Page 1

Model No. KV-S7065C

These instructions contain information on operating the scanner. Before reading these

instructions, please read the installation manual enclosed with this unit.

Please carefully read these instructions, the enclosed installation manual and maintenance

manual. Keep all documentation in a safe place for future reference.

Keep the CD-ROM in the protective case. Do not expose the CD-ROM to direct sunlight or

extreme heat and do not scratch or smudge the surface of the CD-ROM.

Page 2

Thank you for purchasing a Panasonic “High Speed Color Scanner.”

≥ Panasonic supports your imaging needs with a reliable and easy to use document scanner.

≥ Panasonic has developed Panasonic Image Enhancement Technology to improve the quality of your scanned

images even beyond the quality of your original document.

∫ System requirements

When using the scanner, the required host computer conditions are as follows.

SCSI Connection USB Connection

CPU

Memory

OS

Minimum Pentium III, 1 GHz

Recommended Pentium 4, 2 GHz or higher

Minimum 256 MB

Recommended 512 MB or higher

Windows

Windows

®

98 / Windows NT ® 4.0 /

®

2000 / Windows® Me / Windows® XP

Windows

Windows

®

98 / Windows® 2000 /

®

Me / Windows® XP

Display 1024k768 dots or more, 65536 colors or more

Interface

SCSI III

Recommended SCSI board

USB 2.0

Adaptec SCSI 2930U / 2940U / 29160N /19160

§ 1 GB or more free space is required in the HDD.

§ Color images larger than A3 size cannot be scanned in 600 dpi on Windows 98 or Windows Me. A large size

color image may not be scanned in high resolution depending on a computer system or application.

§ The scanning speed differs depending on the host computer operating environment or application.

§ If you connect the scanner to a USB hub, it is not guaranteed to work.

§ When using the scanner with other SCSI devices connected by daisy chain connection, it is not guaranteed to

work.

Important

≥ Do not duplicate currency.

≥ Do not duplicate copyrighted material or the work of others except for the purpose of private use.

≥ Do not duplicate any kind of certificates, licenses, passports, official or private documents, and the like.

®

®

Partner, Panasonic has determined that this product meets the

guidelines for energy efficiency.

≥ Microsoft

As an E

E

(E

®

, Windows® and Windows NT® are either registered trademarks or trademarks of Microsoft Corporation

NERGY STAR

NERGY STAR

NERGY STAR and the ENERGY STAR certification mark are registered US marks.)

in the United States and/or other countries.

Windows

Windows

Windows NT

Windows

Windows

≥ ISIS

≥ Pentium

®

98 is Microsoft® Windows® 98 operating system.

®

Me is Microsoft® Windows® Me operating system.

®

is Microsoft® Windows NT® operating system.

®

2000 is Microsoft® Windows® 2000 operating system.

®

XP is Microsoft® Windows® XP operating system.

®

is a registered trademark of Pixel Translations, a division of Captiva Software Corporation.

®

is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and

other countries.

≥ Adaptec is a registered trademark of Adaptec, Inc.

≥ Each company’s name or company product name is each company’s trademark or registered trademark.

The information given in these Operating Instructions is subject to change without notice.

2

Page 3

Table of Contents

Page

Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before

You Start

Operation

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

≥ Power turn-on sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

≥ About LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

≥ About the SCSI setting (Not required for USB connection) . . . . . . . . . . . . . . 13

Loading Documents on the ADF. . . . . . . . . . . . . . . . . . . . . . . . . 14

≥ When scanning multiple sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Feeding a Document Manually . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Loading Documents on the Flatbed . . . . . . . . . . . . . . . . . . . . . . 19

≥ When scanning with the flatbed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

≥ Scanning thick documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

≥ When scanning with the flatbed repeatedly . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

≥ How to use the control sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Changing the Reference Plate Setting . . . . . . . . . . . . . . . . . . . . 22

≥ ADF reference plate setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

≥ Flatbed sheet setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Care

and

Maintenance

Appendix

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

≥ Removing paper jams from the document feeder . . . . . . . . . . . . . . . . . . . . . 24

≥ Removing paper jams from the exit path . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

≥ Outside of the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

≥ Inside the scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

≥ Cleaning the paper feed roller, separation roller, and retard roller. . . . . . . . . 27

≥ Cleaning the drive rollers and free rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

≥ Cleaning the drive rollers, free rollers, and exit roller. . . . . . . . . . . . . . . . . . . 30

≥ Cleaning the reference plates and ADF glasses . . . . . . . . . . . . . . . . . . . . . . 31

≥ Cleaning the paper and waiting sensors, double feed detector . . . . . . . . . . . 32

≥ Cleaning the starting, skew and ending sensors . . . . . . . . . . . . . . . . . . . . . . 33

≥ Cleaning the flatbed glass and document cover detector . . . . . . . . . . . . . . . 34

Replacing Consumable Roller Modules. . . . . . . . . . . . . . . . . . . 35

≥ Replacing paper feed roller modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

≥ Replacing Retard Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Shading Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Repacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3

Page 4

Notice

Federal Communications Commission Requirements

(For United States only)

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

FCC Warning: To assure continued FCC compliance, the user must use only shielded interface cable and the

provided power supply cord. Also, any unauthorized changes or modifications to this equipment would void the

user’s authority to operate this device.

English

WARNING:

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS PRODUCT TO RAIN OR

ANY TYPE OF MOISTURE.

THE SOCKET-OUTLET MUST BE NEAR THIS EQUIPMENT AND MUST BE EASILY

ACCESSIBLE.

The product should be used only with a power cord that is supplied by the manufacturer.

Power Source

WARNING

≥ (220-240 V equipment)

A certified power supply cord has to be used with this equipment. The relevant national installation and/or

equipment regulations shall be considered. A certified power supply cord not lighter than ordinary polyvinyl

chloride flexible cord according to IEC 60227 (designation H05VV-F 3G 1.0 mm

2

).

4

Page 5

Notice

(For United Kingdom only)

For your safety please read the following text carefully.

This appliance is supplied with a moulded three pin mains plug for your safety and convenience.

A 5 amp. fuse is fitted in this plug. Should the fuse need to be replaced, please ensure that the replacement fuse has

a rating of 5 amps. and that it is approved by ASTA or BSI to BS1362. Check for the ASTA mark or the BSI mark

on the body of the fuse. If the plug contains a removable fuse cover you must ensure that it is refitted when the

fuse is replaced. If you lose the fuse cover the plug must not be used until a replacement cover is obtained. A

replacement fuse cover can be purchased from your local Panasonic Dealer.

If the fitted moulded plug is unsuitable for the socket outlet in your home then the fuse should be removed and the

plug cut off and disposed of safely.

There is danger of severe electrical shock if the cut off plug is inserted into any 13 amp. socket.

If a new plug is to be fitted please observe the wiring code as shown below. If in any doubt please consult a qualified

electrician.

WARNING: This appliance must be earthed.

IMPORTANT: The wires in this mains lead are coloured in accordance with the following code.

Green-and-Yellow : Earth

Blue : Neutral

Brown : Live

As the colours of the wire in the mains lead of this appliance may not correspond with the coloured markings

identifying the terminals in your plug, proceed as follows.

The wire which is coloured Green-and-Yellow must be connected to the terminal in the plug which is marked with the

letter E or by the Earth symbol or coloured Green-and-Yellow.

The wire which is coloured Blue must be connected to the terminal in the plug which is marked with the letter N or

coloured Black.

The wire which is coloured Brown must be connected to the terminal in the plug which is marked with the letter L or

coloured Red.

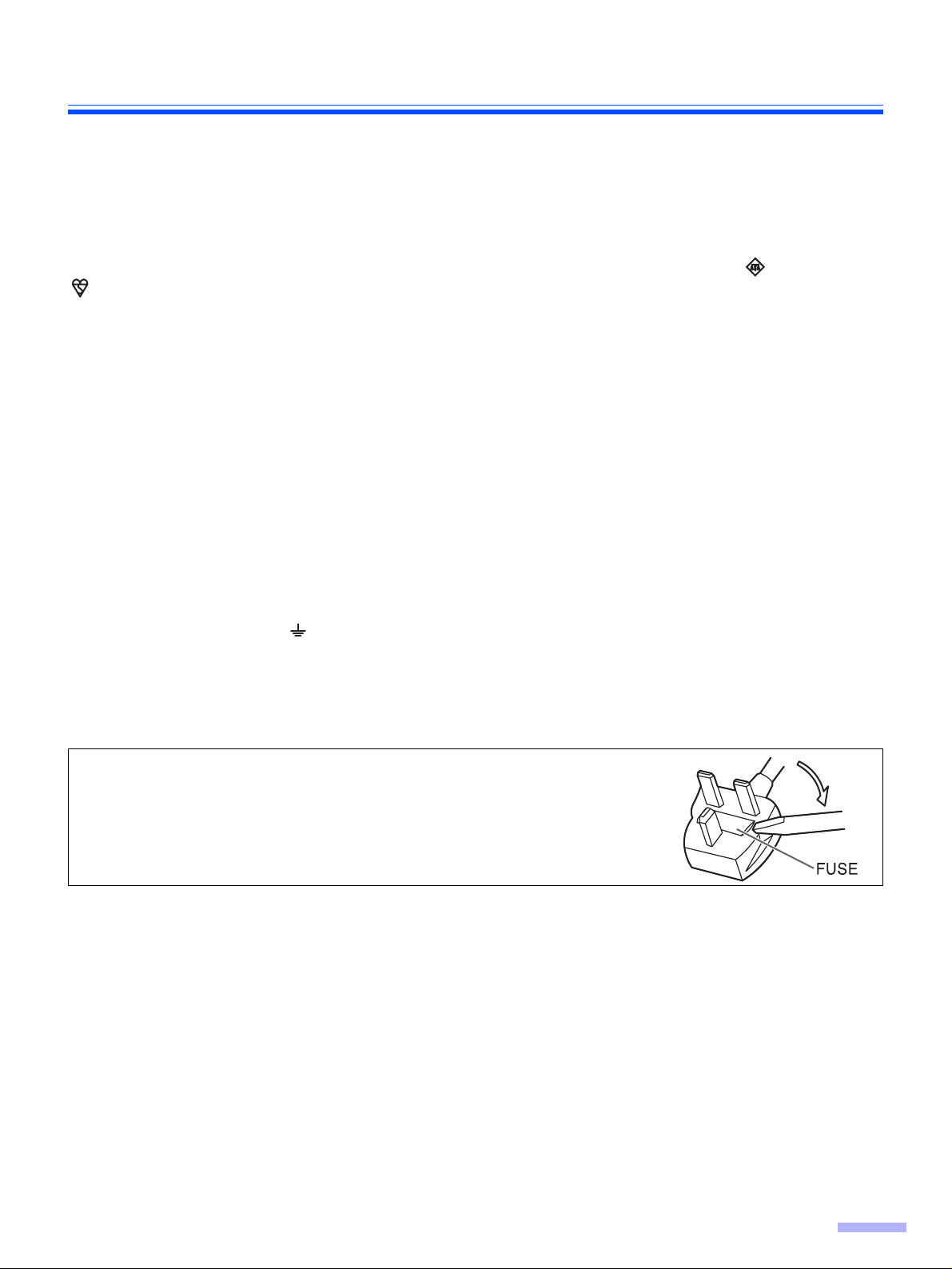

How to replace the fuse :

Open the fuse compartment with a screwdriver and replace

the fuse.

