Page 1

Cordless Drill & Driver

Perceuse et tournevis sur batterie

Taladro y destornillador sin cable eléctrico

Operating Instructions

Instructions d’utilisation

Manual de instrucciones

Model No: EY7411

IMPORTANT

This manual contains safety information. Read manual completely before first using this product and save this

manual for future use.

IMPORTANT

Ce mode d’emploi contient des informations sur la sécurité. Lisez-le en entier avant d’utiliser le produit et

conservez-le pour référence.

IMPORTANTE

Este manual contiene información de seguridad. Lea completamente este manual antes de utilizar por primera

vez este producto, y guárdelo para poder consultarlo en el futuro.

Page 2

-

2 -

Index/Index/Indice

English: Page 4

Français: Page 16

Español: Página 30

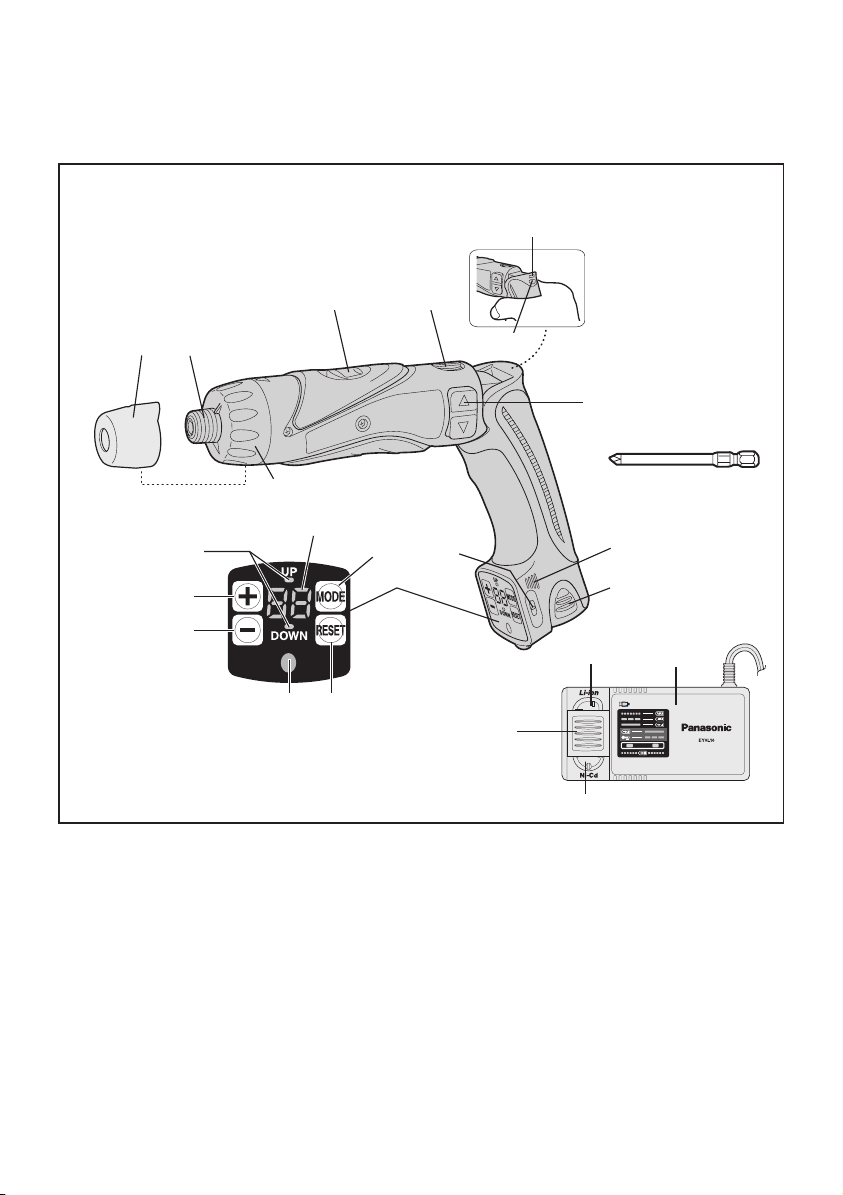

FUNCTIONAL DESCRIPTION

DESCRIPTION DES FONCTIONS

DESCRIPCIÓN FUNCIONAL

(R)

(J)

(I)

(Q)(P)

(K)

(O)

(H)

(L)

(A)

(G)

(M)

(F)

(B)

(N)

(W)

(S)

(X)

(V)

(C)

(T)

(D)

(E)

(U)

Page 3

-

3 -

(A) Speed selector switch Sélecteur de vitesse de rotation Conmutador selector de velocidad

(B) Main switch lock Verrou de l’interrupteur principal Bloqueo de interruptor principal

(C) Forward/Reverse switch Sélecteur de marche avant/marche

(D) Buzzer sound part Pièce de l’alarme Parte de sonido de zumbador

(E) Battery pack (EY9L10) Batterie autonome (EY9L10) Batería (EY9L10)

(F) Control panel Panneau de commande Panel de controle

(G) Reset button Bouton de remise à zéro Botón de reposición

(H) LED light

– (MINUS) button Bouton – (MOINS) Botón – (MENOS)

( I )

(J) + (PLUS) button Bouton + (PLUS) Botón + (MÁS)

(K) Count system display lamp Voyant d’afchage du système de

(L) Count display LED DEL de l’afchage du compteur LED indicadora de cuenta

(M) Mode Button Bouton de Mode Botón de modo

(N) Hold switch Sélecteur de pause Conmutador HOLD

(O) Clutch handle Poignée de l’embrayage Mango de embrague

(P) Clutch lock cover Couvercle du verrou de l’embrayage Cubierta de bloqueo de embrague

(Q) Hexagonal bit chuck Mandrin de mèche hexagonal Portador de broca hexagonal

(R) Battery low warning lamp Témoin d’avertissement de batterie

(S) LED light ON/OFF button Bouton Marche/Arrêt de la lumière

(T) #2 Phillips bit Mèches Phillips #2 Broca Philips No2

(U) Battery charger (EY0L10) Chargeur de batterie (EY0L10) Cargador de la batería (EY0L10)

(V) Ni-Cd battery pack dock Poste d’accueil de la batterie

(W) Battery dock cover Couvercle du poste d’accueil de la

(X) Li-ion battery pack dock Poste d’accueil de la batterie

arrière

Lumière DEL

comptage

basse

DEL

autonome Ni-Cd

batterie

autonome Li-ion

Conmutador de avance/marcha

Luz indicadora

Luz indicadora del sistema de

cuenta

Luz de aviso de baja carga de

batería

Botón ON/OFF de luz LED

Enchufe de carga de batería Ni-Cd

Cubierta de enchufe de carga de

batería

Enchufe de carga de batería Li-ión

Page 4

-

4 -

I

. GENERAL SAFE-

TY RULES

WARNING! Read all instructions

Failure to follow all instructions listed

below may result in electric shock, fire

and/or serious injury. The term “power

tool” in all of the warnings listed below

refers to your mains operated (corded)

power tool and battery operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

Work Area Safety

1) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2)

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or

dust.

Power tools create sparks which may

ignite the dust or fumes.

3)

Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

1) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power tools.

Unmodified plugs and matching outlets

will reduce risk of electric shock.

2)

Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or grounded.

3) Do not expose power tools to rain or

wet conditions.

Water entering a power tool will increase the risk of electric shock.

4)

Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving

parts.

Damaged or entangled cords increase

the risk of electric shock.

5)

When operating a power tool outdoors, use an extension cord suitable

for outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

Personal Safety

1) Stay alert, watch what you are doing

and use common sense when operating a power tool. Do not use a power

tool while you are tired or under the

influence of drugs, alcohol or medication.

A moment of inattention while operating

power tools may result in personal injury.

2)

Use safety equipment. Always wear

eye protection.

Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

3)

Avoid accidental starting. Ensure the

switch is in the off position before

plugging in.

Carrying power tools with your finger on

the switch or plugging in the power tools

that have the switch on invites accidents.

4)

Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a

rotating part of the power tool may

result in personal injury.

5)

Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

6)

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving

parts.

Loose clothes, jewellery or long hair can

be caught in moving parts.

7)

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used.

Use of these devices can reduce dust

related hazards.

Power Tool Use and Care

1)

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

2)

Do not use the power tool if the switch

does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous and

must be repaired.

Page 5

-

5 -

3) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools.

Suc h pre ven tive safe ty measu res

reduce the risk of starting the power tool

accidentally.

4)

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

5)

Maintain power tools. Check for misalignment or binding of moving parts,

breakag e of part s and any other

condition that may affect the power

tools operation. If damaged, have the

power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

6)

Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

7)

Use the power tool, accessories and

tool bits etc. in accordance with these

instructions and in the manner intended for the particular type of power

tool, taking into account the working conditions and the work to be performed.

Use of the power tool for operations

different from those intended could

result in a hazardous situation.

Battery Tool Use and Care

1) Ensure the switch is in the off position before inserting battery pack.

Inserting battery pack into power tools

that have the switch on invites accidents.

2)

Recharge only with the charger specified by the manufacturer.

A charger that is suitable for one type

of battery pack may create a risk of fire

when used with another battery pack.

3)

Use power tools only with specifically designated battery packs.

Use of any other battery packs may

create a risk of injury and fire.

4)

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together

may cause burns, or a fire.

Under abusive conditions, liquid may

5)

be ejected from battery; avoid contact. If contact accidentally occurs,

flush with water. If liquid contacts

eyes, additionally seek medical help.

Liquid ejected from the battery may

cause irritation or burns.

Service

1) Have your power tool serviced by a

qualified repair person using only

identical replacement parts.

This will ensure that the safety of power

tool is maintained.

II

. SPECIFIC SAFE-

TY RULES

1) Wear ear protectors when using the

tool for extended periods.

Prolonged exposure to high intensity

noise can cause hearing loss.

2)

Be aware that this tool is always in an

operating condition, since it does not

have to be plugged into an electrical

outlet.

3)

Hold power tools by insulated grip-

ping surfaces when performing an

operation where the cutting tool may

contact hidden wiring.

Contact with a “live” wire will make ex-

posed metal parts of the tool “live” and

shock the operator.

4) If the bit becomes jammed, immediately

turn the main switch off to prevent an

overload which can damage the battery

pack or motor. Use reverse motion to

loosen jammed bits.

5) Do not touch the rotating parts to avoid

injury.

Do not use the tool continuously for a

6)

long period of time. Stop using the tool

from time to time to avoid temperature

rise and heat overload of the motor.

7) Do not drop the tool.

Page 6

-

6 -

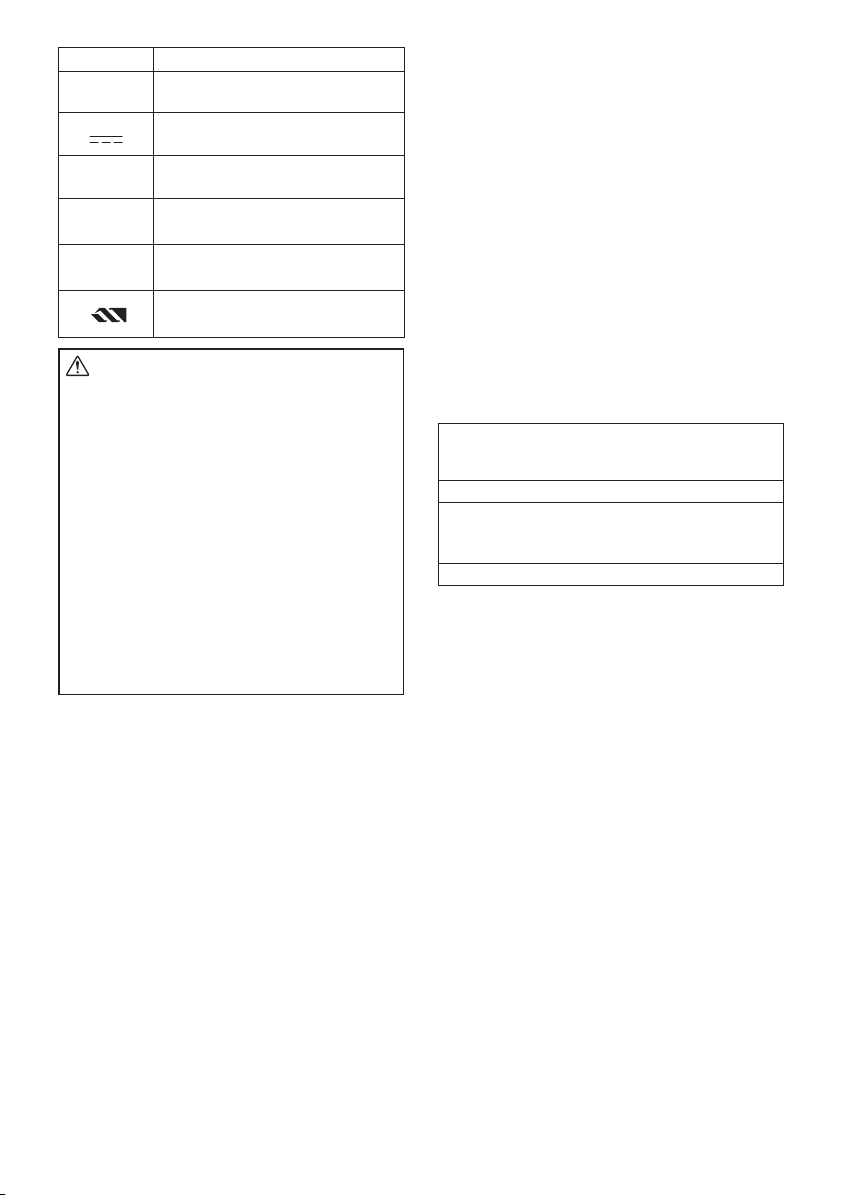

Symbol Meaning

V

n

0

… min

Ah

Revolutions or reciprocations per

-1

Electrical capacity of battery pack

Volts

Direct current

No load speed

minutes

Rotation only

WARNING!

