ORDER NO. DSC1302004CE

Digital Camera

Model No. DMC-XS1P

DMC-XS1PC

DMC-XS1PU

DMC-XS1EB

DMC-XS1EE

DMC-XS1EF

DMC-XS1EG

B26

DMC-XS1EP

DMC-XS1GA

DMC-XS1GC

DMC-XS1GF

DMC-XS1GK

DMC-XS1GN

DMC-XS1GT

Colour

(W)..........White Type

(K)...........Black Type

(R)...........Red Type (except PC)

(WA)........White Type (only EB/EG/EP)

(V)............Violet Type (only EB/EF/EG/EP/GC/GF/GN)

© Panasonic Corporation 2013 Unauthorized copying and distribution is a violation of law.

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure. 1) --------3

1.4. How to Discharge the E.Capacitor on Flash

Top P.C.B.----------------------------------------------------4

2Warning--------------------------------------------------------------5

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------5

2.2. How to Recycle the Lithium Ion Battery (U.S.

Only)-----------------------------------------------------------5

3 Service Navigation------------------------------------------------6

3.1. Introduction --------------------------------------------------6

3.2. Important Notice -------------------------------------------6

3.3. General Description About Lead Free Solder

(PbF) ----------------------------------------------------------7

3.4. How to Define the Model Suffix (NTSC or PAL

model)---------------------------------------------------------8

4 Specifications ---------------------------------------------------- 12

5 Location of Controls and Components------------------ 13

6 Service Mode ----------------------------------------------------- 15

6.1. Error Code Memory Function -------------------------15

7 Service Fixture & Tools --------------------------------------- 18

7.1. Service Fixture and Tools ------------------------------ 18

7.2. When Replacing the Main P.C.B. -------------------- 18

7.3. Service Position ------------------------------------------ 19

8 Disassembly and Assembly Instructions --------------- 20

8.1. Disassembly Flow Chart-------------------------------- 20

8.2. P.C.B. Location ------------------------------------------- 20

8.3. Disassembly Procedure --------------------------------21

8.4. Removal of the CCD FPC Unit ----------------------- 28

9 Measurements and Adjustments -------------------------- 29

9.1. Introduction ------------------------------------------------29

9.2. Before Disassembling the unit ------------------------ 29

9.3. Details of Electrical Adjustment----------------------- 31

9.4. After Adjustment------------------------------------------ 35

10 Maintenance ------------------------------------------------------ 36

10.1. Cleaning Lens and LCD Panel ----------------------- 36

11 Block Diagra m --------------------------------------------------- 37

11.1. Overall Block Diagram ---------------------------------- 37

11.2. Flash / Top Block Diagram----------------------------- 38

11.3. Sub Operation Block Diagram ------------------------38

12 Wiring Connection Diagram --------------------------------- 39

12.1. Interconnection Diagram ------------------------------- 39

2

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during

the servicing of AC Adaptor whose chassis is not isolated

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by accidental shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

5. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

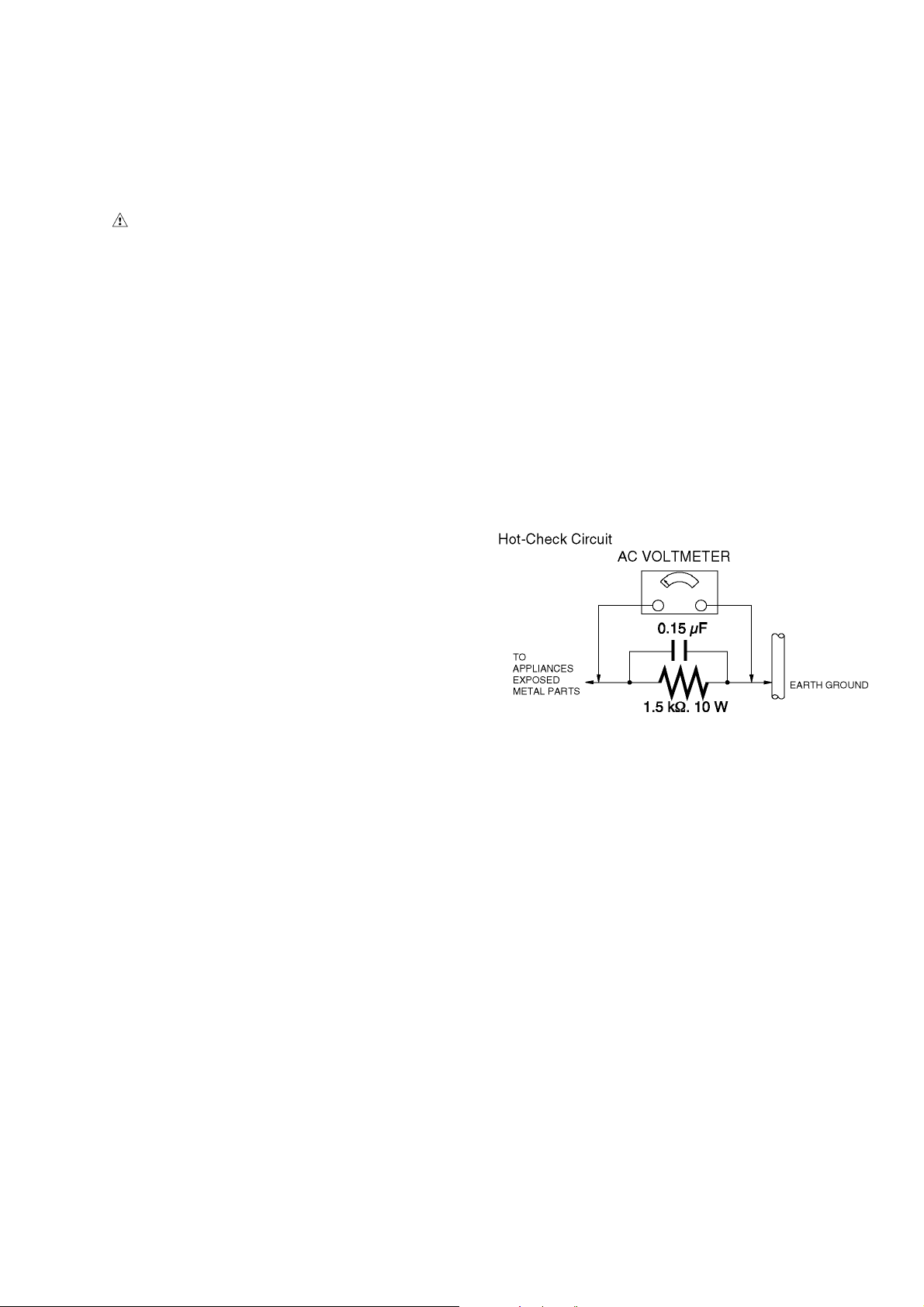

1.3. Leakage Current Hot Check (See Figure. 1)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5 kΩ, 10 W resistor, in parallel with a 0.15 μF

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure. 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1 MΩ and 5.2 MΩ. When the exposed

metal does not have a return path to the chassis, the

reading must be infinity.

