Page 1

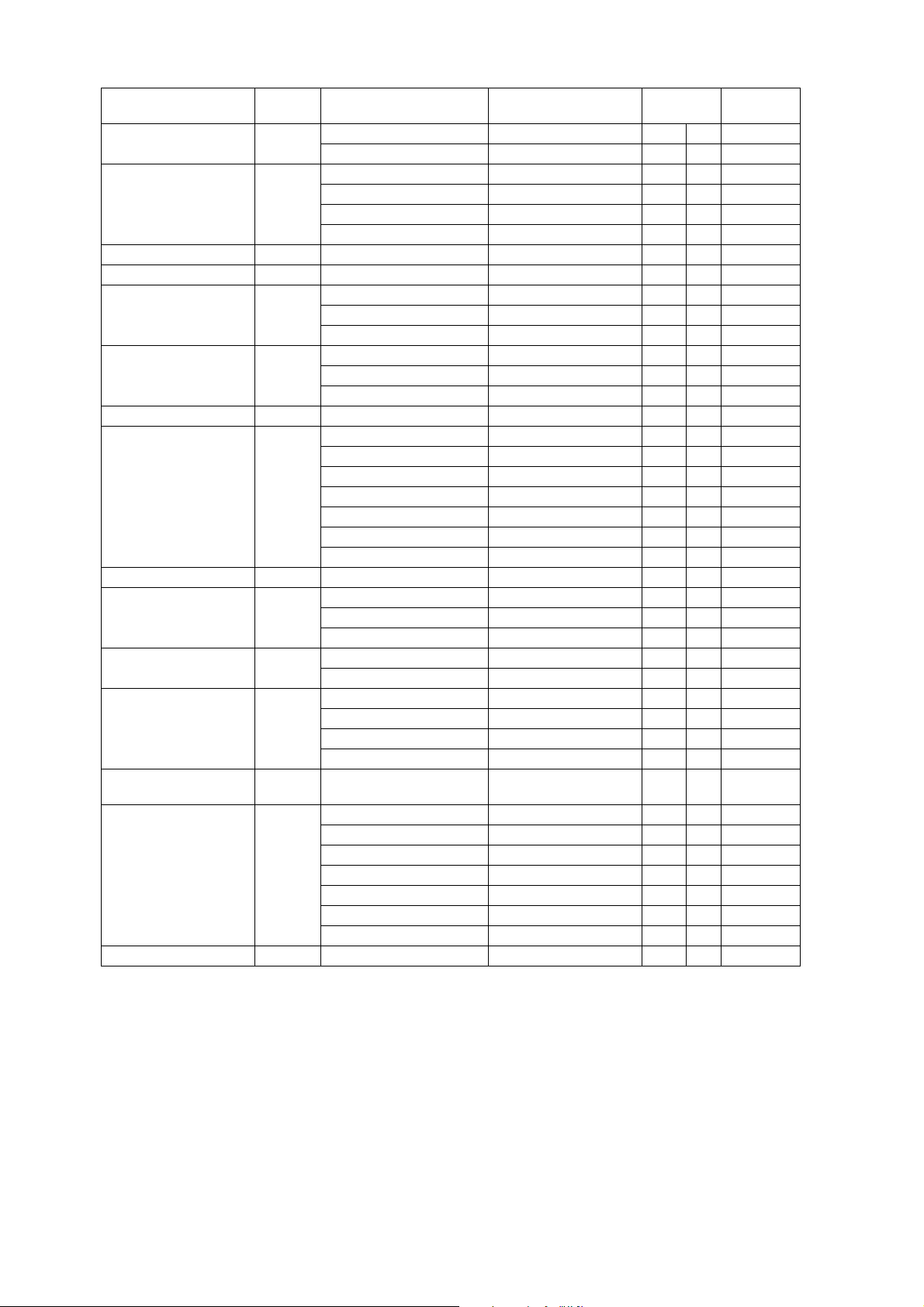

Order Number: MCUK001002C8

Personal Cellular Telephone

EB-GD93

Specification

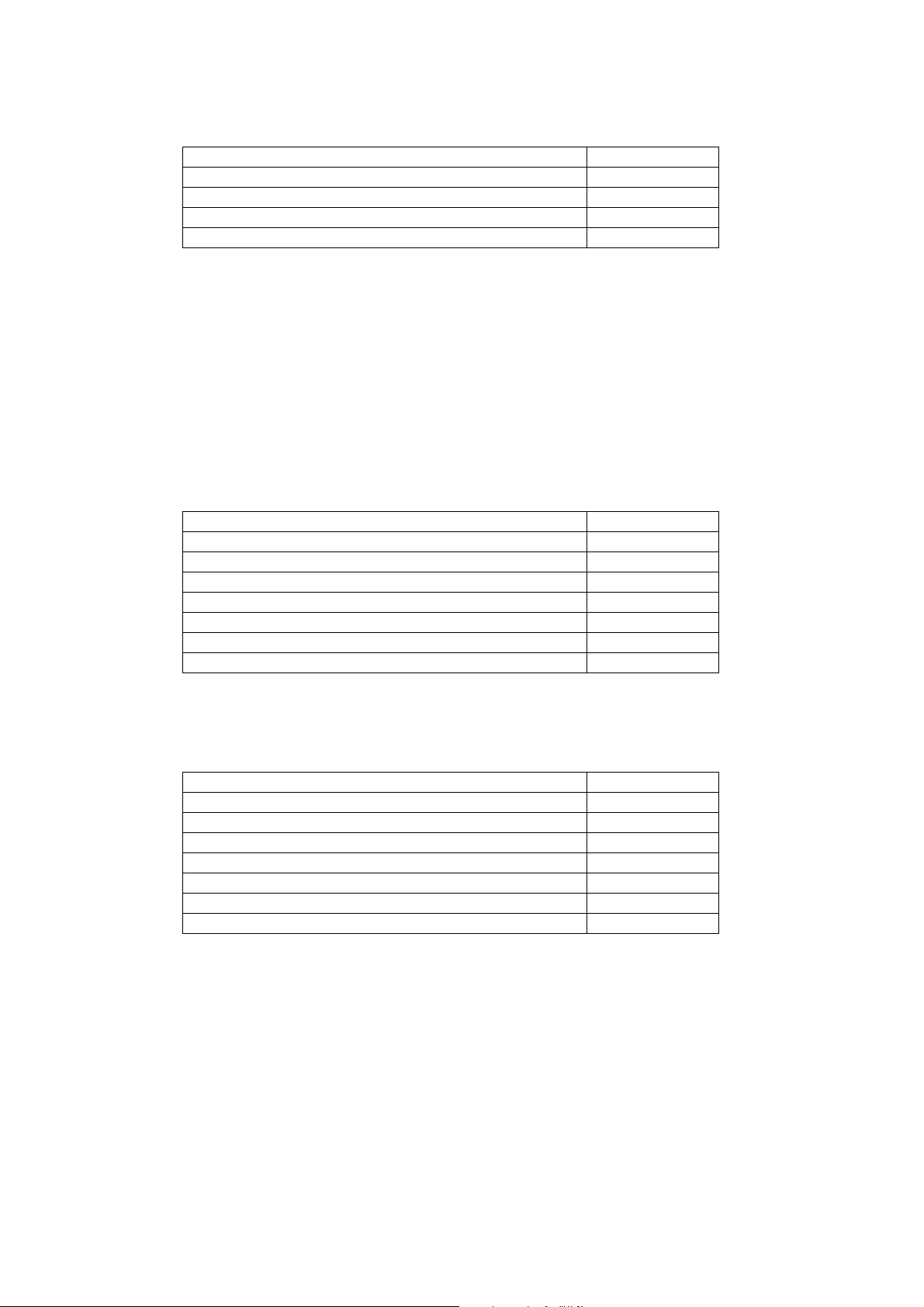

900 MHz 1800 MHz

Frequency Range Tx: 890 - 915MHz

Tx/Rx frequency separation 45 MHz 95 MHz

RF Channel Bandwidth 200 kHz

Number of RF channels 124 374

Speech coding Full rate/Half rate/Enhanced Full rate

Operating temperature -10 °C to +55 °C

Type Class 4 Handheld Class 1 Handheld

RF Output Power 2 W maximum 1 W maximum

Modulation GMSK (BT = 0.3)

Connection 8 ch/TDMA

Voice digitizing 13 kbps RPE-LTP / 13 kps ACLEP / 5.6 kps CELP /

Transmission speed 270.3 kbps

Diversity Frequency hopping

Signal Reception D ouble superheterodyne

Intermediate Frequencies 225 MHz and 45 MHz

Antenna Terminal Impedance 50 τ

Antenna VSWR <2.1 : 1

Dimensions Height: 120 mm

Volume 81 ml

Weight 80 g

Display Graphical chip on glass liquid crystal, Alphanumeric,

Illumination 4 LEDs for the LCD (7-colour)

Keys 18-key Keypad, Navigation key, Memo key.

SIM Plug-in type only

External DC Supply Voltage 5.8 V

Battery 3.7 V nominal, 650mAh, Li-Ion

Standby Battery Life

DRX 9

Conversation Battery Life

PL 7, DTX 50%

Battery life figures are dependent on network conditions.

Rx: 935 - 960 MHz

VSLEP

Width: 45 mm

Depth: 16.4 mm

16 x 4 characters + 2 lines of icons.

8 LEDs for the keypad (Green)

1 LED Incoming call (Green)

1 Charging LED (Red)

170 hrs maximum

210 minutes

Tx: 1710 - 1785 MHz

Rx: 1805 - 1880 MHz

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not

contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or

repair the product or products dealt with in this service manual by anyone else could result in serious injury or death.

© 2000 Matsushita Communication Industrial UK

Ltd. All rights reserved. Unauthorized copying and

distribution is a violation of law.

Issue 1

Revision 0

Page 2

Company Liability

This Service Manual is copyright and issued on the strict understanding that it is not be reproduced, copied, or disclosed to

any third party, either in whole or in part, without the prior written consent of Matsushita Communication Industrial UK Ltd.

Every care has been taken to ensure that the contents of this manual give an accurate representation of the equipment.

However, Matsushita Communication Industrial UK Ltd. accepts no responsibility for inaccuracies which may occur and

reserves the right to make changes to specification or design without prior notice.

The information contained in this manual and all rights in any designs disclosed therein, are and remain the exclusive property

of Matsushita Communication Industrial UK Ltd.

Other patents applying to material contained in this publication:

BULL CP8 PATENTS

Comments or correspondence concerning this manual should be addressed to:

Customer Support Department,

Matsushita Communication Industrial UK Ltd.,

Colthrop, Thatcham,

Berkshire, RG19 4ZD.

ENGLAND

© 2000 Matsushita Communication Industrial UK Ltd.

Issue 1 - ii - MCUK001002C8

Revision 0 Service Manual

Page 3

WARNINGS AND CAUTIONS

WARNING

The equipment described in this manual contains polarized capacitors utilising liquid electrolyte. These devices are entirely safe provided

that neither a short-circuit nor a reverse polarity connection is made across the capacitor terminals.

FAILURE TO OBSERVE THIS WARNING COULD RESULT IN DAMAGE TO THE EQUIPMENT OR, AT WORST, POSSIBLE INJURY TO

PERSONNEL RESULTING FROM ELECTRIC SHOCK OR THE AFFECTED CAPACITOR EXPLODING. EXTREME CARE MUST BE

EXERCISED AT ALL TIMES WHEN HANDLING THESE DEVICES.

Caution

The equipment described in this manual contains electrostatic devices (ESDs). Damage can occur to these devices if the appropriate

handling procedure is not adhered to.

ESD Handling Precautions

A working area where ESDs may be safely handled without undue risk of damage from electrostatic discharge, must be

available. The area must be equipped as follows:

Working Surfaces: - All working surfaces must have a dissipative bench mat, SAFE for use with live equipment, connected via

a 1 Mτ resistor (usually built into the lead) to a common ground point.

Wrist Strap - A quick release skin contact device with a flexible cord, which has a built in safety resistor of approximately 1 Mτ

shall be used. The flexible cord must be attached to a dissipative earth point.

Containers - All containers and storage must be of the conductive type.

Batteries

This equipment may contain an internal battery in addition to the external battery packs. These batteries are recyclable and

should be disposed of in accordance with local legislation. They must not be incinerated, or disposed of as ordinary rubbish.

MCUK001002C8 – iii – Issue 1

Service Manual Revision 0

Page 4

This page is left intentionally blank.

Issue 1 – iv – MCUK001002C8

Revision 0 Service Manual

Page 5

CONTENTS

1 INTRODUCTION

1.1 Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Structure of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Servicing Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . 1

2 GENERAL DESCRIPTION

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Handportable Main Kit . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 OPERATING INSTRUCTIONS

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Location of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Concept of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Alpha Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Incoming Call Line Modification (CLI) . . . . . . . . . . . . . . . 8

3.7 Hot Key Dial Source List . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.8 Features Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . 8

3.9 Public Man Machine Interface (MMI) . . . . . . . . . . . . . . . 9

3.10 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.11 Important Error Messages . . . . . . . . . . . . . . . . . . . . . . 13

3.12 Security Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.13 SIM Personalisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.14 GSM Services Supported by PC Card . . . . . . . . . . . . . 15

3.15 GSM Network Codes and Names . . . . . . . . . . . . . . . . . 15

3.16 Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 DISASSEMBLY / REASSEMBLY INSTRUCTIONS

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5 TECHNICAL SPECIFICA TIONS

5.1 Tx Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Rx Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 TEST AND MEASUREMENT

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Any-Layer Interstitial Via Hole (ALIVH) PCBs . . . . . . . . 31

6.3 External Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4 Complete Unit Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.5 Channel Box Test Commands . . . . . . . . . . . . . . . . . . . . 40

6.6 Adjustment Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 REPLACEMENT PARTS LIST

7.1 Exploded Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Printed Circuit Boards (PCBs) . . . . . . . . . . . . . . . . . . . 57

7.3 Refurbishment Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.4 Repair Jigs and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.5 Printed Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8 CIRCUIT DIAGRAMS

8.1 Main PCB: Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.2 Main PCB: RF (Sheet 1 of 2) . . . . . . . . . . . . . . . . . . . . . 69

8.3 Main PCB: RF (Sheet 2 of 2) . . . . . . . . . . . . . . . . . . . . . 70

8.4 Keypad PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9 LAYOUT DIAGRA MS

9.1 Main PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.2 Keypad PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

MCUK001002C8 Section Issue 1

Service Manual – v – Revision 0

Page 6

This page is left intentionally blank.

Issue 1 Section MCUK001002C8

Revision 0 – vi – Service Manual

Page 7

INTRODUCTION

1 INTRODUCTION

1.1. Purpose of this Manual

This Service Manual contains the information and procedures required for installing, operating and servicing the Panasonic

GSM Personal Cellular Mobile Telephone system operating on the GSM Digital Cellular Network.

1.2. Structure of the Manual

The manual is structured to provide service engineering personnel with the following information and procedures:

1. General and technical information - provides a basic understanding of the equipment, kits and options, together with

detailed information for each of the major component parts.

2. Installation and operating information - provides instructions for unpacking, installing and operating the equipment.

3. Servicing information - provides complete instructions for the testing, disassembly, repair and reassembly of each major

component part. Step-by-step troubleshooting information is given to enable the isolation and identification of a

malfunction, and thus determine what corrective action should be taken. The test information enables verification of the

integrity of the equipment after any remedial action has been carried out.

4. Illustrated parts list - provided to enable the identification of all equipment components, for the ordering of spare /

replacement parts.

1.3. Servicing Responsibilities

The procedures described in this manual must be performed by qualified service engineering personnel, at an authorised

service centre.

The service engineering personnel are responsible for fault diagnosis and repair of all equipment described in this manual.

MCUK001002C8 Section 1 Issue 1

Service Manual – 1 – Revision 0

Page 8

INTRODUCTION

This page is intentionally blank.

