Panasonic FX-100-Z, MEUEN-FX100Z Instruction Manual

1

InstructIon Manual

Digital Fiber Sensor

FX-100-Z Series

MEUEN-FX100Z V1.0

Thank you for purchasing products from Panasonic Electric Works SUNX

Co., Ltd. Please read this Instruction Manual carefully and thoroughly for

the correct and optimum use of this product. Kindly keep this manual in a

convenient place for quick reference.

WARNING

● Never use this product as a sensing device for personnel protection.

● In case of using sensing devices for personnel protection, use prod-

ucts which meet laws and standards, such as OSHA, ANSI or IEC

etc., for personnel protection applicable in each region or country.

1

cautIons

● This product has been developed / produced for industrial use only.

● Make sure that the power supply is off while wiring.

● If a voltage exceeding the rated range is applied, or if an AC power

supply is directly connected, the product may get burnt or damaged.

● Short-circuiting the load or incorrect wiring may burn or damage the

product.

● Do not run the wires together with high-voltage lines or power lines

or put them in the same raceway. This can cause malfunction due to

induction.

● Verify that the supply voltage variation is within the rating.

● If power is supplied from a commercial switching regulator, ensure that

the frame ground (F.G.) terminal of the power supply is connected to

an actual ground.

● If noise generating equipment (switching regulator, inverter motor, etc.)

is used in the vicinity of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

● Do not use during the initial transient time (0.5s) after the power sup-

ply is switched on.

● You can extend the cable up to 100m max. with 0.3mm

2

or more

cable. However, in order to reduce noise, make the wiring as short as

possible.

● Make sure that stress is not applied to the sensor cable joint, e.g. by

forcible bending or pulling.

● Take care that the product is not directly exposed to uorescent lamp

from a rapid-starter lamp, a high frequency lighting device or sunlight,

etc. as it may affect the sensing performance.

● This product is suitable for indoor use only.

● Avoid dust, dirt, and steam.

● Take care that the product does not come in contact with oil, grease,

organic solvents, such as thinner, etc., strong acid or alkalines.

● This product cannot be used in an environment containing inam-

mable or explosive gases.

● Never disassemble or modify the product.

● EEPROM is adopted to this product. Teaching is limited to 100,000

times because of the EEPROM's lifetime.