Figure. 1

3

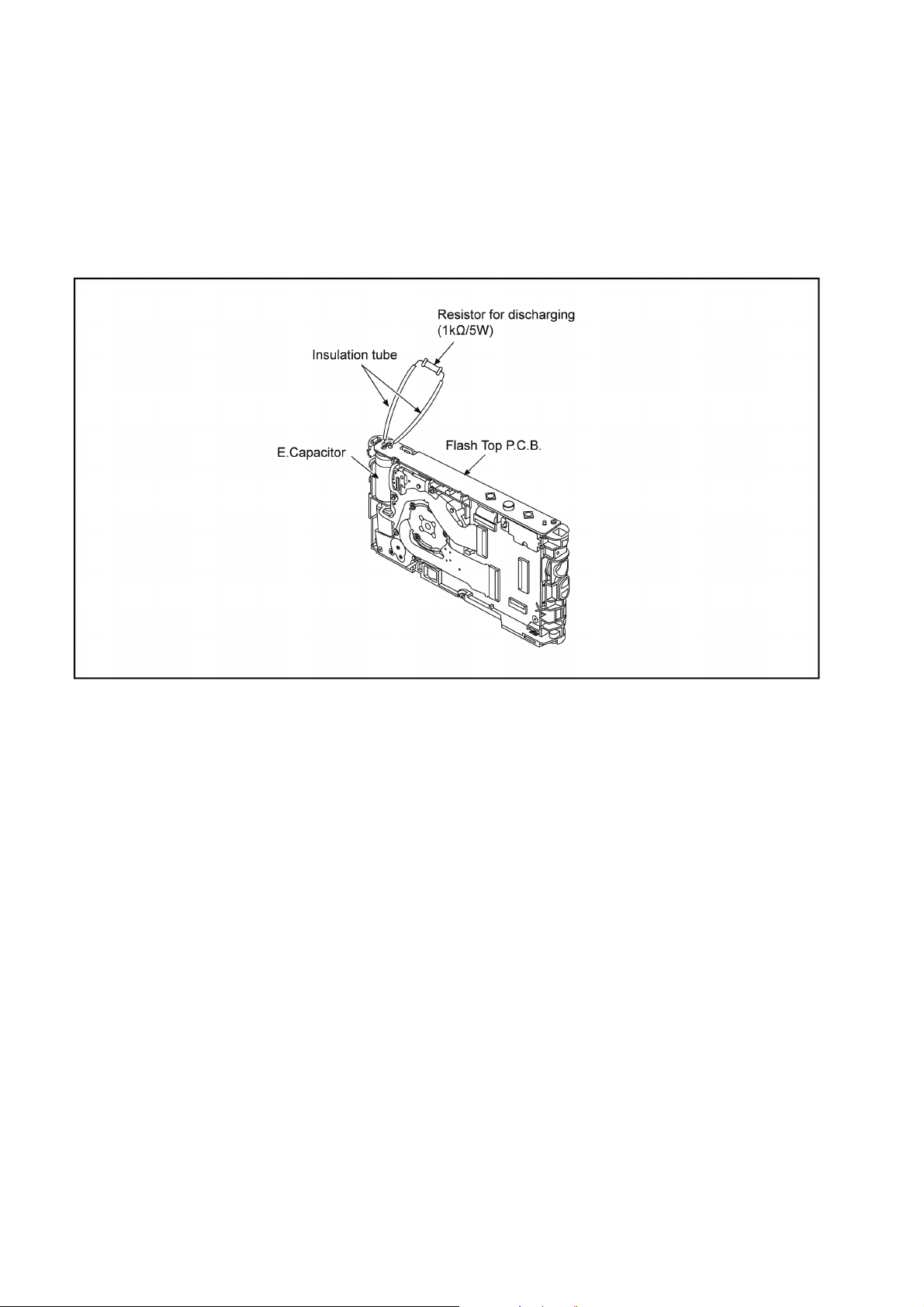

1.4. How to Discharge the E.Capacitor on Flash Top P.C.B.

CAUTION:

• Be sure to discharge the E.Capacitor on Flash Top P.C.B. before disassembling.

• Be careful of the high voltage circuit on Flash Top P.C.B. when servicing.

[Discharging Procedure]

1. Put the insulation tube on the lead part of resistor (ERG5SJ102:1kΩ /5W).

(An equivalent type of resistor may be used.)

2. Put the resistor between both terminals of E.Capacitor on the Flash Top P.C.B. for approx. 5 seconds.

3. After discharging, confirm that the E.Capacitor voltage is lower than 10V by using a voltmeter.

Fig. F1

4

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as “antistatic (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

2.2. How to Recycle the Lithium Ion Battery (U.S. Only)

5

3 Service Navigation

3.1. Introduction

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

3.2. Important Notice

3.2.1. CCD FPC UNIT:

• The image sensor (CCD FPC) unit which are connected to the lens unit with 3 screws.

These screws are adjusted for the Optical tilt.

During servicing, if one of CCD FPC fixing screws are loosened, the Optical tilt adjustment must be performed.

About the Optical tilt adjustment, refer to the “9.3.2. Adjustment Specifications” for details.

3.2.2. P.C.B.:

• In order to remove Main P.C.B., it is necessary to remove the solder (3 points) of the battery terminal.

It is judged that the analysis of the Main P.C.B. which the battery terminal separated is difficult.

So the Main P.C.B. is unit exchange.

Please fix individually about the Flash Top P.C.B..

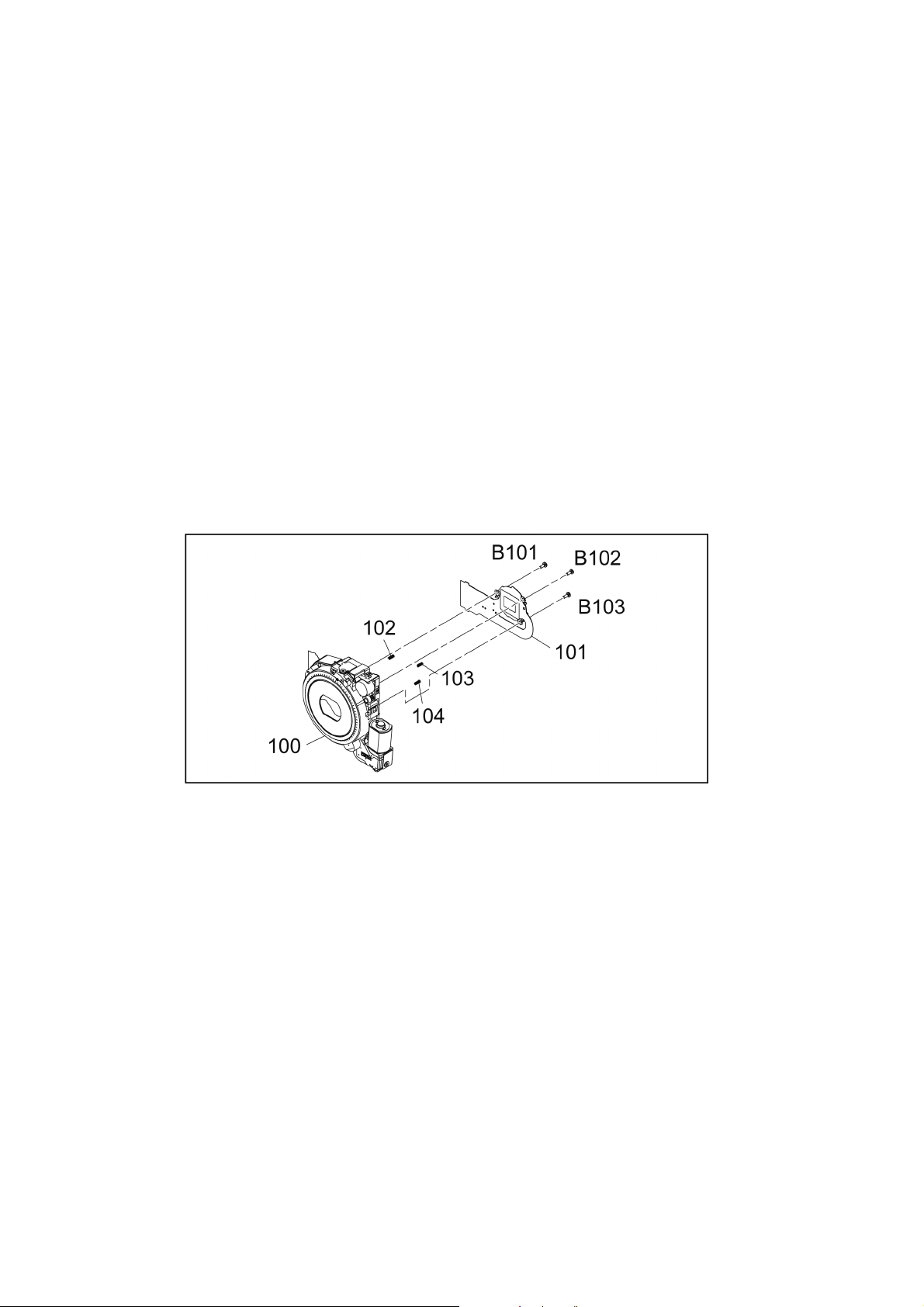

3.2.3. LENS UNIT:

The minimum replacement part size of the Lens part is as shown below.