Issue 1 Section 1 MCUK001002C8

Revision 0 – 2 – Service Manual

Page 9

GENERAL DESCRIPTION

2 GENERAL DESCRIPTION

2.1. General

This section provides a general description and kit composition details for the GSM Handportable Telephone system and

optional kits.

2.2. Features

Panasonic Telephone Model GD93 is a high performance, small, light, handset for business and domestic use. The following

features are provided

1. Triple Rate, which includes Full Rate, Half rate and Enhanced Full Rate (EFR) speech, codec.

2. Dual Band, GSM 900 and GSM 1800 operation.

3. Tegic T9 Text Entry

4. Voice Ringer

5. Desktop Handsfree function comprising integral echo cancellation and noise suppression.

6. Wireless Application Protocol (WAP) Browser.

7. E-Mail access via Point-to-Point Protocol (PPP).

8. Backup Battery.

9. Seven background display colours.

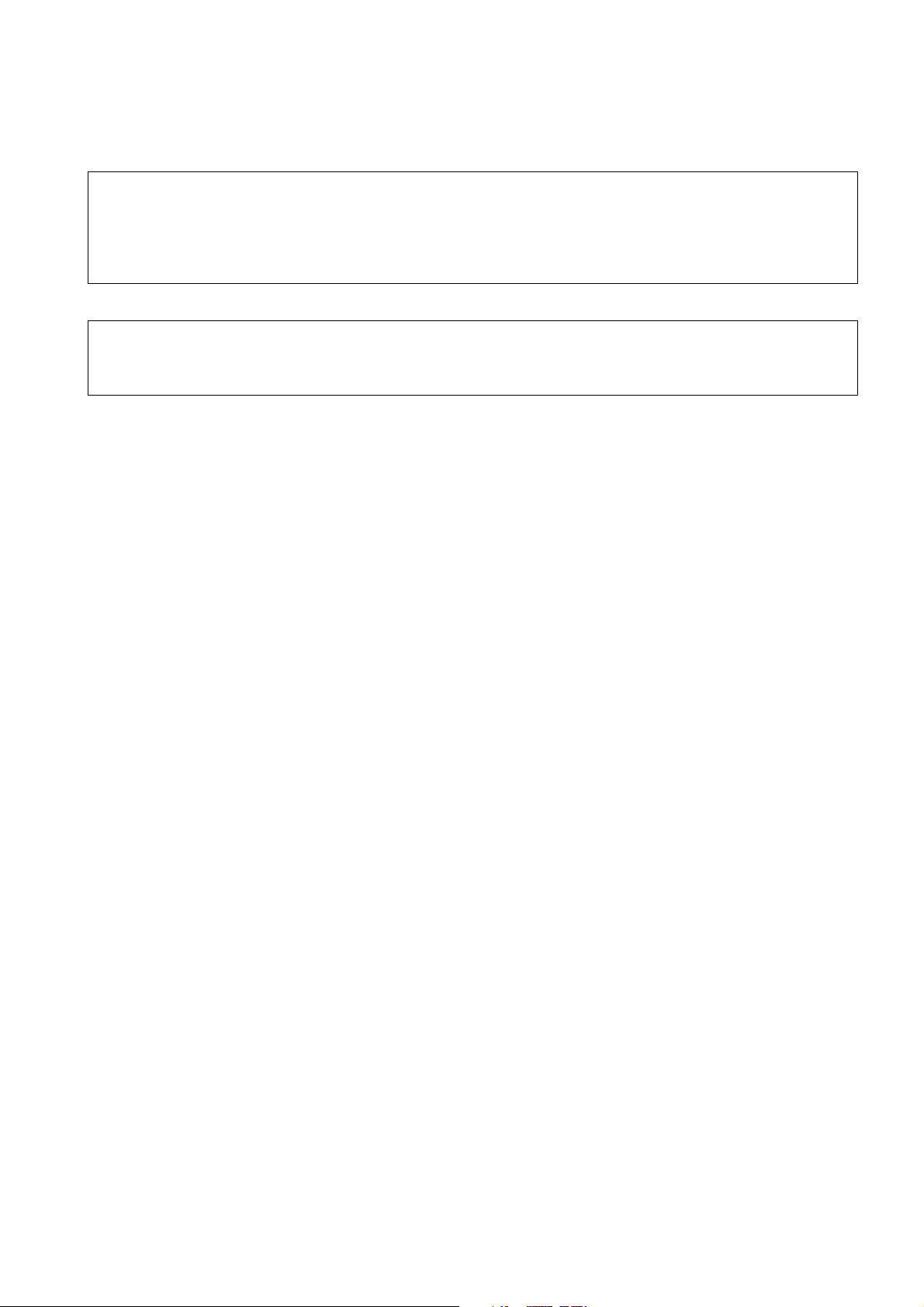

2.3. Handportable Main Kit

1

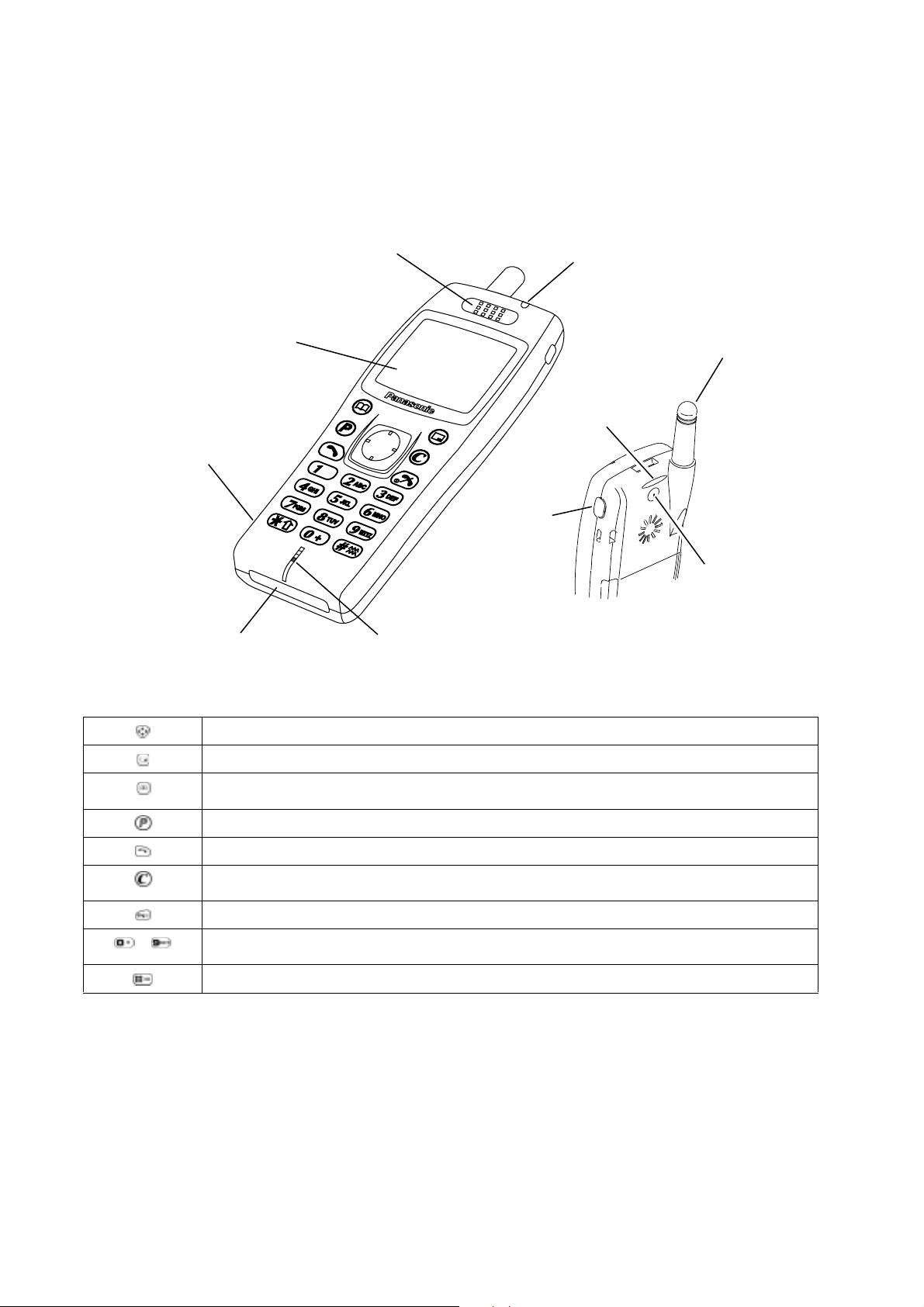

Figure 2.1: Handportable Main Unit Kit Contents

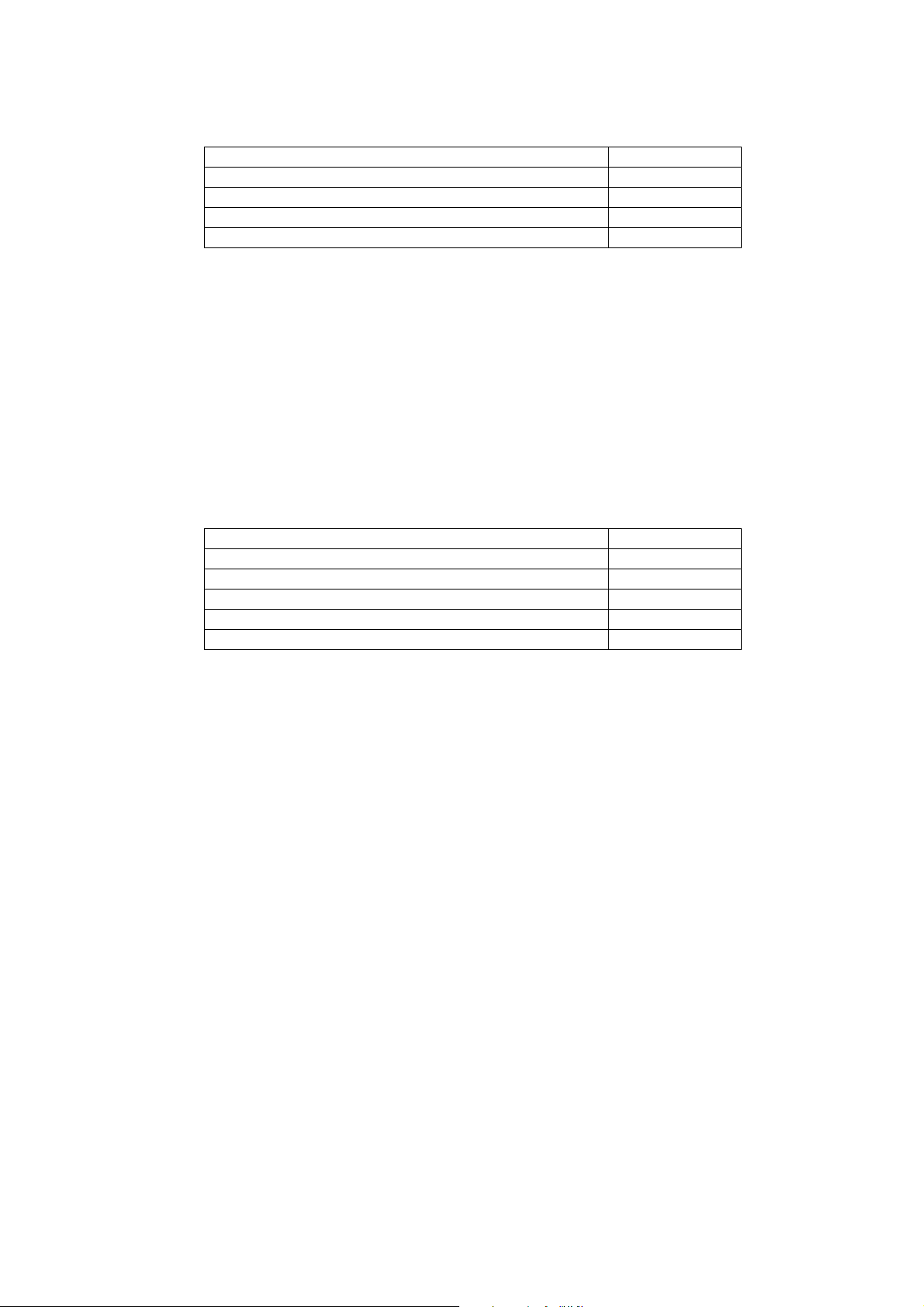

ITEM DESCRIPTION PART NUMBER

1 Main Unit GD93 EB-GD93

2 Battery, Standard EB-BSD93

3 AC Adaptor EB-CAD92

- Documentation See Section 7

2

3

10374-1

MCUK001002C8 Section 2 Issue 1

Service Manual – 3 – Revision 0

Page 10

GENERAL DESCRIPTION

This page is intentionally blank.

Issue 1 Section 2 MCUK001002C8

Revision 0 – 4 – Service Manual

Page 11

OPERATING INSTRUCTIONS

3 OPERATING INSTRUCTIONS

3.1. General

This section provides a brief guide to the operation and facilities available on the telephone handset. Refer to the Operating

Instructions supplied with the telephones for full operational information.

