Page 1

Panasonic

Page 2

Table Of Contents

• Comparison Between Models……..………………………

• Inputs/Outputs Overview………………………………..…

• Run Screen………………………………………………....…

• Main Menu……………………………………….……….……

• Tools…………………………………………………………...

– Learn/Learn Open

– Replace/Edit/Forget (Unlearn)

• Programming Modes…………………………………….….

– Parameter Mode

– Group Mode

– Job Mode

• History………………………………………………………….

• Events………………………………………………………….

• Qualifier Settings…………………………………………….

• Protocols/Network Settings………………………………..

• Inputs/Outputs……………………………….……………….

• Update Firmware…………………………….……………….

Page 3

Page 4

Page 5

Page 6

Page 7

Page 9

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

• Check Firmware……………………………..……………….

• Assembly Manager………………………….........…………

– Connecting A PC

• Data Collection……………………………………………….

– Download Data To USB / Configuration To USB

– Upload Configuration From USB

– Create A .CSV File

Page 22

Page 23

Page 27

Page 3

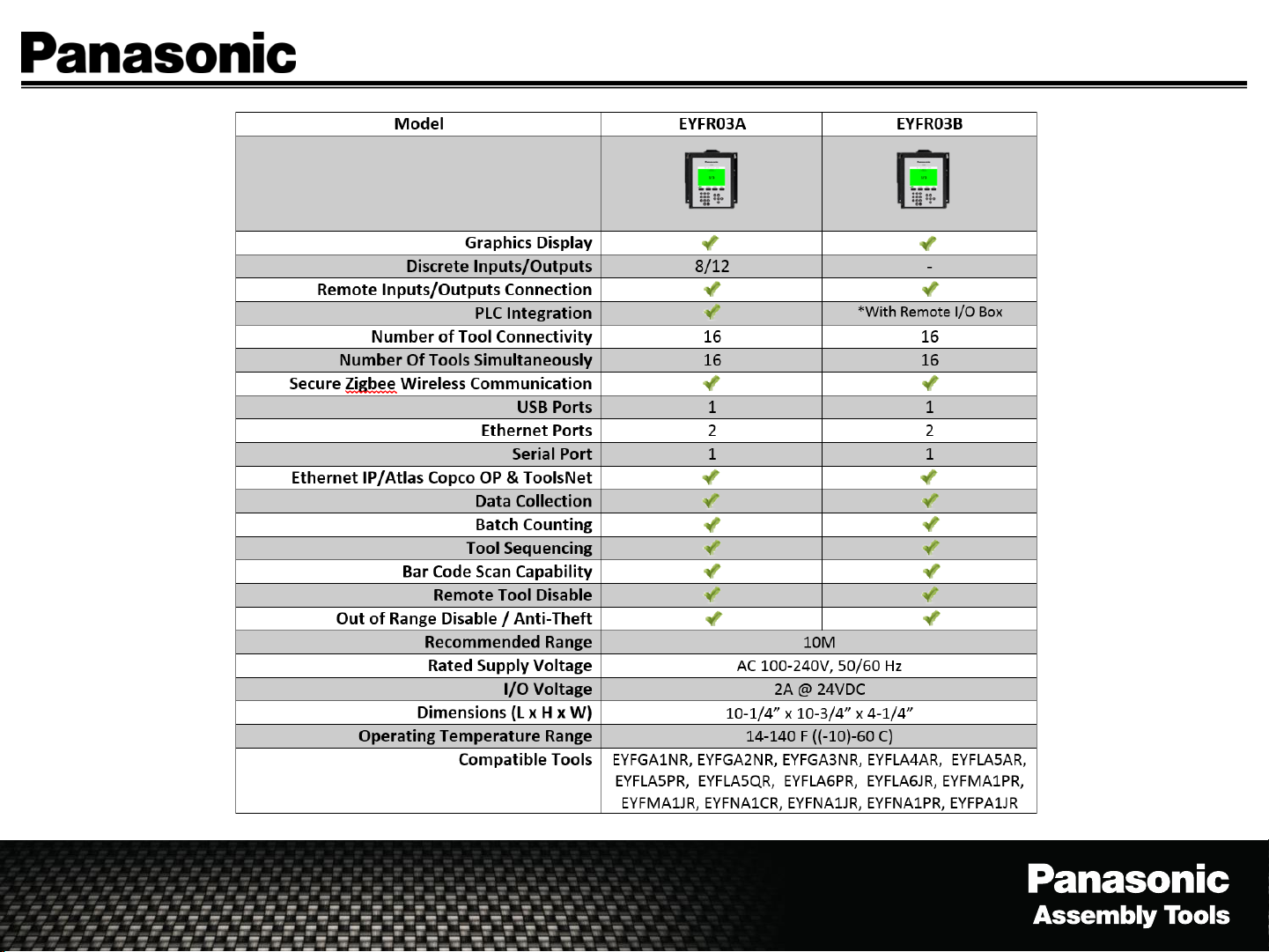

EYFR03 Model Comparison

Page 3

Page 4

PLC

AND/

OR

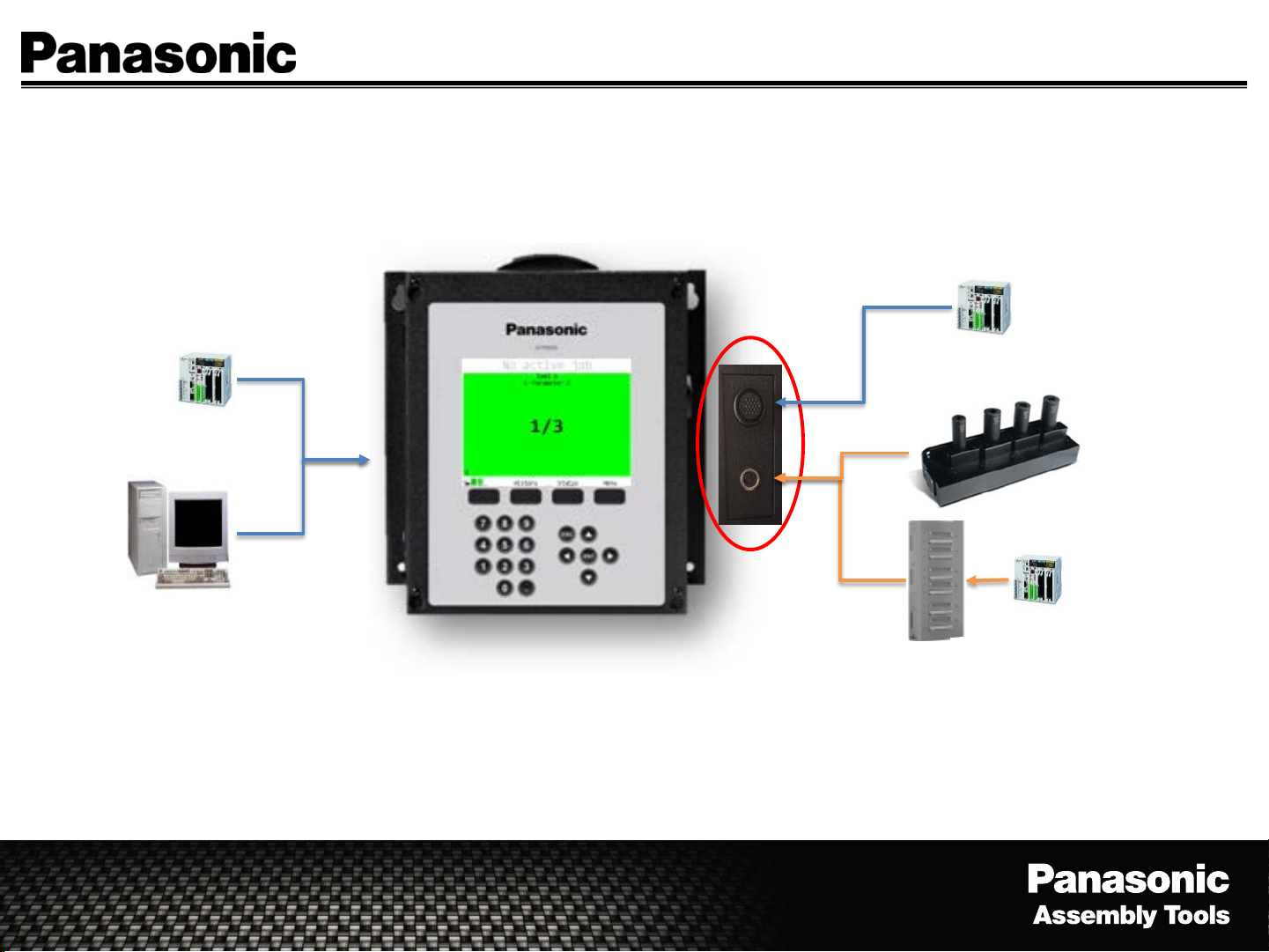

EYFR03 Inputs/Outputs Overview

Discrete I/O (24 Pin Connector)

Used to connect directly to the assembly

line or a PLC.

8 Inputs/12 Outputs

(Used in EYFR03A)

OR

Page 4

PLC

Socket

Tray

PC

Ethernet Connection (RJ45 Qty. 2)

Ethernet IP, Open Protocol, ToolsNet

(EYFR03A/B)

PLC

I/O Module

Remote I/O (5 Pin Connector)

(For Future Use)–I/O Module

(Used in EYFR03A/B)

