Panasonic CU-PC9CKV, CU-PC12CKV, CS-PC12CKV, CS-PC9CKV Service Manual

Order No: GMAC0401004C3

Room Air Conditioners

CS-PC9CKV CU-PC9CKV

CS-PC12CKV CU-PC12CKV

CONTENTS

Page Page

1 Functions 2

2 Product Specifications

3 Dimensions

4 Refrigeration Cycle Diagram

5 Block Diagram

6 Wiring Diagram

7 Operation Details

8 Installation

9 2-way, 3-way Valve

10 Disassembly of the parts

11 Trouble-shooting guide 47

5

12 Technical Data

13 Exploded View

9

12

14 Replacement Parts List

15 Exploded View

13

14

16 Replacement Parts List

17 Exploded View

15

22

18 Replacement Parts List

36

19 ELECTRONIC CIRCUIT DIAGRAM

43

© Guangzhou Matsushita Air Conditioner Co., Ltd.

(GMAC) All rights reserved. Unauthorized copying

and distribution is a violation of law.

49

51

52

53

54

55

56

57

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

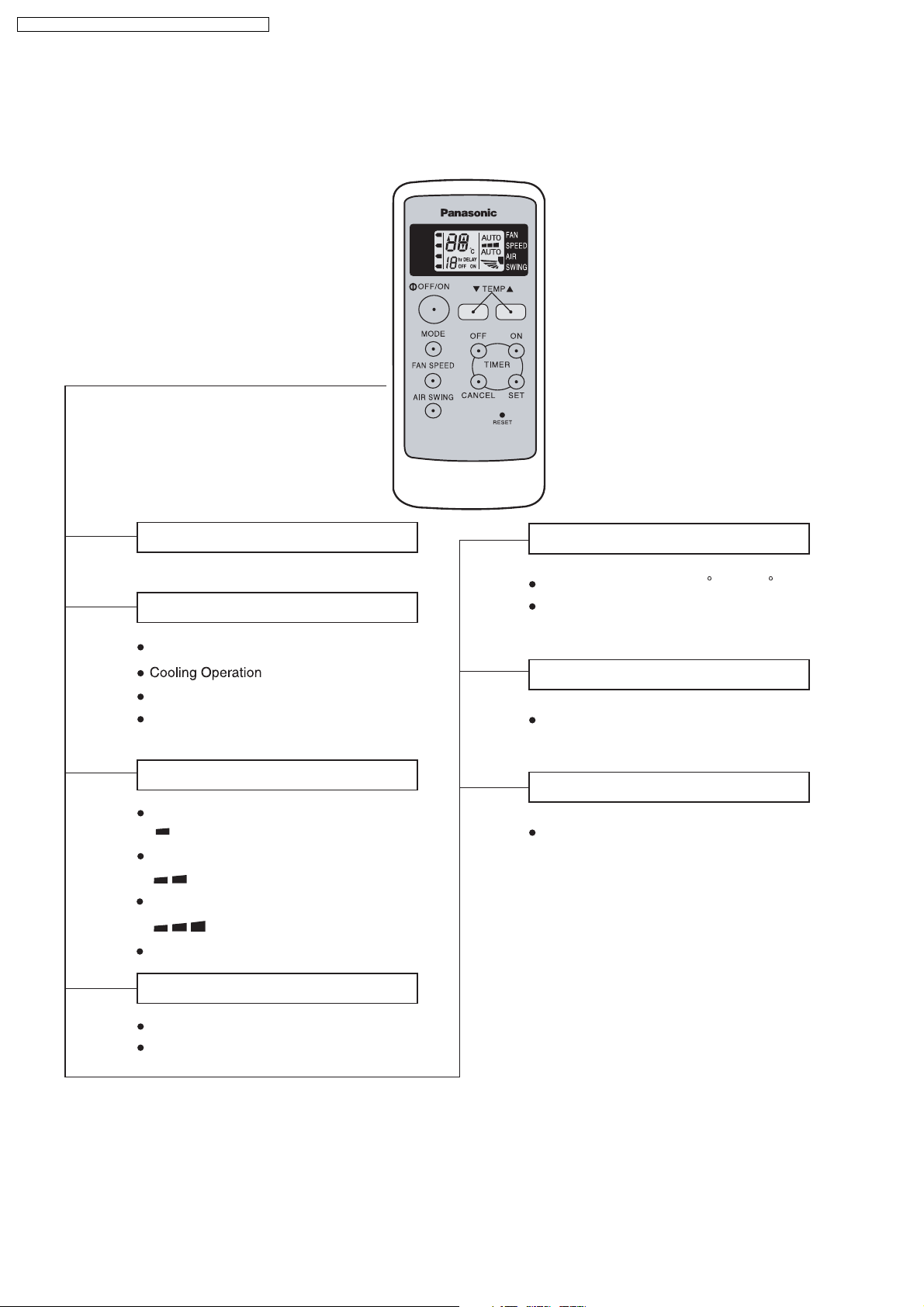

1 Functions

Operation START/ST OP

Operation Mode Selection

Automatic Operation

Soft Dry Mode Operation

Air Circulation Operation

Mode

AUTO

COOL

DRY

FAN

S

T

D

Room Temperature Setting

Temperature Setting(16 C to 30 C)

Auto Operation

Timer Operation Selection

Stop/Start Operation Control

(set the ON/OFF Timer hourly later)

Indoor Fan Speed Selection

Low Speed

Medium Speed

High Speed

Automatic Speed

Airflow Direction Control

Auto Airflow Direction

Airflow Direction Manual Control

Set /Cancel Timer Operation

Set timer/Cancel the set timer

2

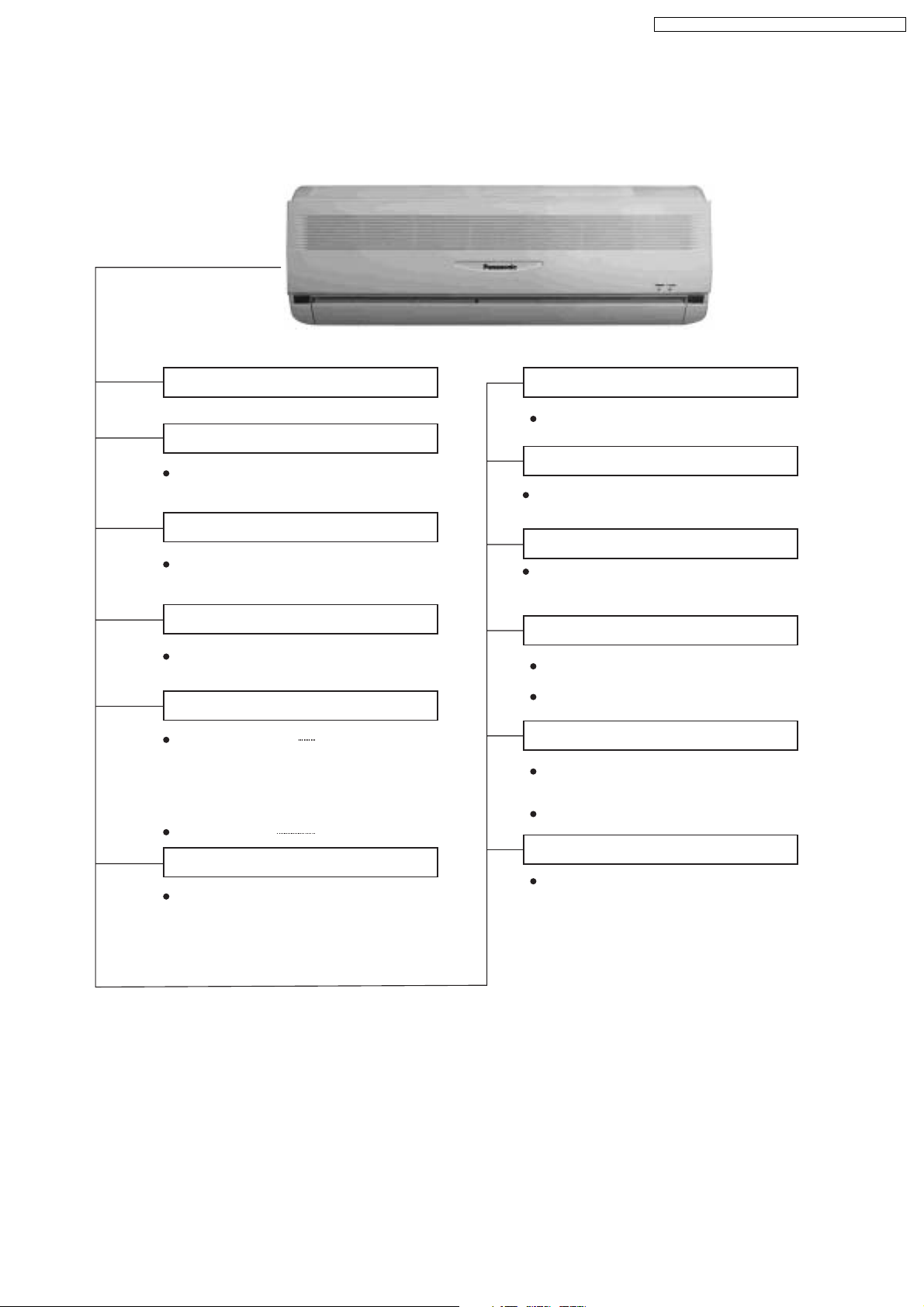

Indoor Unit

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

Power Switch ON/OFF

Auto Mode Operation Selection Button

When the remote control cannot be used,

please use this button.

