Panasonic GX-N12M Installation Manual

Thank you very much for using SUNX products.

Please read this Instruction Manual carefully and

thoroughly for the correct and optimum use of this

INSTRUCTION MANUA

product. Kindly keep this manual in a convenient

place for quick reference.

DC Three-wire Type

Cylindrical Inductive Proximity Sensor

GX-N Series

٨٨Never use this product as a sensing device for personnel protection.

In case of using sensing devices for personnel protection, use products which meet standards,

WARNING

1

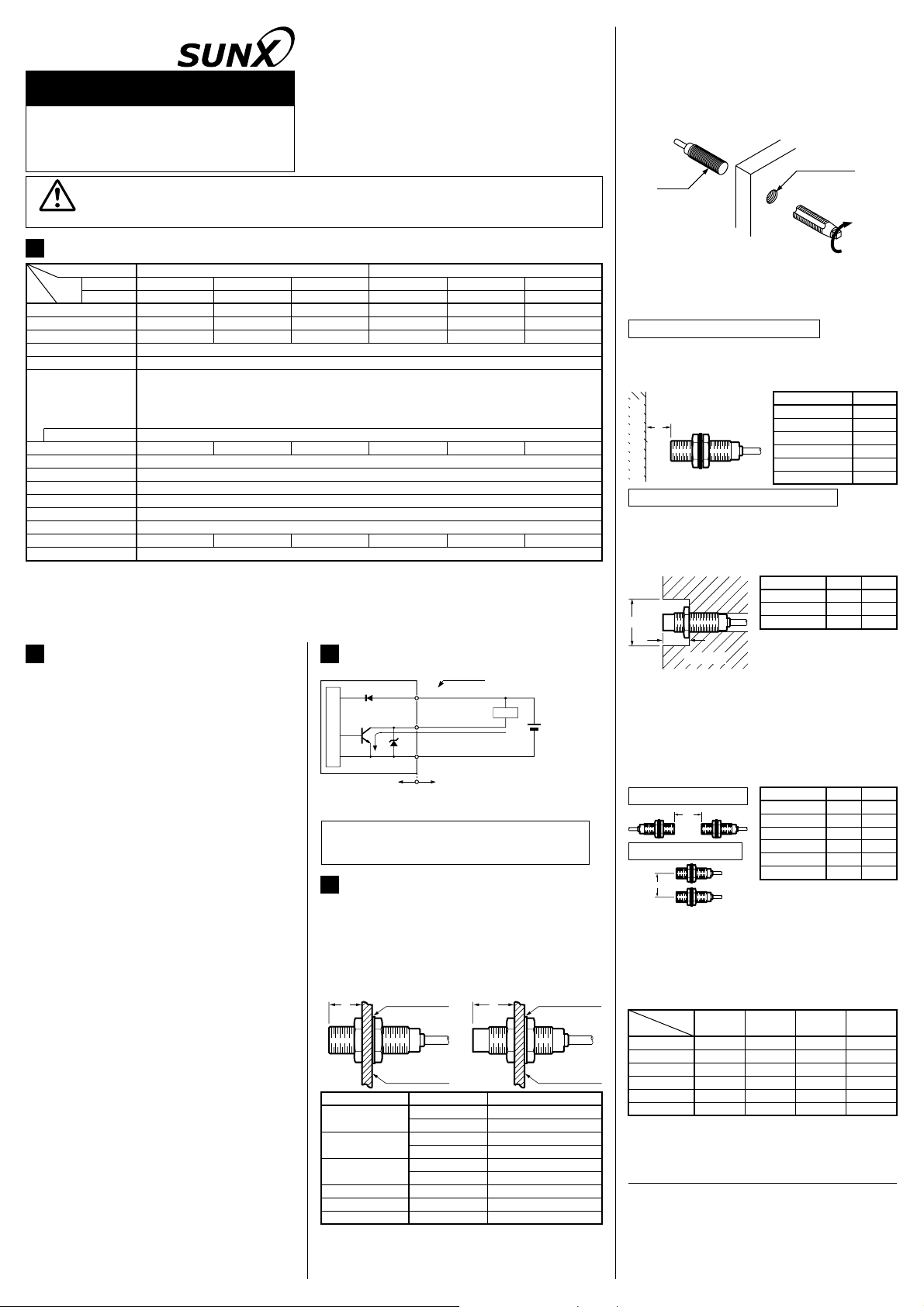

SPECIFICATIONS

Item

Max. operation distance (Note 4)

