Panasonic KX-F900 Owner’s Manual

OHUEHNO.KM[9610089C1

Service Manual

and Technical Guide

900MHz CORDLESS FAX

KX-F900

(for U.S.A.)

,_ WARNING

] his service inlormation is designed for experienced repair technicians only and _snot designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians.

Any attempt to service or repair the product or products dealt with in this service information by anyone else could result in serious

injury or death.

Panasonic

I (_)1996 Kyushu Matsushita Electric Co., Ltd.All rights reserved. Unauthorized copying and distribution is a violation of law.

i

KX-F900

I

When you mention the serial number, write down the 11 digits. The serial number may be found on the bottom of the unit.

...... j

TABLE OF CONTENTS

Page

INTRODUCTION

SAFETY PRECAUTIONS ....................................................................................................................................... 5

INSULATION RESISTANCE TEST ........................................................................................................................ 5

FOR SERVICE TECHNICIANS .............................................................................................................................. 5

BATTERY CAUTION .............................................................................................................................................. 6

AC CAUTION .......................................................................................................................................................... 6

STANDARD BATTERY LIFE .................................................................................................................................. 7

PERSONAL SAFETY PRECAUTIONS .................................................................................................................. 7

SPECIFICATIONS .................................................................................................................................................. 8

OPTIONAL ACCESSORIES .................................................................................................................................. 8

LOCATION OF CONTROLS .................................................................................................................................. 9

FEATURES ........................................................................................................................................................... 10

CONNECTION ...................................................................................................................................................... 11

INSTALLATION .............................................................................................................................................. 12, 13

COMPONENT LOCATIONS ................................................................................................................................. 14

MAINTENANCE ITEM .................................................................................................................................... 14, 15

CLEANING THE UNIT .......................................................................................................................................... 16

TROUBLESHOOTING GUIDE

TROUBLESHOOTING SUMMARY ...................................................................................................................... 18

USER RECEIVERABLE ERRORS ....................................................................................................................... 19

DETAIL OF TROUBLESHOOTING ................................................................................................................ 20~91

PROGRAMMING AND LISTS ........................................................................................................................ 92~97

TEST FUNCTIONS ......................................................................................................................................... 97, 98

ADJUSTMENT

TABLE OF TEST EQUIPMENTS AND TOOL ................................................................................................... 100

ADJUSTING THE FEEDER PRESURE ............................................................................................................. 101

CONFIRMATION OF SEPARATION SPRING ................................................................................................... 101

CCD ADJUSTMENTS ................................................................................................................................ 102-104

DOCUMENT READ START POSITION ADJUSTMENT ............................................................................ 104, 105

CORDLESS ADJUSTMENT ....................................................................................................................... 107-113

DISASSEMBLY INSTRUCTIONS

DISASSEMBLY INSTRUCTIONS .............................................................................................................. 115-125

HOW TO REPLACE FLAT PACKAGE IC .......................................................................................................... 126

-2-

GIR£;UII OPI:RA]IONS

CONNECTION DIAGRAM ................................................................................................................................ 128

GENERAL BLOCK DIAGRAM ................................................................................................................... 129, 130

CONTROL SECTION ................................................................................................................................. 131~136

FACSIMILE SECTION ................................................................................................................................ 137~145

MODEM SECTION ..................................................................................................................................... 146-152

EXPLANATION OF ANALOG SECTION BLOCK DIAGRAM .................................................................... 153, 154

NCU SECTION ........................................................................................................................................... 155, 156

ITS AND MONITOR SECTION ................................................................................................................... 157, 158

TAM INTERFACE SECTION ...................................................................................................................... 159-161

OPERATION PANEL .......................................................................................................................................... 162

LCD COG TYPE ................................................................................................................................................. 163

SWITCHING POWER SUPPLY SECTION ................................................................................................ 164-166

CORDLESS SECTION ............................................................................................................................... 167-183

KX-F900

PRINTED CIRCUIT BOARD (DIGITAL BOARD) ............................................................................................... 185, 186

SCHEMATIC DIAGRAM (DIGITAL CIRCUIT) ............................................................................................................ 187

SCHEMATIC DIAGRAM (ANALOG CIRCUIT) ........................................................................................................... 188

PRINTED CIRCUIT BOARD (ANALOG BOARD) .............................................................................................. 189, 190

SCHEMATIC DIAGRAM AND PRINTED CIRCUIT BOARD (CCD) ........................................................................... 191

PRINTED CIRCUIT BOARD (SWITCHING POWER SUPPLY )................................................................................ 192

SCHEMATIC DIAGRAM (SWITCHING POWER SUPPLY CIRCUIT) ....................................................................... 193

PRINTED CIRCUIT BOARD (OPERATION PANEL) ................................................................................................. 194

SCHEMATIC DIAGRAM (OPERATION PANEL CIRCUIT) ........................................................................................ 195

PRINTED CIRCUIT BOARD (CORDLESS BASE UNIT) ........................................................................................... 196

SCHEMATIC DIAGRAM (CORDLESS BASE UNIT) ................................................................................................. 197

PRINTED CIRCUIT BOARD (RF UNIT) ..................................................................................................................... 198

SCHEMATIC DIAGRAM (RF UNIT) ........................................................................................................................... 199

PRINTED CIRCUIT BOARD (PORTABLE HANDSET) .............................................................................................. 200

SCHEMATIC DIAGRAM (PORTABLE HANDSET) .................................................................................................... 201

SCHEMATIC DIAGRAM AND PRINTED CIRCUIT BOARD (CHARGE) ................................................................... 202

_ERMINAL GUIDE OF IC'S, TRANSISTORS AND DIOE)ES ............................................................................ 203, 2o4

TOOLS ......................................................................................................................................................................