Signal Receiving Sound Control

Keep pressing this button for 10sec to turn

on or turn off the signal receiving sound.

Test Run

Used when testing or repairing

Operation Indication Lamps

Operation (green)

Timer(orange)

Iights up in operation

Blinks during Test

Run operation and

determining Auto

Operation mode

Timer in operation

Operation Mode

Cooling/Soft Dry/Air Circulation/

Auto Operation

Anti-freezing Control for the Evaporator

Cooling or Soft Dry Operation

Time Delay Safety Control

The unit will restart operation after 3-4

minutes after each pause.

Automatic Restarting Control

7-minutes automatic restarting at Cooling

Operation

Indoor Fan Speed Control

High,Med,Low

Auto Fan Speed

Airflow Direction Control

Automatic Airflow Direction Control

The louver automatically swings up and down

Airflow Direction Manual Control

Delayed On-timer Control

For cooling or soft dry mode, the unit

starts 15 minutes before the set time with

the remote control.

3

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

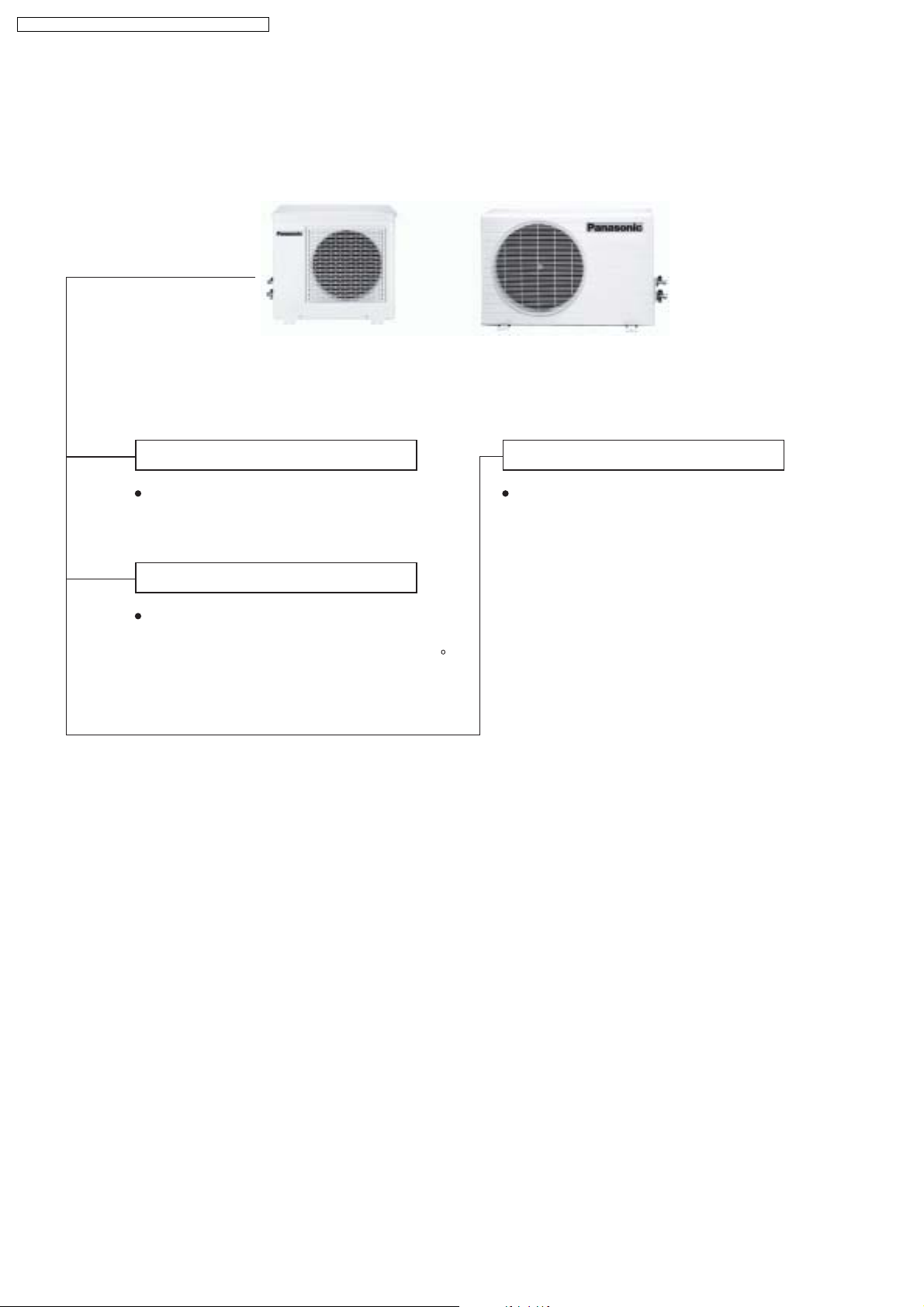

Outdoor Unit

CU-PC9CKV CU-PC12CKV

Anti-reverse Protection

To protect the compressor from reverse

rotation when power off suddenly.

Overload Protector

The 2-step Overload Protector is to protect

the compressor when

1/ temperature of compressor reaches 120 C

2/ high temperature or current enters into the

compressor.

60-seconds Test Operation Control

Once the compressor is activated,it does not

stop for 60 seconds.It stops immediately with

remote controller ON/OFF button.