Some dust created by power sanding, sawing, grinding, drilling, and other construction

activities contains chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

Crystalline silica from bricks and cement

•

and other masonry products

• Arsenic and chromium from chemically-treated lumber.

To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment,

such as dust masks that are specially

designed to filter out microscopic particles.

III

.

FOR BATTERY CHARGER & BATTERY PACK

Important Safety Instructions

1) SAVE THESE INSTRUCTIONS -This

man ual c onta ins i mpo rtan t safety

and operating instructions for battery

charger EY0L10.

2) Before using battery charger, read all

instructions and cautionary markings

on battery charger, battery pack, and

product using battery pack.

3) CAUTION -To reduce the risk of injury,

charge only Panasonic Battery Pack as

shown in last page.

Ot her types of batteries m ay burst

causing personal injury and damage.

4) Do not expose charger and battery pack

to rain or snow.

5) To reduce risk of damaging the electric

plug and cord, pull by plug rather than

cord when disconnecting charger.

6)

Make sure cord is located so that it

will not be stepped on, tripped over, or

otherwise subjected to damage or stress.

7) An extension cord should not be used

unless absolutely necessary.

Use of improper extension cord could

result in a risk of fire and electric shock.

If extension cord must be used, make

sure that:

a. pins on plug of extension cord are

the same number, size and shape as

those of plug on charger.

b. extension cord is properly wired and

in good electrical condition.

c. wire size is large enough for ampere

rating of charger as specified below.

RECOMMENDED MINIMUM AWG SIZE OF

AC Input Rating. Amperes

Equal to or

greater than

0 2 18 18 18 16

8) Do not operate charger with damaged

9) Do not operate charger if it has received

10

11)

12)

13) Do not attempt to charge the battery

14) Do not attempt to disassemble the bat-

15) Do not store the tool and battery pack

EXTENSION CORDS FOR

BATTERY CHARGERS

AWG Size of Cord

But less

than

cord or plug-replace them immediately.

a sharp blow, been dropped, or otherwise damaged in any way; take it to a

qualified service personnel.

) Do not disassemble charger; take it

to a qualified service personnel when

service or repair is required. Incorrect

reassembly may result in a risk of electric shock or fire.

To reduce the risk of electric shock, unplug charger from outlet before attempting

any maintenance or cleaning.

The charger and battery pack are specifically designed to work together. Do

not attempt to charge any other cordless

tool or battery pack with this charger.

pack with any other charger.

tery pack housing.

in locations where the temperature may

reach or exceed 50°C (122

as a metal tool shed, or a car in the

Length of Cord,

Feet

25 50 100 150

°F) (such

Page 7

-

7 -

summer), which can lead to deterioration

of the storage battery.

16) Do not charge battery pack when the

temperature is BELOW 0°C (32°F) or

ABOVE 40°C (104°F). This is very important in order to maintain optimal condition

of the battery pack.

17) Do not incinerate the battery pack. It

can explode in a fire.

18) Avoid dangerous environment. Do not

use charger in damp or wet locations.

19) The charger is designed to operate on

standard household electrical power

only. Do not attempt to use it on any

other voltage!

20) Do not abuse cord. Never carry charger

by cord or yank it to disconnect from

outlet. Keep cord away from heat, oil

and sharp edges.

21) Charge the battery pack in a well ven

tilated place, do not cover the charger

and battery pack with a cloth, etc., while

charging.

22) Use of an attachment not recommended may result in a risk of fire, electric

shock, or personal injury.

23) Do not short the battery pack. A battery

short can cause a large current flow,

over heating and create the risk of fire

or personal injury.

24) NOTE: If the supply cord of this appliance is damaged, it must only be replaced by a repair shop authorized by

the manufacturer, because special purpose tools are required.

25)

TO REDUCE THE RISK OF ELECTRIC

SHOCK , THIS AP PLIANCE HAS A

POLARIZED PLUG (ONE BLADE IS

WIDER THAN THE OTHER).

This plug will fit in a polarized outlet

only one way. If the plug does not fit

fully in the outlet, reverse the plug. If

it still does not fit, contact a qualified

electrician to install the proper outlet.

Do not change the plug in any way.

I

V

. ASSEMBLY &

OPERATION

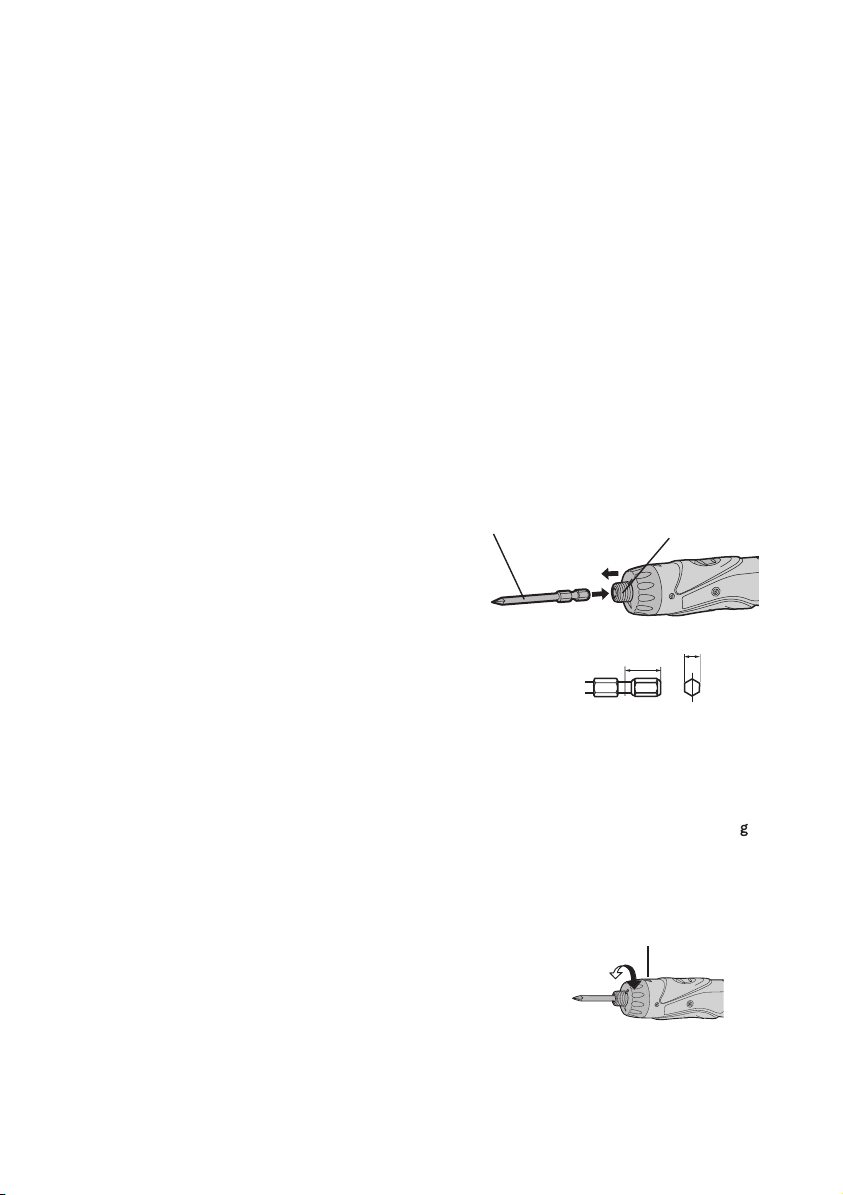

Hexagonal Bit Chuck

Attaching the bits

NOTE:

When attaching or removing drill

bits, disconnect the battery pack

from the tool and switch the lock

button into the lock position.

1. Hold the collar of the chuck and pull it

out from the driver.

2. Insert the bit into the chuck. Release

the collar.

3. The collar will return to its original

position when it is released.

4. Pull the bit to make sure it does not

-

come out.

5. To remove the bit, pull out the collar in

the same way.

Bit

9.5 mm (3/8") - 13 mm (33/64") 6.35 mm (1/4")

Hexagonal bit chuck

Clutch Handle

(Clutch Torque Setting)

Adjust the torque to one of the 21 possible settings to the job. There is an

interval of about 0.13 N·m (1.3 k f-cm

or 1.1 in-lbs) between steps.

CAUTION:

Test the setting before actual operation.

Set the scale at this mark.

Page 8

-

8 -

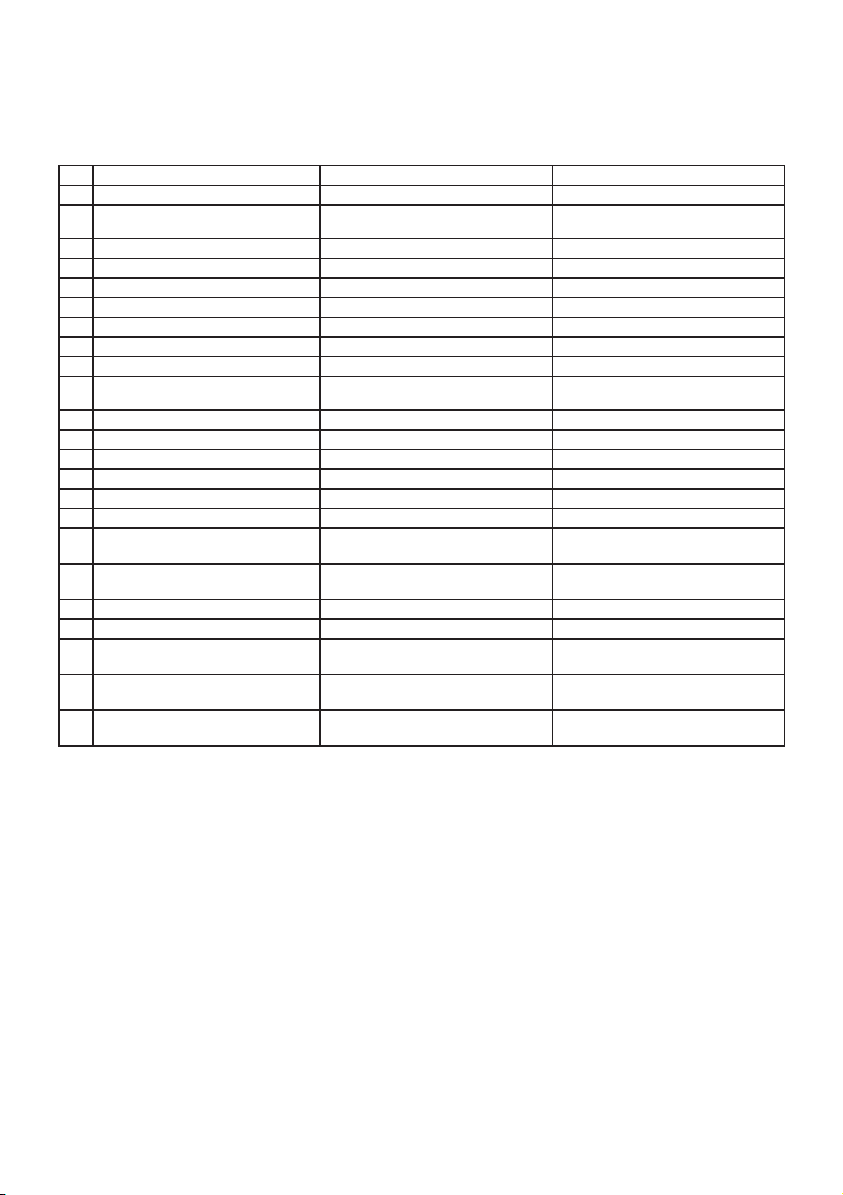

Reference for Adjusting Torque

Setting

1

5

9

13

17

21

Torque Use

Approx: 0.29 N·m

(3.0 kgf-cm or 2.6 in-lbs)

Approx: 0.82 N·m

(8.4 kgf-cm or 7.3 in-lbs)

Approx: 1.35 N·m

(13.8 kgf-cm or 12.0 in-lbs)

Approx: 1.88 N·m

(19.2 kgf-cm or 16.6 in-lbs)

Approx: 2.41 N·m

(24.6 kgf-cm or 21.3 in-lbs)

Approx: 2.94 N·m

(30.0 kgf-cm or 26.0 in-lbs)

Approx: 4.4 N·m

(45.0 kgf-cm or 39.0 in-lbs)

For driving

screws

For powerful driving

screws and

drilling

● When using at high speeds, set the

clutch at 10 or below. (Operation

stops at the maximum torque of 1.5

N·m (15 kgf-cm) when the scale is

higher.)

