Panasonic CW-XC51LE Service Manual

Service Manual

Order No RAC0008058C4

Room Air Conditioner

CW-XC51LE

2001 PT. National Gobel Air Conditioner Division.

All right reserved. Unauthorized copying and

distribution is a violation of law.

This service information is desidned for experienced repair technician only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a

product. Product powered by electricity should be serviced or repaired only by experienced professional technicians. Any

attempt to service or repair the product or product deal with in this service information by anyone else could result in serious

injury or death.

! WARNING

Specification

Model CW-XC51LE

Phase Double

Voltage 220 V

Frequency 50 Hz

Cooling Capacity 1.47 kW

5000 Btu/h

Running Current 2.1 A

Input Power 440 Watt

EER 11.1 Btu/W.h

Starting Current

Compressor Output

Fan Motor Output

Moisture Removal 0.9 Ltr/h

Noise Level Indoor High 46 dB

Low 41 dB

Outdoor High 50 dB

Low 47 dB

Air Circulation 5.1 m3/min

Dimension Height : 340 mm

Width : 525 mm

Depth : 610 mm

Net Weight 29 Kg

Gross weight 31 Kg

Refrigerant (R-22) 330 g

Note : Specification are subject to change

without notice, for further improvement.

There are special components used in this equipment which are important for safety. These parts are marked by ! in the

Schematic Diagrams, Circuit Board Diagrams, Exploded Views and Replacement Part List. It is essential that these critical parts

should be replaced with the manufacturer’s parts to prevent shock, fire or other hazards. Do not modify the original design

without permission of the manufacturer.