4

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

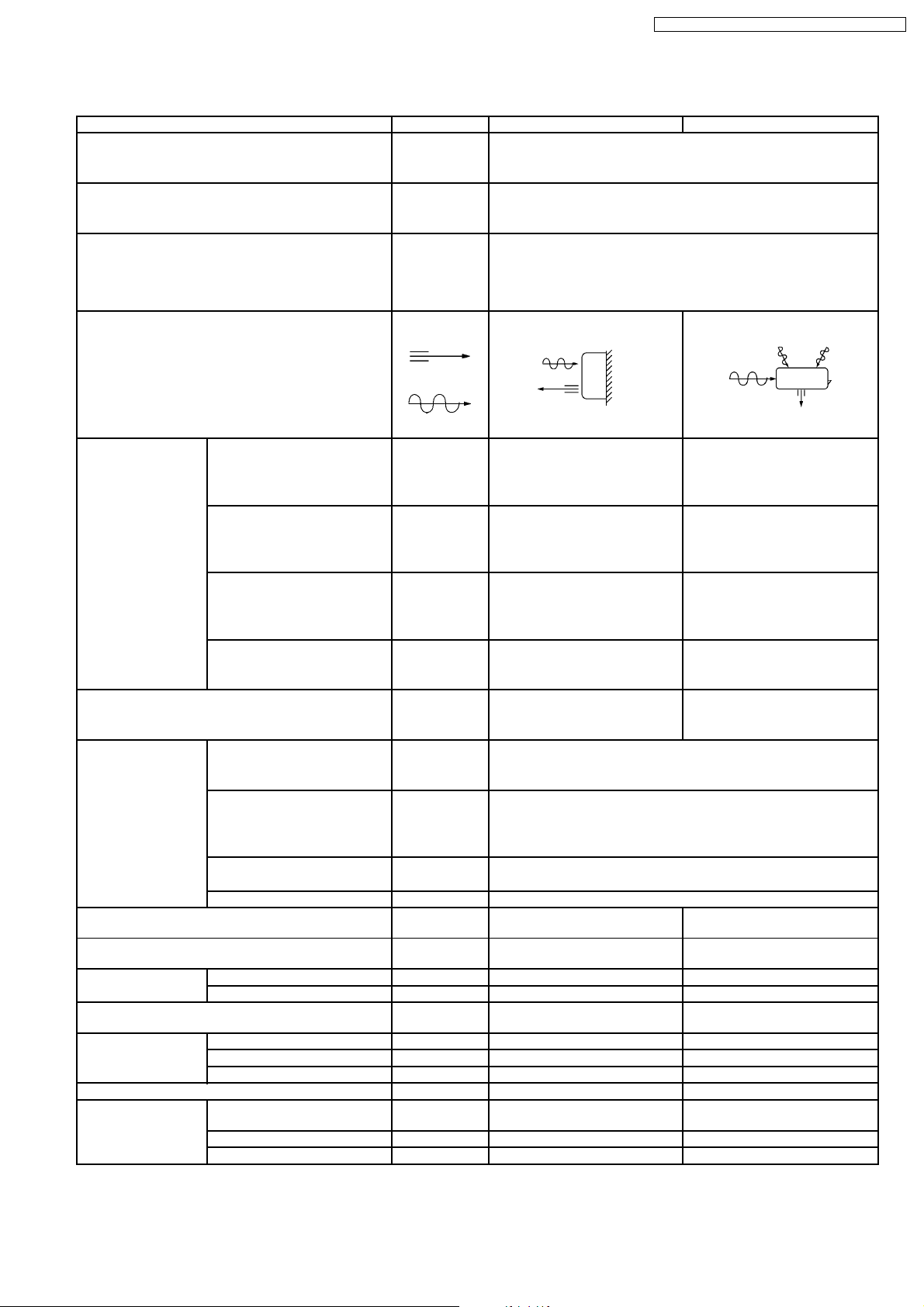

2 Product Specifications

Unit CS-PC9CKV CU-PC9CKV

Cooling Capacity kW 2.50

Moisture Removal L/h 1.40

Power Source Phase

Airflow Method OUTLET

Air Circulation Indoor Air (low) m3/min 7.0 —

Indoor Air (medium) m3/min 7.8 —

Indoor Air (high) m3/min 8.8 —

Outdoor Air m3/min — —

V

Cycle

SIDE VIEW TOP VIEW

INTAKE

Single

220-230

60

Noise Level dB(A) High36, Low30 High49

Electrical Data Input W 830-840

Running Current A 4.0-3.9

EER W/W 3.0-2.98

Starting Current A 19

Piping Connection Port

(Flare piping)

Piping Size

(Flare piping)

Drain

Hose

Power Supply Cord Length

(Number of core-wire)

Dimensions Height mm 250 534

Net Weight kg 8.0 26

Compressor Type — Rotary(1 cylinder)

Inner Diameter mm 12 —

Length m 0.6 —

Width mm 770 590

Depth mm 205 255

Motor Type — Induction(2 pole)

Rated Output W — 650

Inch

Inch

Inch

Inch

m 2.2

G: half union 3/8"

L: half union 1/4"

G: gas side 3/8"

L: liquid side 1/4"

3 core-wire/1.5mm

G: 3-way valve 3/8"

L: 2-way valve 1/4"

G: gas side 3/8"

L: liquid side 1/4"

2

—

—

Rolling piston type

5

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

Unit CS-PC9CKV CU-PC9CKV

Air Circulation Type Cross-flow Fan Propeller fan

Motor Type Induction (4 pole) Induction (4 pole)

Input W 38.4 58.2

Rated Output W 13 22

Fan Speed Low rpm 870±60 —

Medium rpm 980±60 —

High rpm 1100±60 880±60

Heat Exchanger Description Evaporator Condenser

Tube Material copper copper

Fin Type slot type Corrugation type

Rows / Stage (Plate fin configuration, forced draft)

2×12 1×20

FPI 18 18

Dimensions mm 610 × 252 × 25.4 568.8 × 508 × 22

Refrigerant Control Device — Capillary Tube

Refrigeration Oil (c.c) — SUNISO 4GDID or ATMOS M60

Refrigerant (R-22) g — 530*

Thermostat Electronic Control —

Protection Device — O.L.P.(25A/230V)

Capillary Length mm — 630

Circulation L/min — 11.7

Inner Diameter mm — 1.5

Air Filter P.P Honeycomb —

Refrigerant Circulation Control Device Capillary

Compressor Capacitor µFV — 30µF, 370V

Fan Motor Capacitor µFV 1.5µF, 400V 1.5µF, 440V

(M56)

•

•

Specifications are subject to change without notice for further improvement.

• •

* 60g for air purging is not included.

6

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

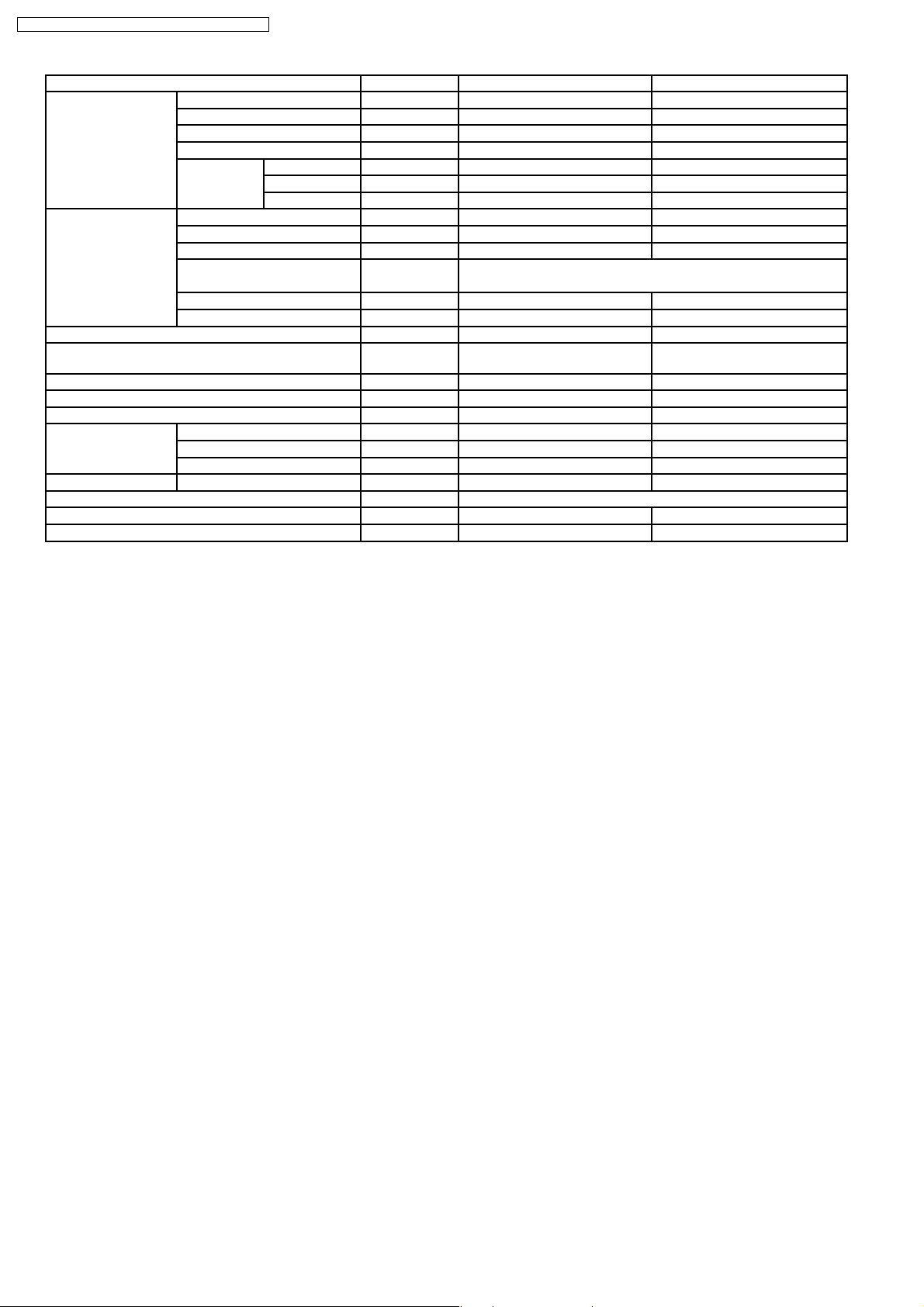

Unit CS-PC12CKV CU-PC12CKV

Cooling Capacity kW 3.50

Moisture Removal L/h 2.1

Power Source Phase

V

Cycle

Airflow Method OUTLET

SIDE VIEW TOP VIEW

Single

220-230

60

INTAKE

Air Circulation Indoor Air (low) m3/min 8.0 —

Indoor Air (medium) m3/min 8.7 —

Indoor Air (high) m3/min 9.9 —

Outdoor Air m3/min — —

Noise Level dB(A) High39, Low33 High47

Electrical Data Input W 1210-1220

Running Current A 5.70-5.50

EER W/W 2.89-2.87

Starting Current A 25

Piping Connection Port

(Flare piping)

Piping Size

(Flare piping)

Drain

Hose

Inner Diameter mm 12 —

Length m 0.6 —

Power Supply Cord Length

(Number of core-wire)

Inch

Inch

Inch

Inch

G: half union 3/8"

L: half union 1/4"

G: gas side 3/8"

L: liquid side 1/4"

m 2.2

3 core-wire/1.5mm

G: 3-way valve 3/8"