● The auto shut-off function may

become inoperable at high clutch

settings when battery power drops.

Recharge the battery in that case.

NOTE:

The chart is only a reference. The

torque settings may differ by materials, types of screws, etc. Please test

it at your own conditions before use.

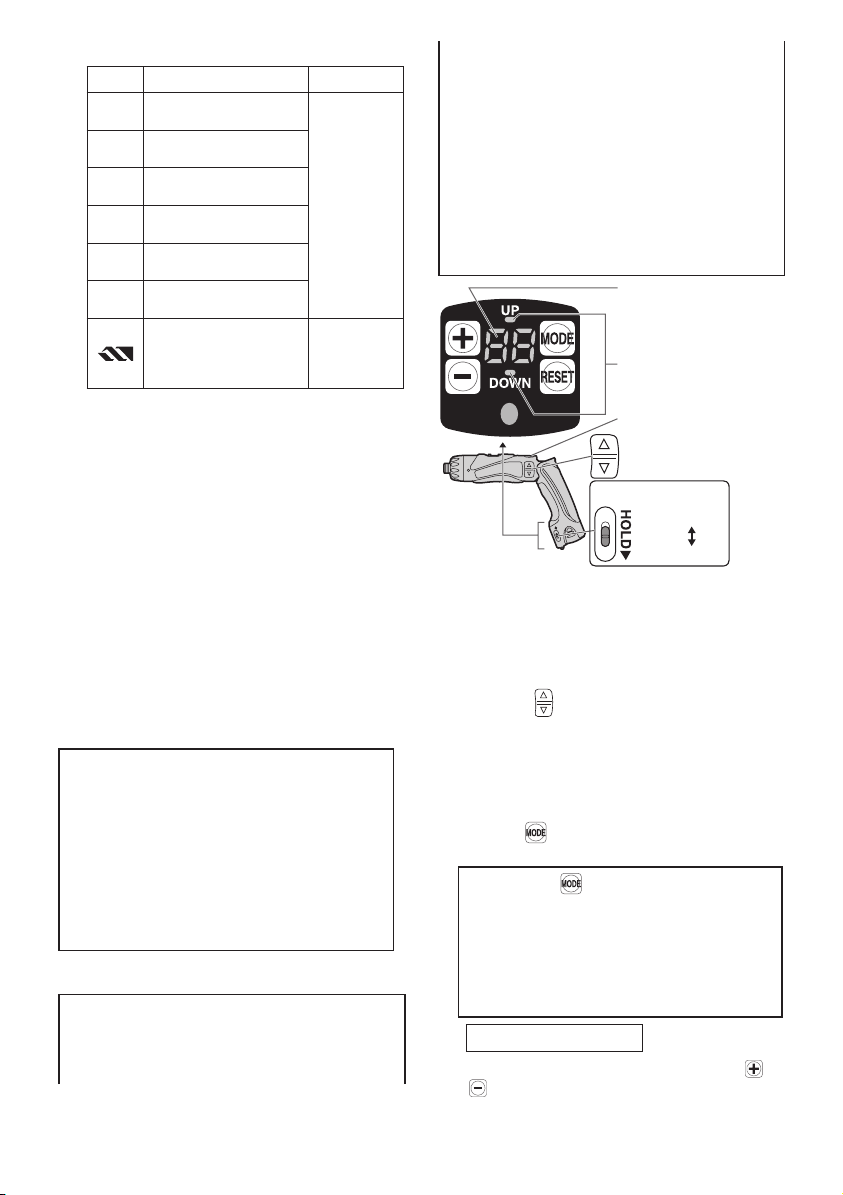

Control Panel

Manufacturer settings upon shipment

●

Count system: Count down system

●

Count setting value: 99

●

Buzzer sound pitch: b1 (Low sound)

●

Double tightening counting preven-

tion count time: 0 (OFF)

●

Hold switch: Released

Please set the settings according to

conditions of use.

Screw count function

● Counts the number of auto stops.

(Counts the number of screws driven)

● The count method can be selected

from “UP” or “DOWN”.

● When the set number of screws to be

driven is reached, a buzzer sounds

and the count value is reset.

● The buzzer sound can be selected

from 3 types of sound.

● Double tightening counting prevention

function

Work (double tightening and screw

driving confirmation, etc.) that began

within the set time is not counted after

the driven screws are counted.

Count display lamp

Count system display

lamp

Lock button

Switch

Hold switch

Release

ON

Starting the control panel

1. Release the hold switch.

2. To illuminate the control panel

1 Release the lock button

2 Press (Control panel is lit.)

●

The count display lamp and “UP” or

“DOWN” are illuminated.

Setting the count functions (Screw

count setting/Count system setting)

1.

Press while the control panel is

illuminated.

Each time is pressed, the screw

count setting and count system setting switch flash.

● Screw count setting

→ Count display lamp flashes.

● Count system setting

→ “UP” or “DOWN” flashes.

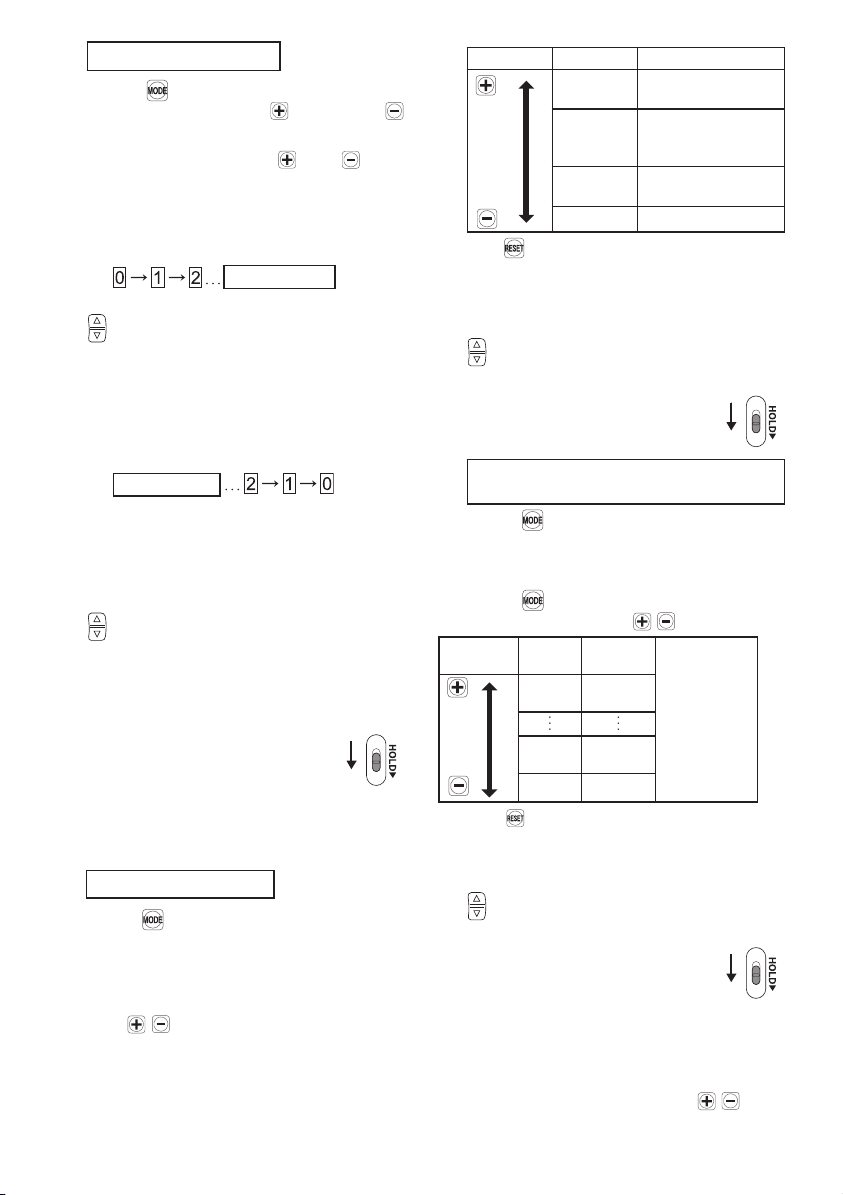

2. Screw count setting

Set the number of screws with

or

.

● The range can be set within 0

– 99.

● 0 is not counted.

Page 9

-

9 -

Count system setting

Press

. “UP” or “DOWN” will begin

to flash. Next select (“UP”) or

(“DOWN”).

Press and hold the ( ) or ( ) but-

●

tons to vary the value continuously.

< Count System “UP” >

● Displays the count for the number

of screws driven.

(

Set number

)

The settings are activated by pushing

.

● When the set number of screws is

reached, the buzzer sounds and

the count value resets to zero.

< Count System “DOWN” >

● Displays the count for the remain

ing number of screws to be driven.

Set number

(

)

● When the set number of screws to

be driven is reached, the buzzer

sounds and the count value resets

to original set number.

3. The settings are activated by pushing

.

● The previous setting will be can

celled and replaced with the new

setting.

4. To prevent changes in the set values

due to operational errors.

● Turn the HOLD switch

to ON.

ON

Convenient function settings (buzzer

sound setting/double tightening

counting prevention time setting)

Buzzer sound setting

1.

Press for 2 or more seconds while

the control panel is illuminated.

● Count display lamp “F1” is illumi

nated.

2. The buzzer sound can be selected

with when “F1” is illuminated.

Operation

Display Sound Frequency

b3 High pitched sound

(Approx. 4 kHz)

b2

Medium pitched

sound (Approx. 3

kHz)

b1 Low pitched sound

(Approx. 2 kHz)

b0 No sound (OFF)

● If is pressed while in the buzzer

mode, the buzzer sound saved

from the previous setting is displayed.

3. The settings are activated by pushing

.

4. To prevent changes in the set values

due to operational errors.

● Turn the HOLD switch

-

to ON.

Double tightening counting prevention time setting

1.

Press for 2 or more seconds while

the control panel is illuminated.

● Count display lamp “F1” is illumi

nated.

2. Press

again to illuminate “F2” and

select the time with .

-

Operation Display

No. of

seconds

30 3

seconds

1 0.1

second

0 OFF

Following the

screw count,

screw driving

within the set

number of

seconds is

not counted.

● If is pressed while in the time

mode, the time setting saved from

the previous setting is displayed.

3.

The settings are activated by pressing

.

4. To prevent changes in the set values

-

due to operational errors.

● Turn the HOLD switch

to ON.

To change the screw count while in

use

1. Release the hold switch.

2. Adjust the count value with

● The displayed number of screws

ON

-

ON

.