CABINET, MECHANICAL AND ELECTRICAL PARTS LOCATION .................................................................. 206~211

ACCESSORIES AND PACKING MATERIALS ..........................................................................................................

REPLACEMENT PARTS LIST ........................................................................................... 213~230

205

212

-3-

KX-F900

INTRODUCTION

Hay_

Safety Precautions ............................................................................ 5

Insulation Resistance Test ........................................................................ 5

For Service Technicians ........................................................................... 5

Batten] Caution ......................................................................................... 6

AC Caution ............................................................................................... 6

Standard Battery Life ................................................................................ 7

Personal Safety Precautions ..................................................................... 7

Specifications ............................................................................................ 8

Optional Accessories ................................................................................ 8

Location of Controls .................................................................................. 9

Features .................................................................................................. 10

Connection .............................................................................................. 11

Installation ......................................................................................... 12, 13

Component Locations ............................................................................. 14

Maintenance Item ............................................................................. 14, 15

Cleaning the Unit .................................................................................... 16

4

KX-F900

SAFETY PRECAUTIONS

1. Before servicing, u_plugthe power cord to prevent an electric shock.

2. When replacing pads, use only the manufacturer's recommended components.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, _hields, etc.

5. Before returning the serviced equipment to the customer, be sure to perform the following insulation resistance

test to prevent the customer from being exposed to shock hazards.

INSULATION RESISTANCE TEST

1. Unplug the power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with an ohmmeter between the jumpered AC plug and each exposed metal cabinet part

(screwheads, control shafts, handle brackets, etc.).

"Note: Some exposed parts may be isolated from the chassis by design. These will read infinity.

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard.

The equipment should be repaired and rechecked before it is returned to the customer.

n

z

-I

3o

0

CJ

c

0

-i

0

z

Exposed --

metal

part

Ohmmeter

Resistance = more than1MQ

(at DC 500 V)

FOR SERVICE TECHNICIANS

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1) Cover the plastic parts boxes with aluminum foil.

2) Ground the soldering irons.

3) Use a conductive mat on the worktable.

4) Do not touch IC or LSI pins with bare fingers.

-5-

KX-F900

BATTERY CAUTION

CAUTION

Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type recommended by the

manufacture. Discard used batteries according to following caution:

Disposal of lithium batteries should be performed by permitted, professional disposal firms knowledgeable in state govern-

ment federal and local hazardous materials and hazardous waste transportation and disposal requirements.

Battery continues to have no transportation limitations as long as they are separated to prevent short circuits and packed

in strong packaging.

Commercial firms that dispose of any quantity of lithium cells should have a mechanism in place to account for their ulti-

mate disposition. This is a good practice for all types of commercial or industrial waste.

Recommend Type Number: CR2032 (BATT)

CR2032 (BATT)

Manufactured by MATSUSHITA

Manufactured by SONY

AC CAUTION

For safety, before closing the lower cabinet, please make sure of the following precautions.

(_ The earth lead is fixed by the screw.

(_) The AC connector is connected properly.

(_) Wrap the AC lead around the core 3 times.

(BOTTOM VIEW)

Earth Lead

AC Inlet

(Ferrite Core)

Earth Lead

/

I

AC

AC Connector

O o

Screw

Earth

Lead

STANDARD BATTERY LIFE

If your Panason_c battery is fully charged;

KX-F900 -_

m

z

.-I

:;o

O

While in use (,TALK) Up to about 4.5 hours

While not in use (Stand-By) Up to about 14 days

• Battery life may vary depending on usage conditions and ambient temperature.

• Clean the handset and the main unit charge contacts with a dry soft cloth once a

month, or the battery may not charge properly.

• Once the battery is fully charged, you do not have to place the handset on the main unit until

the TALK/BATT LOW indicator flashes slowly.

• The battery cannot be overcharged.

PERSONAL SAFETY PRECAUTIONS

Be careful not to let your hair, clothes fingers, accessories, etc., become caught in any moving sections of the unit.

These are driven by the carriage monitor, and the slow down gear, the paper feed roller, the pressure roller, the eject roller,

the spur, the pick-up roller, etc., which are driven by the paper feed motor. These separation roller and document feed roller

which are rotated by the document feed motor and a gear which makes the two rollers rotate.

Also, the spurs are metal and sharply pointed. Be careful not to touch them accidentally by hand.