5

Page 6

Notice

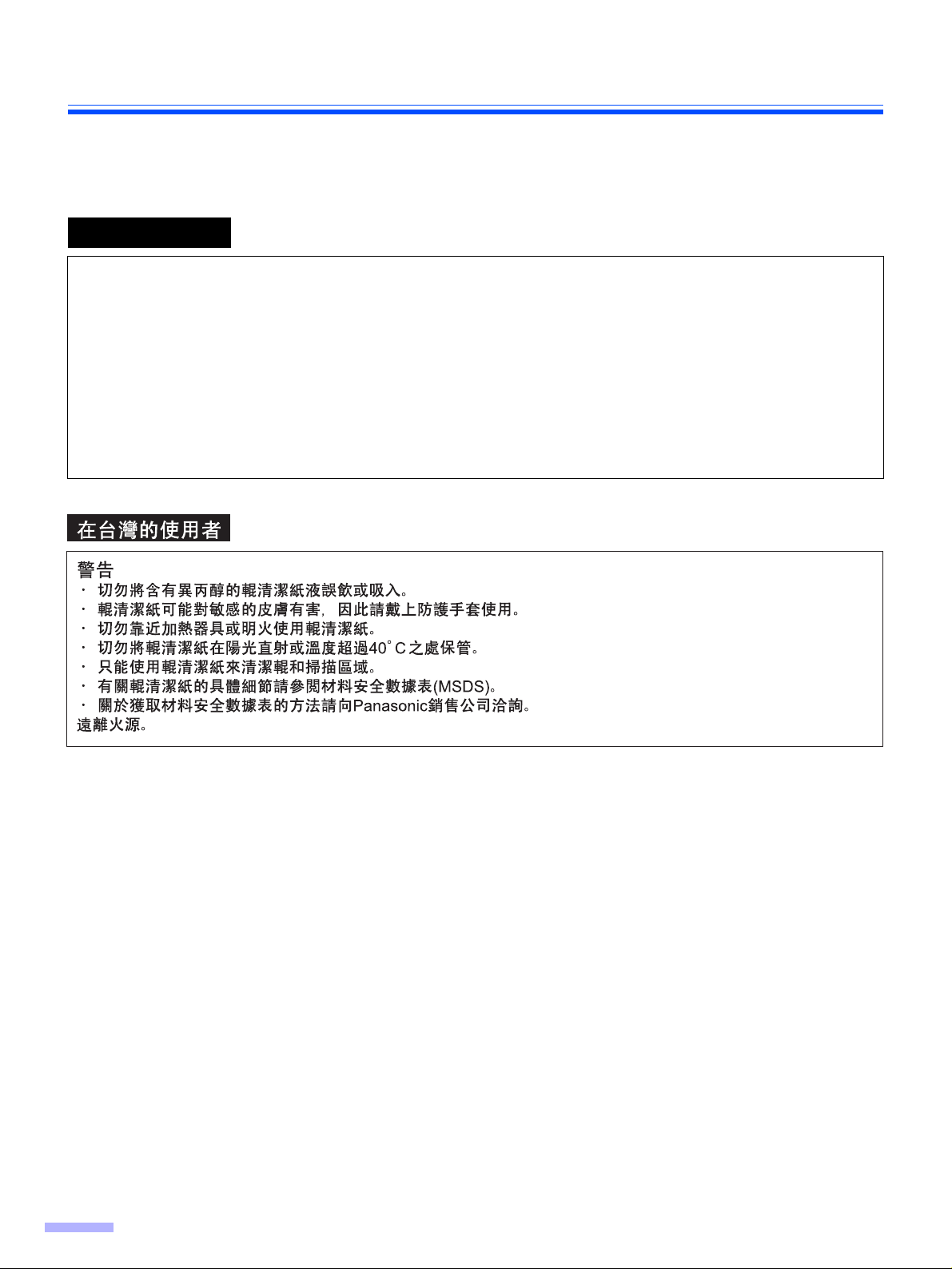

Roller cleaning paper precautions

Before using the roller cleaning paper, please read these instructions completely. Keep these instructions for future

reference.

English

WARNING

• Do not drink or inhale the roller cleaning paper fluid including isopropyl alcohol.

• The roller cleaning paper may be harmful to sensitive skin. Please use protective gloves.

• Do not use the roller cleaning paper near a heater or open flame.

• Do not store the roller cleaning paper in direct sunlight or in a place with temperature over 40 oC (104 oF).

• Only use the roller cleaning paper to clean the rollers and scanning area.

• If you need more information about the roller cleaning paper, please refer to the Material Safety Data Sheet

(MSDS).

• Please ask your Panasonic sales company about obtaining the Material Safety Data Sheet.

KEEP AWAY FROM FIRE.

6

Page 7

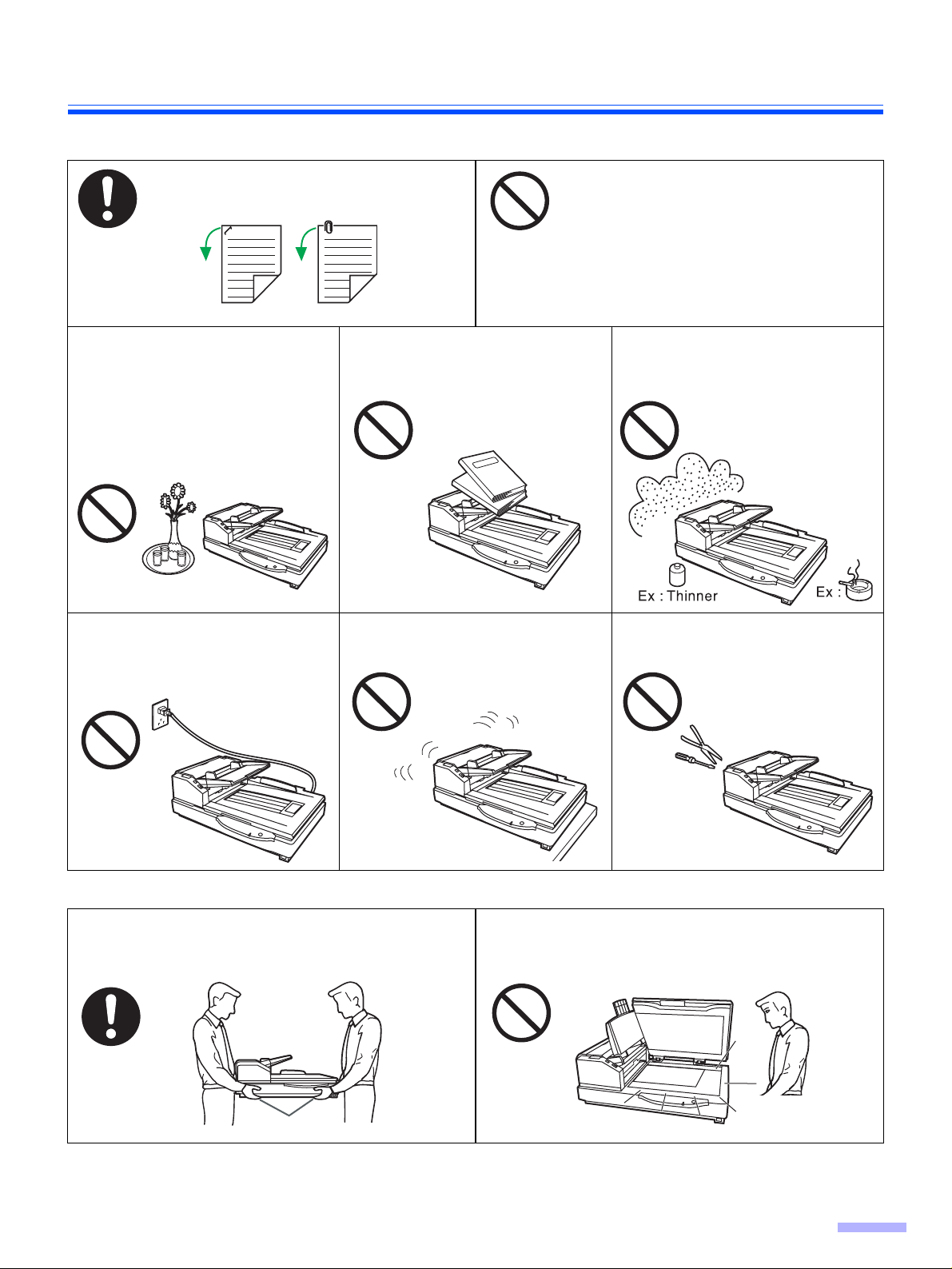

Precautions

The following precautions are recommended to extend the life of the unit:

Prior to scanning, remove all staples and

paper clips from pages.

Do not place any liquids near the

unit.

—Accidental spillage of liquid into

the unit may cause severe damage. If this occurs, turn the unit

off, unplug the power cord and

call for service.

Do not leave the power cord

plugged into the AC outlet if the unit

will not be used for an extended

period.

Do not place floppy disks or any items

containing magnetic data strips on the

flatbed.

—Magnets are located in the flatbed

Do not place books, paper, or other

items on the unit.

Do not place the unit on an uneven

or unstable surface.

cover (flatbed sheet) and may damage

data stored on floppy disks and magnetic strips.

Do not place the unit in an area

where there is a lot of smoke, dust,

chemical fumes or vibration.

Do not disassemble the unit.

This will void your warranty.

It is recommended that at least two people carry the

scanner by holding four hollows on the front and rear

sides.

Hollows

≥ Special care should be taken to protect the unit if it is used in a less than optimum environment, such as a dusty or

sandy area.

Do not look directly at the light.

(You may damage your eyes.)

