Page 1

Subject

Low Resistance Value Chip Resistor

Part No.

ERJM1W

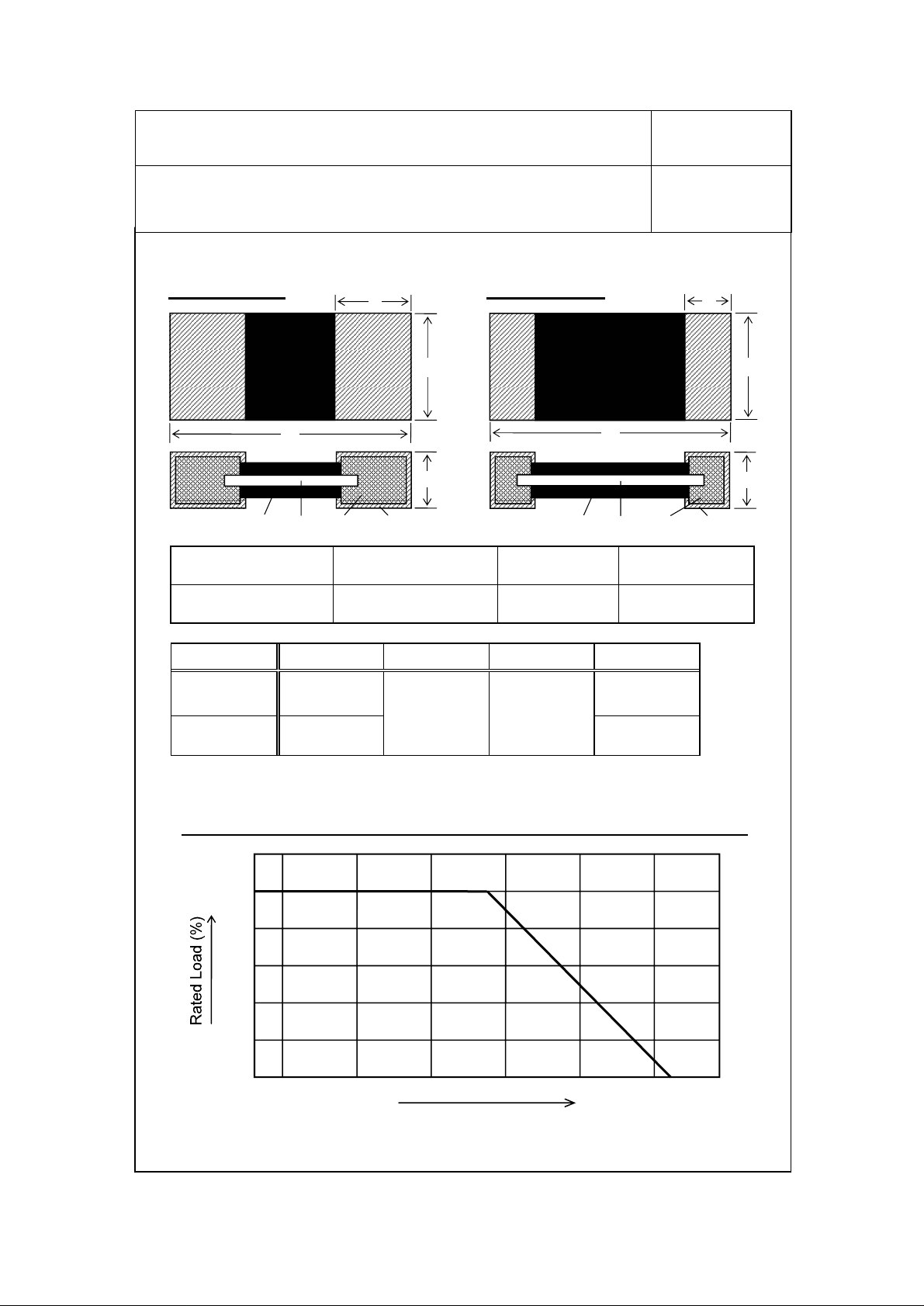

1.Dimension

ERJM1WT type

L

1)

1) Protective Coating 2) Resistive Element 3) Terminal

Resin Alloy Metal Metal

3)

a

W

T

4)2)

ERJM1WS type

1)

L

3)

4) Outer

Terminal

Metal Plating

Spec. No.

