Page 1

Operating Instructions

Instructions d’utilisation

Manual de instrucciones

Destornillador de impacto inalámbrico/Llave de impacto inalámbrica

Perceuse à impact sans l/Clé de serrage à impact sans l

Cordless Impact Driver/Cordless Impact Wrench

Model No: EYFLA1A / EYFLA2A

* Pictured: Cordless impact driver

* Image: Perceuse à impact sans l

* En la imagen: Destornillador de impacto inalámbrico

EYFLA2Q / EYFLA3J

IMPORTANT

This manual contains safety information. Read manual completely before first using this product and save this

manual for future use.

IMPORTANT

Ce mode d’emploi contient des informations sur la sécurité. Lisez-le en entier avant d’utiliser le produit et

conservez-le pour référence.

IMPORTANTE

Este manual contiene información de seguridad. Lea completamente este manual antes de utilizar por primera

vez este producto, y guárdelo para poder consultarlo en el futuro.

Page 2

Index/Index/Indice

English: Page 4

Français: Page

17

Español: Página 31

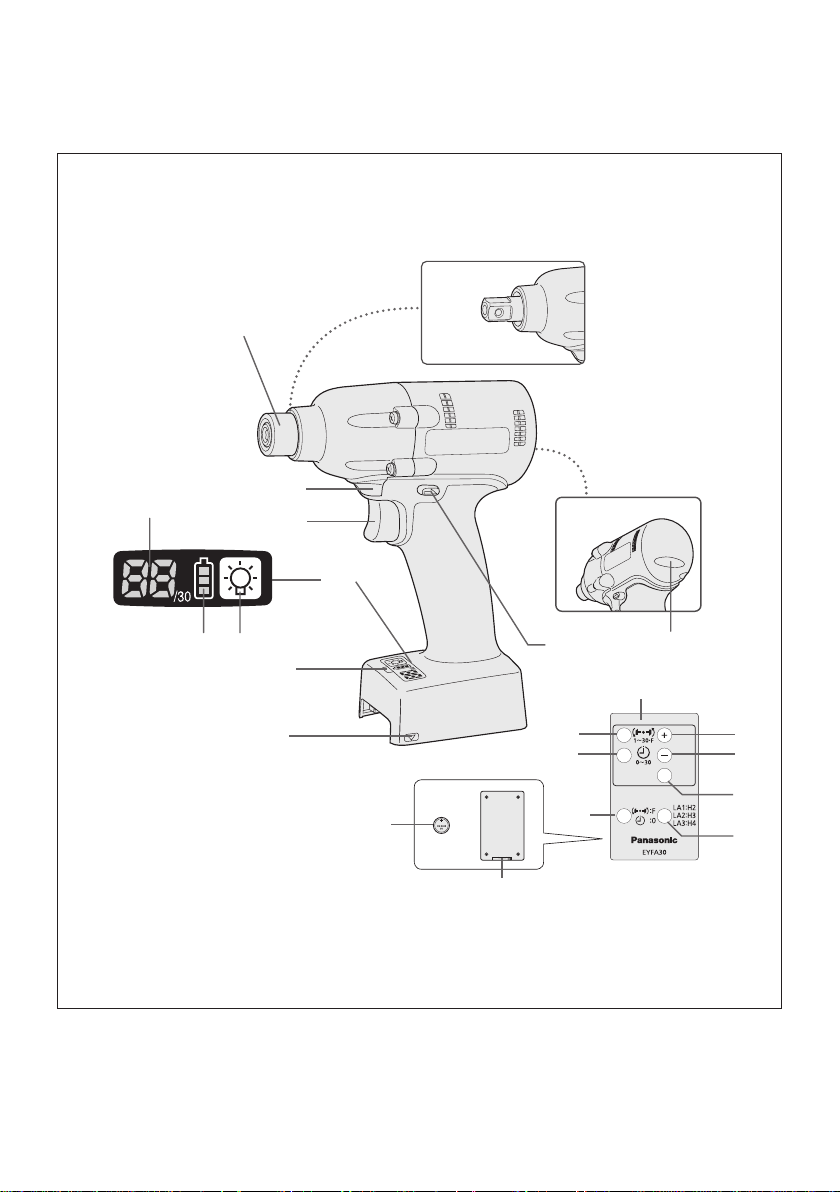

FUNCTIONAL DESCRIPTION

DESCRIPTION DES FONCTIONS

DESCRIPCIÓN FUNCIONAL

(A)

EYFLA1A

EYFLA2A

(K)

(I)

(J)

(F)

EYFLA2Q

EYFLA3J

(G)(H)

(E)

(D)

(S)

Remote control and battery are not included.

La télécommande et la batterie ne sont pas incluses.

El control remoto y la batería no están incluídos.

-

2 -

(R)

(C)

(U)

(T)

(B)

(L)

(M)

(N)

(O)

(Q)

(P)

Page 3

6.35 mm (1/4") hex quick connect chuck (EYFLA1A, EYFLA2A)/square drive (EYFLA2Q, EYFLA3J/Pin type)

Mandrin de connexion rapide hexagonal de 6,35 mm (1/4")/entraînement carré (EYFLA2Q, EYFLA3J/Type à goujon)

(A)

Mandril hexagonal de conexión rápida de 6,35 mm (1/4")/Excitador cuadrado (EYFLA2Q, EYFLA3J/tipo pasador)

Tightening conrmation lamp

Témoin de conrmation de serrage

(B)

Lámpara de conrmación de apriete

Alignment mark

Marques d’alignement

(D)

Marcas de alineación

Control panel

Panneau de commande

(F)

Panel de control

Battery indication lamp

Témoin indicateur de la batterie

(H)

Lámpara de indicadora de la batería

Variable speed control trigger

Gâchette de commande de vitesse

(J)

Disparador del control de velocidad variable

Remote control

Télécommande

(L)

Control remoto

− button

Bouton −

(N)

Botón

−

Torque level button

Bouton de niveau du couple de serrage

(P)

Botón de palanca de par de torsión

Holder

Support

(R)

Retenedor

Interval set button

Bouton de réglage de l’intervalle

(T)

Botón de ajuste de intervalo

Forward/Reverse lever

Levier d’inversion marche avant/marche arrière

(C)

Palanca de avance/marcha atrás

Remote control receiver

Récepteur de la télécommande

(E)

Receptor de control remoto

LED light on/off button

Bouton Marche/Arrêt de la lumière DEL

(G)

Botón ON/OFF de luz LED

Display

Afchage

(I)

Visor

LED light

Lumière DEL

(K)

Luz indicadora

+ button

Bouton +

(M)

Botón +

OK button

Bouton OK

(O)

Botón OK (correcto)

Format button

Bouton de format

(Q)

Botón de formato

Battery

Batterie

(S)

Batería

Torque set button

Bouton de réglage du couple de serrage

(U)

Botón de ajuste de par de torsión

-

3 -

Page 4

I

.

GENERAL SAFETY

RULES

WARNING! Read all instructions

Failure to follow all instructions listed

below may result in electric shock, fire

and/or serious injury. The term “power

tool” in all of the warnings listed below

refers to your mains operated (corded)

power tool and battery operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

Work Area Safety

1) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2)

Do not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may

ignite the dust or fumes.

3)

Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

1) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power tools.

Unmodified plugs and matching outlets

will reduce risk of electric shock.

2

) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

3) Do not expose power tools to rain or

wet conditions.

Water entering a power tool will increase

the risk of electric shock.

4)

Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp edges

or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

5)

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

Personal Safety

1)

Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence

of drugs, alcohol or medication.

A moment of inattention while operating

power tools may result in personal injury.

2

) Use safety equipment. Always wear

eye protection.

Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

3)

Avoid accidental starting. Ensure the

switch is in the off position before

plugging in.

Carrying power tools with your finger on

the switch or plugging in the power tools

that have the switch on invites accidents.

4)

Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

5)

Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

6)

Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away from

moving parts.

Loose clothes, jewellery or long hair can

be caught in moving parts.

7)

If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used.

Use of these devices can reduce dust

related hazards.

Power Tool Use and Care

1)

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

2

) Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be controlled

with the switch is dangerous and must

be repaired.

3)

Disconnect the plug from the power

source and/or the battery pack from

-

4 -

Page 5

the power tool before making any

adjustments, changing accessories,

or storing power tools.

Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

4)

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

5)

Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tools operation. If damaged, have the

power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

6)

Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

7)

Use the power tool, accessories

and tool bits etc. in accordance with

these instructions and in the manner

intended for the particular type of

power tool, taking into account the

working conditions and the work to

be performed.

Use of the power tool for operations

different from those intended could

result in a hazardous situation.

Battery Tool Use and Care

1) Ensure the switch is in the off position

before inserting battery pack.

Inserting battery pack into power tools

that have the switch on invites accidents.

2

) Recharge only with the charger

specified by the manufacturer.

A charger that is suitable for one type

of battery pack may create a risk of fire

when used with another battery pack.

3)

Use power tools only with specifically

designated battery packs.

Use of any other battery packs may

create a risk of injury and fire.

4)

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together

may cause burns, or a fire.

5)

Under abusive conditions, liquid may

be ejected from battery; avoid contact.

If contact accidentally occurs, flush

with water. If liquid contacts eyes,

additionally seek medical help.

Liquid ejected from the battery may

cause irritation or burns.

Service

1) Have your power tool serviced by a

qualified repair person using only

identical replacement parts.

This will ensure that the safety of power

tool is maintained.

II

. INTENDED USE

This tool is a Cordless Impact Driver/Wrench

and can be used to tighten bolts, nuts, and

screws. Additionally, it provides a torque control function that automatically stops tool operation when a preset load is reached to deliver

consistent tightening torque.

Read “the Safety Instructions” booklet

and the following before using.

III

.

ADDITIONAL SAFETY

RULES

1

) Wear ear protectors when using the

tool for extended periods.

2

) Be aware that this tool is always in an

operating condition, since it does not have

to be plugged into an electrical outlet.

3)

Hold power tools by insulated gripping

surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord.

ontact with a “live” wire will make exposed

C

metal parts of the tool “live” and shock the

operator.

4)

Do NOT operate the Forward/Reverse

lever when the main switch is on. The battery will discharge rapidly and damage to

the unit may occur.

5)

During charging, the charger may become

slightly warm. This is normal.

D

o NOT charge the battery for a long period.

6) When storing or carrying the tool, set the

Forward/Reverse lever to the center position (switch lock).

Do not strain the tool by holding the speed

7)

control trigger halfway (speed control

mode) so that the motor stops.

-

5 -

Page 6

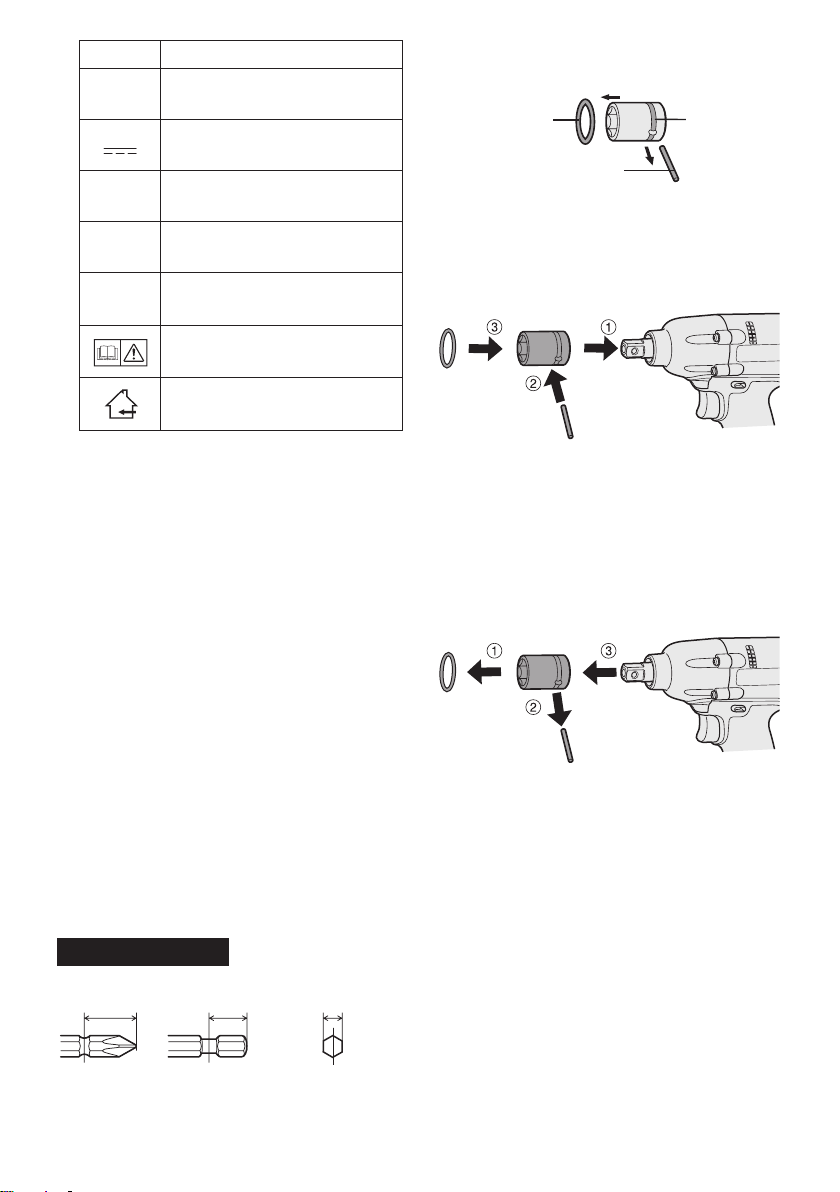

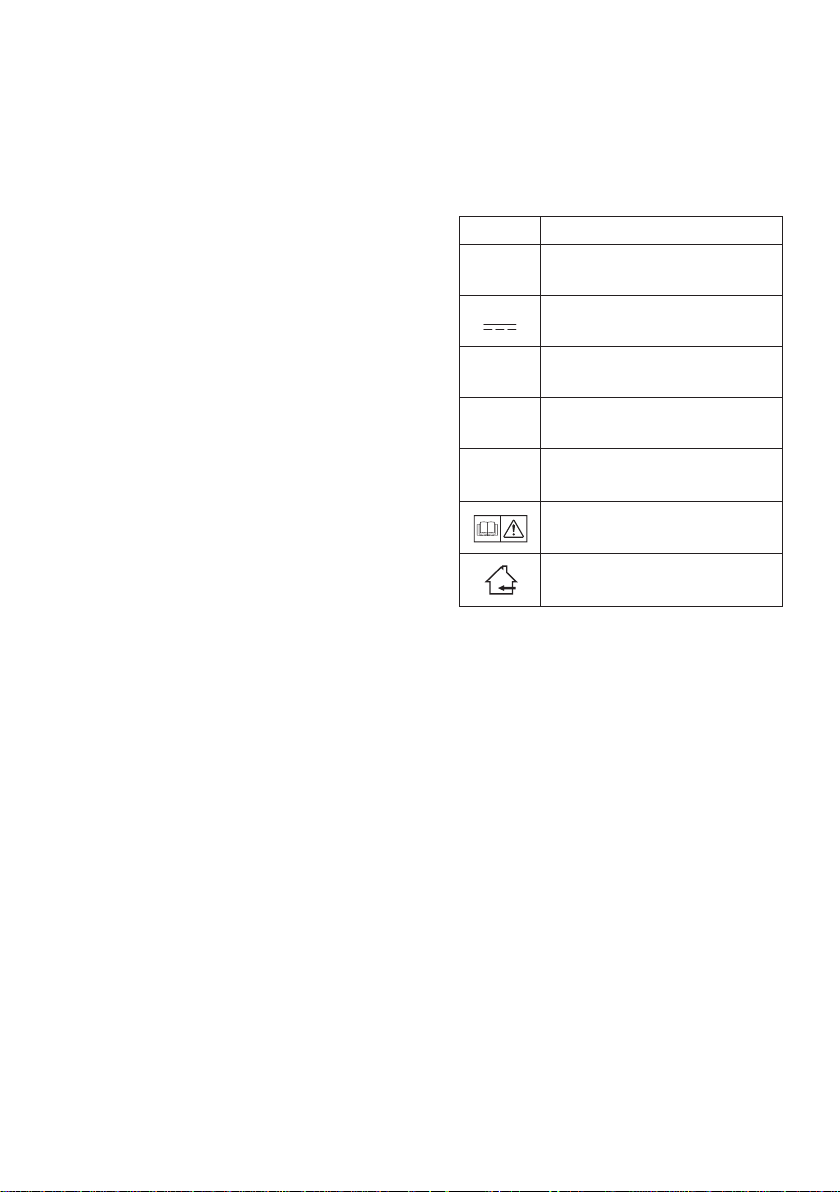

Symbol Meaning

V

n

0

Revolutions or reciprocations

-1

… min

Ah

IV

. ASSEMBLY

Electrical capacity of battery

instructions before use.