Page 5

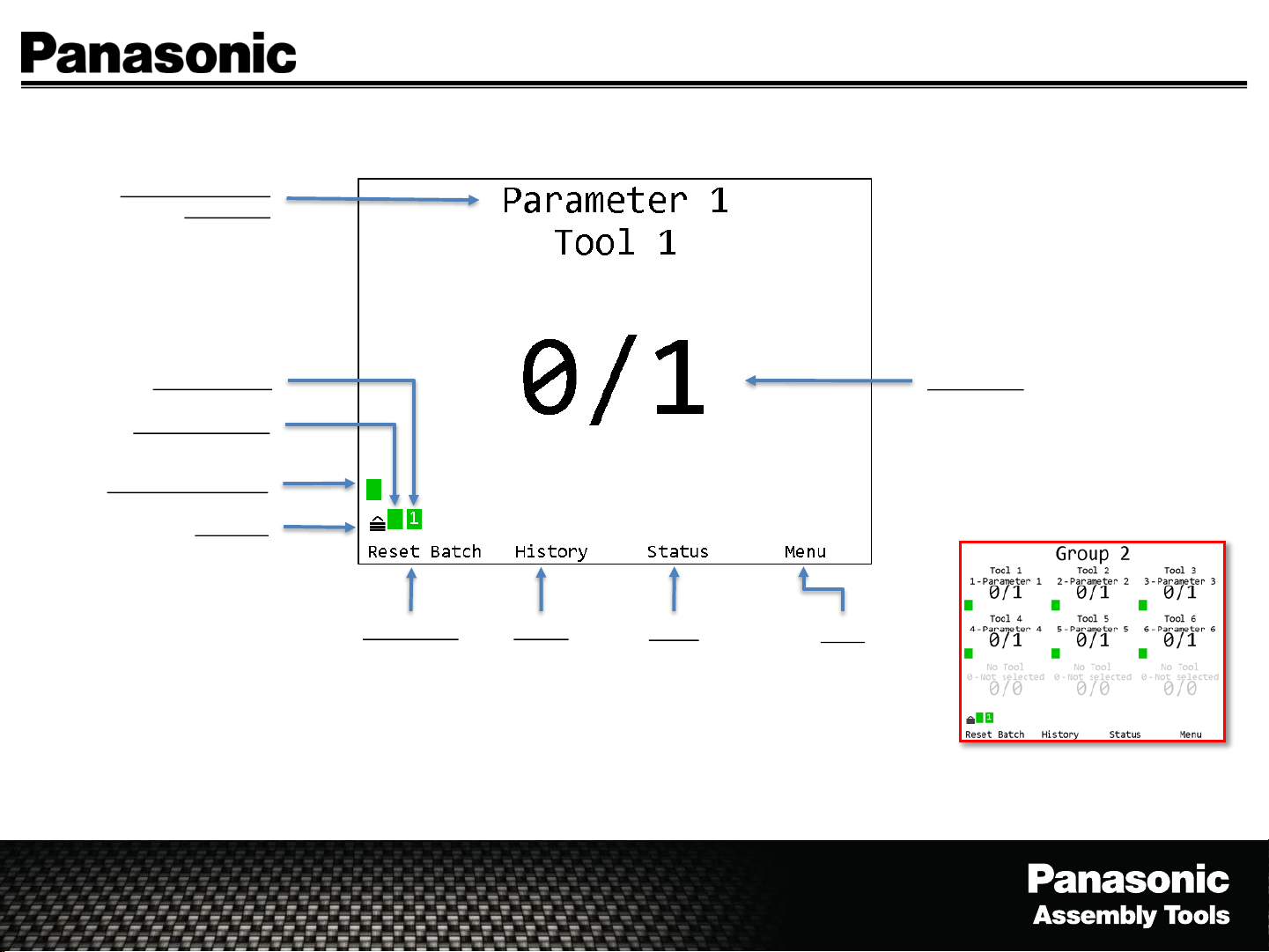

Parameter Name &

Tool Name

EYFR03 Run Screen

Page 5

Network Status

Unit Radio Status

Tool Status Indicator

Unit Lock

Reset Batch

History

Status

Current

configurations

Batch Count

Menu

Access to setting

up the Qualifier

Password - 1011

Group View Screen Shot

Page 6

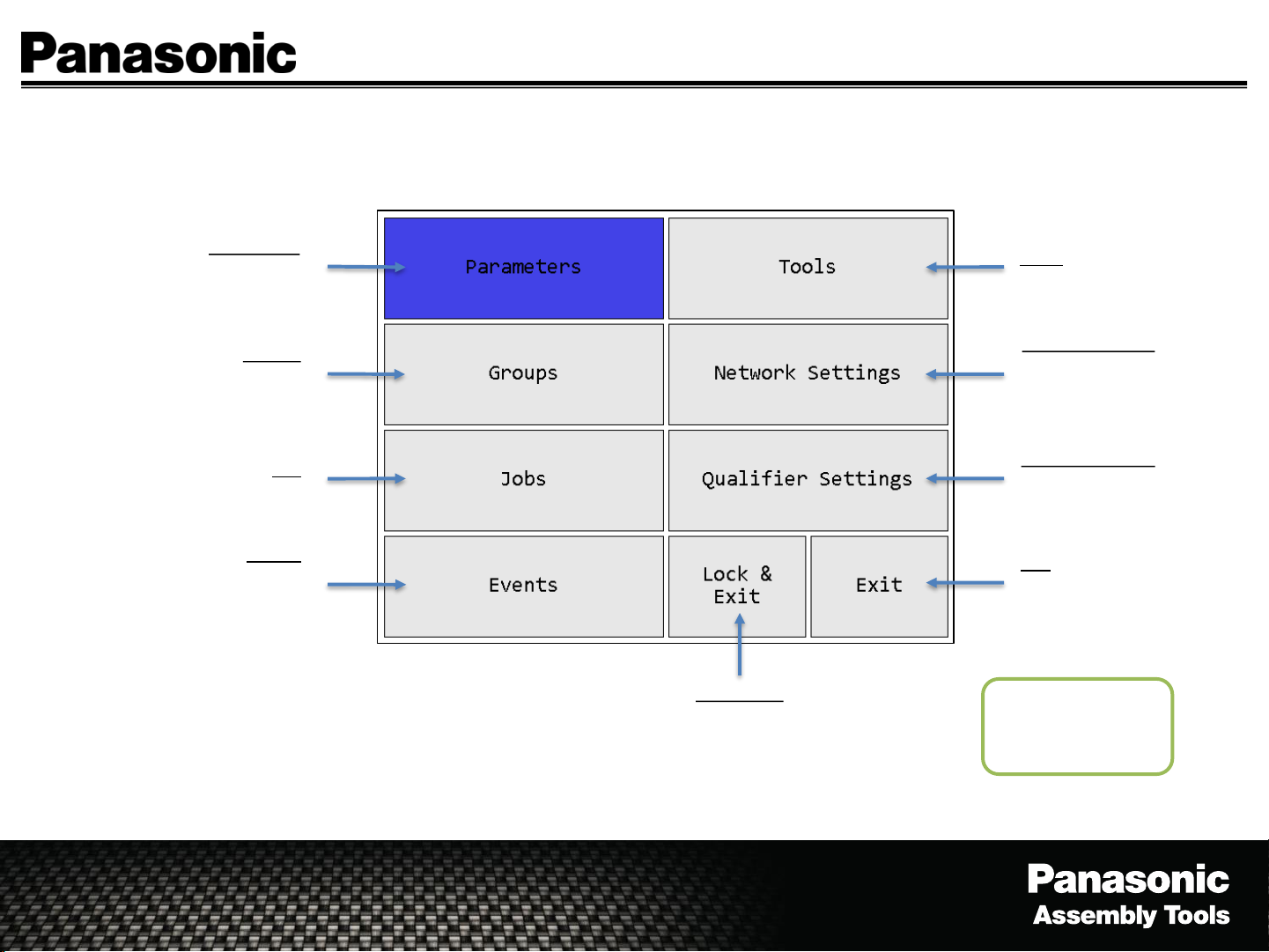

EYFR03 Menu Navigation

Page 6

Parameters

Select, View and Edit

Parameters

Groups

Select, View and Edit

Groups

Job

Select, View and Edit Jobs

Events

View non-tightening events

such as programming and tool

changes, power ups, etc...

