Panasonic CS-MVG103KE, CU-MVG153KE Service Manual

Order number RAC9911058C2

Room Air Conditioners

CS-MVG103KE

CU-MVG153KE

© 1999 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

CS-MVG103KE / CU-MVG153KE

CONTENTS

Page Page

1 Features 2

2 Functions

2.1. REMOTE CONTROL

2.2. INDOOR UNIT

2.3. OUTDOOR UNIT

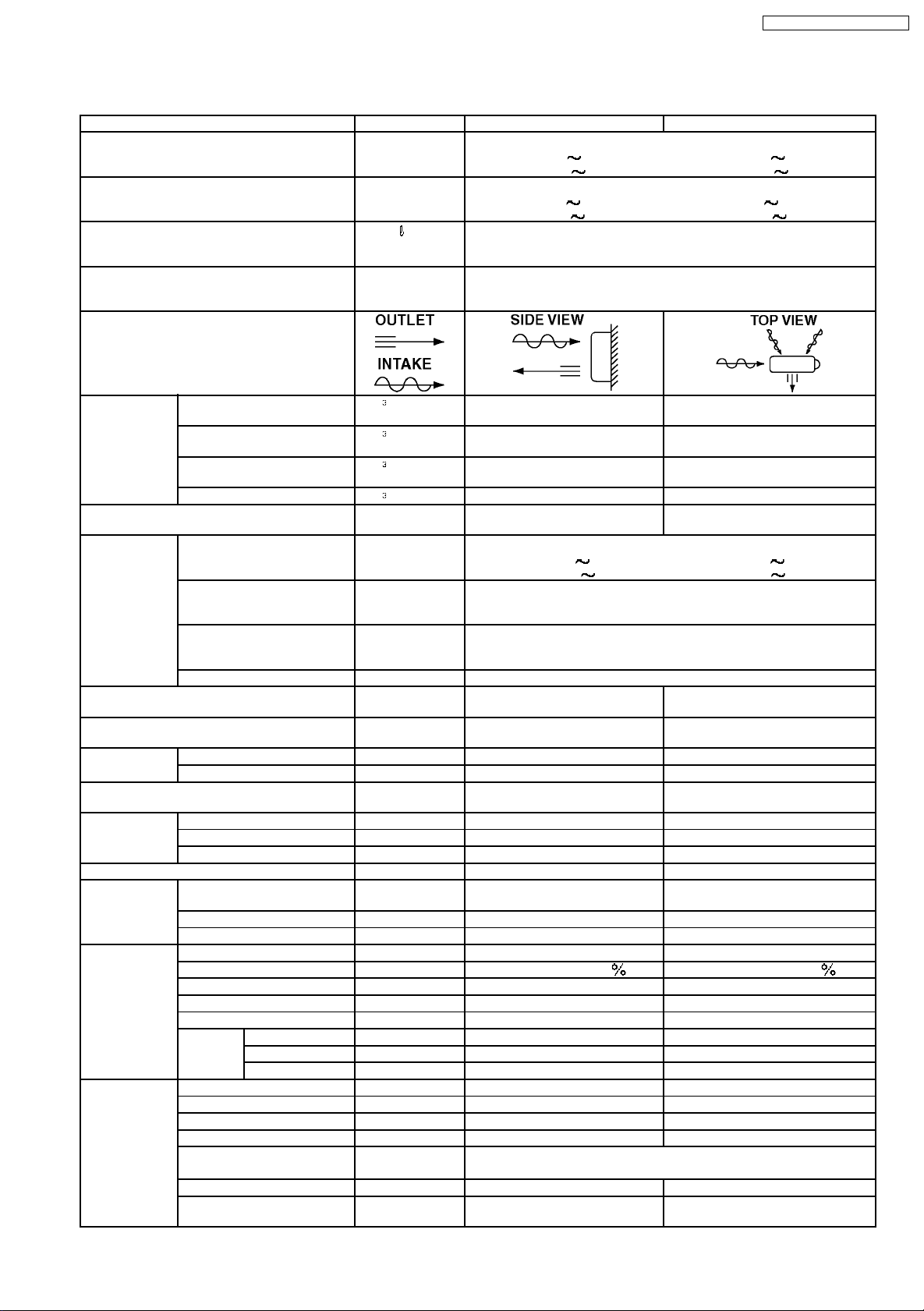

3 Product Specifications

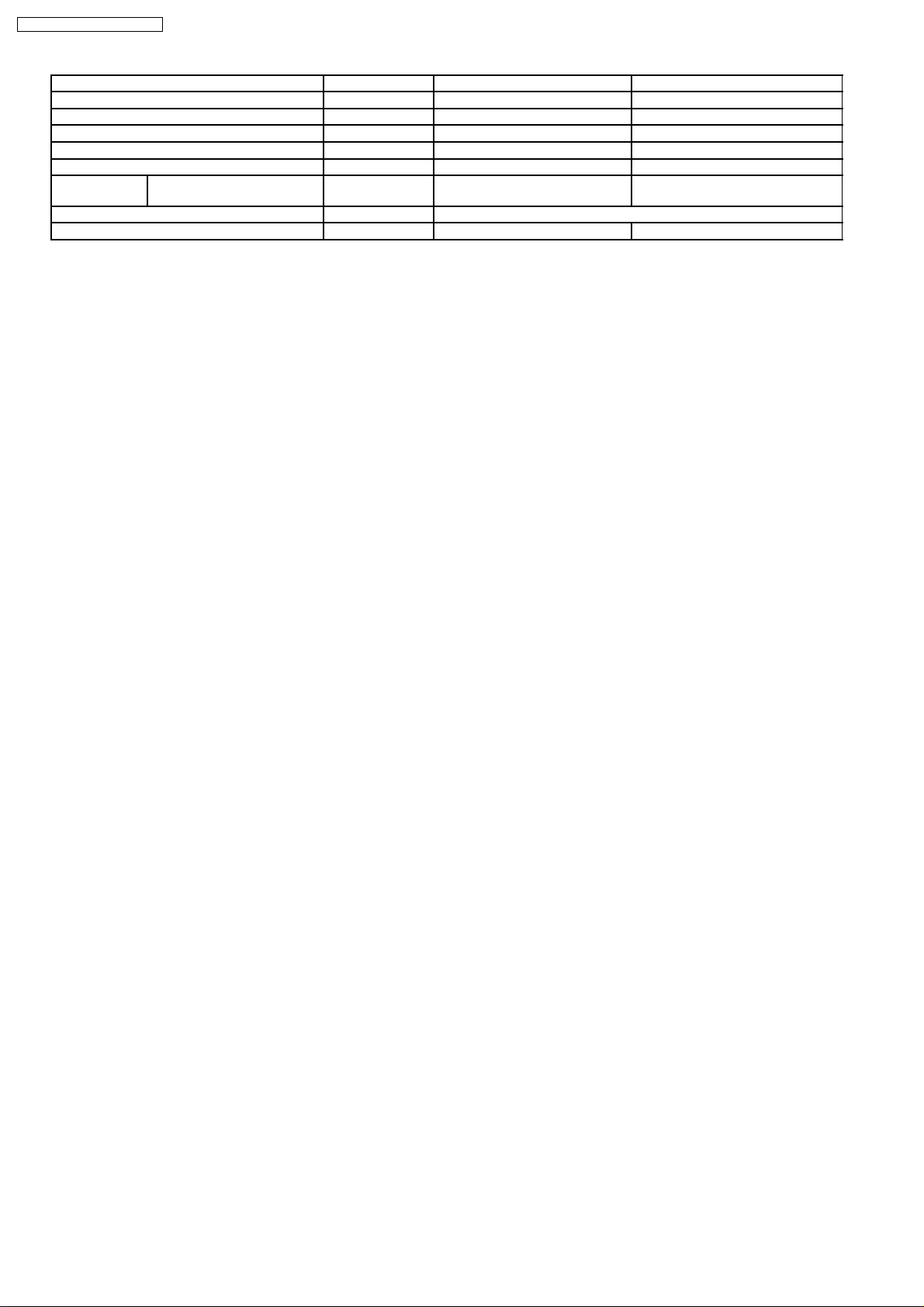

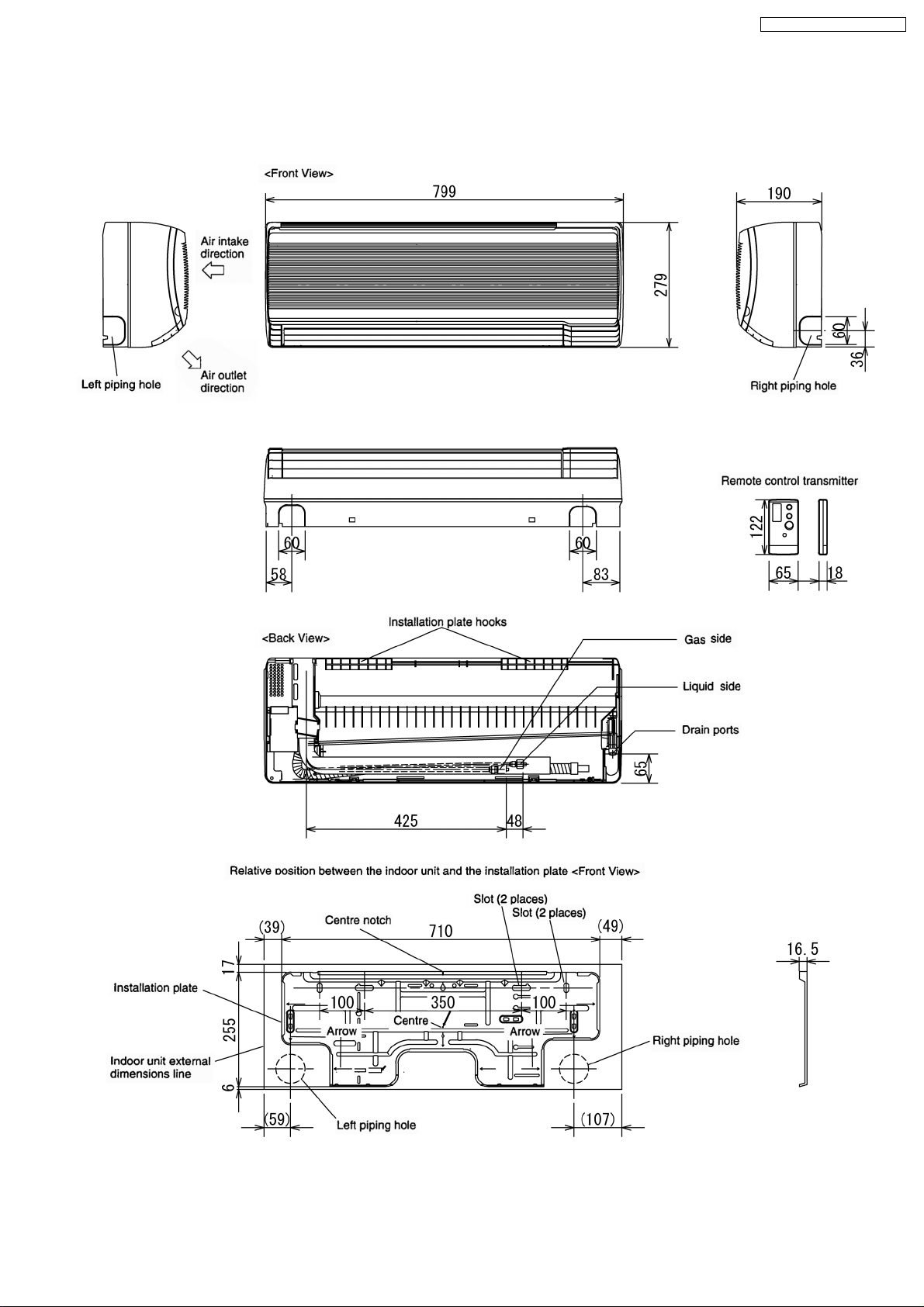

4 Dimensions

4.1. CS-MVG103KE (INDOOR UNIT)

4.2. CU-MVG153KE (OUTDOOR UNIT)

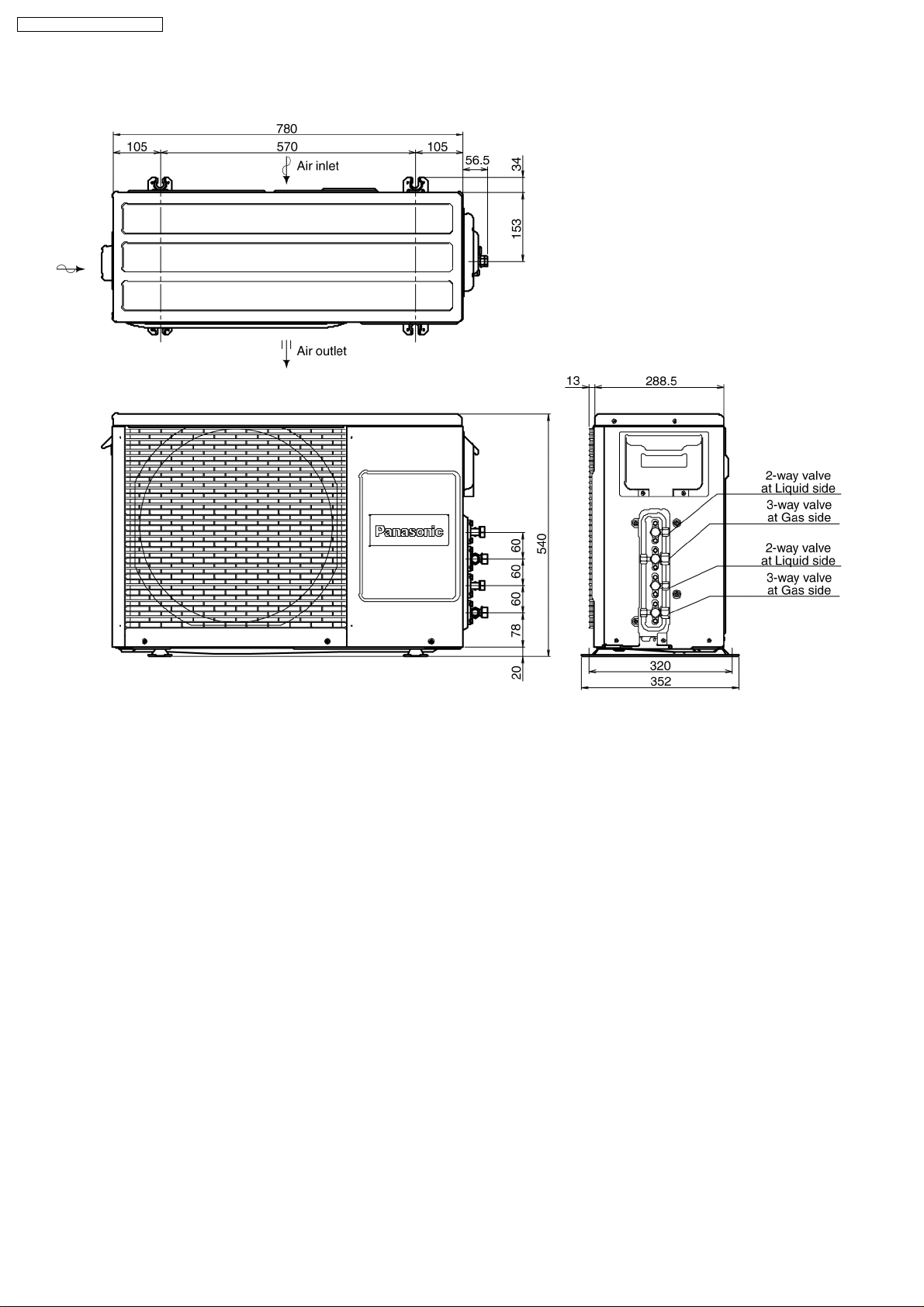

5 Refrigeration Cycle Diagram

6 Block Diagram

7 Wiring Diagram

7.1. CS-MVG103KE ( INDOOR UNIT )

7.2. CU-MVG153KE ( OUTDOOR UNIT )

8 Operation Details (FUNCTIONS)

8.1. SIMULTANEOUS OPERATION CONTROL

8.2. TEMPERATURE SHIFT

8.3. COMPRESSOR OPERATING FREQUENCY OPERATION

8.4. COOLING OPERATION

8.5. SOFT DRY OPERATION

8.6. HEATING OPERATION

8.7. FAN OPERATION

8.8. AUTOMATIC OPERATION

8.9. INDOOR FAN SPEED CONTROL

8.10. OUTDOOR FAN CONTROL

8.11. AIRFLOW DIRECTION

8.12. QUIET OPERATION

8.13. POWERFUL MODE OPERATION

8.14. SLEEP MODE OPERATION

8.15. DELAY ON TIMER CONTROL

8.16. AUTO RESTART CONTROL

8.17. POWER MONITOR DISPLAY

8.18. REMOTE CONTROL SIGNAL RECEIVING SOUND

ON/OFF

9 Operation Details (PROTECTION)

9.1. PROTECTION CONTROL FOR ALL OPERATIONS

10

11

12

13

13

14

15

15

16

17

18

20

21

25

25

27

29

29

31

31

32

33

33

34

34

35

35

3

3

4

6

7

9

9

9.2. PROTECTION CONTROL FOR COOLING & SOFT DRY

9.3. PROTECTION CONTROL FOR HEATING OPERATION

10 Installation And Servicing Air Conditioner Using R410A

10.1. OUTLINE

10.2. TOOLS FOR INSTALLING/SERVICING REFRIGERANT

PIPING

10.3. REFRIGERANT PIPING WORK

10.4. INSTALLATION, TRANSFERRING, SERVICING

11 Installation Information

11.1. ATTACHED ACCESSORIES

11.2. SELECT THE BEST LOCATION

11.3. INDOOR/OUTDOOR UNIT INSTALLATION DIAGRAM

11.4. CONNECTION PIPES FOR AIR CONDITIONER UNITS

WITH R410A

11.5. NOTE

12 Servicing Information

12.1. TROUBLESHOOTING

12.2. SELF DIAGNOSIS DISPLAY

12.3. REMOTE CONTROL

12.4. DISASSEMBLY OF PARTS

13 Technical Data

13.1. OPERATION CHARACTERISTICS

14 Electronic Circuit Diagram

14.1. HOW TO USE ELECTRONIC CIRCUIT DIAGRAM

14.2. TIMER TABLE

14.3. INDOOR UNIT

14.4. OUTDOOR UNIT

14.5. REMOTE CONTROLLER

15 Printed Circuit Board

15.1. INDOOR UNIT