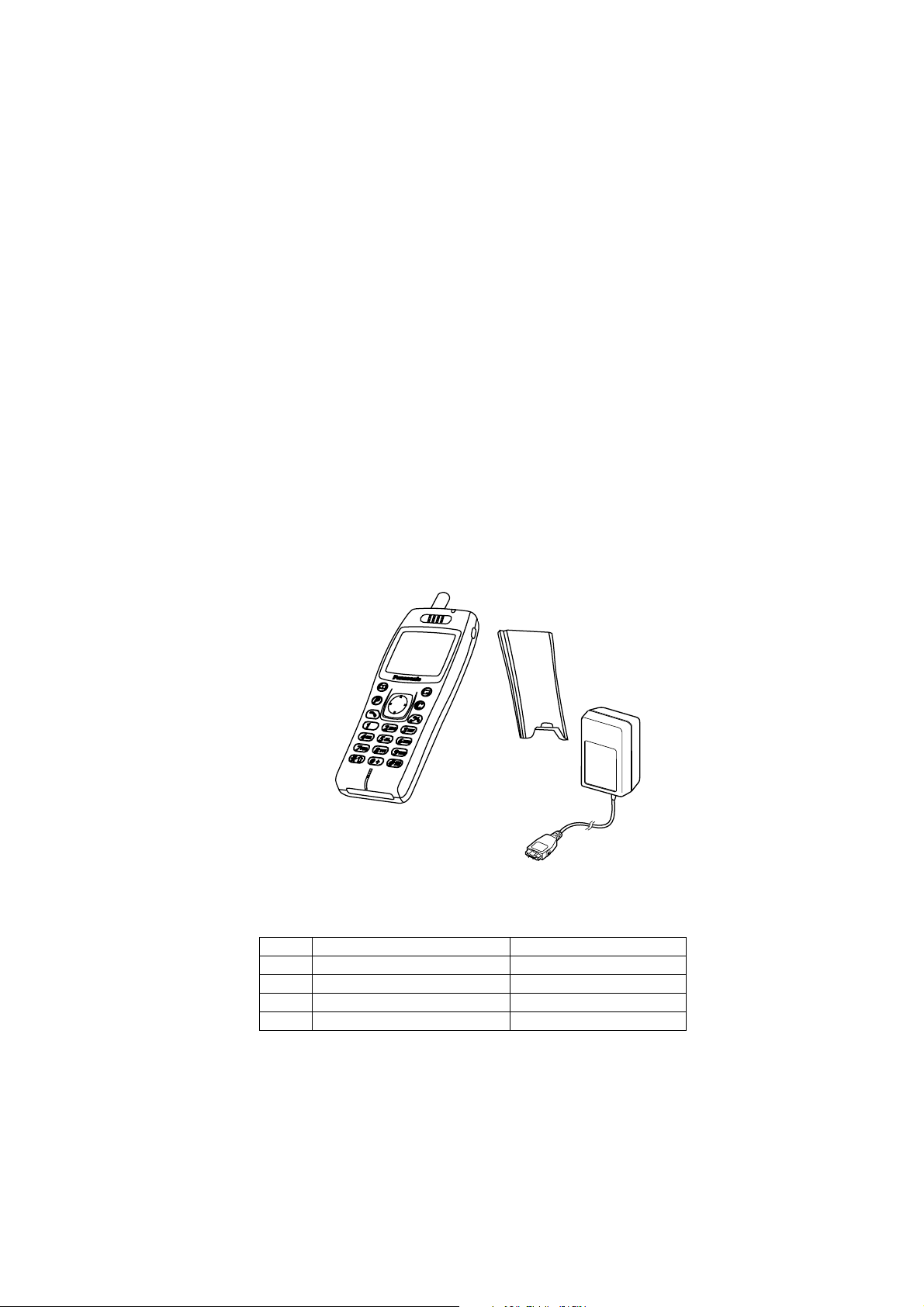

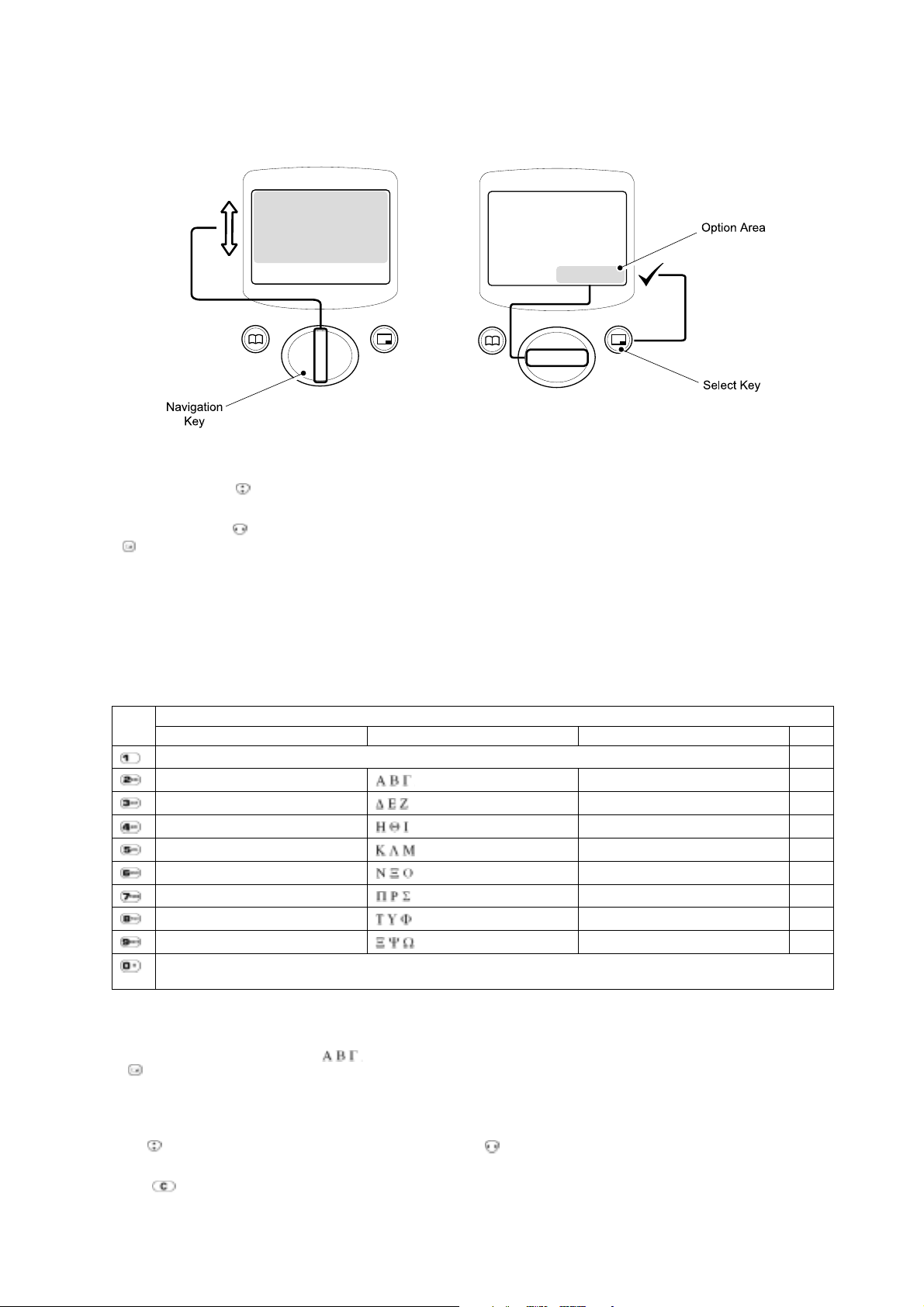

3.2. LCD Display

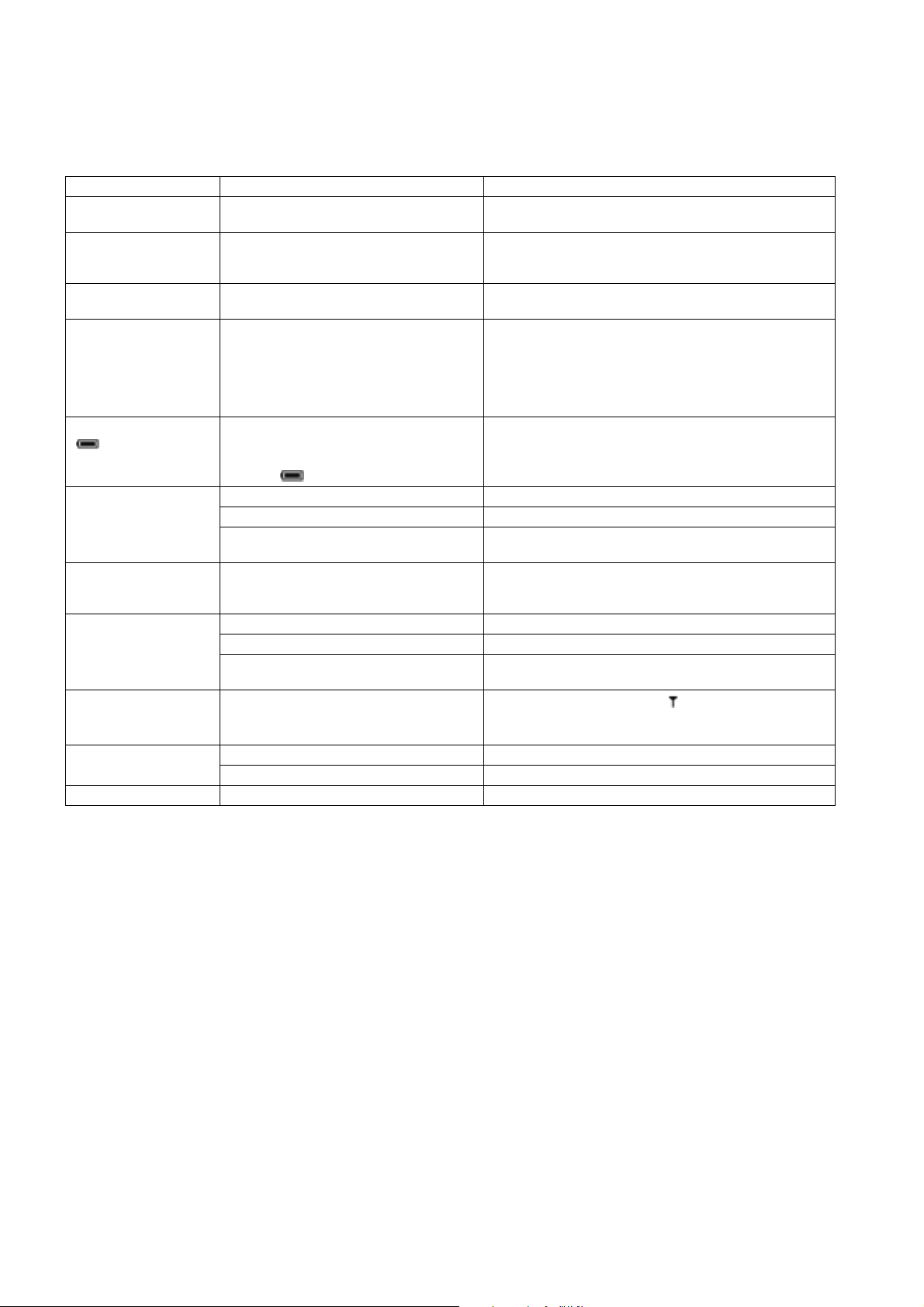

The telephone unit has a graphical chip on glass liquid crystal display in conjunction with the following icons:

Figure 3.1: LCD Display

Indicates received signal strength: strong signal area; weak signal area.

Indicates that it is possible to make an emergency call.

Menu

Number

Menu Icon Displays a small icon related to the current status of the telephone:

Information

Icon

The number of the feature indicated by the pointer. To access a feature enter the menu number on the keypad.

Displays the battery charge level: Battery is at full charge; Battery requires charging; The battery

icon flashes during charging. During car mount use, when the battery is fully charged, the icon will not light.

telephone is roaming on a non-home network.

using the “Call Divert” feature or the telephone has Call-Divert set;

shows that vibration alert is switched on;

shows that the telephone is in silent mode - no tones;

flashes to indicate that there are unread text (SMS) messages. Lit when SMS area is full;

indicates the telephone is locked;

shows that the normal character set has been selected;

shows that the Greek character set has been selected;

shows that the Extended character set has been selected;

shows that numbers have been selected for text entry.

Displays a small icon according to the current menu level:

indicates the alarm is set.

indicates the current Phonebook is sourced from the Mobile Phonebook.

indicates the current Phonebook is sourced from the SIM Phonebook.

Indicates that the navigation key ( ) can be pressed. Each arrow will light individually to indicate which direction is valid.

Option Area

Pressing the select key ( ) will select the option displayed in the option area of the display.

Following some operations, the display will clear automatically after three seconds or after pressing any key except .

MCUK001002C8 Section 3 Issue 1

Service Manual – 5 – Revision 0

Page 12

OPERATING INSTRUCTIONS

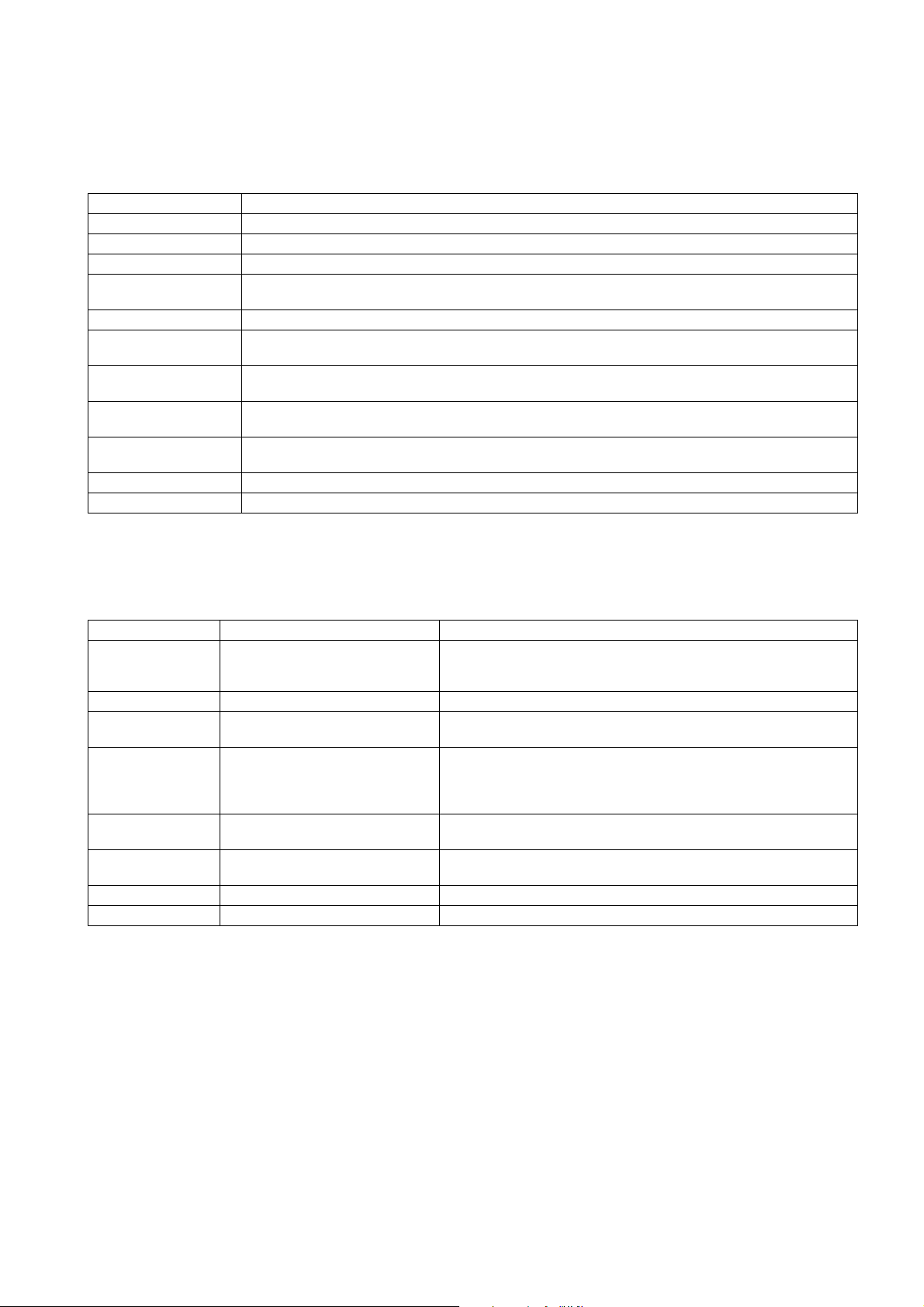

3.3. Location of Controls

Incoming / Charge indicator:

Green - Incoming call.

Red - Charging battery pack.

External connector:

Used to connect to external accessories or to charging equipment.

EARPHONE /

MICROPHONE SOCKET

EXTERNAL CONNECTOR

DISPLAY

EARPIECE

MEMO KEY

MICROPHONE

Figure 3.2: Location of Controls

INCOMING CALL/

CHARGING INDICATOR

BACK

CASE LIGHT

ANTENNA

EXTERNAL

ANTENNA

CONNECTOR

10366-1

to

Navigation Key. Scrolls through options or features menu and increases or decreases volume.

Select Key. Selects option shown in the Option Area of the display.

Phonebook Key. Browses through the Phonebook or stores a number in the Phonebook. Changes the type of

characters entered during Alpha Entry.

Personal Dial Key. Provides instant access to one phone number. Also provides shortcut to WAP Browser.

Send Key. Makes a call.

Clear Key. Clears the last digit entered, clears all digits when pressed and held or returns to the previous

display.

End Key. Ends a call or switches the telephone on/off when pressed and held.

Digit keys. Enter wild numbers or pauses when pressed and held. Where appropriate the

0 key scrolls up or

down through abbreviated control names and then select to reveal the international access code “+”.

Vibrator enable/disable Key. Press and hold to enable or disable the vibrator.

Issue 1 Section 3 MCUK001002C8

Revision 0 – 6 – Service Manual

Page 13

OPERATING INSTRUCTIONS

3.4. Concept of Operation

There is a close relationship between the Select Key, Navigation Key and display.

10025-1

Figure 3.3: Concept of Operation

Pressing up and down ( ) will move the pointer up and down and scroll through more information in the main area of the

display.

Pressing left and right ( ) will scroll through options in the option area of the display. To choose the option press the Select

Key ( ).

