Panasonic eyfr02 Operation Manual

Assembly Qualier

Qualicateur d'Assemblage

Calicador Incorporado

Operating Instructions

Instructions d’utilisation

Manual de instrucciones

Model No: EYFR02

IMPORTANT

This manual contains safety information. Read manual completely before first using this product and save this

manual for future use.

IMPORTANT

Ce mode d’emploi contient des informations sur la sécurité. Lisez-le en entier avant d’utiliser le produit et

conservez-le pour référence.

IMPORTANTE

Este manual contiene información de seguridad. Lea completamente este manual antes de utilizar por primera

vez este producto, y guárdelo para poder consultarlo en el futuro.

Index

English: Page 3

Français: Page 15 Español: Página 27

FUNCTIONAL DESCRIPTION

DESCRIPTION DES FONCTIONS

DESCRIPCIÓN FUNCIONAL

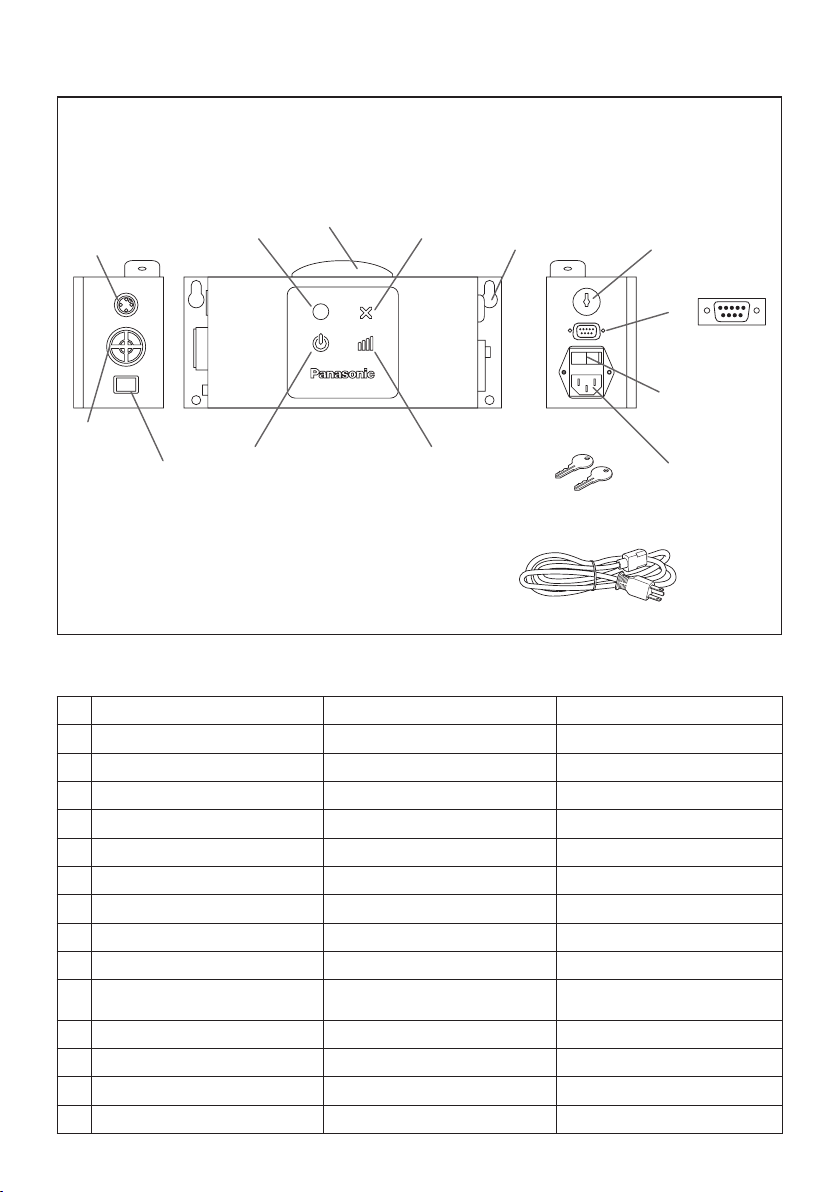

(A)