Lock & Exit

Exit and Lock Out Menu /

Returns to Run Screen

Tools

Learn and Edit Tools

Network Settings

View and Edit General,

ACOP, ToolsNet and

EIP Network Settings

Qualifier Settings

View and Edit Global

Qualifier Settings

Exit

Exit Menu /

Returns to Run Screen

New

Menu Password

1011

Page 7

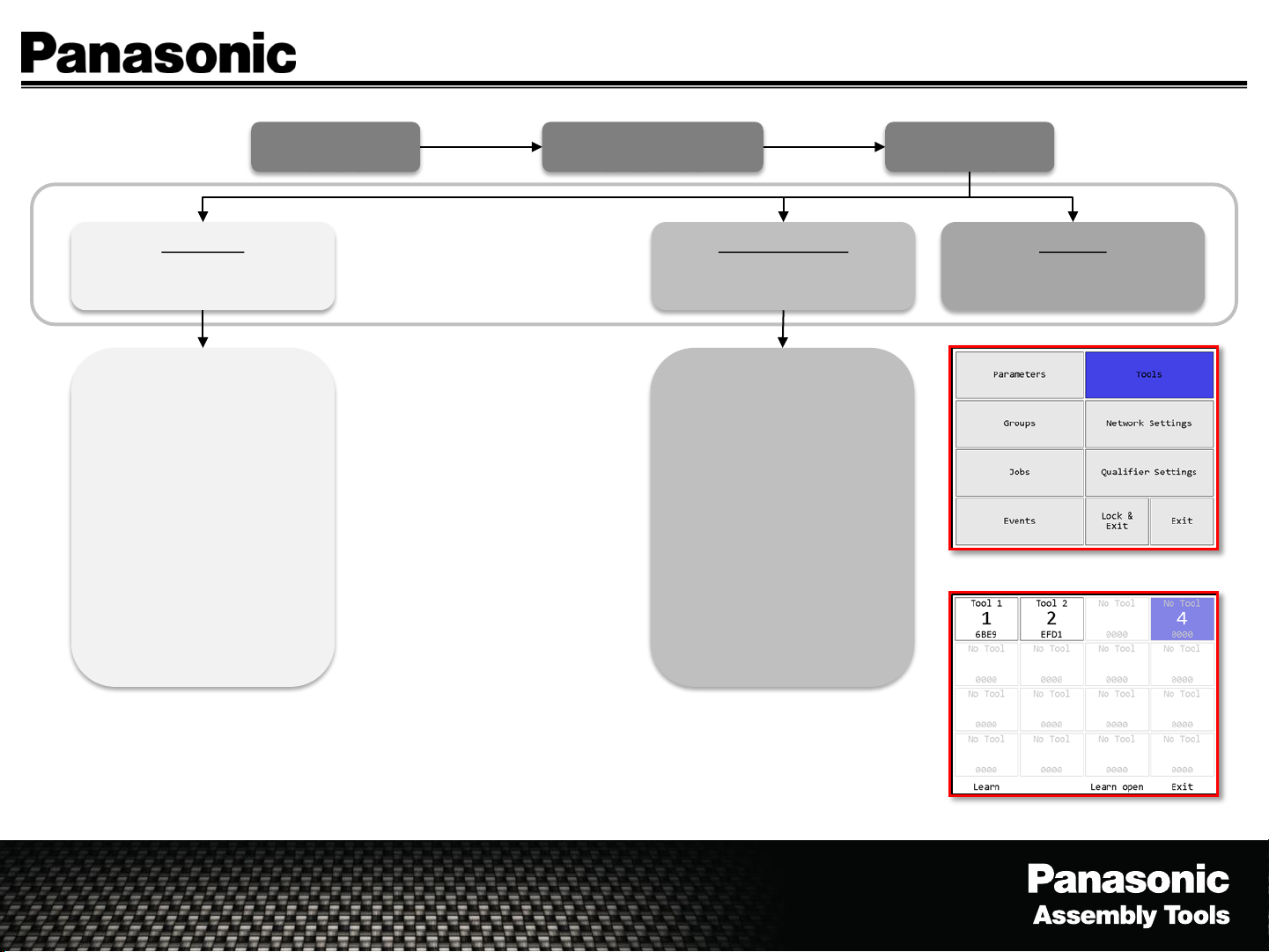

Tools - Learn/Learn Open

Page 7

Learn Tool

(Starts the learn sequence

for the highlighted tool slot)

1. Remove/Replace

Battery, Pull tool

trigger for 2 seconds

2. Successful Learn - the

screen will

automatically returns

to the tool menu and

the box will turn green

3. To learn additional

tools return to the

Learn step above.

4. Exit (Returns to the

Main Menu)

Menu

(Enter)

Password

(1011 Enter)

(Starts the learn sequence

for the first empty tool slot)

1. Remove/Replace

2. Successful Learn - the

3. To learn additional

4. Exit (Returns to the

Learn Open Tool

Battery, Pull tool