Page 10

-

10 -

to be driven can be changed within

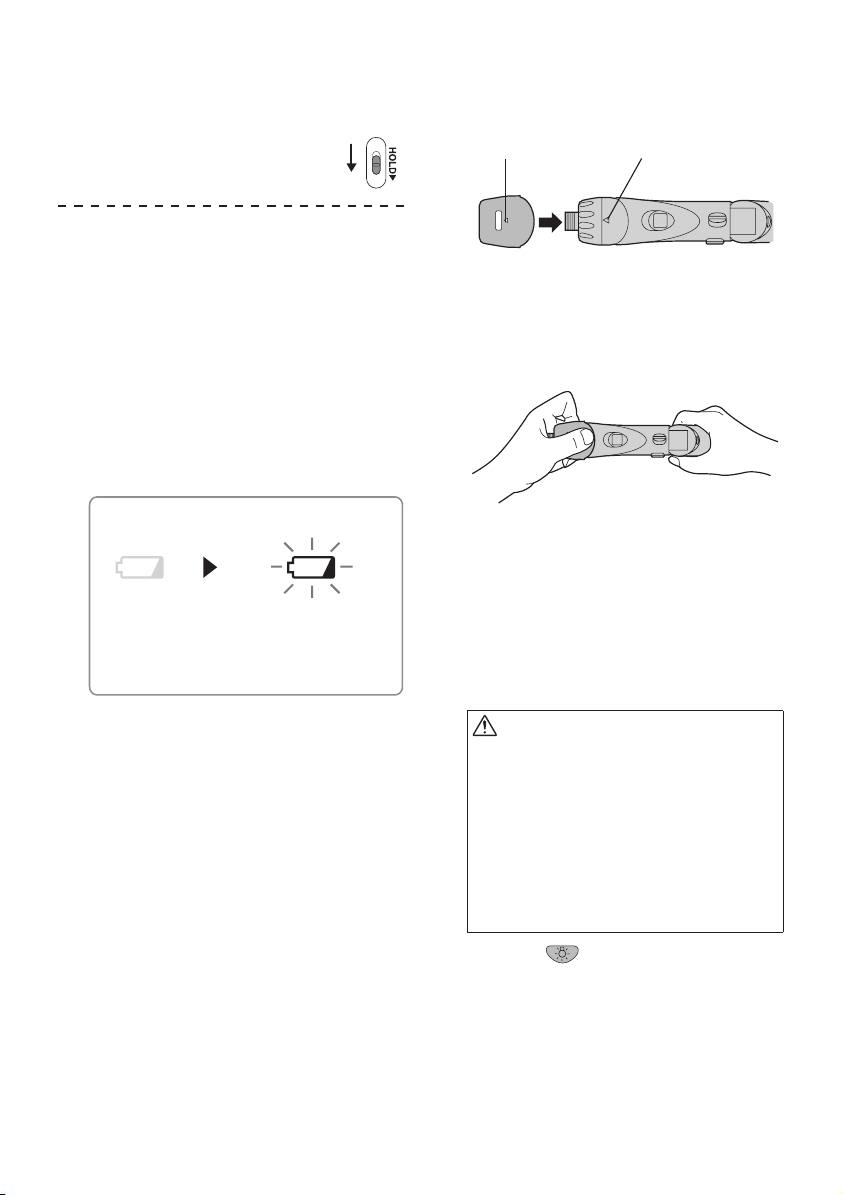

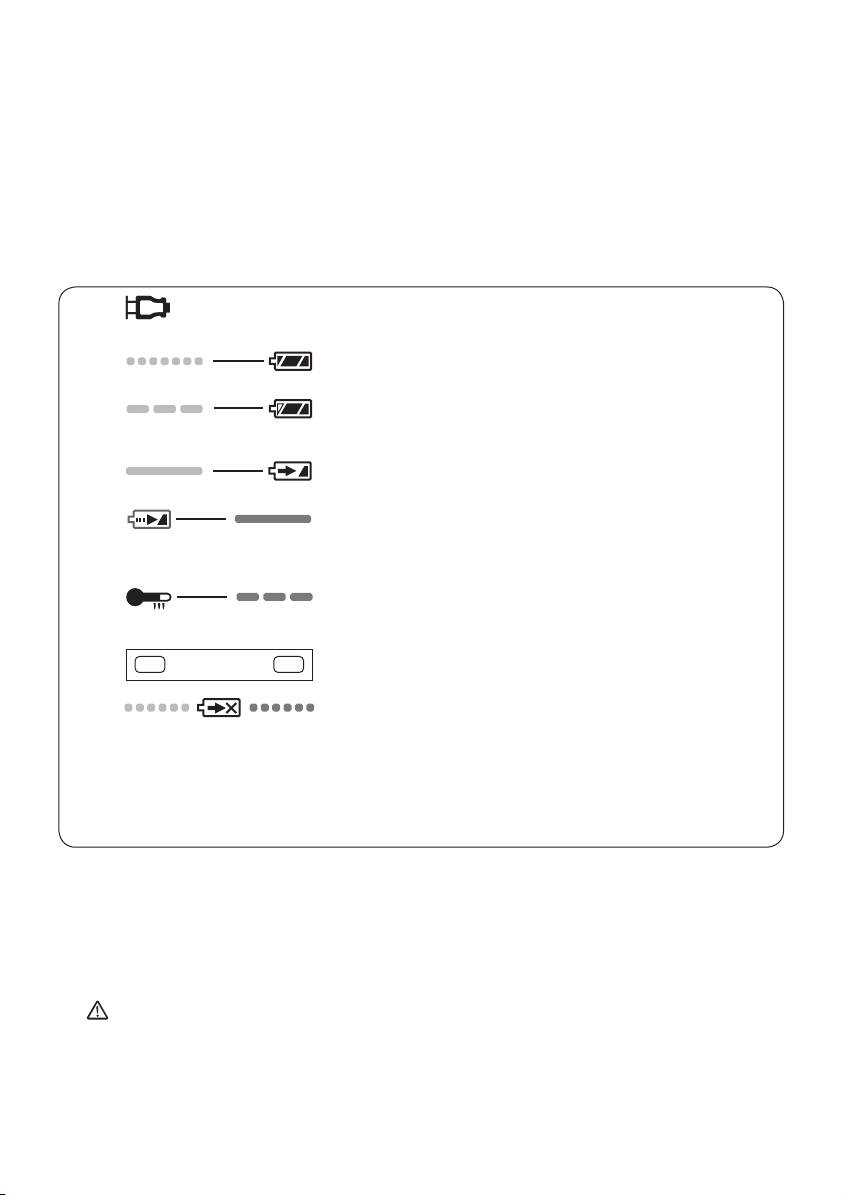

<Battery low warning lamp>

Off

(normal

operation)

Flashing

(No charge)

Battery

protection

feature active

the range of the screw count values.

3. To prevent changes in the set values

due to operational errors.

● Turn the HOLD switch

to ON.

■ While setting, if no operations are

conducted for 60 or more seconds or

when the battery is removed

● Operation for th e set value be

comes invalid.

Please reset the operational values.

■ When batteries are changed while in

use

● When batteries are changed, the

count value is saved. Therefore,

the drill can be used continuously.

Battery Low Warning Lamp

Excessive (complete) discharging of

Li-ion batteries shortens their service

life dramatically. The driver includes a

battery protection feature designed to

prevent excessive discharging of the

battery pack.

● The battery protection feature acti

vates immediately before the battery loses its charge, causing the

battery low warning lamp to flash.

● If you notice the battery low warn

ing lamp flashing, charge the battery pack immediately.

Clutch Lock Cover

The clutch lock cover allows you to

lock the clutch at the selected setting.

Attaching the cover

1. Select the appropriate clutch set

ting for the application.

ON

2. Attach the clutch lock cover.

● Al ign the triangle mark on the

cover with the graduation selection mark on the drill and attach.

Triangle mark Graduation selection

Removing the cover

1. Grip the clutch lock cover with your

fingers on the mark and the bottom of the cover, then push in and

twist to remove.

● It will be difficult to remove the

clutch lock cover from the drill if

you push on the side of the cover

while pulling it off.

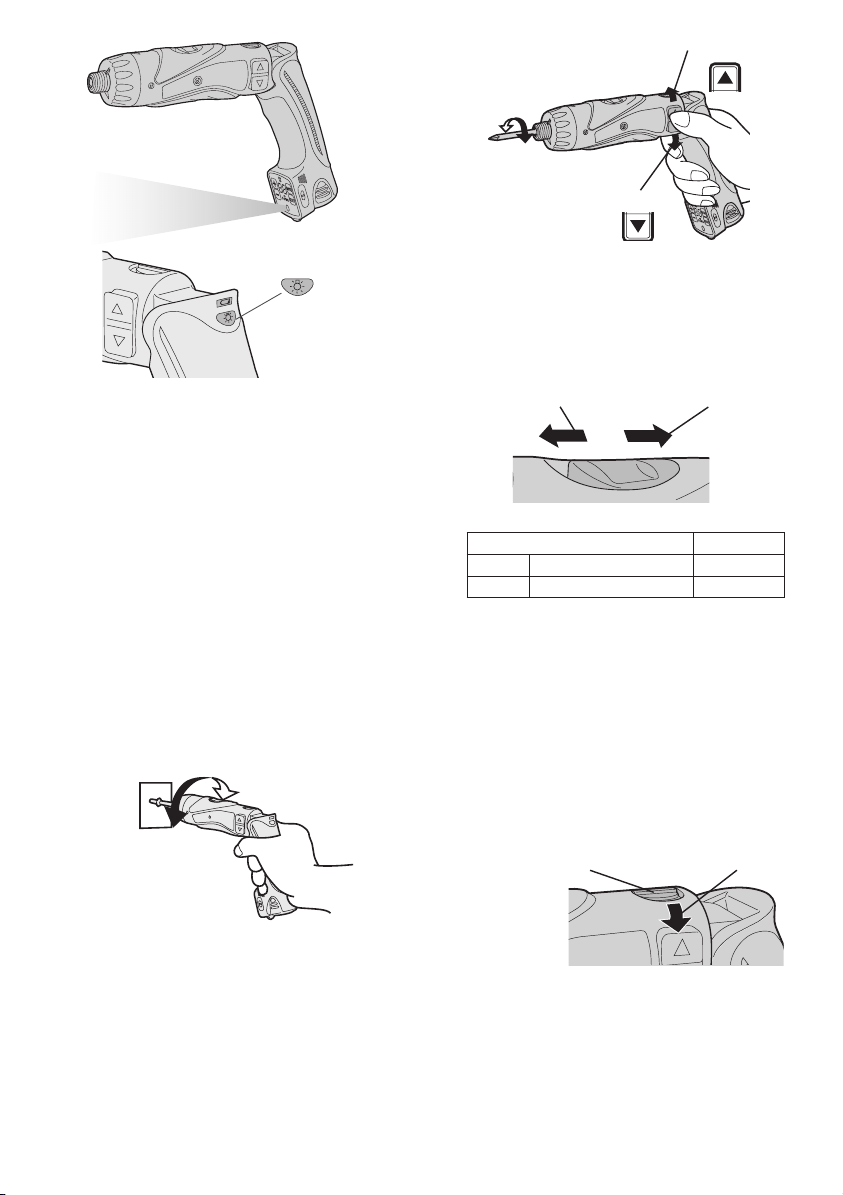

Using the LED Light

Use the LED light on jobs in dark

locations such as attics to illuminate

your workspace.

CAUTION

● The LED light is intended for use as

a supplemental light source. Do not

use it as a ashlight.

Doing so may result in accident or

-

-

-

injury.

● Do not look at the light or shine it

directly into your eyes.

Continuous exposure to the LED

light may damage your eyes.

1. Press to toggle the light on

and off.

● To use the light immediately after

attaching the battery pack or after

the drill has not been used for 5

minutes or more, operate the drill

briefly.

mark

Page 11

-

11 -

● The light will automatically turn

off if the drill is not used for 5

minutes.

● The light uses an extremely small

amount of current. Using the light

has a negligible effect on the

operational capacity of the drill.

● The LED is incapable of lighting

the tip of the bit when the drill is

used in the straight conguration.

Forward

Forward

Reverse

Reverse

Speed Selector Switch

To suit the application of this tool, two

different rotational speeds are available. Depending upon use, either the

high or low speed should be selected.

HIGH

Speed selection Torque

LOW 200 min-1 (rpm) High

HIGH 600 min-1 (rpm) Low

LOW

Bit-locking Function

With the switch at off and the bit locked in place, the tool can be used as a

manual screw-driver - up to 14.7 N·m

(150 kgf-cm, 130 in-lbs).

There will be a little play in the driving

shaft, but this is not a malfunction.

Main Switch (ON/OFF)

Push the upper half of the switch for

forward rotation, or the lower half for

reverse rotation.

CAUTION:

• Check speed selector switch before

use.

• Do not operate the speed selector

switch while the main switch is on

(switch is in the ON position).

Main Switch Lock

After use, set the main switch lock at

the lock position to prevent accidental

operation.