When servicing, replace the following numbered replacement part size as the smallest size.

3.2.4. About Flexible Cable and Connector

Do not touch carelessly so that the foreign body should not adhere to the terminal part of flexible cable and connector.

Wipe off with a clean cloth and the cotton bud, etc. when the terminal part is dirty.

6

3.3. General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30°C (86°F) more than that of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30°C

(662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01KS-----------(0.3mm 100g Reel)

RFKZ06D01KS-----------(0.6mm 100g Reel)

RFKZ10D01KS-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn) 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

7

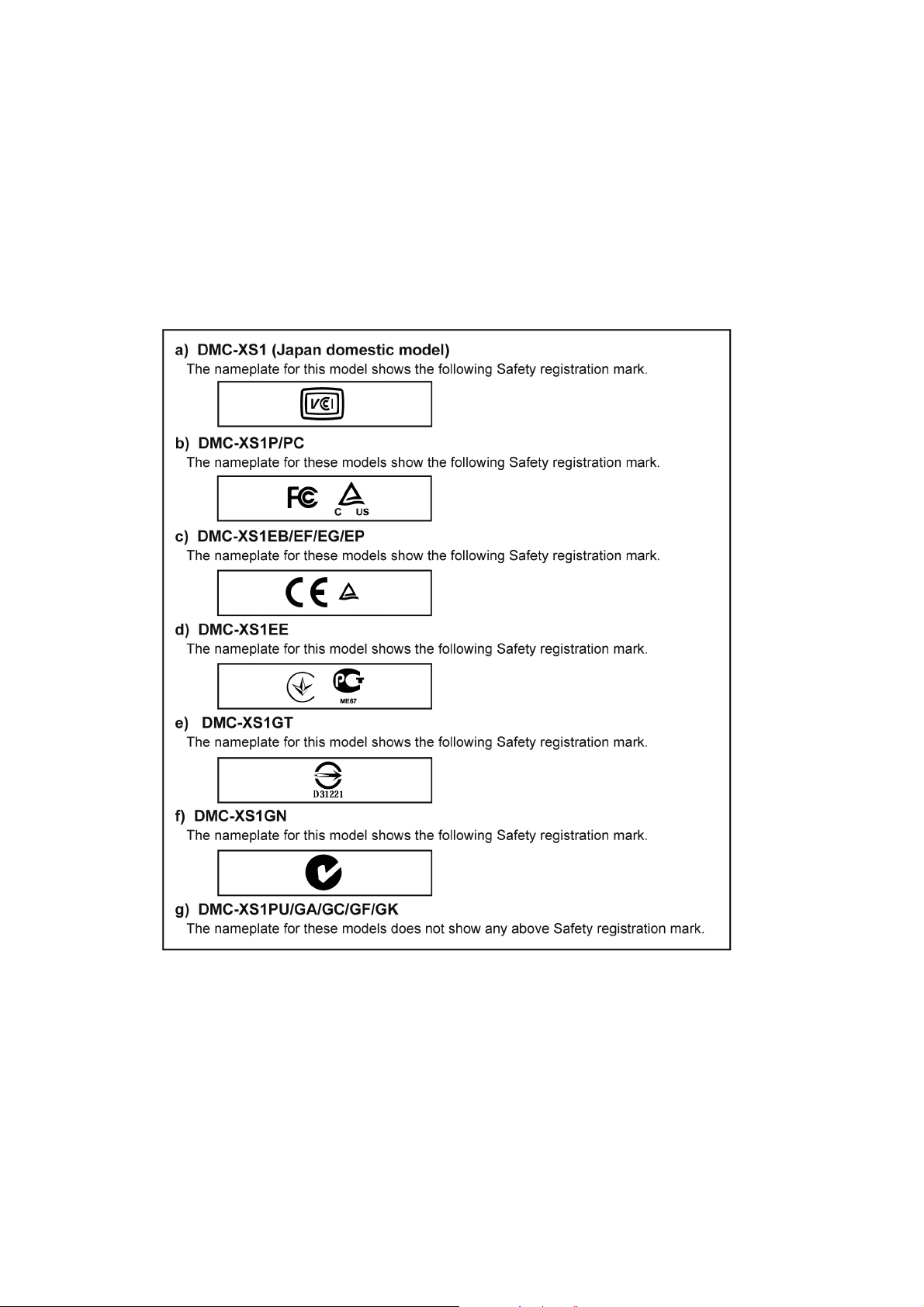

3.4. How to Define the Model Suffix (NTSC or PAL model)

There are seven kinds of DMC-XS1, regardless of the colours.

• a) DMC-XS1 (Japan domestic model)

• b) DMC-XS1P/PC

• c) DMC-XS1EB/EF/EG/EP

• d) DMC-XS1EE

• e) DMC-XS1GT

• f) DMC-XS1GN

• g) DMC-XS1PU/GA/GC/GF/GK

What is the difference is that the “INITIAL SETTINGS” data which is stored in Flash-ROM mounted on Main P.C.B..

3.4.1. Defining methods:

To define the model suffix to be serviced, refer to the nameplate which is putted on the bottom side of the Unit.

NOTE:

After replacing the Main P.C.B., be sure to achieve adjustment.

The service software is available at “TSN Website”.