Volts

Direct current

No load speed

per minutes

pack

Read the operating

For indoor use only.

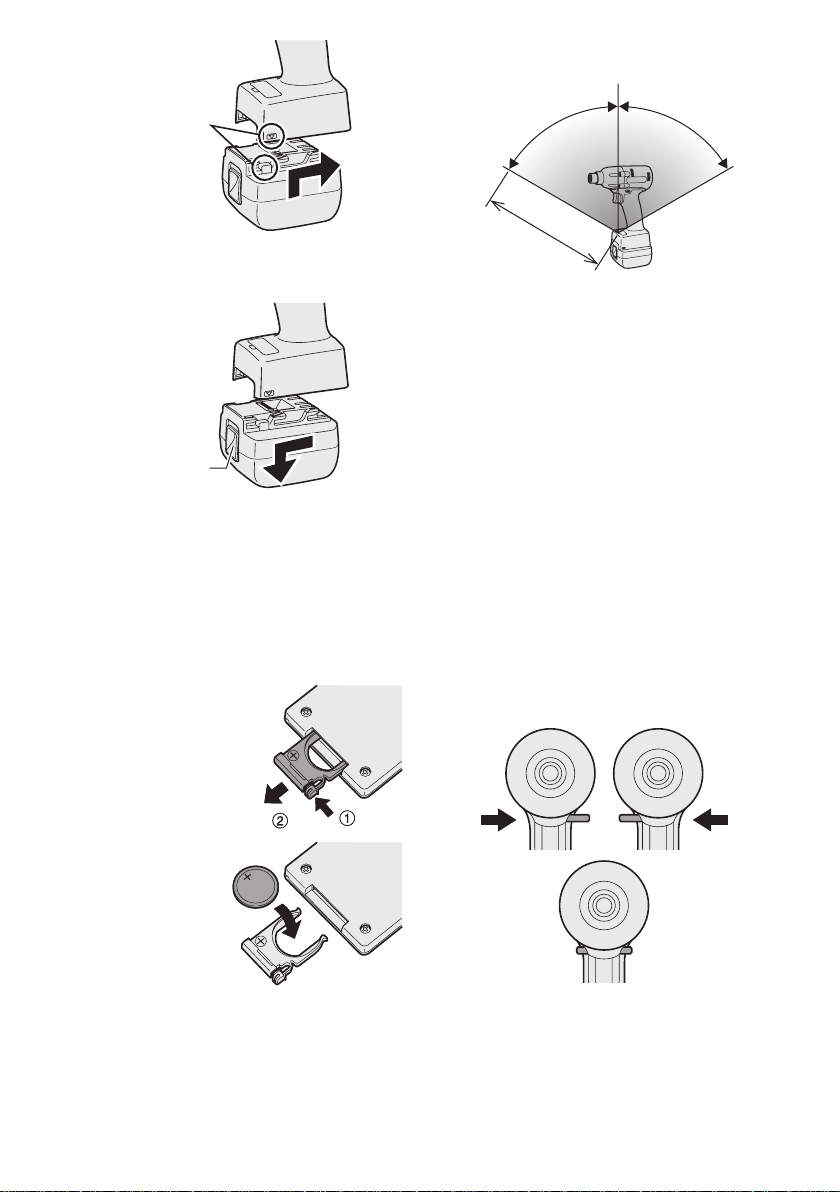

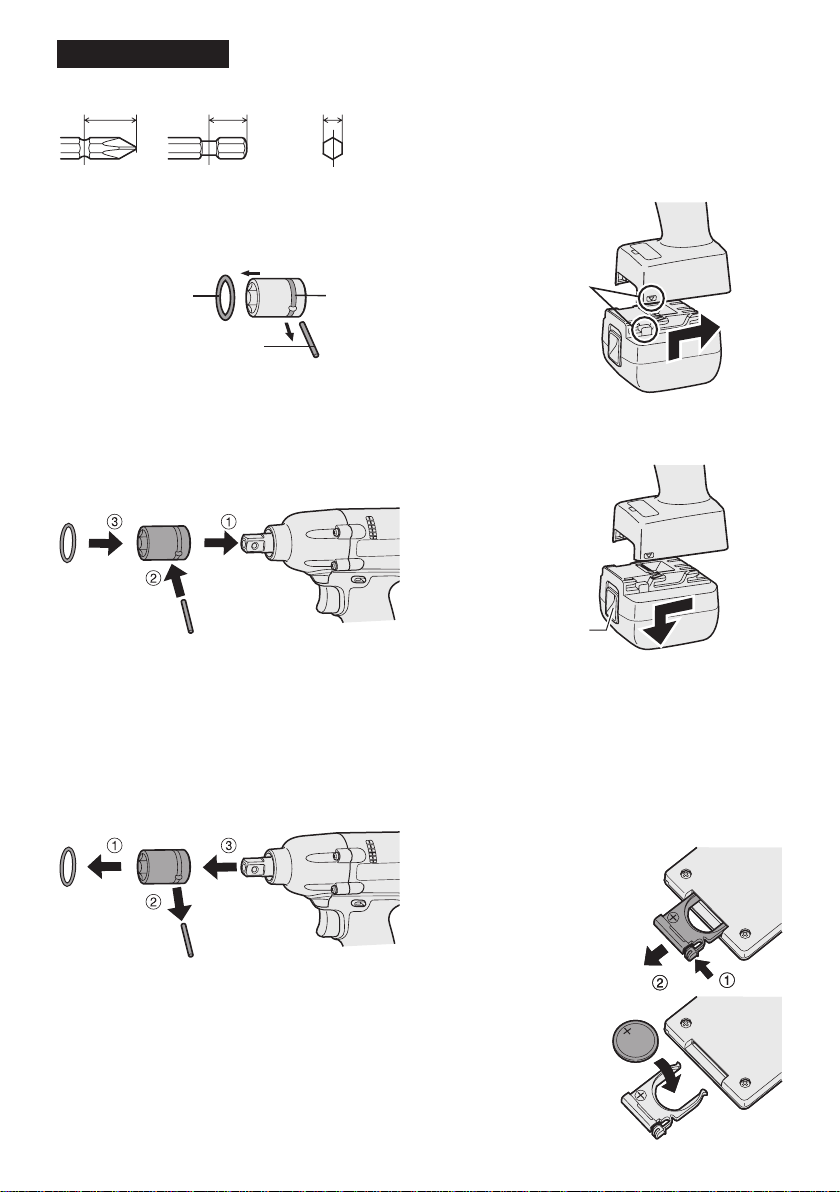

Attaching or Removing Bit

NOTE:

•

When attaching or removing a bit, disconnect battery pack from tool or place the

switch in the center position (switch lock).

1. Hold the collar of quick connect chuck and

pull it out from the tool.

2

. Insert the bit into the chuck. Release the

collar.

The collar will return to its original position

3.

when it is released.

Pull the bit to make sure it does not come out.

4.

5. To remove the bit, pull out the collar in the

same way.

CAUTION:

•

If the collar does not return to its origi-

nal position or the bit comes out when

pulled on, the bit has not been properly

attached. Make sure the bit is properly

attached before use.

EYFLA1A/EYFLA2A

12 mm

(15/32")

9 mm – 9.5 mm

(

23/64" – 3/8")

6.35 mm

(1/4")

Attaching Socket

• Remove the socket’s rubber ring and pin.

ring

rubber

pin

1 Attach the socket to the tool.

2 Insert

3 A

the pin. (Taking care to align the pin

holes on the socket and tool.)

ttach the rubber ring by sliding it into place

over the groove.

NOTE:

Be sure to attach the rubber ring to prevent

the pin from falling out.

groove

Removing Socket

1 Remove the rubber ring.

2 Remove the pin.

emove the socket from the tool.

3 R

NOTE:

Keep the temperature of the tool above

the

freezing point (0°C/32°F) when attaching sockets to or detaching them from

the square drive on the tool. Do not use

excessive

ing sockets.

force when attaching or detach-

Attaching or Removing Battery Pack

1. To connect the battery pack:

Line up the alignment marks and attach

the battery pack.

•

Slide the battery pack until it locks into

position.

-

6 -

Page 7

Alignment

Approx. 50 cm

Vertically

A

p

p

r

o

x

.

6

0

°

A

p

p

r

o

x

.

6

0

°

Forward Reverse

Switch lock

marks

2. To remove the battery pack:

Push up on the button from the front to release the battery pack.

Button

V

. OPERATION

Before Using the Remote

Control (Available as an

optional accessory)

Insert the battery

1. Pull out the battery holder.

1 P

ush in on the fastener as indicated by

the arrow.

2 Pull out the holder

.

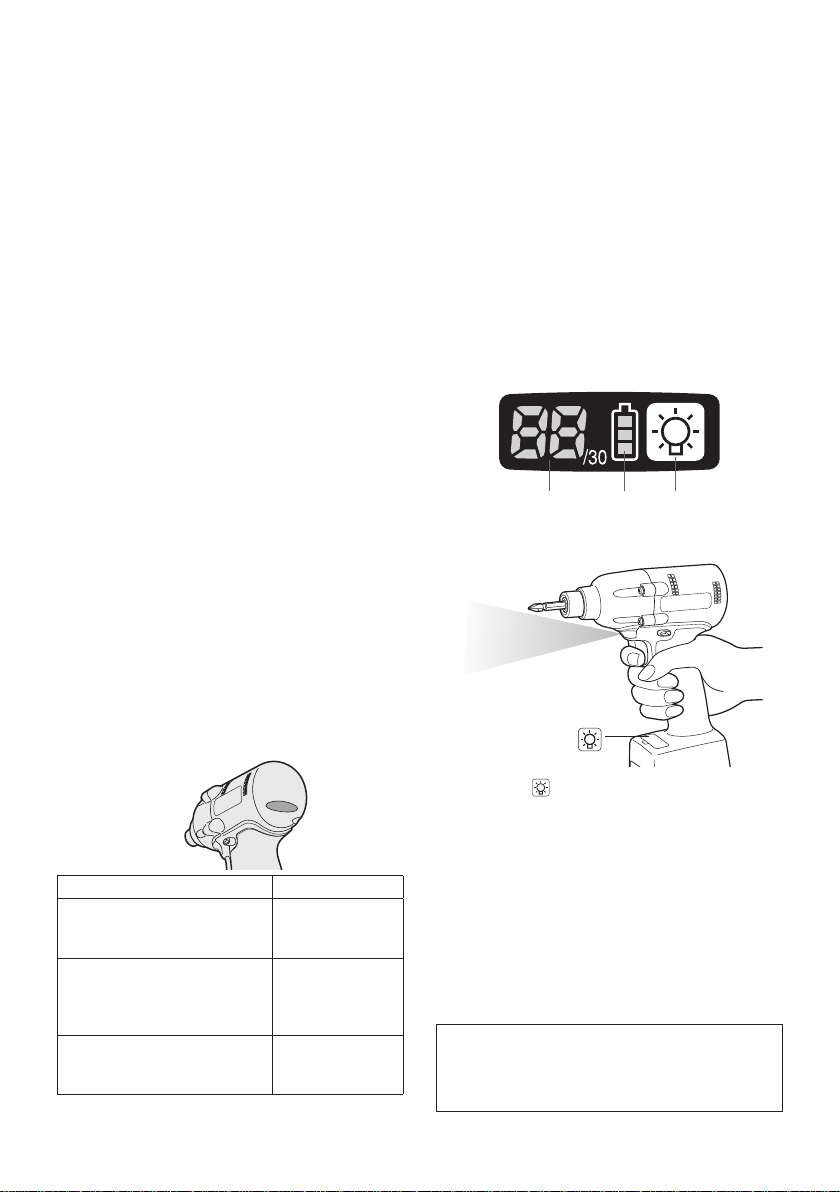

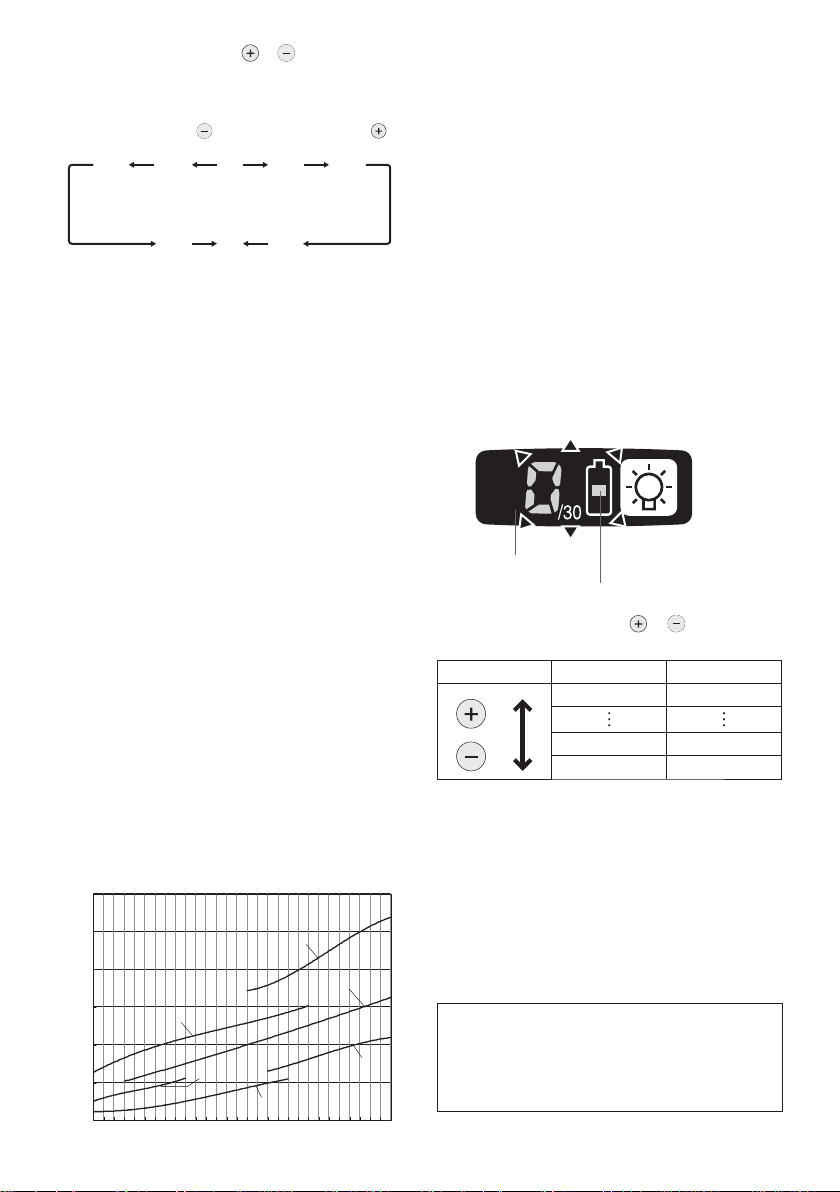

Wireless remote control range

The remote control should be operated within

approximately 50 cm and approximately 60°

vertically and horizontally of the perpendicular

relative to the infrared receiver on the tool.