O

B

O

z

Document rollers

roller gear

)aration roller gear

feedgear

KX-F900

• Main unit

1. Applicable Lines:

2. Document Size:

3. Effective Scanning Width:

4. Printing Paper Size:

5. Effective Printing Width:

6. Transmission Time*:

7, Scanning Density:

8. Halftone Level:

9. Scanner Type:

10. Printer Type:

11, Data Compression System:

12. Modem Speed:

13. Operating Environment:

14. Dimensions (HXWX D):

15. Mass 0Neight):

16, Power Consumption:

17. Power Supply:

SPECIFICATIONS

Public Switched Telephone Network

Max. 216 mm (8 1/2")in width

Max. 600 mm (23 %') in length

208 mm(8 3/18')

216 mm X max. 50 m (8 1/2"X164') roll

216 mm (81/2')

Approx.15 sec/page (Original mode)

Approx.30 sec/page (G3 Normal mode)

Horizontal : 8 pels/mm (203 pels/inch)

Vertical : 3.85 lines/mm (98 lines/inch) -Standard mode

7.7 lines/mm (196 lines/inch) -Fine/Halftone mode

15.4 lines/mm (392 lines/inch) -Superfine mode

64-level

CCD image sensor

Thermal printing

Modified Huffman (MH), Modified READ (MR)

9600/7200/4800/2400 bps; Automatic Fallback

5-35°C (41-95 °F), 45-80 % RH (Relative Humidity)

Approx. 118X366X265 mm (4 21/32"X13 %' X10 7/18')

Approx. 3.4 kg (7.5 lb.)

Standby: Approx. 5W / Transmission: Approx. 15W

Reception: Approx. 35W / Copy: Approx. 40W

Maximum: Approx. 100W

120V AC, 60Hz (This unit will not function at 50 Hz.)

This specifications is for

U.S.A. version only.

Refer to the simplified manual

(cover) for other areas.

• Handset

1. Operating Environment:

2. Dimensions (HX W× D):

3. Weight:

4. Power Supply:

5. Frequency:

6. Security Codes:

*Transmission speed depends upon the contents of the pages, resolution, telephone line conditions and capability of

receiving unit. 15 second speed based upon CCITT No.1 Test Chart.

.Design and specifications are subject to change without notice.

5-35°C (41-95 °F), 45-80 % RH (Relative Humidity)

Approx. 39X55X271 mm (1 17/32"X2 3/32'X10 11/16')

Approx. 200 g (0.4 lb.)

Ni-Cd battery (3.6 V, 600 mAh)

902-904 MHz, 926-928 MHz (30 channels)

1,000,000

OPTIONAL ACCESSORIES

Parts No. Description Comment

KX-A106 Standard Thermal Recording Paper 216 mm X 30 m (8 1/2"X98') roll,

KX-A116 Standard Thermal Recording Paper 216 mm X 50 m (8 1/2"X164') roll,

Super Thermal recording Paper 216 mm X30 m (8 1/2"X98') roll,

KX-A125 (Like plain paper) with 25 mm (1") core

with 25 mm (1") core

with 25 mm (1") core

8

Front view

LOCAl ION OF CON]-ROLS

uattery charger

(beneath the cover)

Spare battery

cover

-- Antenna

Document entrance

KX-F900 I

Paper stacker

-- Document feeder tray

Document guide(s)

i

Z

.-I

0

O

C

0

.-I

0

Z

SPARE CHARGE Indicator

Cont;rol panel

Microphone

CHARGE Indicator

Front lid open button

Document exit

Dial keypad HELP Display panel RESOLUTION

DIRECTORY MENU Direct call stations LOWER

I ......... , III _1# _e"_ll RESOW1,ON..!I'_9 _0 ' - I

I (Z)(D(]DiI_ -__ _ °'1 I_--_--'=' I

I,.4-_@@,_L_____ _ t___

..-iv ;__. __ _;\ \ ", j _ _T*,T,ooP_,r_ I

®( ))

Y -I ! t I -1

FLASH MUTE AUTO RECEIVE VOLUME |

STOP

TONE REDIAL/PAUSE SP-PHQNE

LOCATOR/INTERCOM

IN USE indicator

-9-

START/COPY/SET

Handset

An_ena

INTERCOM indicator

TALK/BAT1 (Battery)

LOW indicator

TALK

TONE

PROGRAM

REDIAL/PAUSE _

General

• Automatic paper cutter

• Answering machine interface

• 64-Level halftones resolution

• Large 165 ft. paper roll

• Help printout

Facsimile

• Easy-to view LCD (16-character)

• Automatic document feeder (up to 15sheets)

• Paper curl reduction technology

• Resolution: Standard/Fine/Super Fine/Half Tone

• Distinctive ring detection

• Super thermal paper

• Correct order reception printout

FEATURES

900MHz Cordless

• Fax activation from handset

• Intercom with 2-way paging

• Lighted keypad

• 14-day battery life

• Sound ChargeF _ technology

• lO-station speed dial

• Spare battery charger

Integrated TelephoneSystem

• Speakerphone

• Telephone directory with alpha-search

• One touch dialer (10 phone-number)

• 50-station speed dialer

-10-

Connect to

"LINE".

CONNEGIION

KX-F900

I

z

--I

30

O

c

m

O

z

Dialing mode switch:

Set to TONE.

• If you cannot dial,

setto PULSE.

Telephone line

cord

Single telephone line

(RJ11 C)

Line-surge

protector )

Power surge_

protector )

Note:

• For additional equipment protection, we recommend the use ofa surge protector. The following types are

available; TELESPIKE BLOK MODEL TSB (TRIPPE MFG. CO.), SPIKE BLOK MODEL SK6-0 (TRIPPE MFG.

CO.), SUPER MAX (PANAMAX) or MP1 (ITW LINX).