7

Page 8

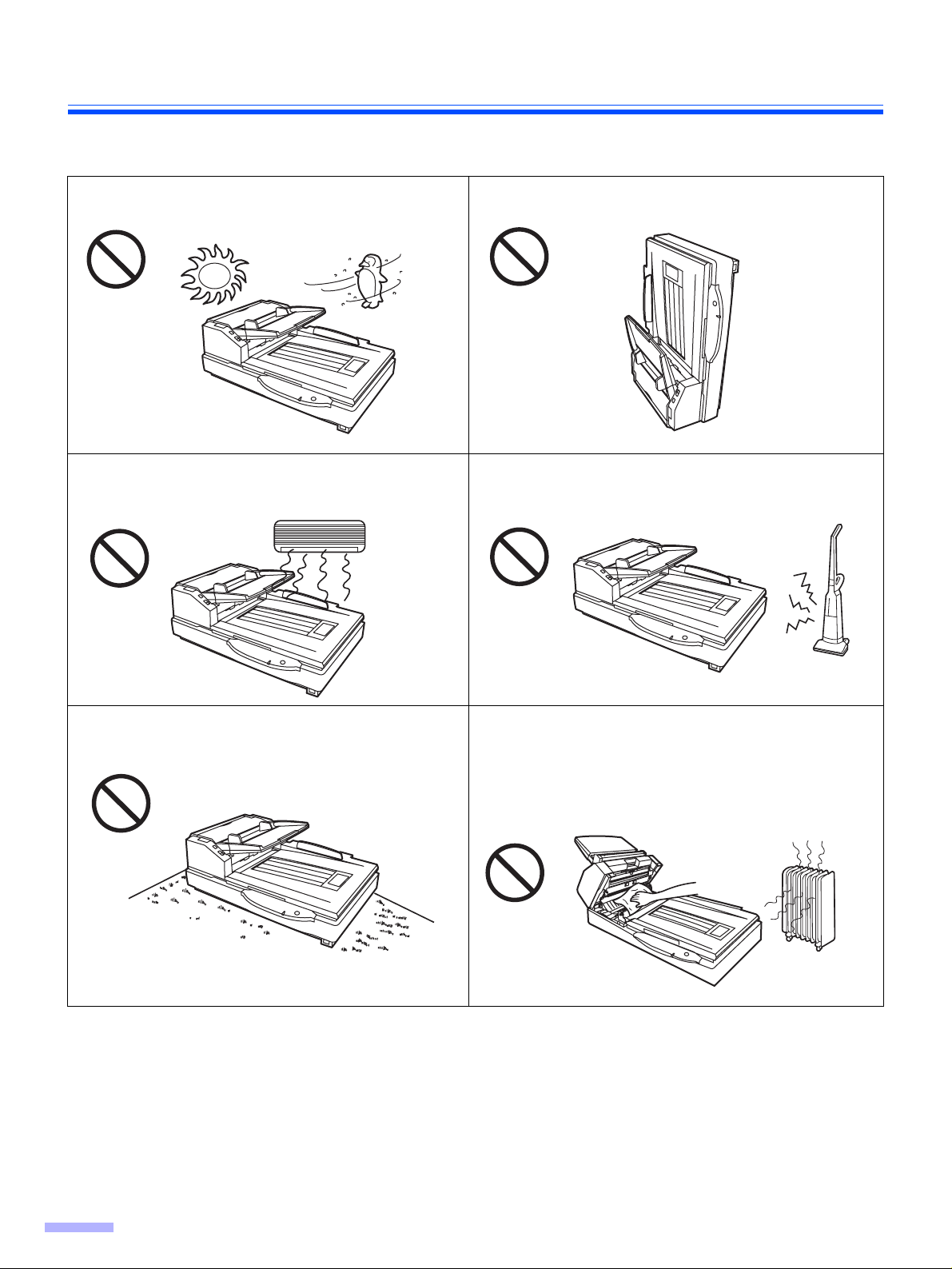

Precautions

Operating Environment

Do not place the unit in direct sunlight or in a cold

draft.

Hot

Do not place the unit near a heating appliance or an

air conditioning vent. Do not place the unit in a room

with extremely high or low humidity.

Cold

Do not operate or place the unit in a vertical position.

Do not place the unit near other appliances which generate large electrical noise.

Do not place the unit on a carpet. (Static electricity

can cause the unit to malfunction.)

Do not drink or inhale the included roller cleaning paper

fluid.

The roller cleaning paper may be harmful to sensitive

skin. Please use protective gloves.

Do not use the roller cleaning paper near a heater or

open flame. This may cause a fire.

≥Power Source

≥ Use a voltage level that does not vary more than d10% from the voltage level marked on the nameplate

(located on the back side of the scanner).

≥ Do not use an extension cord.

≥ This scanner should be connected to a grounded outlet.

≥ Do not use a line conditioner, transient suppressor or surge protector.

8

Page 9

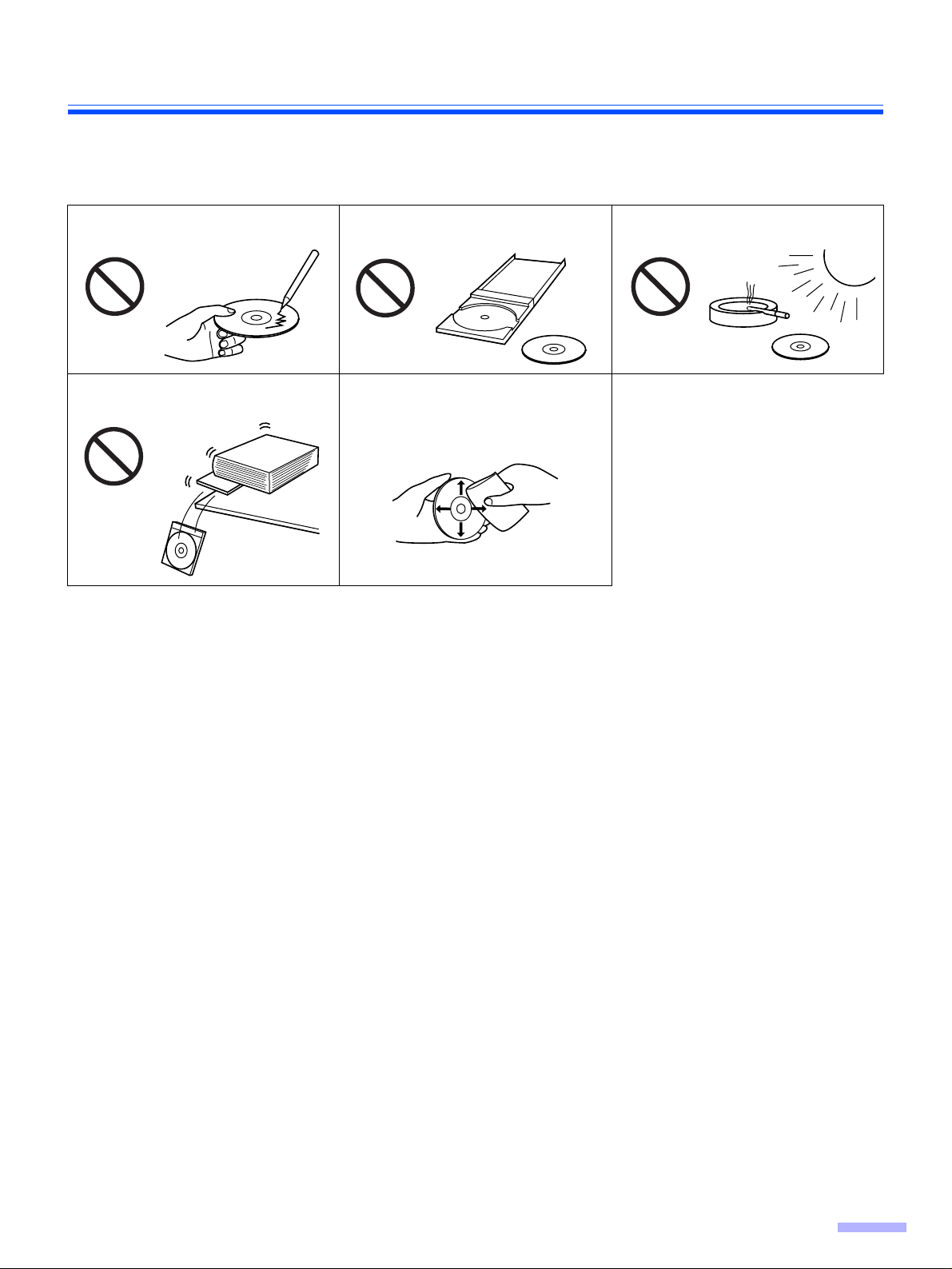

∫ CD-ROM

To prevent the CD-ROMs from accidental damages:

Precautions

Do not touch or write on the surface

of the disc.

Do not place heavy objects on the

disc case or drop the case.

Do not leave the disc out of its

protective case.

To clean the disc, hold the disc by

its edges and wipe it from the

center to the edges with a dry, soft

cloth.

Do not leave the disc in direct

sunlight or near heat sources.

