Page 1

Chip 3-Terminal Capacitor Array

Chip 3-Terminal Capacitor Ar ray

Type:

EZASC

EZANC

GND GND

■ Fea tures

1.

Suitable for EMI suppression fi ltering

● The low residual inductance at high frequency range provides effective reduction of noise

● Equivalent noise reduction to the EMI fi lters with low cost design

2.

Compact design for high density PWB assembly

● EZASC : 4.0 mm ҂ 2.1 mm ҂ 0.65 mm, 0.8 mm pitch

EZANC : 6.4 mm ҂ 3.1 mm ҂ 0.75 mm, 1.27 mm pitch

● Flat and square packages suitable for high speed automatic placement machine

3.

Superior mountability with concave terminals

● Firm solder joint (2 times that of convex terminal type)

● Self-aligning placement during refl ow soldering

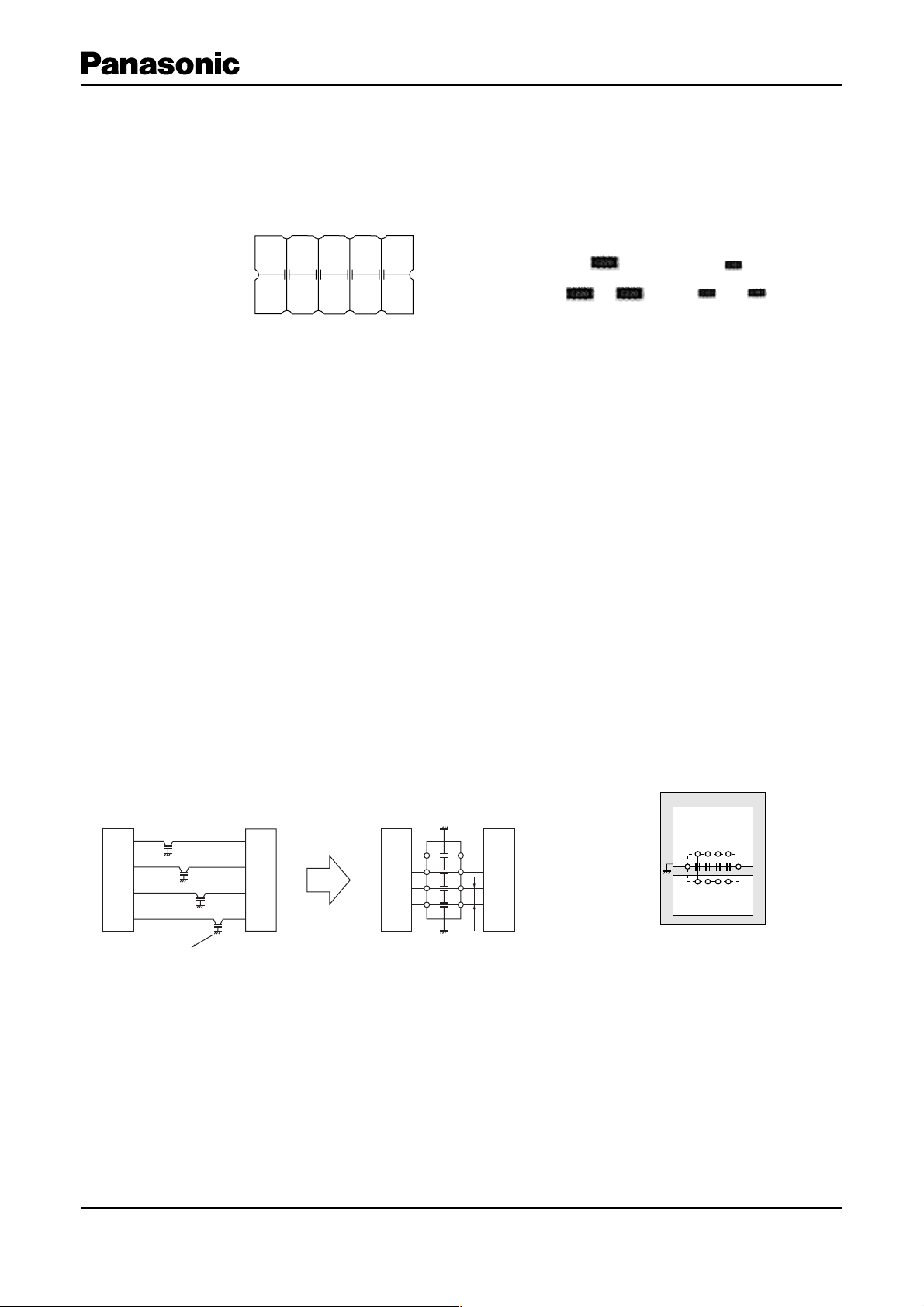

<Effect of high density placing, PWB space saving>

Digital cordless phone

(4 line mounting)

