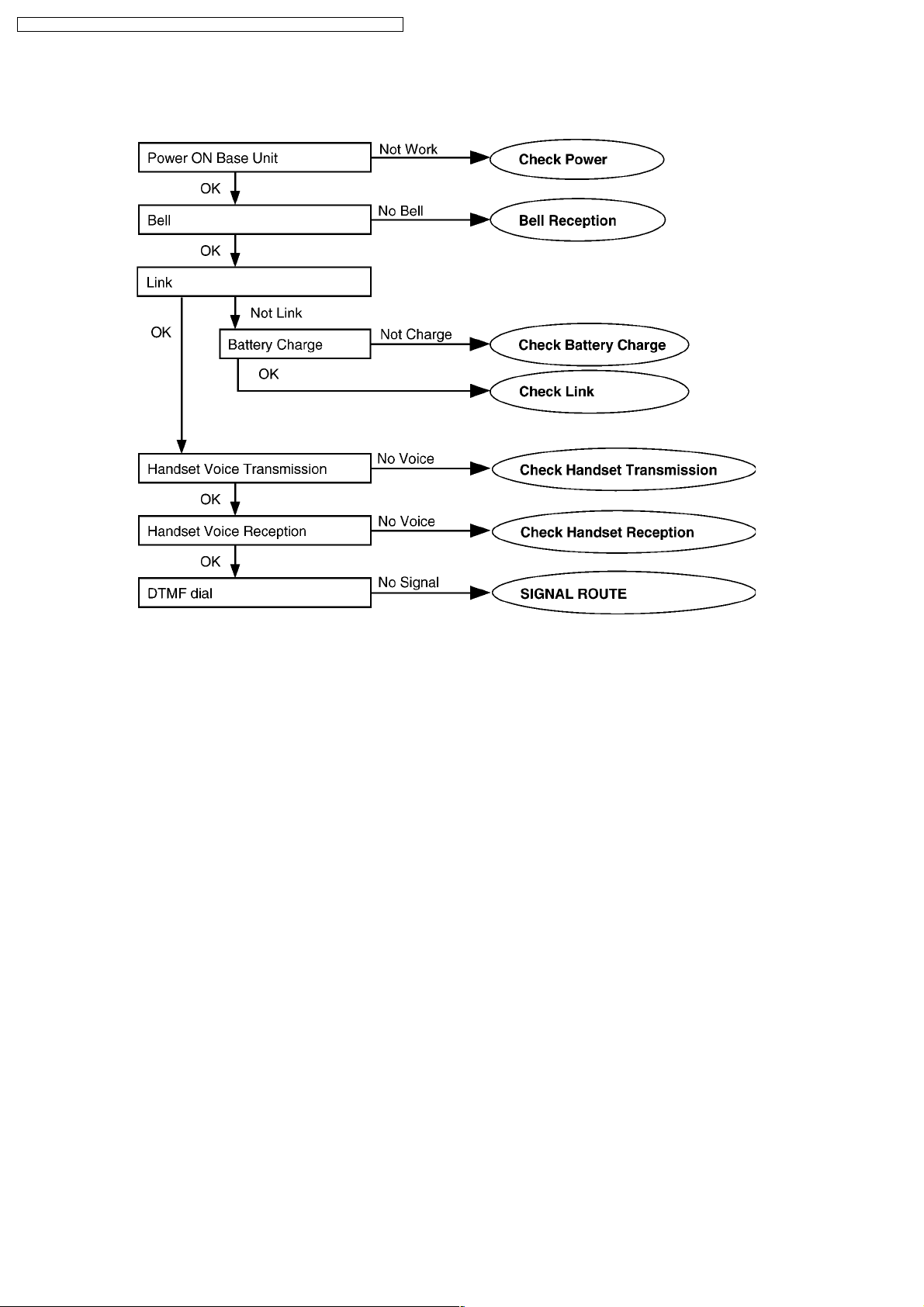

7 TROUBLESHOOTING GUIDE

Flow Chart

Cross Reference:

Check Power (P.17)

Bell Reception (P.22)

Check Battery Charge (P.18)

Check Link (P.19)

Check Handset Transmission (P.21)

Check Handset Reception (P.21)

SIGNAL ROUTE (P.46)