8

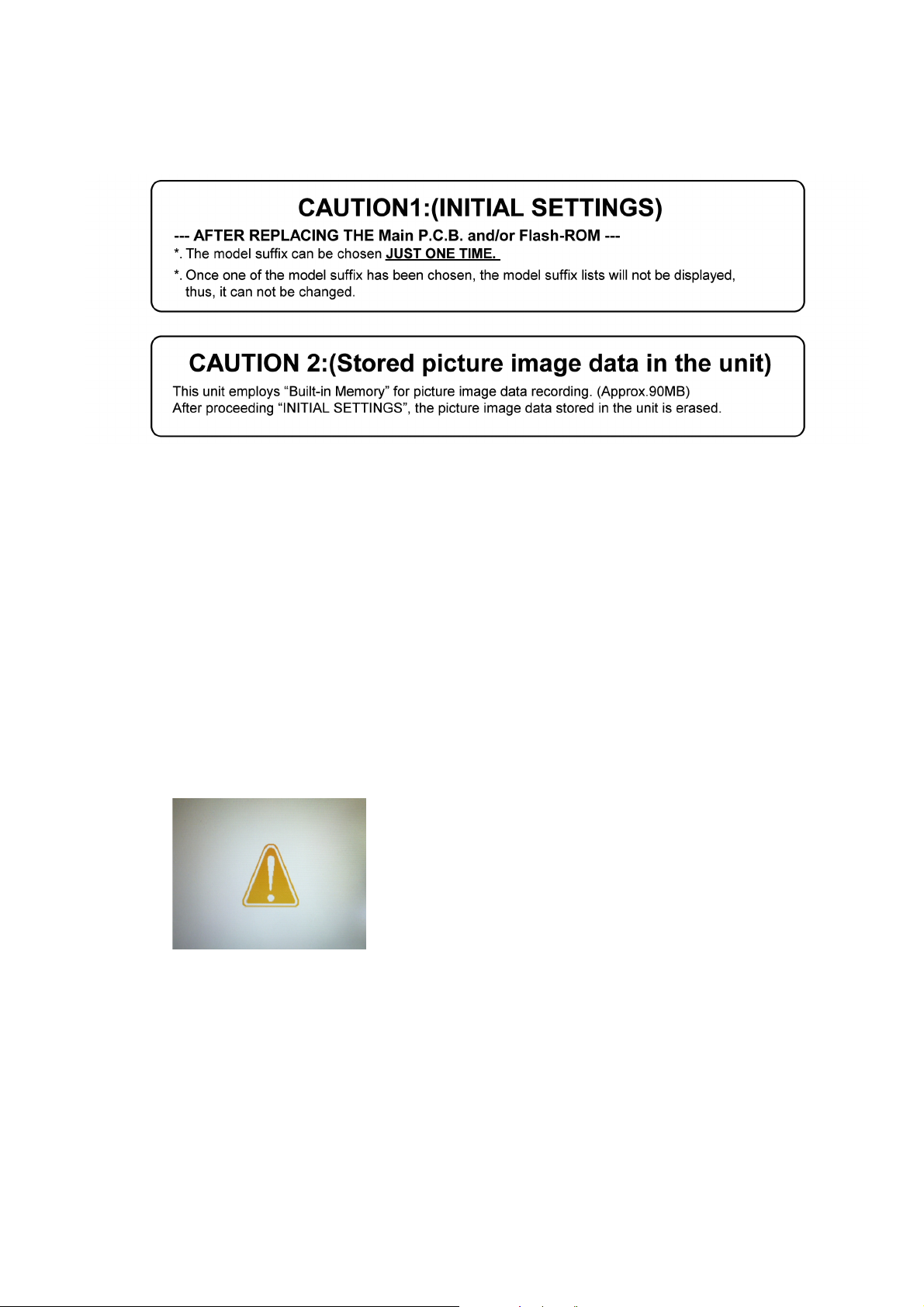

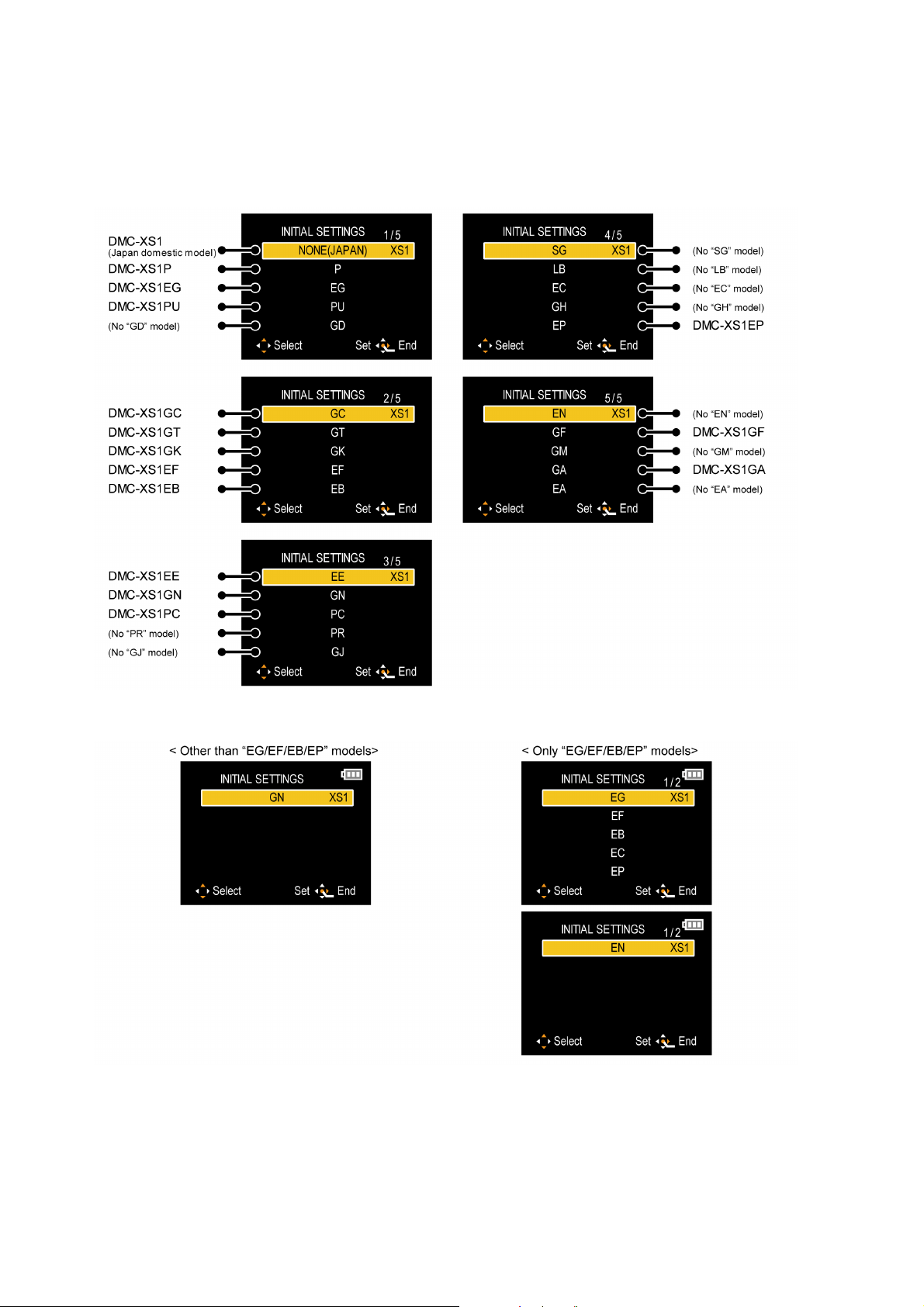

3.4.2. INITIAL SETTINGS:

After replacing the Main P.C.B., make sure to perform the initial settings after achieving the adjustment by ordering the following

procedure in accordance with model suffix of the unit.

1. IMPORTANT NOTICE:

Before proceeding Initial settings, make sure to read the following CAUTIONS.

2. PROCEDURES:

• Precautions: Read the above “CAUTION 1” and “CAUTION 2”, carefully.

• Preparation:

- Attach the Battery.

(Since this unit has built-in memory, it can be performed without inserting memory card.)

1. Turn the Power on.

2. Press the [ MODE ] button, and select the [ NORMAL PICTURE ] mode by Cursor buttons, then press the [ MENU/SET ]

button.

3. Turn the Power off.

(If the unit is other than [ NORMAL PICTURE ] mode, it does not display the initial settings menu.)

• Step 1. The temporary cancellation of “INITIAL SETTINGS”:

Press the [ PLAYBACK ] button, “[ UP ] of Cursor button” and “[ W ] side of Zoom button” simultaneously, turn the Power on.

• Step 2. The cancellation of “INITIAL SETTINGS”:

Press the [ PLAYBACK ] button in order to enter the [ PLAYBACK ] mode.

Press the [ MENU/SET ] button and “[ LEFT ] of Cursor button” simultaneously, turn the Power off.

The LCD displays the “ ! ” mark before the unit powers down.

• Step 3. Turn the Power on:

Turn the Power on.