(D)

(E)

(F)

(G)

(J)

(K)

(L)

(B)

(C)

(I)

(H)

(M)

(N)

(O)

I/O connector Connecteur d'entrée/sortie Conector de entrada/salida

(A)

Beeper Roneur Alarma

(B)

Volume switch Interrupteur de volume Interruptor de volumen

(C)

Fastening accept indicator Témoin d'acceptation de xation

(D)

Antenna cover Cache d'antenne Cubierta de antena

(E)

(F) Fastening reject indicator Témoin de rejet de xation

Mounting holes Trous de montage Oricios de instalación

(G)

Signal strength indicator Témoin de puissance de signal Indicador de fuerza de señal

(H)

Power indicator

(I)

(J) Key lock Verrou à clé Bloqueador de llave

(K) D-sub 9-pin female inch thread

Power switch

(L)

Power plug inlet

(M)

Soft key

(N)

Power cord

(O)

Témoin d'alimentation Indicador de energía

Filet de pouce femelle à

9 broches D-sub

Interrupteur d'alimentation Interruptor de energía

Entrée de che d'alimentation Entrada de corriente eléctrica

Clé d'enregistrement Tecla suave

Cordon d'alimentation Cable de energía

Indicador de aceptación de sujeción

Indicador de rechazo de sujeción

Roscado hembra D-sub de

9 clavijas

-

2 -

I

.

INTRODUCTION

Thank you for purchasing the Panasonic Assembly Qualifier. The AQ Wireless can monitor

battery tools. In its simplest form, the AQ Wireless is configured to monitor a tool while it's

running, determine if the fastening process was successful, report the status of the fastening.

How to Use This Manual

• Please read this manual completely before starting to use your AQ Wireless. If this unit is

mishandled a fatal accident, bodily injury, or damage to the AQ Wireless may occur.

• This manual is intended to be a general guide to the operations of the AQ Wireless. If any

additional questions or concerns arise, please contact a Panasonic Electric Works Power

Tools representative.

• Please keep this manual for future reference. It contains important safety information that

you must follow to use the AQ Wireless safety.

WARNING!

• Do not disassemble the unit for repair or modifications. There is a high electrical voltage

inside the unit that could cause electric shock.

• Do not allow any type of liquid to come into contact with any part of the unit.

• Immediately discontinue use of the unit if smoke, an abnormal odor, or an unusual

sound is detected coming from the unit.

• Insert all fittings fully into their mating receptacles. Failure to do so could result in injury.

• Do not fold, bend or apply excessive force to any cable or fitting.

CAUTION!

• This unit accepts an AC input voltage from 90VAC to 264VAC. Trying to operate this unit with a

voltage outside that range may cause damage to the unit.

• Reception reliability may vary with site conditions. Be sure to verify proper Assembly Qualifier

operation, including data reception, before starting work. Panasonic is not responsible for any

damage sustained as a result of reception problems.

• Avoid placing or storing this unit in a location where it may become wet or dust covered.

• Do not place or mount this unit in an unstable area.

Dropping this unit may result in personal injury or damage to the unit.

Before performing any maintenance on the unit, make sure to turn it off and remove the power plugs.

•

• There are no user serviceable parts inside the main enclosure of the unit.

Proper operation is not guaranteed in the event that the Assembly Qualifier has been modified in any way.

•

• Always use this Assembly Qualifier with a Panasonic tool. Proper operation is not guaranteed

when used with non-Panasonic tools.

Always turn the Assembly Qualifier’s power off when not in use.

• The socket-outlet shall be installed near the equipment and shall be easily accessible.

-

3 -

II

.