3.5. Alpha Entry

3.5.1 Character Set / Key Assignments

Alpha entry is used to enter alphanumeric characters in to the Phonebook, Short Messages and Greeting Message areas

Key

“ @ – , . ; : ! ¡ ? ¿ ( ) ‘ & % + – / < > = £ $ ¥ ¤ § 1

A B C a b c A Ä Å Æ B C Ç a à b c 2

D E F d e f D E É F d e è é f 3

G H I g h i G H I g h i ì 4

J K L j k l J K L j k l 5

M N O m n o M N Ñ O Ö ø m n ñ o ò ö 6

P Q R S p q r s P Q R S p q r s ß 7

T U V t u v T U Ü V t u ù ü v 8

W X Y Z w x y z W X Y Z w x y z 9

Deletes the character above the cursor, deletes the character to the left when at the end of the line or clears the entire

entry when pressed and held.

Normal Greek Extended Num

Each time a key is pressed, it will display the next character. When another key is pressed, or no key is pressed for a short

time, the cursor will move to the next position.

To cycle between Greek characters ( ), extended characters (W), numerals (X) and normal characters (U)

press .

Character / Operation

3.5.2 Editing Alpha Entry

Pressing will move the cursor up or down one line. Pressing will move the cursor left or right one character. When the

cursor is moved over a character and another key pressed this will insert the new character.

Pressing will delete the character to the left of the cursor.

MCUK001002C8 Section 3 Issue 1

Service Manual – 7 – Revision 0

Page 14

OPERATING INSTRUCTIONS

3.6. Incoming Call Line Identification (CLI)

When a call is received the last 6 digits of the CLI information is matched with the phonebook. Therefore an incoming call could

match to the wrong phonebook entry.

3.7. Hot Key Dial Source List

The source for Hot Key Dial Numbers is normally ‘Phonebook’ or ‘Service Dial Numbers’. For some OEMs it may be a

requirement to store these numbers in Flash-ROM. When the source is the Flash-ROM and the telephone software is updated,

the source numbers may be lost. Also, if the user changes the source of the Hot Key Dial numbers, it will not be possible to

redirect the source back to Flash-ROM. However, in the event that an OEM would like the Hot Key Dial source to be stored in

the Flash-ROM, it is unlikely that the user will have the option to change the Hot Key Dial source.

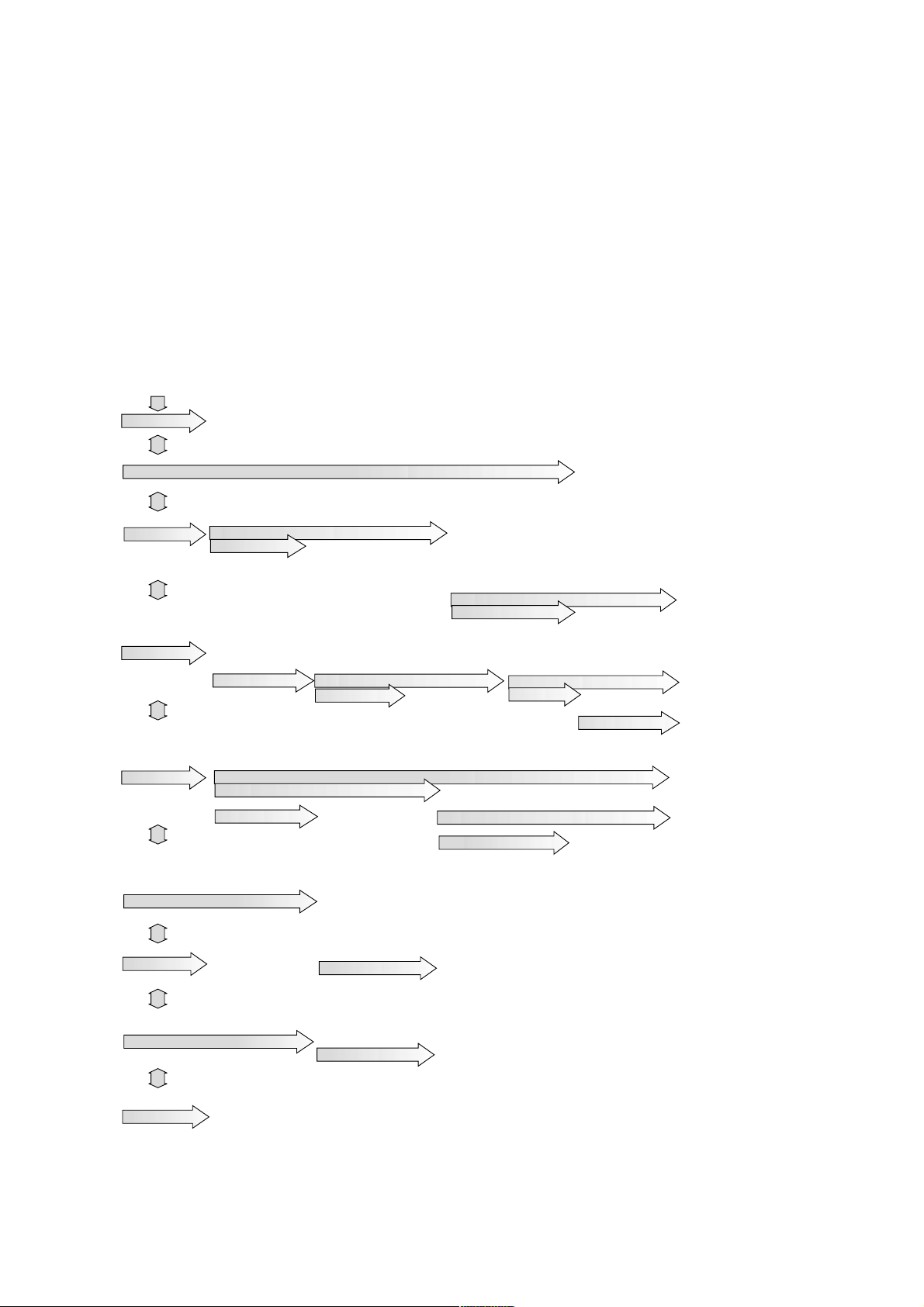

3.8. Features Menu Structure

Keyguard

Browse

Phonebook

Messages

Applications

Short Message

E-Mail

Start Browser

Browser Setting

Clock Function

Calculator

Currency

Inbox

Outbox

Create

Send / Receive

Review

Parameters

Clock Set

Clock Format

Alarm Set

Power On Time

Power Off Time

Received List

Send List

Create

User Defined Msg

Review

Parameters

Broadcasts

Display Pattern

Display Format

Home

Second

Create

Alert Profile

Group Setting

Review

My Numbers

Service Dial *

Hot Key Dial

Personal Dial

Receive

Message List

Topics

Languages

Time Difference

Summer Time

Auto Adjustment

Auto Delete

Lifetime

Message Centre

Report

Protocol

Time Set

Summer Time

Auto Adjustment

Home Country

Personalise

Call Service

Call Divert

Security

Network

Language

Tones

Voice Command

Display Setting

Vibration Alert

Auto Answer

DTMF Length

Defaults

Voice Calls

Fax Calls

Data Calls

Cancel All

Status

New Network

Search Mode

Network List

All Tones

Greeting

Backlight Colour

Contrast

Animation

Key Backlight

Back Case Light

Last Call

All Calls

Call Waiting

Caller’s ID

Withhold ID

Call Charge

Phone Lock

Call Bar

PIN

PIN2

Fixed Dial

Barred Dial

Ring Volume

Ring Type

Melody Composer

Voice Ringer

Key Volume

Warning Tone

Cost Left *

Price/Unit *

Max Cost *

Warning at *

Bar Voice

Bar Fax

Bar Data

Cancel All

Status

Password

Figure 3.4: Features Menu Structure

Display Language

Tegic Language

Voice Calls

Fax Calls

Recording

Playback

* Feature is SIM / Network dependent.

Data Calls

Messages

10367-1

Issue 1 Section 3 MCUK001002C8

Revision 0 – 8 – Service Manual

Page 15

OPERATING INSTRUCTIONS

3.9. Public Man Machine Interface (MMI)

3.9.1 General

It is possible to operate all GSM telephones in the same way using the Public MMI. The following operations will work with all

GSM telephones. However, this information is restricted to those operations supported by the GD93 telephone.

The * and # in the following procedures should be replaced by and respectively. Also <SND> and <END> should be

replaced with and keys.

3.9.2 Reading the Phonebook Memory Location

# <MEMORY LOCATION>

Leading zeros can be left out of the location number, e.g. 007 can be 7.

3.9.3 Presentation of IMEI

* # 0 6 #

3.9.4 Security

Change PIN * * 0 4 * <OLD PIN> * <NEW PIN> * <NEW PIN> #

Change PIN2 * * 0 4 2 * <OLD PIN2> * <NEW PIN2> * <NEW PIN2> #

Unblock PIN * * 0 5 * <PIN UNBLOCKING KEY> * <NEW PIN> * <NEW PIN> #

Unblock PIN2 * * 0 5 * <PIN2 UNBLOCKING KEY> * <NEW PIN2> * <NEW PIN2> #

3.9.5 Call Hold

Place a Call on Hold 2 <SND>

Recall a Held Call 2 <SND>

Make a Second Call <TELEPHONE NUMBER> <SND>

Swap between two Held Calls 2 <SND>

End Held Call 0 <SND>

End Active Call 1 <SND>

Reject Incoming Call 0 <SND>

3.9.6 Call Waiting

Enable Call Waiting * 4 3 * <SND>

Disable Call Waiting # 4 3 * <SND>

Call Waiting Status * # 4 3 * # <SND>

MCUK001002C8 Section 3 Issue 1

Service Manual – 9 – Revision 0

Page 16

OPERATING INSTRUCTIONS

3.9.7 Calling Line Identification

Feature Service Code

Calling Line Identification Presentation (CLIP) 30

Calling Line Identification Restriction (CLIR) 31

Connected Line Presentation (CLOP) 76

Connected Line Restriction (CLOR) 77

Enable * <SERVICE CODE> * # <SND>

Disable # <SERVICE CODE> * # <SND>

Temporary Suppress Identification # 3 1 # <TELEPHONE NUMBER> <SND>

Temporary Display Identification * 3 1 # <TELEPHONE NUMBER> <SND>

3.9.8 Telecommunication Services used for Public MMI

Teleservice

Bearer Service

Service MMI Service Code

All teleservices 10

Telephony 11

All data teleservices 12

Facsimile services 13

Short Message Services (SMS) 16

All teleservices except SMS 19

Voice group services 17

Service MMI Service Code

All bearer services 20

All asynchronous services 21

All synchronous services 22

All data synchronous services 24

All data asynchronous services 25

All dedicated packet access 26

All dedicated PAD access 27

Issue 1 Section 3 MCUK001002C8

Revision 0 – 10 – Service Manual

Page 17

3.9.9 Call Divert

Divert all calls 21

Divert all calls if busy 67

Divert calls if no reply 61

Divert if not reachable 62

OPERATING INSTRUCTIONS

Call Divert Type Service Code

Set (except “No Reply” Call

Bar

Set “No Reply” Call Bar * * <SERVICE CODE> * <FORWARD TELEPHONE NUMBER> * <TELECOM’ SERVICE> * <TIME

Clear # # <SERVICE CODE> * <TELECOMMUNICATION SERVICE> * # <SND>

Status * * # <SERVICE CODE> * <TELECOMMUNICATION SERVICE> * # <SND>

Clear all Call Diverts # # 0 0 2 #

* * <SERVICE CODE> * <FORWARD TELEPHONE NUMBER> * <TELECOMMUNICATION

SERVICE> # <SND>

TO RING (sec)> # <SND>

3.9.10 Call Bar

Call Ball Type Service Code

All outgoing calls 33

Outgoing International calls 331

Outgoing International calls except those to the PLMN country 332

All incoming calls 35

Incoming international calls when roaming 351

Set * <PASSWORD> * <TELECOMMUNICATION SERVICE> # <SND>

Clear # <TELECOMMUNICATION SERVICE> # <SND>

Status # <TELECOMMUNICATION SERVICE> # <SND>

Clear all Call Bar Types # 3 3 0 * <PASSWORD> # <SND>

Change Call Bar Password * * 0 3 * * <OLD PASSWORD> * <NEW PASSWORD> * <NEW PASSWORD> # <SND>

MCUK001002C8 Section 3 Issue 1

Service Manual – 11 – Revision 0

Page 18

OPERATING INSTRUCTIONS

3.10. Troubleshooting

The user is given the following information and advised to contact the dealer if the problems persist:

Problem Cause Remedy

Telephone will not switch

on

Extremely short battery

life for a new battery pack

Short battery life for an

old battery pack

Short battery life for NiMH battery pack

The battery level indicator

does not light when

charging

Calls cannot be made The telephone is locked. Unlock the telephone (Menu: Security: Phone Lock).

Calls cannot be made

from Fixed Dial Store

Calls cannot be received The telephone is not switched on. Switch the telephone on.

Emergency calls cannot

be made

Telephone numbers

cannot be recalled

The network in use and the condition of the

battery pack can affect battery life.

The battery pack was worn out. Replace with a new one.

The life of the battery pack is affected by

improper charging, this is inherent in all NiMH batteries.

If a battery is deeply discharged it will take a

short time before there is sufficient power in

the telephone to light the battery level

indicator .

Outgoing calls are barred. Disable the outgoing call barring (Menu: Security: Call Bar).

The telephone is not registered to a network. Move to a coverage area and operate the telephone after it

Incoming calls are barred. Disable the incoming call barring (Menu: Security: Call Bar).

The telephone is not registered to a network. Move to a coverage area and operate the telephone after it

User’s phone is not in a GSM coverage area.

The telephone is locked. Unlock the telephone (Menu: Security: Phone Lock).

Fixed Dial is switched on. Switch off Fixed Dial (Menu: Security: Fixed Dial).

Check that the battery pack is fully charged and correctly

connected to the telephone.

Avoid areas of poor reception. Ensure batteries are fully

charged. Additionally, for NiMH batteries, ensure batteries are

also discharged fully before recharging.

To maintain maximum performance, always use until the Low

Battery Warning appears and then fully recharge the battery

pack. To revive a Battery Pack, use the telephone until the

Low Battery Warning appears and then fully recharge three

times. However, if the battery life still is short, the battery pack

has eventually worn out. Replace with a new one.

Leave to charge for several minutes in temperatures between

+5°C and +35°C.

has registered with a network.

Check that SIM supports Fixed Dial Check if the Fixed Dial is

switched on (Menu: Security: Fixed Dial). Check the

telephone number is stored in the Fixed Dial.

has registered with a network.

Check that the antenna symbol is displayed. Move to a

coverage area and operate the telephone when the antenna

symbol is displayed.

Issue 1 Section 3 MCUK001002C8

Revision 0 – 12 – Service Manual

Page 19

OPERATING INSTRUCTIONS

3.11. Important Error Messages

The following table is a list of error messages that may occur during use of the telephone, with a description and suggested

course of action:

Error Message Explanation / Remedy

Area not Allowed Roaming in the selected area is not allowed.

Network not Allowed Roaming with the selected network is not allowed.

Security Failure The network has detected authentication failure because the SIM is not registered with that network. Contact

the Service Provider.

SIM Blocked The SIM is blocked because the wrong PUK has been entered ten times. Contact the Service Provider.

SIM Error The telephone has detected a problem with the SIM. Switch the telephone off and then back on. If the

message does not disappear, contact the Service Provider.

Message Rejected

Store Full

PIN2 Invalidated The PIN2 is blocked permanently because the wrong PUK2 has been entered 10 times. Services controlled by

Warning Store Full

Continue?

Auto Redial List Full Redial list of unsuccessfully dialled numbers is full. Switch the telephone off and then on again.

A message has been received but the message store is full. To receive messages, delete some of the currently

stored messages or set messages to automatically clear (Menu: Messages: Parameters: Auto Delete).