• You can connect an extension phone or a telephone answering machine to the unit after removing the stopper on the

external telephone jack (EXT).

• When you operate this product, the power outlet should be near the product and easily accessible.

DIALING MODE

TONE JLPULSE

Power outlet_ _ (120 V, 60 Hz)

NIelpful hint:

If assistance is needed, press _. The unit will print a quick reference.

l

-11 -

KX-F900

I

1. Installing the recording paper

(_) Open the back lid by lifting up the tabs located -

on the both sides, b

(_) Install a recording paper roll in the main unit.

• Make sure that the shiny side of the paper is

facing down and there is no stack, tape, or

glue residue on the paper roll.

correct incorrect

INSTALLATION

,,,,..,....

2

3

Insert the leading edge of the recording paper

between the recording paper roller and the silver

plate.

Closethe backlid by gently pressing down on both

ends.

Note:

• Only use the included roll of paper orspecified recording paper, or else the print quality may be affected

and/or excessive thermal head wear may occur.

• The beginning of some recording paper rollsare secured with glue or tape.

Cut approximately 150 mm (6 inches) from the new roll of paper prior to installation.

Recording paper roller

plate

2. Installing the paper stacker

Install the paper stacker.

-12-

3. InslailirJg [ne _pa_u battery cover on the main unit

Close the spare battery cover.

4. Installing the battery in the handset

Spare battery cover

J

KX-F900 1

I

I u

z

-I

:o

0

c

0

-I

O

z

1

2

Install the battery as shown observing the

proper polarity.

Install the battery cover.

Battery

Battery cover

i3

I KX'FgO0 I

Document ........

Feed Roller

COMPONENT LOCATIONS

Recording Paper Cover

-- Separation Roller

Motor

_rmal Head

Target Glass

Document --

Feed Roller

Mirr

LED Array

Transmission Motor

MAINTENANCE ITEM

1. OUTLINE

MAINTENANCE AND REPAIRS ARE PERFORMED USING THE FOLLOWING STEPS.

Recording Paper Roller

Cutter

Reception Motor

1) Periodic maintenance

Inspect the equipment periodically and if necessary, clean any contaminated parts.

2) Check for breakdowns

Look for signs of trouble and consider how the problems arose.

If the equipment can still be used, perform copying, self-testing or communications testing.

3) Check equipment

Perform copying, self testing and communications testing to determine if the problem originates from the transmitter,

receiver or the telephone line.

4) Determine causes

Determine the causes of the equipment trouble by troubleshooting.

5) Equipment repairs

Repair or replace the defectiveparts andtake appropriate measures at thisstage toensure thatthe problem doesnot recur.

6) Confirm normal operation of the equipment

After completing the repairs, conduct copying, self testing and communications testing to confirm that the equipment operates

normally.

7)

Record keeping

Make a record of the measures taken to rectify the problem for future reference.

-14-

2-1. MAINTENANCE LIST

NO. OPERATION

1 Document Path

2 Rollers

Recording Paper

3

Roller

4 Thermal Head See page 123.

5 LED Array See page 16.

6 Sensors See pages 77, 78.

7 Mirrors and Lens

8 Abnormal, wear and

tear or loose parts

Remove any foreign matter such as scrap of paper.

If a roller is dirty, clean it with a damp cloth, then let dry thoroughly.

If the platen is dirty, clean it with a damp cloth, then let dry thoroughly.

Remove the paper before cleaning.

If the thermal head is dirty, clean the printing surface with a cloth

moistened with denatured alcohol (alcohol without water), then let dry

thoroughly.

If the LED array is dirty, clean the glass with a dry soft cloth.

Confirm the operation of the following sensors: recording paper sensor

(SW273), Document sensor (Pi302), Read position sensor (PI301),

Cover open sensor (SW271), and JAM sensor (SW272).

If the mirror and lens are dirty, clean them with a dry soft cloth.

Replace the part. Be sure that all part's screws are tight.

CHECK ITEM

REMARKS

See page 16.

See page121.

m

z

30

0

D

c

0

0

z

2-2. MAINTENANCE CYCLE

No. Items

Separation Roller

1 3 months See P. 16.

(Ref. No. 58)

Separation Rubber

2

(Ref. No. 23)

Feed Roller

(Ref. No. 49, 53)

Target Glass

(Ref. No. 171)

Thermal Head

(Ref. No. 59)

Recording Paper Roller

(Ref. No. 112)

3 months

3 months

3 months

3 months

3 months

Cleaning

Cycle Procedure

See P. 16.

See P. 16.

See P. 123.

See P. 121.

Replacement

Cycle Procedure

7 years See page 120.

(63,000 documents)

7 years

(63,000 documents)

7 years See page 120.

(63,000 documents)

7 years

(63,000 documents)

7 years See page 123.

(63,000 documents)

7 years See page 121.

(63,000 documents)

These values are only standard ones and may vary depending on

usage conditions.

Remarks

--15--

KX-Fg00

CLEANING THE UNIT

Cleaning the inside of the unit

If misfeeding occursfrequently, or dirty patterns or black bands appear on a copied or transmitteddocument, clean

the document feeder rollers, sub roller, rubber flap, white plate and glass.

Disconnect the power cord and the telephone line

1

cord.

Open the front lid by pressing the front lid open

2

button.