151-RJM-E01MM

1

10 -

a

W

T

4)2)

(Sn)

L W T a

ERJM1WT

ERJM1WS

2.Power Derating Curve

Category Temperature Range (Operating Temperature Range): -55 to +170 deg.C

120

100

80

60

40

20

0

6.40+/-0.40

[.252+/-.016]

6.40+/-0.25

[.252+/-.010]

-40 1200 8040 160

-55

3.20+/-0.25

[.126+/-.010]

0.80+/-0.30

[.031+/-.012]

70

2.10+/-0.30

[.083+/-.012]

1.00+/-0.25

[.039+/-.010]

Unit: mm, [inches]

170

200

Ambient Temperature (deg.C)

Fig.1

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Page 2

Subject

Low Resistance Value Chip Resistor

Part No.

ERJM1W

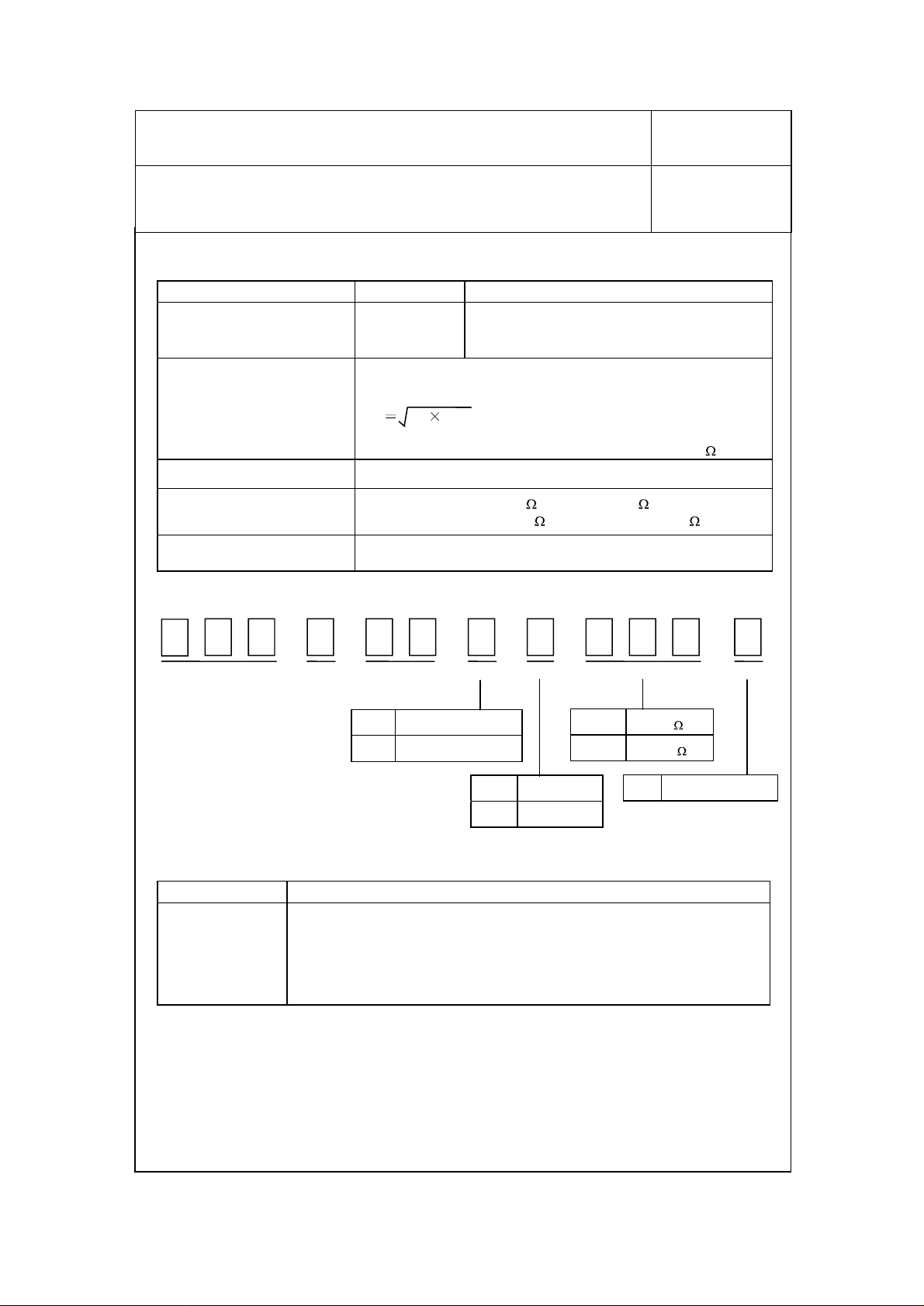

3.Ratings

Item Specifications Explanation

Power Rating

Rated Continuous Working

Voltage (RCWV)

Resistance Tolerance F:+/-1%, J:+/-5%

Resistance Range

(Standard Resistance Value)

Circuit board of use

1.0W

(70deg.C)

The rated voltage at each resistance shall be calculated from the

equation below,

E

P

E: RCWV(V), P: Rated Power(W), R: Resistance Value( )

ERJM1WT type

ERJM1WS type

You shall use the aluminum substrate when the added wattage

exceeds 0.5W.

Spec. No.

151-RJM-E01MM

10 -

When you use one at ambient temperature over

70deg.C, the load power shall be reduced as

shown in Fig.1.

R

: 1m to 4m

: 3m to 20m (3, 4, 5, 6, 10, 15, 20m )

(1, 1.5, 2, 3, 4m

)

2

4. Explanation of Part Number

E

Chip Resistor Structure Rated Power Type Tolerance Resistance Value Packaging

(Ex.)

T Wide Terminal

S Standard Terminal

5. Appearance and Construction

Item Specifications and Explanation

1. The surface of resistor is covered with protective coating and hard to

fade, then don't have unevenness, flaw pinhole and discoloration.

Appearance and

Construction

2. The surface of terminal is covered by the plating. And the plating is

hard to fade, then don't have unevenness, flaw, pinhole and

discoloration.

3. The terminal is connected with resistive plate certainly.

F +/- 1%

J +/- 5%

3M0 3m

10M 10m

U Embossed Taping

UM 03FSW1MJR

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Page 3

Subject

Low Resistance Value Chip Resistor

Part No.