16

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

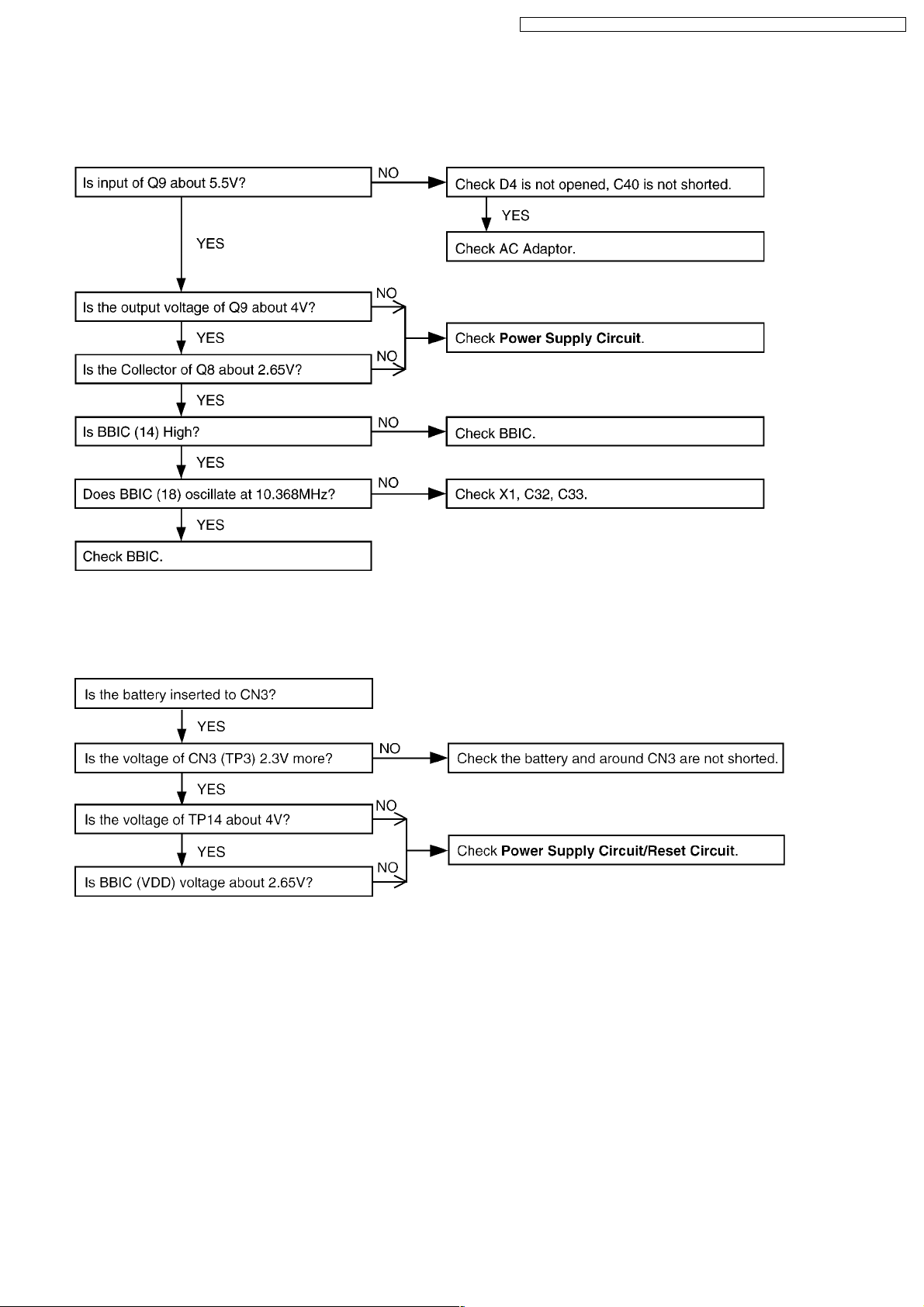

7.1. Check Power

7.1.1. Base Unit

Is the AC Adaptor inserted into AC outlet? (Check AC Adaptor’s specification.)

Cross Reference

Power Supply Circuit (P.41)

7.1.2. Handset

Cross Reference

Power Supply Circuit/Reset Circuit (P.44)

Note:

BBIC is IC2.

Note:

BBIC is IC1.