15.2. OUTDOOR UNIT / MAIN PCB

15.3. OUTDOOR UNIT / TRANSISTOR MODULE

16 Exploded View & Replacement Parts List

16.1. CS-MVG103KE

16.2. CU-MVG153KE

17 Electronic Parts List

39

40

41

41

42

46

48

52

52

52

54

55

55

56

56

58

60

61

69

69

71

71

71

72

74

76

77

77

79

81

82

82

84

86

1 Features

Product

·

−

−

Powerful Mode for quick cool/heat

− −

−

−

Compressor operating frequency control to maintain

− −

desired room temperature

−

−

Automatic Restart after power failure

− −

−

−

Washable front panel

− −

−

−

Power Monitor Display

− −

Serviceability

·

−

−

Self diagnosis

− −

−

−

Test Run at both Cooling and Heating rated frequency

− −

Quality Improvement

·

−

−

High power supply voltage protection

− −

−

−

Low power supply voltage protection

− −

−

−

Gas leakage detection

− −

2

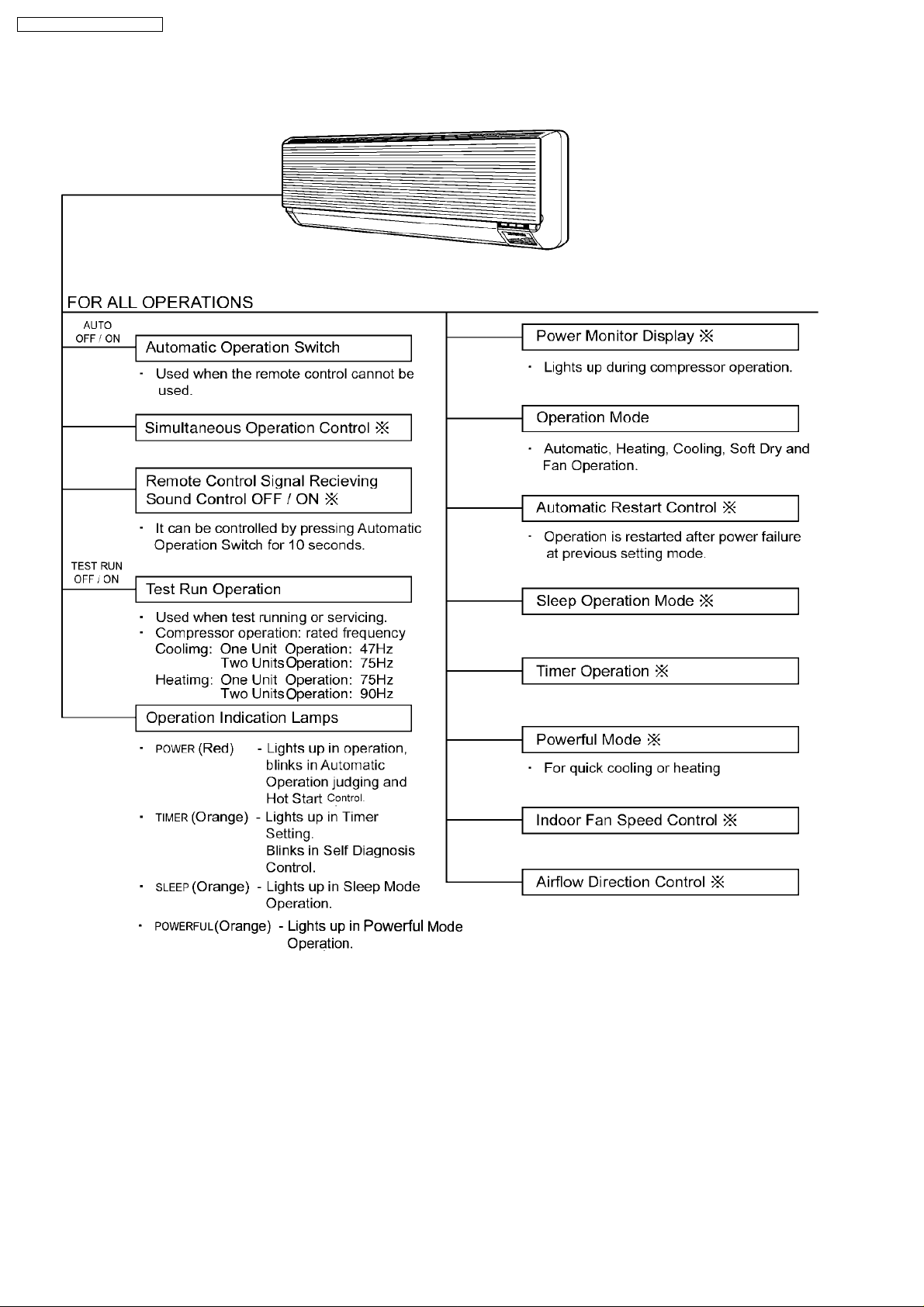

2 Functions

2.1. REMOTE CONTROL

CS-MVG103KE / CU-MVG153KE

3

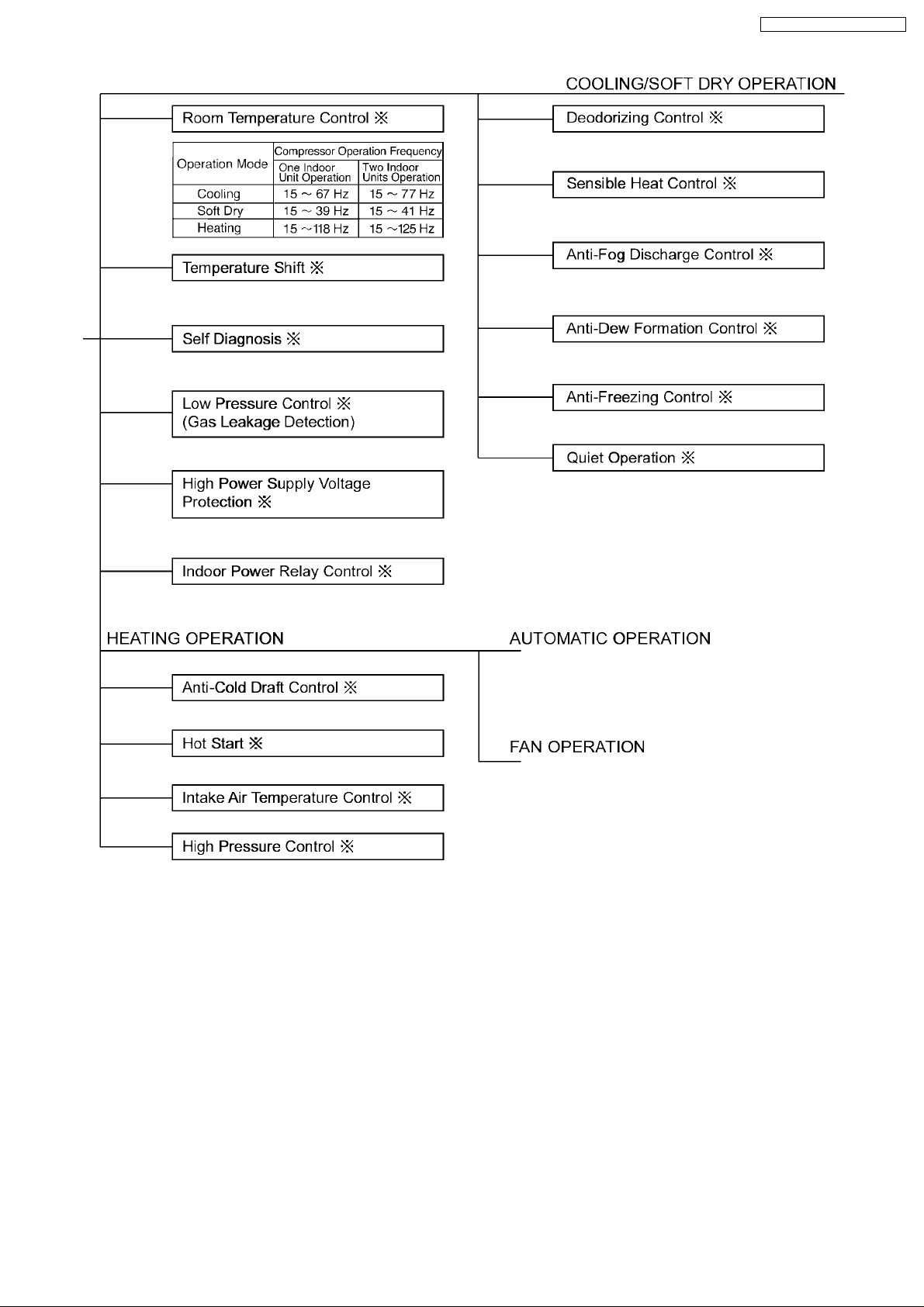

CS-MVG103KE / CU-MVG153KE

2.2. INDOOR UNIT

4

CS-MVG103KE / CU-MVG153KE

5

CS-MVG103KE / CU-MVG153KE

2.3. OUTDOOR UNIT

6

3 Product Specifications

Unit CS-MVG103KE CU-MVG153KE

Cooling Capacity

kW

Btu/h

Heating Capacity

kW

Btu/h

Moisture Removal /h

Pint/h

Power Source Phase

V

Cycle

Airflow Method

CS-MVG103KE / CU-MVG153KE

(1 unit) (2 units)

2.8(0.7 3.5) 2.25(0.45 2.3)

9,500(2,400 11,900) 7,650(1,500 7,850)

(1 unit) (2 units)

4.0(0.7 4.3) 2.6(0.45 3.05) x 2

13,600(2,400

14,700) 8,850(1,500 10,400) x 2

(1 unit) (2 units)

1.6 2.5

3.4 5.3

Single

230

50

x 2

x 2

Air Volume Indoor Air(Lo) m / min(cfm) Cooling ; 7.0(247)

Indoor Air(Me) m / min(cfm) Cooling ; 7.6(268)

Indoor Air(Hi) m / min(cfm) Cooling ; 8.3(293)

Outdoor Air m / min(cfm) - Hi; 30.0(1050)

Noise Level dB(A) Cooling ; High 39,Low 27

Electrical

Data

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Power Cord length

Number of core-wire

Dimensions Height inch(mm) 10 - 31/32(279) 25 - 25/32(540)

Net Weight lb(kg) 20(9.0) 95(43)

Compressor Type - Rotary

Air Circulation Type Cross-flow Fan Propeller Fan

Heat

Exchange

Input

kW

Running Current

A

COP (1 unit) (2 units)

Starting Current A 6.50

inch

inch

inch

inch

Inner diameter mm 12 Length m 0.7 -

Width inch(mm) 31 - 15/32(799) 30 - 3/4(780)

Depth inch(mm) 7 - 15/32(190) 11 - 13/32(289)

Motor Type - Brushless(4-poles)