Clean the document feeder rollers and roller with a

3

cloth moistened with isopropyl rubbing alcohol, and

let dry thoroughly.

Clean the rubber flap with a cotton swab moistened

4

with isopropyl rubbing alcohol, and let dry

thoroughly.

5

7

Clean the white plate and glass with a soft dry

cloth.

Clean the front lid by gently pressing down on both

6

ends.

Connectthe power cord and the telephone line

cord.

Caution:

• Do not use paper products (such as paper towels or

tissues) to clean the inside of the unit.

Rubber fla

Sub Roller

\

Front lid open button

White plate

Document

feeder rollers

Cleaning the charge contacts

Clean the main unit and the handset charge contacts with a dry soft cloth once a month, orthe battery may not

charge properly.

Charge contacts

Charge contacts

--16--

TROUBLESHOOTING GUIDE

Page

1. Troubleshooting Summary ..................................................................... 18

1-1. Troubleshooting ..................................................................... 18

1-2. Precautions ............................................................................ 18

2. User Recoverable Errors ....................................................................... 19

KX-F900

,-I

O

I-

Ill

,1-

O

O

,,-I

Z

Q

3. Detail of Troubleshooting ................................................................. 20~91

3-1. Outline .................................................................................... 20

3-2. Starting up troubleshooting ................................................... 20

3-3. Table of troubleshooting items .............................................. 21

3-4. Easy-check-list ....................................................................... 22

3-5. ADF section ...................................................................... 23-32

3-6. Communication section ................................................... 33-53

3-7. Digital board section ........................................................ 54-67

3-8. Analog board section ...................................................... 68-71

3-9. Power supply section ...................................................... 72-75

3-10. Operation board section ......................................................... 76

3-11. Sensor section ................................................................. 77, 78

3-12. Read section .................................................................... 79-83

3-13. Thermal head section ............................................................. 84

3-14. Cordless section .............................................................. 85~91

4. Programming and Lists .................................................................... 92-97

Ill

5. Test Functions ................................................................................. 97, 98

17-

I KX-F900

1. TROUBLESHOOTING SUMMARY

1-1. TROUBLESHOOTING

After having confirmed the abnormal condition by askingthe user, troubleshootaccording to th_ ,_L_U_;L_,,._In

Observe thefollowing precautionswhentroubleshooting.

1-2. PRECAUTIONS

1) If there is trouble with the print quality or the paper feed, first check that the installation space and the print

paper meets the specifications, that the paper selection lever/paper thickness lever is set correctly, and that the

paper is set correctly without any looseness.

2) Before troubleshooting, first check that the connectors and cables are connected correctly without any looseness.

Especially, if the abnormality occurs randomly, check very carefully.

3) When connecting the AC power cord with the unit case and checking the operation, exercise utmost care in

handling the electric parts in order to avoid electric shock and short-circuits.

4) After troubleshooting, double check that you have not forgotten any connectors, left any loose screws, etc.

5) And always test to verify that the unit is working normally.

18-

2. USER RECOVERABLE ERRORS

If the unit detects a problem, the following messages will app_af in the display.

KX-F900 I

DISPLAY MESSAGE

:ICALL SERvIcE I

I CHECK COVER I

CHECK DOCUMENT [

CHECK MEMORY

NO RESPONSE

OUT OF PAPER

PAPER JAMMED

POLLING ERROR

REDIAL TIME OUT

REMOVE DOCUMENT

CAUSE AND REMEDY

• There is something wrong with the unit.

• The back lid is open. Close it.

• The document is not fed into the unit properly. Reinsert the document.

If the misfeeding occurs frequently, clean the document feeder rollers inside the unit.

If the problem remains, adjust the feeder pressure,

• Memory (phone numbers, parameters, etc.) has been erased. Re-program.

J

• The receiving unit is busy or ran out of recording paper. Try again.

I

• The unit ran out of recording paper. Install a new recording paper.

• A recording paper jam occurred. Clean the jammed paper.

I

• The other fax machine does not provide the polling function. Check with the other

I

party.

• The receiving unit is busy or ran out of recording paper. Try again.

l

• The document is jammed. Remove the jammed document.

I

• Attempted to transmit a document longer than 600 mm (23%"). Press the STOP button

and remove the document. Divide the document into two or more sheets and try again.

-I

O

(=

Im

r-

I1"1

"r

O

O

.-.I

z

¢)

&')

c

Ill

TRANSMIT ERROR

UNIT OVERHEATED

• A transmission error occurred. Try again.

I

• The unit is too hot. Let the unit cool down.

I

-19-

KX-F900

i

3. DETAIL OF TROUBLESHOOTING

3-1. OUTLINE

Troubleshooting is to make quality and reliability recover by finding out the broken component and exchange or

adjustment or cleaning. We have to find out symptoms and then arrange troubleshooting method.

If it's tough to finding out just a broken component, we should so arrange that block or section are specified, for

example "digital board" or image sensor".

A claim tag from customer or dealer gives us many kinds of expression for same trouble. Because they are not

technician or engineer. But we should carefully read it on our supposition comes from experience, and sufficiently

test the function related to that tag. Returns from customer or dealers often have to claim tag. In this case we need

to find out the symptoms. Therefore please test the unit following simple-check-list. A problem difficult to find out

may lurk, so we need to test repeatedly, for example make copy 10 pages or receiving 10 pages ..........