Under the following circumstances, you may

•

not be able to operate the tool, even within

this range.

If there is an object between the remote

•

control’s transmitter and the tool’s receiver.

•

Use outdoors or in other environments

where the remote control receiver is

exposed to a strong light source, or when

the remote control transmitter or receiver is dirty may cause the tool to fail to

respond, even when the remote control is

used within the operating range.

[Main Body]

Switch and Forward/Reverse

Lever Operation

2. Insert the battery and

push the holder

back in.

NOTE:

•

If the tool does not respond to the wire-

less remote control even when the remote

control is operated close to the tool, the

b

a fresh battery.

•

The included battery is provided for sample

use and may not last as long as commercially available batteries.

attery (CR2025) is dead. Replace it with

-

7 -

CAUTION:

To prevent damage, do not operate

Forward/Reverse lever until the bit comes

to a complete stop.

Page 8

Forward Rotation Switch

Operation

1. Push the lever for forward rotation.

2. Depress the trigger switch slightly to start

the tool slowly.

The speed increases with the amount of

3.

depression of the trigger for efficient tightening of screws. The brake operates and

the bit stops immediately when the trigger

is released.

4.

After use, set the lever to its center posi-

tion (switch lock).

Reverse Rotation Switch

Operation

1.

Push the lever for reverse rotation. Check

direction of rotation before use.

Depress the trigger switch slightly to start the

2

.

tool slowly.

3. After use, set the lever to its center position (switch lock).

CAUTION:

•

To eliminate excessive temperature

increase of the tool surface, do not

operate the tool continuously using two

or more battery packs. Tool needs cool

off time before switching to another

pack.

Tightening confirmation lamp

• The tightening confirmation lamp can be

used to check whether the torque control

function was activated.

the

CAUTION:

When the tool stops automatically after

•

the switch is released during impactmode tightening and then re-engaged

within 1 second, the red lamp will light up

to indicate the risk of excessive torque

application as a result of re-tightening.

NOTE

•

The tightening confirmation lamp will

not turn on under the following conditions:

•

When the torque clutch is set to “F”

• During reverse rotation operation

• The lamp turns off when the tool is in

operation.

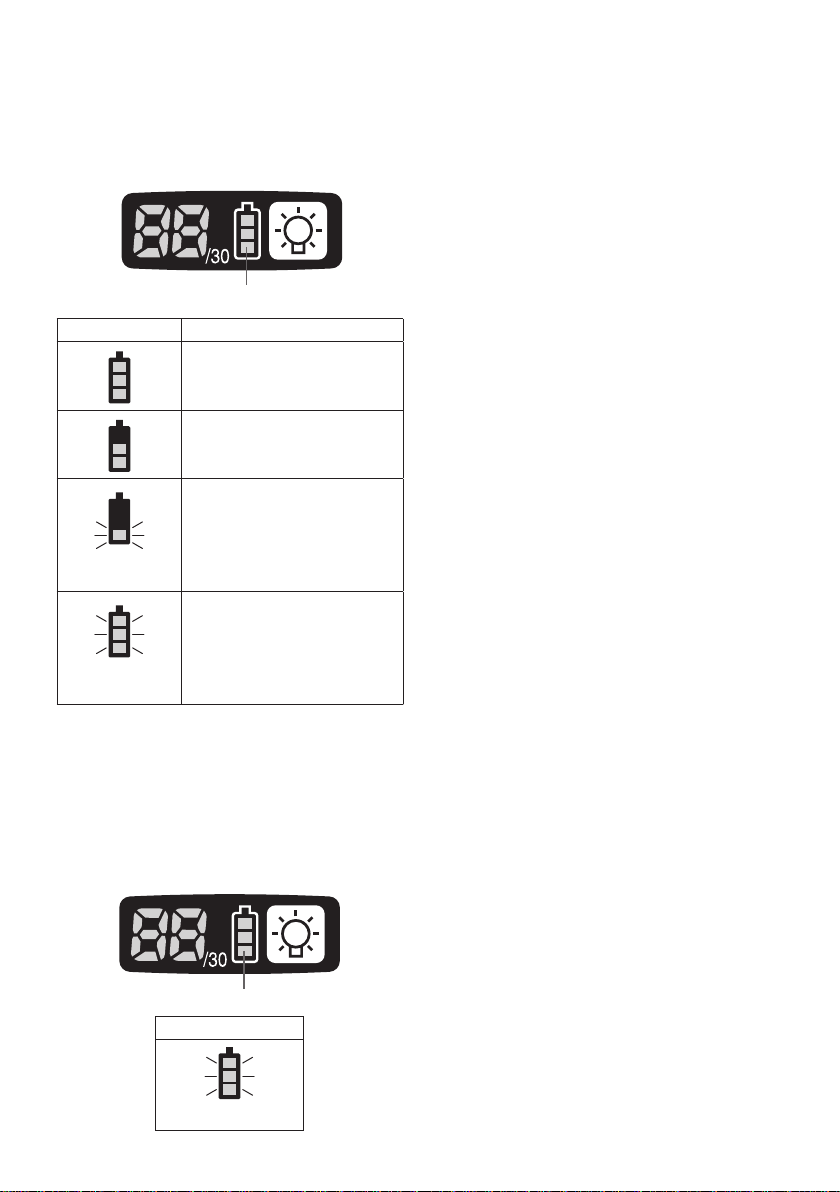

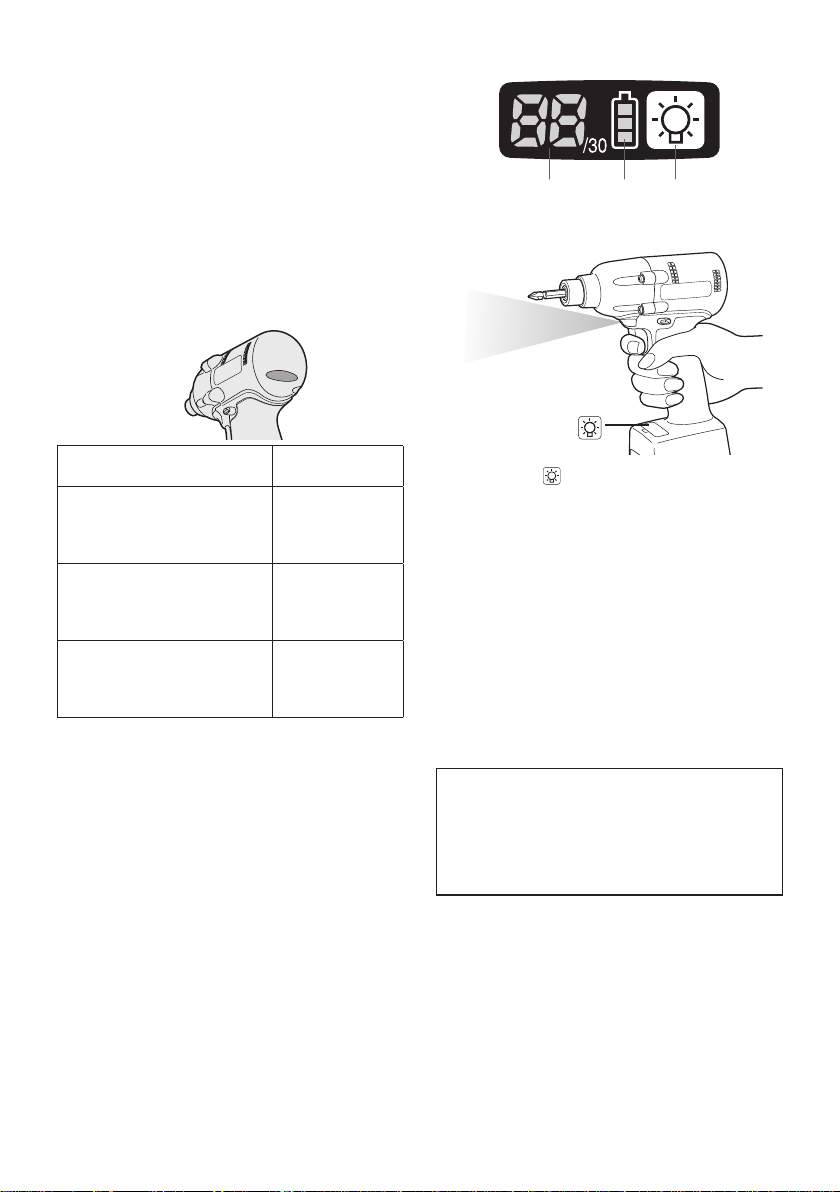

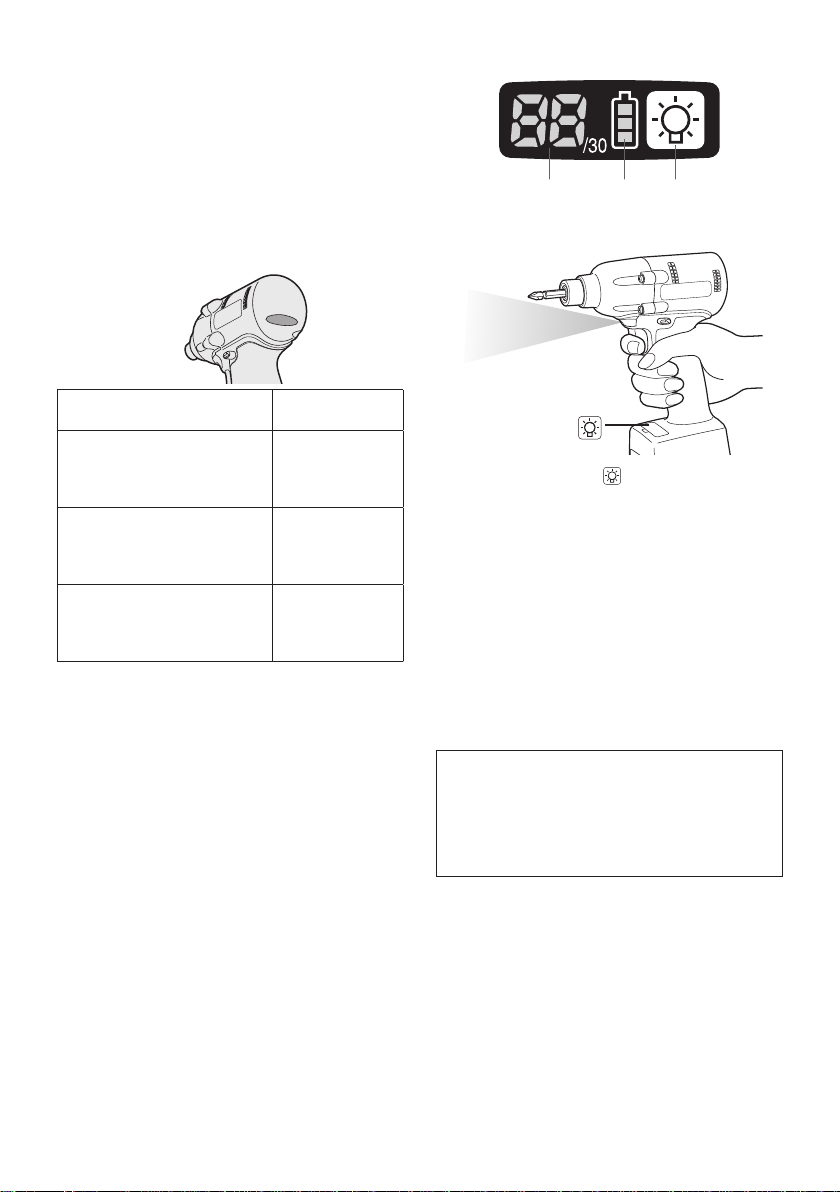

Control Panel

(1) (2) (3)

(1) LED light

Tool status Lamp display

Tightening complete

(with torque control

function operation)

Tightening not complete

•

• Tightening complete

with retightening within 1

second

The automatic stop

function has been

activated.

Green

(For approx.

seconds)

Red

(For approx.

seconds)

Red

(For approx. 5

minutes)

Pressing the button toggles the LED light on

and off.

The light illuminates with very low current, and

it does not adversely affect the performance

tool during use or its battery capacity.

the

CAUTION:

The built-in LED light is designed to illu-

2

2

-

8 -

•

minate the small work area temporarily.

•

Do not use it as a substitute for a regular

flashlight, since it does not have

enough brightness

This tool has the built-in LED light.

Caution: DO NOT STARE INTO BEAM.

Use of controls or adjustments or performance

of procedures other than those specied herein

may result in hazardous radiation exposure.

.

of

Page 9

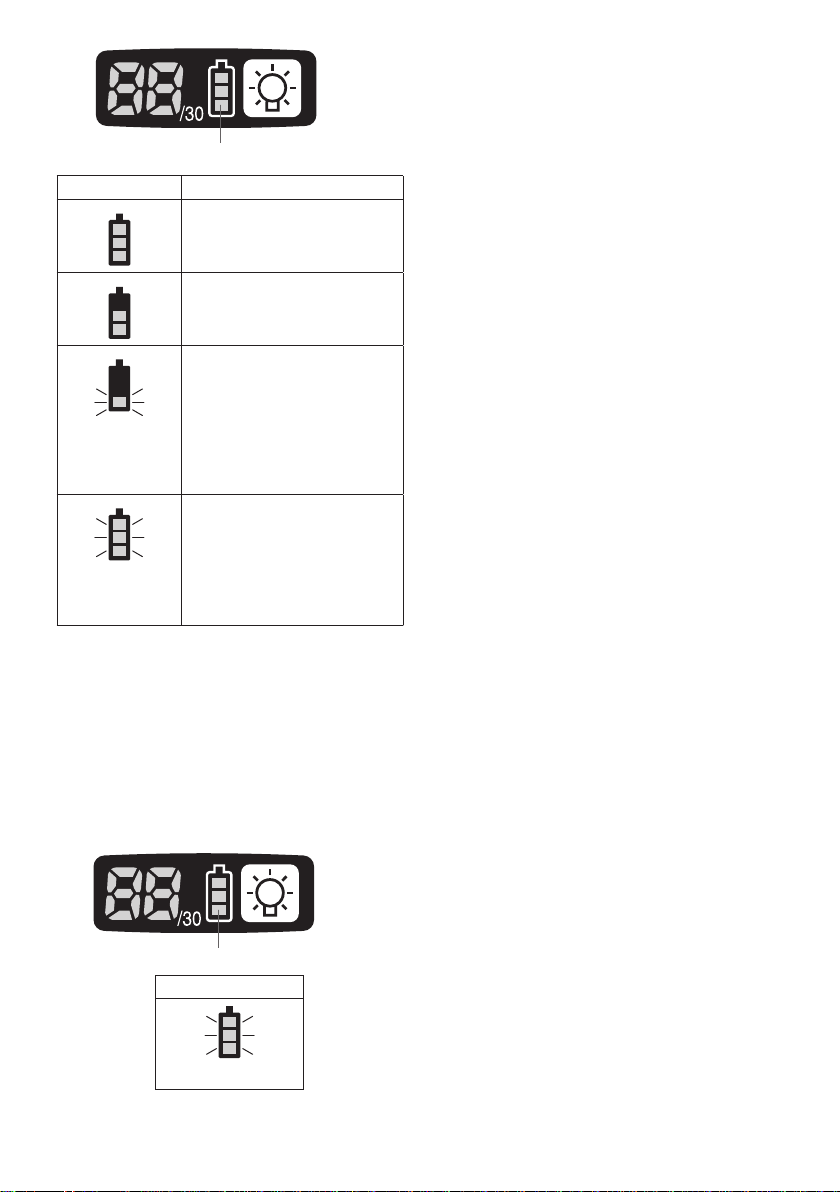

(2) The battery indication lamp

• Use the battery indication lamp to check

how much power is left in the battery.