IMPORTANT SAFETY NOTICE

Panasonic

PanasonicPanasonic

Panasonic

PanasonicPanasonic

PanasonicPanasonic

Panasonic

- 1 -

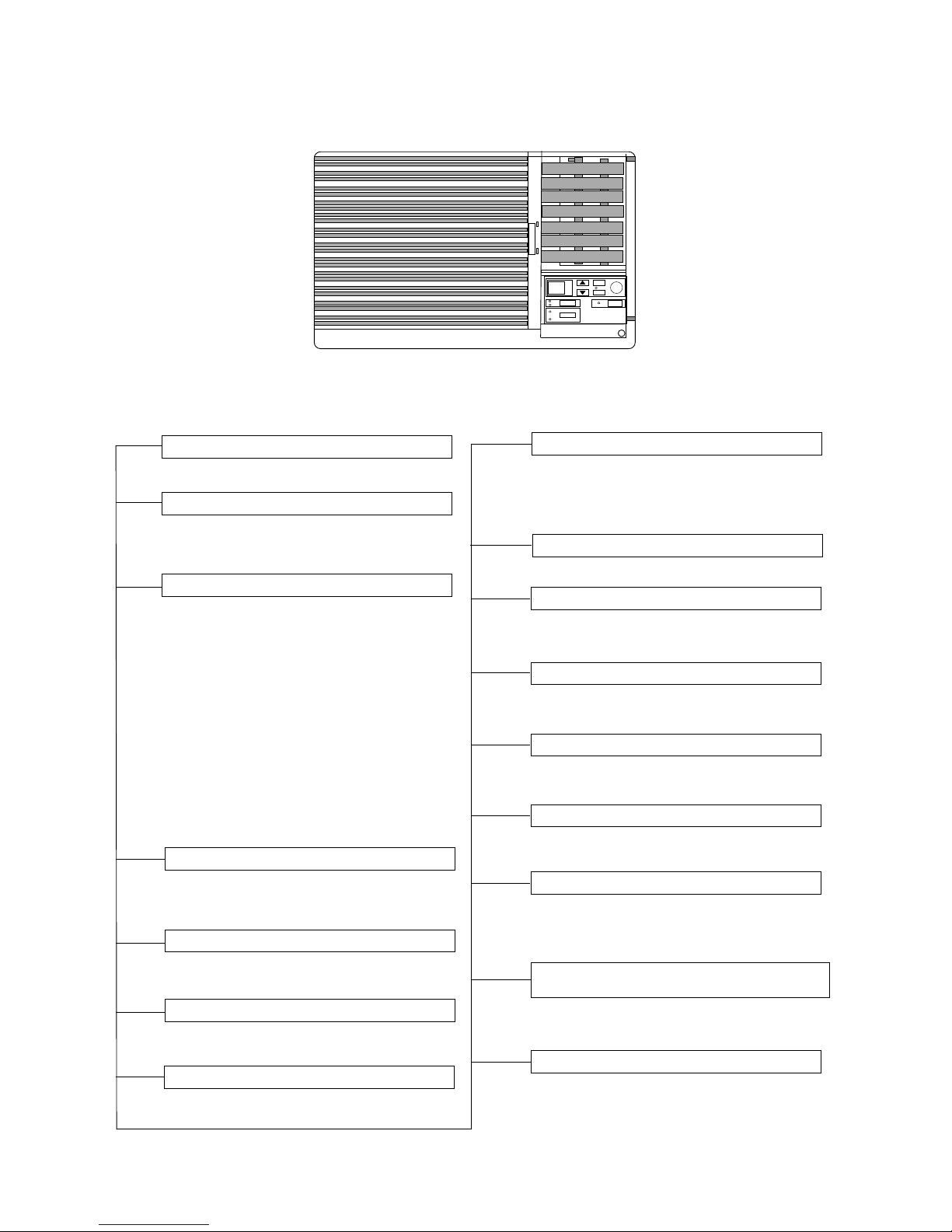

CONTENTS

1 Functions ........................................................... 2

2 Refrigerant Cycle diagram ............................... 4

3 Block Diagram ................................................... 4

4 Wiring Diagram .................................................. 5

5 Air Conditioner Performance Evaluation ....... 5

6 Troubleshooting Guide ..................................... 6

7 Operation Details ............................................... 7

8 Operating instructions ..................................... 10

9 Air ConditionerInstallation ............................. 15

10 Care and Maintenance ................................. 17

11 Service Information ....................................... 18

12 Exploded View .............................................. 19

13 Replacement Part List .................................. 20

14 Electronic Part List ........................................ 21

15 Electronic Circuit / Indicator Complete ...... 21

16 Electronic Circuit / Main ............................... 22

17 Technical Data .............................................. 22

18 Electronic Circuit Diagram ........................... 23

1 Functions

1.1 Remote Control

OPERATION

TEMP/TIMER

TIMER

SET/

CANCEL

MODE JET MODE

FAN SPEED

Panasonic

Signal Transmitter

Operation OFF/ON

Operation Mode Selection

Fan Speed Selection

Jet Mode Operation OFF/ON

OPERA-

TION

FAN

SPEED

JET

MODE

• High Fan Speed or Low Fan Speed

• Jet Mode operation for fast cooling

MODE

• Cooling Operation Mode or Fan Operation

Mode

TIIMER

• To set delay OFF Timer.

TEMP/

TIMER

• Cooling Operation Mode

- Temperature Setting ( 16oC ~ 30oC )

SET/

CANCEL

• To start delay OFF or cancelation

Timer Operation Setting

Room Temperature and Timer Setting

Delay OFF Timer OFF/ON

• Timer Setting

- Timer Setting ( 1 ~ 12 hours )

- 2 -

1.1 Main Unit

Operation OFF/ON

Remote Control signal Receiving Sound

Operation Indicator Light (LED’S)

OPERA-

TION

• Can be enable/disable by pressing down

Operation OFF/ON button for 10 seconds.

• MODE

COOL (Green)

FAN (Orange)

Lights up in Cooling

Mode Operation.

Lights up in Fan Mode

Operation.

• FAN SPEED

HIGH (Orange)

MED (Orange)

LOW (Orange)

Lights up in High Fan

Speed Operation.

Lights up in Medium

Fan Speed Operation.