9

Page 10

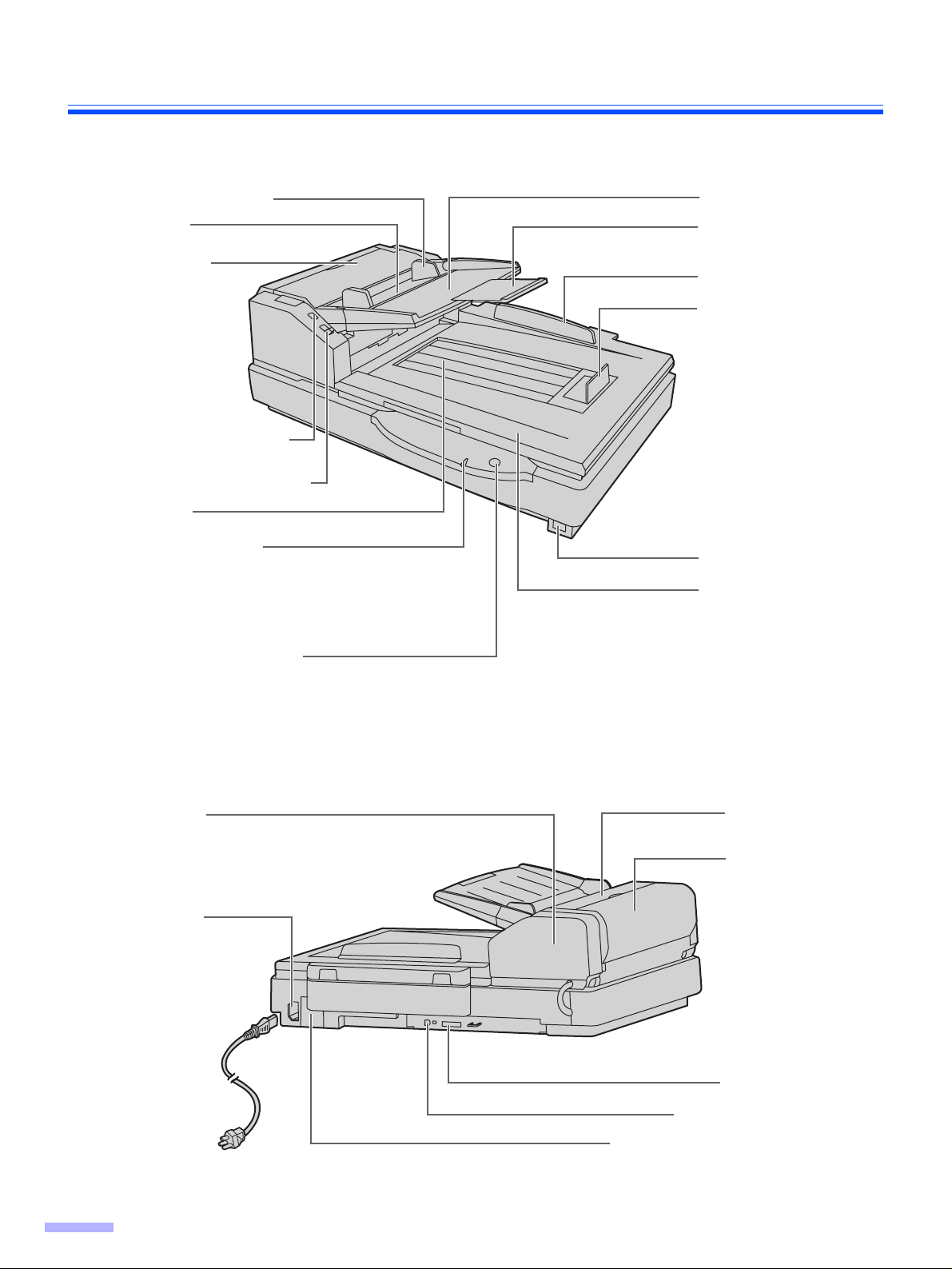

Component Identification

Document guide

Hopper

ADF door

ADF door release

Manual feed selector

Exit tray

Power indicator

When the power is turned on, the green

indicator lights.

When an error occurs, the indicator will

change to red, and light steadily or flash.

STOP/START button

Used to stop or start scanning a document.

Hopper tray

Hopper extension

tray

Back stopper

Exit stopper

Power switch

Document cover

Exit door

Power cord

10

Top cover

Imprinter door

AC inlet

SCSI connector

USB connector

FAN exhaust vent

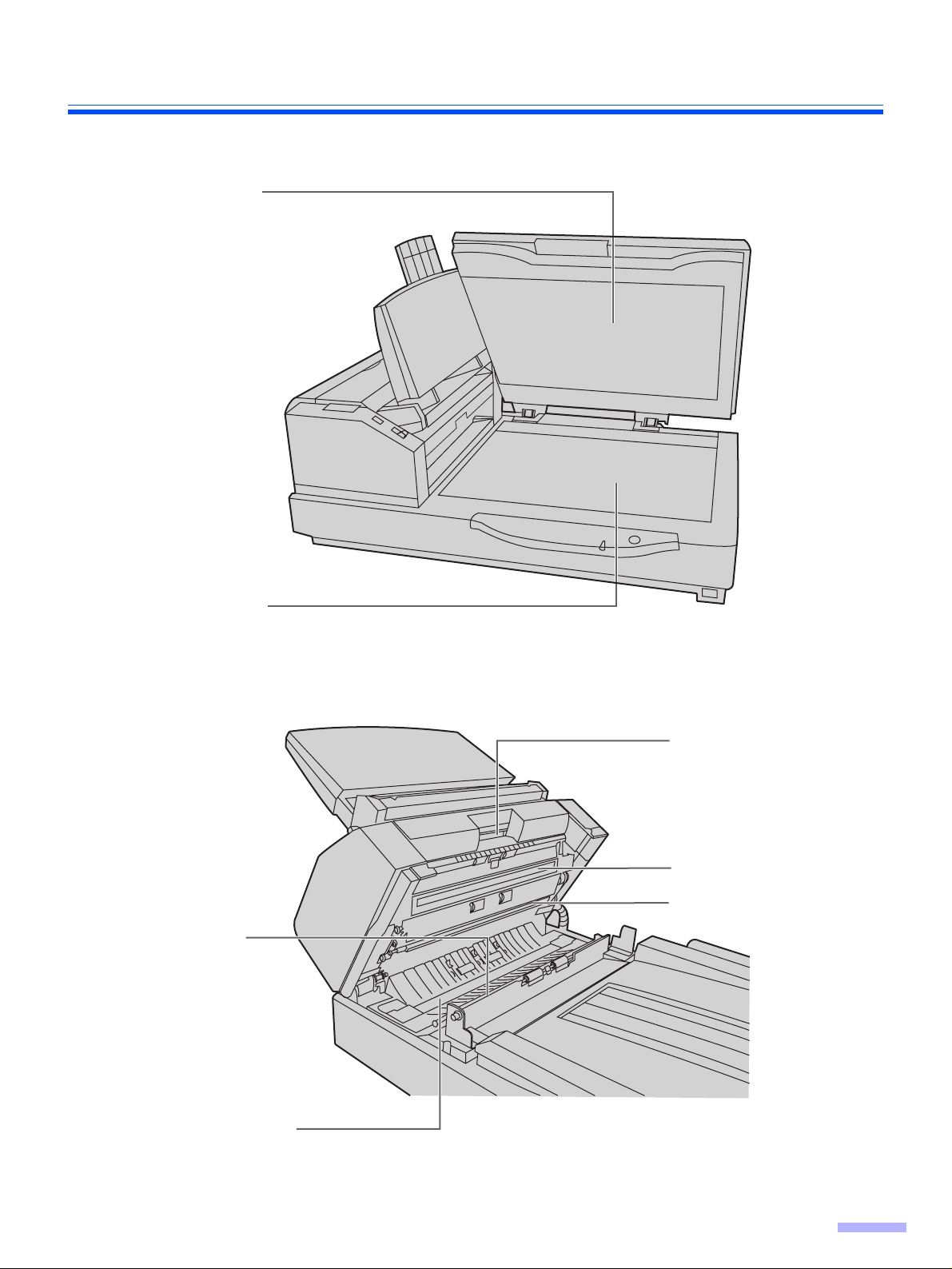

Page 11

Flatbed sheet

Component Identification

Flatbed glass

Reference

plate (B)

Exit door release

ADF glass (B)

Reference plate (F)

ADF glass (F)

11

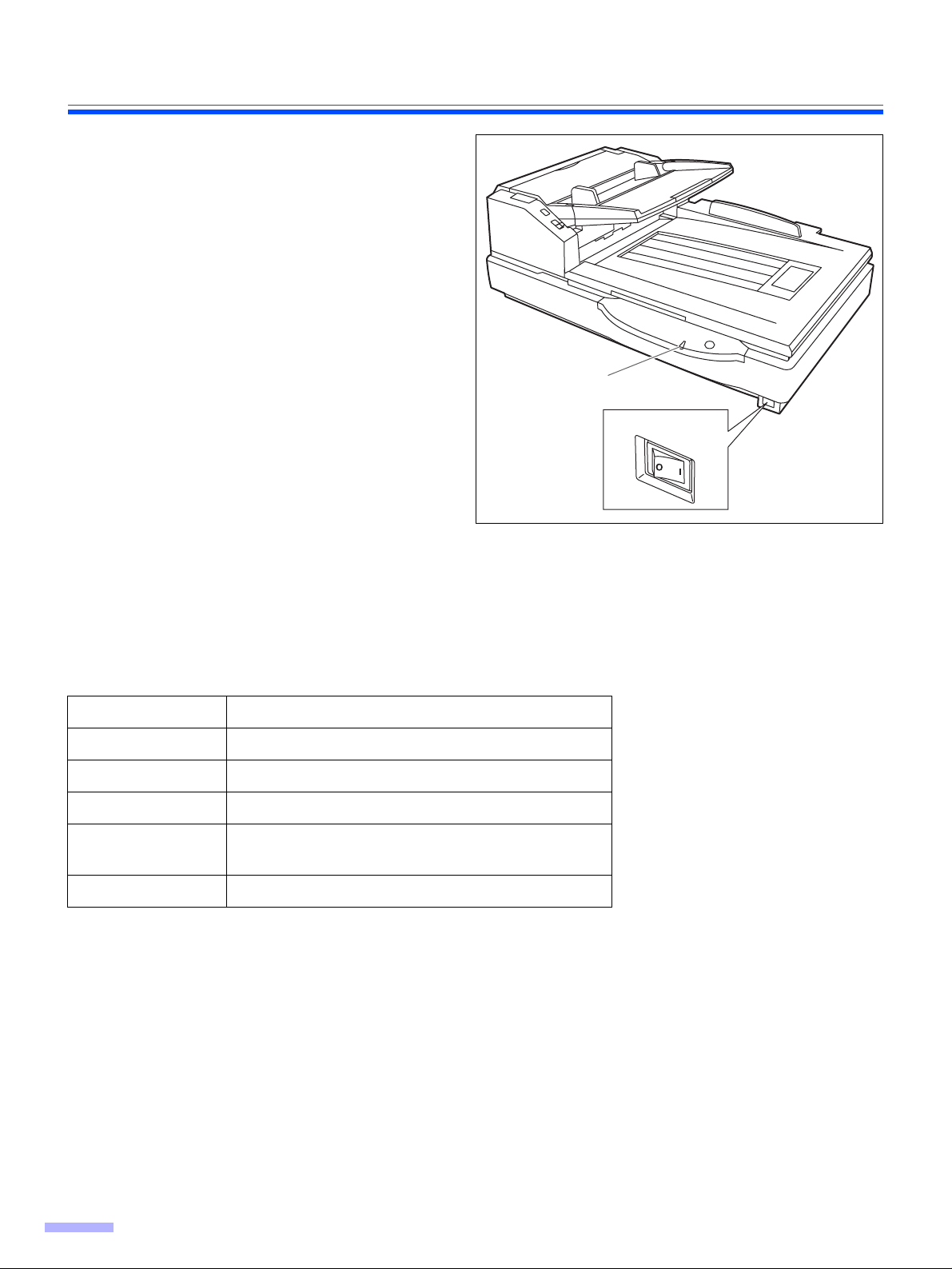

Page 12

Component Identification

∫ Power turn-on sequence

Turn on the power of the scanner.

1

≥ The LED will now light.

Turn on the power of the host

2

computer after scanner’s LED stays

green

.

≥ In case of the USB connection, the host

computer recognizes the scanner automatically when the scanner is powered on

even after the host computer is powered

on.