3-2. STARTING UP TROUBLESHOOTING

• Find out the symptom and troubleshooting method

Power on.

LCD IFchange faitnly

See digital board section.

(See page 54)

LCD good

I 12:00AM I

Not yet

Yes, I know

LCD

I no reaction

I

No reaction means that power line

is broken (short-circuit).

See digital board section.

(See page 54)

AC

r

Find out any symptom with

check list (See page 22).

20-

4'

See table of

troubleshooting item.

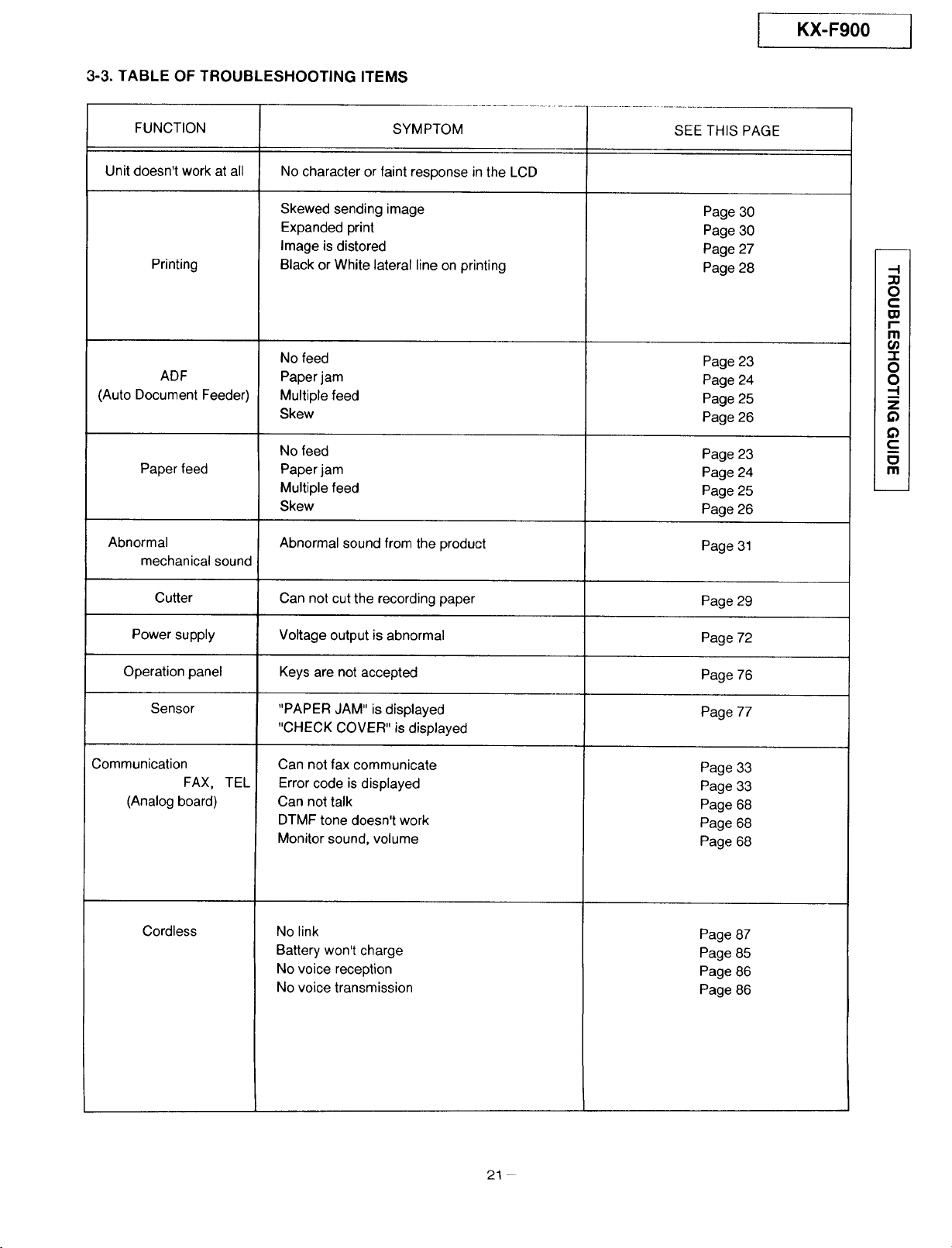

3-3. TABLE OF TROUBLESHOOTING ITEMS

FUNCTION SYMPTOM SEE THIS PAGE

Unit doesn't work at all No character or faint response in the LCD

I KX-F900 1

Printing

ADF

(Auto Document Feeder)

Paper feed

Skewed sending image

Expanded print

Image is distored

Black or White lateral line on printing

No feed

Paper jam

Multiple feed

Skew

No feed

Paper jam

Multiple feed

Skew

Page 30

Page 30

Page 27

Page 28

Page

Page

Page

Page

Page 23

Page 24

Page 25

Page 26

Abnormal Abnormal sound from the product Page 31

mechanical sound

Cutter Page 29

Power supply Page 72

Can not cut the recording paper

Voltage output is abnormal

23

24

25

26

O

c

O

O

-I

z

c

Ill

-I

r-

Ill

"1-

Operation panel Page 76

Sensor Page 77

Keys are not accepted

"PAPER JAM" is displayed

"CHECK COVER" is displayed

Communication

FAX, TEL

(Analog board)