Lights up in Low fan

Speed Operation.

• TIMER

(Orange)

Lights up in Timer

Setting.

• JET MODE

(Orange)

Lights up in Jet Mode

Operation.

Operation Mode Selection

Fan Speed Selection

Jet Mode Operation OFF/ON

• Jet Mode operation for fast cooling

FAN

SPEED

JET

MODE

• High Fan Speed or Low Fan Speed

MODE

• Cooling Operation Mode or Fan Operation

Mode

TIIMER

• To set delay OFF Timer.

Timer Operation Setting

Room Temperature and Timer Setting

TEMP/

TIMER

• Cooling Operation Mode

- Temperature Setting ( 16oC ~ 30oC )

• Timer Setting

- Timer Setting ( 1 ~ 12 hours )

SET/

CANCEL

• To start delay OFF or cancelation

Delay OFF Timer OFF/ON

Random Auto Restart Control

• Random auto restart after power failure at

previous setting mode.

Freeze Prevention Control

• Freeze prevention control for the Evaporator. (Cooling Operation Only)

Starting Current Control

• Fan Motor is delayed for 1.6 seconds

when Compressors starts simultaneously.

Time Delay safety Control

• Restarting is inhibited for approximately 3

minutes.

60 Secs. Forced Operation Control

• Once the compressor is activated, it does

not stop within the first 60 seconds.

However, it stops immediately with

remote control stop signal.

Compressor Reverse Rotation Protection

Control.

• To protect compressor from reverse

rotation when there is an instantaneous

power failure.

Over Load Protector

• Overload protector will trip to protect the

compressor when it is overheated.

Panasonic

- 3-

2 Refrigeration Cycle

2.1 CW-XC51LE

3 Block Diagram

3.1 CW-XC51LE

capillary tube

INDOOR SIDE

OUTDOOR SIDE

CONDENSOR

Intake air

sensor

COMPRESSOR

EVAPORATOR

Overload

Protector

Indicates the electronic control unit.

“C” Indicates the number of core wires. (Example : 7C = 7 core wires)

ZNR1

Transformer

Double Phase

AC 220V

50 Hz

Electronic Controller

RY-PWR

Thermal Fuse

(113oC)

Fuse (3.15A)

RY-H

RY-L

Indicator

Complite

10 C

Fan

Motor

Comp.

7 C

4 C

Sensor

Wireless Remote

Control Transmitter

- 4 -

4 Wiring Diagram

4.1 CW-XC51LE

POWER SUPPLY

CORD 1φ

, 50Hz 220V

BLUE

YELLOW/GREEN

CAPACITOR

COM PRESSOR

RED

BLUE

BROWN

R S

C

RED

RED

OLP

YELLOW

YELLOW

TRANSFORMER

BLACK T1 (BLK)

BLACK T2 (BLK)

CN-T(WHT)

FUSE

ZNR

BLUE

RED

WHITE

C-FM

(RED)

AC

(WHT)

CN-DISP1 (WHT)

CN-DISP1 (WHT)

CN-DISP2 (WHT)

CN-DISP2 (WHT)

RY-H

RY-L

C C

CN-FM

(GRN)

7 5 3 1

YELLOW

ORANGE

RED

BLUE

YELLOW/GREEN

FAN MOTOR

CN-TH(YLW)

1 2 3 4

SENSOR (INTAKE.TEMP)

YELLOW

BLUE

RED

TRADE MARK

COMPRESSOR TERMINAL

10 9 8 7 6 5 4 3 2 1

w w w w w w w w w w w w w w w w w

7 6 5 4 3 2 1

RY-PWR

P L

ELECTRONIC CONTROLLER

(RECEIVER AND DISPLAY)

10 9 8 7 6 5 4 3 2 1

7 6 5 4 3 2 1

WIRELESS

REMOTE CONTROL

REMARKS

WHT : WHITE

YLW : YELLOW

BLK : BLACK

GRN : GREEN

5 Air Conditioner Performance Evaluation

Suction & Discharge Air

Temperature Difference

- 8 C and over

- 8 C and over

- Under 8oC

- Under 8oC

- Under 8oC

Current

- As specified.