trigger for 2 seconds

screen will

automatically returns

to the tool menu and

the box will turn green

tools return to the

Learn step above.

Main Menu)

Tools

(Enter)

Exit Tool

(Returns to the Main Menu)

Main menu - Tools

*In the case a tool can not be learned to a Qualifier, try these steps.

1. Check to see that the tools model or serial number contains an “R” which states it has a wireless card included.

2. Make sure to follow the directions on the screen – remove & replace battery then pull tool trigger and release.

3. Check the serial number to see if the tool was built on or after 15=2015/01=Jan (Ser# XXXXXXX1501XXXX),

if yes the wireless card may be disabled. To re-enable the wireless card, pull the tools trigger “7” times, each

trigger pull should show a bad fastenings (red light turns on). The tool should learn to the Qualifier.

Learn Tool Menu

Page 8

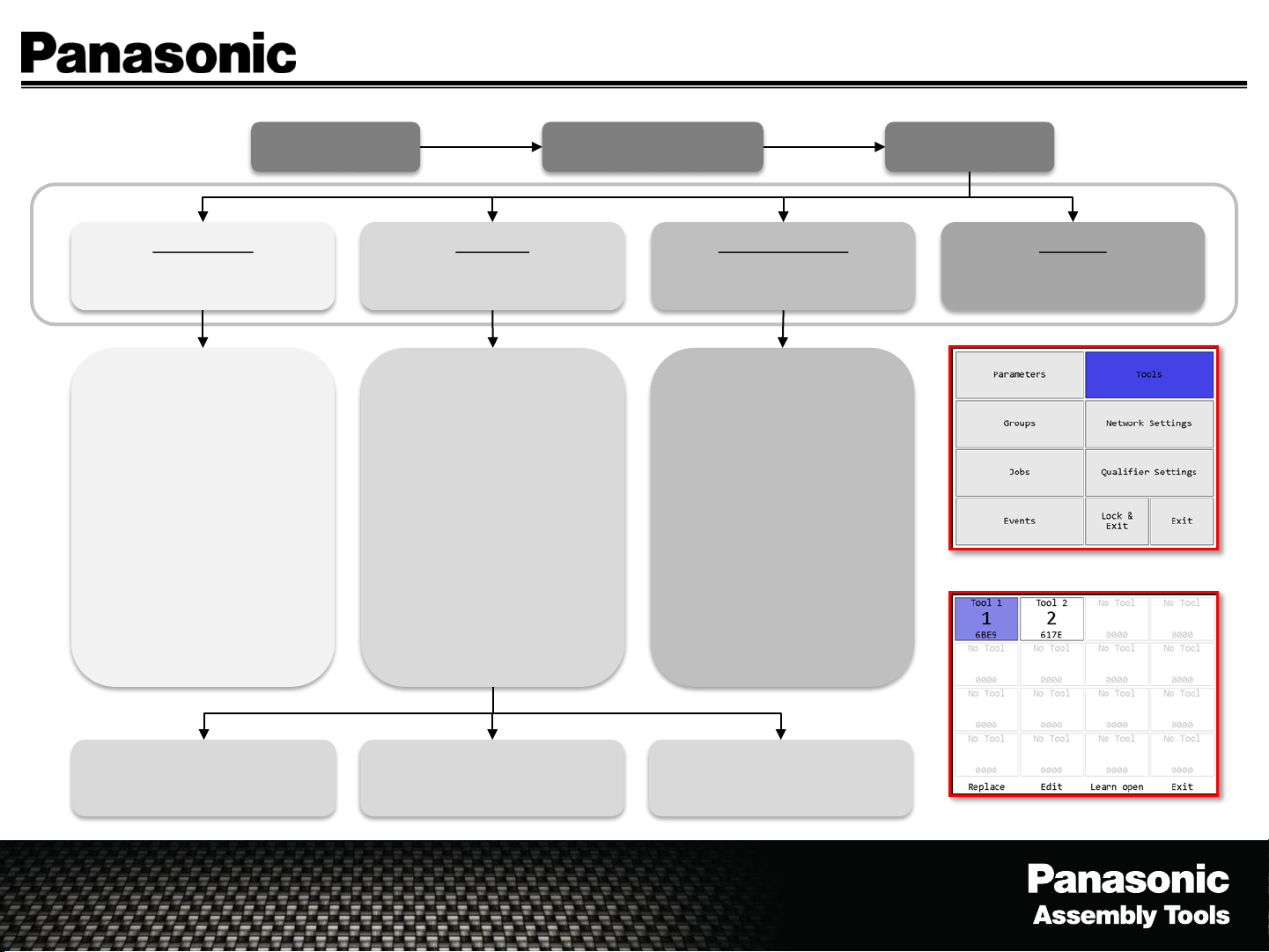

Tools - Replace/Edit/Forget (Unlearn)