L: 2-way valve 1/4"

G: gas side 3/8"

L: liquid side 1/4"

2

—

—

Dimensions Height mm 250 505

Width mm 770 780

Depth mm 205 245

Net Weight kg 8.0 30

Compressor Type — Rotary(1 cylinder)

Rolling piston type

Motor Type — Induction(2 pole)

Rated Output W — 850

7

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

Unit CS-PC12CKV CU-PC12CKV

Air Circulation Type Cross-flow Fan Propeller fan

Motor Type Induction (4 pole) Induction (4 pole)

Input W 43 61

Rated Output W 16 20

Fan Speed Low rpm 980±60 —

Medium rpm 1110±60 —

High rpm 1260±60 740±50

Heat Exchanger Description Evaporator Condenser

Tube Material copper copper

Fin Type slot type Corrugation type

Rows / Stage (Plate fin configuration, forced draft)

2×12 1×19

FPI 21 16

Dimensions mm 610 × 315 × 25.4 706.2 × 482.6 × 22

Refrigerant Control Device — Capillary Tube

Refrigeration Oil (c.c) — SUNISO 4GDID or ATMOS M60

Refrigerant (R-22) g — 800*

Thermostat Electronic Control O.L.P.(25A/230V)

Protection Device — —

Capillary Length mm — 720

Circulation L/min — 11.0

Inner Diameter mm — 1.5

Air Filter P.P Honeycomb —

Refrigerant Circulation Control Device Capillary

Compressor Capacitor µFV — 30µF, 370V

Fan Motor Capacitor µFV 1.5µF, 400V 1.5µF, 400V

(M56)

•

•

Specifications are subject to change without notice for further improvement.

• •

* 60g for air purging is not included.