PIN2 cannot be used. Contact the Service Provider.

The message area is full. New messages cannot be stored until some of the currently stored messages are

deleted.

3.12. Security Codes

Code Type Number of Digits Description

Personal

Identification Number

(PIN)

PIN 2 4 to 8 Controls memory security. Supplied by the service provider.

PIN/PIN 2 Unblocking

Key

(PUK/PUK 2) 8 Used to unblock PIN and PIN 2. A PIN or PIN 2 will become blocked if the

Supplied by the

service provider.

Password 4 Controls the call bar function. If the wrong password is entered three

Lock Code 4 Controls telephone security.

Factory set to “0000”.

4 to 8 Controls SIM security. Supplied by the service provider.

wrong PIN or PIN 2 is entered three times. When the blocked PIN or PIN 2

is unblocked, a new PIN or PIN 2 must be entered. If the wrong PUK or

PUK 2 is entered 10 times, the cursor SIM will be unusable.

times, this service will be revoked. Supplied by the service provider.

3.13. SIM Personalisation

3.13.1 Introduction

SIM personalisation will limit the use of the telephone to a single SIM, a SIM supplied by one Network/Sub-network/Service

Provider or a SIM purchased by a company (corporation). If a personalised handset contains a SIM that is from a different

source, it will display the message “SIM ERROR” when switched on. This personalisation is sometimes referred to as SIM lock

or SIM latch.

3.13.2 Testing

To test a personalised handset when the user has not supplied the SIM, a SIM configured for test purposes (e.g. test SIM or

soft SIM) should be used. The mobile will recognise that the SIM is for testing purposes only and operate as normal.

MCUK001002C8 Section 3 Issue 1

Service Manual – 13 – Revision 0

Page 20

OPERATING INSTRUCTIONS

3.13.3 Personalisation Function

Personalisation is activated during manufacture and then enabled at a later stage. Enabling/disabling is available by entering

a special key sequence immediately after power on. Once the enable/disable menu is shown it is possible to select the type of

personalisation. When personalisation is enabled it is only possible to disable it if the mobile contains an illegal SIM and the

sixteen digit Control Key (CK) is known. When enabled the CK is withheld from the user and cannot be read, for security

reasons.

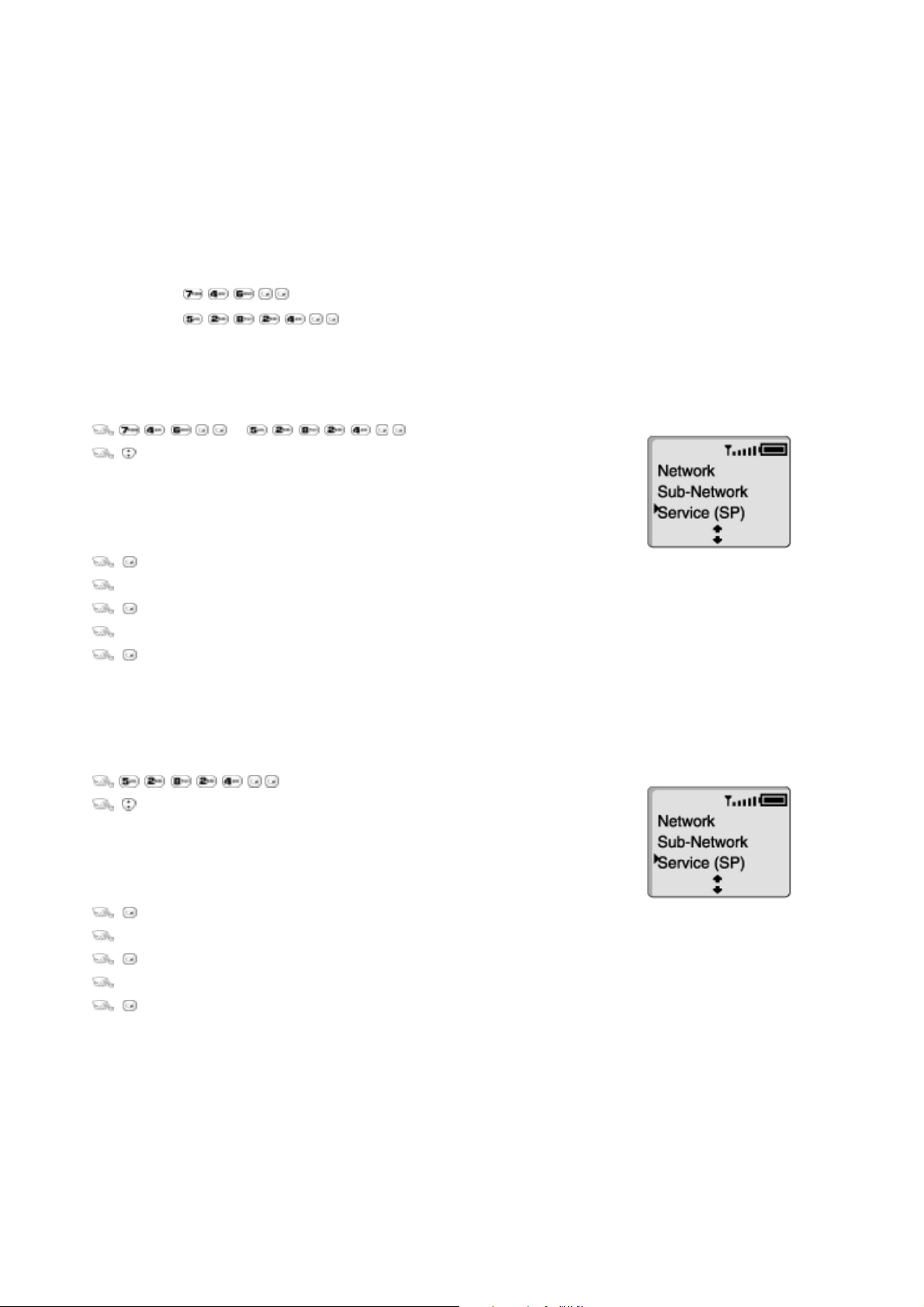

There are two special key sequences to enter the enable/disable menu:

Key Sequence

Notes

Can only disable personalisation

Can both enable and disable personalisation

3.13.4 Disabling Procedure

1. or

2. to point at:

“SIM” for SIM Personalisation

”Network” for Network Personalisation

“Subnetwork” for Subnetwork Personalisation

”SP” for Service Provider Personalisation or

”Corporate” for Company Personalisation.

3. .

4. the 16 digit Control Key.

5. .

6. the 16 digit Control Key.

7. .

The display will confirm which type of Personalisation has been disabled.

3.13.5 Enabling Procedure

1.

2. to point at:

“SIM” for SIM Personalisation

”Network” for Network Personalisation

“Subnetwork” for Subnetwork Personalisation

”SP” for Service Provider Personalisation or

”Corporate” for Company Personalisation.

3. .

4. the 16 digit Control Key.

5. .

6. the 16 digit Control Key.

7. .

The display will confirm which type of Personalisation has been enabled.