Battery life varies slightly with ambient tem-

•

perature and battery characteristics. The

lamp is designed to provide a rough indication of remaining battery life.

Battery indication lamp

Indicator Battery status

Fully charged

Approx. 40% or less

remaining

Flashing

Approx. 20% or less

remaining (indicates need

to recharge battery)

Flashing

Flashing

The battery pack will need

to be charged soon.

No charge

The battery pack needs to

be charged.

(The tool’s automatic

power-off function will

activate at this stage.)

Automatic power-off function

• The automatic power-off function is designed

to prevent a loss of tightening torque due to

reduced battery voltage. Once it has been

activated, the tool will not operate until the

battery pack has been charged (or replaced

with a fresh unit), even if the trigger is

depressed.

Battery indication lamp

Indicator

Flashing

NOTE:

• All 3 bars on the battery indication lamp

will flash when the automatic power-off

function is activated.

When the battery indication lamp begins

•

flashing, the battery pack should be

charged (or replaced with a fresh unit)

immediately.

Be sure to fully charge the battery pack

•

in question after activation of the automatic power-off function. Failure to do

so may prevent the automatic power-off

function from being properly deactivated.

(3) The torque control function

• The torque control function calculates the

load from the motor’s rotational angle during

the hammer impact and determines that the

bolt has been properly seated when a preset load value is exceeded. Driving is then

automatically stopped after a preset number

of impacts have been delivered to the bolt.

CAUTION:

Always check the tool’s tightening

•

torque before use. Improper tool operation may result in excessive or inadequate tightening.

CAUTION:

•

Always operate the tool with the switch

fully engaged. The torque control function will not operate when the switch is

not sufficiently engaged, preventing the

tool from stopping automatically.

In work where a heavy load comes to

•

bear during tightening, the load may be

interpreted as the seating of the bolt,

preventing the bolt from being completely tightened.

Repeated tightening of the same bolt

•

may break the bolt or deform the material into which the bolt is being driven as

a result of excessive tightening.

The tightening torque value and preci-

•

sion vary with factors such as the material into which the bolt is being driven

and the condition of the socket being

used. Adjust the torque as necessary

for the work being performed. Bolt tightening torque varies due to the factors

described below.

1) Bolt

Bolt diameter: Tightening torque gener-

•

ally increases with bolt diameter.

•

Torque coefficient (indicated by the bolt

manufacturer), grade, length, etc.

-

9 -

Page 10

2) Other

3…28

1F30 229

• Bit and socket condition: Material,

amount of play, etc.

•

Use of a universal joint or socket

adapter

•

User: Manner in which the tool is

applied to the bolt, strength with which

the tool is held, manner in which the

tool’s switch is engaged

Condition of object being tightened: Ma-

•

terial, seating surface finish

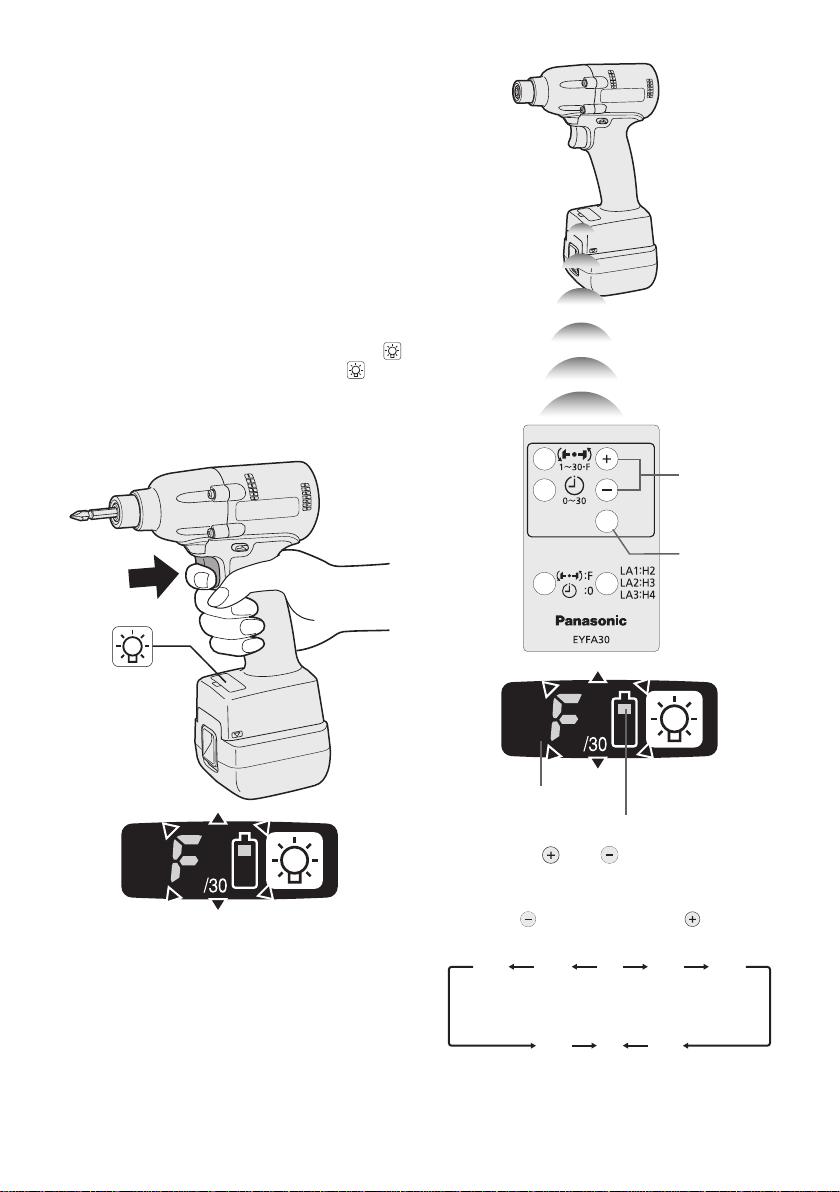

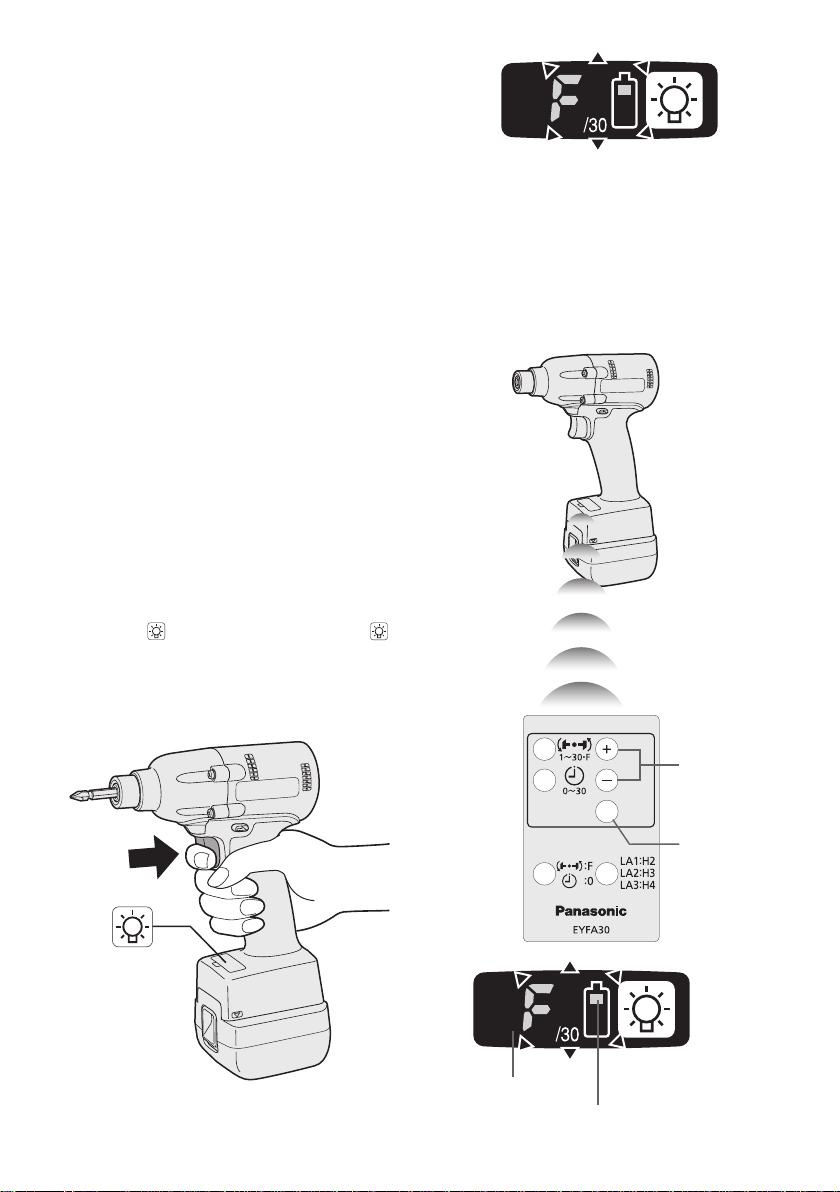

Setting the tool to configuration mode

1.

Turn off the control panel.

• If the control panel is on, remove and

then reinsert the battery pack.

. Engage the switch while pushing the

2

button and then release both the

ton and the switch.

After all the LED lamps have turned off,

•

the control panel will flash and change

to configuration mode.

Configuring the torque clutch setting

but-

(1)

(2)

NOTE:

• Tools ship from the factory set to “F”

mode (torque control function off).

•

The control panel will turn off if the tool

is not operated for a period of 5 minutes.

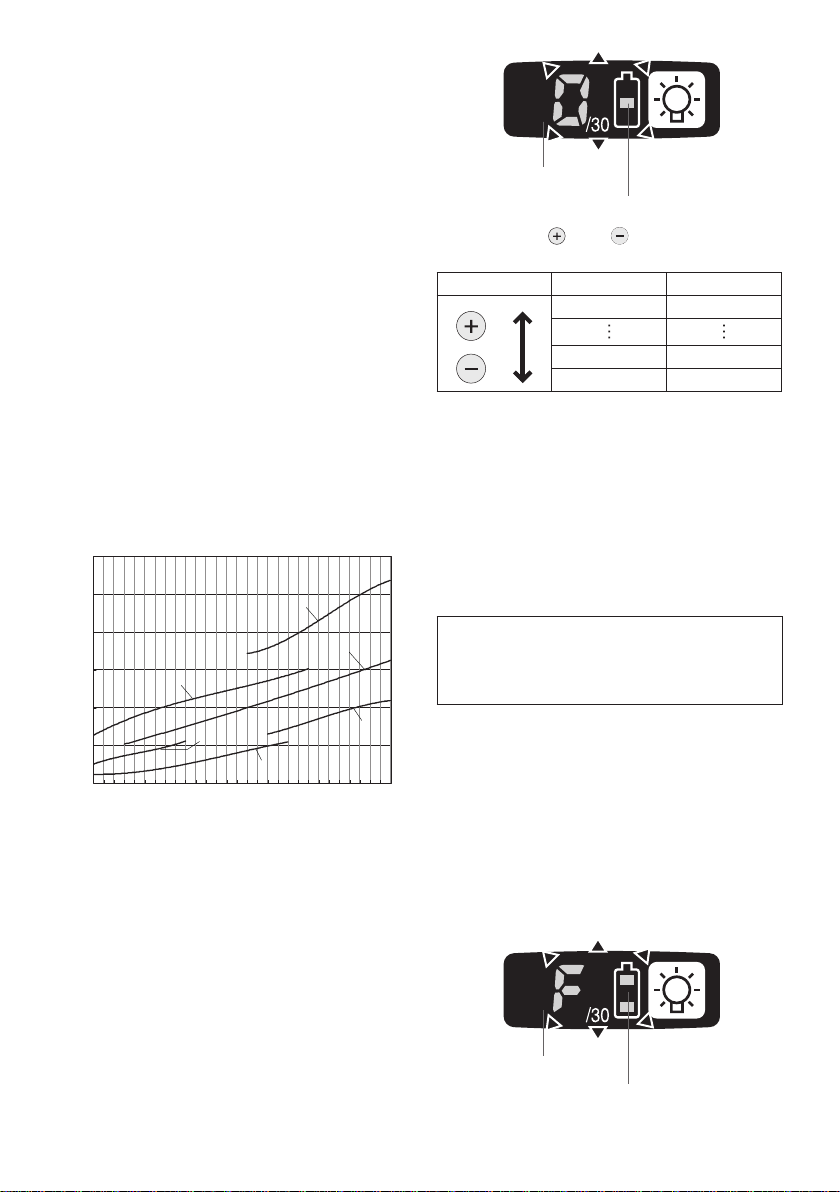

Display

Battery indication lamp

1. Press the and buttons to select the

clutch setting that is appropriate for the

work being performed.

-

10 -

As the button

is pressed

• “F” indicates that the torque control function is off.