Main switch lock

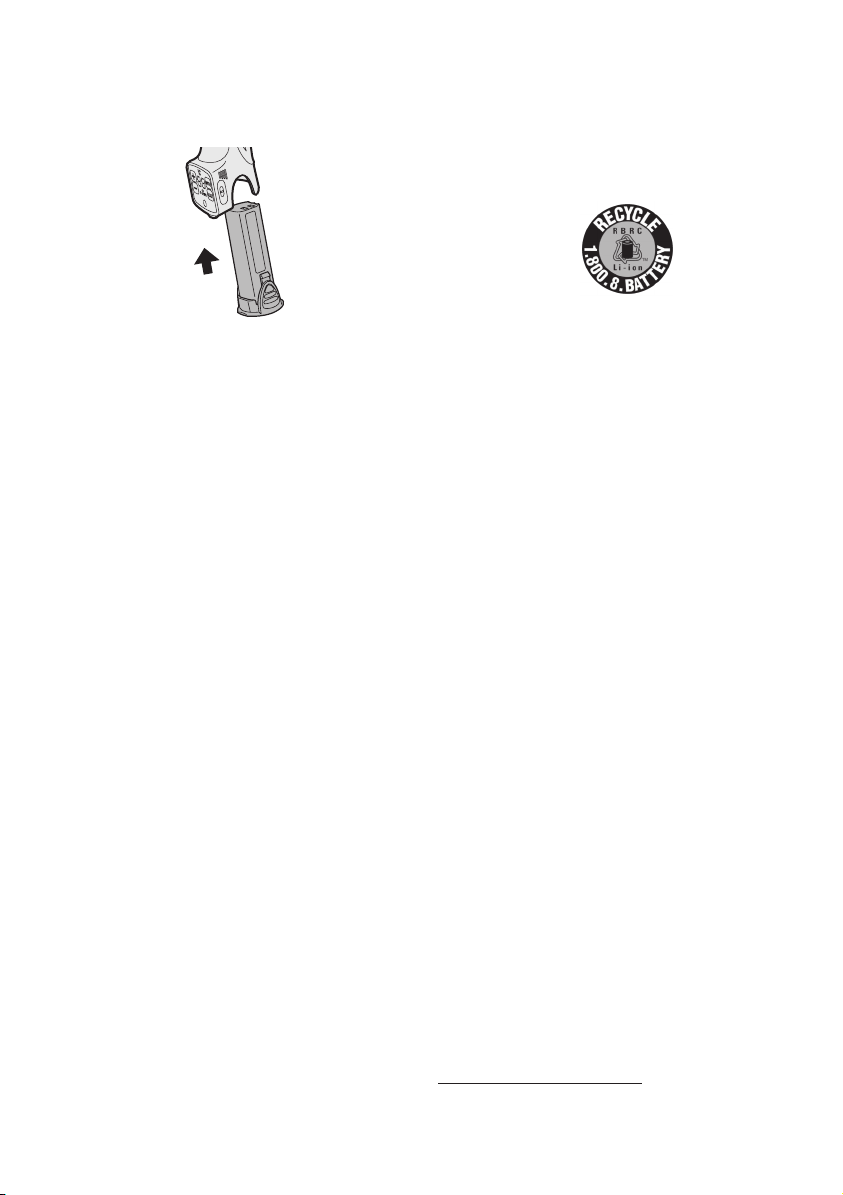

Battery Pack (EY9L10)

CAUTION:

1. Remove the battery pack away from

the tool.

2. Charge the battery pack using the

battery charger.

Lock

Page 12

-

12 -

3. After charging has been completed,

remove the battery pack from the

charger and connect it to the tool.

Disconnect the charger from the

power source when not in use.

Battery Recycling

ATTENTION:

FOR Li-ion Battery Pack, EY9L10

A Li-ion battery that is recyclable powers

the product you have purchased.

Please call 1-800-8-BATTERY for information on how to recycle this battery.

NOTE:

Use under extremely hot or cold

conditions will reduce operating

capacity per charge.

[Battery Pack]

For Appropriate Use of Bat-

tery pack

Li-ion Battery pack (EY9L10)

• For optimum battery life, store the Liion battery pack following use without

charging it.

• The ambient temperature range is

between 0°C (32°F) and 40°C (104°F).

If the battery pack is used when the

battery temperature is below 0°C

(32°F), the tool may fail to function

properly.

• When battery pack is not in use,

keep it away from other metal objects

like: paper clips, coins, keys, nails,

screws, or other small metal objects

that can make a connection from one

terminal to another.

Shorting the battery terminals togeth-

er may cause sparks, burns or a fire.

• When operating the battery pack,

make sure the work place is well ventilated.

Battery Pack Life

The rechargeable batteries have

a limited life. If the operation time

becom e s e x t remely sh o r t a fter

recharging, replace the battery pack

with a new one.

[Battery Charger]

Charging

Common Cautions for the Liion/Ni-Cd Battery Pack

NOTE:

• When a cold battery (of about 0°C

or less) is to be charged in a warm

room, leave the battery in the room

for at least one hour and charge

it when it has warmed up to room

temperature. (Failing to do so may

result in less than a full charge.)

•

Cool down the charger when charging

more than two battery packs consecutively.

• Do not insert your fingers into contact hole, when holding charger or

any other occasions.

CAUTION:

To prevent the risk of fire or damage

to the battery charger.

• Do not use power source from an

engine generator.

• Do not cover vent holes on the

charger and the battery pack.

• Unplug the charger when not in

use.

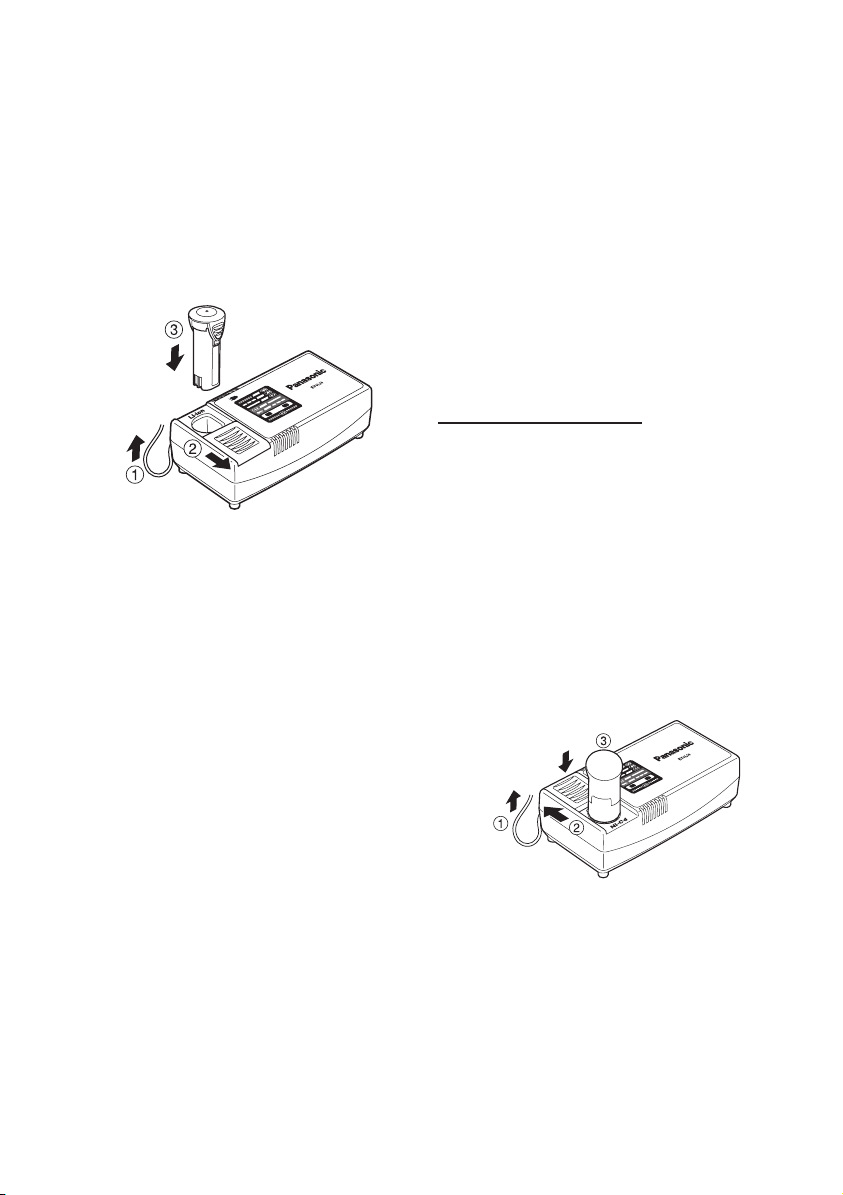

Li-ion Battery Pack

NOTE:

Your battery pack is not fully charged at the time of purchase. Be sure

to charge the battery before use.

Battery charger (EY0L10)

1. Plug the charger into the AC outlet.

Page 13

-

13 -

NOTE:

Sparks may be produced when the

plug is inserted into the AC power

supply, but this is not a problem in

terms of safety.

2. Slide the battery dock cover back to

allow insertion of the Li-ion battery

pack.

● Verify that the cover is locked se

curely in place.

3. Insert the battery pack firmly into the

charger.

To AC

outlet

4. During charging, the charging lamp

will be lit.

When charging is completed, an internal electronic switch will automatically

be triggered to prevent overcharging.

• Charging will not start if the battery

pack is warm (for example, immediately after heavy-duty operation).

The orange standby lamp will be

flashing until the battery cools down.

Charging will then begin automati

cally.

5.

The charge lamp (green) will flash

slowly once the battery is approximately 80% charged.

6.

When charging is complet ed, the

charging lamp will start flashing quickly

in green color.

7. If the temperature of the battery pack

is 0°C or less, charging takes longer to

fully charge the battery pack than the

standard charging time. Even when

the battery is fully charged, it will have

approximately 50% of the power of a

fully charged battery at normal operating temperature.

8. If the power lamp does not light immediately after the charger is plugged

in, or if after the standard charging

time the charging lamp does not flash

quickly in green, consult an authorized

dealer.

9. If a fully charged battery pack is inserted into the charger again, the

charging lamp lights up. After several

minutes, the charging lamp may flash

quickly to indicate the charging is

completed.

Ni-Cd Battery Pack

NOTE:

When you charge the battery pack

for the first time, or after prolonged

storage, charge it for ab out 24

hours to bring the battery up to full

capacity.

Battery charger (EY0L10)

1. Plug the charger into the AC outlet.

NOTE:

Sparks may be produced when the

plug is inserted into the AC power

supply, but this is not a problem in

terms of safety.

2. Slide the battery dock cover back to

allow insertion of the Ni-Cd battery

pack.

● Verify that the cover is locked securely

in place.

3. Insert the battery pack firmly into the

-

charger.

To AC

outlet

4.

During charging, the charging lamp will

be lit.

When charging is completed, an internal electronic switch will automatically

be triggered to prevent overcharging.

• Charging will not start if the battery

pack is warm (for example, immediately after heavy-duty operation).

The orange standby lamp will be

flashing until the battery cools down.

Charging will then begin automatically.

Page 14

-

14 -

5. When charging is completed, the

charging

ly in green color.

6. If the power lamp does not light im

mediately after the charger is plugged in, or if after the standard charging time the charging lamp does not

flash quickly in green, consult an authorized dealer.

lamp will start flashing quick-

LAMP INDICATIONS

Green Lit

Charger is plugged into the AC outlet.

Ready to charge.

Green Flashing Quickly

Charging is completed. (Full charge for Li-ion or Ni-cd.)

Green Flashing

Battery is approximately 80% charged. (Usable charge.

Li-ion only)

Green Lit

Now charging.

Orange Lit

Battery pack is cool.

The battery pack is being charged slowly to reduce the

load on the battery. (Li-ion only)

Orange Flashing

Battery pack is warm. Charging will begin when temperature of battery pack drops.

Charging Status Lamp

Left: green Right: orange will be displayed.

Both Orange and Green Flashing Quickly

Charging is not possible. Clogged with dust or malfunction of the battery pack.

If the temperature of the battery pack is –10°C or less,

the charging status lamp (orange) will also start ashing.

Charging will begin when the temperature of the battery

pack goes up (Li-ion only)

7. If a fully charged battery pack is inserted into the charger again, the

charging lamp lights up. After several

-

minutes, the charging lamp may flash

quickly to indicate the charging is

completed.

V

. MAINTENANCE

Use only a dry, soft cloth for wiping the unit. Do not use a damp cloth, thinner, benzine, or other volatile solvents for cleaning.

VI

. ACCESSORIES

CAUTION:

To prevent the risk of injury, only use accessory or attachment for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your

local service center.

• EY9X007E

Clutch lock cover

Page 15

-

15 -

Use only bits suitable for size of drill’s

chuck.

V

II

. SPECIFICATIONS

9.5 mm (3/8") –

13 mm (33/64")

MAIN UNIT

Model EY7411

Capacity

Motor 3.6 V DC

No load speed

Maximum clutch torque 3.0 N·m (30 kgf-cm, 26 in-lbs)

Overall length 283 mm (11-5/32")

Weight (with battery pack) 0.5 kg (1.1 lbs)

Screw driving

Drilling For metal ø 5 mm (13/64") spc t = 1.6 mm

Machine screw M2.5 - M5

Wood screw ø 3.8 × 38 mm (5/32" × 1-29/64")

-1

LOW: 200 min

HIGH: 600 min-1 (rpm)

(rpm)

BATTERY PACK

Model EY9L10

Storage battery Li-ion Battery

Battery voltage 3.6 V DC (3.6 V × 1 cell)

Capacity 1.5 Ah

6.35 mm

(1/4")

BATTERY CHARGER

Model EY0L10

Weight 0.6 kg (1.3 lbs)

Electrical rating See the rating plate on the bottom of the charger.