BEFORE USING THE ASSEMBLY QUALIFIER

Downloading software

The Assembly Qualifier is configured (relay output time, frequency, etc.) by

connecting it to a computer. The Device Programmer application is required in

order to do this. If you need to configure the Assembly Qualifier, the software

can be downloaded from the following URL:

http://denko.panasonic.biz/Ebox/powertool/factory/download/ENG/

Device Programmer system requirements

Read before use

• You may not be able to use the Device Programmer on some computers, even if they

satisfy the system requirements.

• Depending on the computer being used, actual operation and screen content may

differ from the information presented in this manual.

• The information in this manual is subject to change without notice.

• Unauthorized copying or other reproduction of this manual, in whole or in part, is

prohibited.

• This portion of this manual describing Windows operation uses procedures and

screens for Windows XP.

The Device Programmer application is not compatible with Macintosh

computers. See below for supported operating systems. All illustrations

in this manual are provided for reference purposes only.

Device Programmer system requirements

Supported computers

Windows® 7: IBM® PC/AT compatible computer with Intel® Pentium® III

1 GHz or faster CPU (including compatible CPUs)

Windows Vista®: IBM® PC/AT compatible computer with Intel® Pentium® III

800 MHz or faster CPU (including compatible CPUs)

Windows® XP: IBM® PC/AT compatible computer with Intel® Pentium® III

500 MHz or faster CPU (including compatible CPUs)

Supported operating systems

Pre-installed Japanese language version

Microsoft® Windows® 7 (32-bit) Starter

Microsoft® Windows® 7 (32-bit/64-bit) Home Basic/Home Premium/Professional/

Ultimate

Microsoft® Windows Vista® (32-bit) Home Basic/Home Premium/Business/

Ultimate SP1/SP2

Microsoft® Windows® XP (32-bit) Home Edition/Professional SP2/SP3

Memory

Windows® 7: At least 1 GB (32-bit) or 2 GB (64-bit)

Windows Vista®/Windows® XP: At least 256 MB

-

4 -

Hard disk

Ultra DMA-100 or better

At least 10 MB of space for installing the software

• When recording to disk, space equal to at least twice the size of the data being

created is required.

• An error may occur during recording if the compression setting is enabled.

Deselect the “Compress contents to save disk space” checkbox in the hard

disk’s “Properties.”

Interface

Serial communications port (COM)

Other

Mouse or equivalent pointing device

Required software

.NET framework 3.5 SP1

• The software is not guaranteed to operate properly on all computers that satisfy the

system requirements.

• The software does not support Windows® 3.1, Windows® 95, Windows® 98,

Windows® 98SE, Windows® Me, Windows NT®, or Windows® 2000.

• The software is not guaranteed to operate properly on Windows® XP Media Center

Edition, Tablet PC Edition, Windows Vista® Enterprise or Windows® 7 Enterprise.

• The software is not guaranteed to operate properly on 64-bit versions of Windows®

XP or Windows Vista®.

• The software is not guaranteed to operate properly in Windows® 7 XP mode.

• The software is not guaranteed to operate properly on upgraded operating systems.

• Multi-boot systems are not supported.

• Multi-monitor systems are not supported.

• Only users with system administrator privileges can install or uninstall the software.

• Log in on an administrator account or standard user account before using the

software. The software cannot be used by guest account usernames.

• The software is not guaranteed to operate properly on systems where the language

has been changed using the Windows Vista®/Windows® 7 Ultimate multi-language

user interface (MUI) function.

-

5 -

• Microsoft and Windows are registered trademarks or trademarks of Microsoft

Corporation in the United States and other countries.

• IBM and PC/AT are registered trademarks of International Business

Machines Corporation.

• Apple, the Apple logo, Macintosh, and MacOS are registered trademarks of

Apple Inc.

• Intel, Pentium, and Celeron are registered trademarks or trademarks of Intel

Corporation in the United States and other countries.

• Screenshots have been used in accordance with Microsoft Corporation

guidelines.

• Other model names, company names, and product names are the

trademarks or registered trademarks of their respective companies.

-

6 -

Installing the software

● Before installing the software, quit all other open applications.