LED

Power switch

∫ About LED

LED indicates the status of the scanner as follows:

LED light Status

Green Ready to scan or scanning

Green (flashing) Sleep mode

Orange Ready to scan or scanning with warning *1

Orange (flashing) Initializing

Sleeping with warning *1

Red An error occurred *2

*1: The rollers need to be cleaned or replaced.

Refer to Maintenance Manual or Operating Instructions (CD-ROM) for the way of cleaning or replacing the

rollers.

*1, *2: Check the status of the scanner using the User Utility.

The User Utility is included in the CD-ROM.

12

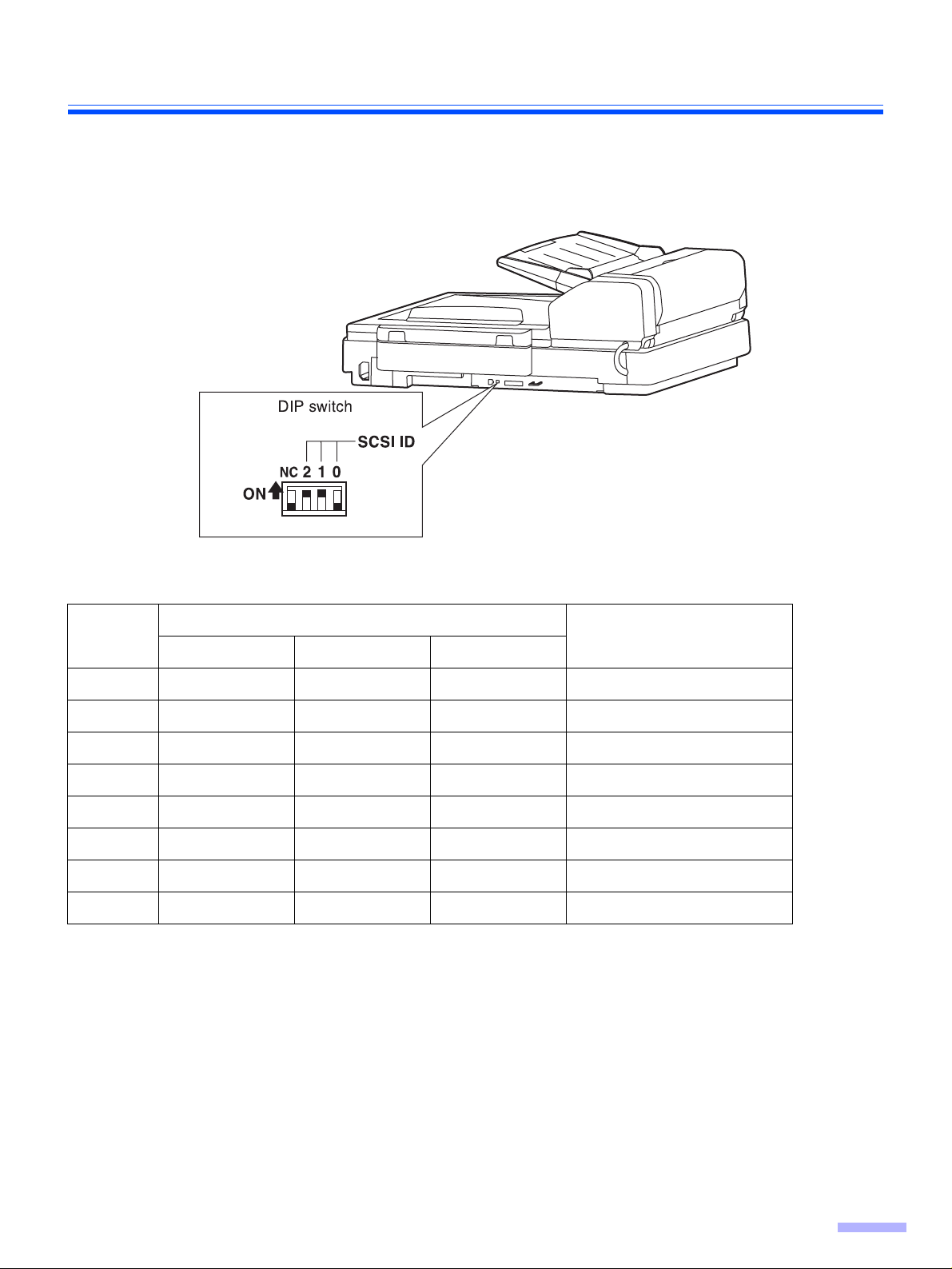

Page 13

Component Identification

∫ About the SCSI setting (Not required for USB connection)

When connecting the scanner to a SCSI chain using a SCSI cable, perform the SCSI ID setting correctly.

The scanner is provided with a DIP switch for the SCSI ID No. setting.

SCSI ID Setting

Switch

ID No.

#2 #1 #0

0 OFF OFF OFF

1OFF OFF ON

2 OFF ON OFF

3 OFF ON ON

4ON OFF OFF

5ON OFF ON

6 ON ON OFF Default setting

7ON ON ON

Remarks

13

Page 14

Loading Documents on the ADF

48~297

)

ADF (Auto Document Feeder) enables multiple sheet scanning.

Acceptable documents

Document size:

mm (1.9~11.7 in.

70~635 mm (2.75~25 in.)

Paper thickness: 40–127 g/m

Maximum number of sheets loadable on the hopper tray

The height of the document should not exceed the limit mark on the document guide.

2

g/m

lb. 1114172021242834

Maximum number of sheets 320 260 200 170 160 140 120 100

Recommendable paper: Plain paper

2

40 52 64 75 80 90 104 127

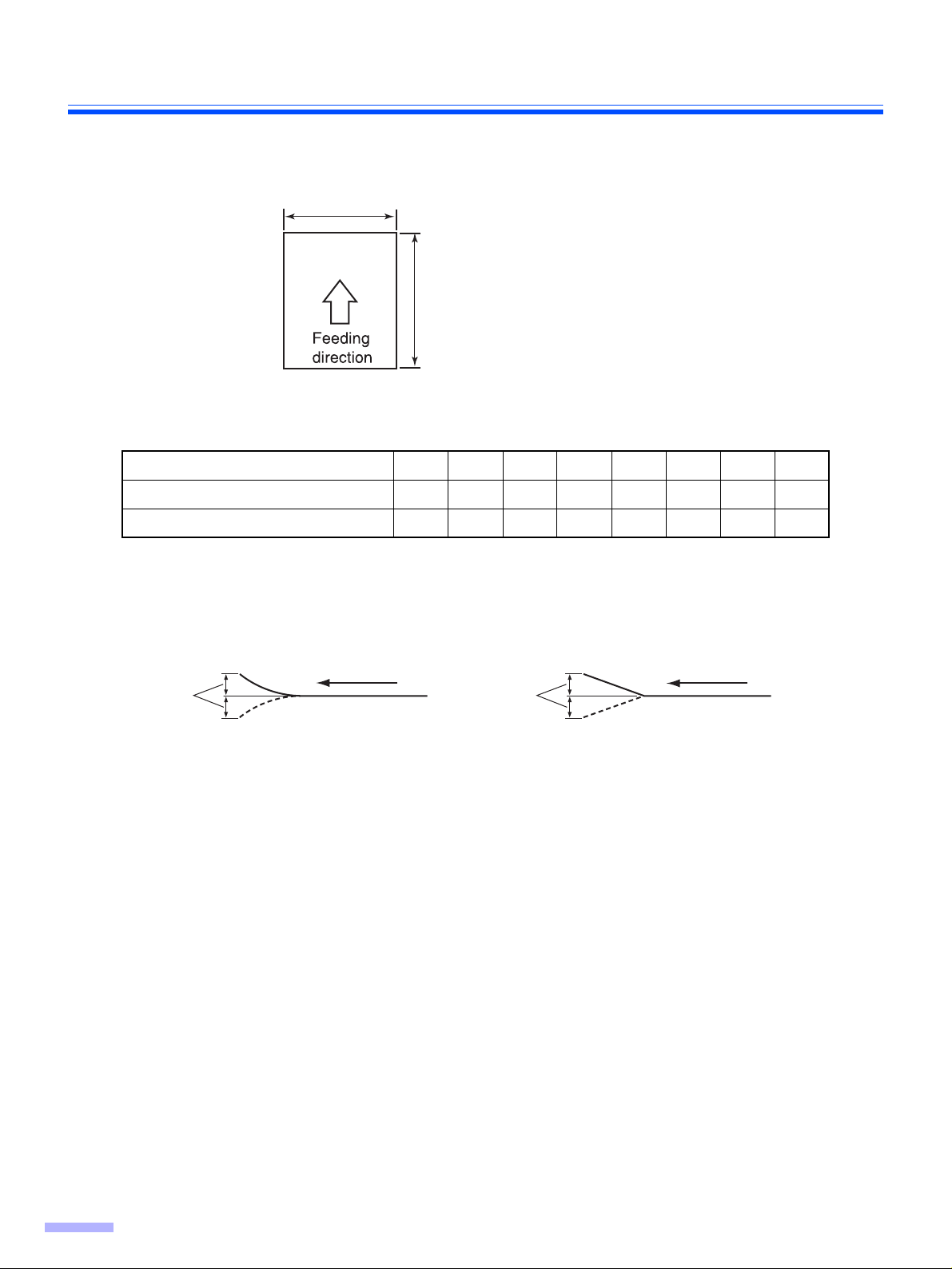

The following types of documents may not be scanned properly.

≥ Broken or notched documents

≥ Curled, wrinkled or folded documents

Curl:

Less than

5 mm

≥ Perforated or punched documents

≥ Not rectangular or irregularly shaped documents

≥ Tracing paper

≥ Thermal paper

When scanning is not performed properly, try the following methods:

≥ Set the feed speed to “Slow”.

≥ Scan the documents by manual feeding.

≥ Scan the documents with the flatbed.

Feeding direction

Fold:

Less than

5 mm

Feeding direction

The following types of documents may cause frequent jams and double feeding.

≥ Extremely smooth or shiny paper or paper that is highly textured

≥ Paper with carbon

≥ Carbonless paper

If a paper jam or double feeding occurs, clean the rollers.

When a jam occurs at the document feeder, reduce the number of sheets loaded on the hopper to about 20.

Types of documents to avoid

≥ OHP sheets, other plastic films, cloths, or metallic sheets.

≥ Paper with irregularities such as tabs, staples, paste, etc.

≥ Documents with wet ink

≥ Thick or irregular documents such as envelopes, documents that are glued together, etc.

Be sure to remove the document from the exit tray after it is scanned.

When scanning different size documents, scanned sheets may need to be reordered for optimum performance.

Thick, thin or important document should be scanned by the flatbed or fed manually one sheet at a time.