- Higher than specified.

- Higher than specified.

- Lower than specified.

- Higher than specified by 50%

Determination

- Nothing wrong.

- Nothing wrong, outdoor

temperature is too high, heat

radiation is not efficient.

- something is preventing heat

radiation.

- leakage of refrigerant or

refrigerant systems is blocked.

- Compressor defect.

Remedy

- None

- Improve heat radiation.

- Excessive amount of

refrigerant.

- Improve heat radiation.

- Locate and repair leak.

- Flush refrigeration cycle.

- Replace the compressor.

- 5 -

- 6 -

6 Troubleshooting Guide

Warning :

Disconnect unit from electrical power supply before making any electrical checks. Discharge the capacitor before checking it.

Check

1. Supply Voltage.

2. Fuse box or Circuit

Breaker.

3. Power cord or wiring

harness.

4. Temp. Setting.

1. Objects around fan.

2. Resistance between

wires.

3. Capacitor Fan Motor.

1. Temperature setting.

2. Resistance between

terminal and the

compressor body.

3. Resistance between

terminals.

4.

Overload Protector (OLP)

.

5.

Capacitor Compressor.

1. Thermostat setting.

2. Air filter dirty.

3.

Location of installation.

4.

Evaporator/Condensor coil

obstructed

.

5. Unit capacity to small or

room to big.

6. Temperature and

current difference.

1. Source of noise.

1. Unit installation.

2. Drain Tray-styrofoam

pieces blocking drain

channel.

Result

Less than 10% by rated.

Open Contacts.

Pulled loose or shorted.

Higher than room temperature.

Locked fan.

Shorted/Open circuit.

Ohm Meter doesn't deflect.

Higher than room temperature.

Shorted.

Shorted.

Infinity between terminals

.

Ohm Meter doesn't deflect.

Higher than room temperature.

Clogged or dirty.

Sunlight hitting outdoor side

obstacles.

Clogged or dirty.

Not satisfied.

Refer performance

evaluation.

Vibration.

Intermitten noise.

Tilted to inside the room.

Clogged.

Cause

Costumer restarted unit

immidiatelly without waiting

3 minutes.

Fan hitting cowling of

foreign materials.

Frozen Bearings.

Shorted or burned out.

Capacitor defect.

Winding coil touch to the body

Rare shorted or burn out.

Overload Protector (OLP) broken

.

Capacitor defect.

Restricted air circulation.

Restricted heat exchanger.

Restricted heat exchanger.

Restricted air circulation.

Leakage of refrigerant or

refrigerant systems is blocked.

Faulty installation.

Fan hitting object.

Refrigerant tubing touching

each other.

Fan splash Drain water.

Restricted run off

.

Clogged or blocked.

Remedy

Consult to an electician.

Repair open circuit.

Wait for 3 minute.

Repair or replace it.

Set it to lower.

Adjust fan position setting

.

Remove foreign materials

.

Replace wires.

Replace capacitor fan motor.

Set it to lower.

Replace compressor.

Replace compressor

terminals.

Replace Overload Protector.

Replace capacitor compressor.

Set it to lower.

Clean or replace air filter.

Consider to build an awning.

Remove obstacle or reinstall

unit.

Clean by steam cleaner.

Replace the unit with bigger

capacity.

Locate and repair leak.

Flush refrigeration cycle.

Reinstall unit or reinforce

the installation.

Adjust fan position or remove

foreign materials.

About 1/2" Clearance.

Set the drain outlet

downward, so that the

drain water can run off.

Tilt unit to out side slightly.

remove the foreign materials.

Trouble

Fan Motor and

Compressor

won't run.

Fan Motor won't

run

Compressor

won't run (Fan

motor runs).