Page 8

Replace Tool

(Starts the learn sequence

for the highlighted tool slot)

1. Remove/Replace

Battery, Pull tool

trigger for 2 seconds

2. Successful Learn - the

screen will

automatically returns

to the tool menu and

the box will turn green

3. To learn additional

tools return to the

Learn step above.

4. Exit (Returns to the

Main Menu)

Menu

(Enter)

Edit Tool

(Edit the highlighted tool)

1. Editable Fields

a. Tool Name

b. Serial Number

c. Last Calibration

d. Next Calibration

e. Last PM

f. Cycles before PM

2. Not Editable Fields

a. Radio Info

b. Cycles

Password

(1011 Enter)

(Starts the learn sequence

for the first empty tool slot)

1. Remove/Replace

2. Successful Learn - the

3. To learn additional

4. Exit (Returns to the

Learn Open Tool

Battery, Pull tool

trigger for 2 seconds

screen will

automatically returns

to the tool menu and

the box will turn green

tools return to the

Learn step above.

Main Menu)

Tools

(Enter)

Exit Tool

(Returns to the Main Menu)

Main menu - Tools

Forget (Removes tool from

Qualifier)

Save (Saves changes and

returns to the Tool Menu)

Cancel (Cancels changes and

returns to the Tool Menu)

Learn Tool Menu

Page 9

EYFR03 Programming Modes

Parameter Mode – Select a single tool, from the learned tools, to run on an application.

• Use - When a single tool is required.

• Not to use - When a group or a sequence is required.

• Reports – Signals batch complete for each tool individually.

Group Mode – Selec t a group of tools, up to 16 tools, to run in any order or

simultaneously.

• Uses - When a group of tools are required with a group batch complete.

• Not to use - When a sequence is required.

• Reports - Signals batch complete once the group all fasteners are completed for each tool.

Free Run Mode – Each tool can run independently and report an independent batch complete for each tool.

• Uses - When a group of tools are required with individual tool batch complete.

• Not to use - When a sequence is required.

• Reports - Signals batch complete for each tool independently.

Page 9

Job Mode – Select up to 16 tools and/or a group of tools to run in a sequence.

• Uses – When a specific sequence is required.

• Not to use – When a basic rundown is needed (such as parameter mode).

• Reports – Signals batch complete when all of the tools have completed their individual steps.

Page 10

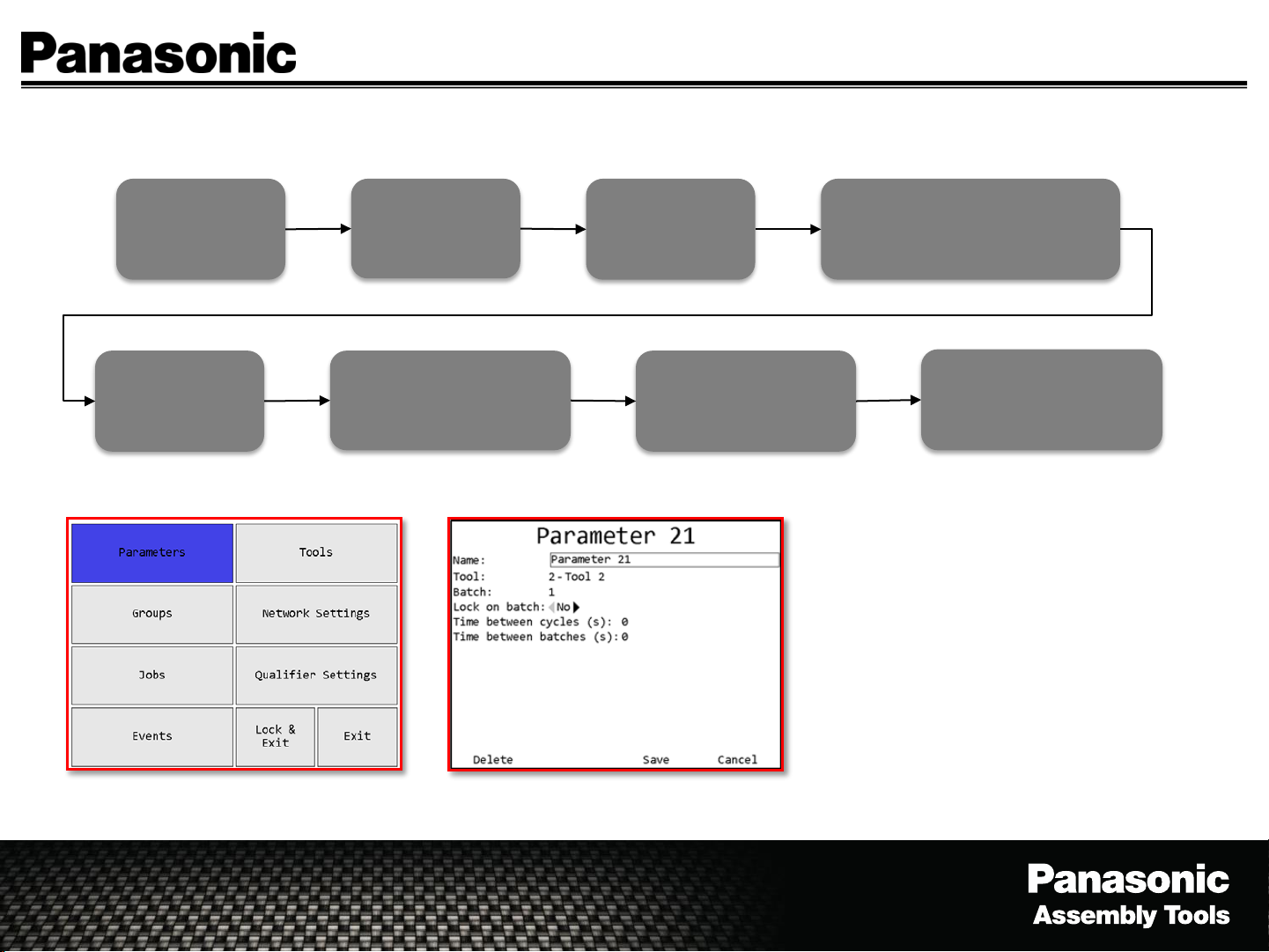

EYFR03 Create And Run A Parameter

Page 10

Menu

(Enter)

Edit the

Parameter as

necessary.