I/O I/O

3-Terminal Capacitors or EMI Filters

I/O

I/O

EZASC: 0.8 mm pitch

EZANC: 1.27 mm pitch

Prevent high frequency harmonic

noise to RF circuits

■ Recommended Applications

● Digital equipment such as PCs, printers, HDD, PCMCIA cards, PDAs, and word processors

● Communication equipment, digital cordless phones, automobile phones, GSM, PHS, DECT

● Digital audio and video equipment

● Electronic musical instruments, and other digital devices

RF Circuit

(EZA SC)

Digital Control Circuit

Design and spec ifi cations a re each subject to change wit hout not ice. A sk factory for the current technica l spec ifi ca tions before purchase and/or use.

Should a safety concern a ris e regarding this product , please be sure to cont act us i mmed iately.

Feb. 2006

Page 2

■ Explanation of Part Number

Chip 3-Terminal Capacitor Array

1

E

Thick Film Noise

Suppression and

Filtering

Components

2

Z

Product Code

4.0 mm

SC

҂2.1 mm

6.4 mm

NC

҂3.1 mm

3

A

4

N

Dimensions and

Circuit Configuration

Four 3-Terminal

Capacitors

5

C

6

E

Temperature

Characteristics

+20 %/–55 %

E

(–25°Cto+85°C)