2

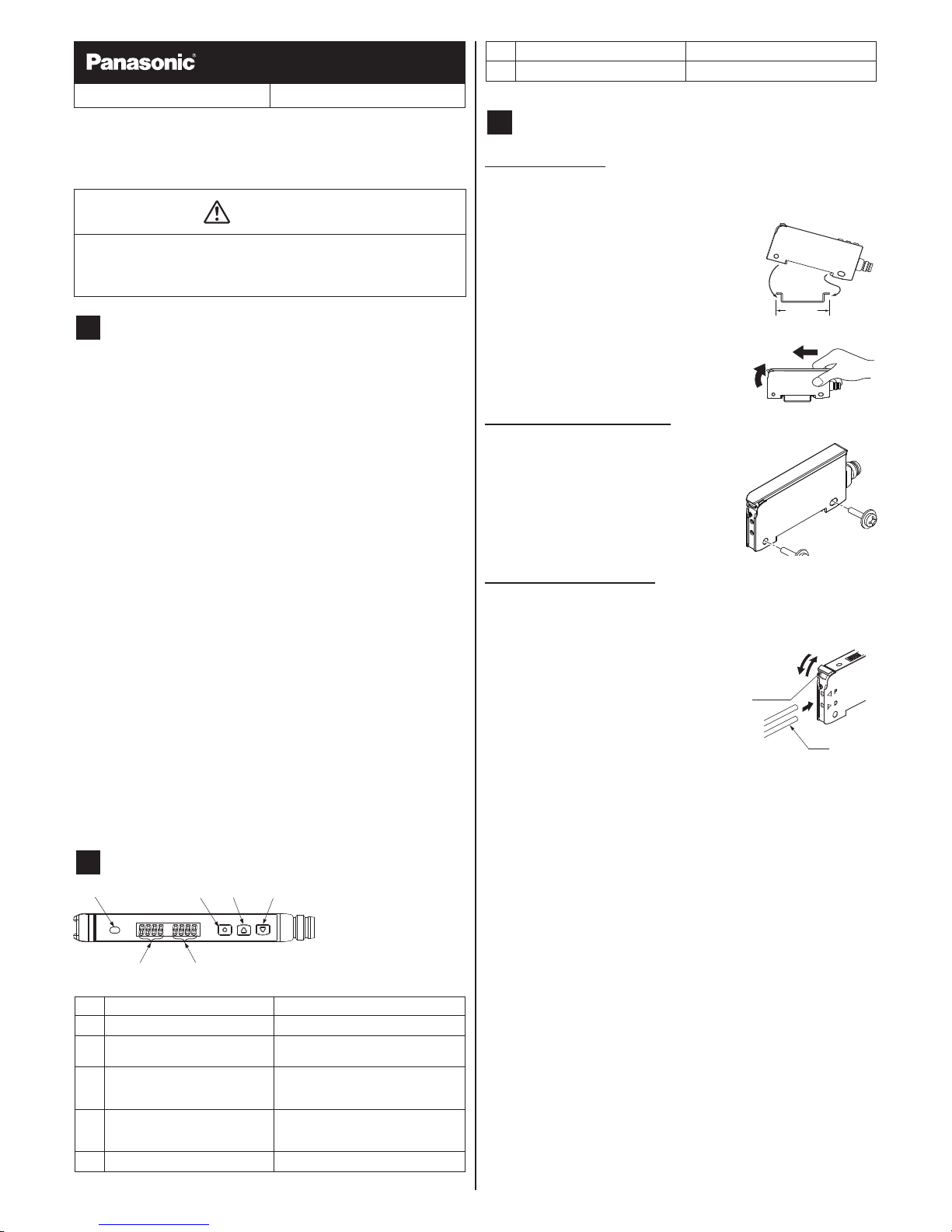

Part DEscrIPtIon

1

65

432

no. Part Description

1

Output indicator (orange) Lit when output is active.

2

Mode key ● Select mode

● Conrm settings

3

ON key / Set value UP key ● Select settings in teaching mode

● Increase set value

● Select various other settings

4

OFF key / Set value DOWN key ● Select settings in teaching mode

● Decrease set value

● Select various other settings

5

Green digital display Threshold value

no. Part Description

6

Red digital display Incident light intensity

3

MountInG

When using a DIn rail

* You may break the spring hook if you do not follow the mounting

instructions carefully.

How to mount the amplier

1. Fit the spring hook on a 35mm DIN rail and

push forward.

2. Slip the front part of the mounting section

over the DIN rail and release.

1

2

35mm

How to remove the amplier

1. Push the amplier forward.

2. Lift up the front part of the amplier.

1

2

When using screws with washers

Use M3 screws with washers to mount the

amplier.

Do not use a tightening torque of more than 0.5

N•m or you may break the housing.

M3 screw

with washers

How to connect the ber cable

Be sure to t the attachment to the bers rst before inserting the bers into

the amplier. For details, refer to the Instruction Manual enclosed with the

bers.

1. Snap the ber lock lever down until it

stops completely.

2. Slowly insert the ber cables into the

inlets until they stop (see note).

If the ber cables are not inserted until

they stop, the sensing range reduces.

Since a exible ber is easily bent, be

careful when inserting it.

3. Return the ber lock lever to the original

position.

1

3

2

Fiber lock

lever

Fiber

* If the cable is a coaxial reective type ber, e.g. FD-G4 or FD-

FM2, insert the single-core ber cable into the beam-emitting

inlet “P” and the multi-core ber cable into the beam-receiving

inlet “D.” If they are inserted in reverse, the sensing perfor-

mance will deteriorate.

2

4

WIrInG

● Use the cable with the connector CN-24A-Cq(optional)when con-

necting this product.

● Tighten the xing ring of the cable with connector completely by hand

when mounting. The tightening torque: 0.3 to 0.4N•m.

● Make sure to hold the side surface of this product when tightening or

loosening the xing ring of the cable with connector.

● If the xing ring is tightened by a tool such as pliers, the connector

may be damaged.

● If the tightening torque is not enough, the xing ring may loosen due to

vibration, etc.

Attaching the connector cable

connection method

Insert the cable with connector CN-24A-Cqas

shown. Tighten the xing ring.

Fixing ring

Cable with

connector

CN-24A-C□

Disconnection method

Loosen the xing ring, and, holding the xing

ring, pull to separate the connector.