1. Double-click “Panasonic Device Programmer.zip.”

2. Double-click “exe file”, then follow the instructions on the screen to install

the software.

● Restart the computer once the installation is complete.

Disclaimer

Be sure to read before use.

Limitations:

The Device Programmer software is designed to be used to configure EYFR02

(Assembly Qualifier) settings.

Caution:

The following precautionary information applies to use of this software:

Use of the software signifies your acceptance of the following terms of use.

Terms of Use:

• Panasonic makes no guarantee concerning the operation of this software.

• Panasonic is not liable for any direct, indirect, secondary, consequential, or

special damage arising from the use or operation of this software, either by

extension or effect.

• It is prohibited to reproduce or distribute this software.

Configuring settings with the software

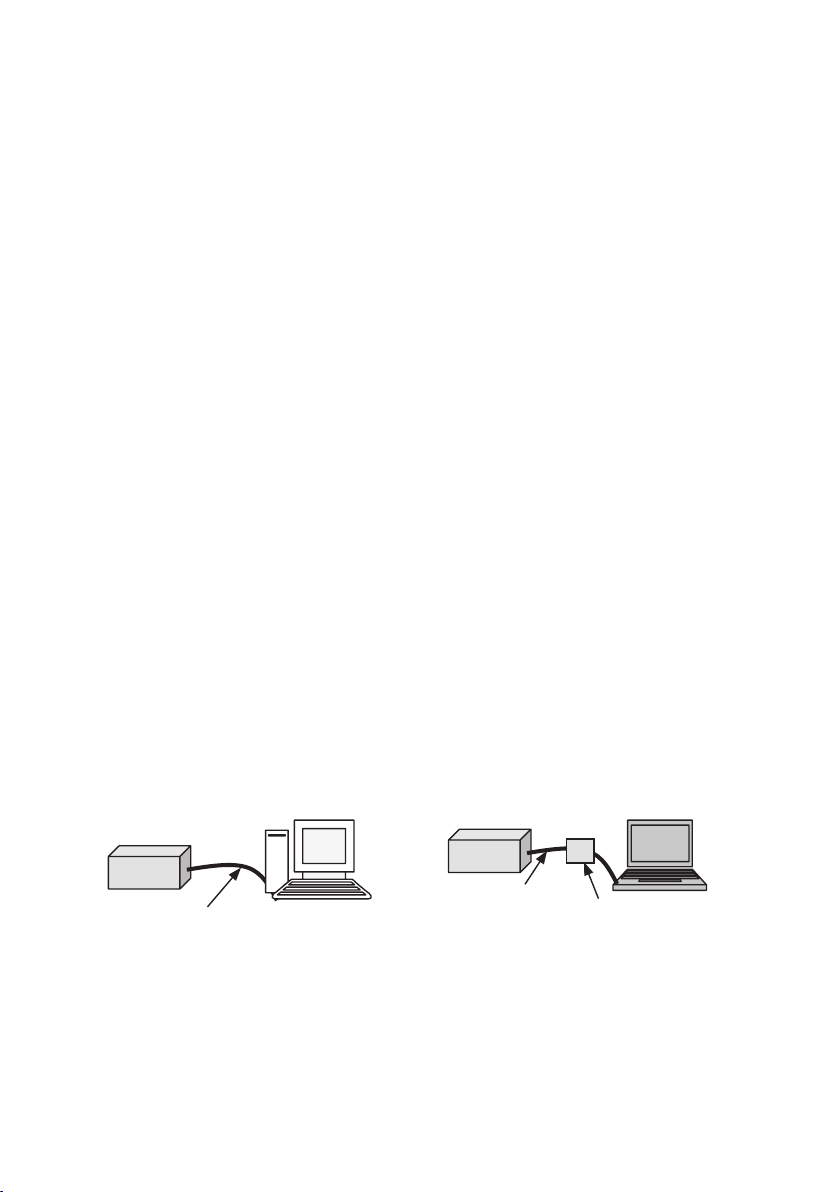

1. Connect the Assembly Qualifier to the computer.

• Use an RS-232C straight cable.