Stable sensing range (Note 4)

Standard sensing object

Supply voltage

Current consumption (Note 5)

Output

Short-circuit protection

Max. response frequency

Operation indicator

Protection

Ambient temperature

Ambient humidity

Material

Cable 0.3mm2 3-core oil, heat and cold resistant cabtyre cable, 2m long

Weight (Note 8) (Note 9)

Accessories

Notes: 1)

2

CAUTIONS

٨

Make sure that the power supply is off while

wiring.

٨

Take care that wrong wiring will damage the

sensor.

٨

Verify that the supply voltage variation is within the rating.

٨

If power is supplied from a commercial

switching regulator, ensure that the frame

ground (F.G.) terminal of the power supply is

connected to an actual ground.

٨

In case noise generating equipment (switching regulator, inverter motor, etc.) is used in

the vicinity of this product, connect the frame

ground (F.G.) terminal of the equipment to an

actual ground.

٨

Do not run the wires together with high-voltage lines or power lines or put them in the

same raceway. This can cause malfunction

due to induction.

Do not use during the initial transient time

٨

(50ms) after the power supply is switched on.

Extension up to total 100m is possible with a

٨

0.3mm

Make sure that stress by forcible bend or pull-

٨

ing is not applied directly to the sensor cable

joint.

Take care that the sensor does not come in

٨

direct contact with organic solvents, such as,

thinner, etc.

Make sure that the sensing end is not cov-

٨

ered with metal dust, scrap or spatter. It will

result in malfunction.

such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

Color code

(Brown) +V

(Black) Output

D

(Blue) 0V

Non-shielded typeShielded typeType

GX-N18ML

GX-N18MLB

15mmr10%

0 to 12mm

Iron sheet 5050t1mm

100Hz 100Hz350Hz300Hz450Hz 300Hz

110g approx. 240g approx.65g approx.240g approx.65g approx. 110g approx.

Load

max.

100mA

Model

No.

Normal open

Normal closed

GX-N12M

GX-N12MB

3mmr10%

0 to 2.4mm

Iron sheet 1212t1mm

GX-N18M

GX-N18MB

7mmr10%

0 to 5.6mm

Iron sheet 1818t1mm

NPN open-collector transistor

Maximum sink current: 100mA

Applied voltage: 30V DC or less (between output and 0V)

Residual voltage: 1.5V or less (at 100mA sink current)

Enclosure: Brass (Nickel plated), Sensing part: Nylon, Indicator part: Nylon

GX-N30M

GX-N30MB

10mmr10%

0 to 8mm

Iron sheet 3030t1mm

12 to 24V DC % Ripple: P-P10% or less

0.4V or less (at 16mA sink current)

Orange LED (lights up when the output is ON)

IP67 (IEC), IP67g (JEM)

-25 to +70, Storage: -30 to +80

45 to 85% RH, Storage: 35 to 95% RH

Nut: 2 pcs., Toothed lock washer: 1 pc.

Iron sheet 3030t1mm

+10

-15

10mA or less

Incorporated

GX-N12ML

GX-N12MLB

8mmr10%

0 to 6.4mm

The maximum operation distance stands for the maximum distance for which the sensor can detect the

standard sensing object.

The stable sensing range stands for the sensing range for which the sensor can stably detect the standard

sensing object even if there is an ambient temperature drift and/or supply voltage fluctuation.

The weight of the threaded type includes the weight of two nuts and one toothed lock washer.