ERJM1W

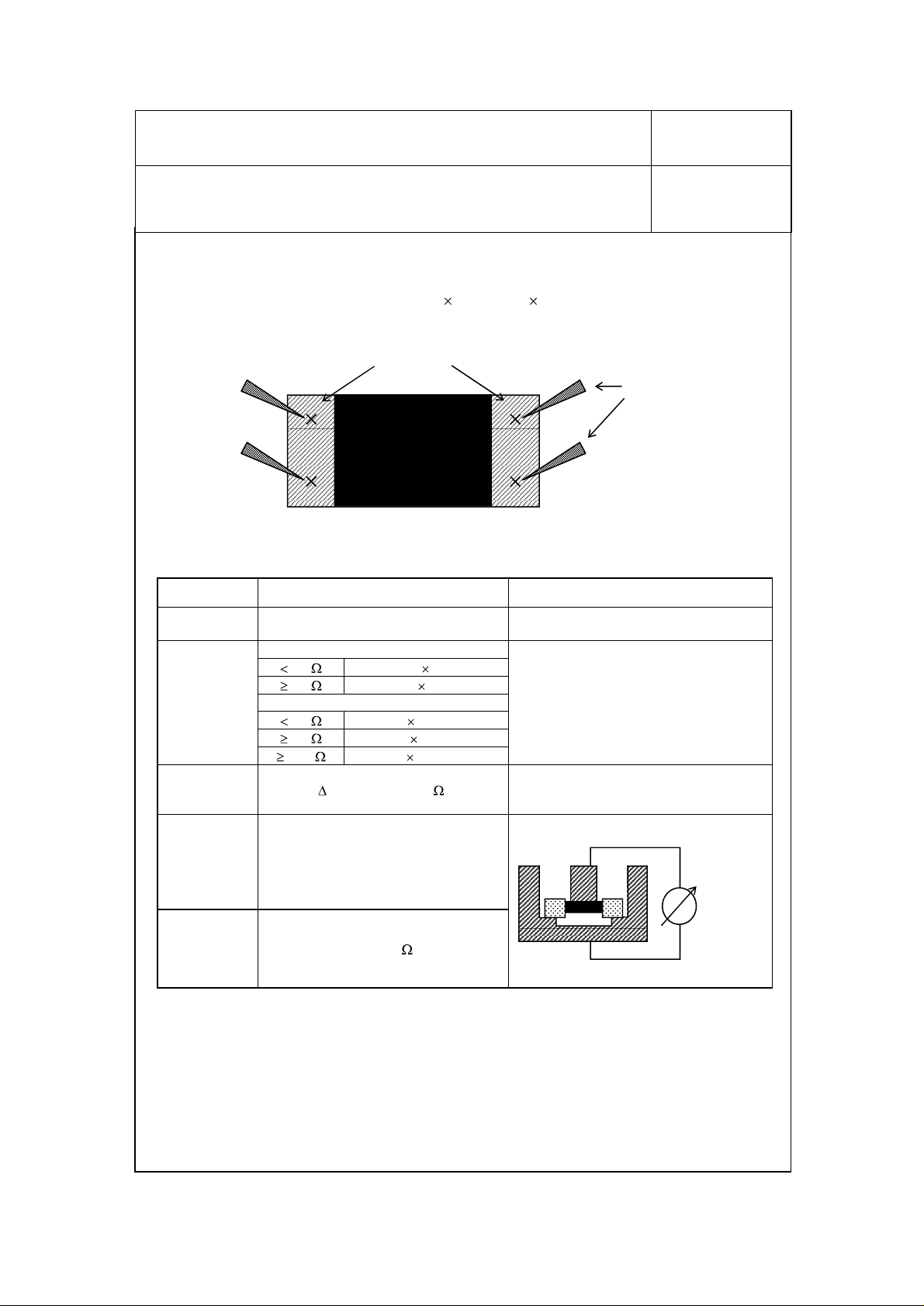

As far as there shall not designation especially, the following test and measurement

shall be operated under normal temperature(5 to 35deg.C), normal humidity(45 to

85%), normal atmospheric pressure(8.6

Resistance value shall be

<Measuring method: In measuring resistance value, 4 wires must be put on top terminal.>

6.Electrical Performance Characteristics

guaranteed as like followings.

Top terminal

104 to 1.06

105Pa).

Spec. No.

151-RJM-E01MM

Wire

10 -

3

Item Specifications Test

DC

Resistance

Temperature

Coefficient

Intermittent

Overload

Dielectric

Withstanding

Insulation

Resistance

DC Resistance value must be within

the specified tolerance.

ERJM1WT type

2m

2m

5m

5m

10m

No evidence of flash over, mechanical

damage, arcing or insulation

breakdown.

350+/-100

100+/-50

ERJM1WS type

+/-350

R = +/-(5%+0.5m

min.1G

+/-100

+/-75

10-6/deg.C

10-6/deg.C

10-6/deg.C

10-6/deg.C

10-6/deg.C

)

Methods(Based on JIS - C5201)

Measuring current: 1A

20deg.C 65%RH

Sequence of temperature:

+25deg.C to +125deg.C

Resistance change after 1,000 cycles (1

second ON, 25 seconds OFF) at 5 times

Rated Power.

AC500V 1 minute

Insulation

Resistance

Meter

or

AC Power

Supply

Measuring Voltage :DC500V

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Page 4

Subject

Low Resistance Value Chip Resistor

Part No.