Using a serial RS-232C port to

connect the Assembly Qualifier

RS-232C straight cable

2. Turn on the Assembly Qualifier.

3. Launch the Device Programmer application.

4. Click the “Read Settings” button.

• The software will load the Assembly Qualifier’s current settings.

Using a USB port to connect the

Assembly Qualifier

RS-232C

straight cable

-

7 -

USB serial conversion

adapter

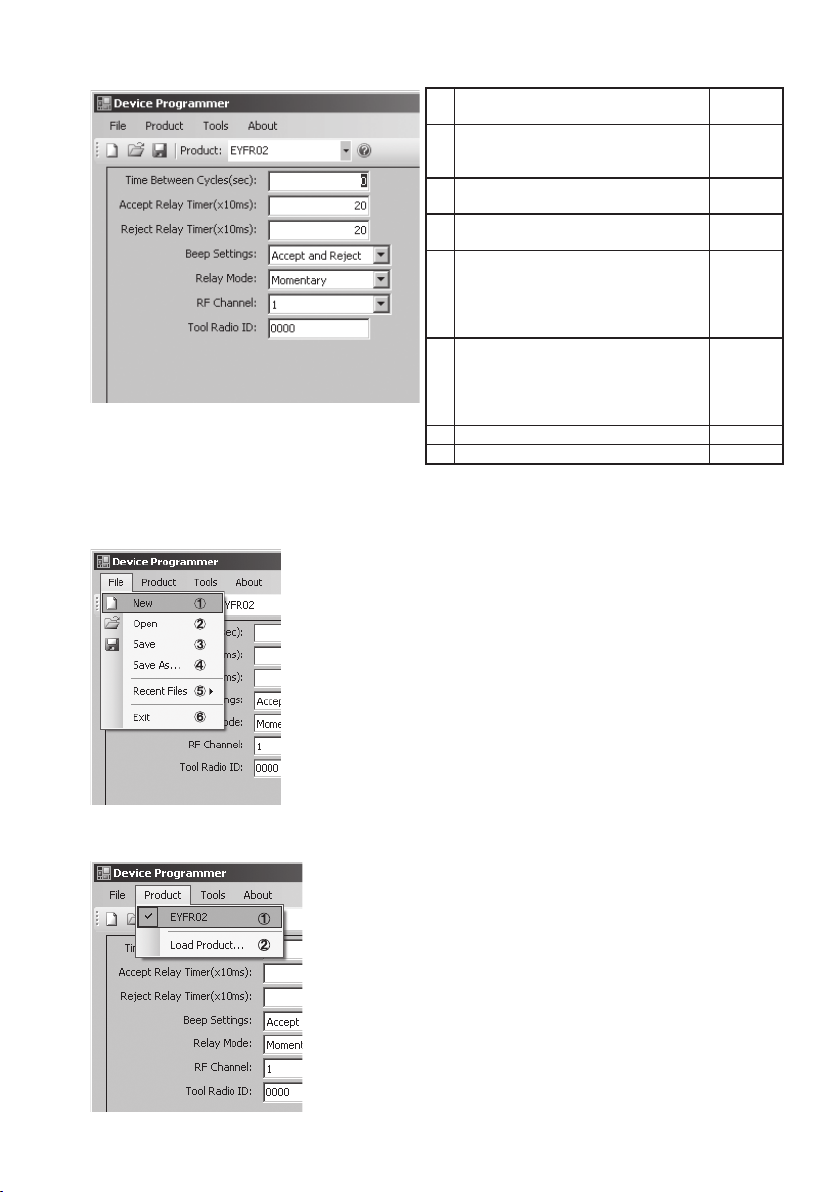

5. Configure the settings as desired.

(A)

(B)

(C)

(D)

(E)

(F)

(G)

• Enter values and select settings.