Insufficient

Cooling

Noise

Water Dripping

7 Operation Details

7.1 Fan Mode Operation

• Fan operation only. Fan in operation according to Remote Control or main Unit ( Touch panel) Setting.

7.1.1 Manual Setting of Fan Speed

• Basic Fan Speed can be manually adjusted (Lo, Hi) by using the Fan Speed Selection Button/Pad at Remote Control or

Main Unit (Touch Control Panel).

7.2 Cooling Mode Operation

• Cooling in operation according to Remote Control or Main Unit ( Touch Control Panel) setting.

7.2.1 Time delay Safety Control ( 3 Minute)

• When the compressor is stopped by Operation Switch at the Remote Control or Main Unit (Touch Control Panel), it restart

after 3 minutes when the Operation Switch at the remote Control or Main Unit (Touch Control Panel) is turned ON.

• When the setting temperature is reached during cooling operation, the compresor stops and it will not startfor 3 minutes.

• Protection of compressor to balance the pressure in the refrigeration cycle for 3 minutes.

7.2.2 7 minutes Time Saved Control

• The compressor will start automatically if it has stopped for 7 minutes even if the room temperature is between the

compressor On temperature and OFF temperature.

7.2.3 Starting Current Control

• When the compressor and fan motor are simultaneously started, the fan motor will operate 1.6 second later.