14

Page 15

Loading Documents on the ADF

∫ When scanning multiple sheets

Cautions:

≥ Please remove any staples from the document before scanning.

≥ Glued or curled documents may cause a paper jam or damage the unit, so please scan using the flatbed.

Documents that have been stapled

1

together or stacked together (as in a

file folder) will need to be separated.

1 Fan the stack of documents to

separate all the edges.

2 Hold both ends and bend the

documents as shown in the

illustration.

3 To flatten the documents, hold firmly

and pull them apart as shown in the

illustration.

Repeat these steps as necessary.

Carefully align the documents.

2

Prior to scanning, remove, all staples and paper clips

from pages.

1

2

3

Adjust the document guides slightly

3

larger than the actual size of the

documents.

Document guide

15

Page 16

Loading Documents on the ADF

Set the manual feed selector to

4

“AUTO”.

Manual feed

selector

When using long paper, pull out the

5

hopper extension tray from the hopper.

Then raise and adjust the exit stopper

to the position a little longer than the

actual length of the document.

Hopper

Exit stopper

Hopper extension

tray

16

Page 17

Loading Documents on the ADF

Place the documents on the hopper

6

with the side to be scanned facing up.

Then push them in the direction of the

arrow until they stop.

≥ The amount of documents should not

exceed the limit mark on the document

guide. This may cause a paper jam or

skew.

Por trait

Fill indicator

(Limit mark)

Landscape

Adjust the document guide to the size

7

of the document to be scanned.

Adjust the exit stopper to the size of the

document to be output.

≥ When scanning the document with the

length between 420 mm (A3 size) or 432

mm (17 in.) and 635 mm (25 in.) close the

exit stopper.

Document guide

Exit stopper

17

Page 18

Feeding a Document Manually

When scanning a document one page at a time with the ADF, set the manual feed selector to “MANUAL” and the

pages can be scanned one page at a time.

Cautions:

≥ Please remove any staples from the document before scanning.

≥ Glued or curled documents may cause a paper jam or damage the unit, so please scan using the flatbed.

Set the manual feed selector to

1

“MANUAL”.

Manual feed

selector

Match the document guide with the

2

size of the document.

Insert the document into the paper slot

3

one page at a time.

Adjust the document guide with the

4

size of the document when the

document guide does not suit the size

of the document. Adjust the exit

stopper to the size of the document to

be output.

Document guide

Paper slot

18

Page 19

Loading Documents on the Flatbed

One sheet or an entire book document can be scanned on the document glass.

Scanning documents in this way is known as “scanning with the flatbed”.

Caution

≥ Do not place floppy disks or any items containing magnetic data strips on the flatbed. Magnets are located in the

flatbed cover (flatbed sheet) and may damage data stored on floppy disks and magnetic strips.

∫ When scanning with the flatbed

Raise the hopper tray.

1

Open the document cover.

2

Place the scanning side of the

3

document face down on top of the

flatbed glass towards the upper left

corner.

≥ If the document is bent or folded,

straighten it.

Document cover

Hopper tray

Standard

mark

Match the shorter side of the document

4

with the left edge of the flatbed glass.

Match the longer side of the document

5

with the standard mark.

≥ If the document is slanted, it will not be

scanned properly.

Standard mark

Shorter side

Document

Longer side

Document

Flatbed glass

19

Page 20

Loading Documents on the Flatbed

Close the document cover gently.

6

≥ If the document cover is slammed, the

document will move and may not be

scanned properly.

≥ Do not open or press down on the docu-

ment cover during scanning.

≥ Do not look directly at the light.

(You may damage your eyes.)

≥ Be sure to close the document cover

before use.

≥ After scanning, open the document cover

and remove the document.

∫ Scanning thick documents

When scanning thick documents such as a book, please note the following items:

≥ Please note that areas of the document which are not touching the flatbed glass will not be scanned properly.

≥ If the document moves during scanning, please note that it will not be scanned properly.

∫ When scanning with the flatbed repeatedly

≥ Keep the hopper tray raised, open and close the document cover only.

20

Page 21

Others

∫ How to use the control sheet

If the control sheet is used, the documents

behind the control sheet are scanned in

accordance with the code on the control

sheet regardless of scanning condition that

is selected previously.

≥ Multiple control sheets can be used.

≥ When using a control sheet, the application

software required depends on the control

sheet.

≥ Print out control sheets from the provided CD-

ROM.

Cautions:

≥ Use the same size control sheet as the

scanning document.

≥ When printing the control sheet, if the pattern

falls in the area from the top side of the

document to 25 mm, adjust the printer.

Also, copy the control sheet so that the pattern

lies in the center of the copy.

≥ Be careful not to get the control sheet dirty.

Do not fold or crease the control sheet.

Scanning will not be performed properly.

A

Documents

Control sheet

Code

Documents

B

21

Page 22

Changing the Reference Plate Setting

You can choose a background color to be scanned from white (black) to black (white). The scanner comes from factory set to black. The reference plate (B), reference plate (F) and flatbed sheet setting must be changed simultaneously. Anytime the background color is changed from its previous setting, the shading adjustment must be

performed. Please refer to page 39 for more information regarding the shading adjustment.

∫ ADF reference plate setting

Turn off the scanner.

1

Pull the exit door release to open the

2

exit door.

Using your finger, turn the reference

3

plate (B) over.

≥ Confirm that the reference plate has

changed and is locked in its proper position.

Exit door release

ADF glass (F)

Reference plate (B)

22

Using your finger, turn the reference

4

plate (F) over.

≥ Confirm that the reference plate has

changed and is locked in its proper position.

Reference plate (F)

ADF glass

(B)

Page 23

Close the exit door slowly until it clicks

5

into place.

∫ Flatbed sheet setting

Changing the Reference Plate Setting

Turn off the scanner.

1

Fold the hopper tray in the direction of

2

the arrow.

Open the document cover.

3

Turn the flatbed sheet over.

4

≥ The flatbed sheet is attached to the docu-

ment cover with magnets.

≥ Set the flatbed sheet to the left.

Document cover

Hopper tray

Flatbed sheet

23

Page 24

Clearing Paper Jams

Torn documents, thin documents or documents that are creased on the top edge may cause paper jams. If a paper

jam occurs, remove the jammed sheet according to the following procedure.

∫ Removing paper jams from the document feeder

Push the ADF door release to open the

1

ADF door.

Pull the jammed document towards the

2

document feeder.

≥ When the jammed paper cannot be

removed, remove it from the exit path.

Refer to page 25.

≥ When only the bottom end of jammed

paper is visible, open the exit door while

leaving the ADF door open to remove the

jammed paper. Pulling the jammed paper

with the ADF door closed may damage

the document.

ADF door

ADF door release

ADF door

24

Close the ADF door.

3

≥ When you close the ADF door, close it

securely until it is locked.

ADF door

Page 25

∫ Removing paper jams from the exit path

Pull the exit stopper and raise the hop-

1

per tray.

Pull the exit door release, open the exit

2

door and pull the jammed document.

Clearing Paper Jams

Hopper tray

Exit stopper

Exit door release

≥ When the jammed paper cannot be

removed, remove it from the document

feeder. Refer to page 24.

Close the exit door.

3

≥ When you close the exit door, close it

securely until it is locked.

Exit door

25

Page 26

Cleaning the Unit

∫ Outside of the scanner

Clean the unit at least once a month.

Turn the power off.

1

Clean the cover with a soft cloth.

2

≥ The ADF insertion and exit slots get dirty

easily, therefore, proper cleaning is

required.

Remove dirt and dust from the fan

3

exhaust vent with a brush.

: Off position

∫ Inside the scanner

Clean the unit at least once a week or when 20,000 sheets have been scanned, whichever comes first.

≥ Clean the rollers, sensors and double feed detector if paper jamming or multiple-sheet feeding occurs

frequently. (Refer to pages 27–33.)

≥ Clean the ADF glass, reference plate when black or white lines appear on the scanned images.

(Refer to page 31.)

≥ Clean the flatbed glass and document cover detector. (Refer to page 34.)

≥ If the documents you scan are dirty, then the scanner components will also become dirty.

To maintain proper scanning, clean the scanner components frequently.

≥ When scanning with the flatbed and black dots or white patches occurs, open the document cover, and clean

the flatbed glass and flatbed sheet using the accessory roller cleaning paper.

Roller cleaning paper

Open the bag on the dotted line and take out

the roller cleaning paper.

≥ If the roller cleaning paper bag is left opened for

a long period of time before using it, the alcohol

will evaporate. Please use the roller cleaning

paper immediately after opening the bag.

Dotted line

§ The roller cleaning paper (Model No. KV-SS03) is available from the dealer where you

purchased your scanner.

For supplies and accessories: Call 1-800-346-4768 (U.S.A. only) or your dealer.

26

Page 27

Cleaning the Unit

∫ Cleaning the paper feed roller, separation roller, and retard roller

Turn the power off.

1

ADF door

Push the ADF door release to open the

2

ADF door.

ADF door release

Use the roller cleaning paper (KV-

3

SS03) to remove the dirt from the

surfaces of the paper feed roller and

separation roller.

Separation roller

Paper feed roller

Note:

≥ When wiping off the dirt on the roller

surfaces, hold the rollers to prevent them

from rotating, and wipe the roller all the

way around them proceeding from one

end to the other in the direction of the

arrows shown in the figure.

Open the retard cover in the direction

4

of the arrow shown in the figure by

using the indent on the back side.

Retard roller

Indent

Retard cover

27

Page 28

Cleaning the Unit

Use the roller cleaning paper (KV-

5

SS03) to remove the dirt from the

surface of the retard roller.

Note:

≥ When wiping off the dirt on the roller

surfaces, hold the rollers to prevent them

from rotating, and wipe the roller all the

way around them proceeding from one

end to the other in the direction of the

arrows shown in the figure.

Close the retard cover in the direction

6

of the arrow shown in the figure.

Retard roller

Retard roller

Retard cover

28

Close the ADF door.

7

≥ When you close the ADF door, close it

securely until the door is locked.

Clear the roller cleaning counter with

8

User Utility.

≥ After cleaning the above rollers, click

[Clear Counter] button for [After Clean

Roller] with User Utility.

ADF door

Page 29

∫ Cleaning the drive rollers and free rollers

Cleaning the Unit

Turn the power off.

1

Push the ADF door release to open the

2

ADF door.

Use the roller cleaning paper (KV-

3

SS03) to remove the dirt from the

surfaces of the 4 drive rollers.

≥ When wiping off the dirt on the roller

surfaces, hold the rollers to prevent them

from rotating, and wipe the roller all the

way around them proceeding from one

end to the other in the direction of the

arrows shown in the figure.

Use the roller cleaning paper (KV-

4

SS03) to remove the dirt from the

surfaces of the 4 free rollers.