Fixing ring

* Before disconnecting the cable, loosen the xing ring com-

pletely. If the cable is pulled by excessive force (15N or more)

when the xing ring is tightened, the cable may break.

connector pin arrangement

1

2

4

3

connector pin no. terminal name

1 +V

2 External input

3 0V

4 Output

5

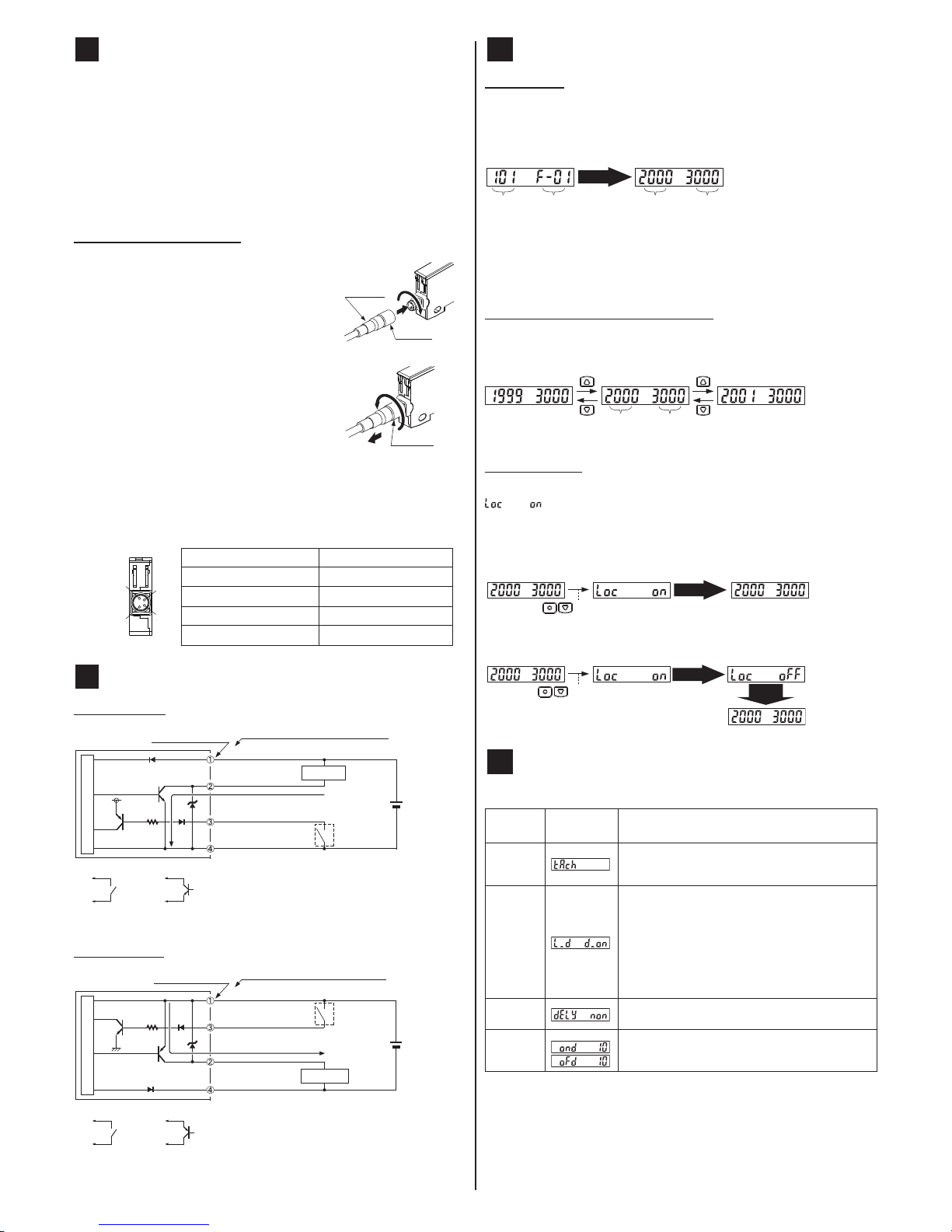

I/o cIrcuIt DIaGraMs

NPN output type

+

–

8V

*

±10%

Main circuit

100mA max.

(Brown) +V

(Black) Output

(Blue) 0V

(White) External input

Color code of cable with connector

Load

Connector pin No.

12 to 24V DC

* Non-voltage contact or NPN open-collector transistor

or

● High (+8V to +V DC or Open): Invalid

● Low [(0 to +2V DC (source current 0.5mA or less)]: Valid

PNP output type

*

+

–

±10%

Main circuit

100mA max.

(Brown) +V

(Black) Output

(Blue) 0V

(White) External input

Color code of cable with connector

12 to 24V DC

Load

Connector pin No.