Password

(1011 Enter)

Press “Save” and the

Qualifier returns to the

Choose Parameter Screen

Parameters

(Enter)

Arrow over to the

Parameter to run,

Press “Select”

Select Parameter

(Arrow over to a Parameter to

Create/Edit (Enter))

The Run Screen should be

showing and is now ready

to run a Parameter

*When a tool is learned into the

Qualifier, a parameter is

automatically created and the tool

is automatically connected to the

corresponding parameter.

(ie. Tool1=Parameter1,

Tool2=Parameter2, …,

Tool16=Parameter16)

Main menu - Parameters

Parameter Edit Screen

Page 11

Parameter - Select/Edit/Copy

Page 11

Select Parameter

(Select the highlighted

parameter to run)

Parameter Edit Screen

Menu

(Enter)

Edit Parameter

(Edit the highlighted

parameter)

1. Editable Fields

a. Parameter Name

b. Batch Count

c. Lock On Batch

d. Time Between Cycles

(Seconds)

e. Time Between

Batches (Seconds)

2. Not Editable Fields

a. Tool Name

Password

(1011 Enter)

Paste (Paste copied

parameter into highlighted

cell (Paste can only be used

on parameters 17-100)

Copy Parameter

(Copy the highlighted

parameter to another

location)

Parameters

(Enter)

Exit Parameter

(Returns to the Main Menu)

Exit (Enter – Returns to the

Main Menu)

Delete (Deletes all

information in the parameter

returns to parameter menu)

Save (Saves changes and

returns to the parameter

menu)

Cancel (Cancels changes and

returns to the parameter

menu)

Page 12

EYFR03 Create And Run A Group

Page 12

Menu

(Enter)

Edit the Group

as necessary.

Password

(1011 Enter)

Press “Parameter”

add/edit the tools

attached to the Group

Press “Save” and the

Qualifier returns to the

Choose Group Screen

Groups

(Enter)

Choose the different

tools to be attached

to the Group

Arrow over to the

Group to run, Press

“Select”

Select Group

(Arrow over to a Group to

Create/Edit (Enter))

Press “Exit” and the

Qualifier returns to the

Group edit screen

The Run Screen should be

showing and is now ready

to run the Group

Page 13

Group - Select/Edit/Copy

Menu (Enter) Password (1011 Enter) Group (Enter)

Page 13

Select Group

(Select the highlighted group

to run)

Group Edit Screen

Delete (Deletes all

information in the group

returns to group menu)

Edit Group

(Create and/or Edit the

highlighted group)

1. Editable Fields

a. Group Name

b. Lock On Done

1. No

2. Yes

c. Batch Beep On

1. Group

2. Parameter

d. Free Run Mode

1. No

2. Yes

Parameters (Goes to the

parameter selection)

Copy Group

(Copy the highlighted group

to another location)

Paste (Paste copied group

into highlighted cell

Save (Saves changes and

returns to the parameter

menu)

Exit Group

(Returns to the Main Menu)

Exit (Enter – Returns to the

Main Menu)

Cancel (Cancels changes and

returns to the group menu)

1-8 (Shows parameter slots

1-8 of the group)

9-16 (Shows parameter slots

1-8 of the group)

Exit (Returns to the group

edit screen)

Page 14

EYFR03 Create And Run A Job

Page 14

Menu

(Enter)

Edit the Job as

necessary.

Password

(1011 Enter)

Press “Steps”

add/edit the tools

attached to the Job

Press “Save” and the

Qualifier returns to the

Choose Job Screen

Jobs

(Enter)

Choose the different

Parameters/Groups to

be attached to the Job

Arrow over to the Job

to run, Press “Select”

Select Job

(Arrow over to a Job to

Create/Edit (Enter))

Press “Exit” and the

Qualifier returns to the

Job edit screen

The Run Screen should be

showing and is now ready

to run the Job

Page 15

Job - Select/Edit/Copy

Menu (Enter) Password (1011 Enter) Job (Enter)

Page 15

Select Job

(Select the highlighted job to

run)

Job Edit Screen

Delete (Deletes all

information in the job and

returns to job menu)

Edit Job

(Edit the highlighted job)

1. Editable Fields

a. Job Name

b. Lock On Done

1. No

2. Yes

c. Batch Beep On

1. Job

2. Parameter

2. Not Editable Fields

a. Number of Steps

Steps (Goes to the

parameter and/or group

selection)

Copy Job

(Copy the highlighted job to

another location)

Paste (Paste copied group

into highlighted cell

Save (Saves the changes and

returns to the job menu)

Exit Job

(Returns to the Main Menu)

Exit (Enter – Returns to the

Main Menu)

Cancel (Cancels changes and

returns to the job menu)

11-20 (Shows steps 11-20)

Parameter (Allows the

parameter to be the selected

step)

Group (Allows the group to

be the selected step)

Exit (Returns to the group

edit screen)

Page 16

History - View

The History screen shows some

information about the tightenings

stored in unit memory.

More information about the

tightenings is not shown but is

available via the network protocols.

Page 16

Main menu - Events

Previous

(Steps back a page of

history)

Run Screen

Next

(Steps to the next page of

history)

History

(Soft Key)

Exit History

(Returns to the Run Screen)

Page 17

The Events screen shows the

log of non-tightening events

that have occurred.

Events - View

Main menu - Events Events Screen

Page 17

Menu

(Enter)

Password

(1011 Enter)

(Steps to the next page of

Next

events)

Events

(Enter)

Exit Events

(Returns to the Main Menu)

Page 18

Qualifier Settings – View/Edit

Page 18

Menu

(Enter)

Edit Setting

(Edit the highlighted setting)

1. Editable Fields

a. Qualifier Name

b. Password

c. XBEE Channel

d. Bar Code Baud Rate

e. Beep On Reject

f. Beep On Batch

g. Beep On Cycle

h. Volume

i. Reject Timeout

j. Batch Timeout

k. Cycle Timeout

l. Require VIN To Run

m. Clear VIN On Batch

n. NOK’s

o. Time

(1011 Enter)

Restore Defaults

(Restores to factory defaults)

Select Items To Reset

1. Editable Fields

a. Tools

b. Parameters

c. Groups

d. Jobs

e. Qualifier Settings

f. Network Settings

g. Tightenings

h. Events

Reset All

(Resets All The Changes)

Password

Save Settings

(Saves changes made to the

qualifier settings)

Reset

(Resets only the selected

changes)

Qualifier Settings

(Enter)

Cancel Settings

(Cancels changes made to

the qualifier settings)

Main menu – Qualifier Settings

Cancel

(Cancels changes and returns

to the qualifier settings)

Reset All Confirmation Reset All Confirmation

Page 19

EYFR03 Protocol Types

General – Configure standard network settings (DHCP

Capable)

ACOP (Open Protocol) – Configure ACOP settings

• Use – select parameters/grou p s /j obs from a remote system (PC).