As the button

is pressed

Page 11

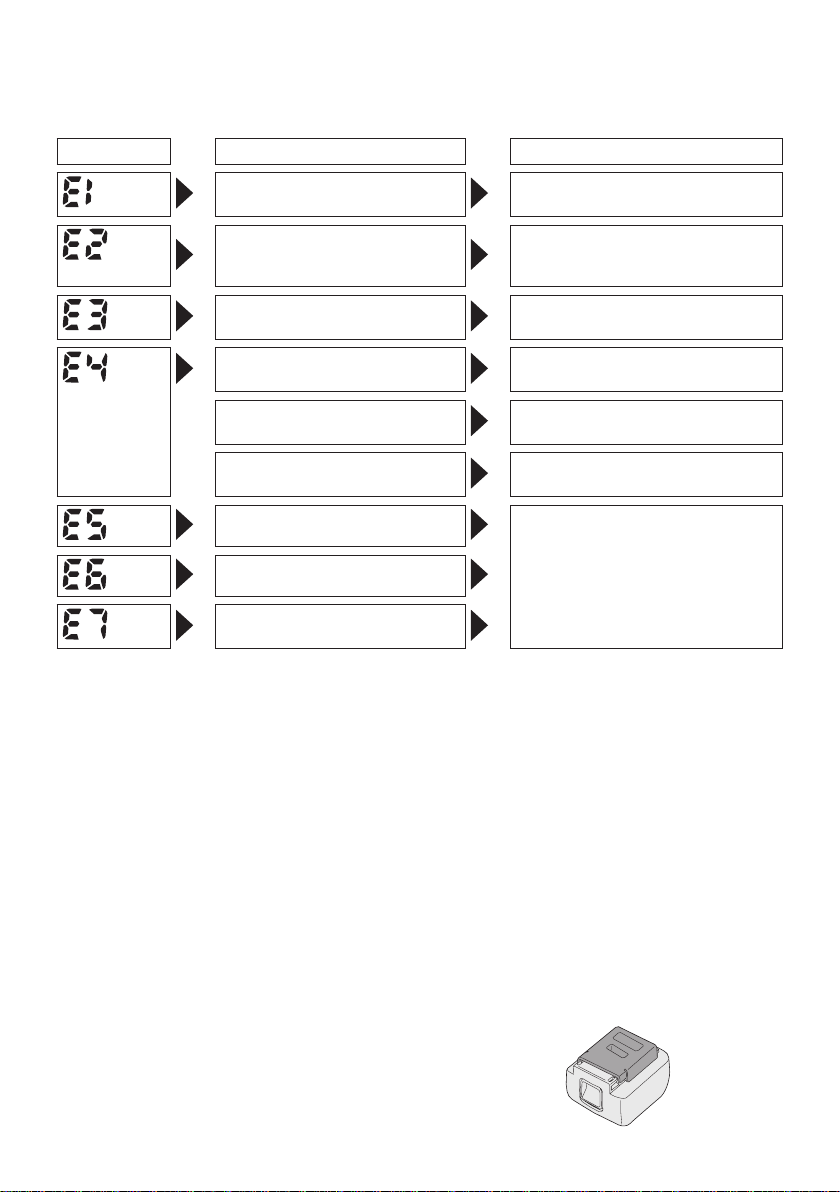

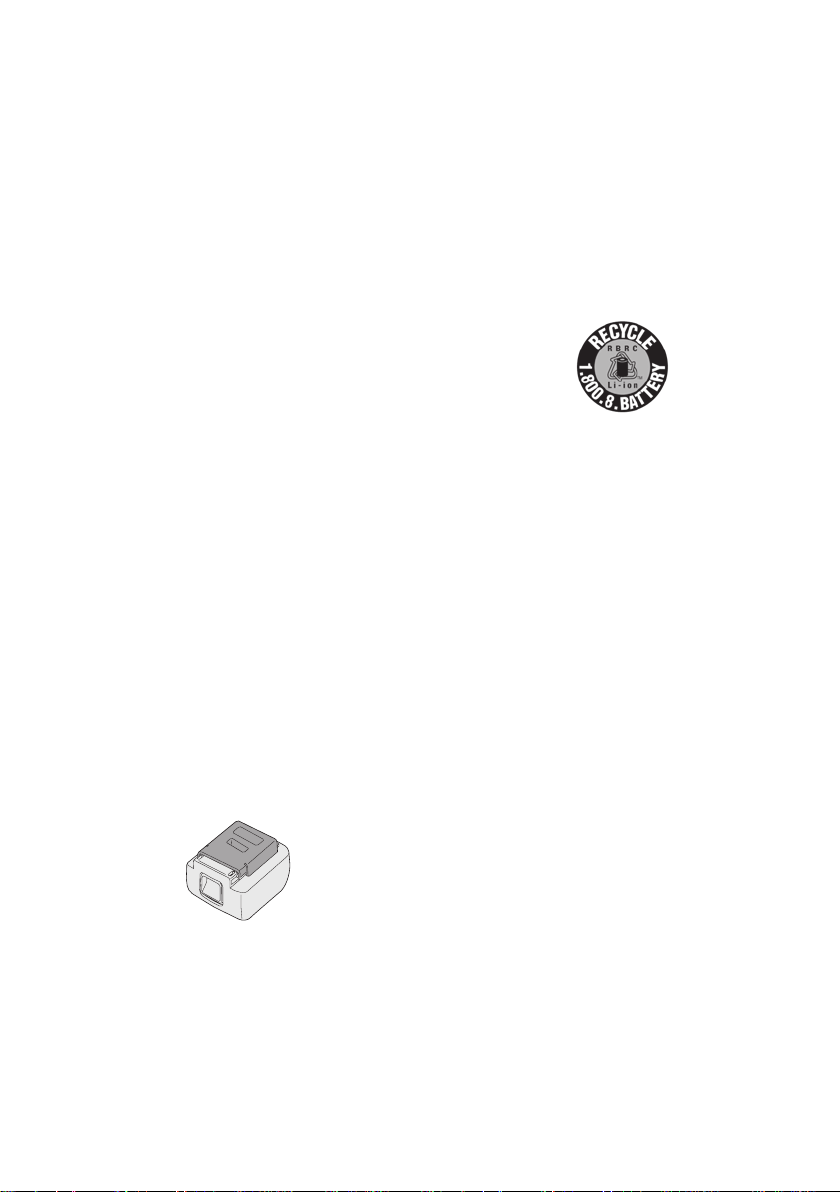

• You can select from 30 torque clutch

0

10

20

30

40

50

60

EYFLA1 (M6)

EYFLA2 (M6)

EYFLA1 (M8)

EYFLA2 (M8)

EYFLA3 (M8)

EYFLA3 (M10)

N • m

1 2 3 4 5 6 7 8 9 101112131415 161718 192021222324252627282930

settings (1 to 30).

Use figures from the Tightening Torque

•

Chart to guide your selection of torque

clutch setting. (See the following tightening torque chart)

. Press the OK button to accept the select-

2

ed torque clutch setting.

•

The control panel will stop flashing and

light up.

CAUTION:

•

You must press the OK button in order

for the selected setting to take effect.

•

Be sure to verify the new value after

changing the setting. (See page 11.)

Tightening Torque Chart (for Reference

Use)

The values illustrated on this chart were measured under the conditions described below

and are provided for reference purposes.

Actual tightening torque varies with ambient

conditions (the particular bolt being tightened,

hardware being used, method of holding the

bolt in place, etc.).

Measurement conditions

• Temperature: Room temperature (20°C/68°F)

Using the Interval Set

•

The interval set operates to prevent the tool

from operating after it automatically stops as

a result of the torque control function, even if

the switch is engaged.

1.

Set the tool to configuration mode.

(See page 10.)

2. Press the interval set button.

• The control panel will begin flashing.

Display: The number 0 ashes on and off.

Battery indication lamp: The middle bar

of the battery ashes on and off.

Display

Battery indication lamp

3. Press the and buttons to set the

desired time.

Buttons Display Seconds

30 3

1 0.1

0 Off

4.

Press the OK button to accept the select-

ed setting.

The control panel will stop flashing and

•

light up, and the torque clutch setting

will be displayed.

CAUTION:

•

Be sure to verify the new value after

changing the setting.

Initializing All Settings

Factory settings

• Torque clutch setting: “F” (torque control function off)

•

Interval setting: 0 (off)

• This section explains how to revert all tool

settings to their default values at the time of

shipment from the factory.

•

The error display will be turned off.

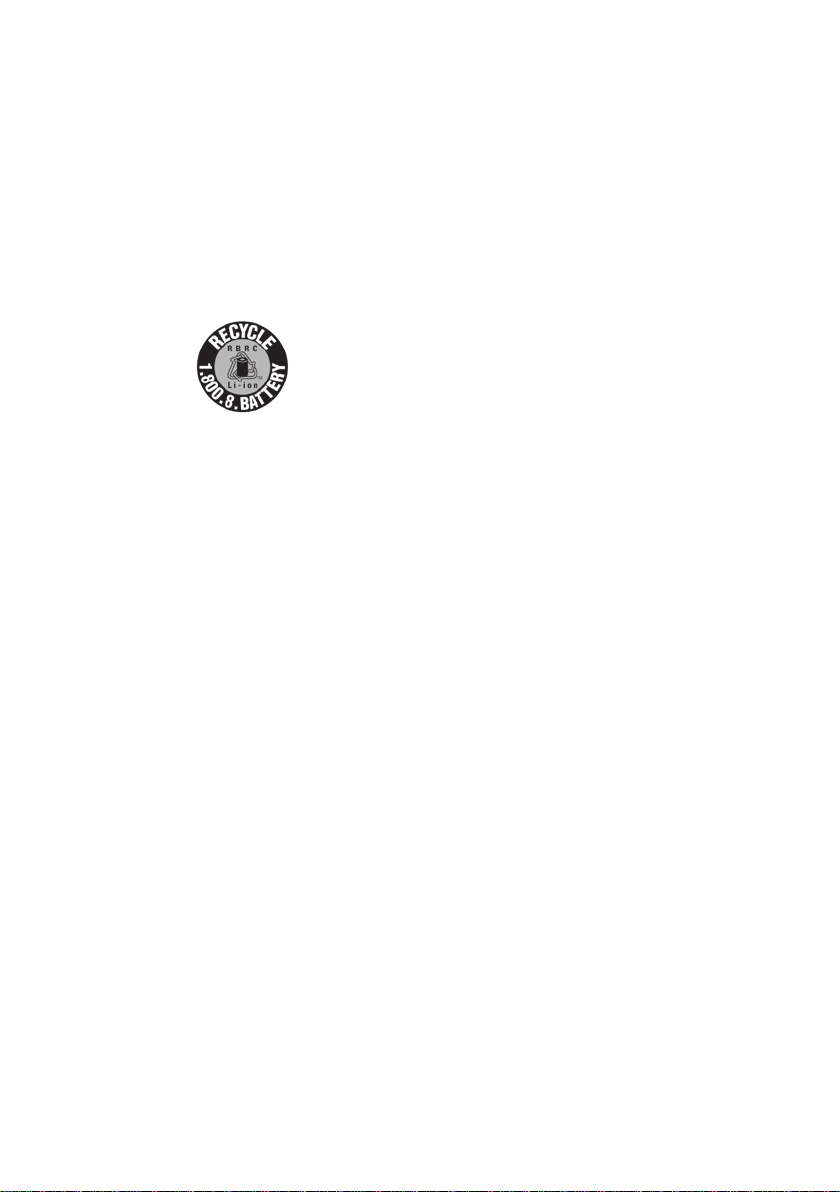

1. Set the tool to configuration mode.

(See page 10.)

2. Press the format button.

• The control panel will begin flashing.

Display: The letter “F” ashes on and off.

Battery indication lamp: The upper and

lower bars of the battery ash on and off.

Display

Battery indication lamp

11 -

-

Page 12

3. Press the OK button to accept the selected setting.

The control panel will stop flashing and

•

light up.

Checking Tool Settings

•

This section describes how to have the

tool display current settings for approximately 3 seconds when the tool is

stopped.

You cannot check tool settings when the

•

control panel is turned off. First, engage

the switch briefly to reactivate the display.

Checking the torque clutch setting

Press the torque set button.

1.

• Control panel display

Display: The torque set lights up.

Battery indication lamp: The upper bar of

the battery ashes on and off.

Checking the interval

Press the interval set button.

1.

• Control panel display

Display: The interval set lights up.

Battery indication lamp: The middle bar

of the battery ashes on and off.

Checking tool circuits

Press the torque set button.

1.

• Control panel display

Display: The torque set display lights up.

Battery indication lamp: The middle and

lower bars of the battery ash on and off.

Display Tool circuit

H2 EYFLA1

H3 EYFLA

H4 EYFLA3

NOTE:

•

If you engage the switch while a setting

is being displayed, the control panel will

revert to the torque clutch setting display.

CAUTION:

The torque set display is not intended

•

to be used to identify the type of drive

component parts (hammer, etc.) used

in a particular tool.

2

-

12 -

Page 13

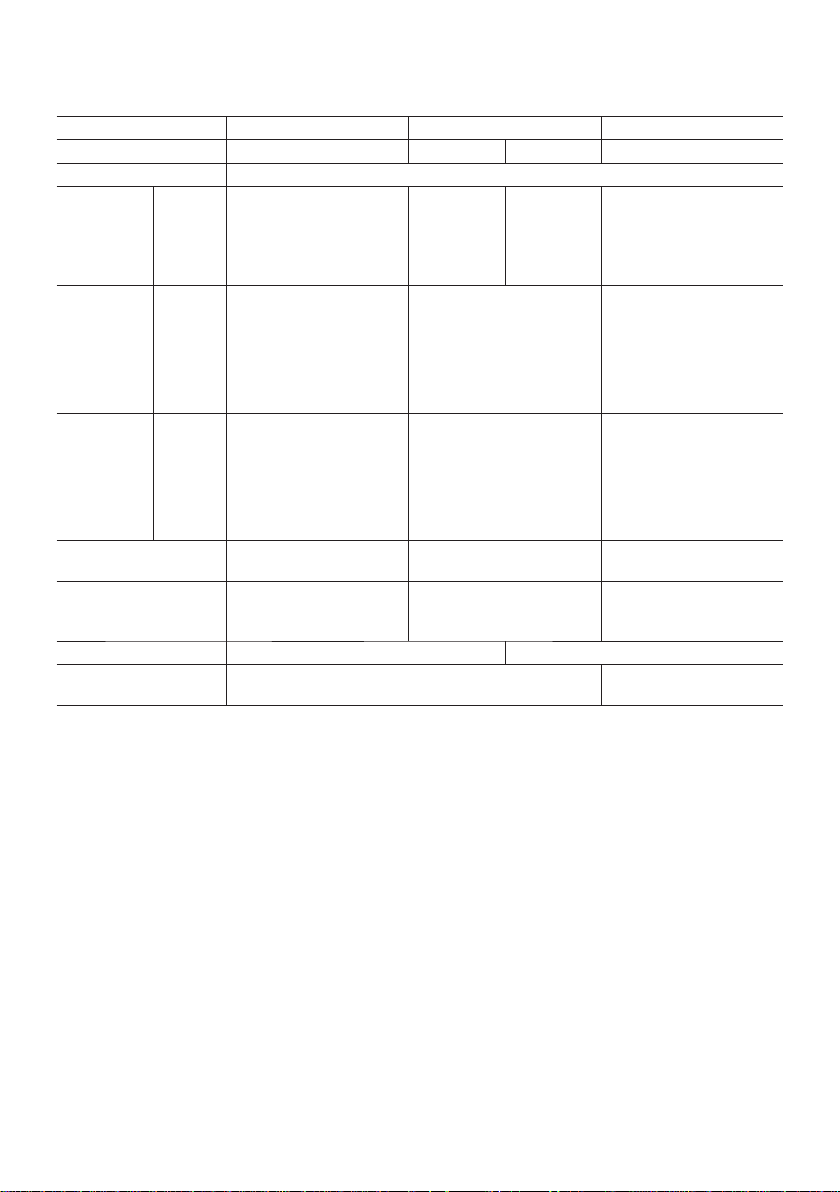

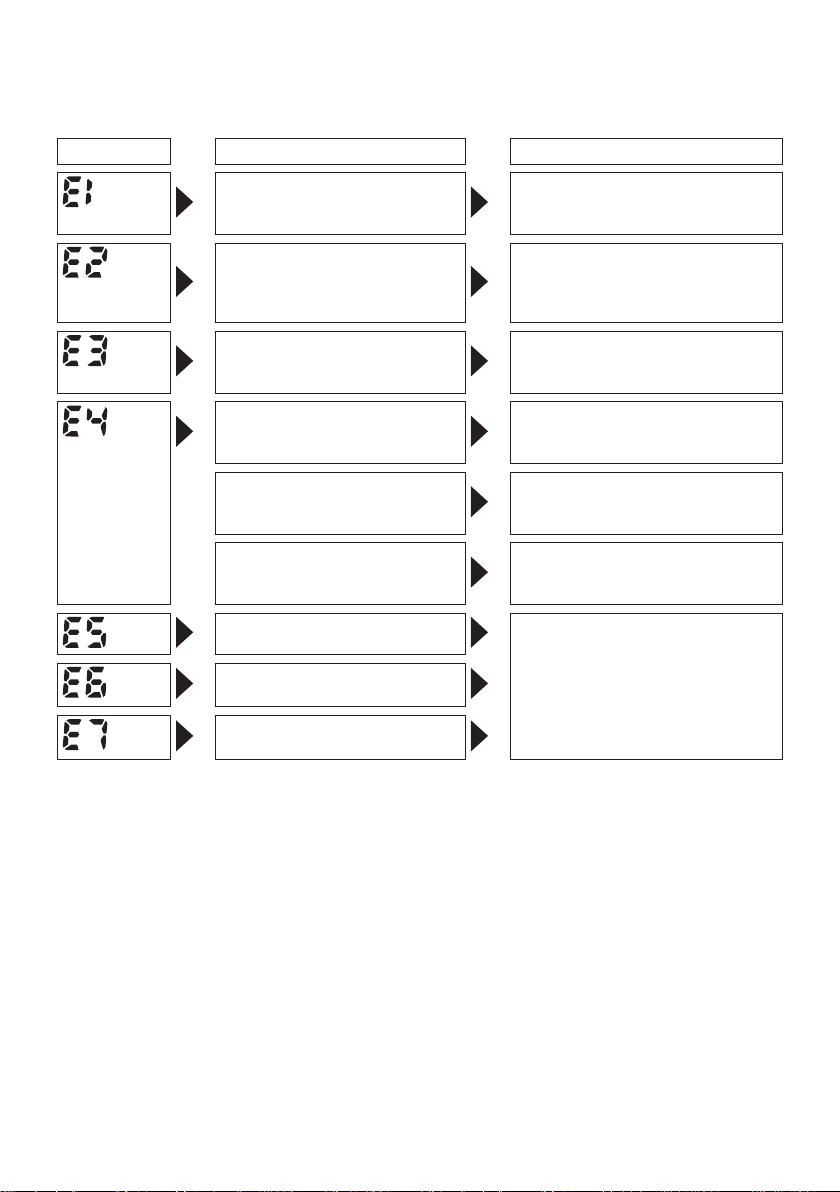

Error Display

In the event of a tool or battery pack malfunction, the control panel will display an error message.