Rated Output W - 1,200

Material AS+Glass Fiber 30 AES+Giass Fiber 12

Motor Type Transiator(4-poles) Induction(6-poles)

Input W - 110

rated Output W 20 25

Fan

Speed

description Evaporator Condenser

Tube material Copper Copper

Fine material Aluminium Aluminium

Fine type Slit Fin Corrugated Fin

Row/Stage

FPI 21 17

Size(W x H x L) mm 600 x 252 x 25.4 673 x 504 x 18.2

Low Cool(Heat) rpm 880(970) Medium Cool(Heat) rpm 1,100(1,170) High Cool(Heat) rpm 1,290(1,310) 700

Heating ; 7.2(254)

Heating ; 7.8(275)

Heating ; 8.5(300)

heating ; High 39,Low 27

Cooling ; 770(250 1,100) 1,350(255 1,380)

Heating ;1,320(215 1,900) 1,280(220 1,800)

Cooling ;;3.70 ( max 5.40 ) 6.50 ( max 6.70 )

Heating 6.35 ( max 9.90 ) 6.15 ( max 9.90 )

Cooling ; 3.64 3.33

Heating ; 3.03 4.06

(1 unit) (2 units)

(1 unit) (2 units)

G ; Half Union 3/8”

L ; Half Union 1/4”

G(gas side) ; 3/8”

L(liquid side) ; 1/4”

-

-

(Plate fin configuration,forced draft)

2/14

G ; 3-Way valve 3/8”

L ; 2-Way valve 1/4”

L(liquid side) ; 1/4”

-

-

-

Cooling ; 46

Heating ; 47

G(gas side) ; 3/8”

-

-

(2 cylinder)

2/24

615 x 504 x 18.2

7

CS-MVG103KE / CU-MVG153KE

Unit CS-MVG103KE CU-MVG153KE

Refrigerant Control Device - Expansion Valve

refrigeration Oil (c.c) - RB88A(290)

Refrigerant(R410A) g(oz) - 1250(44.1)

Thermostat Electronic Control Protection Device Electronic Control

Air Filter Material

Capacity Control Expansion valve

Fan motor Capacitor µF,VAC - 2.0µF,400VAC

·

Specifications are subject to change without notice for further improvement.

style

P.P

Honeycomb

-

8

4 Dimensions

4.1. CS-MVG103KE (INDOOR UNIT)

CS-MVG103KE / CU-MVG153KE

9

CS-MVG103KE / CU-MVG153KE

4.2. CU-MVG153KE (OUTDOOR UNIT)

10

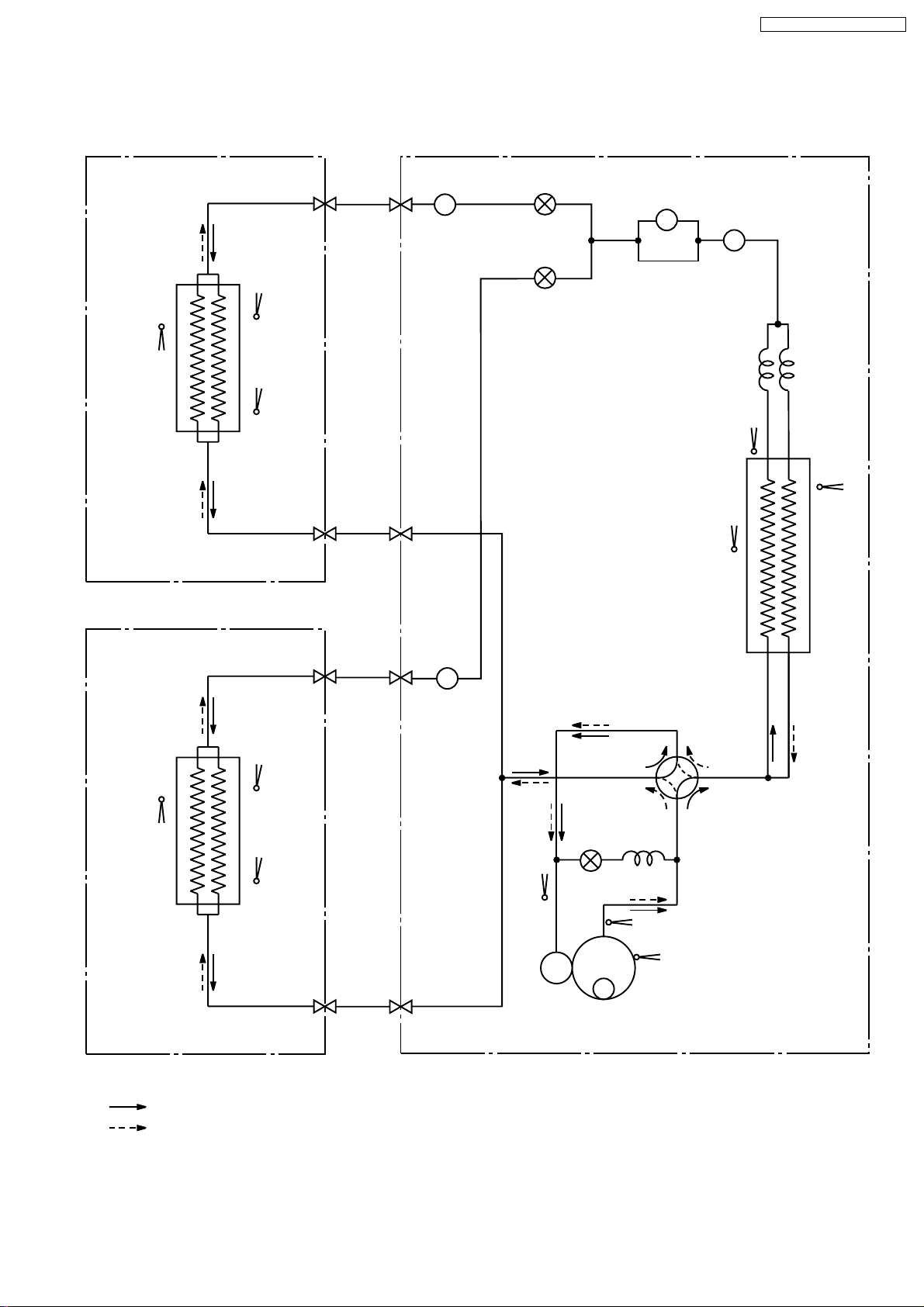

5 Refrigeration Cycle Diagram

4-WAY VAL VE

2-WAY

VALVE

PIPE

TEMP.

SENSOR

PIPE

TEMP.

SENSOR

SENSOR

TEMP.

INTAKE

PIPE

TEMP.

SENSOR

PIPE

TEMP.

SENSOR

INDOOR A

OUTDOOR

COOLING

HEATING

HEAT EXCHANGER

(EVAPORATOR)

HEAT EXCHANGER

(CONDENSER)

2-WAY

VALVE

VALVE

3-WAY

2-WAY

VALVE

VALVE

3-WAY

C1

STRAINER

C ; CAPILLARY TUBE

SENSOR

TEMP.

INTAKE

PIPE

TEMP.

SENSOR

PIPE

TEMP.

SENSOR

INDOOR B

HEAT EXCHANGER

(EVAPORATOR)

DISCHARGE TEMP

SENSOR

COMPRESSOR

COMPRESSOR

TEMP SENSOR

OUTDOOR AIR

TEMP SENSOR

DRYER

STRAINER

STRAINER

EXPANSION

VALVE (A)

EXPANSION

VALVE (B)

SUCTION

TEMP.