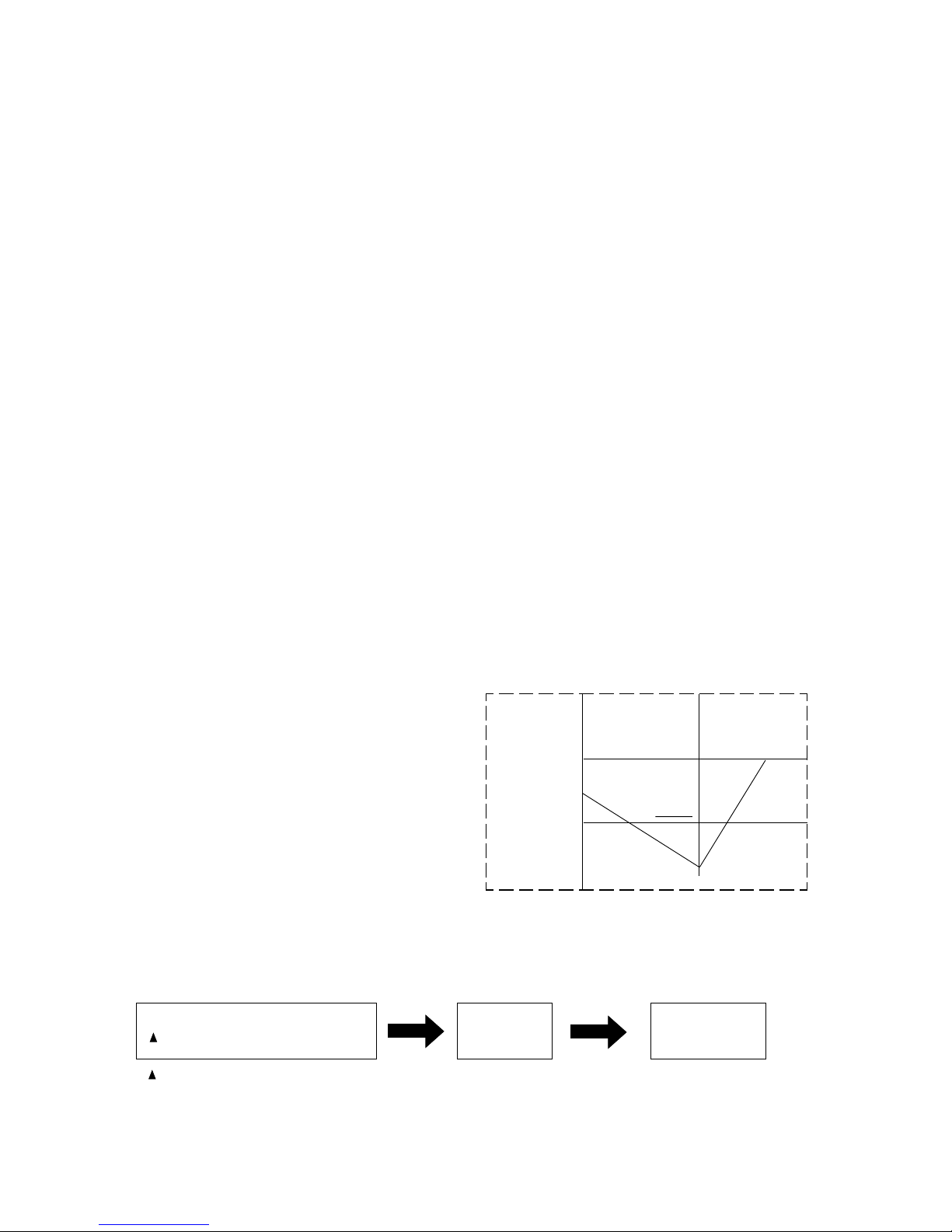

7.2.4 Freeze Prevention Control

If the temperature of the indoor heat exchanger falls continuously below 1°C for 3 minute or more, the compressor turns off to protect the heat exchanger from freezing.

The fan spee setting remains the same.

Compressor restarts when the heat exchanger temperature rises to 12°C (Recovery).

* 3 Minutes waiting of Time Delay Safety control is

valid for Cooling Operation.

7.2.5 Compressor Reverse Rotation Protection Control

• If the compressor is operating continuously for 5 minutes or longer and the temperature difference between intake air

and heat exchanger is - 15°C for 2 minutes, compressor will stop and restart automatically ( Time Delay Safety Control

is valid).

Indoor Heat

Exchanger

Temperature

(°C)

Compressor OFF

Recovery

12

1

3 min

Compressor start for ≤ 5 Minutes

T ≤ -15° C for 2 Minutes

Compressor

OFF

Compressor

restarts (3 minutes

waiting)

T = Intake air temperature - Indoor heat exchanger temperature.

This is to protect reverse rotation of the copressor when there is an instantaneous power failure.

- 7 -

7.3 Jet Mode Operation

7.2.6 Cooling Operation Time Diagram

• This Operation automatically will be running under High Fan speed, even if the LED shown the Low Fan Speed.

• Purpose of this operation is to cool down room temperature at faster speed compare to normal operation.

• When Jet Mode button is pressed, target temperature is shifted -3

o

C from the previous setting, for remote control setting from 19oC to

16oC, setting temperature shifted only to 16oC, the minimum setting temperature.

Operation LED

Fan

Compressor

Basic Time

Intake

Temperature

1.5oC

ON

OFF

Set

Temperature

3’

7’ 3’

60’

7’

60’

Operation

Stop

a b c d e f g h i j k l

< Description of operation >

b - c : Time Delay Safety Control ( waiting for 3 minutes).

d - e : 7 Minutes Time Saved Control.

g - h : 60 sec. forcible operation

• Jet Mode operation will stop with the following condition :

- Jet Mode button is pressed again.

- Jet Mode operation has run for 15 minutes

- Stopped by OFF/ON switch

- Timer OFF activates.

7.4 Random Auto Restart Control

• Restart time is decided randomly with 5 parameters :

- Intake air temperature.

- Setting temperature

- Fan speed

- Indoor heat exchanger temperature.

• If there is a power failure, operation will be automatically restarted after 3 to 4 minutes when the power is resumed. It will start with

previous operation mode (Time Delay Safety Control is Valid). as the operation was not stopped by Remote Control or main Unit (Touch

Control Panel).

• Auto Restart Control is not available when Timer is set.

• If Jet Mode is set during power failure, then after power resume, Jet Mode will not start automatically with previous operation mode.

• The control can be omitted by opening jumper JX1 on Printed Circuit Main Board.

- 8 -

Loading...

Loading...