Issue 1 Section 3 MCUK001002C8

Revision 0 – 14 – Service Manual

Page 21

3.14. GSM Services Supported by PC Card

OPERATING INSTRUCTIONS

Bearer Service

Number

21 Asynchronous 300 bps Asynch 300 bps UDI or modem T or NT

22 Asynchronous 1.2 kbps Asynch 1.2 kbps UDI or modem T or NT

23 Asynchronous 1200/75 bps Asynch 1200/75 bps UDI or modem T or NT

24 Asynchronous 2.4 kbps Asynch 2.4 kbps UDI or modem T or NT

25 Asynchronous 4.8 kbps Asynch 4.8 kbps UDI or modem T or NT

26 Asynchronous 9.6 kbps Asynch 9.6 kbps UDI or modem T or NT

41 Dedicated PAD Access 300 bps Asynch 300 bps UDI T or NT

42 Dedicated PAD Access 1.2 kbps Asynch 1.2 kbps UDI T or NT

44 Dedicated PAD Access 2.4 kbps Asynch 2.4 kbps UDI T or NT

45 Dedicated PAD Access 4.8 kbps Asynch 4.8 kbps UDI T or NT

46 Dedicated PAD Access 9.6 kbps Asynch 9.6 kbps UDI T or NT

Bearer Service Rate

Access Struc-

ture

Access Rate

Information

Transfer

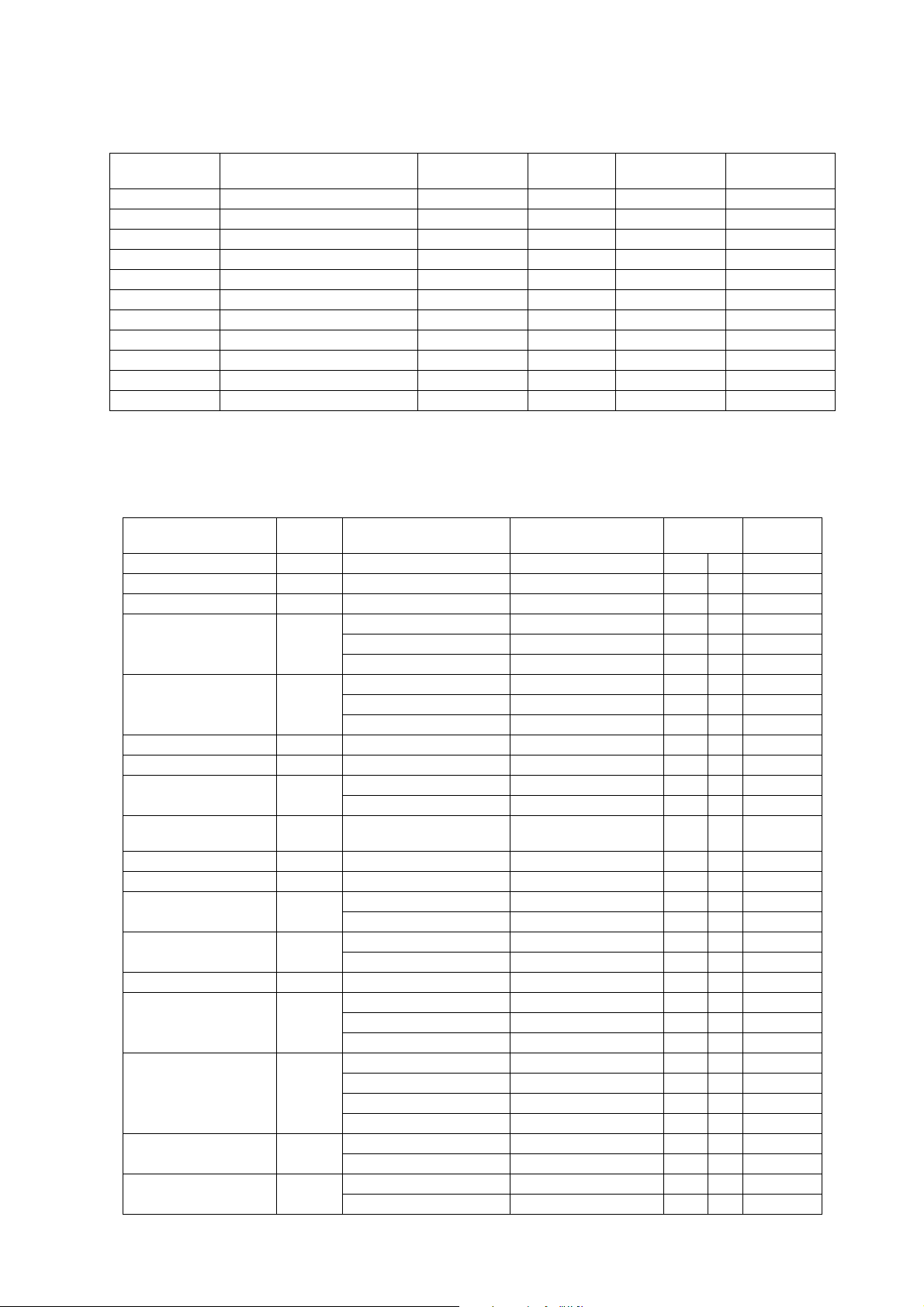

3.15. GSM Network Codes and Names

Country

ALBANIA +355 AMC MOBIL AMC - AL 276 01 GSM 900

ANDORRA +376 MOBILAND STA-MOBILAND 213 03 GSM 900

ARMENIA +374 ARMGSM RA-ARMGSM 283 01 GSM 900

AUSTRALIA +61 MOBILENET TELSTRA 505 01 GSM 900

AUSTRIA +43 A max. A max. 232 03 GSM 900

AZERBAIJAN +994 AZERCELL GSM AZE-AZERCELL GSM 400 01 GSM 900

BAHREIN +973 MOBILE PLUS BHR MOBILE PLUS 426 01 GSM 900

BELGIUM +32 PROXIMUS BEL PROXIMUS 206 01 GSM 900

BOSNIA &

HERZEGOVINA

BULGARIA +359 M-TEL GSM BG M-TEL GSM BG 284 01 GSM 900

CAMEROON +237 CAM CELLNET CAM CELLNET 624 01 GSM 900

CHINA +86 CT-GSM CHINA TELECOM 460 00 GSM 900

CROATIA +385 CRONET HR-CRONET 219 01 GSM 900

CYPRUS +357 CYTAGSM CY CYTAGSM 280 01 GSM 900

CZECH_REPUBLIC +42 EUROTEL GSM EUROTEL-CZ 230 02 GSM 900

DENMARK +45 SONOFON DK SONOFON 238 02 GSM 900

EGYPT +20 EGY CLICK GSM EGY CLICK GSM 602 02 not known

ESTONIA +372 EMT GSM EE EMT GSM 248 01 GSM 900

Access

Code

387 PTT-GSMBIH PTT-GSMBIH 218 90 GSM 900

Service or Operator Phone Display

OPTUS Mobile Yes Optus 505 02 GSM 900

VODAFONE AUS VODAFONE 505 03 GSM 900

A1 A1 232 01 GSM 900

one one 232 05 GSM 1800

mobistar B mobistar 206 10 GSM 900

CU-GSM CHINA UNICOM 460 01 GSM 900

Vip Net GDM d.o.o. HR VIP 219 10 GSM 900

OSKAR OSKAR 230 03 not known

Radio Mobil CZE PAEGAS-CZ 230 01 GSM 900

TDK-MOBIL DK TDK-MOBIL 238 01 GSM 900

Telia DK Telia DK 238 20 GSM 1800

mobilix mobilix 238 30 GSM 1800

MobiNil MobiNil 602 01 GSM 900

RADIOLINJA EESTI EE RLE 248 02 GSM 900

Network

Code

Error Correc-

tion Options

Band

MCUK001002C8 Section 3 Issue 1

Service Manual – 15 – Revision 0

Page 22

OPERATING INSTRUCTIONS

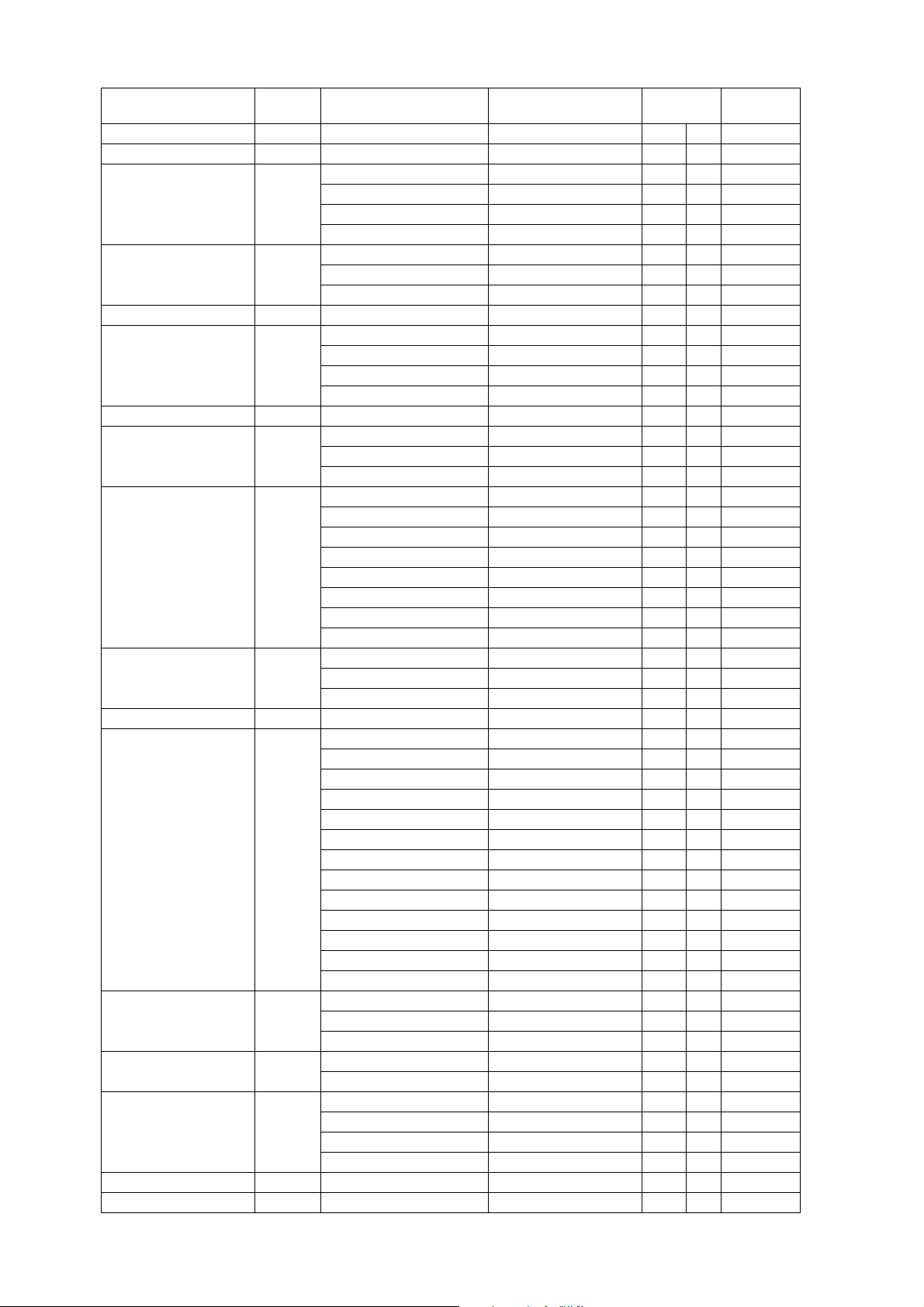

Country

ETHIOPIA +251 ETMTN ETH-MTN 636 01 GSM 900

FIJI +679 VODAFONE FIJI VODAFONE FIJ 542 01 GSM 900

FINLAND +358 FINNET FINNET 244 09 GSM 1800

FRANCE +33 Bouygues Bouygues 208 20 GSM 1800

FRENCH POLYNESIA +689 TIKIPHONE F-VINI 547 20 GSM 900

GERMANY +49 D2 PRIVAT D2 262 02 GSM 900

GIBRALTAR +350 GIBTEL GIBTEL GSM 266 01 GSM 900

GREECE +30 Cosmote Cosmote 202 01 GSM 1800

HONG_KONG +852 HK SMC HK SMC 454 06 GSM 900

HUNGARY

HUNGARY

HUNGARY

ICELAND +354 Postur og simi IS SIMINN 274 01 GSM 900

INDIA +91 AirTel INA-AIRTL 404 10 GSM 900

INDONESIA +62 EXCELCOM IND-EXCELCOM 510 11 GSM 900

IRELAND +353 EIRCELL-GSM IRL EIR-GSM 272 01 GSM 900

ITALY +39 BLU I BLU 222 98 GSM 1800

JORDAN +962 Fastlink Fastlink 416 01 GSM 900

KUWAIT +965 MTCNet KT MTCNet 419 02 GSM 900

Access

Code

+36 PANNON GSM H PANNON GSM 216 01 GSM 900

Service or Operator Phone Display

Finland SONERA SONERA 244 91 GSM 900

RADIOLINJA FI RADIOLINJA 244 05 GSM 900

Telia Telia 244 03 GSM 1800

Itineris F Itineris 208 01 GSM 900

SFR F SFR 208 10 GSM 900

E-Plus E-Plus 262 03 GSM 1800

Telekom Mobilfunk D1 D1-TELEKOM 262 01 GSM 900

Viag Interkom D Interkom 262 07 GSM 1800

PANAFON GR PANAFON 202 05 GSM 900

TELESTET GR TELESTET 202 10 GSM 900

HK TELECOM CAMPERSANDW HKT 454 00 GSM 900

NEW WORLD NEW WORLD 454 10 GSM 1800

Orange Orange 454 04 GSM 900

P Plus P Plus 454 22 GSM 1800

P-Link P-Link 454 18 GSM 1800

PEOPLES PEOPLES 454 12 GSM 1800

SUNDAY SUNDAY 454 16 GSM 1800

Vodafone Vodafone 216 70 not known

WESTEL 900 H-WESTEL 900 216 30 GSM 900

BPL MOBILE BPL MOBILE 404 21 GSM 900

BPL MOBILE BPL MOBILE 404 27 GSM 900

BPL MOBILE BPL MOBILE 404 43 GSM 900

BPL MOBILE BPL MOBILE 404 46 GSM 900

ESSAR CELLPHONE ESSAR CELLPHONE 404 11 GSM 900

INA - TATA CELLULAR TATA CELLULAR 404 07 GSM 900

INA-ESCOTEL INA-ESCOTEL 404 12 GSM 900

INA-ESCOTEL INA-ESCOTEL 404 19 GSM 900

INA-ESCOTEL INA-ESCOTEL 404 56 GSM 900

MaxTouch MaxTouch 404 20 GSM 900

RPG Cellular NA RPG 404 41 GSM 900

SKYCELL SKYCELL 404 40 GSM 900

IND SATELINDOCEL IND SATELINDOCEL 510 01 GSM 900

TELKOMSEL IND TELKOMSEL 510 10 GSM 900

IRL - DIGIFONE IRL DIGIFONE 272 02 GSM 900

I WIND I WIND 222 88 GSM 1800

OMNITEL I OMNITEL 222 10 GSM 900

TELECOM ITALIA MOBIL I TIM 222 01 GSM 900

Network

Code

Band

Issue 1 Section 3 MCUK001002C8

Revision 0 – 16 – Service Manual

Page 23

OPERATING INSTRUCTIONS

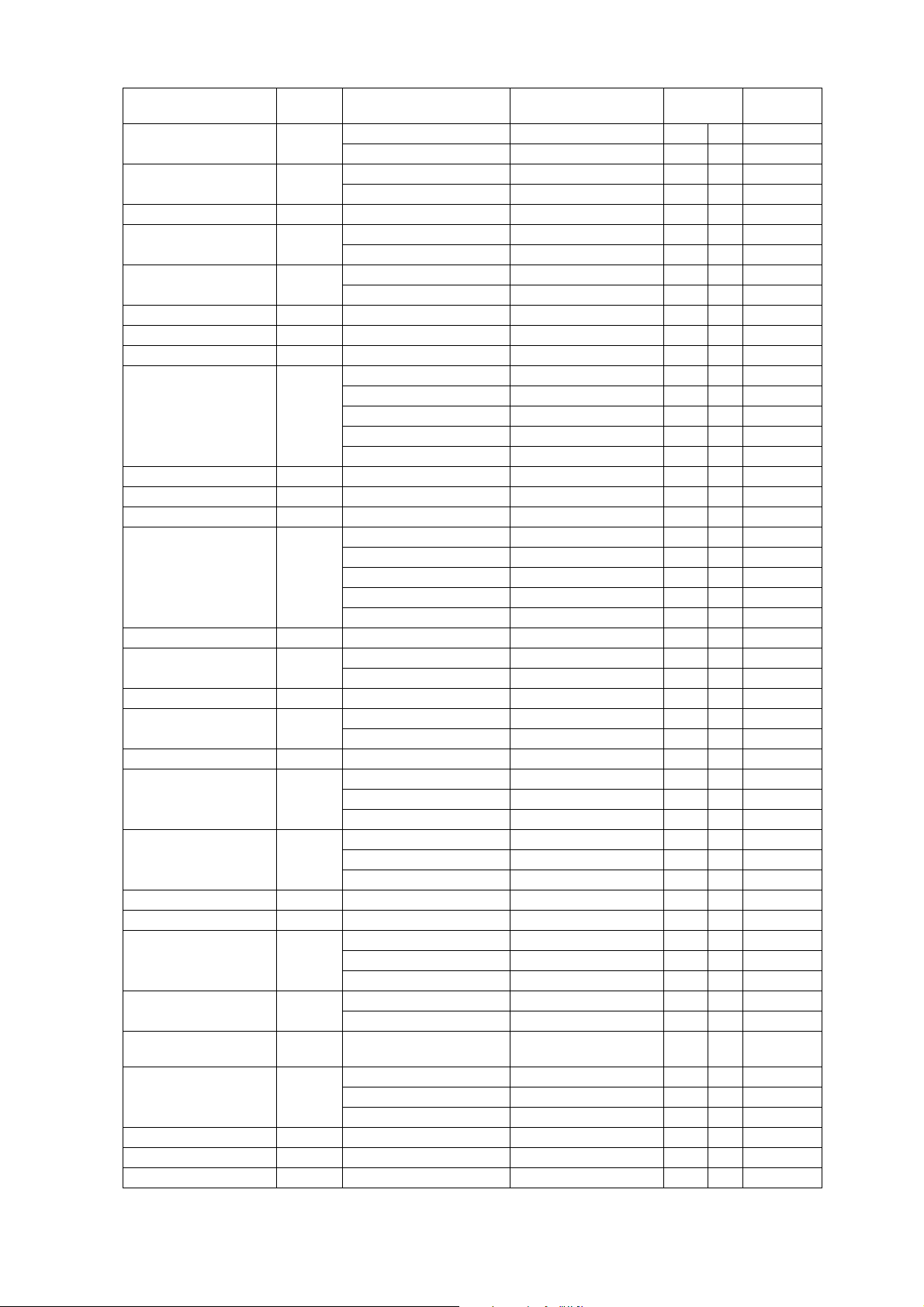

Country

LATVIA

LATVIA

LEBANON +961 Cellis RL Cellis 415 01 GSM 900

LESOTHO +266 VODACOM LESOTHO VCL COMMS 651 01 GSM 900

LITHUANIA +370 BITE GSM LT BITE GSM 246 02 GSM 900

LUXEMBOURG +352 Millicom 1800 -> TANGO TANGO 270 77 GSM 1800

MACAU +853 TELEMOVEL+ MAC-CTMGSM 455 01 GSM 900

MACEDONIA +389 MOBIMAK MKD-MOBIMAK 294 01 GSM 900

MALAWI +265 CALLPOINT 900 MW CP 900 650 01 GSM 900

MALAYSIA +60 MY DiGi MY DiGi 502 16 GSM 1800

MAURITIUS +230 CELLPLUS CELLPLUS-MRU 617 01 GSM 900

MOROCCO +212 ONPTGSM MOR ONPT GSM 604 01 GSM 900

NAMIBIA +264 MTC NAM MTC 649 01 GSM 900

NETHERLANDS +31 Ben NL Ben NL 204 16 GSM 1800

NEW_ZEALAND +64 BELLSOUTH BELLSOUTH NZ 530 01 GSM 900

NORWAY +47 NetCom GSM N NetCom GSM 242 02 GSM 900

OMAN +968 OMAN MOBILE OMAN MOBILE 422 02 GSM 900

PHILLIPINES +63 Globe Telecom PH GLOBE 515 02 GSM 900

PHILLIPINES Smart Communications SMART 515 03 GSM 1800

POLAND +48 ERA GSM PL-ERA GSM 260 02 GSM 900

PORTUGAL +351 P OPTIMUS P OPTIMUS 268 03 GSM 1800

QATAR +974 QATARNET QAT-QATARNET 427 01 GSM 900

RÉUNION +262 SRR SFR REUNION 647 10 GSM 900

RUSSIAN FEDERATION +701 BeeLine BeeLine 250 99 GSM 1800

SAUDI_ARABIA

SAUDI_ARABIA

SEYCHELLES +248 SEYCHELLES CELLULAR

SINGAPORE +65 M1-GSM M1-GSM-SGP 525 03 GSM 900

SLOVAK REPUBLIC +42 EUROTEL SK EUROTEL 231 02 GSM 900

SLOVAKIA GLOBTEL SK GLOBTEL 231 01 GSM 900

SLOVENIA +386 MOBITEL GSM (Slovenia) SI MOBITEL GSM 293 41 GSM 900

Access

Code

+371 BALTEL LV BALTEL 247 02 GSM 900

+966 EAE-ALJAWWAL EAE-ALJAWWAL 420 07 GSM 900

Service or Operator Phone Display

LMT GSM LV LMT GSM 247 01 GSM 900

LibanCell RL LibanCell 415 03 GSM 900

LITHUANIAN OMNITEL OMNITEL LT 246 01 GSM 900

LUXGSM L LUXGSM 270 01 GSM 900

MY TMTOUCH MY TMTOUCH 502 13 GSM 900

MY a.d.a.m MY a.d.a.m 502 17 GSM 900

MY celcom MY celcom 502 19 GSM 900

MY maxis MY maxis 502 12 GSM 900

KPN TELECOM NL KPN TELECOM 204 08 GSM 900

LIBERTEL NL LIBERTEL 204 04 GSM 900

NL Dutchtone NL Dutchtone 204 20 GSM 1800

TELFORT TELFORT 204 12 GSM 1800

Telenor Mobile N Telenor Mobil 242 01 GSM 900

Islacom ISLACOM 515 01 GSM 900

IDEA IDEA 260 03 GSM 1800

PL PLUS PL PLUS 260 01 GSM 900

TELECEL P TELECEL 268 01 GSM 900

TMN P TMN 268 06 GSM 900

MTS MTS-RUS 250 01 GSM 900

North-West GSM North-West GSM 250 02 GSM 900

MoPTT, DMTS-1 ALJAWWAL 420 01 GSM 900

CELLULAR SERVICE 633 01 GSM 900

SERVICES

ST-GSM ST-GSM-SGP 525 01 GSM 900

ST-GSM1800-SGP ST-GSM1800-SGP 525 02 GSM 1800

Network

Code

Band

MCUK001002C8 Section 3 Issue 1

Service Manual – 17 – Revision 0

Page 24

OPERATING INSTRUCTIONS

Country

SOUTH_AFRICA

SOUTH_AFRICA

SPAIN +34 AIRTEL E AIRTEL 214 01 GSM 900

SRI_LANKA +94 DIALOG SRI DIALOG 413 02 GSM 900

SUDAN +249 SDN MOBITEL SDN MobiTel 634 01 GSM 900

SWEDEN +46 COMVIQ S COMVIQ 240 07 GSM 900

SWITZERLAND

SWITZERLAND

SWITZERLAND

SYRIA +963 MOBILE SYRIA SYR MOBILE SYR 417 09 GSM 900

TAIWAN +886 Chunghwa Chunghwa 466 92 GSM 900

TANZANIA +255 Tritel-TZ Tritel-TZ 640 01 GSM 900

THAILAND +66 AIS GSM TH AIS GSM 520 01 GSM 900

TURKEY

TURKEY

UKRAINE +380 GOLDEN TELECOM GOLDEN TELECOM 255 05 GSM 1800

UNITED ARAB

EMIRATES (UAE)

UNITED KINGDOM

(Guernsey)

(Jersey)

(Isle of Man)