Please check the tool or battery pack as described in the following chart before having them

serviced.

Display Likely cause Corrective action

Setting error Re-initialize the tool using the

The battery pack is too hot. Stop work and allow the battery

The tool is too hot to operate. Stop work and allow the tool to

The contacts that connect the

battery pack and tool are dirty.

The battery pack has not been

properly inserted into the tool.

The pins on either the tool or

battery pack have worn down.

Motor failure, etc. Stop using the tool immediately.

Sensor malfunction, failure, etc.

Tool circuit malfunction, failure,

etc.

[Battery Pack]

For Appropriate Use of Bat-

tery Pack

Li-ion Battery Pack (EYFB30)

• For optimum battery life, store the Li-ion battery pack following use without charging it.

When charging the battery pack, confirm

•

that the terminals on the battery charger

are free of foreign substances such as dust

and water etc. Clean the terminals before

charging the battery pack if any foreign substances are found on the terminals.

T

he life of the battery pack terminals may be

affected by foreign substances such as dust

and water etc. during operation.

remote control. (See page 12.)

pack to cool before resuming use

of the tool.

cool before resuming use.

Remove any dirt.

Insert the battery pack rmly into

the tool.

Replace the battery pack.

• When battery pack is not in use, keep it

away from other metal objects like: paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another.

Shorting

cause sparks, burns or a fire.

When operating the battery pack, make sure

•

the work place is well ventilated.

•

When the battery pack is removed from the

main body of the tool, replace the battery

pack cover immediately in order to prevent

dust or dirt from contaminating the battery

terminals and causing a short circuit.

the battery terminals together may

-

13 -

Page 14

-

14 -

Battery Pack Life

The rechargeable batteries have a limited life.

If the operation time becomes extremely short

after recharging, replace the battery pack with

a new one.

Battery Recycling

ATTENTION:

FOR Li-ion Battery Pack, EYFB30

A Li-ion battery that is recyclable powers

the product you have purchased.

Please call 1-800-8-BATTERY for information on how to recycle this battery.

[Battery Charger]

Charging

Read the operating manual for Panasonic battery charger for the battery pack before charging.

Before charging the battery

When charging EYFB30:

Charge the battery at a temperature of 5°C

(41°F) to 40°C (104°F).

The battery pack cannot be charged at a temperature of less than 5°C (41°F). If the temperature of the battery pack is less than 5°C

(41°F), rst remove the battery pack from

the charger and allow it to sit for an hour in a

location where the temperature is 5°C (41°F) or

warmer. Then charge the battery pack again.

VI.

MAINTENANCE

Use only a dry, soft cloth for wiping the unit.

Do not use a damp cloth, thinner, benzine, or

other volatile solvents for cleaning.

VII

. ACCESSORIES

Charger

• EY0L80

Battery pack

• EYFB30

Remote control

• EYFA30

Protector for tool

• EYFA01-A (Blue)

• EYFA01-Y (Yellow)

• EYFA01-H (Gray)

Protector for battery

• EYFA02-H

Page 15

VIII

. SPECIFICATIONS

MAIN UNIT

Model EYFLA1 EYFLA2 EYFLA3

A A Q J

Moter 10.8 V DC

Chuck size Single-

No load

speed

Impact per

minute

Maximum torque 40 N·m

Torque control function

operating range

Overall length 158 mm (6-7/3

Weight (with battery

pack: EYFB30)

ended

Doubleended

Stage 1

Stage 1

9 – 9.5 mm

23/64" – 3/8")

(

1

2 mm (15/32") 12 mm

2

3 – 5

6

7

8

9 – 30·F

2

3 – 5

6

7

8

9 – 30·F

(408 kgf-cm, 354 in-lbs)

Approx. 3 –

(31 – 224 kgf-cm,

27 – 195 in-lbs)

0 – 950

0 – 1000

0 – 1050

0 – 1300

0 – 1450

0 – 1550

0 –

2300

0 – 1900

0 – 1950

0 –

2100

0 – 2500

0 – 2800

0 – 3000

0 – 4000

22 N·m

1.3 kg (

9 – 9.5 mm

(23/64"

– 3/8")

(15/32")

1

2

3

4 – 30·F

1

2

3

4 – 30·F

90 N·m

(918 kgf-cm, 796 in-lbs)

Approx. 6 – 30 N·m

(61 – 306 kgf-cm,

53 – 266 in-lbs)

2") 164 mm (6-7/16")

2.8 lbs) 1.35 kg (2.9 lbs)

□

9.5 mm

(3/8")

0 – 1300

0 – 1450

0 – 1550

0 – 2300

0 – 2500

0 – 2800

0 – 3000

0 – 3600

□

12.7 mm (1/2")

0 – 2300

0 – 3000

1

20 N·m (1224 kgf-cm,

1062 in-lbs)

Approx. 16 – 53 N·m

(163 – 540 kgf-cm,

142 – 469 in-lbs)

-

15 -

Page 16

BATTERY PACK (not included with shipment)

Model EYFB30

Storage battery Li-ion battery

Battery voltage 10.8 V DC (3.6 V/6 cells)

Capacity 3 Ah

BATTERY CHARGER (not included with shipment)

Model EY0L80

Rating See the rating plate on the bottom of the charger.

Weight 0.95 kg (

2.1 lbs)

[Li-ion battery pack]

10.8 V

Charging time

3 Ah

EYFB30

Usable: 40 min.

Full: 65 min.

Remote control (not included with shipment)

Model EYFA30

Battery voltage 3 V DC

Dimensions 54 mm (

Weight (with battery) Approximately

2-1/8") × 86 mm (3-3/8") × 10 mm (13/32”)

29 g (0.6 lbs)

-

16 -

Page 17

I.

CONSIGNES DE SECURITE GENERALES

AVERTISSEMENT! Veuillez lire tou-

tes les instructions.

Si les instructions détaillées ci-dessous ne sont

pas observées, cela peut entraîner une électrocution, un incendie et/ou des blessures graves.

Le terme “outil mécanique” utilisé dans tous les

avertissements ci-dessous se réfère aux outils

mécaniques opérés par cordons d'alimentation

et par batterie (sans l).

CONSERVEZ CES INSTRUCTIONS

Sécurité de la zone de travail

1) Gardez la zone de travail propre et

bien aérée.

Les endroits encombrés et sombres invitent les accidents.

) Ne faites pas fonctionner les outils

2

mécaniques dans des atmosphères

explosives, comme en présence de

liquides inammables, de gaz ou de

poussière.

Les outils mécaniques génèrent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

Gardez les enfants et les spectateurs

3)

éloignés lors du fonctionnement d’un

outil mécanique.

Les distractions peuvent en faire perdre le

contrôle.

Sécurité électrique

1) La fiche des outils mécaniques doit

correspondre aux prises secteur. Ne

modifiez la fiche sous aucun prétexte.

N’utilisez pas de fiche adaptatrice

avec les outils mécaniques mis à la

terre.

Des fiches non modifiées et des prises

secteur correspondant réduisent les

risques d’électrocution.

2

) Evitez tout contact physique avec les

surfaces mises à la terre telles que

t

uyaux, radiateurs, micro-ondes et

réfrigérateurs.

Il y a un risque d’électrocution supplémentaire si votre corps est mis à la terre.

3) N’exposez pas les outils mécaniques à

la pluie ou à des conditions humides.

D

e l’eau pénétrant dans un outil mécani-

que augmente le risque d’électrocution.

-

4)

Ne malmenez pas le cordon. N’utilisez

jamais le cordon pour transporter,

pour tirer ou pour débrancher l’outil

mécanique. Gardez le cordon éloigné

de la chaleur, de l’huile, d’objets aux

bords coupants ou de pièces en

mouvement.

Les cordons endommagés on emmêlés

augmentent le risque d'électrocution.

5)

Lors du fonctionnement des outils méca

niques à l

adaptée à l

L’utilisation d’un cordon adapté à l’utilisation à l’extérieur réduit les risques d’é

trocution.

’

extérieur, utilisez une rallonge

’

utilisation à l

’

extérieur.

Sécurité personnelle

1) Restez alerte, regardez ce que vous

faites et faites preuve de bon sens

lorsque vous utilisez un outil méca

nique. N’utilisez pas un outil méca

nique alors que vous êtes fatigué ou

sous les effets de drogue, d’alcool ou

de médicaments.

Un moment d’inattention pendant que

vous faites fonctionner l’outil mécanique

peut entraîner des blessures graves.

2

) Utilisez des équipements de sécurité.

Portez toujours des protection pour

vos yeux.

Des équipements de sécurité comme

masque antipoussière, chaussures

de sécurité non glissantes, casque de

protection ou protections d’oreilles,

utilisés dans des conditions appropriées

réduisent les blessures corporelles.

3)

Evitez tout démarrage accidentel.

A

ssurez-vous que l’interrupteur est

en position d'arrêt avant de brancher

l’outil.

Le transport d’outils mécaniques avec le

doigt sur l’interrupteur ou le branchement

d’outils mécaniques dont l’interrupteur

est sur la position de marche invite les

accidents.

4)

Retirez toute clé d’ajustement ou

clé de serrage avant de mettre l’outil

mécanique en marche.

Une clé de serrage ou une clé d’ajuste

ment laissée attachée à une pièce

tournante de l’outil mécanique peut

entraîner des blessures corporelles.

5)

Ne vous mettez pas en déséquilibre.

Gardez une bonne prise au sol et votre

équilibre à tout moment.

Ceci permet un meilleur contrôle de l’outil

m

écanique dans des situations inatten-

dues.

17 -

lec-

-

Page 18

-

18 -

6) Habillez-vous correctement. Ne portez

pas de vêtements lâches ou de bijoux.

Gardez vos cheveux, vêtements et

gants éloignés des pièces en mouve

ment.

Des vêtements lâches, des bijoux ou

des cheveux longs peuvent se faire

prendre dans les pièces en mouvement.

7)

Si des dispositifs pour la connexion

d’app

areils d’extraction et de ramas-

sage de la poussière sont fournis,

a

ssurez-vous qu’ils sont connectés et

correctement utilisés.

L’utilisation de ces dispositifs peut réduire

les risques concernés.

Utilisation et soins de l’outil méca

nique

1)

Ne forcez pas l’outil mécanique. Utilisez

l’outil mécanique correct pour votre

application.

L’outil mécanique correct exécute mieux

le travail dans de meilleurs conditions

de sécurité s’il est utilisé à l’allure pour

laquelle il a été conçu.

2

) N’utilisez pas l’outil mécanique si l’inter-

rupteur ne le met pas en marche ou ne

l’arrête pas.

Tout outil mécanique qui ne peut pas

être contrôlé par son interrupteur est

dangereux et doit être réparé.

3)

Débranchez la fiche de la source d’ali

mentation et/ou du bloc de batterie

avant d’effectuer tout ajustement, de

changer d’accessoire ou de ranger

l’outil mécanique.

D

e telles mesures de sécurité préventives

réduisent les risques de faire démarrer

l’outil mécanique accidentellement.

4)

Rangez les outils mécaniques inuti

lisés hors de la portée des enfants

et ne laissez personne qui n’est pas

familiarisé avec l’outil mécanique ou

ses instructions faire fonctionner l’outil

mécanique.

Les outils mécaniques sont dangereux

dans les mains des utilisateurs manquant

d’entraînement.

5)

Entretenez bien les outils mécaniques.

Vérifiez l’alignement ou l’emboîtage

des pièces en mouvement, l’intégrité

des pièces et toute autre condition

pouvant affecter le fonctionnement de

l’outil mécanique. S’il est endommagé,

faites réparer l’outil mécanique avant

de l’utiliser.

De nombreux accidents sont provoqués

p

ar des outils mécaniques mal entre-

tenus.

6)

Maintenez les outils de coupe affûtés

et propres.

Les outils de coupe bien entretenus

avec des lames bien affûtées ont moins

de chances de gripper et sont plus

faciles à contrôler.

7)

Utilisez l’outil mécanique, les acces

s

oires, les mèches, etc., conformément

à ces instructions et de la façon pour

laquelle l’outil particulier a été conçu

e

n tenant compte des conditions de

travail et de la tâche à exécuter.

L’utilisation de l’outil mécanique à des

fins autres que celles pour lesquelles

il

a été conçu peut présenter une situa-

tion à risque.

Utilisation et soins de la batterie

de l’outil

1) Assurez-vous que l’interrupteur est

dans la position d’arrêt avant d’insérer

le bloc de batterie.

L’insertion du bloc de batterie dans un

outil mécanique dont l’interrupteur est

sur la position de marche peut provoquer

des accidents.

2

) N’effectuez la recharge qu’avec le

chargeur spécifié par le fabricant.

Un

chargeur convenant à un bloc de batterie peut entraîner un risque d’incendie

lorsqu’un autre bloc de batterie est

utilisé.

3)

N’u til ise z le s ou til s mé can iqu es

qu’avec les bloc de batterie spécialement conçus pour eux.

L’u

tilisation de tout autre bloc de batterie peut entraîner un risque de blessure et d’incendie.

Lorsqu’un bloc de batterie n’est pas

4)

utilisé, gardezle éloigné d’objets métal

liques comme agrafes, pièces de mon

naie, clés, clous, vis ou tout autre petit

objet métallique pouvant établir une

connexion entre les deux bornes.

Si les bornes de la batterie sont mises

en court-circuit, cela peut entraîner des

brûlures ou un incendie.

5)

Si elle est malmenée, du liquide peut

s’échapper de la batterie. Evitez tout

contact. Si un contact accidentel se

produit, rincez à l’eau. Si du liquide

entre en contact avec les yeux, con-

sultez un médecin.