Can not fax communicate

Error code is displayed

Can not talk

DTMF tone doesn't work

Monitor sound, volume

Cordless

No link

Battery won't charge

No voice reception

No voice transmission

Page 33

Page 33

Page 68

Page 68

Page 68

Page 87

Page 85

Page 86

Page 86

21

I....Kx-egoo

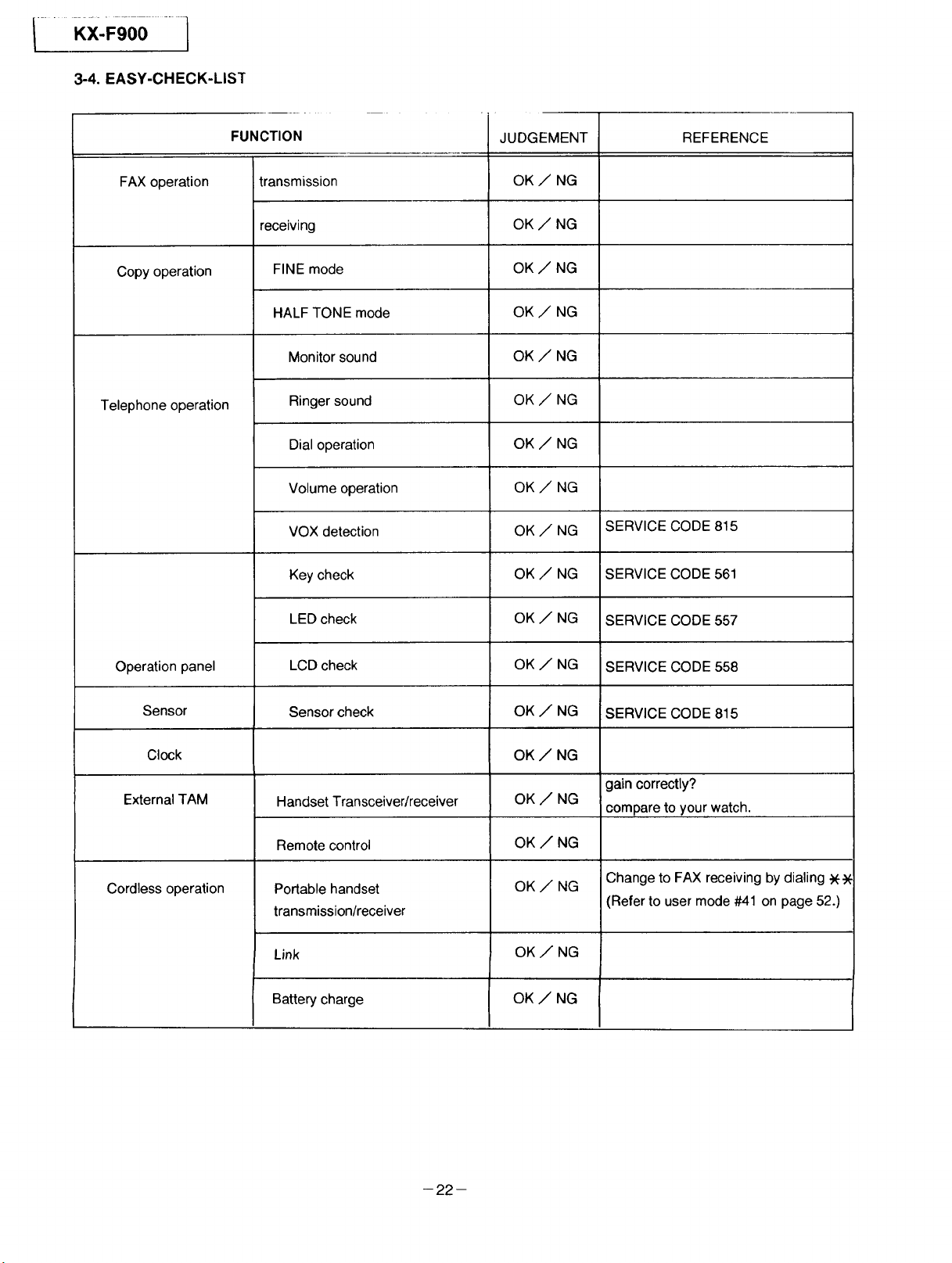

3-4. EASY-CHECK-LIST

FUNCTION

FAX operation transmission

receiving

Copy operation FINE mode

HALF TONE mode

Monitor sound

Telephone operation Ringer sound

Dial operation

Volume operation

VOX detection SERVICE CODE 815

Key check SERVICE CODE 561

REFERENCEJUDGEMENT

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

LED check SERVICE CODE 557

Operation panel LCD check SERVICE CODE 558

Sensor Sensor check SERVICE CODE 815

Clock

External TAM Handset Transceiver/receiver

Remote control

Cordless operation Portable handset Change to FAX receiving by dialing -)(-._

transmission/receiver (Refer to user mode #41 on page 52.)

Link OK J NG

Battery charge OK J NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

OK / NG

gain correctly?

compare to your watch.

-22-

3-5. ADF (Auto document feed) SECTION

(1) No document feed

In document setting, confirm

that beep tone or not.

KX-F900 I

NO

I leaning of separation roller.