17

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

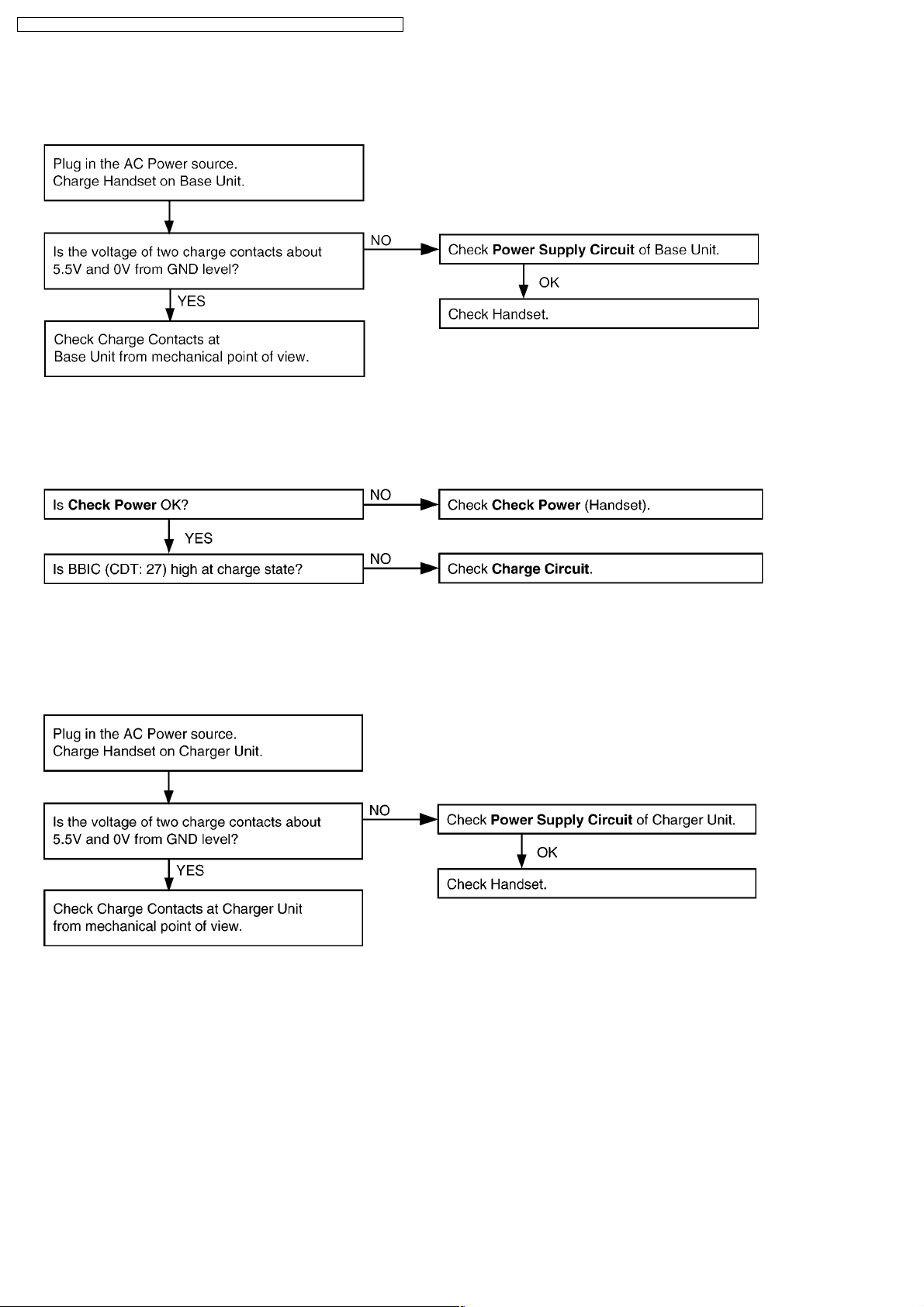

7.2. Check Battery Charge

7.2.1. Base Unit

Cross Reference:

Power Supply Circuit (P.41)

7.2.2. Handset

Cross Reference:

Check Power (P.17)

Charge Circuit (P.44)

7.2.3. Charger Unit

Cross Reference:

Power Supply Circuit (P.45)

Note:

BBIC is IC1.

18

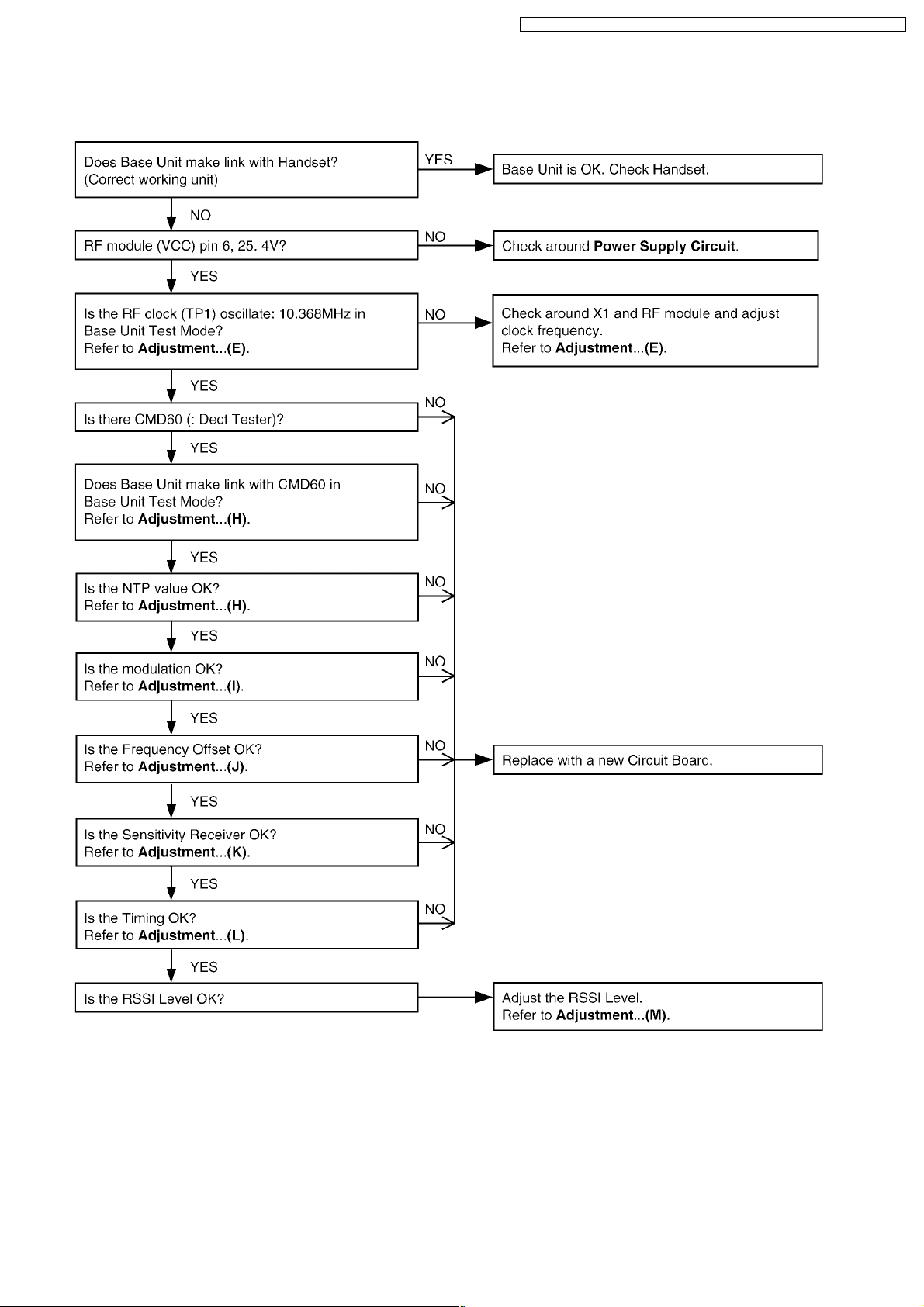

7.3. Check Link

7.3.1. Base Unit

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

Cross Reference:

Power Supply Circuit (P.41)

Check Point (Base Unit) (P.23)

19

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

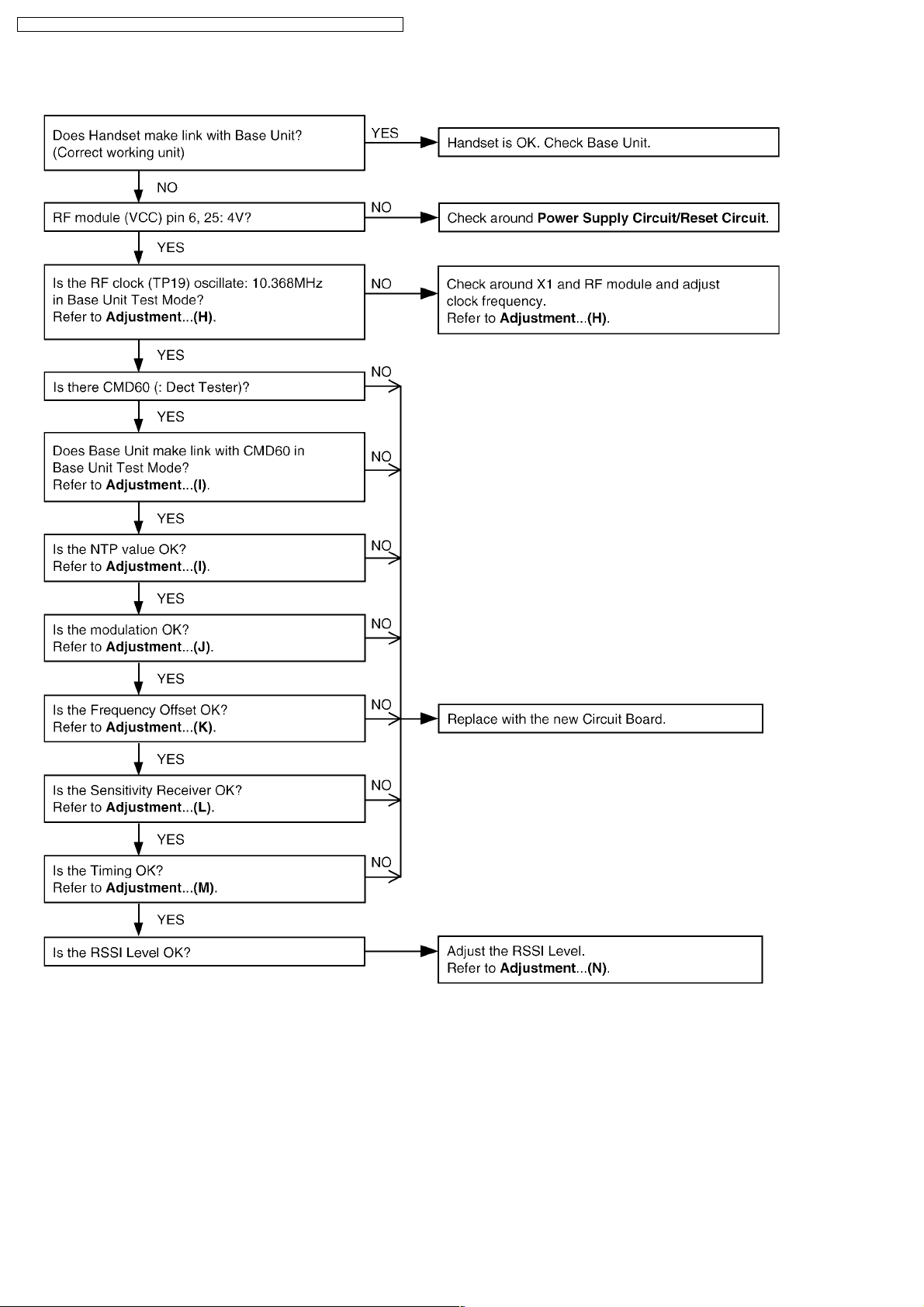

7.3.2. Handset

Cross Reference

Power Supply Circuit/Reset Circuit (P.44)

Check Point (Handset) (P.31)