Page 19

Le liquide éjecté de la batterie peut

entraîner des irritations ou des brûlures.

Réparation

1) Faites réparer votre outil mécanique

par du personnel de réparation quali

fié en n’utilisant que des pièces de

rechange identiques.

Ceci assure le maintien de la sécurité

de l’outil mécanique.

6)

Lorsque vous rangez ou transportez l’outil,

mettez le levier d’inversion marche avant

- marche arrière sur la position centrale

(verrouillage du commutateur).

Ne forcez pas l’outil en maintenant la

7)

gâchette de contrôle de vitesse enfoncée à

moitié (mode de contrôle de la vitesse) de

sorte que le moteur s’arrête.

Symbole Signication

II

.

UTILISATION PREVUE

Cet outil est une perceuse/clé de serrage à

impact sans l pouvant être utilisé pour serrer

des boulons, des écrous et des vis. De plus, il

offre une fonction de commande du couple de

serrage qui arrête automatiquement le fonctionnement de l’outil lorsqu’une charge préré-

glée est atteinte an de fournir un couple de

serrage uniforme.

Lire la brochure “Consignes de sécurité”

et ce qui suit avant l’utilisation.

III

.

CONSIGNES DE SECURITE

SUPPLEMENTAIRES

1

) Porter des protègesoreilles lors de

l’utilisation de l’outil pendant des périodes

prolongées.

2

) N’oubliez pas que cet appareil est toujours

prêt à fonctionner, parce qu’il ne doit pas

être branché dans une prise électrique.

3)

Tenez l’outil par les surfaces de prise

isolées lorsque vo us eff ec tu ez une

opération au cours de laquelle l’outil de

coupe risque d’entrer en contact avec

des câblages cachées ou avec son propre cordon d’alimentation.

L

e contact avec un fil sous tension fera passer le courant dans les pièces métalliques exposées et électrocutera l’opérateur.

4)

NE manœuvrez PAS le levier d’inversion

marche avant-marche arrière lorsque le

commutateur principal est sur la position

de marche. La batterie se déchargerait

rapidement et cela peut endommager

l’unité.

5)

Pendant le chargement, le chargeur peut

devenir légèrement chaud. Cela est normal.

N

E chargez PAS la batterie pendant une

longue période.

V

n

0

-1

… min

Ah

IV

. MONTAGE

Capacité électrique de la

fonctionnement avant l’utilisation.

Pour utilisation à ’intérieur

Tours ou mouvements

Lisez les instructions de

Volts

Courant continu

Vitesse sans charge

alternatifs par minute

batterie autonome

seulement.

Fixation ou retrait d’une

mèche

REMARQUE:

•

Lors de l’installation ou de l’enlèvement

d’une mèche, débranchez la batterie autonome de l’outil ou placez le commutateur

sur la position centrale (verrouillage du

commutateur).

1. Maintenez le collier du mandrin de connexion rapide et retirez-le de l’outil.

2

. Insérez la mèche dans le mandrin. Relâ-

chez le collier.

Le collier reviendra dans sa position

3.

d’origine lorsqu’il sera relâché.

Tirez sur la mèche pour vérifier qu’elle ne res-

4.

sort pas.

5. Pour retirer la mèche, tirez le collier vers

l’extérieur de la même manière.

-

19 -

Page 20

-

20 -

MISE EN GARDE:

• Si le collier ne revient pas dans sa position

d’origine ou si la mèche ressort lorsque

vous tirez dessus, cela signifie que la

mèche n’a pas été fixée correctement.

Assurez-vous que la mèche est bien fixée

avant toute utilisation.

EYFLA1A/EYFLA2A

12 mm

(15/32")

9 mm – 9,5 mm

(

23/64" – 3/8")

6,35 mm

(1/4")

Pour fixer la douille

• Retirez l’anneau en caoutchouc et la goupille

de la douille.

anneau en

caoutchouc

goupille

1 Fixez la douille sur l’outil.

nsérez la goupille. (En prenant soin d’aligner

2 I

les trous de la goupille sur la douille et

l’outil.)

ixez l’anneau en caoutchouc en le faisant

3 F

glisser en place par dessus la rainure.

rainure

REMARQUE:

Maintenez la température de l’outil audessus

du point de congélation (0ºC/32ºF)

lors de la fixation ou de l’enlèvement des

douilles de l’entraînement carré de l’outil.

N’utilisez pas de force excessive lors de la

fixation ou de l’enlèvement des douilles.

Fixation ou retrait de la batterie autonome

1. Pour raccorder la batterie autonome:

Alignez les marques d’alignement et fixez

la batterie autonome.

•

Faites glisser la batterie autonome jus-

qu’à ce qu’elle se verrouille en position.

Marques

d’alignement

2. Pour retirer la batterie autonome:

Appuyez sur le bouton depuis l’avant pour

libérer la batterie autonome.

REMARQUE:

Veillez à fixer l’anneau en caoutchouc pour

empêcher la goupille de tomber.

Pour retirer la douille

1 Retirez l’anneau en caoutchouc.

2 Retirez la goupille.

etirez la douille de l’outil.

3 R

Bouton

V

. FONCTIONNEMENT

Avant d’utiliser la télécommande (Disponible comme

accessoire en option)

Insérez la batterie

1. Faites ressortir le porte-

batterie.

1 R

epoussez l’attache

comme indiqué par

la flèche.

aites ressortir le

2 F

porte-batterie.

Page 21

2. Insérez la batterie

Environ 50 cm

Verticalement

E

n

v

i

r

o

n

6

0

°

E

n

v

i

r

o

n

6

0

°

Rotation en

sens normal

Rotation en

sens inverse

Verrouillage de commutateur

et repoussez le

porte-batterie à

l’intérieur.

REMARQUE:

Si l’outil ne répond pas à la télécommande

•

sans fil, même lorsque vous faites fonctionner la télécommande près de l’outil,

ela signifie que la batterie (CR2025) est

c

épuisée. Remplacez la batterie par une

batterie chargée.

La batterie incluse est fournie comme un

•

échantillon d’utilisation et peut ne pas durer

aussi longtemps que les batteries disponibles dans le commerce.

Portée de la télécommande sans fil

[Corps principal]

Utilisation du commutateur et

du levier d’inversion marche

avantmarche arrière

La télécommande doit être opérée dans les 50

cm environ et à environ 60º verticalement ou

horizontalement de la perpendiculaire par rapport au récepteur à infrarouge de l’outil.

Il se peut que vous ne puissiez pas opérer la

•

télécommande dans ces circonstances, même

à l’intérieur de sa portée.

Si un objet se trouve entre le transmetteur

•

de la télécommande et le récepteur de

l’outil.

Utilisation à l’extérieur ou dans d’autres

•

environnements où le récepteur de la télécommande est exposé à une forte source

de lumière ou lorsque le transmetteur

ou le récepteur de la télécommande est

sale, pouvant faire que l’outil ne répond

pas, même lorsque la télécommande est

utilisée à l’intérieur sa portée de fonctionnement.

MISE EN GARDE:

Pour prévenir tout dégât, n’actionn

le levier d’inversion marche avant-marche

arrière tant que la mèche n’a pas com-

lètement terminé de tourner.

p

ez pas

Utilisation du commutateur pour

une rotation en sens normal

1. Poussez le levier pour obtenir une rotation

en sens normal.

2

. Appuyez légèrement sur la gâchette pour

que l’outil commence à tourner lentement.

La vitesse augmente à mesure où la

3.

gâchette est enfoncée pour un vissage

efficace des vis. Le frein fonctionne et la

mèche s’arrête immédiatement dès que la

gâchette est relâchée.

4.

Ramenez le levier en position centrale

lorsque vous n’utilisez plus l’outil (verrouillage du commutateur).

Utilisation du commutateur

de rotation en sens inverse

1.

Poussez le levier pour obtenir une rotation en

sens inverse. Avant d’utiliser l’outil, vérifiez le

sens de rotation.

2.

Appuyez légèrement sur la gâchette pour que

l’outil commence à tourner lentement.

3. Ramenez le levier en position centrale

lorsque vous n’utilisez plus l’outil (verrouillage du commutateur).

-

21 -

Page 22

-

22 -

MISE EN GARDE:

• Pour empêcher toute élévation excessive de la température de la surface

de l’outil, n'utilisez pas l'outil de façon

continue en utilisant deux batteries autonomes ou plus. L’outil a besoin de se

refroidir pendant un certain temps avant

d'être connecté à une autre batterie

autonome.

Témoin de confirmation de serrage

• Le témoin de confirmation de serrage peut

être utilisé pour vérifier si la fonction de

commande du couple de serrage a été

activée.

Panneau de commande

(1) (2) (3)

(1) Lumière DEL

Etat de l’outil

Serrage terminé

(avec la fonction de

commande du couple de

serrage fonctionnant)

Serrage non terminé

•

• Serrage terminé avec

resserrement dans la

seconde

La fonction d’arrêt

automatique a été activée.

MISE EN GARDE:

Lorsque l’outil s’arrête automatiquement

•

après avoir libéré le commutateur pendant le serrage en mode impact-serrage

et avoir été réengagé dans la seconde,

le témoin rouge s’allume pour indiquer le

risque d’application d’un couple de serrage excessif résultant du resserrement.

REMARQUE

•

Le témoin de confirmation de serrage

ne s’allume pas dans les conditions suivantes:

•

Lorsque l’embrayage du couple de ser-

rage est réglé sur “F”

•

Pendant le fonctionnement en rotation

inverse

Le témoin s’éteint lorsque l’outil fonc-

•

tionne.

Afchage du

témoin

Vert

(Pendant

environ

secondes)

Rouge

(Pendant

environ

secondes)

Rouge

(Pendant

environ 5

minutes)

Appuyez sur pour allumer et éteindre la

lumière DEL.

2

2

La lumière éclaire avec un courant de très

faible intensité qui n’affecte pas négativement

la performance de l’outil ou la capacité de la

batterie pendant son utilisation.

MISE EN GARDE:

La lumière DEL incorporée est conçue

•

pour éclairer temporairement la petite

zone de travail.

•

Ne l’utilisez pas comme remplacement

d’une torche normale, elle n’est pas

assez lumineuse.

Cet outil est équipé d’une lumière DEL

incorporée.

Mise en garde

L’utilisation de commandes ou de réglages ou

l’exécution de procédures autres que ceux spéci-

és dans ce manuel peut entraîner l’exposition à

de dangereuses radiations.

: NE REGARDEZ PAS DIRECTE-

MENT LE FAISCEAU.

(2) Témoin indicateur de la batterie

• Utilisez le témoin indicateur de la batterie pour

vérifier la quantité de charge restant dans la

batterie.

La durée de vie de la batterie varie légèrement

•

en fonction de la température ambiante et des

caractéristiques de la batterie. Le témoin est

conçu pour fournir une indication approximative de la durée de vie restante de la batterie.

Page 23

Témoin indicateur de la batterie

Indicateur Etat de la batterie

Pleinement chargée

Environ 40% ou moins

restant

Clignotant:

Environ 20% ou moins

restant (indique le besoin

de recharger la batterie)

Clignotant

Clignotant

La batterie autonome va

bientôt avoir besoin d’être

chargée.

Pas de charge

La batterie autonome à

besoin d’être chargée.

(A ce stage, la fonction

d’arrêt automatique de

l’outil s’active.)

Fonction d’arrêt automatique

• La fonction d’arrêt automatique est conçue

pour empêcher une perte de couple de serrage à la suite d’une tension réduite de la

batterie. Une fois activée, l’outil ne répondra

pas tant que la batterie n’aura pas été chargée (ou remplacée par une unité chargée),

même si la détente est pressée.

Témoin indicateur de la batterie

Indicateur

Clignotant

REMARQUE:

• Les 3 barres du témoin indicateur de la

batterie clignotent lorsque la fonction

d’arrêt automatique est activée.

Lorsque le témoin indicateur de la batte-

•

rie se met à clignoter, il faut immédiatement charger la batterie autonome (ou

la remplacer par une unité chargée).

Veillez à charger complètement la batterie

•

autonome en question après l’activation

de la fonction d’arrêt automatique. Si cela

n’est pas effectué, cela peut empêcher la

fonction d’arrêt automatique d’être correctement désactivée.

(3) Fonction de commande du couple

de serrage

• La fonction de commande du coupe de serrage calcule la charge de l’angle de rotation

du moteur pendant l’impact du marteau et

détermine que le boulon a été correctement

assis lorsqu’une valeur de charge préréglée est dépassée. L’entraînement est alors

automatiquement arrêté après que le boulon

ait subit un nombre d’impacts préréglé.

MISE EN GARDE:

Vérifiez toujours le couple de serrage de

•

l’outil avant de l’utiliser. Une mauvaise

utilisation de l’outil peut entraîner un serrage excessif ou inadéquat.

MISE EN GARDE:

•

Faites toujours fonctionner l’outil avec

le commutateur complètement engagé.

La fonction de commande du couple

de serrage ne fonctionne pas lorsque

le commutateur n’est pas suffisamment

engagé, empêchant l’outil de s’arrêter

automatiquement.

Lors de travaux pendant lesquels une

•

lourde charge est appliquée pendant le

serrage, la charge peut être interprétée

comme l’assise du boulon, empêchant

le boulon d’être complètement serré.

Le serrage répété du même boulon peut

•

briser le boulon ou déformer le matériau

dans lequel le boulon est enfoncé à la

suite d’un serrage excessif.

La valeur du couple de serrage et la

•

précision varient en fonction de facteurs

tels que le matériau dans lequel le boulon est enfoncé et l’état de la douille

utilisée. Ajustez le couple de serrage en

fonction du travail exécuté. Le couple

de serrage de boulons varie en fonction

des facteurs décrits ci-dessous.

1) Boulon

Diamètre du boulon: la couple de ser-

•

rage augmente généralement avec le

diamètre du boulon.

-

23 -

Page 24

-

24 -

• Coefficient du couple de serrage (indi-

3…28

1F30 229

qué par le fabricant du boulon), qualité,

longueur, etc.

) Autres

2

• Etat de la mèche et de la douille: matériau, quantité de jeu, etc.

Utilisation d’un joint universel ou d’un

•

adaptateur de douille

•

Utilisateur: façon dont l’outil est appliqué

sur le boulon, la force avec laquelle l’outil

est tenu, la façon dont le commutateur de

l’outil est engagé

Condition de l’objet étant serré: matériau,

•

finition de la surface d’assise

Réglage de l’outil dans le mode configuration

1.

Eteignez le panneau de commande.

• Si le panneau de commande est allumé,

retirez et réinsérez la batterie autonome.

. Engagez le commutateur tout en appuyant

2

sur le bouton

et le commutateur.

• Après que tous les témoins DEL se soient

éteints, le panneau de commande clignote

et change au mode configuration.

, puis relâchez le bouton

Configuration du réglage de l’embrayage du

couple de serrage

(1)

(2)

REMARQUE:

• Les outils sont expédiés de l’usine réglés

sur le mode “F” (fonction de commande

du couple de serrage désactivée).

Le panneau de commande s’éteint si

•

l’outil n’est pas opéré pendant une période de 5 minutes.

Afchage

Témoin indicateur de la batterie

1. Appuyez sur les boutons et pour

sélectionner le réglage de l’embrayage

convenant au travail devant être exécuté.

Alors que le bouton

est appuyé

• “F” indique que la fonction de commande

du couple de serrage est désactivée.