SENSOR

CS-MVG103KE / CU-MVG153KE

11

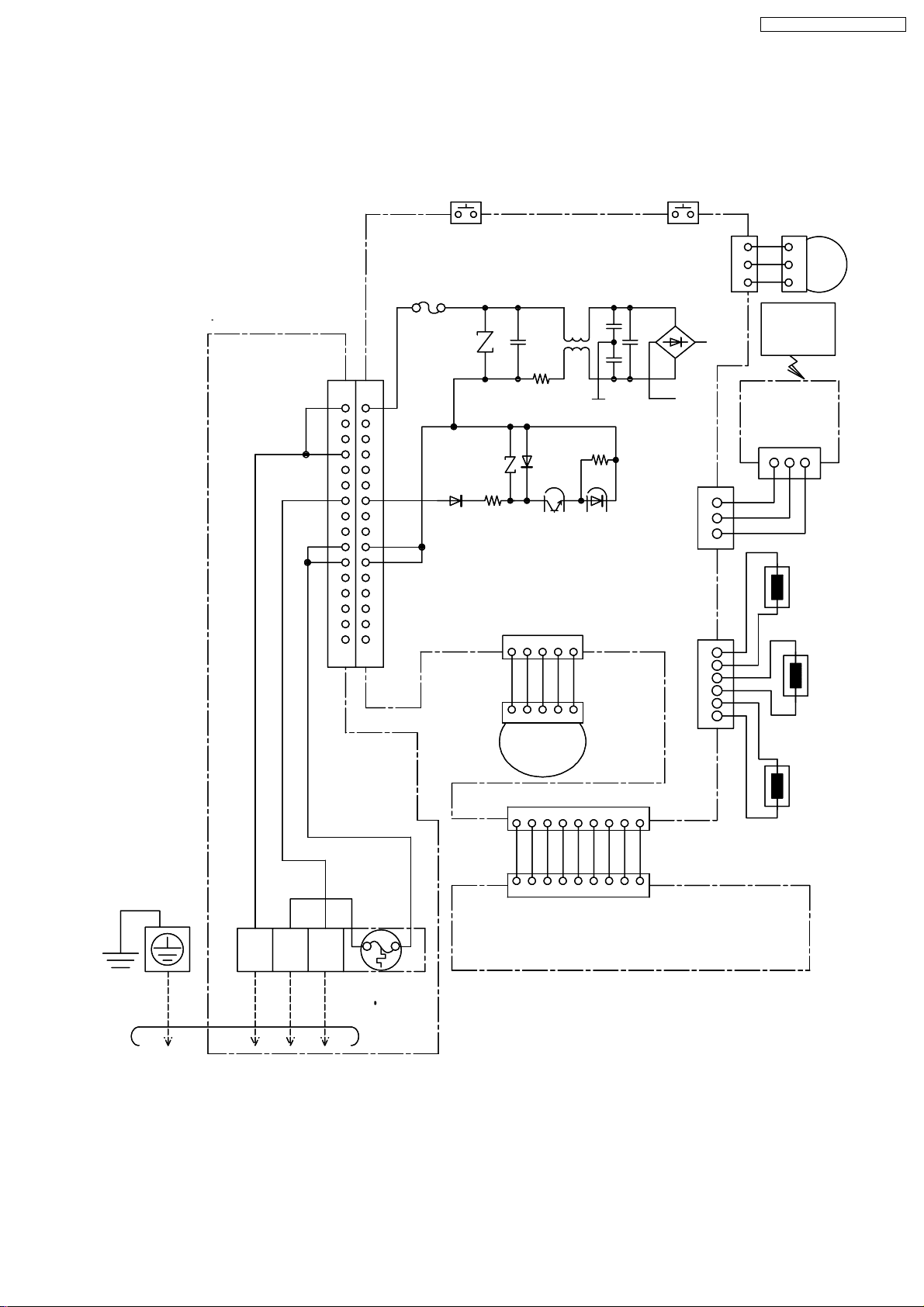

6 Block Diagram

INDOOR UNIT A OUTDOOR UNIT

WIRELESS

REMOTE CONTROL

TRANSMITTER

FUSE

(3.15A)

CS-MVG103KE / CU-MVG153KE

OUITDOOR

POWER

SUPPLY

SINGLE

PHASE

230V 50Hz

1 2

FUSE

(20A)

1

1

C.T.

RY-AC

PTC

RY-PWR

12

RECEIVER

P.C.B.

INCIDATOR

P.C.B.

FAN

MOTOR

LOUVER

MOTOR

FM

3C

9C

3C

5C

ELECTRONIC

CONTROLLER

TERNINAL

THERMAL

FUSE 102

INDOOR UNIT B

SAME AS

UNIT A

RY-L

RY-2CV

RY-HOT

DIODE

-

4-WAY

NOISE FILLTER

ELECTRONIC

CONTROLLER

2

2

3

3

1

1

2

2

3

3

VALVE

2-WAY

VALVE

MOTOR

FM

FAN

REACTOR

++

+

NOISE FILLTER

5C

5C

EXP.VALVE(A)

EXP.VALVE(B)

COMPRESSOR

Indicates the electronic control unit.

"C" Indicates the number of core wires. (Example:5C=5 core wires).

7 Wiring Diagram

Y

7.1. CS-MVG103KE ( INDOOR UNIT )

PUMP DOWN SW.

PUMP DOWN SW.

( TEST RUN)

( TEST RUN)

FUSE

FUSE

T 3. 15A L 250V

T 3. 15A L 250V

1

1

1

1

EL ECTRONIC

EL ECTRONIC

CONTROLLER

CONTROLLER

ZNR

ZNR

AUTO SW.

AUTO SW.

W

W

3

3

2

2

1

1

CS-MVG103KE / CU-MVG153KE

53

12

12

3

3

CN- MTR1( G)

CN- MTR1( G)

E

E

L

L

O

O

C

C

R

R

(

(

C

C

W

W

W

W

W

W

53

1

1

RBY

RBY

L

L

E

E

W

W

I

I

R

R

E

E

E

E

M

M

O

O

T

T

R

R

R

R

C

C

O

O

N

N

T

T

N

N

R

R

O

O

E

E

C

C

T

T

L

L

R

R

O

O

L

L

N

N

T

T

E

E

V

V

E

E

I

I

E

E

C

C

R

R

C

C

V

V

(

(

N

N

-

-

3

3

2

2

1

1

MOT OR

MOT OR

S

S

S

S

E

E

O

O

L

L

C

C

I

I

E

E

R

R

R

R

)

)

W

W

)

)

/G

/G

123

123

TERMINAL

TERMINAL

TO OUT DOOR UNIT

TO OUT DOOR UNIT

16

16

16

16

TERM INAL

TERM INAL

COMPLETE

COMPLETE

THERMAL FUSE

THERMAL FUSE

102 C(3A)

102 C(3A)

CN- RCV1 ( )

CN- RCV1 ( )

SENSOR 2

SENSOR 2

(PIPE TEMP.2)

CN- STM1 (W)

CN- STM1 (W)

2435

1

2435

1

O

O

P

CN-PWR1( B)

CN-PWR1( B)

REMARKS

REMARKS

B : BL UE BR:BROWN W : WHI T E G:GREEN

B : BL UE BR:BROWN W : WHI T E G:GREEN

P : PINK Y: YELLOW O : ORANGE

P : PINK Y: YELLOW O : ORANGE

BL : BL ACK R: RED Y/ G : YEL LOW/GREEN

BL : BL ACK R: RED Y/ G : YEL LOW/GREEN

P

MOTOR

MOTOR

LOUVER

LOUVER

CN- DI SP2(W)

CN- DI SP2(W)

CN-DISP1(W)

CN-DISP1(W)

DISPLAY, SEL F - DIAGNOSIS

DISPLAY, SEL F - DIAGNOSIS

POW E R MONITO R DISPLAY

POW E R MONITO R DISPLAY

BRR

Y

BRR

Y

15

15

65

4

4

321

321

6789

6789

798

65

798

WWWW

WWWW

WWWW

WWWW

W

W

12345

12345

6

6

5

5

4

4

321

321

CN -TH1 (W)

CN -TH1 (W)

(PIPE TEMP.2)

SENSOR 1

SENSOR 1

( PI PE T EMP. 1)

( PI PE T EMP. 1)

SEN SOR

SEN SOR

(AIR TEMP.)

(AIR TEMP.)

13

C

CS-MVG103KE / CU-MVG153KE

7.2. CU-MVG153KE ( OUTDOOR UNIT )

230V/50Hz

SINGLE PHASE

1

BL

FUSE

250V/ 20A

BL

GG

6

7

9

8

1110

BR

-

+

CAPACITOR

OR

R

BL

Y

B

THE PRENTHESIZED

LETTER IS INDICATED

ON TERM I NAL COVER.

R

TRADE MARK

COMP. TERMINAL

R

U

B

V

Y

OMPRESSER

W

TERMINAL

2

WH

B

BL

420V 750 F

R

CAPACITOR

WH

REACTOR

251

43

175V 45 F

BL

-

+

420V 750 F

R

N

P

TO

INDOOR UNIT A

TERMINAL TERMINAL

1

2

3

BL

B

NOISE

FILTER

(BLUE)

(BLACK)

WH

WH

B

BR

BR

-

PTC

AC9

(BROWN)

Y

DIODE

+

SENSOR

AI R T EMP.

SENSOR

PI PE T EMP.

SENSOR

COMP. TEMP.

SENSOR

PIPE TEMP.

CN-V

CN- U

(BLUE)

(RED)

31

R

31

31

CN- U

CN-V

(RED)

(BLUE)

(YELLOW)

1

PBLB

(YELL OW)

CN- W

Y

3131

CN- W

AC10

(YELLOW)

V

TRANSISTOR COMPLETE

TO

INDOOR UNIT B

123

BL

AC1

AC2

AC3

(GRAY)

GR

(WHITE)

1

2

3

4

GR

1

GR

2

1

3

CN-L

(WHITE)

ORYBRRGRPV

GR

421

CN-L

(WHITE)

CN- ROOM B

(GREEN)

FUSE T5. 0A

L250V

+

AC5

RY- AC

L

P

RY- PWR

L

P

RY- L

CN- TH1

(YELLOW)

CN- TANK

(BLUE)

EL ECT RONIC

CONTROL UNIT

CN- T H2

(GREEN)

CN- PW M

(WHIT E)

78654312431

B

876543 1

CN-PWM

(WHIT E)

2

OR

2

B: BLUE

BL : BL ACK

BR: BROWN

G: GREEN

R: RED

WH: WHITE

Y: YELL OW

RBL

WH

OR

GR

1

FUSE T3. 15A

L250V

CT

CR101

RY- HOT

CR102

RY- 2CV

CR103

CN-DIS

(WHITE)

BR

31

SENSOR

PIPE TEMP.

CN-TH3

(YELLOW )

REMARKS

1

CN- HOT

(YELL OW)

CN- 2 CV

(WHITE)

C- FM

CN - F M

(GREEN)

31

SENSOR

AIR T EMP.

GR: GRAY

OR: ORANGE

P: PINK

V: VIOLET

CN-ROOM A

(BLUE)

33

BL

1

BL

3

(4-WAY

B

1

B

3

(2-WAY

Y

5

R

3

B

1

1

2

3

4

5

6

CN- EVA(WHITE)

EXP.

1

2

3

4

5

6

CN-EVB(YELLOW)

EXP. VALVE

COIL

COIL

MOT E R

OR

R

Y

BL

GR

OR

R

Y

BL

GR

VALVE)

VALVE)

FAN

COIL

EXP.

VALVE

VALVE

COIL

EXP.