8

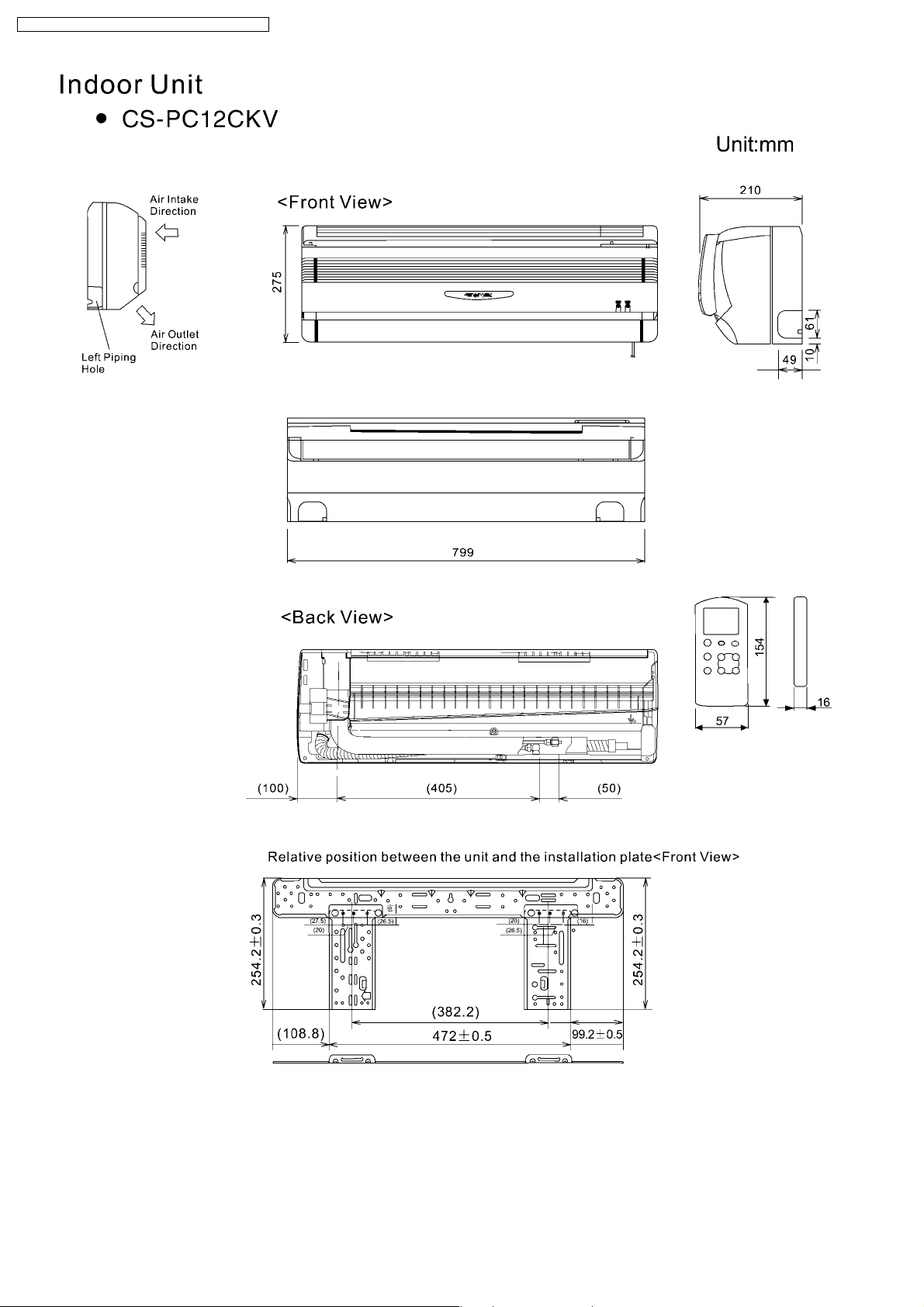

3 Dimensions

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

9

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

10

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

11

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

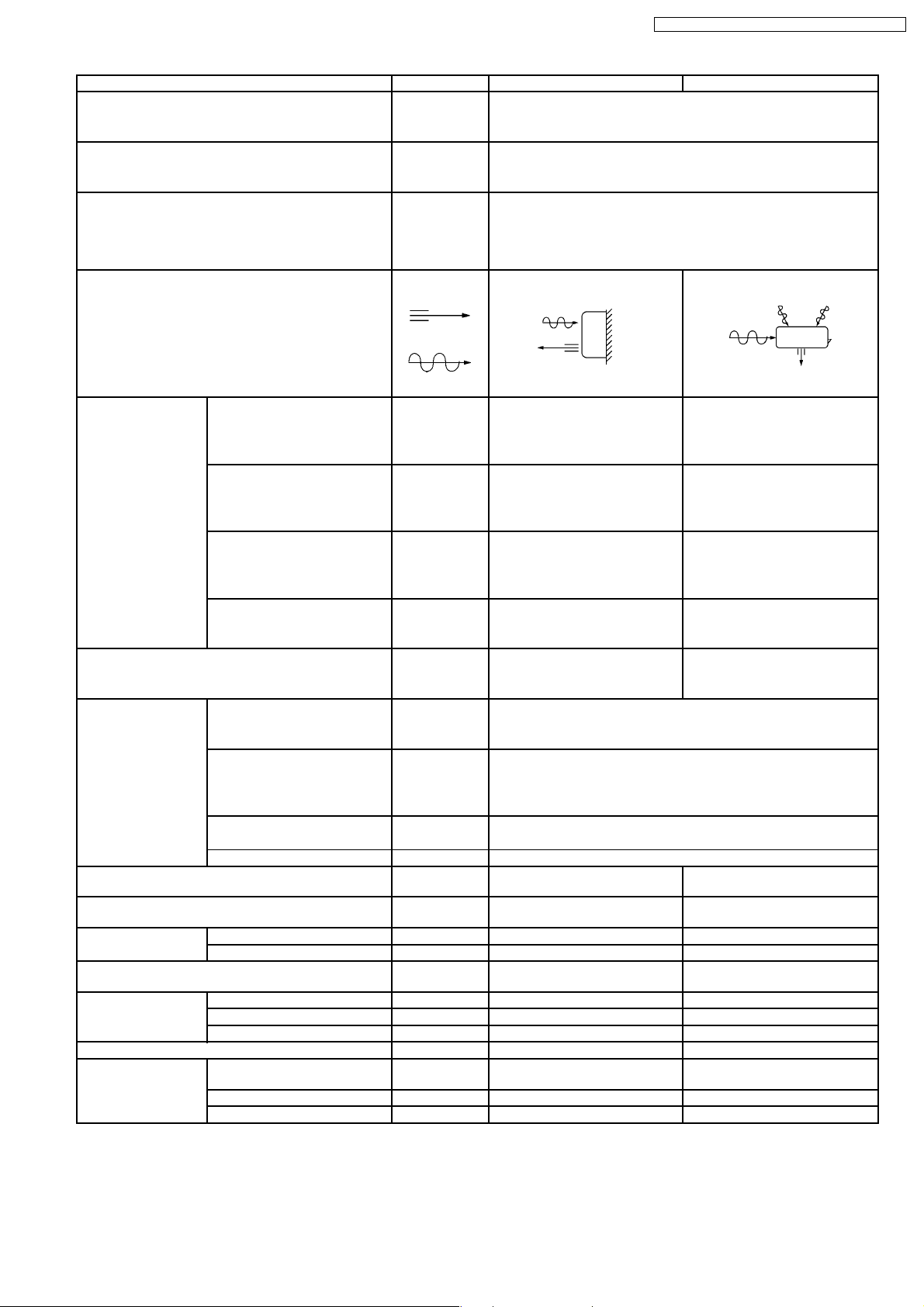

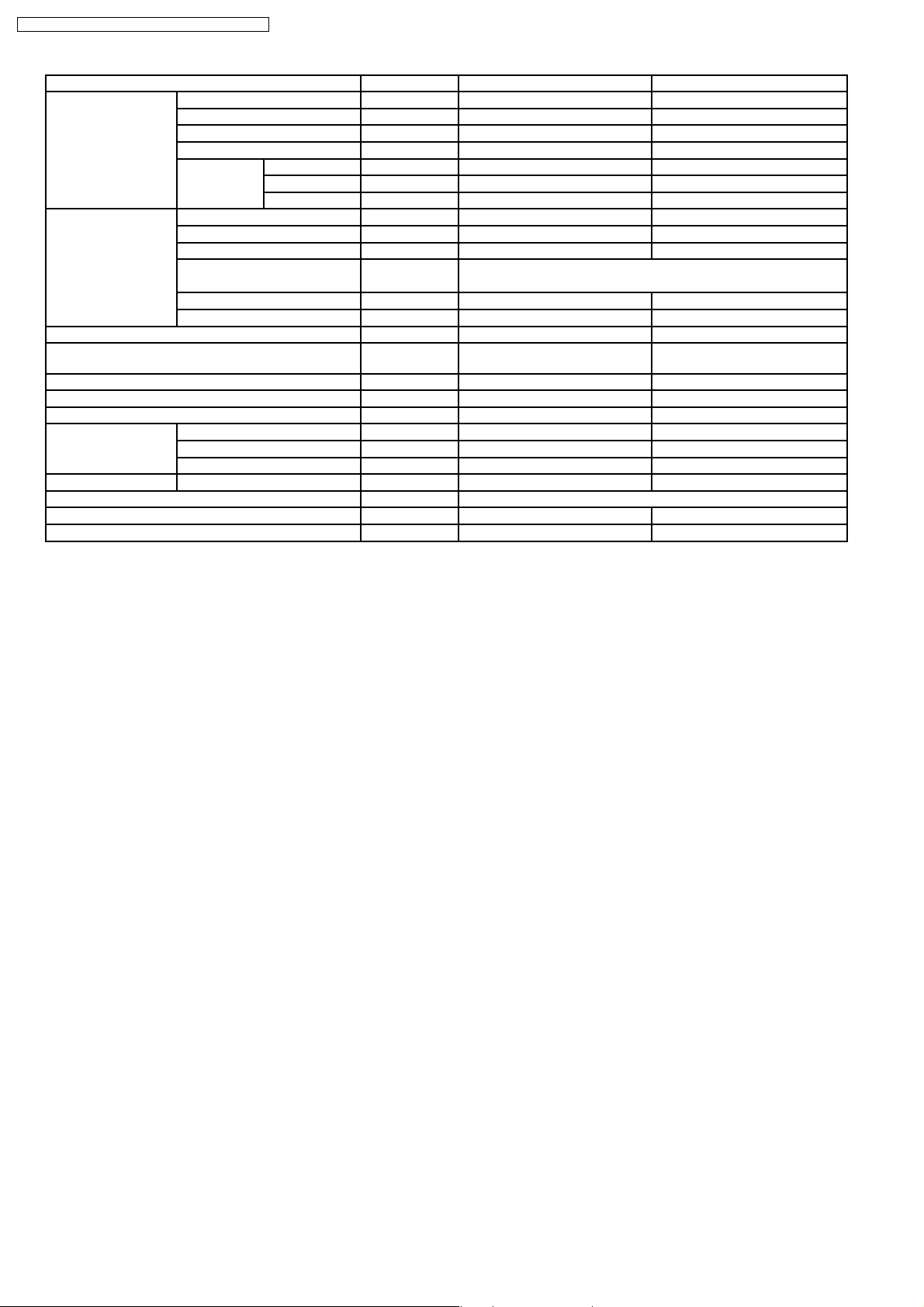

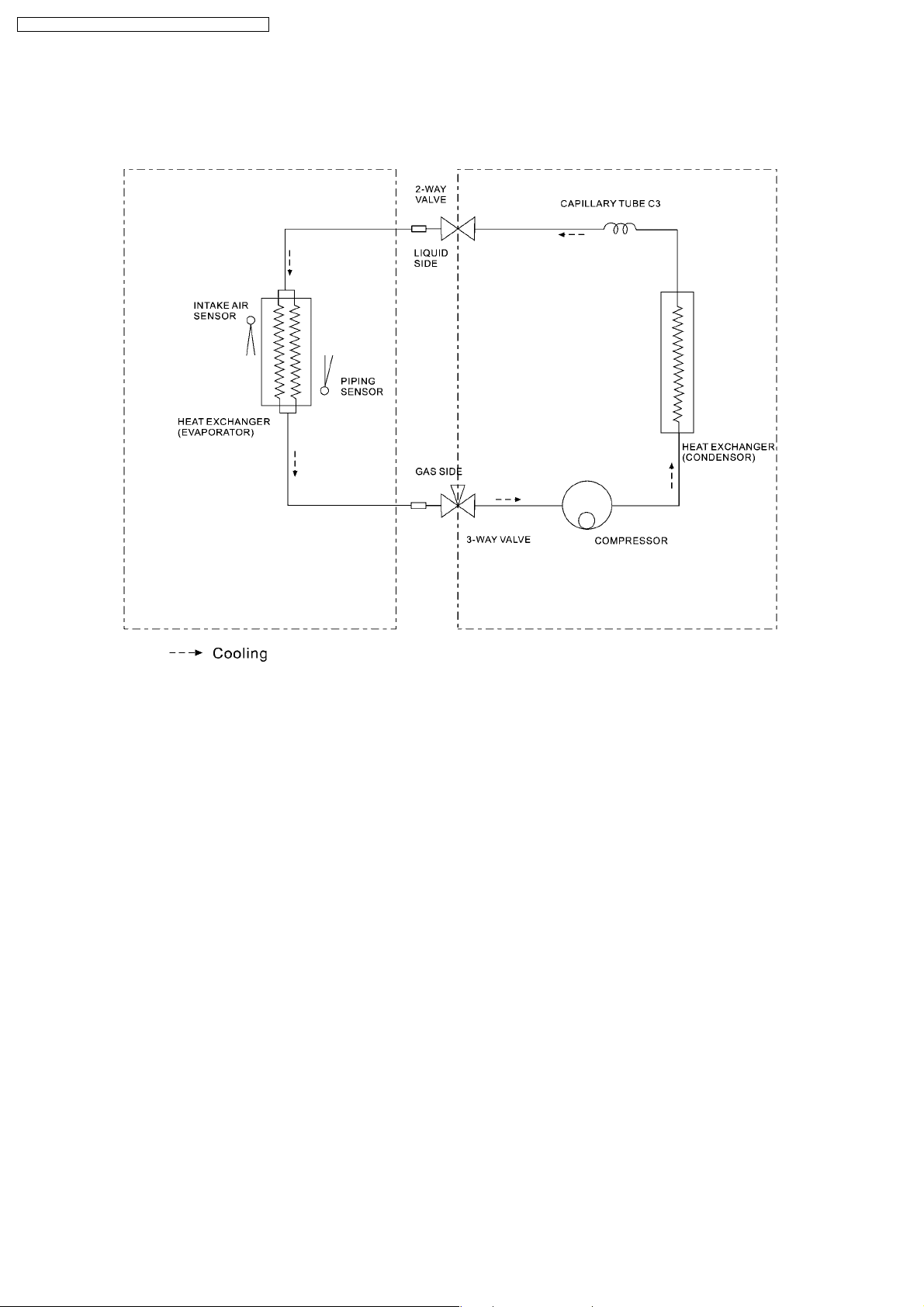

4 Refrigeration Cycle Diagram

4.1. CS/CU-PC9CKV, CS/CU-PC12CKV

12

5 Block Diagram

5.1. CS/CU-PC9CKV,CS/CU-PC12CKV

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

13

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

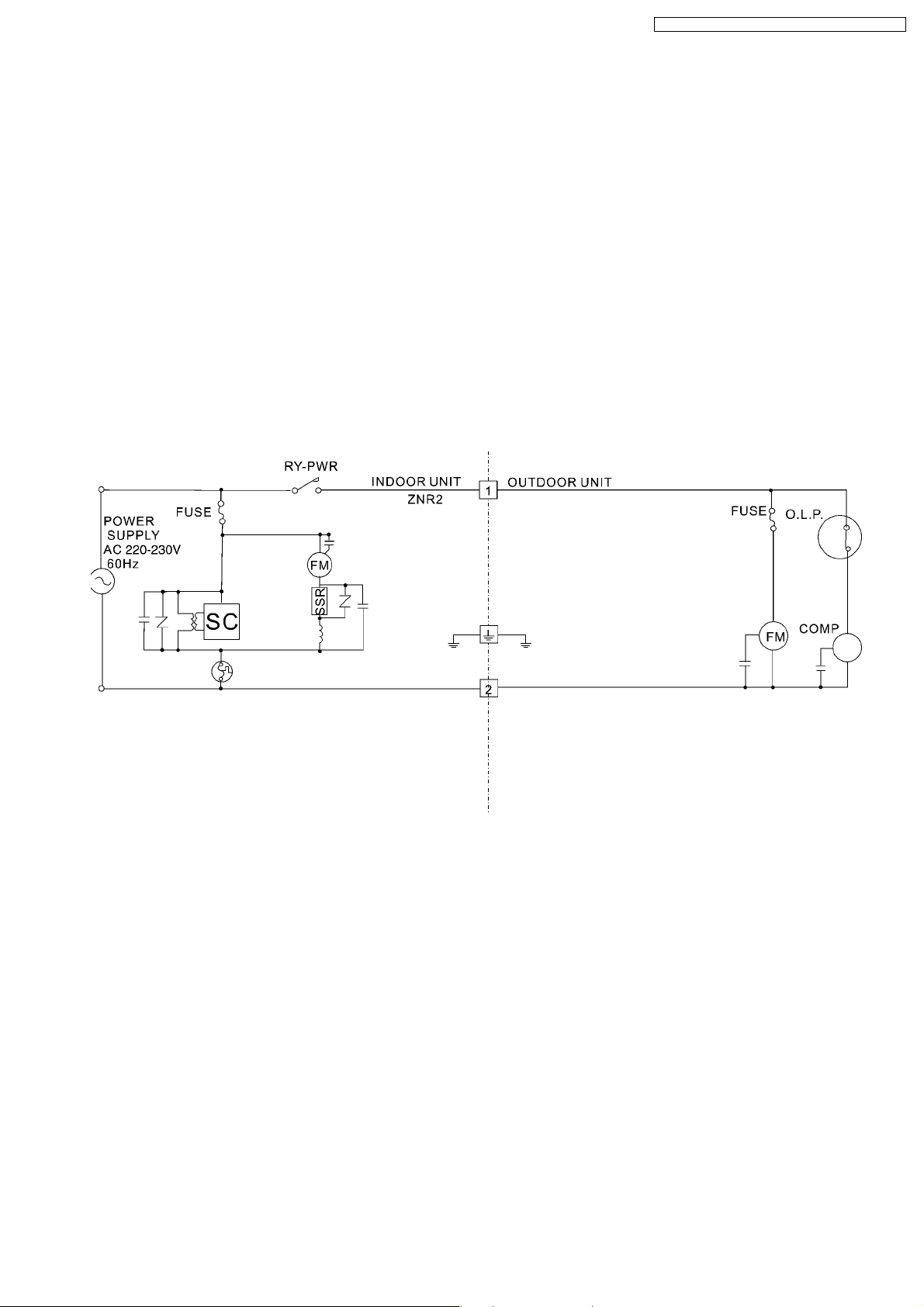

