Page 1

FT-F9SERIES

LIQUID FIBER

Pipe-mountable liquid detection fiber

Worry-free Design That Doesn't Overlook Liquidabsent condition and Sensor Malfunction

•

When liquid is present in the pipe, the lens effect of the liquid condenses the beam, so the sensor become to be in

beam received condition.

•

If the fiber is bent or faulty, if the cable is cut or disconnected,

or if the sensor is not operating correctly, the output is the same

as when the beam is not received (Liquid-absent condition).

Reliably Detect Liquid in Pipe

Beam-receiving signal

Zero

When cable is cut

Safer Fiber Type Sensor

In response to the demand for higher safety standards

throughout the world, including SEMI S2, safer sensing can

be achieved by placing the amplifier for this fiber sensor

away from dangerous locations, such as locations with volatile

chemicals, where electrical circuits increase the risk of fire or

explosion.

Easy to Use and Reliable Detection

Even when the shape and thickness of the pipe vary, this sensor uses a method where the beam axis is always over the diameter of the pipe, and so when compared to conventional

methods, the shape and thickness of the pipe have no influence over the performance of this sensor.

Reliable Detection Not Affected by Bubbles

or Droplets

Problems encountered by conventional pipe-mountable sensors, such as bubbles, droplets, or liquid leakage, have been

solved using the latest optical fiber techniques.

Cut!Cut!Cut!

Liquid present

Liquid absent

Beam-receiving signal

Low

Beam-receiving signal

High

Page 2

SPECIFICATIONS PRECAUTIONS FOR PROPER USE

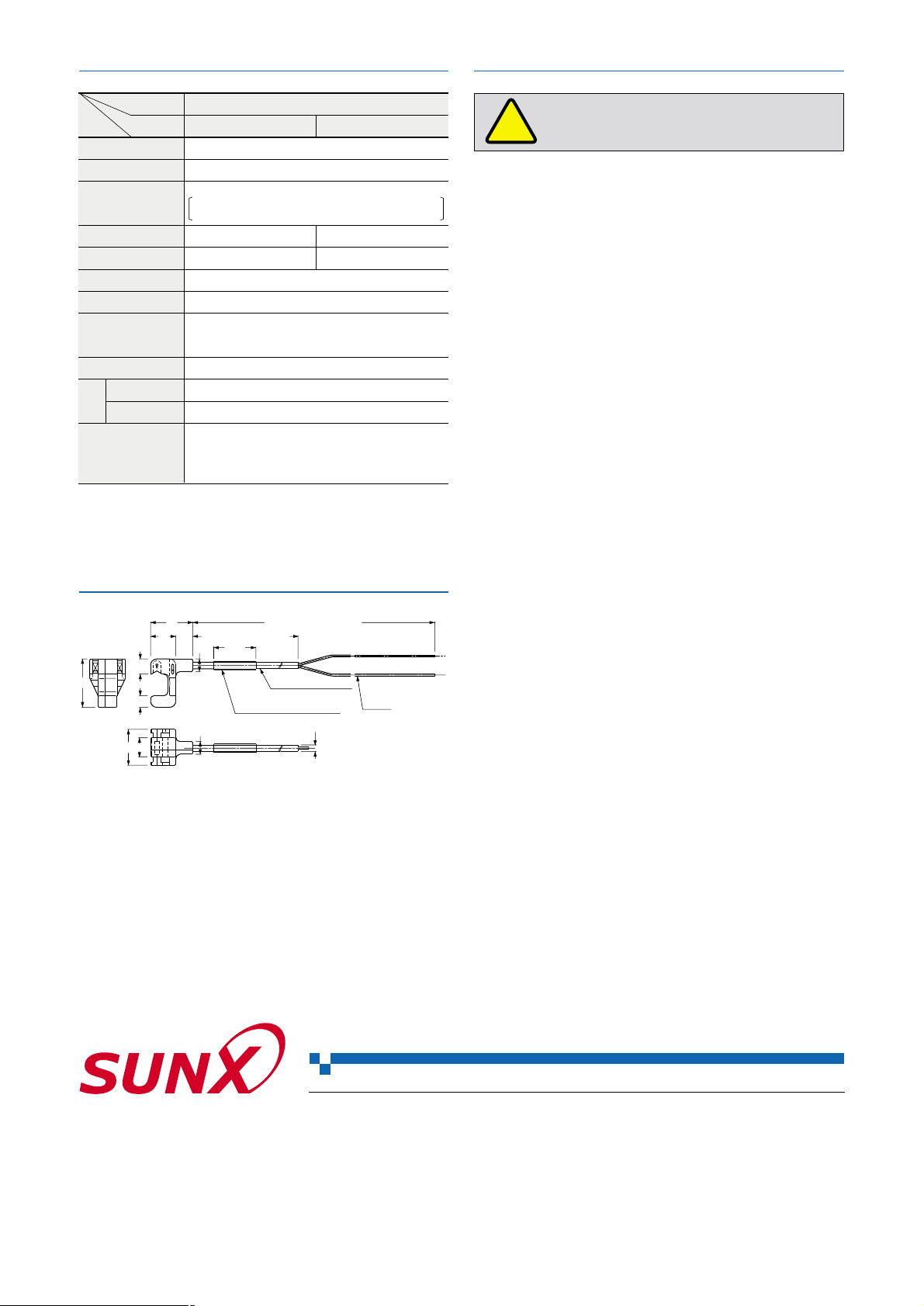

DIMENSIONS (Unit: mm)

Designation

Model No.