ERJM1W

7.Mechanical Performance Characteristics

Item Specifications Test Methods(Based on JIS-C5201)

Terminal Strength min. 4.9N

Spec. No.

151-RJM-E01MM

10 -

Copper plate: t = 0.4mm

Pull speed :10mm/seconds

Fixed

Solder

(Pb/Sn = 40/60)

Substrate : Glass Epoxy (t=1.6mm)

Span : 90mm

Bending Distance : 2mm (10 seconds)

A B C

ERJM1WT

ERJM1WS

3.1 2.2

2.1 4.2

A

3.4

Unit: mm

AB

4

P

Bending Strength

Without distinct deformation

in appearance

Solderability min. 95% coverage

Resistance to

Soldering Heat

R = +/-(5%+0.5m

C

Test Board

100mm

Resistors shall be dipped in the melted

solder bath at 230+/-5deg.C for 3+/-0.5

seconds. Next, flux shall be removed from

the surface of terminal with clean organic

solvent.

Resistors shall be dipped in the melted

solder bath at 270+/-3deg.C for 10+/-1

)

seconds.

40mm

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Page 5

Subject

Low Resistance Value Chip Resistor

Part No.

ERJM1W

8.Enviromental Characteristics

Item Specifications Test Methods(Based on JIS-C5201)

High Temperature

Exposure

Temperature

Cycling

Humidity

(Steady State)

Load Life

Load Life in

Humidity

R = +/-(1%+0.5m

R = +/-(1%+0.5m

R = +/-(1%+0.5m

R = +/-(3%+0.5m

R = +/-(3%+0.5m

Spec. No.

151-RJM-E01MM

Resistors shall be exposed at 125+/-3deg.C

)

for 1000+48/-0 hours.

-55+/-3deg.C 30minutes

Normal temp. 30minutes 5 cycles

)

+125+/-3deg.C 30minutes

Resistors shall be exposed at 60+/-2deg.C

and 90 to 95% relative humidity in a humidity

)

test chamber for 1000+48/-0 hours.

Resistors shall be exposed at 70+/-2deg.C for

1000 +48/-0 hours. During this time the

)

rated voltage shall be applied intermittently for

1.5 hours ON,0.5 hours OFF.

Resistors shall be exposed at 60+/-2deg.C

and 90 to 95% relative humidity for

1000+48/-0 hours. During this time the rated

)

voltage shall be applied intermittently for 1.5

hours ON,0.5 hours OFF.

10 -

5

9.Other Characteristics

Item Specifications Test methods

Surface

Temperature

less than

110deg.C up

10.Resistance Value Marking

Express resistance value on resin side.

ERJM1WT type

ERJM1WS type

1m

:1M0 , 1.5m

3m

11.Recommended Pad Layout

ERJM1WT type

3.1mm

3.4mm

2.2mm

Resistor shall be mounted on aluminum

substrate (t = 1.0mm). A power of 1.0W

shall be applied. The temperature rise at the

center of resistor is measured.

Example

:1M5 , 2m

:R002 , 3m :R003 , 4m

:3M0 , 4m :4M0 , 5m :5M0 , 6m

10m

:10M , 15m

Circuit Pattern

(Cu etc.)

Pad

Resist

:15M, 20m

ERJM1WS type

2.1mm

4.2mm

:R004

:6M0

:20M

3.4mm

12.Manufacturing Country

Indonesia or Japan

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Page 6

Subject

Low Resistance Value Chip Resistor

Part No.

ERJM1W

Spec. No.

151-RJM-E01MM

10 -

13. Precautions in Handling Resistors

! Precautions in Handling Resistors

(1) This specification shows the quality and performance of a unit component. Before adoption,

be sure to evaluate and verify the product mounting it in your product.

(2) We take no responsibility for troubles caused by the product usage that is not specified in this

specification.