* Non-voltage contact or PNP open-collector transistor

or

● High [+4V to +V DC (Sink current 0.5 to 3mA or less)]: Valid

● Low (0 to +0.6V DC or Open): Invalid

6

run MoDE

Digital display

When you turn ON the power, the product name is indicated in green and

the emission frequency is indicated in red. Then the device automatically

switches into RUN mode, in which the threshold value is displayed in green

and the incident light intensity in red.

Power ON

Emission

frequency

Product

name

RUN mode

Incident light

intensity

Threshold

value

Automatic

* What appears on the display is effected by the settings for the

external input and ECO mode. For details, see PRO MODE on

page 4.

Threshold value ne adjustment function

Change the threshold value in RUN mode by pressing <UP> or <DOWN>.

Hold down the key to make the value change faster. The threshold value is

stored after 3s.

RUN mode

Incident light

intensity

Threshold

value

Key lock function

The key lock function prevents settings from being changed inadvertently.

is displayed if you press a key when the key lock function is set.

Press <MODE> + <DOWN> for at least 2s to set or release the key lock

function.

Set key lock

RUN mode

Press for 2 sec.

Automatic

Release key lock

RUN mode

Press for 2 seconds

Automatic

Automatic

7

sEttInG MoDE

To enter SETTING mode, press <MODE> for 2s in RUN mode. While in

SETTING mode, press <MODE> briey to move from one selection to the

Item

Factory setting

Description

Teaching

A threshold value can be set in 2-point teaching, limit

teaching or full-auto teaching.

For details, see tEacHInG MoDE on page 7.

Output

operation

Light-ON or Dark-ON can be set.

● light-on means the output will turn ON when

the incident light intensity is in the brighter of

the two 2 sensing states (object present/object

absent).

● Dark-ON means the output will turn ON when

the incident light intensity is in the darker of

the two 2 sensing states (object present/object

absent).

Timer

selection

Three settings are possible: no timer, ON delay timer,

or OFF delay timer.

Timer

delay

You can specify the delay for the ON delay timer or

OFF delay timer.

If no timer is set, this mode is not displayed.

3

Item

Factory setting

Description

Emission

level

If the incident light intensity is saturated, which makes

sensing impossible or unreliable, you can reduce the

emission level.

● Level 3 (

): Normal

● Level 2 (

): Approx. 40% of normal

● Level 1 (

): Approx. 20% of normal

When you select Auto (

), proper light intensity is

automatically set only during limit teaching.

* For differences between the conventional and

modied units, see unIt VErsIons on page

7.

Emission

frequency

FX-102□-Z

FX-101□-Z

When using ber heads in parallel, interference can be

prevented by setting different emission frequencies.

When emission frequency 0 is set, interference cannot

be prevented. Response time corresponds to emission

frequency. For details, see sPEcIFIcatIons on

page 8.

Flowchart for sEttInG mode

run mode

Press for 2s.

sEttInG mode

Automatic

teaching

output operation

Light-ONDark-ON

timer operation

1, 5, 10, 20, 40, 50, 100, 500, 1000ms

:

Without timer

Timer delay Timer delay

Timer delays setting mode Timer delays setting mode

ON delay timer

OFF delay

timer

Timer delays available (ms):

Emission level

Level 2Level 3 Auto + Level 3Level 1

Emission frequency

FX-101□-Z FX-102□-Z

FX-101□-Z

FX-102□-Z

Emission

frequency 0

Emission

frequency 1

Emission frequencies available:

Emission frequencies available:

* The operation indicator and the beam-emitting inlet blink while the

emission frequency is being set. When the emission frequency is

set to 0, they light up. The blinking cycle depends on each emission

frequency (emission frequency 1: fast ↔ emission frequency 4:

slow).