VIETNAM +84 Mobi Fone VN Mobi Fone 452 01 GSM 900

Access

Code

+27 MTN MTN-SA 655 10 GSM 900

+41 Orange Orange 228 03 GSM 900

+90 PTT TELSIM GSM TR TELSIM 286 02 GSM 900

+971 UAE ETISALAT ETISALAT-G2 424 02 GSM 900

+44 BTCellnet UK BTCELLNET 234 10 GSM 900

Service or Operator Phone Display

VodaCom VodaCom-SA 655 01 GSM 900

AMENA AMENA 214 03 not known

MOVISTAR MOVISTAR 214 02 not known

MOVISTAR MOVISTAR 214 07 GSM 900

EUROPOLITAN S EUROPOLITAN 240 08 GSM 900

TELIA MOBITEL TELIA S 240 01 GSM 900

SWISS GSM SWISS GSM 228 01 GSM 900

diAx Swiss diAx Swiss 228 02 GSM 900

Far EasTone Far EasTone 466 01 GSM 900

KGT-ONLINE KGT-ONLINE 466 88 GSM 1800

ROC MOBITAI MOBITAI 466 93 GSM 900

TUNTEX TUNTEX 466 06 GSM 1800

TWN GSM TWN GSM 466 97 GSM 1800

TransAsia Telecom GSM TransAsia GSM 466 99 GSM 900

HELLO HELLO 520 10 GSM 1800

WP-1800 WP-1800 520 18 GSM 1800

PTT/TURKCELL GSM TR TURKCELL 286 01 GSM 900

UA KYIVSTAR UA KYIVSTAR 255 03 GSM 900

UA UMC UA UMC 255 01 GSM 900

UA WELLCOM UA WELLCOM 255 02 GSM 900

ONE2ONE one2one 234 30 GSM 1800

ORANGE ORANGE 234 33 GSM 1800

VODAFONE UK VODAFONE 234 15 GSM 900

GUERNSEY TELECOMS GUERNSEY TEL UK 234 55 GSM 900

Jersey Telecoms GSM Jersey Telecoms 234 50 GSM 900

PRONTO GSM MANX PRONTO GSM 234 58 GSM 900

Network

Code

Band

Issue 1 Section 3 MCUK001002C8

Revision 0 – 18 – Service Manual

Page 25

3.16. Glossary of Terms

Term Definition

DTMF Dual Tone Multiple Frequency tones. The numeric keys 0 to 9, and * and # will generate different

GSM Global System for Mobile communications. The name given to the advanced digital technology that the

Home country The country in which the home network operates.

Home network The GSM network on which subscription details are held.

Hot Key Dial Hot Key Dial allows quick access to numbers stored in the Phonebook of Service Dial Number list. The

Lock code Used for security of the telephone. Factory set to “0000”.

Message Centre Where messages are sent before they are forwarded onto their destination. The Message Centre

Network operator The organisation responsible for operating a GSM network. Each country will have at least one

Password Used for the control of the call bar function. Supplied by the service provider.

PIN Personal Identification Number used for SIM security. Supplied by the service provider.

PIN2 Personal Identification Number used for the control of Fixed Dial Memory and call charge metering.

PUK/ PUK2 PIN/PIN2 Unblocking Key. Used to unblock the PIN/PIN2. Supplied by the service provider.

Registration The act of locking on to a GSM network. This is usually performed automatically by the telephone.

Roaming The ability to use the telephone on networks other than the Home network.

Service Dial

Numbers

Service provider The organisation responsible for providing access to the GSM network.

SIM Subscriber Identification Module. A small smart-card which stores unique subscriber and user-entered

Supplementary

service

Wild numbers Spaces in a stored telephone number. When the telephone number is recalled pressing a numeric key

DTMF tones when pressed during conversation. These are used to access voice mail, paging and

home banking services.

telephone uses.

source of the Hot Key Dial may be defined by the user or preprogrammed by the Service Provide. It is

most likely to be preprogrammed to the Service Dial Numbers by the Service Provider.

telephone number may be programmed into the SIM or supplied by the service provider.

network operator.

Supplied by the service provider.

Service Dial Numbers are predefined numbers that allow the user to access a set of special services

provided by the Service Provider. For example billing information or access to Voice Mail.

information such as Phone Book, Fixed Dial Memory and short messages. Supplied by the service

provider.

Network-controlled GSM functions supported by the telephone. Supplementary services may only be

available on a subscription bases.

will fill in a space. This can be used to restrict dialling to a specific area.

OPERATING INSTRUCTIONS

MCUK001002C8 Section 3 Issue 1

Service Manual – 19 – Revision 0

Page 26

OPERATING INSTRUCTIONS

This page is intentionally blank.

Issue 1 Section 3 MCUK001002C8

Revision 0 – 20 – Service Manual

Page 27

DISASSEMBLY / REASSEMBLY INSTRUCTIONS

4 DISASSEMBLY / REASSEMBLY INSTRUCTIONS

4.1. General

This section provides disassembly and reassembly procedures for the main components of the telephone.

These assemblies MUST be performed by qualified service personnel at an authorised service centre.

The following Warnings and Cautions MUST be observed during all disassembly / reassembly operations:

WARNING

The equipment described in this manual contains polarised capacitors utilising liquid electrolyte. These devices are entirely safe provided

that neither a short-circuit nor a reverse polarity connection is made across the capacitor terminals. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN DAMAGE TO THE EQUIPMENT OR, AT WORST, POSSIBLE INJURY TO PERSONNEL RESULTING

FROM ELECTRIC SHOCK OR THE AFFECTED CAPACITOR EXPLODING. EXTREME CARE MUST BE EXERCISED AT ALL TIMES

WHEN HANDLING THESE DEVICES.

Caution

The equipment described in this manual contains electrostatic devices (ESDs). Damage can occur to these devices if the appropriate

handling procedure is not adhered to.

4.1.1. ESD Handling Precautions

A working area where ESDs may be handled safely without undue risk of damage from electrostatic discharge, must be

available. The area must be equipped as follows:

Working Surfaces

All working surfaces must have a dissipative bench mat, safe for use with live equipment, connected via 1M2 resistor

(usually built into the lead) to a common ground point.

Wrist Strap

A quick release skin contact device with a flexible cord, which has an integral safety resistor of between 5k2 and 1M2, shall

be used.

Containers

All containers and storage must be of the conductive type.

4.2. Disassembly

4.2.1 Case Removal

1. Remove the battery from the back of the telephone. Remove the four case screws located inside the battery compartment.

10375-1

Figure 4.1: Case Screw Removal

MCUK001002C8 Section 4 Issue 1

Service Manual – 21 – Revision 0

Page 28

DISASSEMBLY / REASSEMBLY INSTRUCTIONS

anasonic

2. Remove the cover from the case by pulling from the connector end of the telephone. Care must be taken when separating

the case from the cover as the retaining clips may be very stiff. If necessary, re-attach the battery to provide extra support

for the case.

Panasonic

GHI

ABC

P

Q

R

JKL

S

+

Figure 4.2: Case-Cover Separation

DEF

TUV

MNO

W

X

Y

Z

Panasonic

10376-1

3. Remove the PCB assembly from the cover.

nic

aso

n

a

P

10377-1

Figure 4.3: PCB Assembly Removal

4.2.2 Changing the Backup Battery

Remove the case as previously described. The backup battery is held in a retainer on the Main PCB. Observe polarity when

replacing the battery.

Panasonic

10007-1

Figure 4.4: Backup Battery Polarity

Issue 1 Section 4 MCUK001002C8

Revision 0 – 22 – Service Manual

Page 29

DISASSEMBLY / REASSEMBLY INSTRUCTIONS

4.2.3 Access to Printed Circuit Boards

1. Remove the case as described previously. While applying slight pressure to the side retaining clips, lift the Main PCB away

from the chassis.

10195-1

Figure 4.5: Main PCB Removal

2. While applying slight pressure to the side retaining clips, slide the Keypad PCB towards the bottom (I/O) connector until it

is released from the chassis.

10196-1

Figure 4.6: Key PCB Removal

3. Insert a small screwdriver blade or similar blunt object into the chassis recess to the side of the LCD, and gently prise the

LCD from the chassis assembly.

10226-1

Figure 4.7: LCD Removal

4. The Light Guide and Reflector can be removed in turn by prising one side away from the chassis.

MCUK001002C8 Section 4 Issue 1

Service Manual – 23 – Revision 0

Page 30

DISASSEMBLY / REASSEMBLY INSTRUCTIONS

4.2.4. Case-Mounted Components

1. Remove the keypad membrane by peeling it away from the case front.

10231-1

Figure 4.8: Keypad Membrane Removal

2. Remove the microphone assembly by prising upward with a small screwdriver blade or similar blunt object through the slot

in the side of the microphone holder.

10230-1

Figure 4.9: Removal of Microphone

3. Unclip the speaker holder and lift out the speaker.

10229-1

Figure 4.10: Speaker Removal

4. Remove the RF Shield by depressing one of the side retaining clips with a small screwdriver blade or similar blunt object.

10227-1

Figure 4.11: Removal of RF Shield

Issue 1 Section 4 MCUK001002C8

Revision 0 – 24 – Service Manual

Page 31

DISASSEMBLY / REASSEMBLY INSTRUCTIONS

2

5. Once the RF Shield has been removed, the Memo button and Desktop Handsfree (DTHF) speaker may be lifted out from

the case.

6. The Vibrate motor may be removed by gently applying pressure under the spindle / counterweight.

10212-

Figure 4.12: Removal of Vibrate Motor

7. Using a small screwdriver blade or similar blunt object, depress the lug on the antenna base in order to release the entire

antenna unit.

10228-2

Figure 4.13: Antenna Removal

4 .3 . Re a sse m bl y

Reassembly is the reverse of disassembly, except that the Keypad PCB should be located in the chassis guides adjacent to

the base I/O connector before sliding it in to its normal location.

Ensure that the securing screws are not over-tightened as this may affect the operation of the keypad.

MCUK001002C8 Section 4 Issue 1

Service Manual – 25 – Revision 0

Page 32

DISASSEMBLY / REASSEMBLY INSTRUCTIONS

This page is intentionally blank.

Issue 1 Section 4 MCUK001002C8

Revision 0 – 26 – Service Manual

Page 33

5 TECHNICAL SPECIFICATIONS

5.1. Tx Characteristics

All data is applicable to GSM 900 and GSM 1800 except where stated.

5.1.1. Frequency Error

±0.1 ppm max., relative to base station frequency.

5.1.2. Modulation Phase Error

RMS: 5°

Peak: 20 °

5.1.3. Output RF Spectrum due to Modulation

Offset from Centre Frequency (kHz) Maximum Level Relative to Carrier (dB)

±100

±200

±250

±600 to 1800

+0.5

-30

-33

-60

TECHNICAL SPECIFICATIONS

5.1.4. Output RF Spectrum due to Switching Transients

Offset from Centre Frequency (kHz)

±400 -19 -22

±600 -21 -24

±1200 -21 -24

±1800 -24 -27

Measurement conditions for output RF spectrum measurements:

Frequency Span 0 Hz

Measurement Bandwidth: 30 Hz

Video Bandwidth: 100 kHz

Peak Hold

Maximum Level (dBm)

GSM 900 GSM 1800

5.1.5. Spurious Emissions at Antenna Connector

Frequency Range Frequency Offset Filter Bandwidth

30 to 50 MHz - 10 kHz 30 kHz -36 -36

50 to 500 MHz - 100 kHz 300 kHz -36 -36

500 MHz to 1GHz 0 to 1MHz 100 kHz 300 kHz -36 -36

1 GHz to 4GHz

Excl. relevant TX band:

P-GSM: 890 to 915 MHz;

DCS: 1710 to 1785 MHz

Relevent TX band:

P-GSM: 890 to 915 MHz;

DCS: 1710 to 1785 MHz

0 to 10 MHz

Š 10 MHz

Š 20 MHz

(offset from edge of

relevant TX band)

1.8 to 6.0 MHz

(offset from carrier)

100 kHz

300 kHz

1 MHz

30 kHz 100 kHz -30 -30

Approximate Video

Bandwidth

300 kHz

1 MHz

3 MHz

Limits (dBm)

GSM 900 GSM 1800

-30

-30

-30

-36

-36

-36

MCUK001002C8 Section 5 Issue 1

Service Manual – 27 – Revision 0

Page 34

TECHNICAL SPECIFICATIONS

5.1.6. Output Level, Dynamic Operation

GSM 900

Power Control

Level

TBA

Transmitter Output Power

(dBm)

Tolerance for Conditions (dB)

Normal Extreme

GSM 1800

Power Control

Level

TBA

Transmitter Output Power

(dBm)

Tolerance for Conditions (dB)

Normal Extreme

5.1.7. Residual Peak Power

70 dBc (BW = 300 kHz)

5.2. Rx Characteristics

5.2.1. Sensitivity

GSM 900 Full Rate Speech

The reference sensitivity performance in terms of frame erasure, bit error, or residual bit error rates (whichever is

appropriate) is specified in the following table, according to the propagation conditions.

Channels

TCH/FS FER 6.742*∼ 8900 0.122*∼ 164000

class Ib (RBER) 0.42/∼ 1,000,000 0.41/∼ 20,000,000

class II (RBER) 8.33 120,000 7.5 24000 9.333 60000 2.439 8200

Propogation Conditions

TUhigh

Test Limit

error rate

%

Minimum

No. of

samples

Propogation Conditions RAPropogation Conditions

HT

Test Limit

error rate

%

Minimum

No. of

samples

Test Limit

error rate

%

Minimum

No. of

samples

Static Conditions

Test Limit

error rate

%

Minimum

No. of

samples

The reference sensitivity level is < -102 dBm.

NOTE: 1 ∼ 1.6. The value of a can be different for each channel condition but must remain the same for FER and

class Ib RBER measurements for the same channel condition.

GSM 900 Half Rate Speech

The reference sensitivity performance in terms of frame erasure, bit error, or residual bit error rates (whichever is

appropriate) is specified in the following table, according to the propagation conditions.

Channels

TCH/HS (FER) 4.598 13050

TCH/HS class Ib (BFI=0) 0.404 148500

TCH/HS class II (BFI=0) 7.725 25500 8500 20000 7600 20000

TCH/HS (UFR) 6.250 9600

TCH/HSL class Ib ((BFI or UFI)=0) 0.269 227000

Propogation Conditions

TUhigh

Test Limit

error rate

%

Minimum

No. of

samples

Propogation Conditions RAPropogation Conditions

HT

Test Limit

error rate

%

Minimum

No. of

samples

Test Limit

error rate

%

Minimum

No. of

samples

Issue 1 Section 5 MCUK001002C8

Revision 0 – 28 – Service Manual

Page 35

TECHNICAL SPECIFICATIONS

GSM 1800 Full Rate Speech

The reference sensitivity performance in terms of frame erasure, bit error, or residual bit error rates (whichever is

appropriate) is specified in the following table, according to the propagation conditions.

Channels

TCH/FS FER 4.478*∼ 13400 0.122*∼ 164000

class Ib (RBER) 0.32/∼ 1,500,000 0.41/∼ 20,000,000

class II (RBER) 8.333 60,000 7.5 24000 9.333 30000 2.439 8200

Propogation Conditions

Test Limit

TUhigh

error rate

%

Minimum

No. of

samples

Propogation Conditions RAPropogation Conditions

Test Limit

error rate

%

Minimum

No. of

samples

Test Limit

error rate

HT

Minimum

No. of

%

samples

Static Conditions

Test Limit

error rate

%

Minimum

No. of

samples

The reference sensitivity level is < -102 dBm.

NOTE: 1 ∼ 1.6. The value of a can be different for each channel condition but must remain the same for FER and

class Ib RBER measurements for the same channel condition.

GSM 1800 Half Rate Speech

The reference sensitivity performance in terms of frame erasure, bit error, or residual bit error rates (whichever is

appropriate) is specified in the following table, according to the propagation conditions.