7

1

Capacitance Value

8

0

The first two digits are significant

figures of capacitance value,

and the third one denotes the

number of zeros following

ex. 101촞100 pF

9

1

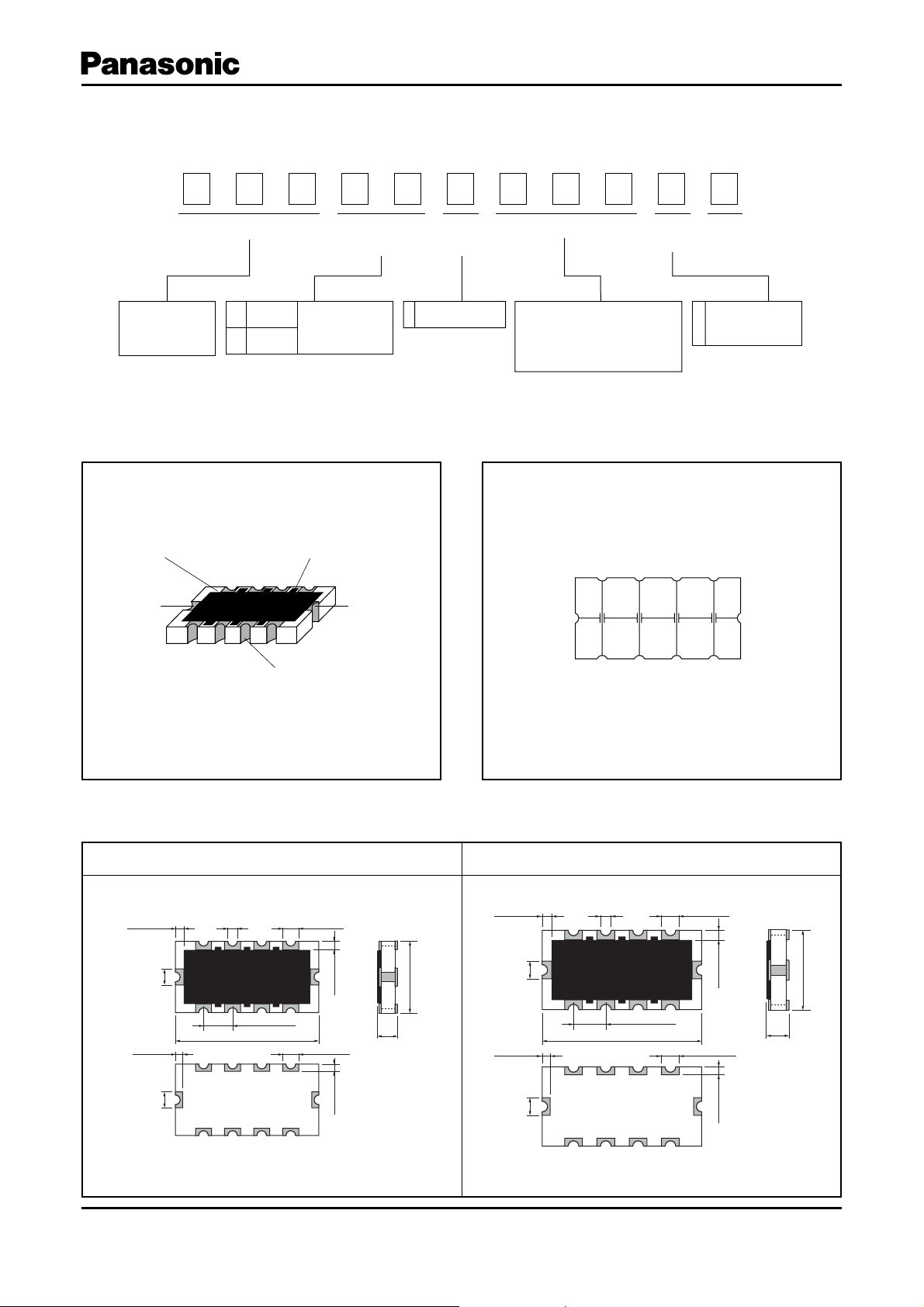

■ Construction ■ Circuit Confi guration

Alumina substrate

GND

Electrode

(Outer)

CIOI

Protective coating

GND

Electrode

(Outer)

10 9 8 7

1

GND GND

10 11

M

Capacitance

Tolerance

M

Suffix for Special

Requirement

±20 %

+30 %

When less

–20 %

than 22 pF

6

Electrode

(Outer)

■ Dimensions in mm (not to scale)

EZASC EZANC

0.25±0.20

0.5±0.2

0.4±0.2

0.5±0.2

+0.1

f 0.3

–0.2

CIOI

0.8±0.1

4.0±0.2

0.45±0.20

0.5±0.2

0.25±0.20

0.4±0.2

0.65

+0.20

–0.10

2.1±0.2

0.4±0.2

0.3±0.2

0.8±0.2

0.8±0.2

2345

+

0.1

f 0.4

–

0.2

0.7±0.2

CIOI

1.27±0.10

6.4±0.2

0.56±0.20

0.4±0.2

0.4±0.2

0.75

+0.20

–0.10

3.1±0.2

Size : 1608 inches

Mass (Weight) [1000 pcs.] : 17 g

Design and spec ifi cations a re each s ubject to change wit hout not ice. A sk factory for the current technica l spec ifi ca tions before purchase and/or use.

Should a safety concern a ris e regarding this product , please be sure to cont act us i mmed iately.

Size : 2512 inches

Mass (Weight) [1000 pcs.] : 52 g

Feb. 2006

Page 3

■ Ratings

Chip 3-Terminal Capacitor Array

Specifi cation

Item

EZASC EZANC

Capacitance Values

(25 °C, 1 kHz

(1)

, 1 Vrms)

Standard : 22 pF, 47 pF, 100 pF

Capacitance Tolerance ±20% (

10 pF to 180 pF

+30%

–20%

22 pF, 47 pF, 100 pF, 220 pF, 470 pF

in the case of Less than 22 pF)

Temperature Characteristic E Characteristic: +20 %/±55 % (±25 °C to +85 °C)

Dissipation Factor Less than 2 % (25 °C, 1 kHz

(1)

, 1 Vrms)

Rated Voltage 25 V

Rated Current

Resistance

Category Temperature Range (Operating Temperature Range)

(1) In measuring at 1 MHz, Capacitance Value and Dissipation Fac tor are different.

(2) Rated Current between Input terminal and Output ter mi nal.

(3) Resistance value between Input terminal and Out put terminal.

(2)

(3)

200 mA 300 mA

Less than 1

액

–25 °C to +85 °C

■ Attenuation Characteristics

Measurement Circuit

액

50

~

EZANC

1k액 1k액

액

50

촞

MN74HC04 MN74HC04

Measurement Circuit

2000 pF

MN74HC04

Chip 3-Terminal Capacitor Array ( EZANC)

0

0

10

10

20

20

30

30

40

40

Attenuation (dB)

Attenuation (dB)

50

50

1M 10M 100M 1G 3G

1M 10M 100M 1G 3G

Frequency (Hz)

Equivalent to EMI fi lter

✽

■ Packaging Methods (Taping)

● Standard Quantity

Type Kind of Taping Pitch (P1) Quantity

EZASC

EZANC

Embossed Carrier Taping 4 mm 4000 pcs./reel

47

220pF

0p

F

47pF

100pF

22pF

100

80

60

40

Electric fi eld intensity (dBµV)

20

100

200 400 600 800 1000

Frequency (MHz)

8MHz

EZA

SCE470M

100

80

60

40

Electric fi eld intensity (dBµV)

20

100

200

400 600 800

Frequency (MHz)

1000

Design and spec ifi cations a re each subject to change wit hout not ice. A sk factory for the current technica l spec ifi ca tions before purchase and/or use.