6 Wiring Diagram

6.1. CS/CU-PC9CKV, CS/CU-PC12CKV

14

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

7 Operation Details

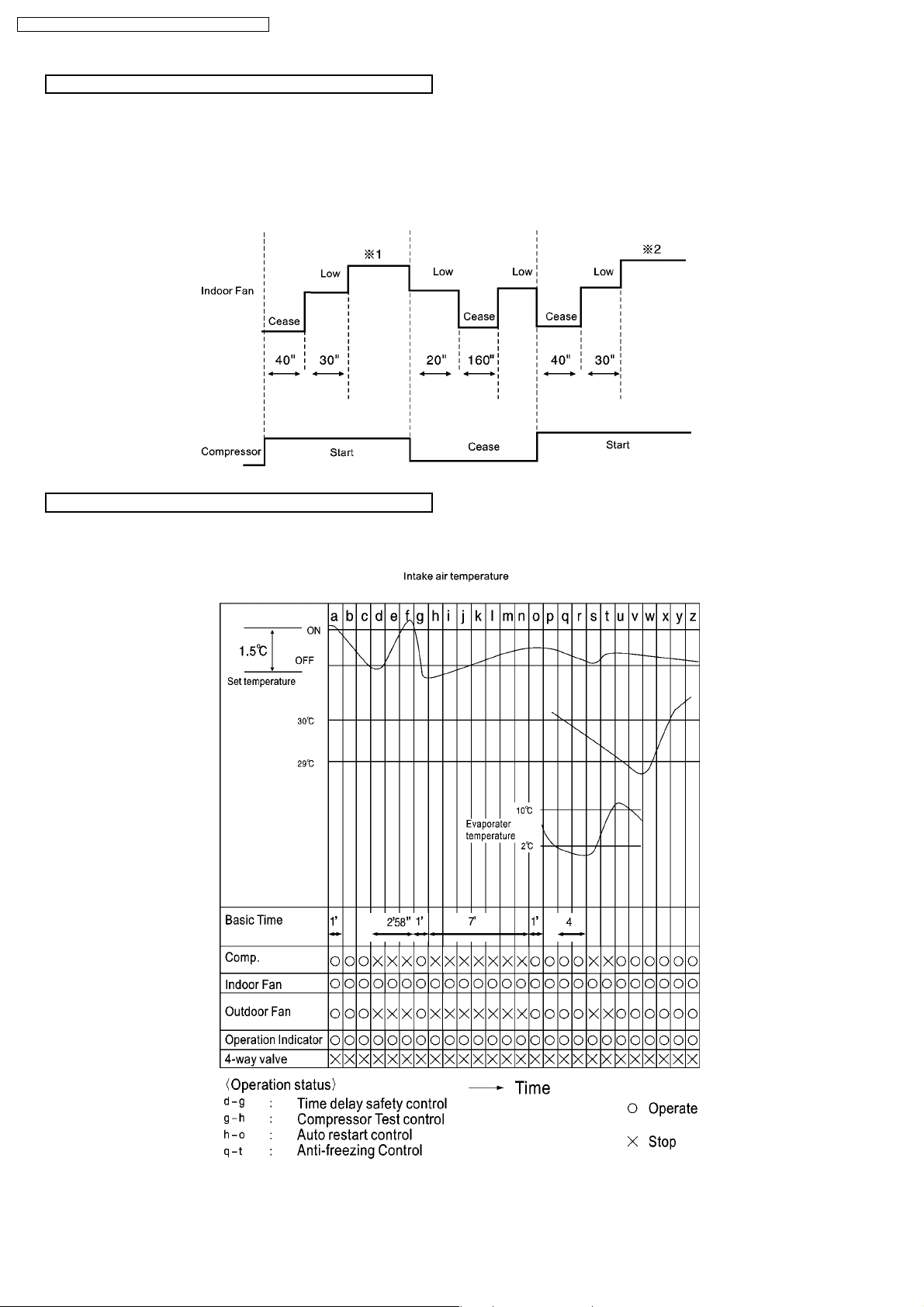

7.1. Cooling Mode Operation

•

•

When selecting the Cooling Mode Operation, the unit will operate according to the setting by the Remote Control and the

• •

operation is as the following.

Time Delay Safety Control

•

•

3 min. ---- The compressor is ceased for 3 minutes to balance the pressure in the refrigeration cycle.

• •

•

•

(Protection of compressor).

• •

Automatic Restarting Control

•

•

7 min. ---- The unit will automatically operate in 7 minutes even if the room temperature is not reached.