Channels

TCH/HS (FER) 4.706 12750

TCH/HS class Ib (BFI=0) 0.426 141000

TCH/HS class II (BFI=0) 7.725 25500 8735 20000 7600 20000

TCH/HS (UFR) 6.383 9400

TCH/HSL class Ib ((BFI or UFI)=0) 0.291 206000

Propogation Conditions

Test Limit

error rate

%

TUhigh

Minimum

No. of

samples

Propogation Conditions RAPropogation Conditions

Test Limit

error rate

%

Minimum

No. of

samples

Test Limit

error rate

HT

Minimum

No. of

%

samples

Blocking:

Frequency

FR 600 kHz to FR 800 kHz 70 70

FR 800 kHz to FR 1.6 MHz 70 70

FR 1.6 MHz to FR 3 MHz 80 80

915 MHz to FR -3 MHz 90 FR 3 MHz to FR 980 MHz 90 -

FR 600 kHz to FR 800 kHz - 87

1785 MHz to FR - 3 MHz - 87

835 MHz to <915 MHz 113 >980 MHz to 1000 MHz 113 100 kHz to <835 MHz 90 >1000 MHz to 12.75 GHz 90 100 kHz to 1705 MHz - 113

>1705 MHz to<1785 MHz - 101

>1920 MHz to 1980 MHz - 101

>1980 MHz to 12.75 GHz - 90

Measurement Conditions:

Wanted carrier is 3 dB above reference sensitivity.

Interferer is CW.

Spurious response exceptions:

Six exceptions are permitted IN band 915 - 980 MHz.

24 exceptions are permitted OUTSIDE band 915 - 980 MHz.

Small MS level in dBµVemf()

GSM 900 GSM 1800

MCUK001002C8 Section 5 Issue 1

Service Manual – 29 – Revision 0

Page 36

TECHNICAL SPECIFICATIONS

Intermodulation Characteristics

Interferer Level (f1 & f2) dBm Interferer Frequencies (f1 & f2)

-49 Wanted frequency = 2f1 -f2,

and [f1 - f2] = 800 kHz.

Issue 1 Section 5 MCUK001002C8

Revision 0 – 30 – Service Manual

Page 37

TEST AND MEASUREMENT

6 TEST AND MEASUREMENT

6.1. Introduction

This section provides information on testing the GD93 telephone. The layout is as follows

1. Section 6.2 ALIVH PCBs: Description and repair procedures.

2. Section 6.3 External testing: describes equipment requirements and general set up procedure.

3. Section 6.4 Complete Unit Test Setup: describes how the items of test equipment are used together and general set up

procedure.

4. Section 6.5 Channel box test commands: provides detailed explanation of the different commands available using the test

equipment and channel-box software.

5. Section 6.6 Adjustment mode: describes adjustments available on the handheld unit.

6.2. Any-Layer Interstitial Via Hole (ALIVH) PCBs

CAUTION

The telephone handset uses an ALIVH PCB assembly, the substrate of which is hydrophilic. To avoid damaging the ALIVH

PCB, the specialist equipment and procedures described below must be employed when replacing suspect or faulty

components.

6.2.1. General Information

To reduce overall size and provide enhanced speech and data performance, an Any-Layer Interstitial Via Hole (ALIVH) PCB

is used in this telephone. ALIVH PCBs are multi-layer boards which have an IVH structure in all inter-layers and can provide

an inter-layer connection immediately under the land of a component. In addition, the PCB has no through holes and any

number of layers can be interconnected.

As the specification and performance characteristics of ALIVH PCBs differ from that of conventional multi-layered boards,

special attention is required when handling and repairing these assemblies.

Moisture Absorbency

The ALIVH PWB is more absorbent than a conventional PCB because of the nature of its material. Its aramid substrate is

hydrophilic, i.e. it absorbs moisture from the air. If, after having absorbed moisture, the ALIVH PWB is submitted to re-flow or

repair process, moisture in the board can suddenly evaporate and cause vapour explosion.

Copper Foil Peel Strength (Land Detachment Resistance)

The ALIVH PCB is slightly less resistant to copper detachment force than conventional boards. Therefore, it is necessary to

ensure that solder is melted sufficiently before a component is removed from the board.

Warping Property

The ALIVH PCB has a smaller Young's Modulus and is therefore more pliant than conventional boards. It is important that the

ALVIH PCB is not bent when component placement is performed.

6.2.2. Repair Procedures

To prevent problems caused by moisture absorption, it will be necessary to perform dehydration of ALIVH PCBs in a suitable

oven or similar heating device prior to repair. The boards should be heated at 85 °C for a duration of at least ten hours.

The repair should also be performed under the following conditions:

Soldering Iron

The temperature of the tip of the soldering iron should be 350 °C ±10 °C for an application time of five seconds or less.

Removal and re-mounting of components should be performed only once at any component position.

Note: To avoid land detachment, do NOT apply excessive force on the soldering iron when heating the board.

Ensure that the solder has melted sufficiently to allow component removal without damaging the board.

Hot-Air Blower

The blower air temperature should be at:

MCUK001002C8 Section 6 Issue 1

Service Manual – 31 – Revision 0

Page 38

TEST AND MEASUREMENT

295 °C ±5 °C for an application time of 120 seconds or less,

or:

395 °C ±5 °C for an application time of 30 seconds or less.

Removal and re-mounting of components should be performed only once at any component position.

Note: To avoid land detachment, do NOT apply excessive force on the soldering iron when heating the board.

Ensure that the solder has melted sufficiently to allow component removal without damaging the board.

Re-flowing / Re-touching

1. Re-touching by soldering iron:

HAKKO 928 soldering iron is recommended.

900S-T-B tip for thicker solder joints and 900M-T-LB tip for thinner solder joints are recommended

2. Tip temperature/time

Normal pad : 325±10°C, less than five seconds

Large Pad : 400±10°C, less than five seconds

3. Pressure at solder tip

· Weight of soldering iron, (50gm) + 100gm to 150gm

· Do not exert pressure in the horizontal direction

4. Retouching small components

Pinch the component using two soldering irons and retouch within four seconds

6.3. External Testing

6.3.1. General Information

The handset can be connected to a compatible personal computer for electronic adjustment and fault diagnosis. This section

provides a description of the equipment required to perform those tasks.

Testing and adjustment of the handheld unit can be performed with the outer case in place and the cradle connected. For indepth fault finding the unit should first be disassembled, as detailed in Section 4, and then the PCB Repair Jig used to connect

the PCBs together externally as they would be found in normal use. Fault tracing can then be performed on the PCBs using

suitable test equipment, such as spectrum analysers and oscilloscopes.

The unit must now be tested and calibrated for both frequency bands (900 MHz and 1800 MHz).

6.3.2. Jigs and Tools

Interface Box (Part No. IFB003 / IFB004)

The Interface box provides:

IFB003: Voltage regulation for +7.2 V, +5.6 V or 4.8 V DC outputs. The +7.2 V switch setting is used as a supply to Li-Ion type

batteries (compatible for other products), the 5.6 V switch setting is used for PCB testing and the 4.8 V switch setting is used

for testing the complete unit.

Interface Box IFB004 is a later version that provides +4.8 V, +7.2V and +8.2 V DC outputs. It also allows selection of external

power via the Interface cable.

RS 232 interface. Ensures that the Unit Under Test is supplied with the correct signal levels and format.

Issue 1 Section 6 MCUK001002C8

Revision 0 – 32 – Service Manual

Page 39

INTERFACE BOX

P

O

W

E

R

IG

N

O

V

TEST AND MEASUREMENT

C

S

IB

S

0

E

0

R

0

IA

2

L

4

.8

V

P

O

W

E

R

M

C

P

H

U

O

N

K

E

O

U

T

P

U

T

N

C

O

O

M

.2

P

8

5

U

5

T

0

E

0

R

0

1

IN

P

U

T

1

2

V

D

C

10016-1

FRONT

REAR

Figure 6.1: Interface Box IFB003 / IFB004

6.3.3. Personal Computer (PC)

The PC (IBM compatible) is used as a Unit Under Test controller. This in conjunction with the channel box software, allows all

of the test facilities normally provided through the keypad of the Unit Under Test.

6.3.4. Power Supply

Provides 12 V DC supply to Interface box IFB003 or IFB004.

Test Battery (Part Number JT00042)

Provides 3.6 V DC supply to Interface Box IFB003 or IFB004 to compensate for the current drain when the Unit Under Test is

used at full transmit power.

10017-1

Figure 6.2: Test Battery

PCB Repair Jig (Part No. JT00057)

This unit provides the necessary connections between the Main and Keypad PCBs, and the connections between Main PCB

and external test equipment.

MCUK001002C8 Section 6 Issue 1

Service Manual – 33 – Revision 0

Page 40

TEST AND MEASUREMENT

10265-1

Figure 6.3: PCB Repair Jig

RF Adaptor (Part No JT00055)

This unit provides an RF connection between the Unit Under Test and external test equipment.

10232-1

Figure 6.4: RF Adaptor

GSM Tester

This unit acts as a base station providing all the necessary GSM signalling requirements and also provides GSM signal

measuring facilities.

Interface Cable (Part No. JT00043)

The interface cable allows connection between a computer and the Unit Under Test via IFB003 or IFB004.

10266-1

Figure 6.5: Interface Cable

Issue 1 Section 6 MCUK001002C8

Revision 0 – 34 – Service Manual

Page 41

TEST AND MEASUREMENT

Battery Calibration Voltage Control Unit (Part No. JT00010)

The Battery Calibration Voltage Control Unit (BCVCU) provides three voltage levels (3 V, 4.1 V and 0 V) to the Test Battery,

and is used during battery calibration checks. It is powered from the Interface Box.

10163-1

Figure 6.6: Battery Calibration Control Unit

6.3.5. Channel Box Software

This is the test software for the telephone unit and should be installed onto the personal computer to be used for testing.

MCUK001002C8 Section 6 Issue 1

Service Manual – 35 – Revision 0

Page 42

TEST AND MEASUREMENT

6.4. Complete Unit Setup

MAIN

PCB

(INTERNAL CONNECTOR)

RF CABLE

KEYPAD PCB

10199-1

Figure 6.7: Complete Unit Test Setup

Issue 1 Section 6 MCUK001002C8

Revision 0 – 36 – Service Manual

Page 43

TEST AND MEASUREMENT

6.4.1. External Testing Setup Procedure

IMPORTANT NOTE

To allow accurate measurement of the complete unit the test equipment must be connected as shown (Figure 6.6). The PCB

Test Setup must be used to enable repair to PCBs. Once repair/replacement is complete, the assembled unit must be tested

and calibrated with the jigs and tools connected as shown in Figure 6.7.

Full Test Equipment Requirements

For testing the handheld unit the following equipment is required:

1. Interface box

2. 12 V power supply

3. Personal computer (IBM compatible) with RS232 interface

4. RS232 interface cable (9 pin straight through connection)

5. GSM test station

6. RF Adaptor

7. Interface cable – JT00004

The channel box software (supplied on floppy disk) should be installed onto the main drive of the personal computer.

The RF cable is connected to the GSM test station via a suitable adapter. The 12 V supply is connected to the rear socket of

the Interface box.

Two modes are available for testing the handheld unit:

1. Test Mode.

The Test Mode facility allows various sections of the handheld unit to be individually activated.

2. Normal Mode.

The Normal Mode facility allows the handheld unit to be powered externally for call origination/receiving operations.

NOTE: A suitable test SIM card will be required which is compatible with the GSM test station.

Power On into Test Mode

1. Connect the test equipment into test mode configuration.

TO GSM TEST SET

F

E

D

C

B

A

O

N

M

L

K

J

I

H

G

Z

Y

X

W

V

U

T

S

R

Q

P

+

INTERFA

P

O

CE BO

W

E

R

O

F

X

F

O

N

M

P

H

CUK

O

N

E

O

U

T

P

U

T

10238-1

Figure 6.8: External test equipment setup

2. Ensure that the following settings are made:

a. Interface box IFB003 or IFB004

Power: UP position

IGN: UP position

Mode DOWN position

Voltage Middle Position (7.2 V)

N

C

O

O

M

P

U

T

E

R

O

U

T

P

U

T

1

2

V

D

C

MCUK001002C8 Section 6 Issue 1

Service Manual – 37 – Revision 0

Page 44

TEST AND MEASUREMENT

b. Power supply

+12V DC: ON

c. PC

Channel box software loaded and the screen indicating as shown:

Figure 6.9: PC Screen (SCRN10)

3. Press ENTER on the PC keyboard.

4. At the PC press F10.

5. After approximately 1 second, set the Interface Cable switch to ON (position is marked by a dot).

NOTE: The display will read:

GET STATION

ADDRESS = _ _

INFO = _ _

The back light will be illuminated and all LEDs will be lit.

Go to Section 6.5 (Channel Box Test Commands) for further testing information.

Power On In Normal Mode

1. Connect the test equipment as shown in the diagram.

TO GSM TEST SET

F

E

D

C

B

A

O

N

M

L

K

J

I

H

G

Z

Y

X

W

V

U

T

S

R

Q

P

+

IN

TER

FACE B

P

O

W

E

R

O

O

F

X

F

O

N

P

H

10238-1

Figure 6.10: External test equipment setup

2. Ensure that the following settings are made:

a. Interface box IFB003 or IFB004

Power: DOWN position

IGN: UP position

MODE: UP position

b. Power supply:

+12V DC:ON

c. PC

Channel box software loaded and the screen indicating as shown:

N

C

O

O

M

P

U

T

E

R

O

U

T

P

U

T

1

2

V

D

C

M

CUK

O

N

E

O

U

T

P

U

T

Issue 1 Section 6 MCUK001002C8

Revision 0 – 38 – Service Manual

Page 45

TEST AND MEASUREMENT

Figure 6.11: PC Screen (SCRN9)

3. On the PC, select NORMAL MODE and press ENTER.

4. Press F10 on the PC.

5. After approximately 1 second, set the interface cable switch to ON (position is marked by a dot).

Entering Call Mode from Test Mode

Ensure that a fully-charged battery is attached to the telephone.

The screen of the PC should resemble the one shown below:

Figure 6.12: PC Screen (SCRN11)

1. At the PC, change the SOFT SIM field to read <ENABLE>. Press ENTER.

2. At the PC, change the TEST MODE field to read <TERM>. Press ENTER.

The UUT will power down and up again. If the UUT is connected to a GSM test set,after a delay of approximately five

seconds, the UUT will register service.

3. To return to test mode, set the SOFT SIM field to <DISABLE> and set the TEST MODE field to <TEST>. Press Enter.

MCUK001002C8 Section 6 Issue 1

Service Manual – 39 – Revision 0

Page 46

TEST AND MEASUREMENT

6.5. Channel Box Test Commands

The following table outlines the commands available using the channel box software.

After the telephone unit has been switched on (Section 6.4), use the up / down cursor keys on the PC keyboard to select the

channel box command. Use the left / right cursor keys to display the required indication and then press the ENTER key to

select the displayed function.

CHANNEL BOX COMMAND INDICATION FUNCTION

TEST MODE <TERM>

<ReST>

INITIALIZE <INIT> When RETURN is pressed this will reset the

CHANGE CH GSM <xxx> Sets up predefined channel settings for GSM fre-

CHANGE CH DCS <xxx> Sets up predefined channel settings for DCS fre-

POWER LEVEL <xxx> Allows a specified power level to be set at the

TX DATA <NRL 0>

RSSI (DBM) <xxx> Provides an RSSI reading on the User specified

SET AGC 1

SET AGC 2

SET AGC 3

SP LOOP BACK <START>

PATH CONT <MOSO>

VOL. BUZZ <xx> Sets buzzer volume between values

VOL. SIDE <xx> Sets 4 side tone volume levels between

VOL. MIC <xx> Sets 8 MIC volume levels between

VOL. SP1 <xx> Sets speaker pre-amp volume levels

VOL. SP2 <xx> Sets speaker volume levels