2.4 V

1.2 Ah

Charging time

1.5 Ah

NOTE:

• For applicable battery packs to this charger, see the label on the charger or the

latest general catalog.

The instruction label on the battery packs also shows the applicable charger.

EY9021

Full: 15 min.

3.6 V

EY9025

Full: 15 min.

EY9L10

Usable: 15 min.

Full: 30 min.

Page 16

-

16 -

I

.

CONSIGNES DE SECURITE GENERALES

AVERTISSEMENT! Veuillez lire tou-

tes les instructions.

Si les instructions détaillées ci-dessous ne

sont pas observées, cela peut entraîner une

électrocution, un incendie et/ou des blessures

graves. Le terme “outil mécanique” utilisé dans

tous les avertissements ci-dessous se réfère

aux outils mécaniques opérés par cordons

d'alimentation et par batterie (sans l).

CONSERVEZ CES INSTRUCTIONS

Sécurité de la zone de travail

1) Gardez la zone de travail propre et

bien aérée.

Les endroits encombrés et sombres invitent les accidents.

Ne faites pas fonctionner les outils

2)

mécaniques dans des atmosphères

explosives, comme en présence de

liquides inflammables, de gaz ou de

poussière.

Les outils mécaniques génèrent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

Gardez les enfants et les spectateurs

3)

éloignés lors du fonctionnement d’un

outil mécanique.

Les distractions peuvent en faire perdre le

contrôle.

Sécurité électrique

1) La fiche des outils mécaniques doit

correspondre aux prises secteur. Ne

modifiez la fiche sous aucun prétexte.

N’utilisez pas de fiche adaptatrice

avec les outils mécaniques mis à la

terre.

Des fiches non modifiées et des prises

secteur correspondant réduisent les

risques d’électrocution.

2)

Evitez tout contact physique avec les

surfaces mises à la terre telles que

tuyaux, radiateurs, micro-ondes et

réfrigérateurs.

Il y a un risque d’électrocution supplémentaire si votre corps est mis à la terre.

3) N’exposez pas les outils mécaniques à

la pluie ou à des conditions humides.

De l’eau pénétrant dans un outil mécanique augmente le risque d’électrocution.

Ne malmenez pas le cordon. N’utilisez

4)

jamais le cordon pour transporter,

pour tirer ou pour débrancher l’outil

mécanique. Gardez le cordon éloigné

de la chaleur, de l’huile, d'objets aux

bords coupants ou de pièces en mouvement.

Les cordons endommagés on emmêlés

augmentent le risque d'électrocution.

5)

Lors du fonctionnement des outils mécaniques à l’extérieur, utilisez une rallonge

adaptée à l’utilisation à l’extérieur.

L’utilisation d’un cordon adapté à l’utilisation à l’extérieur réduit les risques d’électrocution.

Sécurité personnelle

1) Restez alerte, regardez ce que vous

faites et faites preuve de bon sens

lorsque vous utilisez un outil mécanique. N’utilisez pas un outil mécanique alors que vous êtes fatigué ou

sous les effets de drogue, d’alcool ou

de médicaments.

Un moment d’inattention pendant que

vous faites fonctionner l’outil mécanique

peut entraîner des blessures graves.

2)

Utilisez des équipements de sécurité.

Portez toujours des protection pour

vos yeux.

Des équipements de sécurité comme

ma sque antipou ssière, chaussur es

de sécurité non glissantes, casque de

protection ou protections d’oreilles,

utilisés dans des conditions appropriées

réduisent les blessures corporelles.

3)

Evitez tout démarrage accidentel.

Assurez-vous que l

en position d'arrêt avant de brancher

l’outil.

Le transport d’outils mécaniques avec le

doigt sur l’interrupteur ou le branchement

d’outils mécaniques dont l’interrupteur

est sur la position de marche invite les

accidents.

4)

Retirez toute clé d’ajustement ou

clé de serrage avant de mettre l’outil

mécanique en marche.

Une clé de serrage ou une clé d’ajusteme nt laissée attachée à un e pièce

tournante de l’outil mécanique peut

entraîner des blessures corporelles.

5)

Ne vous mettez pas en déséquilibre.

Gardez une bonne prise au sol et votre

équilibre à tout moment.

Ceci permet un meilleur contrôle de l’outil

mécanique dans des situations inattendues.

’interrupteur est

Page 17

-

17 -

6) Habillez-vous correctement. Ne portez

pas de vêtements lâches ou de bijoux.

Gardez vos cheveux, vêtements et

gants éloignés des pièces en mouvement.

Des vêtements lâches, des bijoux ou

des cheveux longs peuvent se faire

prendre dans les pièces en mouvement.

7)

Si des dispositifs pour la connexion

d’appareils d’extraction et de ramassage de la poussière sont fournis,

assurez-vous qu

correctement utilisés.

L’utilisation de ces dispositifs peut réduire

les risques concernés.

’ils sont connectés et

Utilisation et soins de l’outil mécanique

1)

Ne forcez pas l’outil mécanique. Utilisez

l’outil mécanique correct pour votre

application.

L’outil mécanique correct exécute mieux

le travail dans de meilleurs conditions

de sécurité s’il est utilisé à l’allure pour

laquelle il a été conçu.

2)

N’utilisez pas l’outil mécanique si l’interrupteur ne le met pas en marche ou ne

l’arrête pas.

Tout outil mécanique qui ne peut pas

être contrôlé par son interrupteur est

dangereux et doit être réparé.

3)

Débranchez la fiche de la source d’alimentation et/ou du bloc de batterie

avant d’effectuer tout ajustement, de

changer d’accessoire ou de ranger

l’outil mécanique.

De telles mesures de sécurité préventives

réduisent les risques de faire démarrer

l’outil mécanique accidentellement.

4)

Rangez les outils mécaniques inutilisés hors de la portée des enfants

et ne laissez personne qui n’est pas

familiarisé avec l’outil mécanique ou

ses instructions faire fonctionner l’outil

mécanique.

Les outils mécaniques sont dangereux

dans les mains des utilisateurs manquant

d’entraînement.

5) Entretenez bien les outils mécaniques.

Vérifiez l’alignement ou l’emboîtage

des pièces en mouvement, l’intégrité

des pièces et toute autre condition

pouvant affecter le fonctionnement de

l’outil mécanique. S’il est endommagé,

faites réparer l’outil mécanique avant

de l’utiliser.

De nombreux accidents sont provoqués

par des outils mécaniques mal entretenus.

6)

Maintenez les outils de coupe affûtés

et propres.

Les outils de coupe bien entretenus

avec des lames bien affûtées ont moins

de chances de gripper et sont plus

faciles à contrôler.

7)

Utilisez l’outil mécanique, les accessoires, les mèches, etc., conformément à ces instructions et de la façon

pour laquelle l’outil particulier a été

conçu en tenant compte des conditions de travail et de la tâche à exécuter.

L’utilisation de l’outil mécanique à des

fins autres que celles pour lesquelles

il a été conçu peut présenter une situation à risque.

Utilisation et soins de la batterie

de l’outil

1) Assurez-vous que l’interrupteur est

dans la position d’arrêt avant d’insérer

le bloc de batterie.

L’insertion du bloc de batterie dans un

outil mécanique dont l’interrupteur est

sur la position de marche peut provoquer

des accidents.

2) N

’effectuez la recharge qu’avec le

chargeur spécifié par le fabricant.

Un chargeur convenant à un bloc de batterie peut entraîner un risque d’incendie

lorsqu’un autre bloc de batterie est

utilisé.

3)

N’uti lisez les out ils mécaniqu es

qu’avec les bloc de batterie spécialement conçus pour eux.

L’utilisation de tout autre bloc de batterie peut entraîner un risque de blessure et d’incendie.

4)

Lorsqu’un bloc de batterie n’est pas

utilisé, gardez-le éloigné d

liques comme agrafes, pièces de monnaie, clés, clous, vis ou tout autre petit

objet métallique pouvant établir une

connexion entre les deux bornes.

Si les bornes de la batterie sont mises

en court-circuit, cela peut entraîner des

brûlures ou un incendie.

Si elle est malmenée, du liquide peut

5)

s’échapper de la batterie. Evitez tout

contact. Si un contact accidentel se

produit, rincez à l’eau. Si du liquide

’objets métal-

Page 18

-

18 -

entre en contact avec les yeux, consultez un médecin.

Le liquide éjecté de la batterie peut

entraîner des irritations ou des brûlures.

Réparation

1) Faites réparer votre outil mécanique

par du personnel de réparation qualifié en n’utilisant que des pièces de

rechange identiques.

Ceci assure le maintien de la sécurité

de l’outil mécanique.

II

.

REGLES DE SECURITE

PARTICULIERES

1) Portez des lunettes lorsque vous utilisez l’outil pendant de longues périodes.

L’exposition prolongée à du bruit de

haute densité peut entraîner la perte de

l’ouïe.

2)

N’oubliez pas que cet appareil est toujours prêt à fonctionner, parce qu’il ne

doit pas être branché dans une prise

électrique.

3)

Tenez l’outil par les surfaces de prise

isolées lorsque vous effectuez une

opération lors de laquelle l’outil de

coupe risque d’entrer en contact avec

des câblages cachés.

Le contact avec un fil sous tension fera

passer le courant dans les pièces métalliques exposées et électrocutera l’opérateur.

4) Si la mèche est coincée, mettez immédiatement le commutateur de la gâchette

hors tension afin de prévenir une surcharge pouvant endommager la batterie

autonome ou le moteur. Dégagez la

mèche en inversant le sens de rotation.

5) Ne touchez pas les pièces rotatives pour

éviter toute blessure.

6) N’utilisez pas l’outil continuellement pen-

dant une longue période. Arrêtez d’utiliser

l’outil de temps en temps pour éviter une

augmentation de la température et de

surchauffer le moteur.

7) Ne laissez pas tomber l’outil.

Symbole Signication

V

n

0

… min

Ah

Tours ou mouvements alternatifs

-1

Capacité électrique de la batterie

Volts

Courant continu

Vitesse sans charge

par minute

autonome

Rotation seulement

AVERTISSEMENT!

La poussière résultant de ponçage, sciage,

meulage, perçage à haute pression et de

toute autre activité de construction, contient

des produits chimiques réputés être cause

de cancer, de malformations congénitales ou

autres problèmes reproductifs. Ces produits

chimiques sont, par exemple :

• Le plomb contenu dans les peintures à

base de plomb

• La silice cristalline, contenue dans les

briques, le ciment et autres produits de

maçonnerie; et

• L’arsenic et le chrome provenant du

bois traité chimiquement.

Pour réduire l’exposition à ces produits

chimiques, il faut travailler dans un lieu bien

aéré et porter un équipement de sécurité

approprié tel que certains masques antipoussière conçus spécialement pour filtrer

les particules microscopiques.

III

.

CHARGEUR DE BATTERIE ET BATTERIE

AUTONOME

Instructions de sécurité importantes

1) CONSERVEZ CES INSTRUCTIONS

– La présente notice contient des ins-

tructions de sécurité et d’utilisation

importantes pour le chargeur de batterie

EY0L10.

2) Avant d

rie, lisez toutes les instructions et les

marques d’avertissement figurant sur

’utiliser le chargeur de batte-

Page 19

-

19 -

le chargeur de batterie, la batterie autonome et le produit utilisant la batterie

autonome.

3)

MISE EN GARDE

– Pour réduire le ris-

que de blessures, chargez la batterie

autonome Panasonic seulement comme

indiqué à la dernière page.

Les autres types de batteries risquent

d’exploser et de causer des blessures

corporelles et des dommages matériels.

’exposez pas le chargeur à la pluie ou

4) N

à la neige.

5) Pour réduire les risques de dommages

à la fiche et au cordon secteur, débranchez le chargeur en tirant la fiche et non

le cordon.

6) Veillez à acheminer le cordon de façon

que personne ne risque de le piétiner,

de trébucher dessus, d’endommager ou

d’étirer le cordon.

’utilisez une rallonge qu'en cas de né-

7) N

cessité absolue.

Si vous utilisez une rallonge inadéquate,

vous risquez de causer un incendie ou

une électrocution. Si vous devez absolument utiliser une rallonge, veillez à respecter les points suivants:

a.

Le nombre, la taille et la forme des

broches de la fiche de la rallonge doivent être identiques à ceux de la fiche du

chargeur de batterie.

b.

La rallonge doit avoir des conducteurs

en bon état et être elle-même en bon

état d'utilisation.

c.