Should a safety concern a ris e regarding this product , please be sure to cont act us i mmed iately.

Feb. 2006

Page 4

● Embossed Carrier Taping ● Taping Reel

t

1

t

2

Chip component

Sprocket hole

f

D

A

f

D

1

0

B

Compartment

P

1P2P0

E

F

W

Tape running direction

Chip 3-Terminal Capacitor Array

T

fC

fB

Type A B W F E P

EZASC

Dimensions

(mm)

EZANC

Type P

EZASC

Dimensions

(mm)

EZANC

2.50

3.50

4.00

±0.20

±0.20

1

±0.10

4.40

6.80

2.00

±0.20

±0.30

12.00

±0.20

f

P

2

±0.05

1.50

D

+0.10

−0

±0.20

5.50

t

0

1

±0.05

0.25

■ Recommended Land Pattern Design

Chip 3-Terminal Capacitor Array

(EZANC/EZASC)

1.75

1.15

1.30

t

±0.20

2

±0.20

±0.20

4.00

f

1.50

D

0

±0.10

1

+0.10

−0

f2

c

Dimensions

(mm)

Dimensions

(mm)

f

180

fA

A

+0

−3.0

60 min. 13.0

W

f

B

f

C

±1.0

WT

13.0

±1.0

15.4

±2.0

d

a

e

f1

b P

Land pattern Solder resistant

GND

Type a b c d e f1 f2 P

Dimensions

(mm)

Design and spec ifi cations a re each s ubject to change wit hout not ice. A sk factory for the current technica l spec ifi ca tions before purchase and/or use.

Should a safety concern a ris e regarding this product , please be sure to cont act us i mmed iately.

EZASC

EZANC

1.2 to 1.4 0.4 3.1 to 3.3 0.4 to 0.5 0.8 2.9 to 3.3 4.8 to 5.2 0.8

2.2 to 2.4 0.4 to 0.6 5.7 to 5.9 0.4 to 0.8 1.8 4.2 to 4.6 7.5 to 7.9 1.27

Feb. 2006

Page 5

Chip 3-Terminal Capacitor Array

■ Recommended Soldering Conditions

Recommendations and precautions are described below.

● Recommended soldering conditions for refl ow

·Refl ow soldering shall be performed a maximum of

two times.

·Please contact us for additional information when

used in conditions other than those specifi ed.

·Please measure the temperature of the terminals and

study every kind of solder and printed circuit board

for solderability before actual use.

Peak

Preheating

Heating

Temperature

Time

● Flow Soldering

We do not recommend flow soldering to the Chip 3-Terminal Capacitor Array: EZASC, because solder

bridging may occur due to the narrow 0.8 mm pitch of EZASC. Please contact us regarding flow soldering

of EZANC type.

For soldering (Example : Sn/Pb)

Temperature Time

Preheating 140 °C to 160 °C 60 s to 120 s

Main heating Above 200 °C 30 s to 40 s

Peak 235 ± 5 °C max. 10 s

For lead-free soldering (Example : Sn/Ag/Cu)

Temperature Time

Preheating 150 °C to 180 °C 60 s to 120 s

Main heating Above 230 °C 30 s to 40 s

Peak max. 260 °C max. 10 s

Safety Precautions

The following are precautions for individual prod ucts. Please also refer to the precautions common to EMI Filters,

Fuses, and Sensors(MR Elements) shown on page EX2 of this catalog.

1. Take measures against mechanical stress during and after mounting of Chip 3-Terminal Capacitor Array (hereafter

called the capacitor arrays) so as not to damage their electrodes and pro tec tive coat ings.

Be careful not to misplace the capacitor arrays on the land patterns. Otherwise, solder bridging may occur.

2. Do not use halogen-based or other high-activity flux. Otherwise, the residue may impair the capacitors arrays'

per for mance and/or reliability.

3. When soldering with a soldering iron, never touch the capacitor arrays' bodies with the tip of the soldering iron. When

using a soldering iron with a high temperature tip, fi nish soldering as quickly as possible (within three seconds at 350

C max.).

4. As the amount of applied solder becomes larger, the mechanical stress applied to the capacitor arrays increases,

causing problems such as cracks and faulty characteristics. Avoid applying an excessive amounts of solder.

5. Do not apply shock to the capacitor arrays or pinch them with a hard tool (e.g. pliers and tweezers). Otherwise, the

capacitor arrays' protective coatings and bodies may be chipped, af fect ing their per for mance.