VALVE

Resistance of Outdoor Fan Motor Windings

CONNECTION

YELLOW -RED

YELLOW - BLUE

CWA951029

257.2

265.2

( )

Resistance of Compressor Windings

CONNECTION

U-V

U-W

V-W

( )

1.0

1.0

1.0

14

8 Operation Details (FUNCTIONS)

8.1. SIMULTANEOUS OPERATION CONTROL

CS-MVG103KE / CU-MVG153KE

15

CS-MVG103KE / CU-MVG153KE

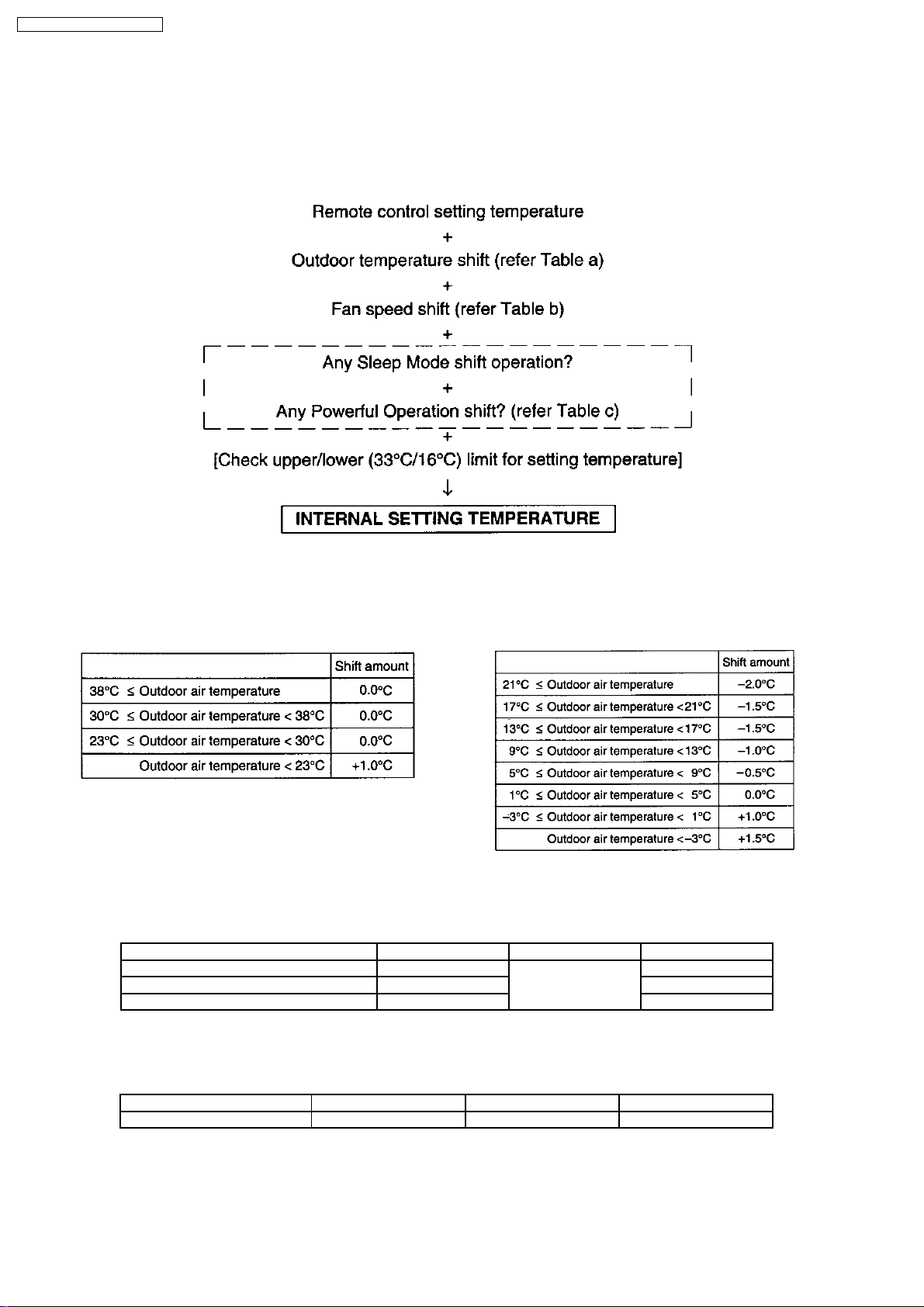

8.2. TEMPERATURE SHIFT

Once the operation starts, the remote control setting temperature will be shifted internally based on the setting fan speed and

outdoor air temperature. In addition, if Sleep Mode or Powerful Mode are set, the temperature shift will be carried out.

Setting of internal Setting Temperature

The internal setting temperature can be decided as follows:

8.2.1. Table a

Setting Temperature Shift based on outdoor air temperature.

1. Cooling, Soft Dry 2. Heating

8.2.2. Table b

Setting Temperature Shift based on fan speed.

Remote control setting fan speed Cooling Dry Heating

Lo +1.0°C +1.0°C +1.0°C

Me-, Me, Me+, Auto fan speed +1.0°C +1.0°C

Hi +1.0°C +1.0°C

8.2.3. Table c

Powerful Mode Shift

Cooling Dry Heating

Powerful -4.0°C -3.0°C +6.0°C

16

CS-MVG103KE / CU-MVG153KE

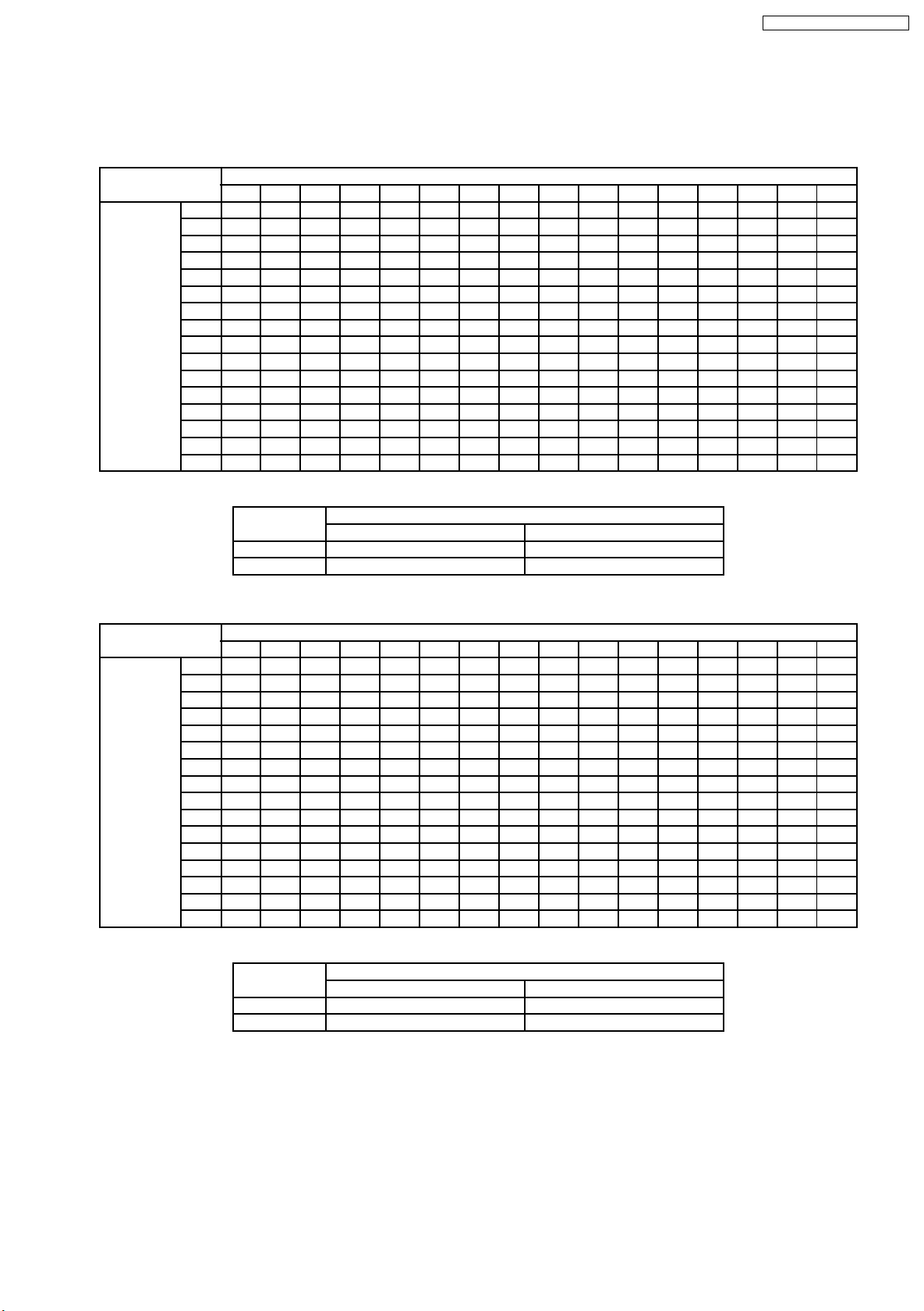

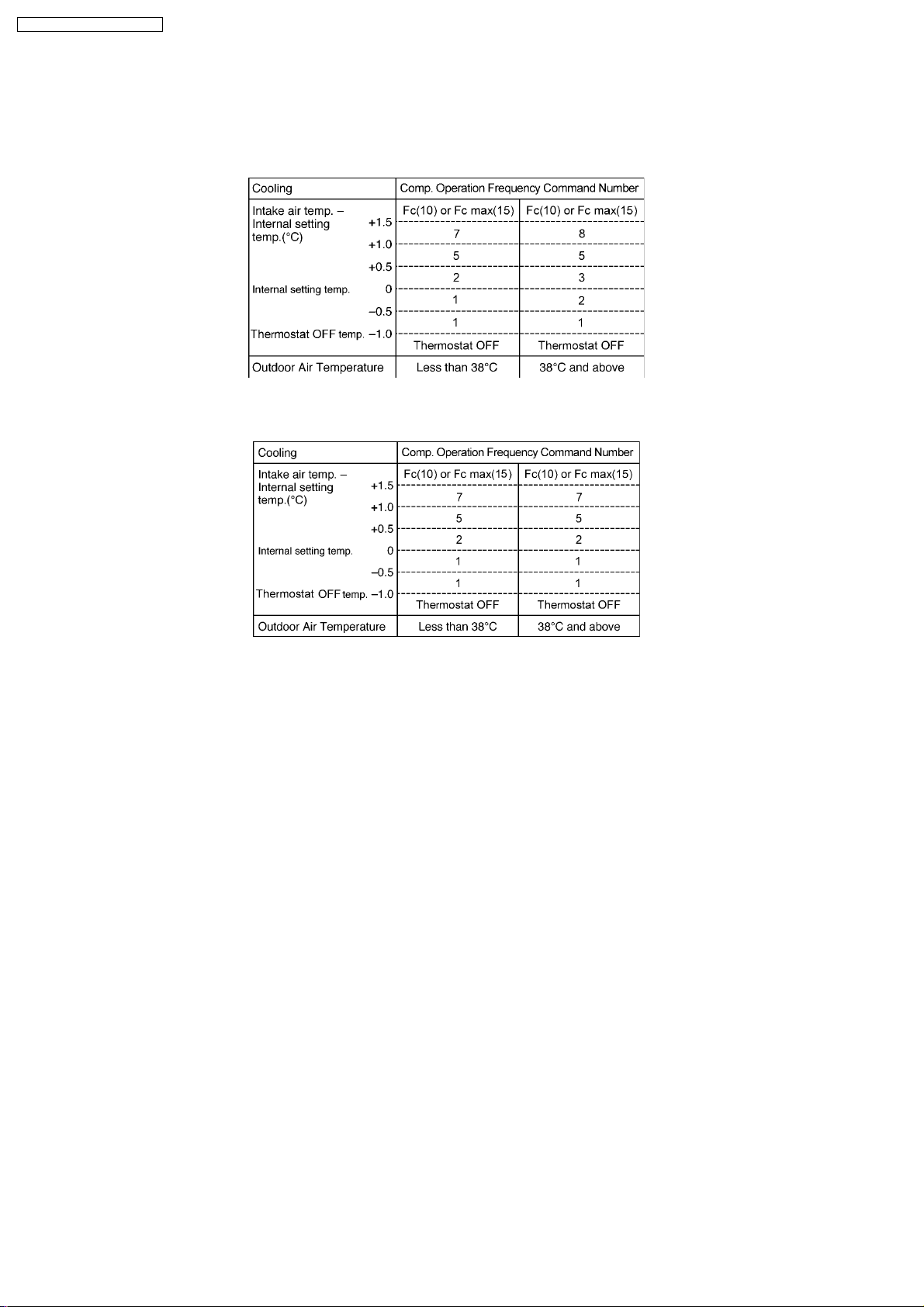

8.3. COMPRESSOR OPERATING FREQUENCY OPERATION

Compressor Operation Frequency According to Comp. Operation Frequency Command Number(INDOOR UNIT)

8.3.1. Cooling & Soft Dry

(Unit : Hz)

Comp.