La taille des conducteurs doit être suffisante pour les normes d'intensité en

ampères du chargeur, comme indiqué

ci-dessous.

TAILLE AWG MINIMUM RECOMMANDÉE DES

RALLONGES POUR CHARGEURS

Norme d’entrée CAAmpères Taille AWG du

Egal ou

supérieur à

0 2 18 18 18 16

DE BATTERIES

Mais

inférieur à

cordon

Longueur du

cordon, pieds

25

50 100 150

8) N’utilisez pas un chargeur dont la fiche

ou le cordon est endommagé – rem

placez-les immédiatement.

’utilisez pas le chargeur s’il a reçu un

9) N

choc violent, s'il a subi une chute ou s’il

a été endommagé de quelque manière

que ce soit; confiez-le à un technicien

qualifié.

10) Ne démontez pas le chargeur; si des

travaux d’entretien ou de réparation sont

nécessaires, confiez-le à un technicien

qualifié. Si vous le remontez incorrectement, vous risquez de causer une électrocution ou un incendie.

11) Pour réduire le risque d

’électrocution, débranchez le chargeur de la prise de courant avant d’entreprendre des travaux

d’entretien ou de nettoyage.

12) Le chargeur et la batterie autonome ont

été conçus spécifiquement pour fonctionner ensemble.

Ne tentez pas de charger un autre outil à

batterie ou une autre batterie autonome

avec ce chargeur.

13) Ne tentez pas de charger la batterie au

tonome avec un autre chargeur.

14) Ne tentez pas de démonter le logement

de la batterie autonome.

15) Ne rangez pas l

’outil ou la batterie autonome à des endroits où la température

est susceptible d'atteindre ou de dépasser 50°C (122°F) (par exemple dans

une remise d’outils électriques, ou dans

une voiture en été), car ceci risquerait

d'abîmer la batterie stockée.

Ne chargez pas la batterie autonome

16)

lorsque la température est INFÉRIEURE

À 0°C (32°F) ou SUPÉRIEURE à 40°C

(104°F). Ceci est très important pour conserver le bon état de fonctionnement de

la batterie autonome.

’incinérez pas la batterie autonome.

17) N

Elle risquerait d'exploser dans les flammes.

18) Evitez toute utilisation dans un environnement dangereux. N’utilisez pas le

chargeur à un endroit humide ou mouillé.

19) Le chargeur a été conçu pour fonction

ner uniquement sur des prises secteur

domestiques standard. Ne l’utilisez pas

sous des tensions différentes!

20) Ne manipulez pas brutalement le cor

don secteur. Ne transportez jamais le

chargeur en le tenant par le cordon, ou

ne le tirez pas brutalement pour le débrancher de la prise. Gardez le cordon à

l’abri de la chaleur, de l’huile et de bords

-

coupants.

Chargez la batterie autonome à un en-

21)

droit bien ventilé; ne couvrez pas le chargeur et la batterie autonome avec un chiffon, etc., pendant la charge.

Si vous utilisez un accessoire non recom-

22)

mandé, un incendie, une électrocution,

des blessures risqueraient de s’ensuivre.

-

-

-

Page 20

-

20 -

23) Ne court-circuitez pas la batterie autonome. Un court-circuit de la batterie

risquerait de faire passer un courant de

forte intensité, et une surchauffe, un incendie ou des blessures risqueraient de

s'ensuivre.

24) REMARQUE: Si le cordon secteur de

cet appareil est endommagé, il doit être

remplacé exclusivement dans un atelier

agréé par le fabricant, car ces travaux

exigent l’utilisation d’outils spéciaux.

25) POUR R É D U I R E L E S RISQUES

D’ÉLECTROCUTION, CET APPAREIL

EST ÉQUIPÉ D’UNE FICHE POLARISÉE (UNE LAME EST PLUS LARGE

QUE L’AUTRE).

Cette fiche ne pourra être insérée que

d'une seule façon dans une prise polarisée. Si la fiche ne peut pas être insérée

à fond dans la prise, insérez la fiche

sens dessus dessous. Si vous ne parvenez toujours pas à insérer la fiche, adressez-vous à un électricien qualifié pour

installer une prise de courant adéquate.

Ne modifiez la fiche en aucune façon.

IV

.

ASSEMBLAGE &

FONCTIONNEMENT

Mandrin de mèche hexagonal

Fixation des mèches

REMARQUE:

Lors de la fixation ou de l’enlèvement de mèches de perceuse, débranchez la batterie autonome de

l’outil et mettez le bouton de verrouillage dans la position verrouillée.

1. Maintenez le collier du mandrin de

connexion rapide et retirez-le de la

perceuse.

2. Insérez la mèche dans le mandrin.

Relâchez le collier.

3. Le collier reviendra dans sa position

d’origine lorsqu’il sera relâché.

4. Tirez sur la mèche pour vérifier qu’elle

ne ressort pas.

5. Pour retirer la mèche, tirez le collier

vers l’extérieur de la même manière.

Mèche

Mandrin de mèche hexagonal

9,5 mm (3/8") - 13 mm (33/64") 6,35 mm (1/4")

Poignée de l’embrayage

(Réglage du couple de ser-

rage de l’embrayage)

Ajustez le couple de serrage sur l’un

des 21 réglages possibles pour le tra

vail. Il y a un intervalle d’environ 0,13

N·m (1,3 kgf/cm ou 1,1 po-lbs) entre

chaque étape.

MISE EN GARDE:

Essayez le réglage avant l’utilisation effective.

Réglez l’échelle sur cette marque.

-

Page 21

-

21 -

Références pour l’ajustement du

couple de serrage

Réglage

Couple de serrage Utilisation

Environ 0,29 N·m

1

kgf/cm ou 2,6 po-lbs)

Environ 0,82 N·m (8,4

5

kgf/cm ou

Environ 1,35 N·m

9

kgf/cm ou 12,0 po-lbs)

Environ 1,88 N·m

13

kgf/cm ou 16,6 po-lbs)

Environ 2,41 N·m

17

kgf/cm ou 21,3 po-lbs)

Environ 2,94 N·m

21

kgf/cm ou 26,0 po-lbs)

Environ 4,4 N·m (45,0

kgf/cm ou

7,3

39,0

po-lbs

po-lbs

(3,0

)

(13,8

(19,2

(24,6

(30,0

)

Pour visser

des vis

Pour un

vissage et

un perçage

puissants

● Lors de l’utilisation à hautes vitesses,

réglez l’embrayage sur 10 ou plus

bas. (Le fonctionnement s’arrête au

couple de serrage maximum de 1,5

N·m (15 kgf/cm) lorsque l’échelle est

plus élevée.)

● La fonction d’arrêt automatique

peut ne pas fonctionner à des réglages de l’embrayage plus élevés

lorsque la puissance de la batterie

diminue. Dans ce cas, rechargez la

batterie.

REMARQUE:

Le tableau n’est qu’une référence.

Le réglage du couple de serrage

peut différer selon les matériaux, le

type des vis, etc. Veuillez effectuer

des essais de vos conditions particulières avant l’utilisation.

Panneau de commande

Réglages du fabricant à l’expédition

●

Système de comptage: système de

compte à rebours

●

Valeur de réglage du compte: 99

●

Force de l’alarme: b1 (son bas)

●

Double serrage empêchant la durée

du compte: 0 (OFF)

●

Sélecteur de pause: dégagé

Veuillez effectuer les réglages en

fonction des conditions d’utilisation.

Fonction de comptage des vis

● Compte le nombre d’arrêts automatiques. (Compte le nombre de vis vissées)

● La méthode de comptage peut être

sélectionnée entre “UP” (haut) ou

“DOWN” (bas).

● Lorsque le nombre de vis devant être

vissées est atteint, l’alarme retentit et

la valeur de comptage est remise à

zéro.

● Le son d’alarme peut être sélectionné

parmi 3 types de sons.

● Fonction de prévention du compte

des doubles serrages

Le travail (confirmation de doubles

serrages et de vissage de vis, etc.)

commencé dans le temps réglé n’est

pas compté après que les vis vissées

ait été comptées.

Voyant d’afchage du

compte

Voyant d’afchage du

système de comptage

Bouton de verrouillage

Sélecteur

Sélecteur de pause

Dégagement

ON (marche)

Démarrage du panneau de commande

1. Dégagez le sélecteur de pause

2. Pour éclairer le panneau de com

mande

1 Dégagez le bouton de verrouillage

2 Appuyez sur (le panneau de

commande est allumé)

●

Le voyant d’affiche du compte et

“UP” ou “DOWN” sont allumés.

-

Page 22

-

22 -

Réglage des fonctions de compte

(Réglage du compte-vis/Réglage du

système de comptage)

1.

Appuyez sur alors que le panneau

de commande est allumé.

A chaque pression sur , le réglage

du compte-vis et le sélecteur du

réglage du système de comptage

s’enclenchent et clignotent.

● Réglage du comptevis

→ Le voyant d’affiche de comp

tage clignote.

● Réglage du système de comptage

→ “UP” ou “DOWN” clignote.

2. Réglage du compte-vis

Réglez le nombre de vis à l’aide de

ou de .

● La four chett e pe ut ê tre réglé e

entre 0 et 99.

● Zéro n’est pas compté.

Réglage du système de comptage

Appuyez sur

. “UP” ou “DOWN”

pour commencer le clignotement.

Ensuite, sélectionnez “UP” ou

“DOWN”.

●

Appuyez sur et maintenez le bouton

ou le bouton tout en réglant

le couple de serrage de façon à ce

que la valeur varie continuellement.

< Système de comptage “UP” >

● Affiche le compte du nombre de vis

vissées.

(

Nombre réglé

)

Les réglages sont activés en appuyant

sur .

● Lorsque le nombre de vis réglé est

atteint, l’alarme retentit et la valeur

du compte est remise à zéro.

< Système de comptage “DOWN” >

● Affiche le compte des vis restante

devant être vissées.

(

Nombre réglé

)

● Lorsque le nombre de vis à visser

réglé est atteint, l’alarme retentit et

la valeur du compte est remise à

zéro au nombre original réglé.

3.

Les réglages sont activés en appuyant

sur .

●

Le réglage précédent est libéré.

4. Pour prévenir tout changement des

valeurs réglées à la suite d’erreurs de

fonctionnement.

● Mettez le sélecteur de

HOLD sur ON.

ON

Réglages pratiques des fonctions

(Réglage du son de l’alarme/Réglage

de la durée de prévention du compte

des doubles serrages)

1.

Appuyez sur pendant au moins

2 secondes alors que le panneau de

commande est allumé.

● Le voyant d’affichage de compte

“F1” est allumé.

A chaque pression sur , le réglage

du son de l’alarme et la durée de

prévention du compte des doubles

serrages peuvent être commutés.

● “Réglage du son de l’alarme”

→ “F1” est allumé.

“Réglage de la durée de prévention

●

du compte des doubles serrages”

→ “F2” est allumé.

2. Réglage du son de l’alarme

Le son de l’alarme peut être sélec

tionné à l’aide de lorsque “F1”

est allumé.

Opération Affichage Fréquence du son

b3 Son aigu

(Environ 4 kHz)

b2

Son moyen

(Environ 3 kHz)

b1 Son grave

(Environ 2 kHz)

b0 Pas de son (OFF)

● Si est pressé, le son d’alarme

enregistré lors du réglage précédent s’affiche.

Réglage du son de l’alarme/Réglage

de la durée de prévention du compte

des doubles serrages

Appuyez sur

pour allumer “F2” et

sélectionnez la durée à l’aide de

.

-

Page 23

-

23 -

Opération

<Témoin d’avertissement de batterie basse>

Arrêt

(fonctionnement

normal)

Clignotant

(Pas de charge)

Caractéristique de

protection de la

batterie active.

Affichage

30 3

1 0,1

0 OFF

Nbre de

secondes

secondes

seconde

En suivant

le compte

des vis, le

vissage dans

le nombre

de secondes

réglé n’est

pas compté

● Si est pressé, le réglage de la

durée enregistré lors du réglage

précédent s’affiche.

3. Les rég lages s ont ef fect u és en

appuyant sur .

4. Pour prévenir tout changement des

valeurs réglées à la suite d’erreurs de

fonctionnement.

● M ett ez l e sélecteur

HOLD sur ON.

Pour changer le compte des vis

pendant l’utilisation

1. Dégagez le sélecteur de pause.

2. Ajustez la valeur du compte à l’aide

de .

● Le nombre affiché de vis devant

être viss ées peut être changé

dans la fourchette des valeurs de

compte des vis.

3. Pour prévenir tout changement des

valeurs réglées à la suite d’erreurs de

fonctionnement.

● M ett ez l e sélecteur

HOLD sur ON.