2)

3

I/O CIRCUIT DIAGRAM

D

Tr

Sensor circuit

Internal circuit Users' circuit

Z

Note: If a capacitive load is directly connected to the

output, malfunction may occur.

Symbols...

4

D

:

Reverse supply polarity protection diode

Z

:

D

Surge absorption zener diode

:

NPN output transistor

Tr

MOUNTING

٨٨The tightening torque should be under the value

given below.

Mount such that the nuts do not protrude from

the threaded portion.

2

, or more, cable.

<Shielded type>

Attached toothed lock washer

A

Mounting plate

Model No.

GX-N12M(B)

GX-N18M(B)

GX-N30M(B)

GX-N12ML(B)

GX-N18ML(B)

GX-N30ML(B)

Dimension A (mm)

<Non-shielded type>

A

3.5 to 13.5

13.5 or more

4 to 18

18 or more

5 to 21

21 or more

15 or more

25 or more

30 or more

GX-N30ML

GX-N30MLB

22mmr10%

0 to 17.6mm

Iron sheet 7070t1mm

+

12 to 24V DC

+10

%

-15

-

Attached toothed lock washer

Mounting plate

Tightening torque

10N㨯m

20N㨯m

45N㨯m

80N㨯m

80N㨯m

180N㨯m

20N㨯m

80N㨯m

180N㨯m

٨

Caution with GX-N12M(B) and GX-N12ML(B)

The root truncation of the threaeds is shallow

owing to strengthening of the sensors against

tightening.

When tapping holes on equipment to fix the

sensors, the prepared hoels must be Ǿ11.2mm

or more with GX-N12M(B) and GX-N12ML(B).

Tapping holes

Sensor

٨Distance from surrounding metal

As metal around the sensor may affect the

sensing performance, pay attention to the following points.

Influence of surrounding metal

The surrounding metal will affect the sensing

performance. Keep the minimum distance

specified in the table below.

B

Background metal

Model No. B (mm)

GX-N12M(B)

GX-N18M(B)

GX-N30M(B)

GX-N12ML(B)

GX-N18ML(B)

GX-N30ML(B)

8

20

40

22

45

75

Embedding of the sensor in metal

Sensing range may decrease if the sensor is completely embedded in metal. Especially for the nonthreaded type and the non-shielded type, keep the

minimum distance specified in the table below.

Model No.

GX-N12ML(B)

GX-N18ML(B)

C

D

Metal

GX-N30ML(B)

Note: With the non-shielded type, the sensing range

may vary depending on the position of the nuts.

C (mm)

Ǿ50

Ǿ75

Ǿ105

D (mm)

15

25

30

٨Mutual interference

When two or more sensors are installed in

parallel or face to face, keep the minimum

separation distance specified below to avoid

mutual interference.

Face to face mounting

E

Parallel mounting

F

Model No.

GX-N12M(B)

GX-N18M(B)

GX-N30M(B)

GX-N12ML(B)

GX-N18ML(B)

GX-N30ML(B)

E (mm)

25

50

90

120

180

F (mm)

15

35

55

70

125

190290

٨Sensing range

The sensing range is specified for the standard sensing object. With a non-ferrous metal,

the sensing range is obtained by multiplying

with the correction coefficient specified below.

Correction coefficient

Metal

Model No.

GX-N12M(B)

GX-N18M(B)

GX-N30M(B)

GX-N12ML(B)

GX-N18ML(B)

GX-N30ML(B)

Note: The sensing range also changes if the sensing

object is plated.

SUNX Limited

Iron

1

1

1

1

1

1

Stainless steel

(SUS304)

0.77 approx.

0.73 approx.

0.70 approx.

0.66 approx.

0.68 approx.

0.65 approx.

http://www.sunx.co.jp/

Brass

0.52 approx.

0.50 approx.

0.45 approx.

0.44 approx.

0.46 approx.

0.44 approx.

Aluminum

0.51 approx.

0.48 approx.

0.44 approx.

0.43 approx.

0.44 approx.

0.43 approx.

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901,

Japan

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

PRINTED IN JAPAN

Loading...

Loading...