Operation

Frequency

Command

Number of

Indoor Unit B

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0 0 15 15 15 15 15 22 30 39 45 47 65 67 67 67 67

1 30 30 39 43 45 47 50 52 56 57 61 61 61 61 61

15

2 30 30 39 43 45 47 50 52 56 57 61 61 61 61 61

15

3 39 39 41 45 47 48 52 54 57 59 63 63 63 63 63

15

4 15

5 15 45 45 47 50 52 54 57 59 63 65 68 68 68 68 68

6 22 47 47 48 52 54 56 59 61 65 67 70 70 70 70 70

7 30 50 50 52 56 57 59 63 65 68 70 74 74 74 74 74

8 39 52 52 54 57 59 61 65 67 70 72 75 75 75 75 75

9 45 56 56 57 61 63 65 68 70 74 75 75 75 75 75 75

10 47 57 57 59 63 65 67 70 72 75 75 76 76 76 76 76

11 65 61 61 63 67 68 70 74 75 75 76 77 77 77 77 77

12 67 61 61 63 67 68 70 74 75 75 76 77 77 77 77 77

13 67 61 61 63 67 68 70 74 75 75 76 77 77 77 77 77

14 67 61 61 63 67 68 70 74 75 75 76 77 77 77 77 77

15 67 61 61 63 67 68 70 74 75 75 76 77 77 77 77 77

43 43 45 48 50 52 56 57 61 63 67 67 67 67 67

Rated and Maximum Operation frequency

Fc (10) 47 75

Fc max (15) 67 77

8.3.2. Heating

Comp.Operation Frequency Command Number of Indoor Unit A

Compressor Operation Frequency (Hz)

One Indoor Unit Operation Two Indoor Units Operation

(Unit : Hz)

Comp.

Operation

Frequency

Command

Number of

Indoor Unit B

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0 0 15 25 35 45 55 55 65 69 74 75 93 106 118 118 118

1 15 45 55 65 69 71 72 74 75 77 77 78 81 83 83 83

2 25 55 65 69 71 72 74 75 77 78 78 80 83 84 84 84

3 35 65 69 71 72 74 75 77 78 80 80 81 84 86 86 86

4 45 69 71 72 74 75 77 78 80 81 81 83 86 87 87 87

5 55 71 72 74 75 77 78 80 81 83 83 84 87 89 89 89

6 55 72 74 75 77 78 80 81 83 84 84 86 89 90 90 90

7 65 74 75 77 78 80 81 83 84 86 86 87 90 92 92 92

8 69 75 77 78 80 81 83 84 86 87 87 89 92 93 93 93

9 74 77 78 80 81 83 84 86 87 89 89 90 93 94 94 94

10 75 77 78 80 81 83 84 86 87 89 90 92 93 100 100 100

11 93 78 80 81 83 84 86 87 89 90 92 93 94 106 106 106

12 106 81 83 84 86 87 89 90 92 93 93 94 106 112 112 112

13 118 83 84 86 87 89 90 92 93 94 100 106 112 125 125 125

14 118 83 84 86 87 89 90 92 93 94 100 106 112 125 125 125

15 118 83 84 86 87 89 90 92 93 94 100 106 112 125 125 125

Rated and Maximum Operation frequency

Fh (10) 75 90

Fh max (15) 118 125

Comp.Operation Frequency Command Number of Indoor Unit A

Compressor Operation Frequency (Hz)

One Indoor Unit Operation Two Indoor Units Operation

17

CS-MVG103KE / CU-MVG153KE

8.4. COOLING OPERATION

8.4.1. Room Temperature Control

1. When the remote control setting temperature is less than 24°C.

Refer to8.3.2. Compressor Operation Frequency

2. When the remote control setting temperature is 24°C and above.

Refer to8.3.1. Compressor Operation Frequency

· Thermostat OFF temperature = Thermostat ON temper ature.

· The Comp. Operation Frequency Command can be changed every 30 seconds.

· 30 minutes from the start of the operation, the compressor is operating at Fc max.

· The Thermostat OFF when the intake air temperature reaches 1°C below internal setting temperature and continues for 3

minutes.

· When the Thermostat of both Indoor Units OFF, the Compressor stops.

· When the compressor stops, it will not begin operation for 3 minutes. (Time Delay Safety Control)

· When the intake air temperature reaches the Compressor ON temperature, the Compressor starts operation.

· When the compressor stops, the outdoor fan motor stops 30 seconds later.

18

CS-MVG103KE / CU-MVG153KE

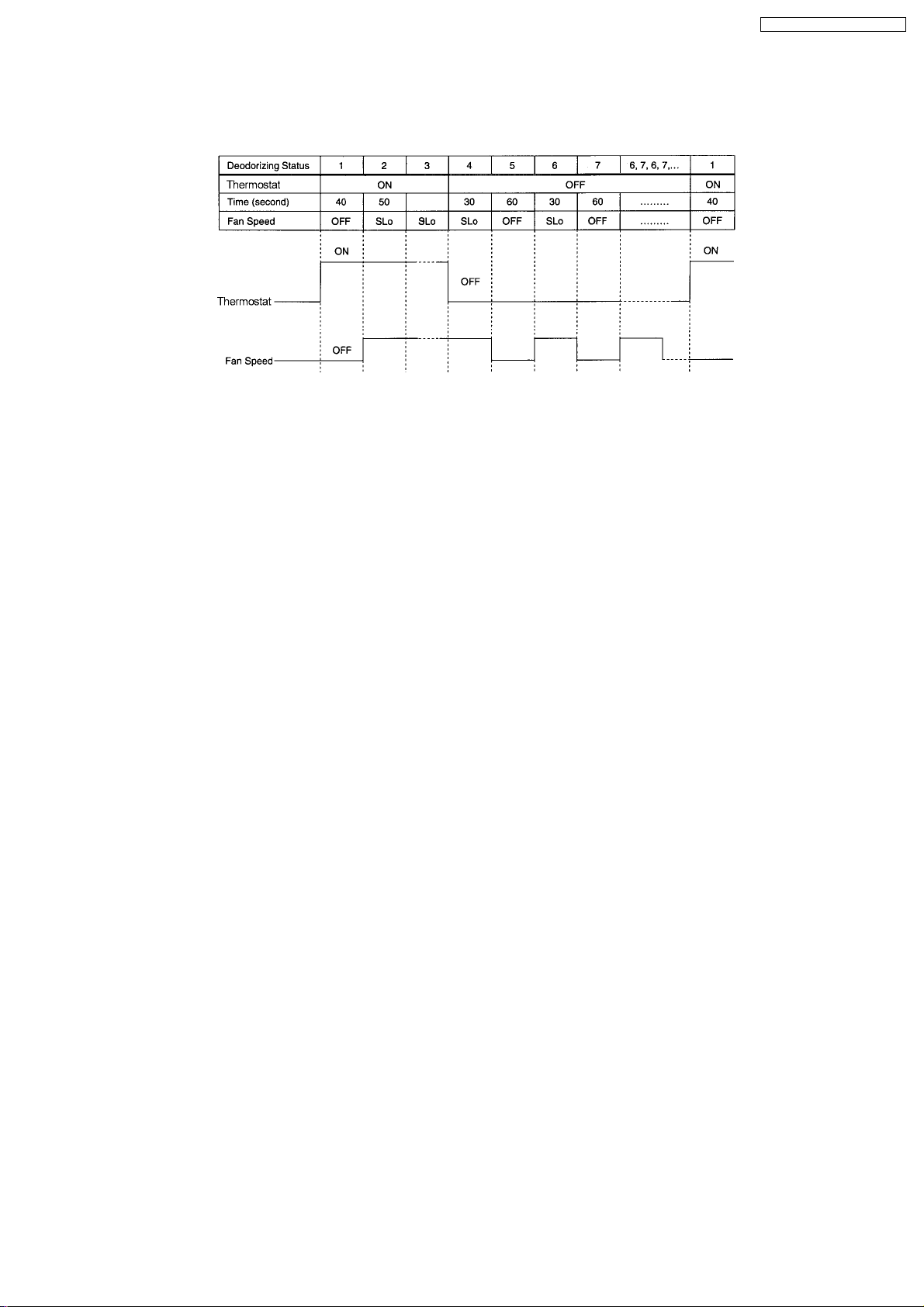

8.4.2. Deodorizing Control

· This control is available during automatic fan speed for Cooling and Soft Dry Operation. It is not available during anti-freezing

control.

· When the Thermostat ON operation, the deodorizing status starts from 1 → 2 → 3.

· When the Thermostat OFF operation, the deodorizing status starts from 4 → 5 → 6 → 7.

· If the Thermostat OFF operation after 3 minutes, the deodorizing status will start from 6.

8.4.3. Sensible Heat Control

· This control is to improve the feeling in high fan speed during low Comp. Operation Frequency Command Number. When the

Comp. Operation Frequency Command Number is less than 4, the fan speed will reduce. When the Comp. Operation

Frequency Command Number is above 5 continuously for 5 minutes, the fan speed will resume to normal condition.

19

CS-MVG103KE / CU-MVG153KE

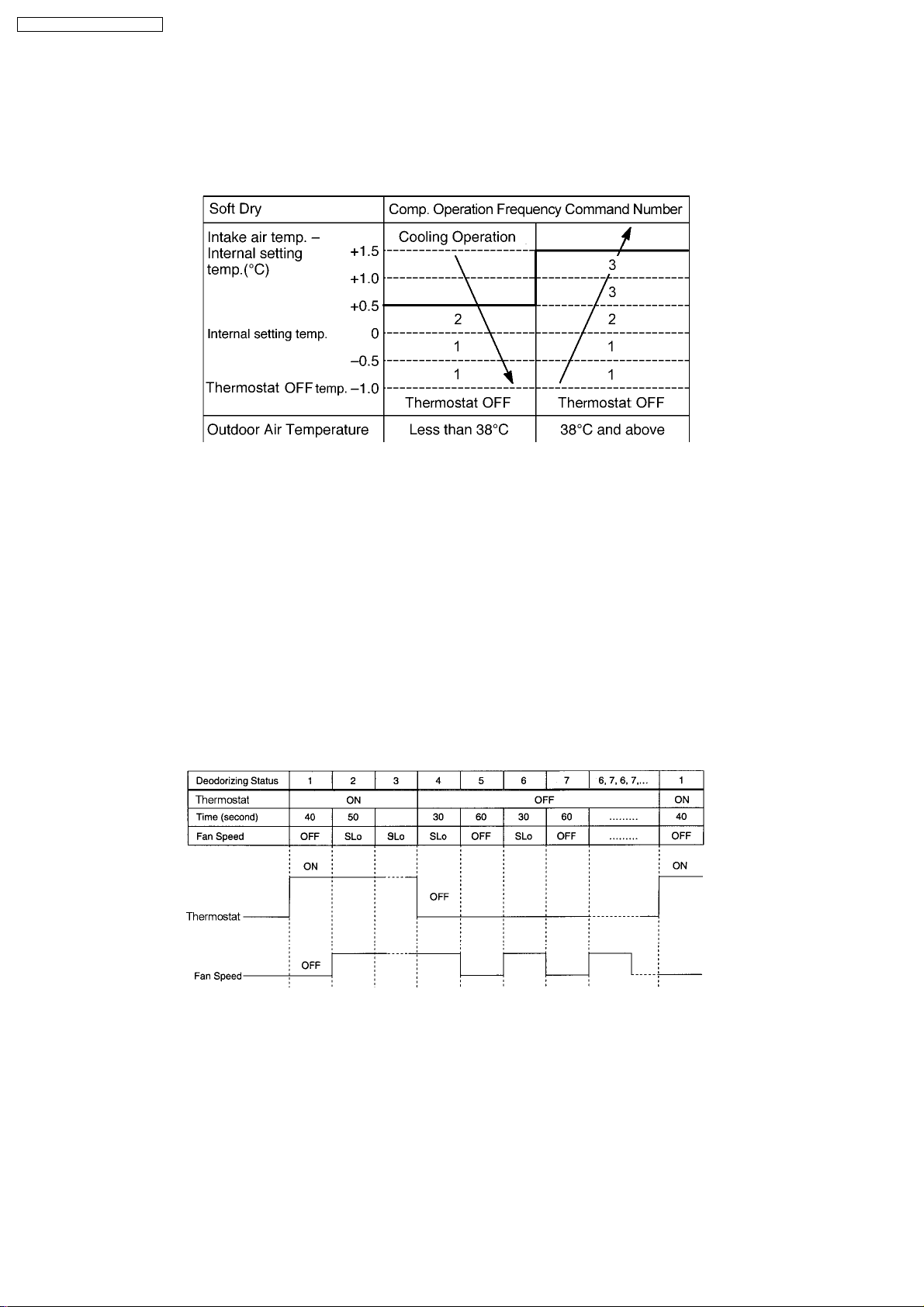

8.5. SOFT DRY OPERATION

8.5.1. Room Temperature Control

At the start of operation, cooling operation is running until the intake air temperature is 0.5°C higher than internal setting

temperature, then the operation will shift to Soft Dry with indoor fan speed SLo.

