Panasonic GXL-N12FB Installation Manual

INSTRUCTION MANUAL

Inductive Proximity Sensor

GXL-N12Fغ

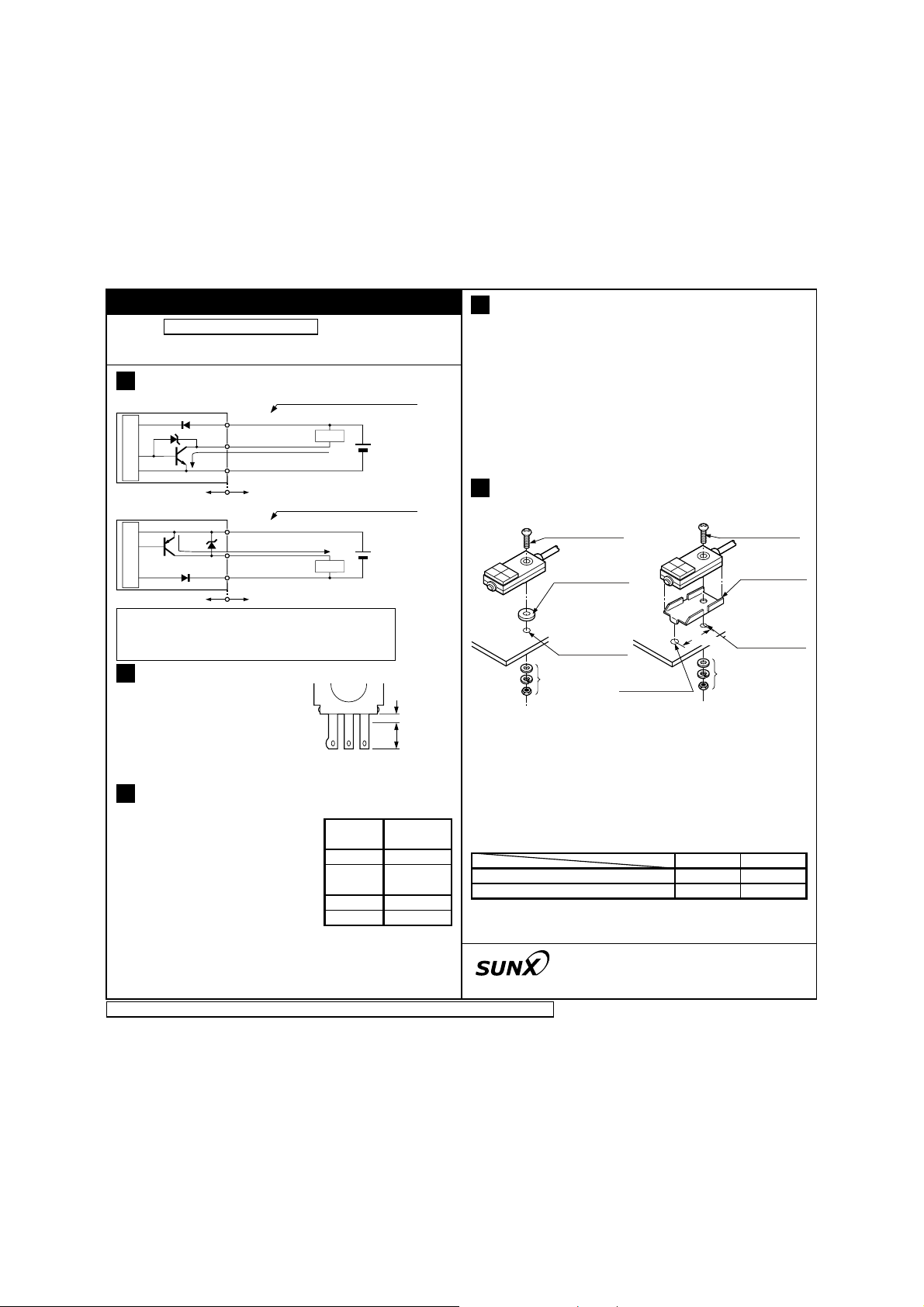

I/O CIRCUIT DIAGRAMS

1

٨ NPN output type

1

D

Z

D1

r1

T

Sensor circuit

Internal circuit Users' circuit

٨ PNP output type

r2

T

2

D

Sensor circuit

Internal circuit Users' circuit

Symbols...D1, D2:

2

ZD1, ZD2: Surge absorption zener diode

r1: NPN output transistor

T

r2: PNP output transistor

T

SOLDERING

٨ To solder the terminals of the

sensor observe the following

conditions. Soldering temperature: 260 or less Soldering

time: 5 sec. or less Soldering position: 1.5mm, or more, away

from the sensor body.

SENSING RANGE

3

٨

Please use it by 2mm or less. However, this value is a value over a

standard detection object (iron 20

20t1mm). With a non-ferrous metal, the sensing range is obtained by

multiplying with the correction coefficient specified on the right.

٨

Keep in mind that detection distance becomes short when a detection object is small.

Further, the sensing range also changes if the sensing object

٨

(Brown / +V) +V

(Black / OUT) Output

100mA max.

(Blue / 0V) 0V

(Brown / +V) +V

Z

D2

Reverse supply polarity protection diode

100mA max.

(Black / OUT) Output

(Blue / 0V) 0V

Front sensing

Color code / Terminal symbol

Load

+

12 to 24V DC

r10%

-

Color code / Terminal symbol

+

12 to 24V DC

r10%

-

Load

1.5mm

Correction coefficient

Sensing

object

Stainless steel

(SUS304)

Brass

Aluminum

Correction

coefficient

Iron

0.70 approx.

0.40 approx.

0.35 approx.

Soldering

position

1

CAUTIONS

4

٨

If power is supplied from a commercial switching regulator,

ensure that the frame ground (F.G.) terminal of the power

supply is connected to an actual ground.

٨

The output does not incorporate a short-circuit protection circuit.

Do not connect it directly to a power supply or a capacitive load.

٨

Do not run the wires together with high-voltage lines or power

lines or put them in the same raceway. This can cause malfunction due to induction.

Do not use during the initial transient time (10ms) after the

٨

power supply is switched on.

٨

Extension up to total 100m is possible with a 0.3mm2, or more, cable.

However, in order to reduce noise, make the wiring as short as possible.

MOUNTING

5

<One point fixing>

٨

Do not use a washer between the sensor and the mounting screw.

The tightening torque be 0.49N㨯m or less.

٨

Influence of surrounding metal

٨

When there is a metal near the sensor, keep the minimum

separation distance specified in the figures shown on the reverse side.

Mutual interference prevention

٨

When two or more sensors are installed in parallel or face to

face, keep the minimum separation distance specified below

to avoid mutual interference.

Refer to the figures shown on the reverse side.

Between 'I' type and non 'I' type

Between two 'I' types or two non 'I' types

Note: Close mounting is possible for up to two sensors. When mount-

ing three sensors or more, at an equal spacing, in a row, the

minimum value of dimension 'A' should be 4mm.

is plated.

SUNX Limited

This bag is a product made from polyethylene. Even if it burns, harmful gas is not generated.

M3 (length 12mm)

truss head screw

(Accessory)

Rubber washer

(Accessory)

M3 0.5mm

tapped hole

(Depth: 10mm

or more) or Ǿ

3.4mm thru-hole

If mounting using

nut and washers

(Accessories)

Head office: 2431-1 Ushiyam-cho, Kasugai-shi,

Overseas Sales Dept.: Phone: +81-(0)568-33-7861

<Two point fixing>

Ǿ2.5mm hole

(Depth: 3mm or more)

Aichi, 486-0901,Japan

Phone: +81-(0)568-33-7211

M3 (length 12mm)

truss head screw

16mm

If mounting using

nut and washers

(Accessories)

A

0mm (Note)

20mm

PRINTED IN JAPAN

M3 0.5mm

tapped hole

(Depth: 10mm

or more) or Ǿ

3.4mm thru-hole

(Accessory)

MS-GXL12-1

(Accessory)

15mm

40mm

B

Loading...

Loading...