ToolsNet – Configure ToolsNet settings

• Use – data collection purposes only.

EtherNet/IP – Configure general network settings

• Use – select parameters/groups/jobs, change qualifier settings and

data collection from a remote system (PC or PLC).

Page 19

Page 20

EYFR03 Inputs/Outputs Overview

Discrete I/O (24 Pin Connector)

Used to connect directly to the assembly line or a P LC.

(Applies to EYFR03A)

Inputs (8) – The inputs can be configured to meet the needs of the customer.

• Select Parameter, Group or Job

• Stop Operation

• Suspend Qualifier

• Batch Reset

• Operation Reset

• Clear VIN

• Clear ID

• Bypass VIN

Outputs (12) – The outputs can be configured to meet the needs of the customer.

• Active Parameter, Group or Job

• Tool # Cycle Accept

• Tool # Cycle Reject

• Tool # Batch Complete

• Qualifier Suspended

Page 20

I/O Schematic

*Located in the User Manual or available upon request.

Remote I/O (5 Pin Connector) (For Future Use)

Used for an expanded I/O Module

(Applies to EYFR03A/B)

*Assembly Manager Software is required

for the initial setup and for making changes

to the Input and Outputs.

Page 21

EYFR03 Updating Firmware

Page 21

Put firmware on

a USB drive in

the root folder

Turn Qualifier

Select “Upload

USB File to

Device” (Enter)

The Qualifier will

automatically update

then reboot itself.

On

Insert USB into

Select Items To

Upload

Firmware = “Yes”

Select “Exit”

Qualifier

Wait for

Qualifier to

detect USB Drive

Press “Upload”

Button

Remove USB

from Qualifier

Page 22

EYFR03 Checking Firmware Version

Firmware

Run Screen

Click “Status”

Version is Listed

at the Top

Page 22

Page 23

EYFR03 Assembly Manager Software

View/Download History – Data Collection

Setup Inputs/Outputs – Not available through

the Qualifier keypad/screen

Backup/Restore Settings

Program Parameters/Groups/Jobs

View Qualifier Events

Connect Via Ethernet Cable Directly/Network

Standard or Crossover Ethernet Cable

*Learning a tool has to be done at the Qualifier

through the keypad/screen.

Page 23

To obtain a copy of the software, please find the

link in the owners manual or visit our website at

www.panasonic.com/assemblytools

Page 24

Installing EYFR03 Assembly Manager

EYFR03 Assembly Manager

Install file name “EYFR03 Assembly Manager

1_0 setup.exe.

Follow the prompts

1. Click “Next” to continue install.

2. Select Destination Location, Click “Next”

3. Select Start Menu Folder, Click “Next”

4. Select Additional Tasks (Desktop Icon), Click

“Next”

Page 24

5. Ready to Install, Click “Install”

6. Finished, Click “Finish”

Page 25

Connecting A PC To A EYFR03 Qualifier

Items Needed – PC, Ethernet Cable, Assembly Manager Installed

1. Connect the Ethernet cable into both the PC & Qualifier.

2. Configure the Qualifier Network Settings

1. Go to “Menu” / “Network Setting” / “General”

1. Configure General Menu with the following

1. IP Address – 192.168.1.68

2. Subnet – 255.255.255.0

3. Gateway – 192.168.1.1

4. DHCP - No

2. Cycle power of the Qualifier after changing the IP

address.

3. Configure the PC Network Settings

1. Configure the PC’s network address to the following

1. IP Address – 192.168.1.5

2. Subnet – 255.255.255.0

3. Gateway – 192.168.1.1

Page 25

Page 26

Connecting EYFR03 Assembly Manager

1. Enter the IP address of the Qualifier, click “Connect”

2. Choose what you would like to read from the Qualifier and click “Read”.

3. If the PC connects correctly to the Qualifier, this screen will appear.

Page 26

4. Final screen after connection has been established.

Page 27

EYFR03 Assembly Manager Software – Data Collection

TID Job Seq # Time J# P# P Name Last Write Time Tool SN OK Torque Status Angle Status Count Batch Batch Status Torque Unit Torque Min Torque Max Torque Angle Min Angl e Max An gle Torque Dir Torque Mode T # VIN

1 1 12/8/2014 16: 25 45 1 P arameter 1 12/6/2014 13: 15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

2 1 12/8/2014 16: 25 45 1 P arameter 1 12/6/2014 13: 15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

3 1 12/8/2014 16: 25 45 1 P arameter 1 12/6/2014 13: 15 TRUE 35 0 1 1 0 0 0 0 0 0 0 0 0 0 1

4 2 12/8/2014 16: 27 45 1 P arameter 1 12/6/2014 13: 15 TRUE 35 0 1 1 0 0 0 0 0 0 0 0 0 0 1

5 2 12/15/2014 14: 34 45 1 Parameter 1 12/6/2014 13: 15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

6 2 12/15/2014 14: 34 45 1 Parameter 1 12/6/2014 13: 15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

7 2 12/15/2014 14: 34 45 1 Parameter 1 12/6/2014 13: 15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

8 2 12/15/2014 14: 34 45 1 Parameter 1 12/6/2014 13: 15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

9 2 12/15/2014 14: 34 45 1 Parameter 1 12/6/2014 13: 15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

10 2 12/15/ 2014 14:34 45 1 Paramete r 1 12/6/ 2014 13:15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

11 2 12/15/ 2014 14:34 45 1 Paramete r 1 12/6/ 2014 13:15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

12 3 12/15/ 2014 14:34 45 1 Paramete r 1 12/6/ 2014 13:15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

13 3 12/15/ 2014 14:34 45 1 Paramete r 1 12/6/ 2014 13:15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

14 3 12/15/ 2014 14:34 45 1 Paramete r 1 12/6/ 2014 13:15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

15 3 12/15/ 2014 14:34 45 1 Paramete r 1 12/6/ 2014 13:15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

16 3 12/15/ 2014 14:35 45 1 Paramete r 1 12/6/ 2014 13:15 FALSE 35 0 1 1 0 0 0 0 0 0 0 0 0 0 1