( page120 )

Does the separation roller

rotate?

YES

Check the separation spring

and. pad?

_ YES

Replace the separation

roller unit.

, YES

Replace the operation cover

unit.

Check the separation

spring is distorting.

connector.

__ Check the Motor and J

NO

Check the sensor

lever movement.

Check the sensor

and digital board.

(pages 54 and 77)

OK _ END

OK

OK

END

END

_ eplace the sen- ]

sor lever.

,_ oK

Replace the defec-tive parts.

_ OK? _ Replace the motor

Check the gear.

_ Replace the gear.

YES

and connector.

-I

3o

O

c:

El

r-

m

(/)

-r

O

O

-.I

m

z

¢)

¢)

c_

m

To digital board

section. (page 54)

I Repair.

pins 73-77 of ICl out-

___ s the phase signal from

put?

NO _L

ls the solder at pins 73-

77 of IC1 OK?

I YES

l Replace IC7.

YES

of Q1 +24 V?

ls the voltage at emitter

I YES

I I Isthev°ltageatc°llect°r L--_ofQ1+24V?

No

J Is the voltage at pin 11 of J

IC7 less than 2V? [ N----O---

,_ YES

[ Replace Q1. _1

-23-

___ Check power supply

unit section. (page 72)

Replace IC7.

/, _ , I aeplaoe

/ ENDII m°t°r I

NO

OK? I

I

KX-FgO0 I

(2) Paper JAM

Check feed route. J

r

I

Checks the paper jam lu_ markings up ubjeui.s stuck on the sheet.

I

l

Cleaning the each rollers.

i

(pages 120 and 121 )

Check each sensors

movement.

I

Check each rollers

mount.

Cleaning or replace of

defective parts.

Confirms that the location tip of the read start

sensor flag works smoothly.

I

NO _! Repair or replace the

Check the separation, feed and pinch rollers are

attached correctly.

sensor lever

I

OK

OK ._

I

END

OK

To Sensor section, reacts while the flag is

(page 77) moving.

I Check il the senso_

, END

_ END

Check the white plate.

Replacethe white plate.

I

NG

NO

I

Repair defective parts.

>

-_ END

Operation-] Wh.ite Plate

cover _ OK

Document

_-'_ NG

Operation Board Cover

Fig. A

-24-

(3) Multiple feed

KX-F900 I

Check separation pad.

f

Check the separation

spring is distorting.

Cleaning the each rollers.

I

(pages 120 and 121)

1

Confirms whether the pad is dirty or not and

is attached correctly.

NO

Cleaning or replace the

defective parts.

OK

OK

rEND

._ END

OK

. END

0

c

r-

Ill

-!-

0

0

-I

z

c

m

I'll

pad, roller and pressure

l eplace the separation

spring.

25--

(3) Multiple feed

l Check separation pad. [

Confirms whether the pad is dirty or not and

is attached correctly.

NO

spring is distorting.

I heckthe separation [

1.

Cleaning the each rollers. I

(pages 120 and 121)

Replace the separation |

pad, roller and pressure

spring.

I

/

J

_1 defective parts.

Cleaning or replacethe I

OK

OK

END

,_ END

OK

• END

-26-

(4) Skew

KX-F900 1

Checks whether the document is folded or

Document setting OK?

Check feed route.

Check the balance of

both separation pressure

springs.

whether a different size document is set at

I ape or staples are attached. Also checks

the same time.

NO

Checks whether there are same foreign

objects, or missing parts.

NO

Reset document.

Cleaning or replace the

defective parts.

I Replacethe separation ]

pressure spring. I

OK

OK

OK

END

END

END

-.I

O

C

F

m

-r

O

O

.-I

z

Q

¢}

t-

Ill

Cleaning the each rollers.

(page 120 and 121)

1'

Check the white plate.

(Refer to Fig. A of page 24)

Check CCD unit.

END

NO

J

Replace white plate.

1

defective parts.

J epair or replace the

OK >END

I

I

NG-'_

OK

END

END

27

f.....KX:-F'O0.......I

(6) Black or white vertical lines appear.

I Please copy the test chart.

NO_ YES

To thermal head section.

(page 84)

Cleaning feed route.

Replace white plate,

CCD unit etc.

To digital board section.

(page 54)

Please the white plate and target glass thoroughly.

Ifthe dirt cannot be removed, change the white plate.

NO

OK

-_ END

END

28

(7) (.;an noi cu[ the recording paper.

KX-F900

Check the cutter unit. I

Check the each sensor

levers movement.

Check the each sensor.

NG

I

Cleaning the cutter unit.

(page 121)

Replace the defective

parts.

Replace the defective [

parts.

I

I

-I

0

c

r

rn

-I-

0

0

n

z

ffJ

c

i

m

Test the cutter movement. I

YES

END

Check the connector, ]

]p

gear and arm.

1

Replace the cutter unit.

I

and arm.

I

Replace the motor, gear

OK

Replace the digital board. /

29-

i ,x:FoooI

(8) Skewed sending image

Check the setting of

recording paper

OK

_v

I Replace the ]

recording paper roller.

(9) Expanded print

button locked.

Check the front lid open NG

OK

NG

Reset the recording paper.

Lock the front lid open

button.

l leaning the each rollers, j(pages 120 and 121)

30--

Loading...

Loading...