20

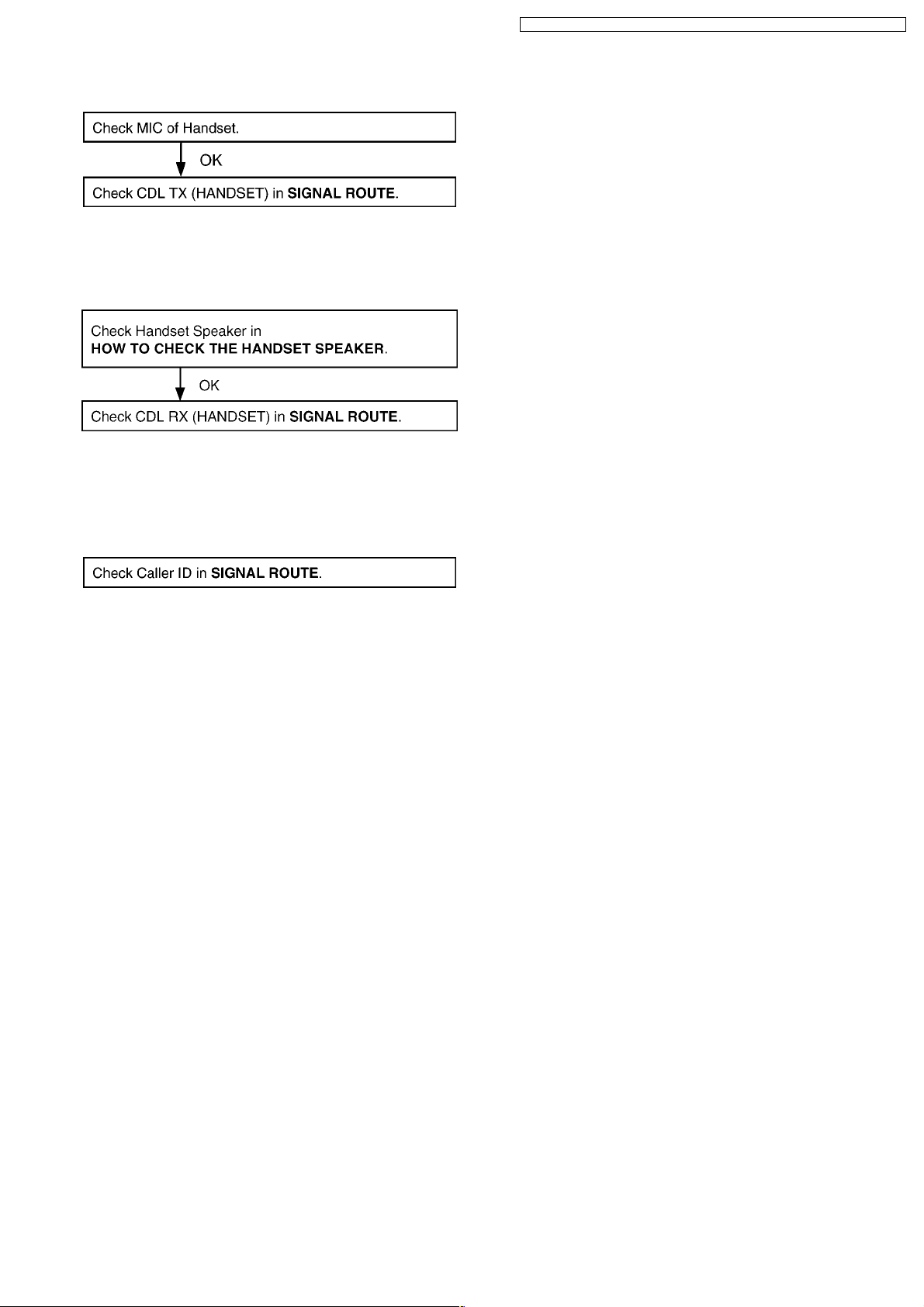

7.4. Check Handset Transmission

Cross Reference:

SIGNAL ROUTE (P.46)

7.5. Check Handset Reception

Cross Reference:

HOW TO CHECK THE HANDSET SPEAKER (P.37).

SIGNAL ROUTE (P.46)

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

7.6. Check Caller ID

Cross Reference:

SIGNAL ROUTE (P.46)