17 4 12/17/ 2014 11:37 0 1 Pa rameter 1 12/6/2014 13: 15

FALSE 0 0 1 1 0 0 0 0 0 0 0 0 0 0 1

18 4 12/17/ 2014 11:37 0 1 Pa rameter 1 12/6/2014 13: 15 T RUE 0 0 1 1 0 0 0 0 0 0 0 0 0 0 1

19 4 12/17/ 2014 11:37 0 1 Pa rameter 1 12/6/2014 13: 15 T RUE 0 0 1 1 0 0 0 0 0 0 0 0 0 0 1

20 6 12/17/ 2014 11:39 45 1 Paramete r 1 12/6/ 2014 13:15 TRUE 35 0 1 1 0 0 0 0 0 0 0 0 0 0 1

21 6 12/17/ 2014 11:39 45 2 Paramete r 2 12/6/ 2014 13:15 FALSE 0 0 1 2 0 0 0 0 0 0 0 0 0 0 2

22 6 12/17/ 2014 11:39 45 2 Paramete r 2 12/6/ 2014 13:15 FALSE 35 0 2 2 0 0 0 0 0 0 0 0 0 0 2

23 7 12/17/ 2014 11:40 45 2 Paramete r 2 12/6/ 2014 13:15 FALSE 0 0 0 2 0 0 0 0 0 0 0 0 0 0 2

24 7 12/17/ 2014 11:40 45 2 Paramete r 2 12/6/ 2014 13:15 FALSE 0 0 0 2 0 0 0 0 0 0 0 0 0 0 2

25 7 12/17/ 2014 11:40 45 2 Paramete r 2 12/6/ 2014 13:15 FALSE 0 0 0 2 0 0 0 0 0 0 0 0 0 0 2

26 7 12/17/ 2014 11:40 45 2 Paramete r 2 12/6/ 2014 13:15 TRUE 0 0 1 2 0 0 0 0 0 0 0 0 0 0 2

27 7 12/17/ 2014 11:40 45 2 Paramete r 2 12/6/ 2014 13:15 TRUE 35 0 2 2 0 0 0 0 0 0 0 0 0 0 2

28 8 12/17/ 2014 11:41 45 2 Paramete r 2 12/6/ 2014 13:15 FALSE 0 0 0 2 0 0 0 0 0 0 0 0 0 0 2

29 8 12/17/ 2014 11:41 45 2 Paramete r 2 12/6/ 2014 13:15 FALSE 0 0 0 2 0 0 0 0 0 0 0 0 0 0 2

30 8 12/17/ 2014 11:42 45 2 Paramete r 2 12/6/ 2014 13:15 TRUE 0 0 1 2 0 0 0 0 0 0 0 0 0 0 2

31 8 12/17/ 2014 11:42 45 2 Paramete r 2 12/6/ 2014 13:15 TRUE 35 0 2 2 0 0 0 0 0 0 0 0 0 0 2

32 8 12/17/ 2014 11:43 45 1 Paramete r 1 12/6/ 2014 13:15 TRUE 35 0 1 1 0 0 0 0 0 0 0 0 0 0 1

33 9 12/17/ 2014 11:43 1 1 Pa rameter 1 12/6/2014 13: 15 T RUE 35 0 1 1 0 0 0 0 0 0 0 0 0 0 1

34 9 12/17/ 2014 11:44 1 2 Pa rameter 2 12/6/2014 13: 15 T RUE 35 0 1 1 0 0 0 0

0 0 0 0 0 0 2

35 9 12/17/ 2014 11:44 1 1 Pa rameter 1 12/6/2014 13: 15 T RUE 35 0 1 1 0 0 0 0 0 0 0 0 0 0 1

36 10 12/ 17/2014 12:41 45 2 P arameter 2 12/6/2014 13: 15 FALSE 0 0 0 2 0 0 0 0 0 0 0 0 0 0 2

37 10 12/ 17/2014 12:48 45 1 P arameter 1 12/6/2014 13: 15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

38 11 12/ 18/2014 17:28 0 1 Paramete r 1 12/6/ 2014 13:15 FALSE 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1

39 11 12/ 18/2014 17:28 0 1 Paramete r 1 12/6/ 2014 13:15 TRUE 0 0 1 1 0 0 0 0 0 0 0 0 0 0 1

40 11 12/ 18/2014 17:34 0 1 Paramete r 1 12/6/ 2014 13:15 TRUE 0 0 1 1 0 0 0 0 0 0 0 0 0 0 1

Page 27

Collect Data Via

• Assembly Manager Software

• ACOP/ToolsNet

• EtherNet/IP – USB Flash Drive

View Data Collection

• At the Qualifier - Live

• Assembly Manager Software - Download

• ACOP/ToolsNet – Live

• EtherNet/IP – Live

• USB Flash Drive

Page 28

EYFR03 Download Data To USB Drive

Page 28

Turn Qualifier

On

Select

“Download

Device Data To

USB” (Enter)

The Qualifier will

automatically

download the file.

Insert USB into

Qualifier

Select Items To

Upload

Results = “Yes”

Press

“Cancel”

Button

Wait for

Qualifier to

detect USB Drive

Press

“Download”

Button

Select “Exit”

(Enter)

Remove USB

from Qualifier

Page 29

EYFR03 Save The Configuration To US B Dr i ve

Page 29

Turn Qualifier

Select

“Download

Device Data To

USB” (Enter)

The Qualifier will

automatically

download the file.

On

Insert USB into

Qualifier

Select Items To

Upload

Configuration = “Yes”

Press

“Cancel”

Button

“Download”

Select “Exit”

(Enter)

Wait for

Qualifier to

detect USB Drive

Press

Button

Remove USB

from Qualifier

Page 30

EYFR03 Upload Configuration From USB Drive

Page 30

Put the

configuration file on

a USB drive in the

root folder

Turn Qualifier

Select “Upload

USB File To

Device” (Enter)

The Qualifier will

automatically upload

the file.

On

Insert USB into

Qualifier

Select Items To

Upload

Configuration = “Yes”

Press

“Cancel”

Button

Press “Upload”

Select “Exit”

(Enter)

Wait for

Qualifier to

detect USB Drive

Button

Remove USB

from Qualifier

Page 31

EYFR03 Assembly Manager Software – Create CSV Data File

Page 31

Connect PC To

Qualifier Via

Ethernet Cable

Connection Window

Type in Qualifier IP

Address, Click Connect

View/Save

Tightening Results

Configure PC

IP Address

Sync with Device

Select what to

sync, click “Read”

To Save

Click “Save” and save

the csv file to the PC

Configure Qualifier

IP Address

Upload tightenings

to the PC

Click the X at the

top right to close

the window.

Start Up “EYFR03

Assembly

Manager”

Top Menu

click the “Upload

tightening results”

Open .CSV file in

Excel for best

viewing

Loading...

Loading...