(3) In traffic transportation equipment(trains, cars, traffic signal equipment, etc.), medical

equipment, aerospace equipment, electric heating appliances, combustion and gas

equipment, rotating equipment, disaster and crime preventive equipment, etc. in cases where

it is forecast that the failure of this product gives serious damage to the human life and

others, use fail-safe design and ensure safety by studying the following items to

Ensure safety as the system by setting protective circuits and protective equipment.

Ensure safety as the system by setting such redundant circuits as do not cause danger by

a single failure.

(4) When a doubt shall be occurred about safety for this product, be sure to inform us rapidly,

operate your techni

(5) The products in this specification are intended for use in general standard applications for

general electronic equipment(AV products, household electric appliances, office equipment,

information and communication equipment, etc.); hence, they do not take the use under the

following special environments into consideration. Accordingly, the use in the following

special environments, and such environmental conditions may affect the performance of the

products; prior to use, verify the performance, reliability, etc. thoroughly

1) Use in liquids such as water, oil, chemical, and organic solvent

2) Use under direct sunlight and in outdoor and dusty atmospheres

3) Use in places full of corrosive gases such as sea breeze, Cl2, H2S, NH3, SO2, AND NOX.

4) Use in environment with large static electricity and strong electromagnetic waves.

5) Where the product is close to a heating component, and where an inflammable such as

a polyvinyl chloride wire is arranged close to the product.

6) Where the resistor is sealed and coated with resin, etc.

7) Where water or a water-soluble detergent is used in cleaning free soldering and in flux

cleaning after soldering. (Pay particular attention to a water-soluble flux.)

(6) If transient load (heavy load in a short time) like pulse is expected to be applied, carry out

evaluation and confirmation test with resistors actually mounted on your own board. When

the load more than rated power is applied under the load condition at steady state, it may

impair performance and/or reliability of resistor. Never exceed the rated power.

(7) The resistor temperature is dependent on the circuit board and pattern to be used, the heat

from the neighboring components and ambient temperatures. The resistor temperature may

rise up to 170deg.C (upper limit of Category Temperature Range (Operating Temperature

Range)) or higher even if you keep the rated power. Prior to use, be sure to evaluate the

product mounted on your own board, and then use it under the condition not to damage the

board and the neighboring components. When the product shall be used under special

condition, be sure to ask us in advance.

(8) Halogen type (Chlorine type, Bromine type, etc.) or other high-activity flux is not recommended

as the residue may affect performance or reliability of resistors.

(9) When soldering with soldering iron, never touch the body of the chip resistor with a tip of the

soldering iron. When using a soldering iron with a tip at high temperature, solder for a time

as short as possible. (3 seconds or less up to 350deg.C)

(10)Avoid physical shock to the resistor and nipping of the resistor with hard tool (a pair of pliers

or tweezers) as it may damage protective film or the body of resistor and may affect resistor's

performance.

(11)Keep the rated power and ambient temperature within the specified derating curve.

(12)Avoid immersion of chip resistor in solvent for a long time. Prior to use, verify the

performance.

cal examination.

6

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Page 7

Subject

Low Resistance Value Chip Resistor

Part No.

14.Storage Method

ERJM1W

Spec. No.

151-RJM-E01MM

7

10 -

If the product is stored in the fo

performance and solderability may be badly

llowing environments and conditions, the

affected, avoid the storage in the

following environments.

1) Storage in places full of corrosi

ve gases such as sea breeze, Cl2, H2S, NH3, SO

and NOX.

2) Storage in places expos

3) Storage in places outside the tem

ed to direct sunlight.

perature range of 5 to 35deg.C and humidity

range of 45 to 85%RH.

4) Storage over one year after our delivery (T

the storage method specified in

Item 1) - 3) have been followed.)

his item also applies to the case that

15. Law, Regulation

1) This product has not been manufactur

controlled under the M

ontreal Protocol.

2) This product complies with the RoHS Dire

Hazardous. Substances in elec

trical and electronic equipment

ed with any ozone depl

ctive (Restriction of

(DIRECTIVE 2002/95/EC)).

3) All the materials used in this par

Concerning the Examinat

ion and Regulation of Manuf

t are registered material under the Law

actures, etc. of

Chemical substances.