≥ When wiping off the dirt on the roller

surfaces, hold the rollers to prevent them

from rotating, and wipe the roller all the

way around them proceeding from one

end to the other in the direction of the

arrows shown in the figure.

Drive rollers

Drive rollers

Free rollers

Close the ADF door.

5

≥ When you close the ADF door, close it

securely until it is locked.

29

Page 30

Cleaning the Unit

∫ Cleaning the drive rollers, free rollers, and exit rollers

Turn off the scanner.

1

Pull the exit door release to open the

2

exit door.

Use the roller cleaning paper (KV-

3

SS03) to remove the dirt from the

surfaces of the 4 drive rollers and the 2

exit rollers.

≥ When wiping off the dirt on the roller

surfaces, hold the rollers to prevent them

from rotating, and wipe the roller all the

way around them proceeding from one

end to the other in the direction of the

arrows shown in the figure.

Exit door release

Exit rollers

Drive rollers

Drive rollers

30

Use the roller cleaning paper (KV-

4

SS03) to remove the dirt from the

surfaces of the 6 free rollers.

≥ When wiping off the dirt on the roller

surfaces, hold the rollers to prevent them

from rotating, and wipe the roller all the

way around them proceeding from one

end to the other in the direction of the

arrows shown in the figure.

Free rollers

Page 31

Close the exit door.

5

≥ When you close the exit door, close it

securely until it is locked.

∫ Cleaning the reference plates and ADF glasses

Turn off the scanner.

1

Pull the exit door release to open the

2

exit door.

Cleaning the Unit

ADF glass (F)

Reference plate (B)

Clean the ADF glass (F) and reference

3

plate (B) with the roller cleaning paper

(KV-SS03).

Clean the ADF glass (B) and reference

4

plate (F) with the roller cleaning paper

(KV-SS03).

Close the exit door.

5

≥ When you close the exit door, close it

securely until it is locked.

Reference plate (F)

ADF glass

(B)

31

Page 32

Cleaning the Unit

∫ Cleaning the paper and waiting sensors, double feed detector

How to clean sensors (detectors) and reflectors.

Remove the brush from the accessory blower and blow off the dirt with the blower.

Blower

Sensor or detector

Turn off the scanner.

1

Reflector sheet

Push the ADF door release to open the

2

ADF door.

Waiting sensor

for waiting sensor

Paper sensor

Blow off the dirt on the surface of the

3

paper sensor and waiting sensor with

an accessory blower.

And also blow off the dirt on the

4

surface of the reflector sheet for the

waiting sensor with the accessory

blower.

Blow off the dirt from the double feed

5

detector (G) and double feed detector

(R) with the accessory blower.

Close the ADF door.

6

≥ When you close the ADF door, close it

securely until it is locked.

Double feed detector (G)

Double feed detector (R)

32

Page 33

Cleaning the Unit

∫ Cleaning the starting, skew and ending sensors

How to clean sensors (detectors) and reflectors.

Remove the brush from the accessory blower and blow off the dirt with the blower.

Blower

Sensor or detector

Turn off the scanner.

1

Ending sensor

Pull the exit door release to open the

2

exit door.

Blow off the dirt on the surface of the

3

starting, skew (L), skew (R), and

ending sensors with the accessory

blower.

And blow off the dirt from the reflector

4

sheets for the starting, skew (L), skew

(R), and ending sensors with the

blower.

Close the exit door.

5

≥ When you close the exit door, close it

securely until it is locked.

Skew (L) sensor

Reflector sheet for

skew (R) sensor

Reflector sheet for

starting sensor

Reflector sheet

for skew (L)

sensor

Skew (R) sensor

Starting sensor

Reflector sheet for

ending sensor

33

Page 34

Cleaning the Unit

∫ Cleaning the flatbed glass and document cover detector

Turn off the scanner.

1

Fold the hopper tray in the direction of

2

the arrow.

Document cover

Open the document cover.

3

Clean up the surface of flatbed glass

4

with the roller cleaning paper (KVSS03) to remove the dirt.

(Also clean up the surface of the

flatbed sheet, as required.)

Blow off the dirt from the document

5

cover detector.

Close the document cover and put

6

back the hopper tray to the original

position.

Hopper tray

Flatbed sheet

Flatbed glass

Document cover detector

How to clean sensors (detectors) and reflectors.

Remove the brush from the accessory blower and blow off the dirt with the blower.

Blower

Sensor or detector

34

Page 35

Replacing Consumable Roller Modules

∫ Replacing paper feed roller modules

Recommended change : 300,000 scans

Turn the power off.

1

Push the ADF door release to open the

2

ADF door.

ADF door release

ADF door

Pull down the paper feed roller module

3

in the direction of the arrow.

Remove the paper feed roller module

4

as shown on the figure.

Open the optional roller exchange kit

5

(KV-SS015), and take out the new

paper feed roller module.

35

Page 36

Replacing Consumable Roller Modules

Install the new paper feed roller

6

module.

Push up the new paper feed roller

7

module in the direction of the arrow, so

that it is locked by the magnets on both

sides.

Close the ADF door.

8

≥ When you close the ADF door, close it

securely until it is locked.

36

Page 37

∫ Replacing Retard Roller

Turn the power off.

1

Push the ADF door release to open the

2

ADF door.

Replacing Consumable Roller Modules

ADF door

ADF door release

Open the retard cover in the direction

3

of the arrow shown in the figure by

using the indent on the back side.

Remove the retard roller, pulling up the

4

shaft in the direction of the arrow.

Take out the new retard roller in the

5

optional roller exchange kit (KVSS015).

Retard roller

Indent

Retard cover

37

Page 38

Replacing Consumable Roller Modules

Install the new retard roller by matching

6

the groove of its shaft with the groove

of the metal holder.

Close the retard cover.

7

Close the ADF door.

8

≥ When you close the ADF door, close it

securely until it is locked.

Groove

Clear the roller replacing counter with

9

User Utility.

≥ Click [Clear Counter] button for [After

Replace Roller] with User Utility.

38

Page 39

Shading Adjustment

¥What is the purpose of the shading adjustment?

The process whereby the variations in the distribution of the lamp’s light quantity are transformed into a fixed output

within the scanning range is known as shading adjustment. It can be carried out by means of the User Utility using

the special shading paper which is provided with this scanner.

¥When shading adjustment is required

Proceed with the compensation when the colors in some parts of the scanned images differ in the extreme, or when

the image quality fails to be improved even after the inside the scanner is cleaned.

¥Before proceeding with the shading adjustment

Before proceeding, be absolutely sure to thoroughly clean the ADF glass (F) area, ADF glass (B) area, reference

plate (F) and reference plate (B) as well as the transport path and drive rollers of the scanning unit.

If the shading adjustment is carried out while these parts are still dirty, it will not be possible to eliminate the lines that

form on the scanned images.

¥Shading adjustment procedure

1. Start the User Utility.

2. Click “User Shading” on the main menu, and operate as the image display dictates. For further details, refer to

section 4.6 in the User Utility Reference Manual.

¥Caution

If the scanned images are still lined after the shading adjustment has been performed and if these lines are not eliminated even after the ADF glass areas have been cleaned, it means that the shading has not been compensated

properly. Clean the parts again, and then proceed with the shading adjustment.

39

Page 40

Repacking Instructions

It is highly recommended that you keep the original carton and ALL packing materials. If you need to transport or

ship your scanner, please follow these instructions:

≥ Use the original carton and all of the original packing materials.

≥ Improper repacking of the scanner may result in a service charge to repair the unit.

≥ The scanner should be handled in the correct (horizontal) position.

Materials Required:

≥ Original scanner carton & packing materials

≥ Shipping tape and scissors

Turn the power switch off and disconnect your scanner from the electrical outlet and the

1

interface cable.

Remove the hopper tray and attach the protective sheets with tapes.

2

Pack the scanner.

3

CD-ROM

(Operating instructions)

(Driver software)

Installation manual

Maintenance manual

Roller cleaning paper (3 pieces)

Shading chart

Blower

USB2.0 cable

Hopper tray

Power cord

40

Page 41

Specifications

Model No.

Item

Scanner Scanning face Duplex scanning

Scanning method CIS (Contact-type color Image Sensor)

Readout

speed

Resolution Flatbed/ADF Main scanning direction: 100-600 dpi (1 dpi step)

Tonal gradation Binary mode, Grayscale mode (8 bit), 64-step gradation

Image control Image emphasis, Dynamic Threshold, Automatic

Paper Size for Flatbed ~ 297k432 mm (11.7k17 in.)

Flatbed 0.704 sec (Letter, 200 dpi) 320 µsec/line

ADF Simplex scanning:

Approx. 60 sheets/min. (Letter, fed lengthwise, 200 dpi)

Approx. 60 sheets/min. (A4, fed lengthwise, 200 dpi)

Duplex scanning:

Approx. 50 sheets/min. (Letter, fed lengthwise, 200 dpi)

Approx. 50 sheets/min. (A4, fed lengthwise, 200 dpi)

Sub-scanning direction: 100-600 dpi (1 dpi step)

The optical resolution is 600 dpi.

(dither) mode, Error diffusion mode

separation, Invert, White level from paper

Size for ADF Scanning size: 48k70 mm (1.9k2.8 in.)~

297 mm (11.7 in.)k635 mm (25 in.)

KV-S7065C

Thickness for ADF 0.05 to 0.15 mm (2.0 to 5.9 mils)

Business card: Thicker than 0.15 mm (5.9 mils)

Note: 1 mil = 1/1000 in.

Weight for ADF 40 to 127 g/m

Business card: Thicker than 127 g/m

Hopper capacity 200 sheets [64 g/m

Unit External dimensions

(WidthkDepthkHeight)

Mass (Weight) 29 kg (64 lbs.)

Power requirement AC100–120 V 50/60 Hz AC220–240 V 50/60 Hz

Power

consumption

Operating

Environment

Storage

Environment

Option Roller exchange kit (KV-SS015), Imprinter unit (KV-SS014), Ink cartridge (KV-SS021),

Operating temperature and

humidity

Storage temperature and humidity 0 °C to 35 °C (32 °F to 95 °F), 10% to 80% RH

Roller cleaning paper (KV-SS03)

Maximum

(Scanning)

Minimum (Standby)

Sleep mode 8 W (AC100–120 V) 8 W (AC220–240 V)

755k508k289 mm (29.7k20k11.4 in.)

1.5 A (AC100–120 V) 0.7 A (AC220–240 V)

0.6 A (AC100–120 V) 0.3 A (AC220–240 V)

15 °C to 30 °C (59 °F to 86 °F), 30% to 80% RH

2

(10.6 to 34 lbs.)

2

(17 lbs.)]