• File menu

1 Creates a new file.

2 Opens a previously created file.

3 Saves the current settings.

4 Saves the current settings as a new file.

5 Opens recently used files.

6 Exits the Device Programmer application.

Initial

Function description

Function description

Time during which to invalidate the next

Time during which to invalidate the next

(A)

reception (so that cycles are not counted

(A)

reception (so that cycles are not counted

twice)

twice)

(B)

Fastening accept signal relay output time*

(B)

Fastening accept signal relay output time*

(C)

Fastening reject signal relay output time*

(C)

Fastening reject signal relay output time*

Sets the beep mode to any of three options.

Sets the beep mode to any of three options.

1 Accept and Reject: Fastening accept

1 Accept and Reject: Fastening accept

(D)

and fastening reject

(D)

and fastening reject

2 Accept only: Fastening accept only

2 Accept only: Fastening accept only

3 Reject only: Fastening reject only

3 Reject only: Fastening reject only

Sets the relay output method to either of

Sets the relay output method to either of

two options.

two options.

(E)

1 Latching: Output continuously.

(E)

1 Latching: Output continuously.

2 Momentary: Output for duration

2 Momentary: Output for duration

defined by relay output time.

defined by relay output time.

(F)

Sets the frequency to any of 12 channels. 1

(F)

Sets the frequency to any of 12 channels. 1

(G)

Displays the registered tool ID. 0000

(G)

Displays the registered tool ID. 0000

* Valid only when (E) has been set to 2 (“Momentary”).

Setting a long relay output time slows the reception process.

Initial

setting

setting

0 (0 sec)

0 (0 sec)

20

20

(0.2 sec)

(0.2 sec)

20

20

(0.2 sec)

(0.2 sec)

Accept and

Accept and

Reject

Reject

Momentary

Momentary

• Product menu

1 Selects the Assembly Qualifier.

(This setting does not need to be changed.)

2 Not used

-

8 -

• Tools menu

• About menu

Configures the port used to connect the Assembly

Qualifier to the computer.

1 Selects the port.

2 Sets the baud rate.

Initial setting: 9600

Allows you to check the software’s version.

Installing the Assembly Qualifier

Installation method

Mount the Assembly Qualifier securely with screws using the four mounting holes.

NOTE

Before mounting the Assembly Qualifier, test it where you plan to install it to ensure

that there are no communications issues.

CAUTION

Verify that the Assembly Qualifier is not affected by other wireless equipment before

mounting it.

-

9 -

III

. OPERATION

Registering the tool with the Assembly Qualifier

● Preparing the Assembly Qualifier

1. Connect the power cord to the Assembly Qualifier.

2. Plug the power cord into a wall outlet.

3. Turn on the Assembly Qualifier.

All indicators will turn on and off, leaving only the power indicator on.

4. Insert a soft key into the key lock and turn to the left.

The power indicator will flash, and the Assembly Qualifier will enter tool

registration standby mode.

● Preparing the tool to be registered

1. Operate the tool so that all the panel lights are off (if any panel lights are on).

2. Pull the tool’s trigger.

Once the tool has been registered, the Assembly Qualifier’s fastening accept

signal will turn on.

3. Turn the Assembly Qualifier’s soft key to the right.

The power indicator will turn on and the Assembly Qualifier will enter receive

mode, completing the registration process.

CAUTION

The registration procedure should be performed away from other transmitterequipped tools. When registering multiple tools, do so one pair at a time. Failure to

do so may cause an unintended tool to be registered with the Assembly Qualifier.

Indicators

Indicator State

Fastening

accept indicator

Fastening

reject indicator

Power indicator

Signal strength

indicator

Green Fastening accept signal received.

Off No fastening accept signal is being received.

Red Fastening reject signal received.

Off No fastening reject signal is being received.

Blue Power on (receive mode)

Off Power off

Flashing blue Tool registration standby mode

Yellow Strong signal

Orange Medium-strength signal

Red Weak signal

Flashing red

Off No fastening signal is being received.

Signal received during double-count prevention

time.