21

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

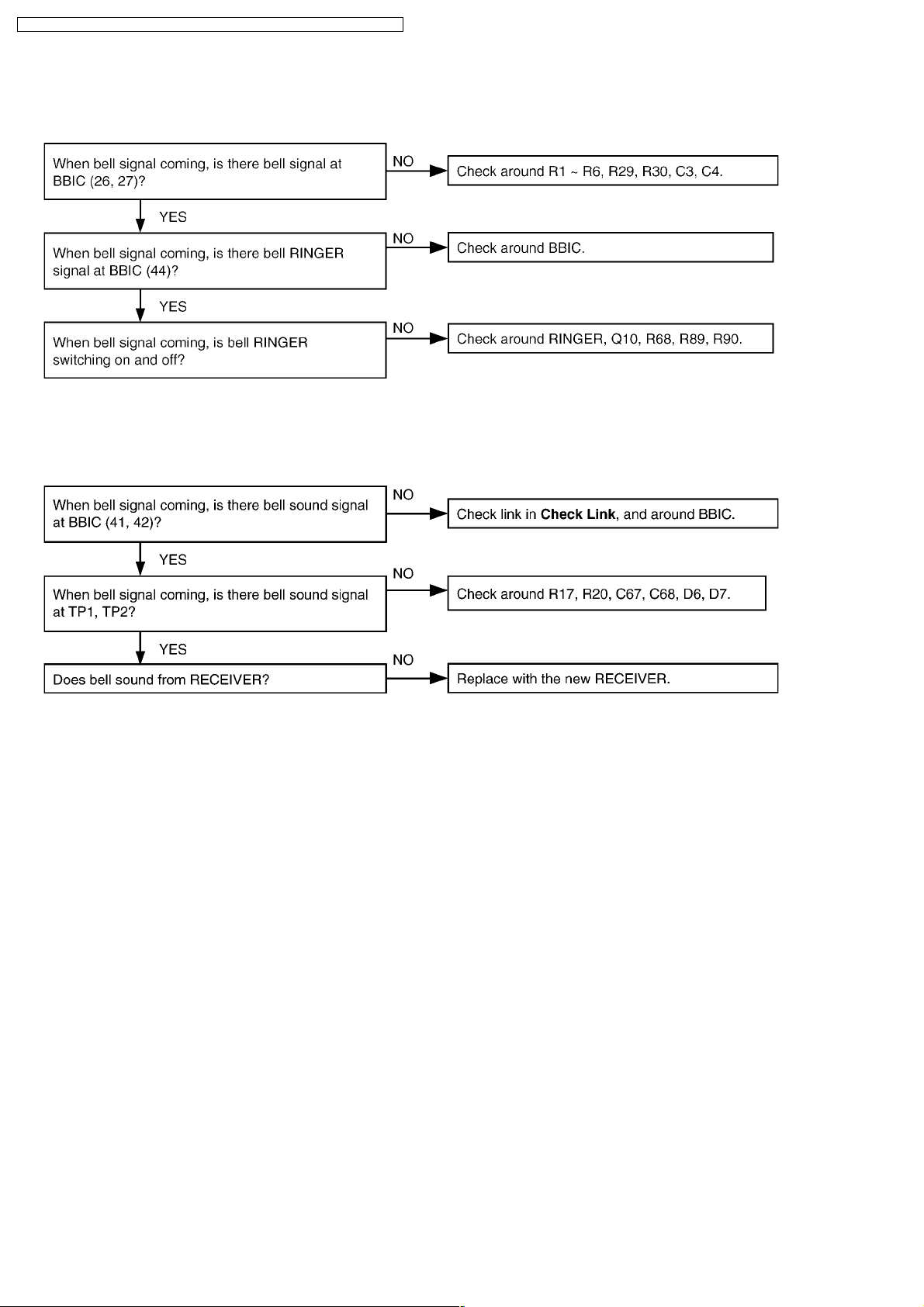

7.7. Bell Reception

7.7.1. Base Unit

Note:

BBIC is IC2.

7.7.2. Handset

Cross Reference:

Telephone Line Interface (P.42)

Check Link (P.19)

Note:

BBIC is IC1.