6. Avoid excessive bending of printed circuit boards in order to protect the capacitor arrays from ab nor mal stress.

7. The static capacitance may decrease by a few percent from the time of shipment due to the char ac ter is tics peculiar to

dielectric materials having a high dielectric constant.

°

Design and spec ifi cations a re each subject to change wit hout not ice. A sk factory for the current technica l spec ifi ca tions before purchase and/or use.

Should a safety concern a ris e regarding this product , please be sure to cont act us i mmed iately.

Feb. 2006

Page 6

Safety Precautions (Common precautions for EMI Filters, Fuses, and Sensors[MR Elements])

• When using our products, no matter what sort of equipment they might be used for, be sure to make a written

agreement on the specifi cations with us in advance. The design and specifi cations in this catalog are subject

to change without prior notice.

• Do not use the products beyond the specifi cations described in this catalog.

• This catalog explains the quality and performance of the products as individual components. Before use, check

and evaluate their operations when installed in your products.

• Install the following systems for a failsafe design to ensure safety if these products are to be used in equip ment

where a defect in these products may cause the loss of human life or other signifi cant dam age, such as damage to

vehicles (automobile, train, vessel), traffi c lights, medical equipment, aerospace equipment, electric heating

appliances, combustion/gas equipment, rotating equipment, and disaster/crime prevention equipment.

Systems equipped with a protection circuit and a protection device

✽

Systems equipped with a redundant circuit or other system to prevent an unsafe status in the event of a sin gle fault

✽

(1) Precautions for use

• These products are designed and manufactured for general and standard use in general elec tron ic equipment

(e.g. AV equipment, home electric appliances, offi ce equipment, information and communication equipment)

• These products are not intended for use in the following special conditions. Before using the products,

carefully check the effects on their quality and performance, and determine whether or not they can be used.

1. In liquid, such as water, oil, chemicals, or organic solvent

2. In direct sunlight, outdoors, or in dust

2

3. In salty air or air with a high concentration of corrosive gas, such as Cl

, H2S, NH3, SO2, or NO

4. Electric Static Discharge (ESD) Environment

These components are sensitive to static electricity and can be damaged under static shock (ESD).

Please take measures to avoid any of these environments.

Smaller components are more sensitive to ESD environment.

5. Electromagnetic Environment

Avoid any environment where strong electromagnetic waves exist.

6. In an environment where these products cause dew condensation

7. Sealing or coating of these products or a printed circuit board on which these products are mounted, with

resin or other materials

• These products generate Joule heat when energized. Carefully position these products so that their heat will

not affect the other components.

• Carefully position these products so that their temperatures will not exceed the category temperature range due

to the effects of neighboring heat-generating components. Do not mount or place heat-generating components

or infl ammables, such as vinyl-coated wires, near these products (except Thermal Cutoffs).

• Note that non-cleaning solder, halogen-based highly active fl ux, or water-soluble fl ux may deteriorate the

performance or reliability of the products.

• Carefully select a fl ux cleaning agent for use after soldering. An unsuitable agent may deteriorate the performance

or reliability. In particular, when using water or a water-soluble cleaning agent, be careful not to leave water

residues. Otherwise, the insulation performance may be deteriorated.

2

(2) Precautions for storage

The performance of these products, including the solderability, is guaranteed for a year from the date of ar riv al

at your company, provided that they remain packed as they were when delivered and stored at a tem per a ture

of 5 °C to 35 °C and a relative humidity of 45 % to 85 %. (Micro Chip Fuses: Guaranteed for 6 months from the

date of arrival at your company)

The performance of EMI Filters is guaranteed for 6 months or a year from the out go ing inspection date indicated on

the packages, provided that they are stored at a temperature of -5 °C to +40 °C and a relative humidity of 40 %

to 60 %. Check the guarantee period in the specifi cations. The performance of Thermal Cut offs is guaranteed for a

year from the outgoing inspection date indicated on the packages, provided that they are stored at a temperature of

-10 °C to +40 °C and a relative humidity of 30 % to 75 %.

Even within the above guarantee periods, do not store these products in the following conditions. Otherwise,

their electrical performance and/or solderability may be deteriorated, and the packaging materials (e.g. taping

materials) may be deformed or deteriorated, resulting in mounting failures.

1. In salty air or in air with a high concentration of corrosive gas, such as Cl

2

, H2S, NH3, SO2, or NO

2

2. In direct sunlight

<Package markings>

Package markings include the product number, quantity, and country of origin.

In principle, the country of origin should be indicated in English.

Feb. 2006

– EX2 –

Loading...

Loading...