■ Pendant le réglage, si aucune opération n’est effectuée pendant au moins

60 secondes et lorsque la batterie est

retirée

● L’opération pour la valeur réglée

est invalidée.

Veuillez réinitialiser les valeur de

fonctionnement.

■ Lorsque les batteries sont chargées

pendant l’utilisation

● Lorsque les batteries sont chan

gées, la valeur du compte est sauvegardée. La perceuse peut donc

être utilisée continuellement.

ON

ON

Témoin d’avertissement de

batterie basse

.

Une décharge excessive (totale) des

batteries aux ions de lithium réduit

leur durée de vie de façon notable.

L’outil comprend une caractéristique

de protection de la batterie conçue

pour empêcher une décharge excessive de la batterie autonome.

● La caractéristique de protection de

la batterie s’active automatiquement avant que la batterie ne perde

sa charge, entraînant le clignotement du témoin d’avertissement de

batterie basse.

● Dès que vous remarquez le clignotement du témoin d’avertissement de

batterie basse, rechargez immédiatement la batterie autonome.

Couvercle du verrouillage

de l’embrayage

Le c ouvercle du ver rouillage d e

l’embrayage vous permet de verrouiller l’embrayage au réglage sélectionné.

Fixation du couvercle

1. Sélectionnez le réglage d’embray

age pour l’application.

2. Fixez le couvercle du verrouillage

de l’embrayage.

● Alignez la marque triangulaire sur

le couvercle avec la marque de

-

sélection de gradation sur la perceuse et fixez.

Marque triangulaire Marque de sélection

de gradation

-

Page 24

-

24 -

Enlèvement du couvercle

1.

Saisissez le couvercle du verrouillage d e l’embrayage avec vos

doigts sur la marque triangulaire

et le fond du couvercle, puis tirez et

tournez pour le faire ressortir.

● Retirer le couvercle du verrouillage de l’embrayage de la perceuse peut être difficile si vous

faites pression sur le côté du

couvercle tout en le retirant.

Utilisation de la lumière DEL

Utilisez la lumière DEL pou r les

travaux effectués dans des endroits

sombres comme des greniers pour

éclairer votre espace de travail.

MISE EN GARDE

● La lumière DEL est conçue pour

être utilisée comme une source de

lumière supplémentaire. Ne l’utilisez pas comme une lampe torche.

Cela peut entraîner un accident ou

des blessures.

● Ne regardez pas la lumière et ne

la dirigez pas directement vers vos

yeux.

Une exposition continue à la lu

mière DEL peut endommager vos

yeux.

1. Appuyez sur pour allumer et

éteindre la lumière DEL.

● Pour utiliser la lumière immédi

atement après avoir installé la

batterie autonome ou après que

la perceuse n’ait pas été utilisée

pendant 5 minutes ou plus, faites

brièvement fonctionner la perceuse.

-

● La lumière s’éteint automatiquement si la perceuse n’est pas

utilisée pendant 5 minutes.

● La lumière utilise une inme quan

tité de courant. L’utilisation de la

lumière n’a qu’un effet négligeable

sur la capacité de fonctionnement

de la perceuse.

● Le DEL est incapable d’éclairer le

bout de la mèche lorsque la per-

ceuse est utilisée selon la congu

ration normale.

Fonction de verrouillage de

la mèche

Avec le commutateur sur la position

d’arrêt et la mèche verrouillée en place,

l’outil peut être utilisé comme un tournevis manuel - jusqu’à 14,7 N·m (150

kgf/cm, 130 po-lbs).

L’arbre d’entraînement présentera un

peu de jeu, mais cela n’est pas un

mauvais fonctionnement.

-

Interrupteur principal (ON/OFF)

Poussez la moitié supérieure de l’interrupteur pour une rotation vers l’avant

ou la moitié inférieure pour une rotation en arrière.

Page 25

-

25 -

Vers l’avant

Vers l’avant

Vers l’arrière

Vers l’arrière

Commutateur du sélecteur

de vitesse

Pour adapter l’application de cet outil,

deux vitesses de rotation différentes sont disponibles. En fonction de

l’utilisation, sélectionnez soit la haute

vitesse, soit la basse vitesse.

Batterie autonome (EY9L10)

MISE EN GARDE:

1. Retirez la batterie autonome de

l’outil.

2. Chargez la batterie autonome en

utilisant le chargeur de batterie.

3. Lorsque la charge est terminée,

retirez la batterie autonome du

chargeur et connectez-la à l’outil.

Déconnectez le chargeur de la

source d’alimentation lorsqu’il n’est

pas utilisé.

HAUT

Sélection de la vitesse

BAS 200 min-1 (t/mn) Haut

HAUT 600 min-1 (t/mn) Bas

BAS

Couple de

serrage

MISE EN GARDE:

• Vérifiez le commutateur du sélecteur de vitesse avant l’utilisation.

• Ne faites pas fonctionner le commu

tateur du sélecteur de vitesse alors

que l’interrupteur principal est sur la

position de marche (le commutateur

est sur la position ON).

Verrou de l’interrupteur prin-

cipal

Après l’utilisation, mettez l’interrupteur principal sur la position verrouillée pour empêcher tout fonctionnement accidentel.

Verrou de l’interrupteur principal

Verrou

REMARQUE:

L’utilisation dans des conditions

extrêmes de chaleur ou de froid

réduit la capacité de fonctionnement

par charge.

[Batterie autonome]

Pour une utilisation correcte

de la batterie autonome

-

Batterie autonome Li-ion (EY9L10)

• Pour une longévité optimale de la batterie, rangez la batterie autonome

Li-ion sans la charger après l’avoir utilisée.

•

Le niveau de température ambiante

moyenne se situe entre 0°C (32°F) et

40°C (104°F).

Si la batterie autonome est utilisée

alors que sa température est inférieure

à 0°C (32°F), l’outil pourrait ne pas

fonctionner correctement.

•

Lorsque vous n’utilisez pas la batterie autonome, éloignez-la d’autres

objets métalliques tels que: trombones,

pièces de monnaie, clés, clous, vis et

autres petits objets métalliques susceptibles de connecter les bornes entre

elles.

Page 26

-

26 -

Si vous court-circuitez les bornes de

la batterie, vous risquez de causer

des étincelles, de vous brûler ou de

provoquer un incendie.

• Lors de l’utilisation de la batterie autonome, assurez-vous de la bonne ventilation du lieu de travail.

Longévité des batteries autonomes

Les batteries rechargeables ont une

longévité limitée. Si le temps de fonction nement devient très court après

la recharge, remplacez la batterie

auto nome par une neuve.

Recyclage de la batterie autonome

ATTENTION:

Pour une batterie autonome Li-ion

EY9L10

La batterie Li-ion que vous vous êtes

procurée est recyclable. Pour des

renseignements sur le recyclag e

de la batterie, veuillez composer le

1-800-8-BATTERY.

[Chargeur de batterie]

Recharge

Mises en garde communes pour

la batterie autonome Li-ion/Ni-Cd

REMARQUE:

• Lo rsqu’une ba tte rie a utonome

froide (en-dessous de 0°C) doit être

rechargée dans une pièce chaude,

laissez la batterie autonome dans la

pièce pendant une heure au moins

et rechargez-la quand elle a atteint la

température ambiante. (Sinon, il est

possible que la batterie autonome ne

soit pas complètement chargée.)

•

Laissez refroidir le chargeur quand

vous rechargez plus de deux bat teries

autonomes à la suite.

• Ne mettez pas vos doigts dans les

trous des connecteurs lorsque vous

prenez les chargeurs ou à n’importe

quelle occasion.

MISE EN GARDE:

Pour éviter les risques d’incendie ou

d’en dommagement du chargeur de

batterie.

• N’utilisez pas de source d’alimentation provenant d’un générateur de

moteur.

• Ne bouchez pas les trous d’aération du chargeur et de la batterie

autonome.

• Débranchez le chargeur lorsque

vous ne l’utilisez pas.

Batterie autonome Li-ion

REMARQUE:

Votre batterie autonome n’est pas

complètement chargée au moment

de l’achat. Veillez à bien charger

complètement la batterie avant son

utilisation.

Chargeur de batterie (EY0L10)

1. Branchez le cordon d’alimentation du

chargeur dans une prise secteur.

REMARQUE:

Des étincelles peuvent être produites lorsque la fiche est introduite

dans la prise d’alimentation secteur;

toutefois, ceci ne pose aucun problème de sécu rité.

2. Faites glisser le couvercle du poste

d’accueil de la batterie vers l’arrière

pour permettre l’insertion de la batterie autonome Li-ion.

● Assurezvous que le couvercle est

bien verrouillé en place.

3. Introduisez soigneusement la batterie

autonome dans le chargeur.

Vers la prise

CA

4. Pendant la charge, le témoin s’allume.

Lorsque la charge est terminée, un

inter rupteur électronique s’actionne

pour pro téger la batterie.

Page 27

-

27 -

• La charge ne peut pas être réalisée

si la batterie autonome est chaude

(par exemple, à la suite d’un long

travail de perçage).

Le témoin d’attente orange clignote

jusqu’à ce que la batterie se soit

refroidie.

La charge commence alors auto-

matiquement.

Le témoin de charge (vert) clignote

5.

lentement dès que la batterie est

chargée à environ 80%.

6.

Lorsque la charge est terminée, le

témoin de charge se met à clignoter

rapidement en vert.

7. Lorsque la température de la batterie

autonome est de 0°C ou moins, la batterie autonome prend plus longtemps

à charger que la durée standard.

Même lorsque la batterie est complète-

ment chargée, elle n’aura qu’environ

50% de la puissance d’une batterie

complètement chargée à une température de fonctionnement normale.

8.

Lorsque le témoin d’alimentation ne

s’allume pas immédiatement après

avoir branché le chargeur, ou si après

la durée de charge standard, le témoin

de charge ne clignote pas rapidement

en vert, consultez un concessionnaire

autorisé.

9. Si une batterie complètement chargée

est à nouveau insérée dans le chargeur,

le témoin de charge s’allume. Après

quelques minutes, le voyant de charge

risque de clignoter rapidement pour

indiquer que la charge est terminée.

Batterie autonome Ni-Cd

REMARQUE:

Chargez une nouvelle batterie autonome, ou une batterie autonome

qui n’a pas été utilisée pendant

une période prolongée, pendant 24

heures pour lui redonner sa pleine

capacité.

Chargeur de batterie (EY0L10)

1. Branchez le cordon d’alimentation du

chargeur dans une prise secteur.

REMARQUE:

Des étincelles peuvent être produ-

ites lorsque la fiche est introduite

dans la prise d’alimentation secteur;

toutefois, ceci ne pose aucun problème de sécurité.

2. Faites glisser le couvercle du poste

d’accueil de la batterie vers l’arrière

pour permettre l’insertion de la batterie autonome Ni-Cd.

● Assurezvous que le couvercle est

bien verrouillé en place.

3. Introduisez soigneusement la batterie

autonome dans le chargeur.

Vers la prise

CA

4. Pendant la charge, le témoin s’allume.

Lorsque la charge est terminée, un

interrupteur électronique s’actionne

pour protéger la batterie.

La charge ne peut pas être réalisée

•

si la batterie autonome est chaude

(par exemple, à la suite d’un long travail de perçage).

Le témoin d’attente orange clignote

jusqu’à ce que la batterie se soit

refroidie. La charge commence alors

automatiquement.

5.

Lorsque la charge est terminée, le

témoin de charge se met à clignoter

rapidement en vert.

6. Si le voyant de charge ne s’allume

pas immédiatement après le brancheme nt du chargeur ou, si après la

durée de charge standard, le voyant

ne s’éteint pas, consultez un revendeur agréé pour de l’assistance technique.

7. Si une batterie complètement chargée

est à nouveau insérée dans le chargeur, le témoin de charge s’allume.

Après quelques minutes, le voyant de

charge risque de clignoter rapidement

pou r indi quer que la char ge est

terminée.

Page 28

-

28 -

INDICATION DU VOYANT

Allumé en vert

Le chargeur est branché dans la prise secteur.

Prêt pour la charge.

Clignotant rapidement en vert

Chargement terminé. (Pleine charge)

Clignotant en vert

La batterie est chargée à environ 80%. (Charge utile.

Li-ion seulement)

Allumé en vert

Chargement en cours.

Allumé en orange

La batterie autonome est froide

La batterie autonome est chargée lentement pour réduire l’effort de la batterie. (Li-ion seulement)

Clignotant en orange

La batterie autonome est chaude. La charge commence

lorsque la température de la batterie autonome descend.

Témoin de l’état de charge

Gauche: vert Droite: orange s’afchent.

Clignotant rapidement en orange et en vert

Impossible de charger. Colmatage par la poussière ou

mauvais fonctionnement de la batterie autonome.