22

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

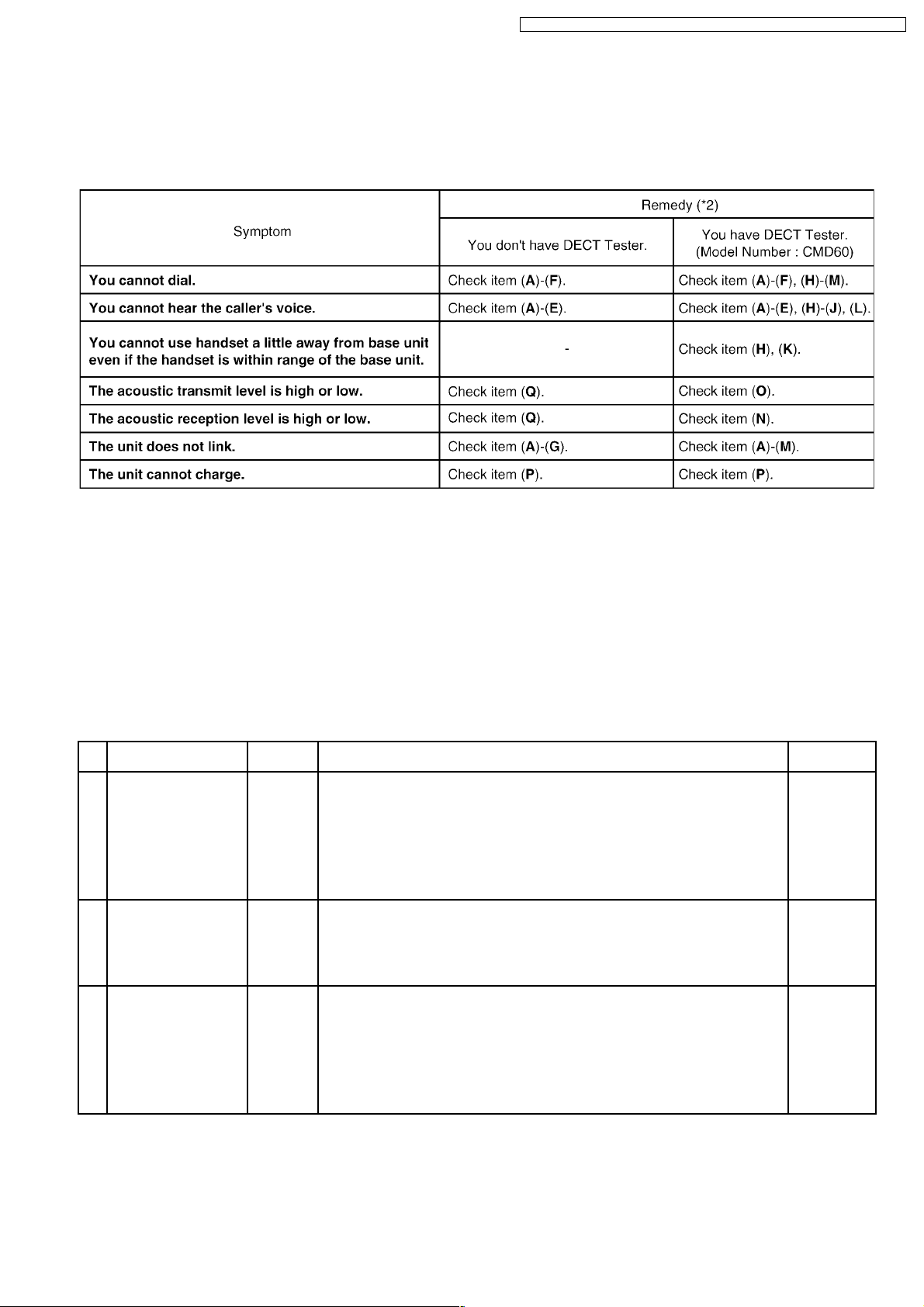

8 TROUBLESHOOTING BY SYMPTOM (BASE UNIT AND

CHARGER UNIT)

If your unit has below symptoms, follow the instructions in remedy column. Remedies depend on whether you have DECT

tester (*1) or not.

Note:

(*1) A general repair is possible even if you don’t have the DECT tester because it is for confirming the levels, such as

Acoustic level in detail.

(*2) Refer to Check Point (Base Unit) (P.23)

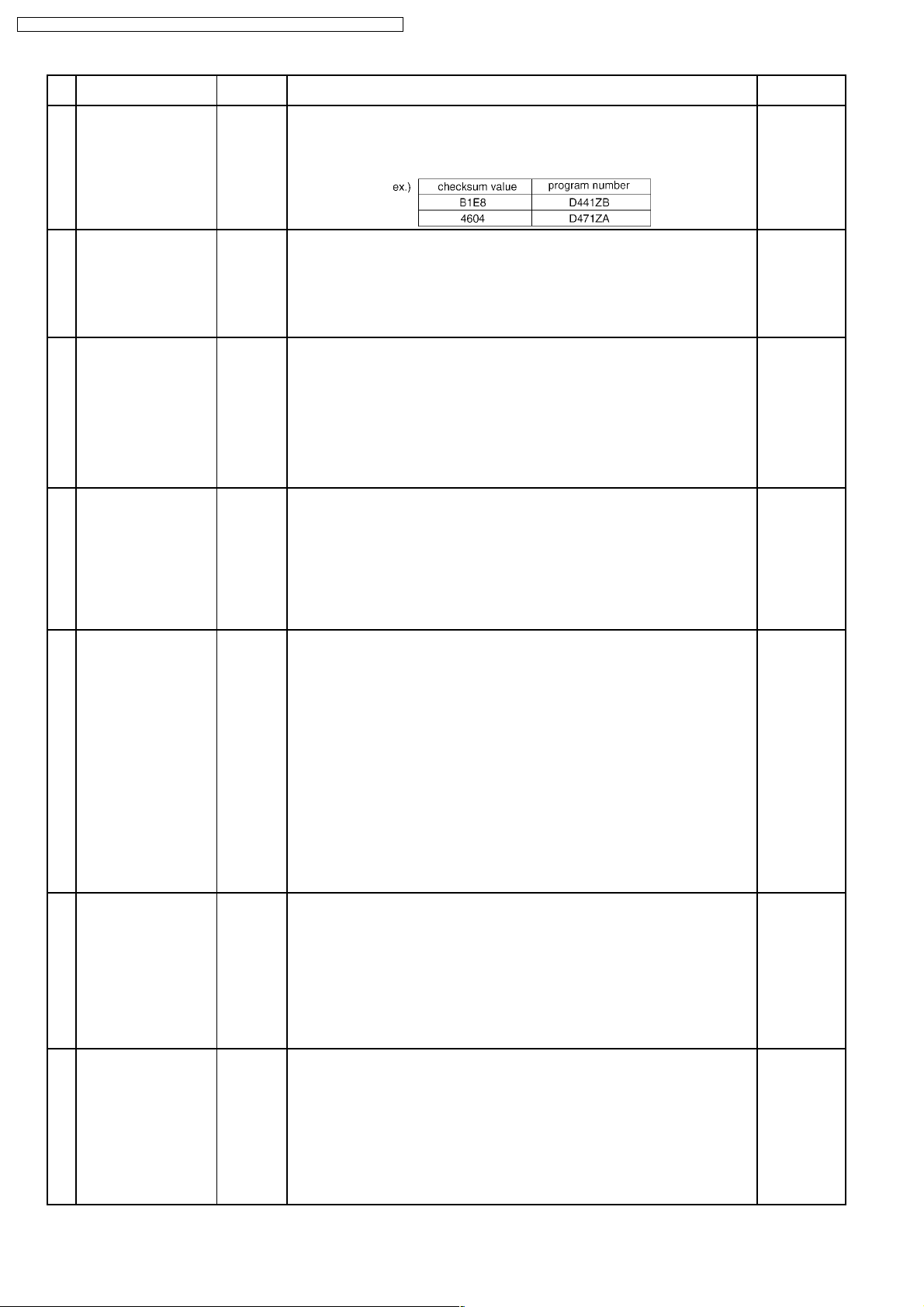

8.1. Check Point (Base Unit)

Please follow the items below when BBIC or EEPROM is replaced.