9

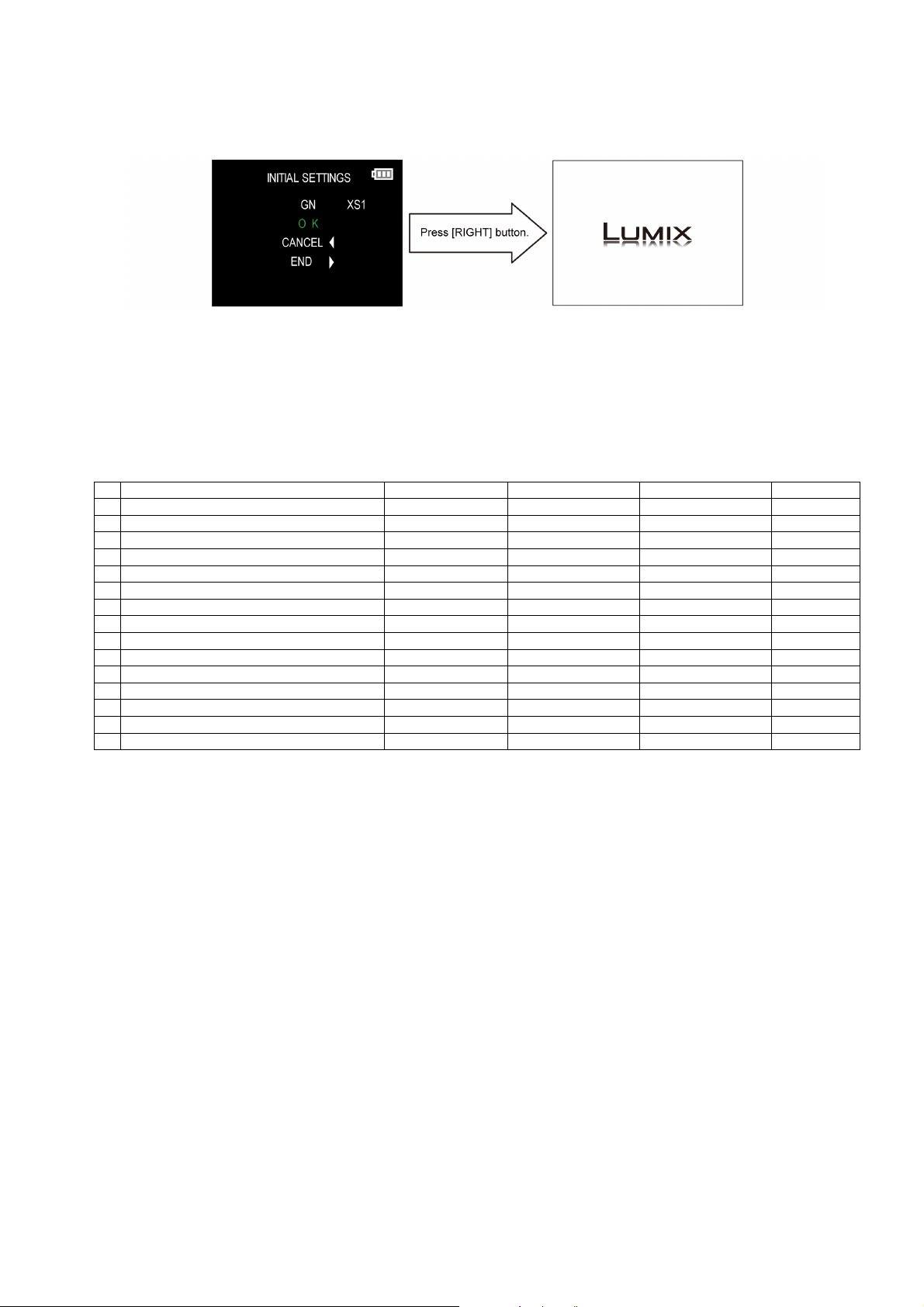

• Step 4. Display the INITIAL SETTING:

While pressing [ MENU/SET ] button and “[ RIGHT ] of Cursor button” simultaneously, turn the Power off.

The “INITIAL SETTINGS” menu is displayed.

There are two kinds of “INITIAL SETTINGS” menu form as follows:

[CASE 1. After replacing Main P.C.B.]

When Main P.C.B. has just been replaced, all of the model suffix is displayed as follows. (Five pages in total)

[CASE 2. Other than “After replacing Main P.C.B.”]

• Step 5. Choose the model suffix in “INITIAL SETTINGS”: (Refer to “CAUTION 1”)

[Caution: After replacing Main P.C.B.]

The model suffix can been chosen, JUST ONE TIME.

Once one of the model suffix have been chosen, the model suffix lists will not be displayed, thus, it can not be changed.

Therefore, select the area carefully.

Select the area with pressing “[ UP ] / [ DOWN ] of Cursor buttons”.

10

• Step 6. Set the model suffix in “INITIAL SETTINGS”:

Press the “[ RIGHT ] of Cursor buttons”.

The only set area is displayed, and then press the “[ RIGHT ] of Cursor buttons” after confirmation.

(The unit is powered off automatically.)

• Step 7. CONFIRMATION:

Confirm the display of “PLEASE SET THE CLOCK” in concerned language when the unit is turned on again.

When the unit is connected to PC with USB cable, it is detected as removable media.

(When the “GK” or “GT” model suffix is selected, the display shows “PLEASE SET THE CLOCK” in Chinese.)

1) As for your reference, major default setting condition is as shown in the following table.

• Default setting (After “INITIAL SETTINGS”)

MODEL VIDEO OUTPUT LANGUAGE DATE REMARKS

a) DMC-XS1(Japan domestic model) NTSC Japanese Year/Month/Date

b) DMC-XS1P NTSC English Month/Date/Year

c) DMC-XS1PC NTSC English Month/Date/Year

d) DMC-XS1PU NTSC Spanish Month/Date/Year

e) DMC-XS1EB PAL English Date/Month/Year

f) DMC-XS1EE PAL Russian Date/Month/Year

g) DMC-XS1EF PAL French Date/Month/Year

h) DMC-XS1EG PAL English Date/Month/Year

i) DMC-XS1EP PAL English Date/Month/Year

j) DMC-XS1GA PAL English Date/Month/Year

k) DMC-XS1GC PAL English Date/Month/Year

l) DMC-XS1GF PAL English Date/Month/Year

m) DMC-XS1GK PAL Chinese (simplified) Year/Month/Date

n) DMC-XS1GN PAL English Date/Month/Year

o) DMC-XS1GT NTSC Chinese (traditional) Year/Month/Date

11

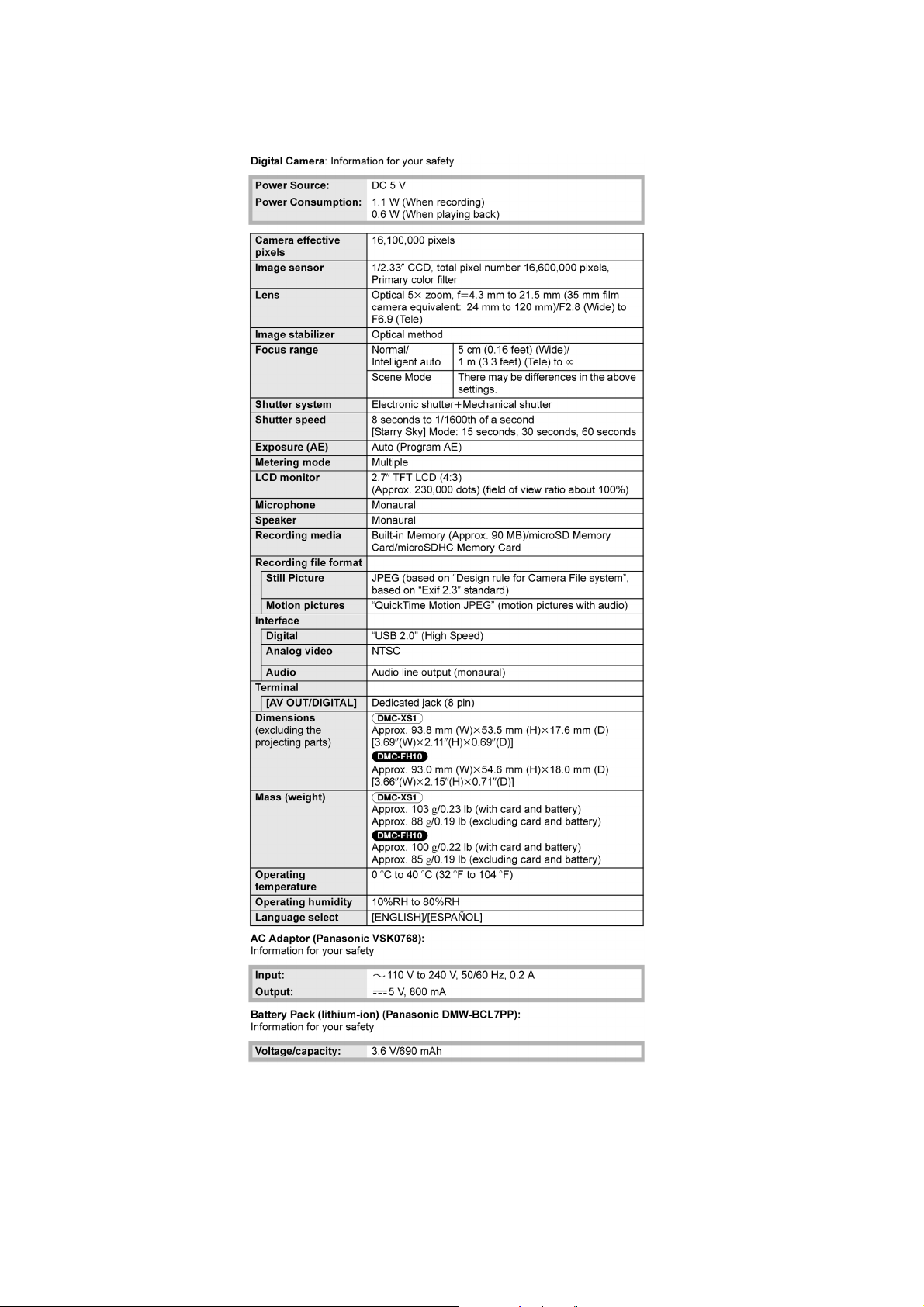

4 Specifications

The following specification is for DMC-XS1P/DMC-FH10P.