Refer to8.3.1. Compressor Operation Frequency

· Thermostat OFF temperature = Thermostat ON temper ature.

· The Comp. Operation Frequency Command can be changed every 30 seconds.

· 30 minutes from the start of the operation, the compressor is operating at Fc max.

· The Thermostat OFF when the intake air temperature reaches 1°C below internal setting temperature and continues for 3

minutes.

· When the Thermostat of both Indoor Units OFF, the Compressor stops.

· When the compressor stops, it will not begin operation for 3 minutes. (Time Delay Safety Control)

· When the intake air temperature reaches the Compressor ON temperature, the Compressor starts operation.

· When the compressor stops, the outdoor fan motor stops 30 seconds later.

8.5.2. Deodorizing Control

· This control is available during automatic fan speed for Cooling and Soft Dry Operation. It is not available during anti-freezing

control.

· When the Thermostat ON operation, the deodorizing status starts from 1 → 2 → 3.

· When the Thermostat OFF operation, the deodorizing status starts from 4 → 5 → 6 → 7.

· If the Thermostat OFF operation after 3 minutes, the deodorizing status will start from 6.

8.5.3. Sensible Heat Control

· This control is to improve the feeling in high fan speed during low Comp. Operation Frequency Command Number. When the

Comp. Operation Frequency Command Number is less than 4, the fan speed will reduce. When the Comp. Operation

Frequency Command Number is above 5 continuously for 5 minutes, the fan speed will resume to normal condition.

20

CS-MVG103KE / CU-MVG153KE

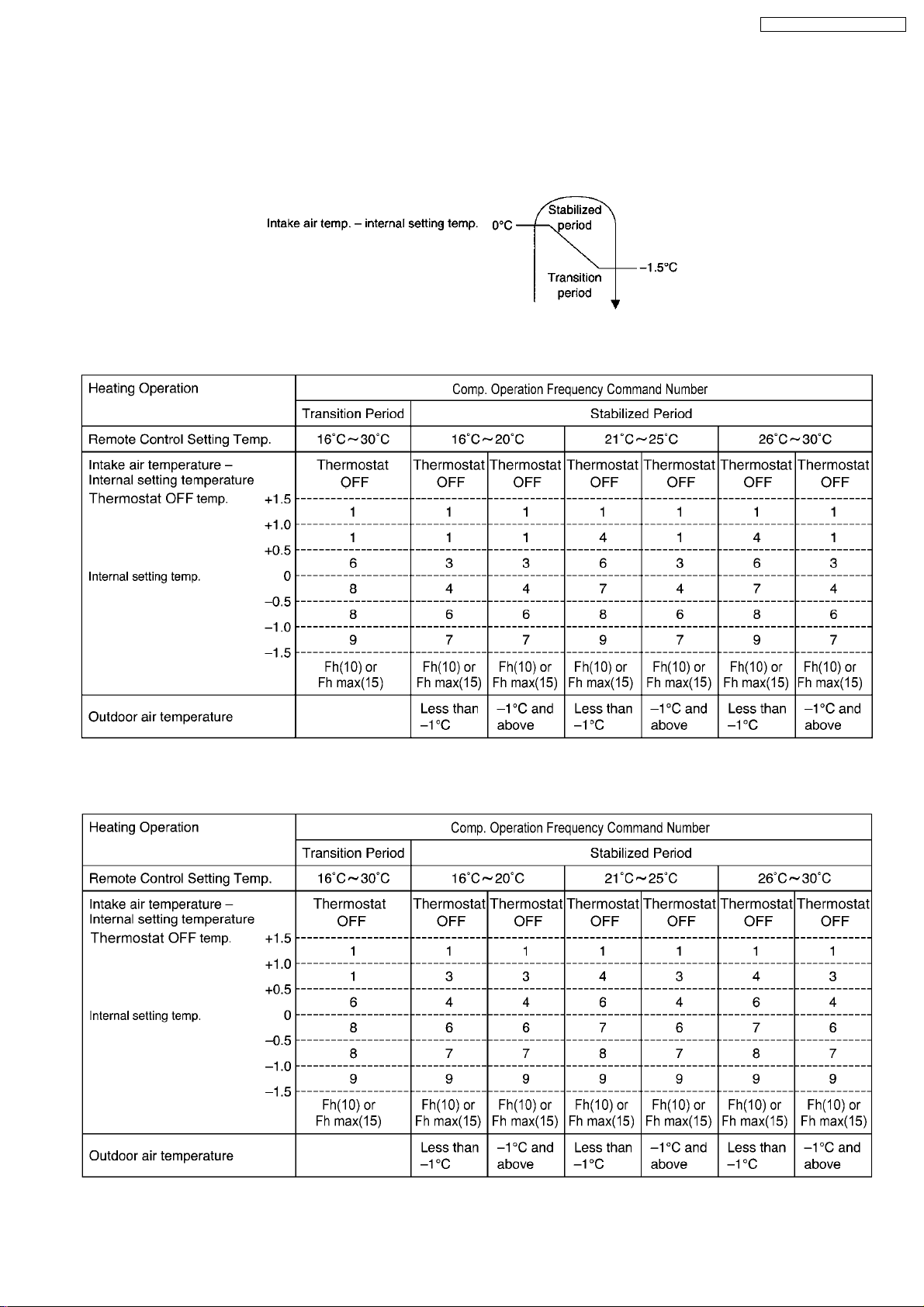

8.6. HEATING OPERATION

8.6.1. Room Temperature Control

· During heating operation, the room temperature control depends on intake air temperature and internal setting temperature.

Basically it can be divided into 2 periods as shown below:

1. When indoor fan speed is Medium or above.

Refer to8.3.2. Compressor Operation Frequency

2. When indoor fan speed is lower than Medium.

Refer to8.3.2. Compressor Operation Frequency

21

CS-MVG103KE / CU-MVG153KE

· Thermostat OFF temperature = Thermostat ON temper ature.

· The operation frequency changes every 30 seconds.

· When the difference of the intake air temperature and Internal setting temperature is -1.5°C or more, compressor will operate

at Fh continuously for 3 minutes and then change over to Fh max.

· The Thermostat OFF when the intake air temperature reaches 1.5°C above internal setting temperature and continues for 3

minutes.

· When the Thermostat of both Indoor Units OFF, the Compressor stops.

· When the compressor stops, it will not start operation for 3 minutes. (Time Delay Safety Control)

· When the intake air temperature decreases to the compre ssor ON temperature, the compressor starts immediately.

· When the compressor stops, the outdoor fan motor stops 30 seconds later.

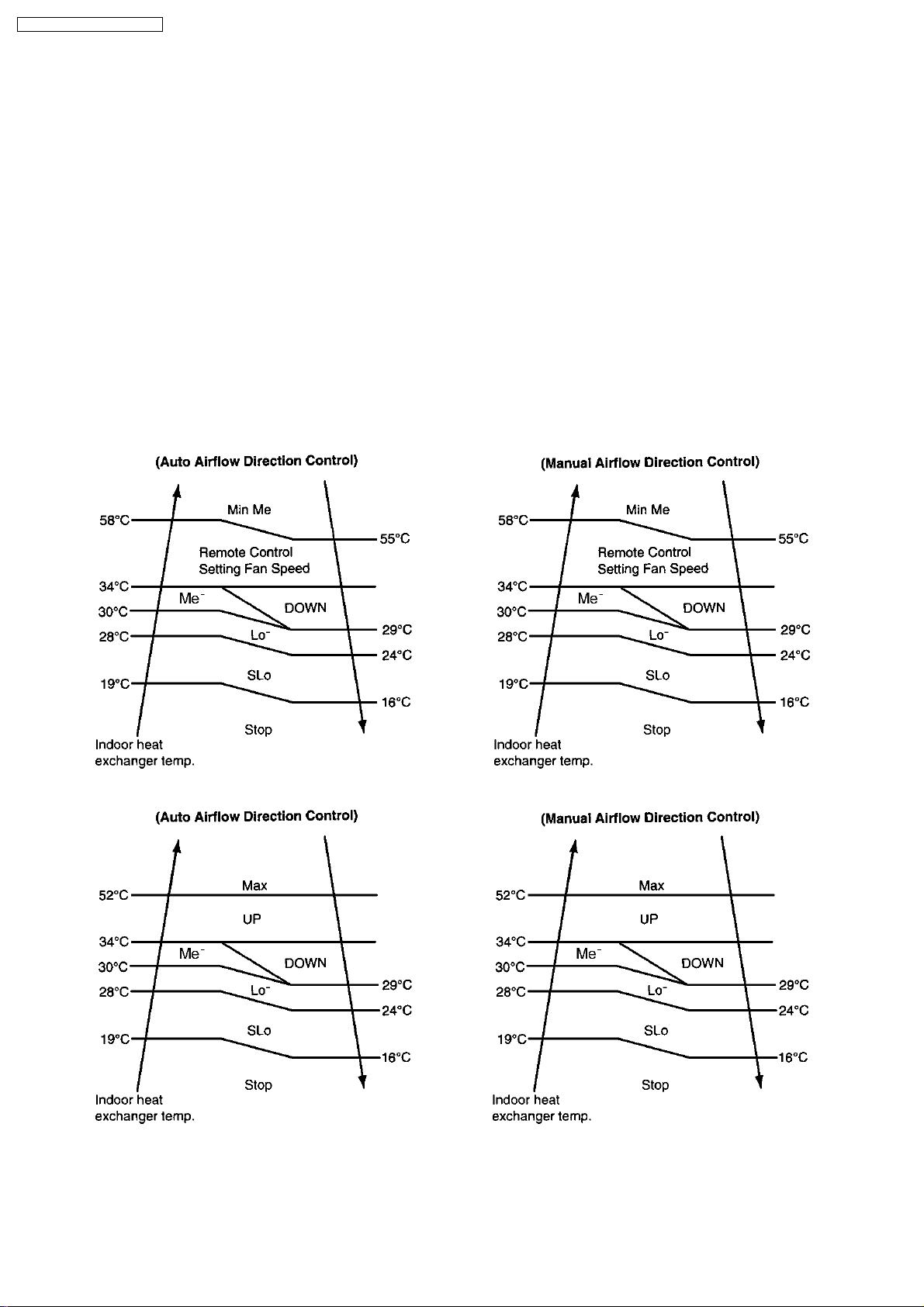

8.6.2. Anti Cold Draft Control

1. Indoor Fan Control

Indoor fan speed and airflow direction varies in accordance to the indoor heat exchanger temperature as shown below:

a. Manual Fan speed control

b. Auto Fan speed control

Note:

· UP means fan speed is increased by 1 rank.

· DOWN means fan speed is decreased by 1 rank.

· Max means fan speed is running at maximum auto fan speed.

22

CS-MVG103KE / CU-MVG153KE

2. Hot Start

· At the start of heating operation, the indoor fan stops and Comp. Operation Frequency Command Number at Fh max. This

is to heat up the indoor heat exchanger in order to avoid cold air discharged.

· Hot Start ends when

a. Indoor heat exchanger temperature reaches over 15°C

or

b. 4 minutes after heating operation starts

· After Hot Start operation, Comp. Operation Frequency Command Number at Fh max for 2 minutes.