• •

(Prevention of raising the humidity)

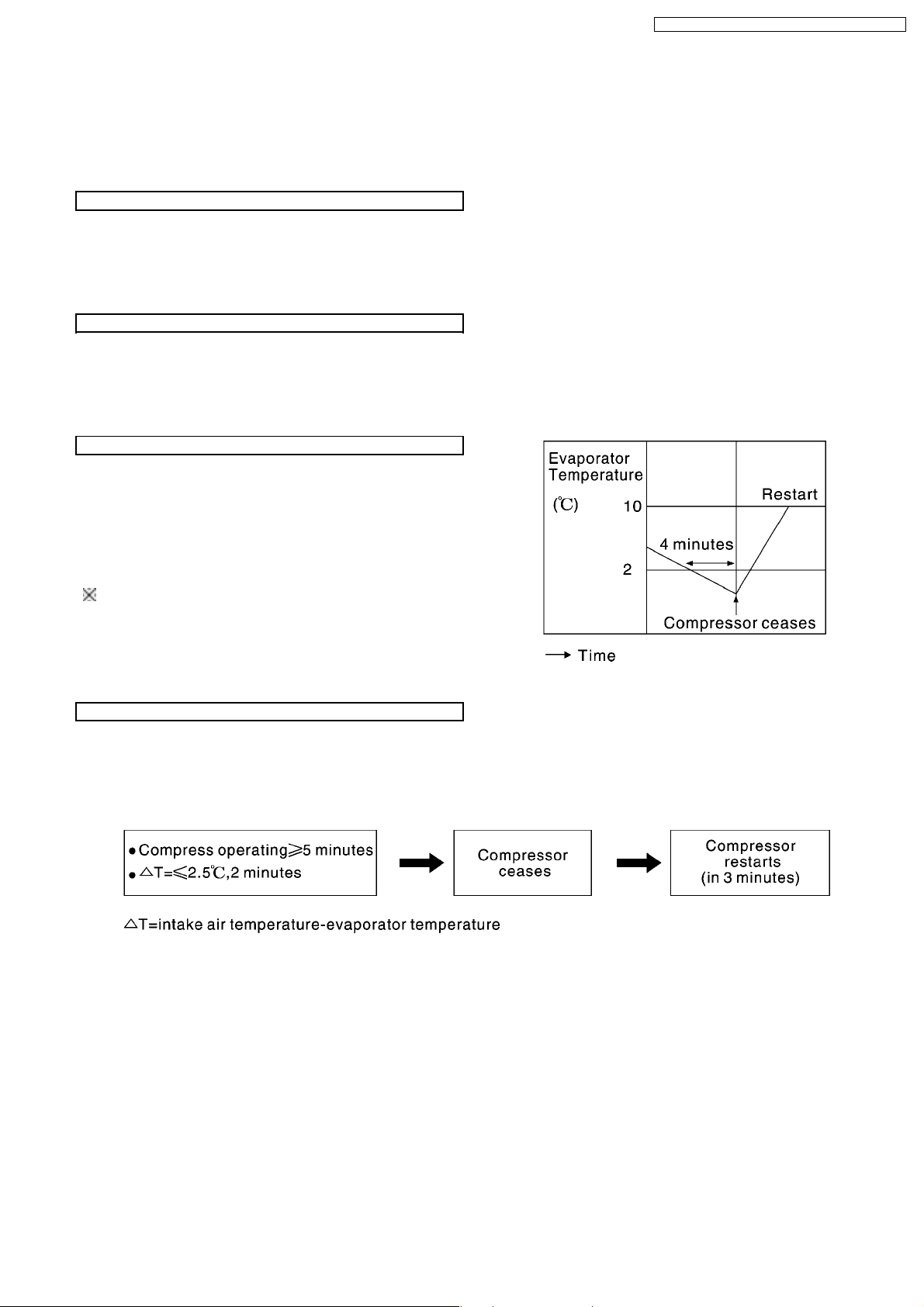

Anti-freezing Control

•

•

If temperature of evaporator is lower than 2°C continuously

• •

for 4 minutes, the compressor will cease to prevent the

evaporator from freezing. Fan speed setting will not be

changed.

•

•

When temperature of evaporator reaches 10°C,

• •

compressor will restart.

During Cooling Mode Operation, the Time Delay Safety Control

is available.

Anti-reversing Control

•

•

If the compressor has been continuously running for 5 minutes, and the difference of temperature between intake air and

• •

evaporator is continuously lower than 2.5°C for 2 minutes, the compressor is ceased for 3 minutes then restarts. (Time Delay

Protection Control is effective.)

15

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

Automatic Fan Speed Mode

During Cooling Mode Operation, use remote control to select Automatic Fan Speed.

•

•

Fan speed will be at the point between "high speed" and "medium speed".

• •

•

•

Deodorization control.