Some specifications may differ depending on model suffix.

12

5 Location of Controls and Components

The following description is for DMC-XS1P.

Some descriptions may differ depending on model suffix.

13

14

6 Service Mode

6.1. Error Code Memory Function

1. General description

This unit is equipped with history of error code memory function, and can be memorized 16 error codes in sequence from the

latest. When the error is occurred more than 16, the oldest error is overwritten in sequence.

The error code is not memorized when the power supply is shut down forcibly (i.e.,when the unit is powered on by the battery,

the battery is pulled out) The error code is memorized to Flash-ROM when the unit has just before powered off.

2. How to display

The error code can be displayed by ordering the following procedure:

• Preparation

- Attach the Battery.

(Since this unit has built-in memory, it can be performed without inserting memory card.)

1. Turn the Power on.

2. Press the [ MODE ] button, and select the [ NORMAL PICTURE ] mode by Cursor buttons, then press the [ MENU/SET ]

button.

3. Turn the Power off.

(If the unit is other than [ NORMAL PICTURE ] mode, it does not display the initial settings menu.)

• Step 1. The temporary cancellation of “INITIAL SETTINGS”:

Press the [ PLAYBACK ] button ,“[ UP ] of Cursor button” and “[ W ] side of Zoom button” simultaneously, turn the Power on.

• Step 2. Execute the error code display mode:

Press the [ PLAYBACK ] button in order to enter the [ PLAYBACK ] mode.

Press in order of [ PLAYBACK ] button, [ SHUTTER BUTTON ] fully, and “[ LEFT ] of Cursor button”.

Finally those states are press simultaneously.

The display is changed as shown below when the above buttons are pressed simultaneously.

Normal display → Error code display → Operation history display →Normal display →.....

Example of Error Code Display

15

Error Code List

The error code consists of 8 bits data and it shows the following information.

16

Important notice about “Error Code List”

1) About “*” indication:

The third digit from the left is different as follows.

- In case of 0 (example: 180

When the third digit from the left shows “0”, this error occurred under the condition of INITIAL SETTINGS has been

completed.

It means that this error is occurred basically at user side.

- In case of 8 (example: 188

When the third digit from the left shows “8”, this error occurred under the condition of INITIAL SETTINGS has been

released.

(Example; Factory assembling-line before unit shipment, Service mode etc.)

It means that this error is occurred at service side.

2) About “?” indication: (“18*0 0?01” to “18*0 0?60”):

The third digit from the right shows one of the hexadecimal (“0” to “F”) character.

• Step 3. How to exit from Error Code display mode:

Simply, turn the power off. (Since Error code display mode is executed under the condition of temporary cancellation of “INITIAL SETTINGS”, it wake up with normal condition when turn off the power.)

NOTE:

The error code can not be initialized.

01000)

01000)

17

7 Service Fixture & Tools

7.1. Service Fixture and Tools

The following Service Fixture and tools are used for checking and servicing this unit.

7.2. When Replacing the Main P.C.B.

After replacing the Main P.C.B., be sure to achieve adjustment.

The service software is available at “TSN Website”.

18

7.3. Service Position

Check the Flash Top P.C.B., when servicing this DSC.(Refer to the following.)

CAUTION. (When servicing Flash Top P.C.B.)

1. Be sure to discharge the E.Capacitor on Flash Top P.C.B..

Refer to “How to Discharge the E.Capacitor on Flash Top P.C.B.”.

The E.Capacitor voltage is not lowered soon even if the AC Cord is unplugged or the battery is removed.

2. Be careful of the high voltage circuit on Flash Top P.C.B..

3. DO NOT allow other parts to touch the high voltage circuit on Flash Top P.C.B..

19

8 Disassembly and Assembly Instructions

8.1. Disassembly Flow Chart

This is a disassembling chart.

When assembling, perform this chart conversely.

8.2. P.C.B. Location

20

8.3. Disassembly Procedure

No. Item Fig Removal

1 Rear Case Unit (Fig. D1) Memory Card

Battery

2 Screws (A)

3 Screws (B)

(Fig. D2) Rear Case Unit

2 Rear Op Plate Unit (Fig. D3) 1 Screw (C)

1 Locking tab

2 Hooking parts

Connector (A)

Rear Op Plate Unit

3 Front Case Unit (Fig. D4) 1 Locking tab

Front Case Unit

4 LCD Unit (Fig. D5) 2 Locking tabs

Connector (B)

LCD Unit

5 Frame Plate (Fig. D6) 1 Screw (D)

1 Locking tab

1 Convex

Frame Plate

6 Top Case Unit (Fig. D7) 2 Locking tabs

Top Case Unit

(Fig. D8) (Discharge the E.Capacitor)

7 Flash Top P.C.B. (Fig. D9) Connector (C)

1 Screw (E)

1 Locking tab

2 Convexes

Flash Top P.C.B.

8 Lens Unit (W/CCD) (Fig. D10) Connector (D)

Connector (E)

Lens Unit (W/CCD)

9 Main P.C.B.

Speaker

10 Battery Door Unit (Fig. D13) Battery Door Shaft

(Fig. D11) Terminal Cover

(Fig. D12) 3 Solders

1 Screw (F)

2 Convexes

Main P.C.B.

2 Solders

Speaker

Battery Door Spring

Battery Door Unit

8.3.1. Removal of the Rear Case Unit

21

(Fig. D1)

8.3.2. Removal of the Rear Op Plate Unit

(Fig. D2)

(Fig. D3)

22

8.3.3. Removal of the Front Case Unit

8.3.4. Removal of the LCD Unit

(Fig. D4)

(Fig. D5)

23

8.3.5. Removal of the Frame Plate

(Fig. D6)

8.3.6. Removal of the Top Case Unit

(Fig. D8)

(Fig. D7)

24

8.3.7. Removal of the Flash Top P.C.B.

8.3.8. Removal of the Lens Unit (W/CCD)

(Fig. D9)

(Fig. D10)

8.3.9. Removal of the Main P.C.B. and Speaker

25

(Fig. D11)

[ When Installing ]

CATION: Before soldering the Terminal A (Connecting part

of Main P.C.B. and Frame Unit).

Before soldering the Terminal A, make sure to tighten the

“Screw (F)” first in order to eliminate the gap between Main

P.C.B. and Frame Unit. Otherwise, soldered terminal A part

may be damaged after assembling.

(Fig. D12)

26

8.3.10. Removal of the Battery Door Unit

(Fig. D13)

NOTE: (When Installing)

Make sure to confirm the following points when installing:

• The Screw is tightened enough.

• Installing conditions are fine. (No distortion, no abnormalspace.)

• No dust and/or dirt on Lens surfaces.

• LCD image is fine. (No dust and dirt on it, and no gradient

images.)

27

8.4. Removal of the CCD FPC Unit

When remove the CCD FPC Unit once (the screw (G) is loosened even a little), the optical tilt adjustment is required.

When loosen the screw (G), necessary the optical tilt adjustment at the end of assembling. (Refer to item “9.3.2.”)