Note:

After the measuring, sock up the solder of TP.

*: PC Setting (P.27) is required beforehand.

The connections of simulator equipments are as shown in Adjustment Standard (Base Unit) (P.28).

Items Adjustment

(A) 2.65V Supply

Confirmation

(B) 4.0V Supply

Confirmation

(C) VBACK Status

Confirmation

Point

- 1. Confirm that the voltage between TP187 and GND is 2.65V ± 0.2V. IC2,Q8,C23,

- 1. Confirm that the voltage between TP91 and GND is 4.0V ± 0.2V. D4,C40,Q9,

- 1. Confirm that the voltage between J102 and GND is 0V ± 0.4V. IC2,Q8,C23,

Procedure Check or

Replace Parts

C24,C25,

C26,C27,C38,

R33,R36,

D5,C41,R41,

R42,Q9,

C40,D4,X1,

C32,C33,

C36,C37

R41,R42,

C41,D5,C75,

C78,C69,

C66,C67,C76,

IC3

C24,C25,

C26,C27,C38,

R33,R36,

D5,C41,R41,

R42,Q9,

C40,D4,R33,

X1,C32,

C33

23

KX-TCD150FXB / KX-TCD150FXC / KX-TCD152FXB / KX-TCA115EXB / KX-TCA115EXC

Items Adjustment

Procedure Check or

Point

(D)* BBIC Confirmation - 1. BBIC Confirmation (Execute the command “getchk”).

2. Confirm the returned checksum value.

Connection of checksum value and program number is shown below.

(E)* BBIC Clock Adjustment

(Important)

TP1 1. Execute the command “deactmac”.

2. Execute the command “conttx”.

3. Input Command “rdeeprom 00 00 02”, then you can confirm the current value.

4. Adjust the frequency of TP1 executing the command “setfreq 00 xx (where xx

is the value)” so that the reading of the frequency counter is 10.368000MHz ±

10Hz.

(F)* Hookswitch Check with

DC Characteristics

- 1. Connect J1 (Telephone Socket) to Tel-simulator which is connected with 600

Ω.

2. Set line voltage to 48V at on-hook condition and line current to 40mA at offhook condition of normal telephone.

3. Execute the command “hookoff”

4. Confirm that the line current is 40mA ± 5mA.

5. Execute the command “hookon”.

6. Confirm that the line current is 0mA + 2mA.

(G)* DTMF Generator

Confirmation

- 1. Connect J1 (Telephone Socket) to DTMF tester.

2. Execute the command “hookoff” and “dtmf_up”.

3. Confirm that the high frequency (1477.06Hz) group is -6.5dBm ~ -9.5dBm.

4. Execute the command “dtmf_lo”.

5. Confirm that the low frequency (852.05Hz) group is -9.0dBm ~ -12.0dBm.

(H)* Transmitted Power

Confirmation

- Remove the Antenna before starting steps from 1 to 5.

1. Configure the DECT tester (CMD60) as follows;

<Setting>

· Short TP10 and GND

· Test mode: FP

· Traffic Channel: 5

· Traffic Slot: 4

· Mode: Loopback

· PMID: 00000

2. Execute the command “testmode”.

3. Initiate connection from DECT tester. (“set up connect”)

4. Execute the command “ANT 1”.

5. Confirm that the NTP value at ANT is 20dBm ~ 25dBm.

(I) Modulation Check and

Adjustment

ANT Follow steps 1 to 3 of (H) above.

4. Confirm that the B-Field Modulation is 340kHz/div ~ 402kHz/div using data

type Fig31.

5. Adjust the B-Field Modulation if required. (Execute the command “readmod”

and “wrtmod xx”, where xx is the value.)

(J) Frequency Offset

Confirmation

- Follow steps 1 to 3 of (H) above.

4. Confirm that the frequency offset is -50kHz ~ +50kHz.

Replace Parts

IC2,X1,C32,

C33

IC2,IC3,L1,

C48,X1,C32,

C33

IC2,R7,R8,

R9,R10,R77,

Q2,Q3,D2,

C1,C2

IC2,R32,C22,

R23,C80,

C14,C13,Q6,

R22,R21,

R19,R20,C12,

D2,C1,

C2,R77,D3,

R12,Q2,

R7,R8,R9,

R10,Q3

IC2,IC3,L1,

C43,C78,

C75,C69,C48,

C72,C66,

C67,C76,C57,

C73,L3,

DA1,R66,R67,

C55,C56,

R78,R79,C54,

C58,C86,

R38

IC2,IC3,L1,

C43,C78,

C75,C69,C48,

C72,C66,

C67,C76,C57,

C73,L3,

DA1,R66,R67,

C55,C56,

R78,R79,C54,

C58,C86,

R38

IC2,IC3,L1,

C43,C78,

C75,C69,C48,

C72,C66,

C67,C76,C57,

C73,L3,

DA1,R66,R67,

C55,C56,

R78,R79,C54,

C58,C86,

R38

24

Loading...

Loading...