Alors que le bouton

est appuyé

Page 25

• Vous pouvez sélectionner entre 30

0

10

20

30

40

50

60

EYFLA1 (M6)

EYFLA2 (M6)

EYFLA1 (M8)

EYFLA2 (M8)

EYFLA3 (M8)

EYFLA3 (M10)

N • m

1 2 3 4 5 6 7 8 9 101112131415 161718 192021222324252627282930

réglages de l’embrayage du couple de

serrage (1 à 30).

Utilisez les chiffres du Graphique du cou-

•

ple de serrage pour guider votre sélection du réglage de l’embrayage du couple

de serrage. (Reportez-vous au graphique

du couple de serrage suivant.)

. Appuyez sur le bouton OK pour accepter le

2

réglage de l’embrayage du couple de serrage sélectionné.

Le panneau de commande s’arrête de

•

clignoter et s’allume.

MISE EN GARDE:

•

Vous devez appuyer sur le bouton OK

afin que le réglage sélectionné prenne

effet.

Veillez à vérifier la nouvelle valeur après

•

avoir changé le réglage. (Reportezvous à la page

25.)

Graphique du couple de serrage (Pour

référence)

Les valeurs illustrées dans ce graphique ont

été mesurées dans les conditions décrites cidessous et sont fournies pour référence. Le

couple de serrage réel varie en fonction des

conditions ambiantes (le boulon particulier

devant être serré, le matériel utilisé, la méthode de maintien du boulon en place, etc.).

Régler l’outil sur le mode configuration.

1.

(Reportez-vous à la page 24.)

2. Appuyez sur le bouton de réglage de

l’intervalle.

Le panneau de commande se met à

•

clignoter.

Afchage: le numéro 0 clignote.

Témoin indicateur de la batterie: la barre

du milieu de la batterie clignote.

Afchage

Témoin indicateur de la batterie

3. Appuyez sur les boutons et pour

régler l’heure désirée.

Boutons Afchage Secondes

30 3

1 0.1

0 Désactivé

4.

Appuyez sur le bouton OK pour accepter

le réglage sélectionné.

Le panneau de commande s’arrête

•

de clignoter et s’allume et le réglage

de l’embrayage du couple de serrage

s’affiche.

MISE EN GARDE:

•

Veillez à vérifier la nouvelle valeur

après avoir changé le réglage.

Conditions de la mesure

• Température: température de la pièce (20ºC/

68ºF)

Utilisation du réglage de l’intervalle

Le réglage de l’intervalle fonctionne pour

•

empêcher l’outil de fonctionner après qu’il

se soit automatiquement arrêté à la suite du

fonctionnement de la fonction de commande

du couple de serrage, même lorsque le

commutateur est engagé.

Initialisation de tous les réglages

Réglages d’usine

• Réglage de l’embrayage du couple de

serrage: “F” (fonction de commande du

couple de serrage désactivée)

Réglage de l’intervalle: 0 (désactivé)

•

• Cette section explique comment faire reve

nir tous les réglages de l’outil à leur valeur de

défaut au moment de l’expédition de l’usine.

L’affichage d’erreur s’éteint.

•

1. Réglez le mode configuration de l’outil.

(Reportez-vous à la page 24.)

2. Appuyez sur le bouton de formatage.

• Le panneau de commande se met à

clignoter.

Afchage: la lettre “F” clignote.

25 -

-

-

Page 26

-

26 -

Témoin indicateur de la batterie: les barres

supérieure et inférieure de la batterie

clignotent.

Afchage

Témoin indicateur de la batterie

3. Appuyez sur le bouton OK pour accepter

le réglage sélectionné.

Le panneau de commande s’arrête de

•

clignoter et s’allume.

Vérication des réglages de l’outil

•

Cette section décrit comment faire que

l’outil affiche les réglages en cours pendant environ 3 secondes lorsque l’outil est

arrêté.

Vous ne pouvez pas vérifier les réglag-

•

es de l’outil lorsque le panneau de commande est éteint. D’abord, engagez

brièvement le commutateur pour réactiver

l’affichage.

Vérication du réglage de l’embrayage du

couple de serrage

Appuyez sur le bouton de réglage du cou-

1.

ple de serrage.

•

Affichage du panneau de commande

Afchage: le couple de serrage réglé

s’allume.

Témoin indicateur de la batterie: la barre

supérieure de la batterie clignote.

Vérication de l’intervalle

Appuyez sur le bouton de réglage de

1.

l’intervalle.

•

Affichage du panneau de commande

Afchage: la couple de serrage réglé

s’allume.

Témoin indicateur de la batterie: la barre

du milieu de la batterie clignote.

Vérication des circuits de l’outil

Appuyez sur le bouton de réglage du cou-

1.

ple de serrage.

•

Affichage du panneau de commande

Afchage: l’afchage du couple de serrage réglé s’allume.

Témoin indicateur de la batterie: les barres

du milieu et du bas clignotent.

Afchage Circuit de l’outil

H2 EYFLA1

H3 EYFLA

H4 EYFLA3

REMARQUE:

• Si vous engagez le commutateur alors

qu’un réglage est affiché, le panneau

de commande revient à l’affichage du

réglage de l’embrayage du couple de

serrage.

MISE EN GARDE:

L’affichage du couple de serrage n’est

•

pas supposé être utilisé pour identifier le type des pièces (marteau, etc.)

utilisées composant l’entraînement d’un

outil particulier.

2

Page 27

Affichage d’erreur

Dans le cas où un outil ou la batterie autonome présentent un mauvais fonctionnement, le panneau

de commande afche un message d’erreur. Veuillez vérier l’outil ou la batterie autonome comme

décrit dans le graphique suivant avant de les faire réparer.

Afchage Cause probable Action correctrice

Erreur de réglage Réinitialiser l’outil en utilisant la

La batterie autonome est trop

chaude.

L’outil est trop chaud pour

pouvoir fonctionner.

Les contacts connectant la

batterie autonome et l’outil sont

sales.

La batterie autonome n’a pas

été correctement insérée dans

l’outil.

Les goupilles de l’outil ou de la

batterie autonome sont usées.

Panne du moteur, etc. Arrêter immédiatement d’utiliser

Mauvais fonctionnement du

capteur, panne, etc.

Mauvais fonctionnement du

circuit de l’outil, panne, etc.

télécommande. (Reportez-vous à

26.)

la page

Arrêter le travail et laisser la

batterie autonome refroidir avant

de reprendre l’utilisation de l’outil.

Arrêter le travail et laisser l’outil

refroidir avant de reprendre

l’utilisation.

Retirer toute crasse.

Bien insérer la batterie autonome

dans l’outil.

Remplacer la batterie autonome.

l’outil.

-

27 -

Page 28

-

28 -

[Batterie]

Pour une utilisation correcte

de la batterie autonome

Batterie autonome Li-ion (EYFB30)

• Pour une longévité optimale de la batterie,

rangez la batterie autonome Li-ion sans la

charger après l’avoir utilisée.

• Lors de la charge de la batterie autonome,

assurez-vous que les bornes du chargeur

de batterie sont libres de tout corps étranger

comme de la poussière et de l’eau, etc. Nettoyez les bornes avant de charger la batterie

autonome si des corps étrangers se trouvent

sur les bornes.

La durée de vie des bornes de la batterie

autonome peut être affectée par des corps

étrangers comme de la poussière et de l’eau,

etc. pendant le fonctionnement.

• Lorsque vous n’utilisez pas la batterie autonome, éloignez-la d’autres objets métalliques

tels que: trombones, pièces de monnaie, clés,

clous, vis et autres petits objets métalliques

susceptibles de connecter les bornes entre

elles.

Si vous court-circuitez les bornes de la bat-

terie, vous risquez de causer des étincelles,

de vous brûler ou de provoquer un incendie.

• Lors de l’utilisation de la batterie autonome,

assurez-vous de la bonne ventilation du lieu

de travail.

• Lorsque la batterie autonome est retirée du

corps de l’outil, replacez immédiatement

le couvercle de la batterie autonome afin

d’empêcher la poussière ou la crasse de

contaminer les bornes de la batterie et de

provoquer un court-circuit.

Longévité des batteries auto

nomes

Les batteries rechargeables ont une longévité

limitée. Si le temps de fonc tion nement devient

très court après la recharge, remplacez la batterie auto nome par une neuve.

Recyclage de la batterie autonome

ATTENTION:

Pour une batterie autonome Li-ion

EYFB30

La batterie Li-ion que vous êtes procurée

est recyclable. Pour des renseigne ments

sur le recyclage de la batterie, veuillez

composer le 1-800-8-BATTERY.

[Chargeur de batterie]

Recharge

Lisez le mode d’emploi du chargeur de batterie Panasonic de la batterie autonome avant

d’effectuer la charge.

Avant de charger la batterie

Lors de la charge du EYFB30:

Chargez la batterie à une température de 5ºC

(41ºF) à 40ºC (104ºF).

La batterie autonome ne peut pas être chargée

à une température inférieure à 5ºC (41ºF). Si

la température de la batterie autonome est

inférieure à 5ºC (41ºF), retirez d’abord la batterie

autonome du chargeur et laissez-la pendant

une heure dans un endroit où la température

est d’au moins 5ºC (41ºF). Puis effectuez de

nouveau la charge de la batterie autonome.

VI.

ENTRETIEN

Nettoyez l’appareil au moyen d’un chif fon sec

et propre. N’utilisez ni eau, ni solvant, ni produit

de nettoyage volatile.

Page 29

VII

. ACCESSOIRES

Chargeur

• EY0L80

Batterie

•

EYFB30

Télécommande

•

EYFA30

Protection pour l’outil

•

EYFA01-A (Bleu)

• EYFA01-Y (Jaune)

• EYFA01-H (Gris)

Protection pour la batterie

EYFA02-H

•

VIII

. CARACTERISTIQUES TECHNIQUES

UNITE PRINCIPALE

Modèle EYFLA1 EYFLA2 EYFLA3

A A Q J

Moteur 10,8 V CC

Taille du

mandrin

Vitesse sans

charge

Percussions

par minute

Couple maximum 40 N·m

Portée de

fonctionnement de la

fonction de commande

du couple de serrage

Simple

extrémité

Double

extrémité

Etape 1

Etape 1

9 – 9,5 mm

23/64" – 3/8")

(

1

2 mm (15/32") 12 mm

2

3 – 5

6

7

8

9 – 30·F

2

3 – 5

6

7

8

9 – 30·F

(408 kgf-cm, 354 in-lbs)

Environ 3 –

(31 – 224 kgf-cm,

27 – 195 in-lbs)

Longueur totale

Poids (avec la batterie

autonome: EYFB30)

9 – 9,5 mm

(23/64"

– 3/8")

(15/32")

0 – 950

0 – 1000

0 – 1050

0 – 1300

0 – 1450

0 – 1550

0 –

2300

0 – 1900

0 – 1950

0 –

2100

0 – 2500

0 – 2800

0 – 3000

0 – 4000

22 N·m

158 mm (6-7/32") 164 mm (6-7/16")

1

2

3

4 – 30·F

1

2

3

4 – 30·F

90 N·m

(918 kgf-cm, 796 in-lbs)

Environ 6 – 30 N·m

(61 – 306 kgf-cm,

53 – 266 in-lbs)

1,3 kg (

2,8 lbs) 1,35 kg (2,9 lbs)

□

9,5 mm

(3/8")

0 – 1300

0 – 1450

0 – 1550

0 – 2300

0 – 2500

0 – 2800

0 – 3000

0 – 3600

□

12,7 mm (1/2")

0 – 2300

0 – 3000

1

20 N·m (1224 kgf-cm,

1062 in-lbs)

Environ 16 – 53 N·m

(163 – 540 kgf-cm,

142 – 469 in-lbs)

-

29 -

Page 30

BATTERIE AUTONOME (non inclue dans l’expédition)

Modèle EYFB30

Stockage de la batterie Batterie Li-ion

Tension de la batterie

Capacité 3 Ah

10,8 V CC (3,6 V/6

piles

)

CHARGEUR DE BATTERIE (non inclue dans l’expédition)

Modèle EY0L80

Puissance nominale Voir la plaque signalétique se trouvant sur le côté

Poids 0,95 kg (

inférieur du chargeur.

2,1 lbs)

[Batterie autonome Li-ion]

10,8 V

Durée de

chargement

3 Ah

EYFB30

Utilisable: 40 min.

Plein: 65 min.

Télécommande (non inclue dans l’expédition)

Modèle EYFA30

Tension de la batterie 3 V CC

Dimensions 54 mm (

Poids (avec la batterie) Environ

2-1/8") × 86 mm (3-3/8") × 10 mm (13/32”)

29 g (0,6 lbs)

-

30 -

Page 31

.

REGLAS DE SEGURI-

I

DAD GENERALES

¡ADVERTENCIA! Lea todas las

instrucciones.

Si no cumple con todas las siguientes

instrucciones puede recibir una descarga eléctrica, incendio y/o heridas

graves. El término “herramienta

eléctrica” en todas las advertencias a

continuación se refiere a su herramienta

eléctrica conectada al tomacorriente

(cableado) y a la herramienta eléctrica

que funciona con batería (sin cable).

GUARDE ESTAS INSTRUCCIONES

Seguridad del lugar de trabajo

1) Mantenga el lugar de trabajo limpio y

bien iluminado.

Un área desprolija u oscura es una causa

de accidentes.

2) No haga funcionar herramientas eléctri

cas en un ambiente explosivo como en

lugares donde hay líquidos inflamables

cajas o polvo.

Las herramientas eléctricas producen

chispas que pueden encender el polvo

o el vapor.

3)

Mantenga a los niños y personal no

relacionado lejos mientras haga funcio-

nar la herramienta eléctrica.

Una distracción puede hacer que pierda

el control.

Seguridad eléctrica

1) Los enchufes de herramientas eléc

tricas deben coincidir con el tomacorriente. Nunca modifique el

enchufe. No utilice ningún adaptador

de enchufe con herramientas eléctri

cas con tierra (conexión a tierra).

U

n enchufe no modificado y tomacorrientes que coincidan reducirán el

riesgo de descarga eléctrica.

2

) Evite el contacto de su cuerpo con

una superficie de tierra o conectado a una tierra tales como tubos,

radiadores, microondas y refrigeradores.

Existe un mayor riesgo de descarga

eléctrica si su cuerpo queda conectado a

una tierra.

3) No exponga herramientas eléctricas a

la lluvia o condiciones de humedad.

El agua que entra en una herramienta

e

léctrica aumentará el riesgo de des-

carga eléctrica.

No abuse del cable. Nunca utilice

4)

el cable para transportar, tirar de o

desenchufar la herramienta eléctrica.

Mantenga el cable lejos de fuentes de

calor, aceite, bordes afilados o piezas

móviles.

U

n cable dañado o enredado puede au-

mentar el riesgo de descarga eléctrica.

5)

Cuando haga funcionar una herra-

mienta eléctrica en exteriores, utilice

un cable de extensión adecuado para

uso en exteriores.

El uso de un cable adecuado para uso en

exteriores reduce el riesgo de descarga

eléctrica.

Seguridad personal

1) Manténgase alerta, vigile lo que haga

y utilice sentido común cuando haga

funcionar la herramienta eléctrica. No

utilice una herramienta eléctrica mien

tras está cansado o bajo la influencia

de drogas, alcohol o medicamentos.

Un descuido instantáneo mientras hace

funcionar las herramientas eléctricas

puede provocar una herida personal de

gravedad.

2

) Utilice equipo de seguridad. Utilice

siempre gafas protectoras.

Un equipo de seguridad como máscara

antipolvo, zapatos antideslizamiento,

casco duro o protección contra los

oídos