To prevent the CCD FPC Unit from catching the dust and dirt,

do not remove the CCD FPC Unit except for replacing.

28

(Fig. D14)

9 Measurements and Adjustments

9.1. Introduction

When servicing this unit, make sure to perform the adjustments necessary based on the part(s) replaced.

Before disassembling the unit, it is recommended to back up the camera data stored in Flash-ROM as a data file.

IMPORTANT NOTICE (After replacing the Main P.C.B.)

After replacing the Main P.C.B., it is necessary to use the “DIAS” software to allow the release of adjustment flag(s).

The Adjustment software “DIAS” is available at “TSN Website”.

*DIAS (DSC Integrated Assist Software)

NOTE: (When replacing the Lens unit and CCD FPC unit)

• When the CCD FPC unit is unavoidably removed for Lens unit and CCD FPC unit replaced, an optical tilt adjustment is necessary after parts are exchanged.

• The adjustment software (DSC_Tilt) is necessary to execute an optical tilt adjustment.

• The adjustment software “DSC_Tilt” is available at “TSN Website”.

NOTE: (When replacing the Main P.C.B.)

• Number of necessary adjustment items decreases by copying the backup data to new Main P.C.B. when adjustment data in old

Main P.C.B. can be read by ROM_BACKUP “DSC→SD” in “9.2.2. Flash-ROM Data Backup”.

For more details, please refer an item “Main P.C.B. (to which the backup data was copied)” in the table of “9.3.2. Adjustment

Specifications”.

9.2. Before Disassembling the unit

9.2.1. Initial Setting Release

The cameras specification are initially set in accordance with model suffix (such as EB/EG/GK/GC and so on.).

Unless the initial setting is not released, an automatic alignment software in the camera is not able to be executed when the alignment is carried out.

Note:

The initial setting should be again done after completing the alignment. Otherwise, the camera may not work properly.

Therefore as a warning, the camera display a warning symbol “ ! ” on the LCD monitor every time the camera is turned off.

Refer to the procedure described in “3.4.2. INITIAL SETTINGS” for details.

[ How to Release the camera initial setting ]

Preparation:

• Attach the Battery.

(Since this unit has built-in memory, it can be performed without inserting memory card.)

1. Turn the Power on.

2. Press the [ MODE ] button, and select the [ NORMAL PICTURE ] mode by Cursor buttons, then press the [ MENU/SET ] button.

3. Turn the Power off.

(If the unit is other than [ NORMAL PICTURE ] mode, it does not display the initial settings menu.)

Step 1. The temporary cancellation of “INITIAL SETTINGS”:

Press the [ PLAYBACK ] button ,“[ UP ] of Cursor button” and “[ W ] side of Zoom button” simultaneously, turn the Power on.

Step 2. Cancellation of “INITIAL SETTINGS”:

Press the [ PLAYBACK ] button in order to enter the [ PLAYBACK ] mode.

Press the [ MENU/SET ] button and “[ LEFT ] of Cursor button” simultaneously, turn the Power off.

The LCD displays the “ ! ” mark before the unit powers down.

29

9.2.2. Flash-ROM Data Backup

Number of necessary adjustment items decreases by copying the backup data to new Main P.C.B. when adjustment data in old

Main P.C.B. is usually read by ROM_BACKUP “DSC→SD”.

It is recommended to backup the Flash-ROM data as the way of return when trouble occurs before disassembling the unit depending on each case.

[ ROM_BACKUP (Method of Non-PC backup) ]

1. Insert the memory card into the camera.

2. Set the camera to “Temporary cancellation of the initial settings”.

3. Select the “SETUP” menu.

From the “SETUP” menu, select “ROM_BACKUP”.

NOTE:

This item is not listed on the customer's “SETUP” menu.

4. When this “ROM_BACKUP” item is selected, the following submenus are displayed.

Fig.2-1

[ DSC Integrated Assist Software (Method of Using PC) ]

Same as TATSUJIN software for previous models.

9.2.3. Light Box

If using VFK1164TDVLB Light Box, remove the lens connection ring by loosing three hexagon screws.

Fig.2-2

30

9.3. Details of Electrical Adjustment

9.3.1. How to execute the Electrical Adjustment

It is not necessary to connect the camera to a PC to perform adjustments.

“Flag reset operation” and “Initial setting operation” are required when carrying out the alignment, follow the procedure below.

9.3.1.1. Startup Electrical Adjustment mode

1. Release the initial settings.

2. Insert a recordable memory card (32MB or more).

(Without a momery card, the automatic adjustment can

not executed.)

3. Procedure to set the camera into adjustment mode:

a. Turn the Power on.

b. Press the [ MODE ] button, and select the [ NORMAL

PICTURE ] mode by Cursor button, then press the

[ MENU/SET ] button.

c. Turn the Power off.

d. Turn the Power on pressing [ MENU/SET ] and

[ MOTION PICTURE ] simultaneously.

LCD monitor displays “SERVICE MODE”.(Refer to

Fig. 3-1)

9.3.1.2. Status Adjustment Flag Setting

Reset (Not yet adjusted) the status flag condition.

1. After pressing the “[ W ] side of Zoom button”, the LCD

monitor displays the Flag status screen (Refer to Fig.3-2)

2. Select item by pressing the Cursor buttons. (Gray cursor

is moved accordingly.)

3. Press the [ Delete/Cancel ] button.

NOTE:

The selected item's flag has been changed from

“F (green)” to “0 (yellow)”.

*Flag conditions:

F (green)

means that the alignment has been completed and the

status flag condition is set. In this case, the flag condition

should be reset, if you try to carry out the automatic alignment.

0 (yellow)

means that the alignment has been not “completed” and

the status flag condition is “reset”. In this case, automatic

alignment is available.

• In case of setting the status flag into set condition again without completion of the alignment, the status flag should be SET by

using PC, or UNDO by using ROM BACKUP function.

Fig.3-1

Fig.3-2

31

9.3.1.3. Execute Adjustment (In case of “OIS Adjustment”)

1. Perform step “9.3.1.1.” to “9.3.1.2.”, to reset the OIS flag

status “F” (Set) to “0” (Reset)

2. Press “[ W ] side of the Zoom button” after Flag reset.

OIS Adjustment screen is displayed on the LCD panel.

(Refer to Fig.3-3)

3. Press the [ Shutter ] button.

The adjustment will start automatically.

4. When the adjustment is completed successfully, adjustment report menu appears with Green OK on the LCD

monitor. (Refer to Fig.3-4)

Fig.3-3

Fig.3-4

9.3.1.4. Attention point during Adjustment

1. Step “9.3.1.3.” procedure shows OIS adjustment as an

example. To perform the adjustment, refer to the “9.3.2.

Adjustment Specifications” table which shows key point

for each adjustment.

2. Do not move the light box, the camera or the chart while

adjusting. If one of these is moved accidentally, start the

adjustment again.

3. Do not press any buttons/keys until the default menu

(Refer to Fig.3-5) is displayed on the LCD monitor. Otherwise, adjustment data may not be stored properly.

4. If the adjustment is interrupted accidentally, the alignment

data may not be properly saved in the Flash-ROM.

Fig.3-5

9.3.1.5. Finalizing the Adjustment

1. Several adjustment flags can be reset (“F” into “0”) at the same time. In this case, when the adjustment has been completed,

the screen will change showing the adjustment for the next item until all reset items are completed.

Also, when the [ Shutter ] button is pressed, the screen jump to the next adjustment item.

2. To cancel the adjustment mode while in the process of performing the adjustment, follow this procedures.

3. Operate the following, when escaping the Electrical Adjustment mode on the way.

(1) Press “[ Delete/Cancel ] button”.

(2) Press “[ RIGHT ] of Cursor button”.

NOTE:

• If adjustment is cancelled with above procedure, adjustment is not completed. Make sure to adjust it later.

• Adjustment software “DIAS” is able to control the status of the adjustment flags.

32

9.3.2. Adjustment Specifications

The following matrix table shows the relation between the replaced part and the Necessary Adjustment.