• •

Time Graph for cooling Operation

16

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

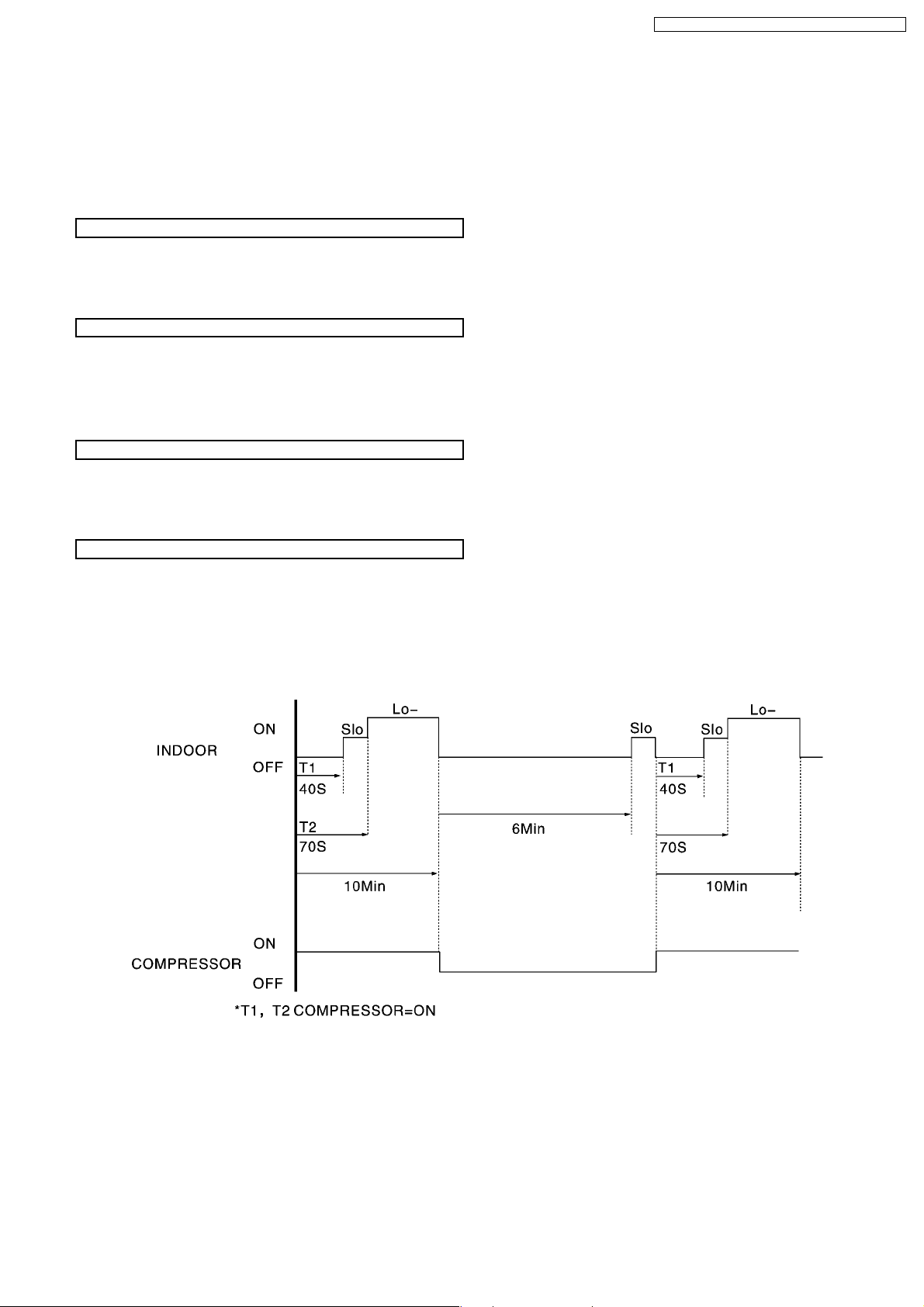

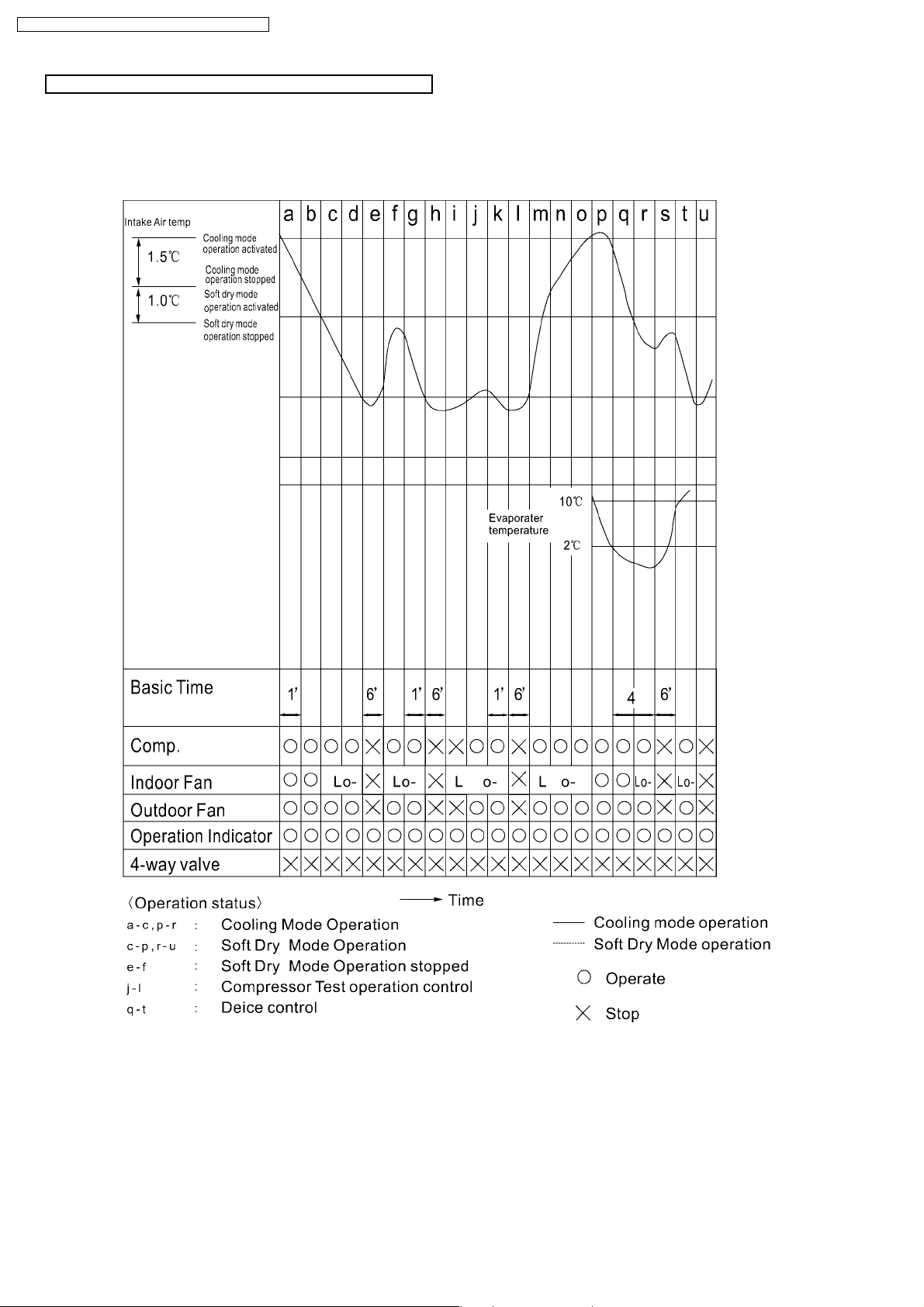

7.2. Soft Dry Mode Operation

•

•

When selecting Soft Dry mode operation, the operation will be cooling until the room temperature reaches the set temp on the

• •

remote control, and then Soft Dry will be activated. (During Soft Dry Mode the fan of indoor unit will operate at super low speed.)

•

•

Once soft Dry mode operation is turned off, indoor fan, compressor and outdoor fan will stop for 6 minutes.

• •

Time Delay Safety Protection

•

•

During cooling mode operation, if the compressor ceased, it will not restart within 3 minutes.

• •

Anti Freezing Control

•

•

Same as the denotation in Cooling Operation. (P.15)

• •

(During Soft Dry Mode Operation, compressor will stop for at least 6 min.)

Anti-reverse Control

•

•

Same as the denotation in Cooling Operation. (P.15)

• •

Automatic Fan Speed

During Soft Dry Operation, use remote control to select Auto Fan Speed mode.

•

•

Indoor Fan Speed is at super low.

• •

•

•

Deodorization control.

• •

17

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

Time Graph for soft dry operation

18

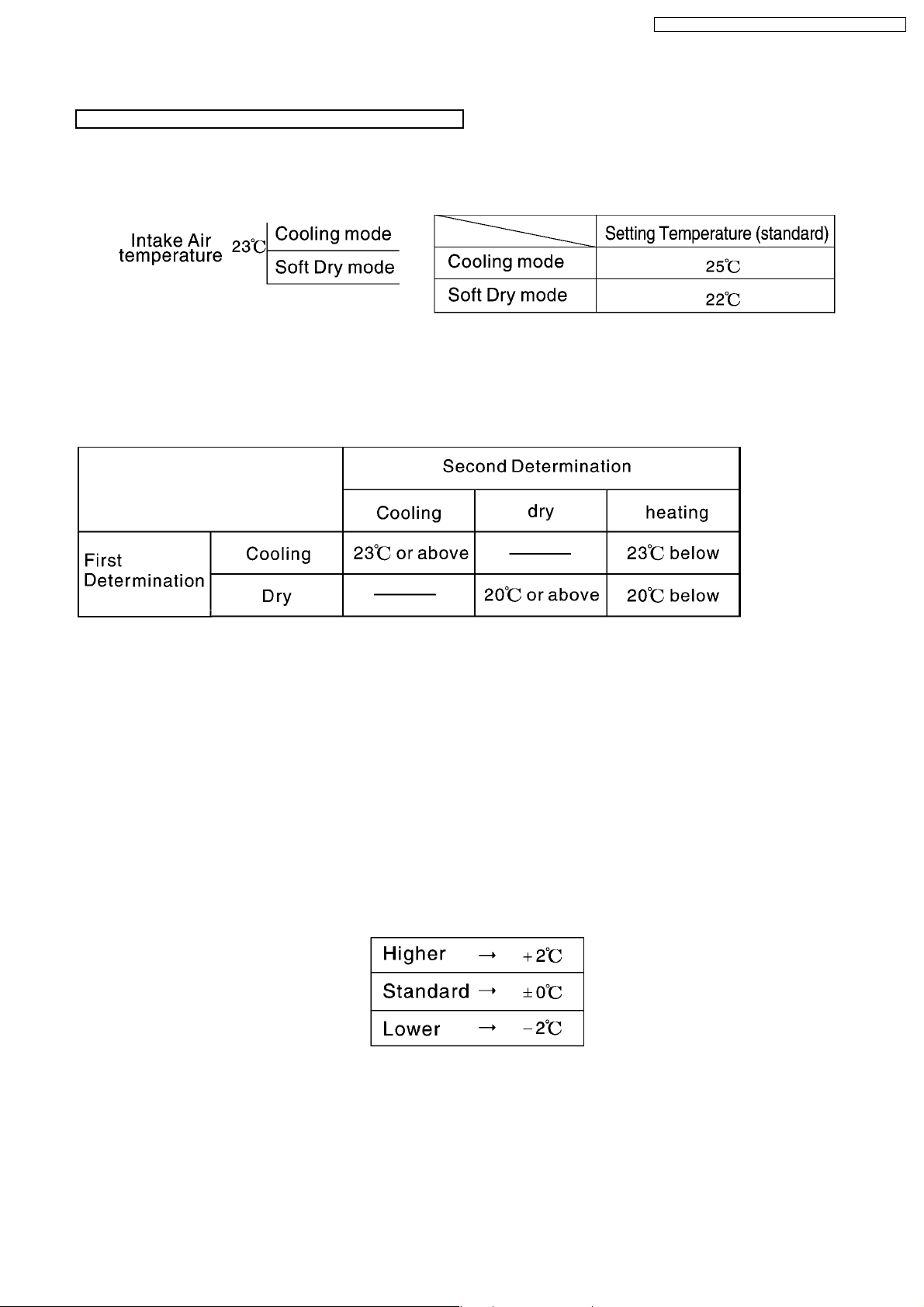

7.3. Automatic Mode Operation

Standard for determining operation mode

First Determination:

Second Determination:

One hour after the above determination, the unit will operate according to the table below.

CS-PC9CKV CU-PC9CKV / CS-PC12CKV CU-PC12C KV

1. Indoor fan operates at super low speed for 20 seconds.

2. After judging indoor air temperature, the operation is determined and operation continued at the mode determined.

3. After the operation mode has been determined, the mode does not change. However, Soft Dry mode operation includes cooling

mode operation.

4. If automatic mode operation is started while the unit is operating, operation will continue.

If current operation is in cooling mode (including the cooling mode operation when is a part of Soft Dry mode operation) it will

be maintained, and if current operation is not cooling mode, the appropriate operation mode is determined for 20 seconds at

super slow fan speed. Then the selected mode will continue.

5. Room temperature adjustment

19

Loading...

Loading...