-

10 -

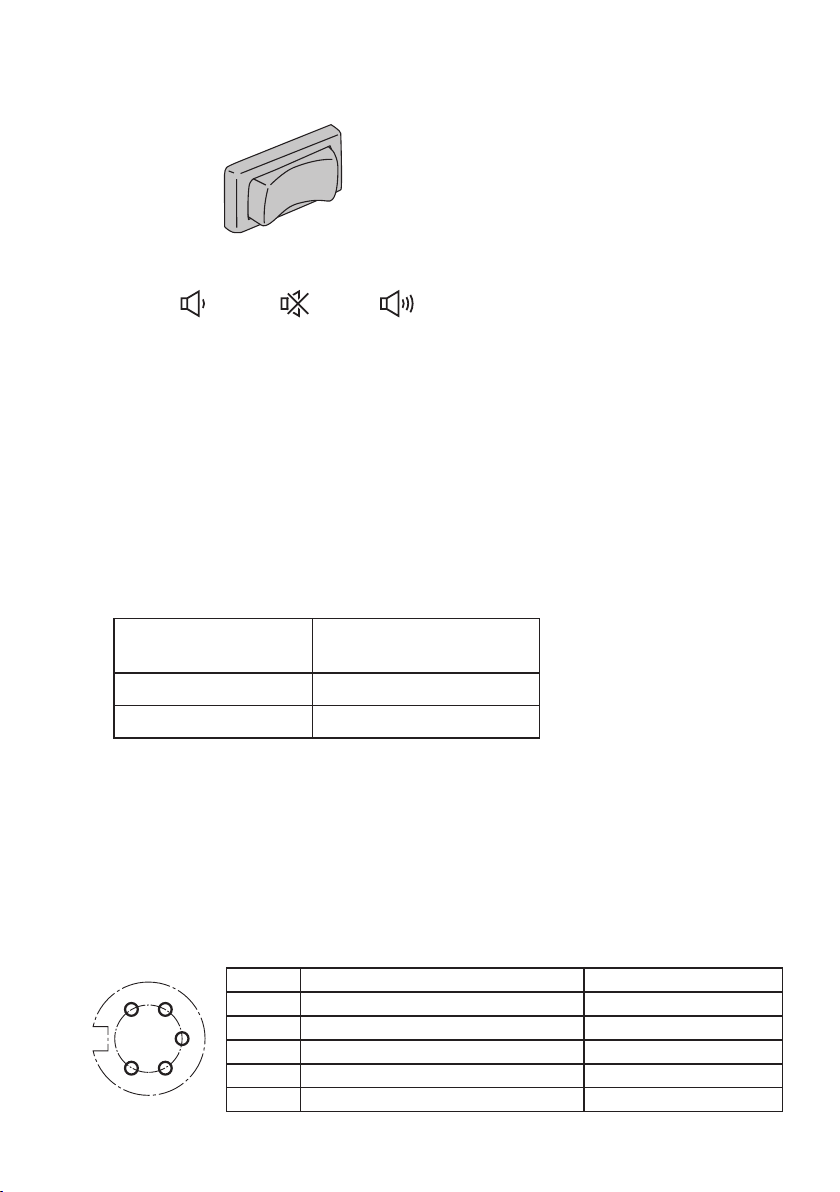

Setting the beep volume

1

5

2

4

3

Set the beep volume with the volume switch.

Low volume

(Approx. 75 dB)

NOTE

The beep mode setting is configured while the Assembly Qualifier is connected to a

computer. See page 7.

OFF High volume

(Approx. 90 dB)

Using the software

1. Turn on the Assembly Qualifier’s power switch.

All indicators will turn on and off, leaving only the power

indicator on.

2. Use the registered tool to perform fastening work.

Status of tool’s fastening

confirmation indicator

Green Fastening accept indicator

Red Fastening reject indicator

Assembly Qualifier

indicators

Finishing work

Turn off the Assembly Qualifier’s power switch.