8.6.3. Standby Control

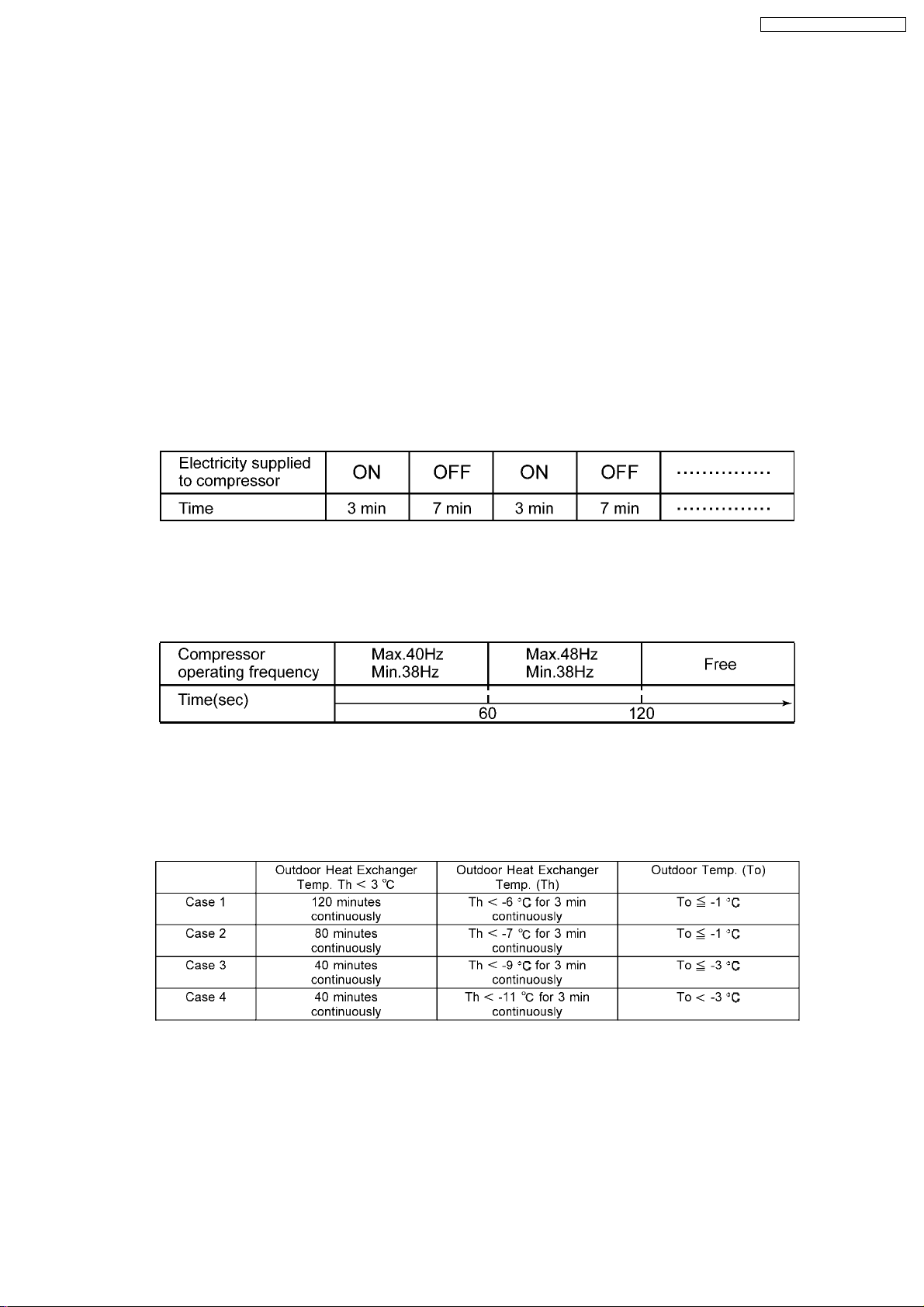

1. The purpose of Standby Control is to warm up the compressor when outdoor temperature is low.

the standby control will be activated when all of the followings occur.

· Unit is not operating.

· Compressor temperature is below 7°C.

2. When the standby control is activated, low electricity will be supplied to compressor for 3 minutes and stops for 7 minutes.

This condition is repeated until standby control is cancelled.It will consume about 35W of electric power.

3. Standby control will be cancelled when one of the following conditions occurs.

· Unit starts operation.

· Compressor temperature is over 9°C.

4. When the unit is switched on by the remote control, the compressor operates at frequency as shown in below:-

5. The standby control can be cancelled by cutting off the jumper wire on the outdoor electronic controller.

8.6.4. Deice Operation

Deice operation occurs when the deice operation starting signal is generated. This happens when one of the following conditions

occurs. However, the first deice operation will begin 1 hour after start of heating operation.

Note:

The above 4 cases are under compressor operating condition.

23

CS-MVG103KE / CU-MVG153KE

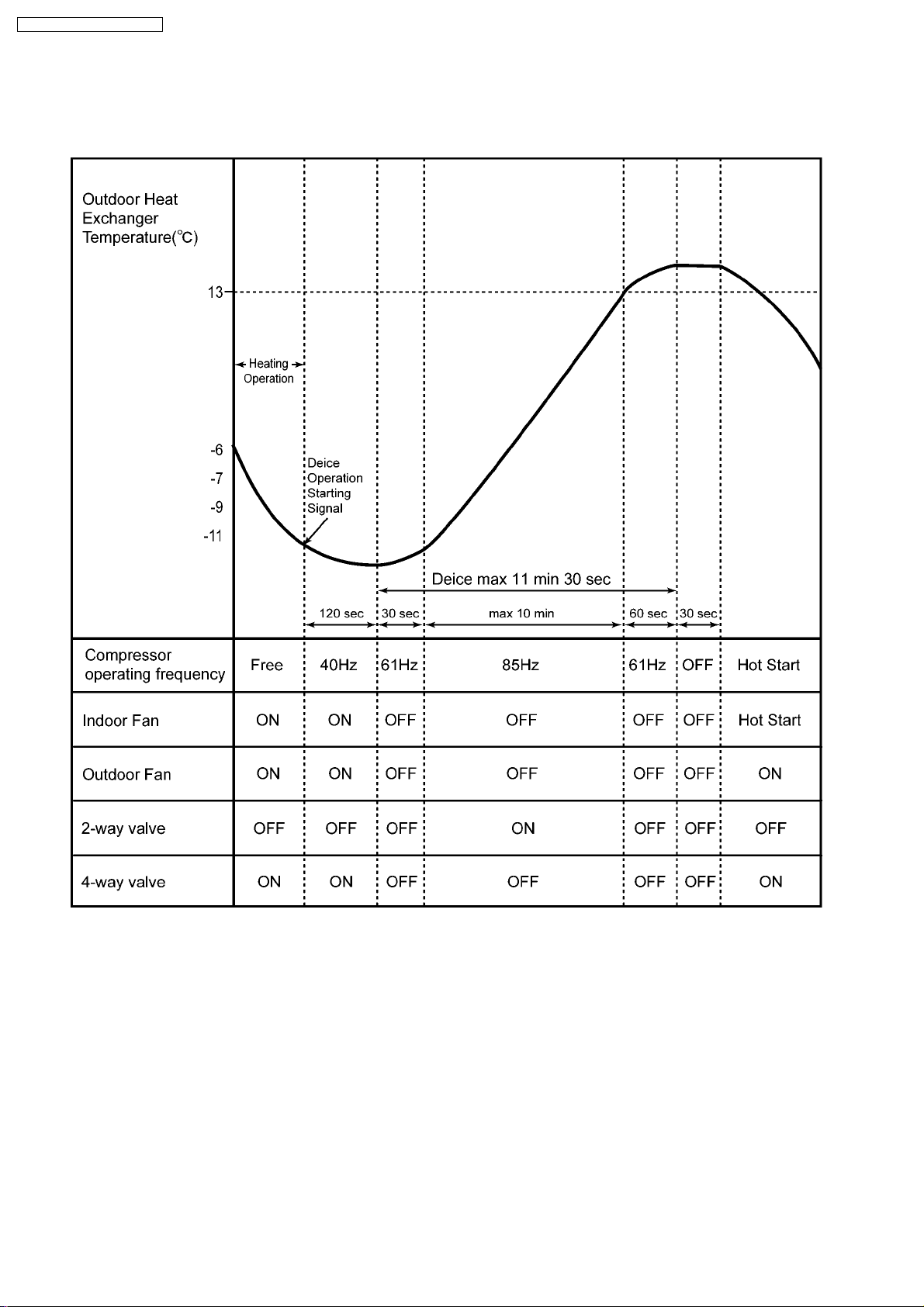

Deice Operation Time Chart

· Compressor frequency is set at 40Hz when the deice operation starting signal is generated.

· 120 seconds later deice operation starting signal is generated, indoor fan, outdoor fan, 4-way valve are turned off and

compressor operates at 61Hz for 30 seconds. (Deice operation starts)

· During deice operation, the compressor operating frequency is set at 85Hz.

· Deice will end when the outdoor heat exchanger temperature rises to 13°C or after 11 min 30sec.

24

CS-MVG103KE / CU-MVG153KE

8.7. FAN OPERATION

This operation is to enable the fan operation without compressor running. Timer operation is valid for fan operation.

8.8. AUTOMATIC OPERATION

When the Automatic mode is selected, the operation mode is decided in accordance to remote control setting temperature, intake

air temperature and outdoor air temperature.

· During judging the operati on mode, indoor fan is running at Lo-speed and outdoor fan at ON in order to sense the indoor intake

air temperature and outdoor air temperature for 20 seconds. At this time, Power LED is blinking. After the operation mode is

selected, Power LED light up.

There are 4 determination charts when automatic mode is selected.

25

CS-MVG103KE / CU-MVG153KE

Setting temp °C T1 T2 T3

18 and below +10 +8 -5

19 - 22 +8 +7 -7

23 - 26 +7 +6 -7

27 and above +6 +5 -8

Note:

Base temperature for T1 is 29 °C

Base temperature for T2 is 27 °C

Base temperature for T3 is 21 °C

· When the operation mode is changed over, the value for t1, t2 and t3 are shifted as follows:

Cooling/Soft dry → Heating: -2°C

Heating → Cooling/Soft dry: +2°C

· When the indoor intake air temperature is lower than 16°C, heating operation is immediately started.

· When the outdoor air temperature is more than 25°C, and the intake air temperature is over 16°C, cooling operation is

immediately started.

· The operation mode is judged every 3 hours.

8.8.1. Temperature Shift

· When the operation mode (Heating, Cooling or Soft Dry) is decided, the internal setting temperature will shift as shown below:

26

8.9. INDOOR FAN SPEED CONTROL

CS-MVG103KE / CU-MVG153KE

Fan

speed

no.

0 OFF OFF OFF OFF OFF

2 13.0 SLO

3 13.7 Lo-

6 16.0 Lo

8 18.2 Lo

9 19.1

10 20.6 Me-

11 21.5 Auto

12 21.8 Me

13 22.7 Auto

14 23.6

15 23.9 Auto

16 24.5

17 25.1

19 26.0 Me+

21 26.6

22 27.2 Hi

27 29.5

28 29.9

30 33.2 SHI

31 33.8

Voltage

Supply to

Fan Motor

DC(V)

Cooling Soft

Manual Auto MAnual Auto

Fan

Fan

Fan

Dry

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

Remarks Heating Remarks

Deodorizing control

Sleep Mode

Auto operation mode

judgement

Quiet operation

Sensible Heat Control

On Timer preparatory

operation + Auto Fan

Manual Fan + Powerful

On Timer preparatory

operation + Manual Fan

+ powerful

Sensible Heat Control

Sensible Heat Control +

Auto Fan

Manual Fan + Powerful

On Timer preparatory

operation + Manual Fan

+ powerful

Sensible Heat Control +

Auto Fan

Sensible Heat Control

Auto Fan + Powerful

Manual Fan + Powerful

On Timer preparatory

operation + Manual Fan

+ powerful

Sensible Heat Control +

Auto Fan

Auto Fan + Powerful

Sensible Heat Control

Auto Fan + Powerful

Manual Fan + Powerful

On Timer preparatory

operation + Manual Fan

+ powerful

Test Run

SHi:Maximum Capacity

Operation

Manual Fan + Powerful

On Timer preparatory

operation + Manual Fan

+ powerful

Me- Auto

Me

Me+

Fan

(Min)

Auto

Fan

(Max.)

hot Start Control

·

Slo:Hot Start Control

·

Lo-:Hot Start Control

·

Sleep Mode

Thermo OFF

Anti Cold Draft

Control

On Timer preparatory

·

operation + Auto Fan

Auto Fan + Powerful

·

Manual Fan + Powerful

·

On Timer preparatory

·

operation + Manual Fan +

Powerful

Temporary Operation

·

Auto Fan + Powerful

·

Manual Fan + Powerful

·

On Timer preparatory

·

operation + Manual Fan +

Powerful

Test Run

·

SSHI:Maximum Capacity

·

Operation

27

Loading...

Loading...