Item

Applicable amplifier

Sensing object

Applicable pipe

diameter (Note 2)

Protective tube length

Fiber cable length

Allowable bending radius

Bending durability

Ambient temperature

Ambient humidity

Accessories

FX-D1-F

Liquid (Note 1)

Outer dia "3.0 to "10.0mm

Protective tube: R20mm or more, Fiber cable: R4mm or more

Fiber cable: 1,000,000 times or more (at R4mm)

− 20 to + 60°C (No dew condensation or icing allowed),

Storage: −20 to +60°C (Note 3)

35 to 85% RH, Storage: 35 to 85% RH

Fiber core: Acrylic, Fiber sheath: Vinyl chloride, Protective tube: PFA

Enclosure: Heat-resistant ABS, Lens: Acrylic

Tying band: 2 Nos., Anti-slip tube: 2 Nos.

FX-CT1 (Fiber cutter): 1 No.

FX-AT10 ("1mm fiber attachment): 1 set

1m

2m free-cut

3m

5m free-cut

FT-F902 FT-F905

Liquid fiber (Pipe-mountable liquid detection fiber)

Notes: 1) Reliable detection may not be possible for unclear or heavily colored

liquid.

2) Liquid in an opaque pipe cannot be detected correctly.

3) Liquid being detected should also be kept within the rated ambient

temperature range.

·

There is a white stripe on the beam-emitting fiber cable. When

setting the amplifier, put the fiber cable with white stripe into the

beam-emitting side.

·

Keep the fiber head surface intact. If it is scratched or spoiled,

the detectability will deteriorate.

(Caution: Do not use any organic solvents.)

·

Do not use the fiber head in places where it may come in direct

contact with water. A water drop on the fiber head deteriorates

the sensing. No dew or liquid drop is present on either surface of

the pipe wall.

·

Do not apply excessive tensile force to the fiber cable.

·

Bending radius of the fiber cable must be R4mm or more. If the

bending radius is smaller than the specified value, the sensing

performance may deteriorate.

·

Ensure that any strong extraneous light is not incident on the receiving face of the fiber head.

·

The fiber cable can be cut for adjustment using the attached fiber

cutter, however, the performance of the sensor may greatly decrease depending the condition of the cut fiber cable and the

connection to the amplifier.

·

Shortening the fiber cable excessively may result in loss of reliable

detection due to an insufficient light intensity difference. (As a reference, adjust the length of the fiber cable so that the amplifier

reads 3,500, or less, when there is no liquid present in the pipe.)

·

Unclear or highly viscous liquid may not be sensed correctly.

·

Do not scratch the fiber sheath while cutting the protective tube.

·

The detection results may vary greatly if the protective tube is not

firmly secured. Use the attached anti-slip tube to firmly secure it to

the pipe so that it does not move.

·

Be sure to adjust the sensitivity of the amplifier after installing the fiber

head and when there is no liquid present in the pipe. Perform the

same sensitivity adjustment after changing the layout or re-mounting

the fiber head to the pipe.

·

Note that light intensity may greatly decrease when used under

high temperature and high humidity for long periods.

!

This product is not a safety sensor. Its use is not intended

or designed to protect life and prevent body injury or

property damage from dangerous parts of machinery. It is

a normal object detection sensor.

Cautions

Set the sensitivity of the FX-D1-F amplifier using the ‘Limit teaching’

function as described below.

1

Set the fiber head on the pipe.

2Set the mode selection switch to either ‘RUN’ or ‘MODE’.

3

Set to either Output 1 or Output 2 by turning the jog switch to the

‘+’ or the ‘−’ side.

4

Set the mode selection switch to ‘SET’ the present threshold value is displayed.

5

Press the jog switch in the liquid absent condition and release it

within 3 sec.

6

The read incident light intensity is displayed for 0.5 sec. approx.

Subsequently, ‘2nd’ is displayed on the LCD display.

7

Turn the jog switch to the ‘−’ side. ‘good’ is displayed on the

LCD display.

8

Set the mode selection switch to ‘RUN’, and setting is completed.

Amplifier setting procedure

6

6

"3.1

1,000 (FT-F905: 3,000)

3,000 (FT-F905: 5,000)

10.3

5.5

7.2

23

17

20

12

9

(20)

("4) Model No. tube (PVC)

Protective tube (PFA)

"1

×2

Fiber cable

Fiber head

Material

PFA (fluorine resin) or equivalently transparent pipe,

wall thickness 0.3 to 1.0mm

No. CE-FTF9-5 January, 2001

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7211

FAX: +81-(0)568-33-2631

SUNX Limited

Phone: +81-(0)568-33-7861

FAX: +81-(0)568-33-8591

Overseas Sales Dept.

Printed on 100% recycled paper

PRINTED IN JAPAN

http://www.sunx.co.jp/

All information is subject to change without prior notice.

Loading...

Loading...