run mode

8

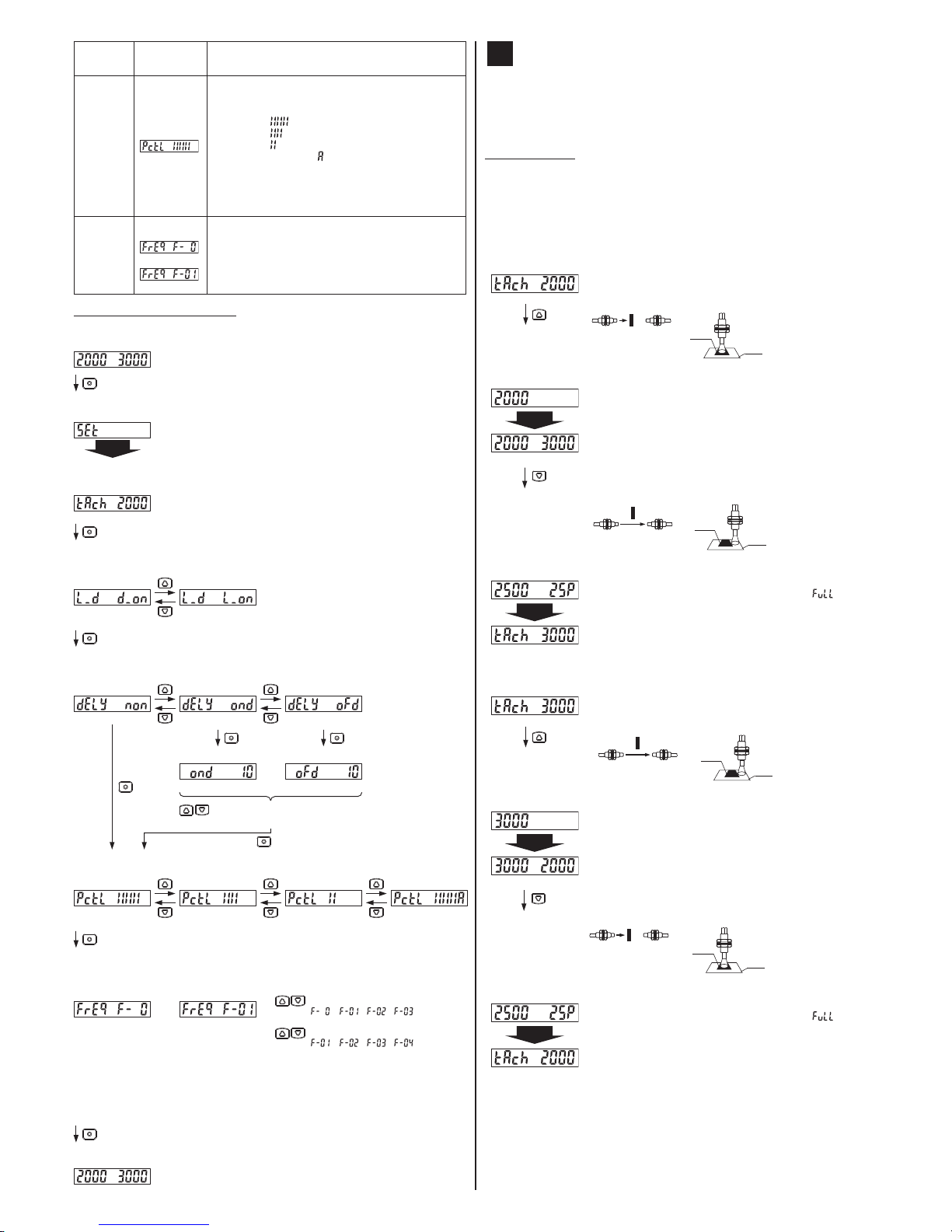

tEacHInG MoDE

* Beware that detection may become unstable if too little margin

between the theshold value and incident light intensity is allowed for the environment when teaching.

2-point teaching

2-point teaching is the most common teaching method and means the

threshold value is taught using two points that correspond to the object

present and object absent conditions.

Light-ON or Dark-ON is determined automatically for the output operation

setting.

Output indicator ON when object is present

In teaching mode, press <ON> when object is present to set

the rst incident light intensity.

Thru-beam type

Light interrupted

condition

Light received condition

Mark

Reflective type

Base

Automatic

The rst incident light intensity is set and is displayed in

green. The red LED display blinks and is ready to be set to

the object absent condition.

To cancel, press <MODE>.

Remove the object and press <OFF> to complete 2-point

teaching.

Thru-beam type

Light received condition

Light interrupted condition

Mark

Reflective type

Base

Automatic

The margin between the rst and second incident is displayed

in red (P=%). When the margin is 200% or more,

is

displayed.

Output indicator ON when object is absent

In teaching mode, press <ON> when object is absent to set

the rst incident light intensity.

Thru-beam type

Light received condition

Light interrupted condition

Mark

Reflective type

Base

Automatic

The rst incident light intensity is set and is displayed in

green. The red LED display blinks and is ready to be set to

the object present condition.

To cancel, press <MODE>.

Place the object so that it is sensed and press <OFF> to

complete 2-point teaching.

Thru-beam type

Light interrupted

condition

Light received condition

Mark

Reflective type

Base

Automatic

The margin between the rst and second incident is displayed

in red (P=%). When the margin is 200% or more,

is

displayed.

Loading...

Loading...