When a part is replaced, make sure to perform the necessary adjustment(s) in the order indicated.

The table below shows all the information necessary to perform each adjustment.

33

34

9.4. After Adjustment

9.4.1. Initial Setting

Since the initial setting has been released to execute the built-in adjustment software, it should be set up again before shipping the

camera to the customer.

Refer to the procedure described in “3.4.2. INITIAL SETTINGS” for details.

[ IMPORTANT ]

1. The initial setting should be done again after completing the alignment. Otherwise, the camera will not work properly.

Therefore as a warning, the camera display a warning symbol “ ! ” on the LCD monitor every time the camera is turned off.

2. Confirm that status of all adjustment flag show “F”. Even if one of the adjustment flag shows “0”, initial setting programmed is

never executed.

35

10 Maintenance

10.1. Cleaning Lens and LCD Panel

Do not touch the surface of lens and LCD Panel with your hand.

When cleaning the lens, use air-Blower to blow off the dust.

When cleaning the LCD Panel, dampen the lens cleaning paper with lens cleaner, and the gently wipe the its surface.

Note:

The Lens Cleaning KIT ; VFK1900BK (Only supplied as 10 set/Box) is available as Service Aid.

36

11 Block Diagram

CCD SIGNAL

PROCESSOR

FOCUSIRIS

SDRAM/1G-bit

NAND FLASH ROM/1G-bit

MEMORY

CARD

REAR OPERATION UNIT

OVERALL BLOCK DIAGRAM

OIS UNIT

VENUS ENGINE

CAMERA PROCESS

J-PEG COMP/EX PANDS

MEDIA I/F

USB I/F

MAIN MICROPROCESSOR

FLASH

TOP OPERATION UNIT

SHUTTERZOOM

OIS CONTROL

LENS DRIVE

LCD DRIVE

MICROPHONE AMP

SPEAKER CONTROL

VIDEO OUT

(25mm ~ 125mm)

GYRO

SENSOR & AMP

MICROPHONE

SPEAKER

CDS, AGC,

A/D, TG,

CCD DRIVER

(12MHz)

(32.768MHz)

IC8001

IGBT DRIVER

LENS DRIVER

DMC-XS1 OVERALL BLOCK DIAGRAM

COLOR LCD

PANEL

2.7" PANEL

230k dots

MAIN P.C.B.

CCD

1/2.33" 16.1 MEGA PIX

IC7101

(POWER SUPPLY)

BATTERY

POWER

AV OUT / DIGITAL

TERMINAL

BATTERY CHARGER/

USB POWER SOURCE

CONNECTOR I/F

REGULATOR

11.1. Overall Block Diagram

37

11.2. Flash / Top Block Diagram 11.3. Sub Operation Block Diagram

DMC-XS1 FLASH TOP BLOCK DIAGRAM

FLASH TOP BLOCK DIAGRAM

F8001

3

5

2

1

T8001

CL8004

C8003

(For Flash

Charge)

FLASH

UNIT

FLASH TOP P.C.B.

CL8008

(FLASH TRG)

TL8003

IC8001

(IGBT DRIVER)

GND

DRV OUT

VDD

DRVIN

CHARGE

10

9

8

7

6

SW

TEST

CS

FB

STAT

1

2

3

4

5

CL8006

CL8003

CL8005

CL5001

CL5002

(STB CHG STRT)

81765

23

4

Q8001

LAMP(+)

TL8001

TRG

LAMP(-)

TL8002

(STB CHG DET)

(AF3R6V)

(UNREG+)

To MAIN P.C.B.

FULL

HALF

3

1

4

2

5

6

S8101

SHUTTER SW

D8101

AF ASSIST LED

(SHUTTER 0)

(SHUTTER 1)

(AF CATHODE)

B6301

Timer

Back UP

BATTERY

(RTC BAT)

M5001

MICROPHONE

(MIC P)

(MIC N)

CL8001

CL8002

CL8007

(D GND)

ET8003

SLEEVE GND

(POWER SW)

2 1

4 3

S8102

POWER

FP8001

17

FP8001

4

FP8001

3

FP8001

5

FP8001

6

FP8001

7

FP8001

15

FP8001

13

FP8001

16

FP8001

18-21

FP8001

8-11

FP8001

14

FP8001

12

(CPWR)

FP8001

1

DMC-XS1 SUB OPERATION BLOCK DIAGRAM

SUB OPERATION P.C.B.

SUB OPERATION BLOCK DIAGRAM

DEL

(DEL)

To MAIN P.C.B.

FP9005

12

TELE

(TELE)

FP9005

11

WIDE

(WIDE)

FP9005

10

MOVIE

(MOTION)

FP9005

9

RIGHT

(RIGHT)

FP9005

8

UP

(UP)

FP9005

7

DOWN

(DOWN)

FP9005

6

MENU

(MENU)

FP9005

5

MODE

(MODE)

FP9005

4

LEFT

(LEFT)

FP9005

3

PLAY

(PLAY)

FP9005

2

(GND)

FP9005

1

38

12 Wiring Connection Diagram

DMC-XS1 INTERCONNECTION DIAGRAM

INTERCONNECTION DIAGRAM

MAIN P.C.B.

(COMPONENT SIDE)

:

(FOIL SIDE)

FLASH TOP P.C.B.

(COMPONENT SIDE)

:

(FOIL SIDE)

LCD UNIT

CCD FPC

UNIT

LENS

UNIT

BATTERY

SPEAKER

SUB

OPERATION

FPC

RL6501

RL6502

TL9002 TL9003TL9001

FLASH

UNIT

M5001

MICROPHONE

TL8001

TL8002

TL8003

FP8001

UNREG+

UNREG+

RTC BAT

AF CATHODE

STB CHG DET

D GND

D GND

POWER SW

SHUTTER 0

MIC N

CPWR

2119171513

11

97531

2018161412

10

864

2

UNREG+

UNREG+

AF3R6V

FLASH TRG

STB CHG STRT

D GND

D GND

SHUTTER 1

MIC P

NC

16151413121110

987654321

UNREG+

UNREG+

RTC BAT

AF3R6V

AF CATHODE

FLASH TRG

STB CHG DET

STB CHG STRT

D GND

D GND

POWER SW

SHUTTER 1

SHUTTER 0

MIC P

MIC N

CPWR

FP9004

FP9002

YDR-

SH+

SHIRIS+

IRISXDR+

XHO+

XHOYHOYHO+

GND

FMAP

FMBP

FMAN

ZM+

ZMZENC LED

FZHP VCC

FZHP ABS

YDR+

SH+

SH-

IRIS+

IRIS-

XDR-

XHIXHI+

YHI+

YHIFMBN

FMAP

FMBP

FMAN

ZM+

ZM-

ZENC ABS

FZHP LED

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

FP9003

VCOM

CS

SCL

VSYNC

D7

D5

D3

D1

GND

LCD DET1

DVDD

V2

V4

V5

VDD3

V7

VGH

AGND

COMDC

VCOM

VLED-

GRB

SDA

HSYNC

DCLK

D6

D4

D2

D0

LCD DE0

VDDIO

V1

V3

VDD2

V6

VDD5

V8

VGL

FRP

VCAC

VLED+

41

39

37

35

33

31

29

27

25

23

21

19

17

15

13

11

9

7

5

3

1

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

FP9001

CON CHK

V4A

V3A

V2A

V1A

VL

CCD GND

CCD OUT

RG

H2

H3

CCD GND

SUBSW1

MSUBSW

V12

V11

V9Z

V9X

V8Y

V8A

V7A

V6

CON CHK

CCD THERMO

V4B

V3B

V2B

V1B

VH

CCD GND

CCD GND

HL

H1

H4

SUBSW2

SUB

MSUB

V11D

V10

V9Y

V8Z

V8X

V8B

V7B

V5

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

123456789

101112

GND

PLAY

LEFT

MODE

MENU

DOWN

UP

RIGHT

MOTION

WIDE

TELE

DEL

FP9005

12.1. Interconnection Diagram

39

Loading...

Loading...