2

(34 lbs.)

≥ “Weight in pounds” of paper represents the weight of 500 [432k559 mm (17k22 inches)] sheets.

41

Page 42

Troubleshooting

If a problem occurs while the unit is being used, check the following items and check the scanner status with the User

Utility. If the unit still malfunctions, turn it OFF, unplug the power cord and call for service.

Symptom Possible Cause Remedy

The LED does not light when

the power switch is turned

ON.

The computer does not

recognize the scanner.

SCSI

connection

USB

connection

The power cord is not plugged in. Insert the power plug firmly.

Problem with power supply.

The scanner is not connected to the

computer correctly.

The scanner is not registered

correctly.

The computer cannot recognize the

SCSI card.

The same ID number is used for the

scanner and the other device.

The scanner was turned on after the

computer was turned on.

The USB interface of the computer is

not installed correctly.

The scanner is connected via USB

hub.

Disconnect the scanner from the

electric outlet and call for service.

Connect the cables correctly.

Uninstall the scanner from the

computer.

Register the scanner hardware again.

(Refer to the Installation Manual on

pages 18 and 19.)

Check your computer whether the

SCSI card is installed correctly using

the device manager’s property. Refer

to the Installation Manual on page 17.

Use the different SCSI ID numbers for

each devices. (See page 13.)

Turn the computer OFF. Turn the

scanner ON, and then turn the

computer ON again.

Check the computer whether the USB

interface of your computer is installed

correctly using the device manager’s

property.

Do not connect via USB hub.

Scan speed is slow at USB

connection.

The ADF does not open

when the ADF door release

is pushed.

(ADF)

The document has been

loaded on the hopper tray.

But the scanner does not

start scanning.

42

The cable without High-Seed logo is

used.

The scanner is connected with USB

1.1.

The ADF door is not closed properly.

The document is not loaded

properly.

The sensor cannot detect the

document as the edge of the document

is curled.

Use the cable with High-Speed logo.

Connect with USB 2.0.

Push the ADF door release again after

you close the ADF door until it is

locked.

Load the document correctly.

(See page 14.)

Flatten the document and load it again.

Page 43

Troubleshooting

Symptom Possible Cause Remedy

The rollers are dirty. Clean all of the rollers. (See page 27.)

(ADF)

Double feeding problems

occurs frequently or the

scanner stops loading while

scanning.

(ADF)

Scanned image is aslant.

(ADF)

The scanned document is

blank.

The rollers have reached their life

expectancy.

The document is curled or folded.

The irregular type document is to be

scanned.

The document has a length of less

than 70 mm (2.75 in.).

The document guides are not adjusted

to the size of the document to be

scanned.

The document to be scanned is set

aslant on the hopper tray.

Right and left sides of the document to

be scanned are not the same in height,

because of curl and fold.

The document to be scanned was

loaded face down (upside down).

Replace the paper feed roller module

and the retard roller module. (See

page 35 and page 37.)

Flatten the document and load it again

after reducing the pages.

Make a copy of the document on

specified paper (see page 14) and

scan the copy.

Make a copy of the document on paper

of the specified size and scan the copy.

(See page 14.)

Adjust the document guides properly to

the size of the document to be

scanned.

Remove curl and fold then reduce the

amount of the document.

Load the document correctly.

(See page 17.)

Vertical lines appear on the

scanned document.

The scanning density is

uneven.

The color of the scanned

document is extremely

different from the original

document.

Dark spots or noise appear

on the scanned documents.

Scanned image has moire

fringes such as stripe or

wavy pattern noise.

The ADF glasses and flatbed glass are

dirty.

The reference plate and flatbed sheet

are dirty.

The ADF glass, reference plate, flatbed

glass and flatbed sheet are dirty.

The quantity distribution of light varies.

The settings of the computer monitor is

wrong.

The ADF glass, reference plate, flatbed

glass and flatbed sheet are dirty.

It is caused by printing pattern of the

document and the congeniality of the

scanning resolution.

Clean the ADF glasses and flatbed

glass. (See page 31.)

Clean the reference plate and flatbed

sheet. (See page 31 and page 34.)

Clean the ADF glass, reference plate,

flatbed glass and flatbed sheet. (See

page 31 and See page 34.)

Adjust shading. Please refer to section

4.6 of a user utility reference manual.

Adjust the computer monitor settings.

Clean the ADF glass, reference plate,

flatbed glass and flatbed sheet. (See

page 31 and See page 34.)

Please use the moire reduction

function or change the resolution and

try to scan.

43

Page 44

Index

Page Page

A

AC inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Acceptable documents . . . . . . . . . . . . . . . 14

Accessories . . . . . . . . . . . . . . . . . . . . . . . 26

ADF door . . . . . . . . . . . . . . . . . . . 10, 24, 27

ADF door release . . . . . . . . . . . . . 10, 24, 27

ADF glass . . . . . . . . . . . . . . . . . . . . . . 11, 31

B

Back stopper. . . . . . . . . . . . . . . . . . . . . . . 10

Blower. . . . . . . . . . . . . . . . . . . . . . 32, 33, 34

C

CD-ROM . . . . . . . . . . . . . . . . . . . . . . 1, 9, 40

Cleaning the unit. . . . . . . . . . . . . . . . . 26–34

Component identification . . . . . . . . . . . . . 10

Control sheet . . . . . . . . . . . . . . . . . . . . . . 21

CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

F

FAN exhaust vent . . . . . . . . . . . . . . . . . . 10

Fan exhaust vent . . . . . . . . . . . . . . . . . . . 26

Flatbed . . . . . . . . . . . . . . . . . . . . . 19, 23, 41

Flatbed glass . . . . . . . . . . . . . . . . 11, 26, 34

Flatbed sheet . . . . . . . . . . . . . . . . 11, 23, 34

Free rollers. . . . . . . . . . . . . . . . . . . . . 29, 30

H

Hopper . . . . . . . . . . . . . . . . . . . . . . . . 10, 16

Hopper extension tray . . . . . . . . . . . . 10, 16

Hopper tray . . . . . . . . . . . . . . . . . 10, 14, 19

I

Image control . . . . . . . . . . . . . . . . . . . . . . 41

Imprinter door. . . . . . . . . . . . . . . . . . . . . . 10

Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

D

DIP switch. . . . . . . . . . . . . . . . . . . . . . . . . 13

Document cover . . . . . . . . . . . . . . . . . 10, 23

Document cover detector . . . . . . . . . . . . . 34

Document feeder . . . . . . . . . . . . . . . . . . . 24

Document guide . . . . . . . . 10, 14, 15, 17, 18

Documents to avoid . . . . . . . . . . . . . . . . . 14

Double feed detector . . . . . . . . . . . . . . . . 32

Drive rollers. . . . . . . . . . . . . . . . . . . . . 29, 30

E

Ending sensors. . . . . . . . . . . . . . . . . . . . . 33

Energy Star. . . . . . . . . . . . . . . . . . . . . . . . . 2

Exit door . . . . . . . . . . . . . . . . . . . . 10, 22, 25

Exit door release. . . . . . . . . . . . . . 11, 22, 33

Exit rollers. . . . . . . . . . . . . . . . . . . . . . . . . 30

Exit stopper. . . . . . . . . . . . . . . . . . . . . . . . 10

Exit tray. . . . . . . . . . . . . . . . . . . . . . . . 10, 14

External dimensions . . . . . . . . . . . . . . . . . 41

L

Landscape . . . . . . . . . . . . . . . . . . . . . . . . 17

LED . . . . . . . . . . . . . . . . . . . . . . . . . . 12, 42

Limit mark . . . . . . . . . . . . . . . . . . . . . . . . 17

Loading Documents. . . . . . . . . . . . . . 14, 19

M

Manual feed selector . . . . . . . . . . 10, 16, 18

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Multiple sheets. . . . . . . . . . . . . . . . . . . . . 15

N

Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

O

Operating Environment . . . . . . . . . . . . . . 41

Option . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

44

Page 45

Page Page

P

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Paper feed roller . . . . . . . . . . . . . . . . . 27, 35

Paper jams . . . . . . . . . . . . . . . . . . . . . . . . 24

Paper sensor . . . . . . . . . . . . . . . . . . . . . . 32

Paper slot . . . . . . . . . . . . . . . . . . . . . . . . . 18

Portrait . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power consumption . . . . . . . . . . . . . . . . . 41

Power cord . . . . . . . . . . . . . . . . . . . 4, 10, 40

Power indicator. . . . . . . . . . . . . . . . . . . . . 10

Power requirement . . . . . . . . . . . . . . . . . . 41

Power switch. . . . . . . . . . . . . . . . . . . . 10, 12

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . 7

R

Index

USB connector. . . . . . . . . . . . . . . . . . . . . 10

USB hub. . . . . . . . . . . . . . . . . . . . . . . . 2, 42

User utility . . . . . . . . . . . . . . . 12, 28, 38, 39

W

Waiting sensor . . . . . . . . . . . . . . . . . . . . . 32

Reference plate . . . . . . . . . . . . . . 11, 22, 31

Repacking. . . . . . . . . . . . . . . . . . . . . . . . . 40

Replacing Consumable. . . . . . . . . . . . . . . 35

Retard cover . . . . . . . . . . . . . . . . . 27, 28, 37

Retard roller . . . . . . . . . . . . . . . . . . . . 27, 37

Roller cleaning paper . . . . . . . . . . . . . . 6, 26

S

SCSI Connection . . . . . . . . . . . . . . . . . . . . 2

SCSI connector. . . . . . . . . . . . . . . . . . . . . 10

SCSI ID setting . . . . . . . . . . . . . . . . . . . . . 13

Separation roller . . . . . . . . . . . . . . . . . . . . 27

Shading. . . . . . . . . . . . . . . . . . . . . . . . 39, 43

Specifications . . . . . . . . . . . . . . . . . . . . . . 41

Starting sensor . . . . . . . . . . . . . . . . . . . . . 33

STOP/START button . . . . . . . . . . . . . . . . 10

System requirements . . . . . . . . . . . . . . . . . 2

T

Top cover . . . . . . . . . . . . . . . . . . . . . . . . . 10

Troubleshooting . . . . . . . . . . . . . . . . . . . . 42

U

USB connection . . . . . . . . . . . . . . . 2, 12, 13

45

Page 46

Panasonic Digital Document Company

A Unit of Matsushita Electric Corporation of America

Two Panasonic Way, Secaucus, New Jersey 07094

Panasonic Canada Inc.

5770 Ambler Drive, Mississauga, Ontario, L4W 2T3

Matsushita Electric Industrial Co., Ltd.

http://www.panasonic.co.jp/global/

© 2004 Panasonic Communications Co., Ltd. All Rights Reserved.

E-040406

Loading...

Loading...