I/O connector

Pin no. Description Rating

1

Reset input pin (input) Input rating: 24 V/60 mA

2

Reset input pin (common) —

3

Relay output pin (common) —

4

Relay output pin (fastening accept) Output rating: 30 VDC/5 A

5

Relay output pin (fastening reject) Output rating: 30 VDC/5 A

-

11 -

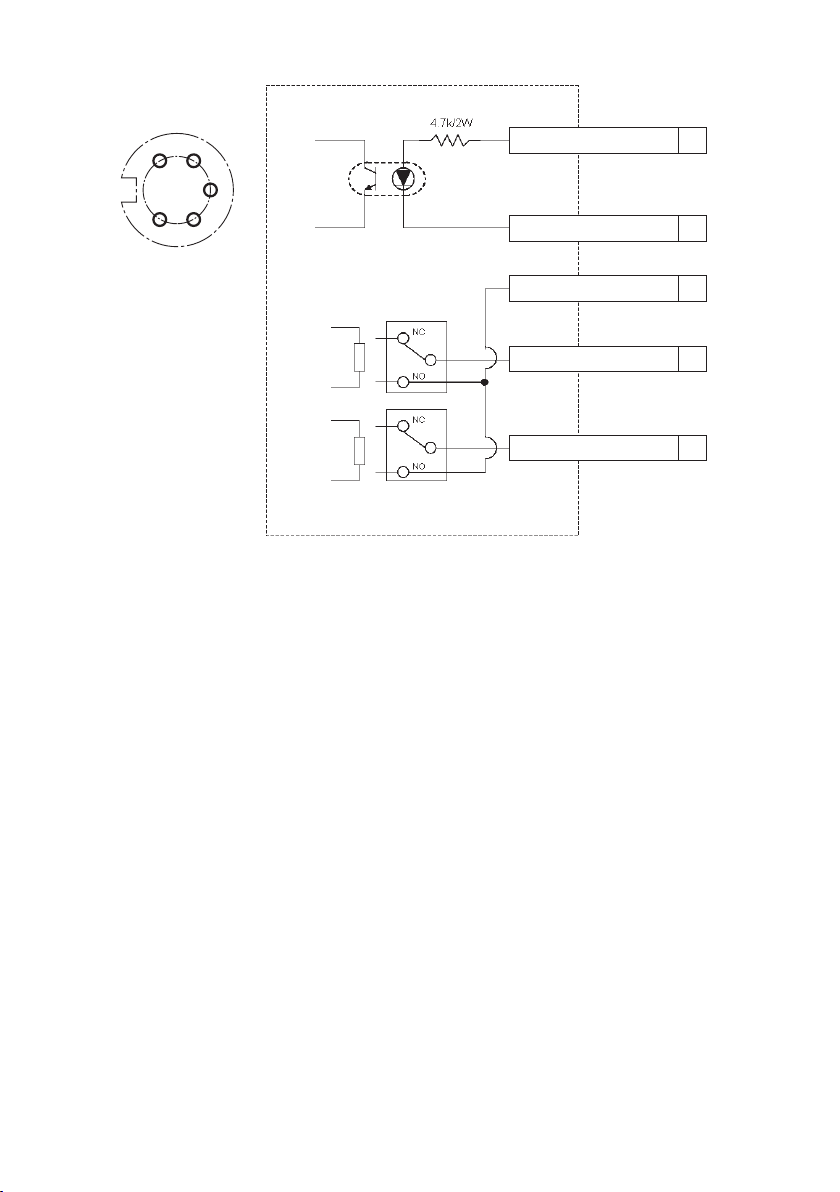

5-pin connector schematic and pin out

1

5

2

4

3

RESET INPUT

RESET COMMON

RELAY COMMON

Relay

ACCEPT RELAY

INTERNAL CONTROL

REJECT RELAY

INTERNAL CONTROL

Relay

ACCEPT RELAY

REJECT RELAY

To connect to the 5-pin connector, you will need:

A commercially available round connector

(manufacturer: Amphenol ; model no.: T3360 001)

1

2

3

4

5

-

12 -

Loading...

Loading...