4 All the materials used in this part c

ontain no brominated materials of PBBOs

or PBBs as the flame-retardant.

5) If you need the notice by letter of "A

preliminary judgement on the Laws of Japan

foreign exchange and Foreign Trade control", be sure to let us know.

2

eting chemical

the use of certain

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Page 8

Subject

Low Resistance Value Chip Resistor

Part No.

ERJM1W

16. Recommendable reflow soldering profile

Spec. No.

151-RJM-E01MM

8

10 -

Soldering by the above-menti

Notes

Soldering profile is measured at t

oned conditions is available.

he mounting position of the resistor.

Reflow soldering shall be within two times.

The regulation is for the resistor and applies to

10-4

Resistance to Soldering Heat 2

The problems caused by solder and flux are not our responsibility.

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Page 9

Subject

Low Resistance Value Chip Resistor

Part No.

ERJM1W

Taping

1. Application Range

This specification covers t

2. Physical Dimensions

2-1 Structure and reel dimensions s

Carrier Tape

(Embossed)

Adhesive Tape

aping spec. of ERJM1W Type.

Top Tape

Spec. No.

151-RJM-E01MM

hall be as shown in the figure below.

15.4+/-1.0

13+/-1.0

min.60

13+/-1.0

9

10 -

180+0/-3.0

2-2 Carrier Tape Dimensions

T

T2

A B W F E P1

3.60+/-0.20

[.141+/-.008]

P2 P0

4.00+/-0.05

[.157+/-.002]

D0

D1

6.90+/-0.20

[.272+/-.008]

8.00+/-0.10

[.314+/-.004]

P1

P2 P0

Compartment

12.0+/-0.30

[.472+/-.012]

D0 D1

1.50+0.10/-0

[.059+0.04/-0]

B

A

5.50+/-0.05

[.217+/-.002]

Min. 1.50

[Min. .059]

Sprocket Hole

E

F

Chip Resistor

1.75+/-0.10

[.069+/-.004]

T T2

Max. 0.40

[Max. .016]

Unit: mm, [inches]

Unit : mm

W

8.00+/-0.10

[.314+/-.004]

1.60+/-0.10

[.063+/-.004]

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Page 10

Subject

Low Resistance Value Chip Resistor

Part No.

Spec. No.

ERJM1W

3. Specifications

3-1 Specifications of Taping

When the test shall be operated with the

be 0.098N to 0.686N and the t

<Test Method>

Carrier Tape

Minimum Bending Radius

When the carrier tape shall be bent to

shall be no defection of chip and no break of

shall be done for 1 time.

Resistance to climate

When resistors shall be exposed at 60deg.

shall be no defection of chip and no break of carrier tape. When the top tape

shall be peeled, it shall

not have flash and tear.

ape shall not have flash

10

below conditions, the peel strength shall

and tear after peeling.

Peeling Direction

Top Tape

Minimum Bending Radius (15mm), there

the carrier tape. However the test

C, 90 to 95 %RH for 120 hours, there

151-RJM-E01MM

10

10 -

3-2 Quantity in Reel : 3000 pcs./reel

3-3 Taping Condition

Chip resistors shall not be st

Chip resistors shall be easy to take out from carrier tape.

Compartment and sprocket hole shall not have flash

4. Outer Packaging

When reels shall not reach Max. quantity, the remaining empty space shall be

buried with buffer material.

When the quantity shall be few, alternative packaging methods may be used. No

problem must occur during t

5. Marking

Side of Reel(Marking shall be on one side.)

1) Part Name('Fixed metal plate flat ch

2) Part Number 3) Quantity 4) Lot Number 5) Maker Name

6) Manufacturing Country

Packaging Box

1) Part Number 2) Quantity 3) Maker Name

icking to top tape and bottom tape.

and break.

Tape

Marking

he exportation of the product.

ip resistor' following part name on invoice)

PANASONIC ELECTRONIC DEVICES CO.,LTD.

Loading...

Loading...