© 2006 Panasonic HA Air-Conditioning (M) Sdn Bhd

(11969-T). All rights reserved. Unauthorized copying

and distribution is a violation of law.

Order No. MAC0608038C2

Air Conditioner

CS-F28DTE5 CU-L50DBE5

CS-F50DTE5 CU-L50DBE5

TABLE OF CONTENTS

PAGE PAGE

1 Service Information---------------------------------------------- 2

1.1. Operation range-------------------------------------------- 2

2 Specifications ----------------------------------------------------- 3

2.1. Product Specification------------------------------------- 3

3 Refrigeration Cycle ---------------------------------------------- 5

4 Block Diagram----------------------------------------------------- 6

4.1. CU-L50DBE5----------------------------------------------- 6

5 Wiring Diagram---------------------------------------------------- 7

5.1. CU-L50DBE5----------------------------------------------- 7

6 Electronic Circuit Diagram------------------------------------ 8

6.1. CU-L50DBE5----------------------------------------------- 8

7 Installation Instruction------------------------------------------ 9

7.1. Outdoor Unit Installation----------------------------------9

8 Technical Data--------------------------------------------------- 20

8.1. Sound Data------------------------------------------------ 20

8.2. Capacity And Power Consumption------------------21

8.3. Safety device---------------------------------------------- 28

8.4. Operating characteristics-------------------------------29

9 Exploded View and Replacement Parts List----------- 30

9.1. Outdoor Unit----------------------------------------------- 30

Please file and use this manual together with the service manual for Model No. CS-F24DTE5 CU-L24DBE5,

CS-F28DTE5 CU-L28DBE5, CS-F34DTE5 CU-L34DBE5, CS-F43DTE5 CU-L43DBE5, CS-F50DTE5 CUL50DBE8, Order No. MAC0504060C2.

2

1 Service Information

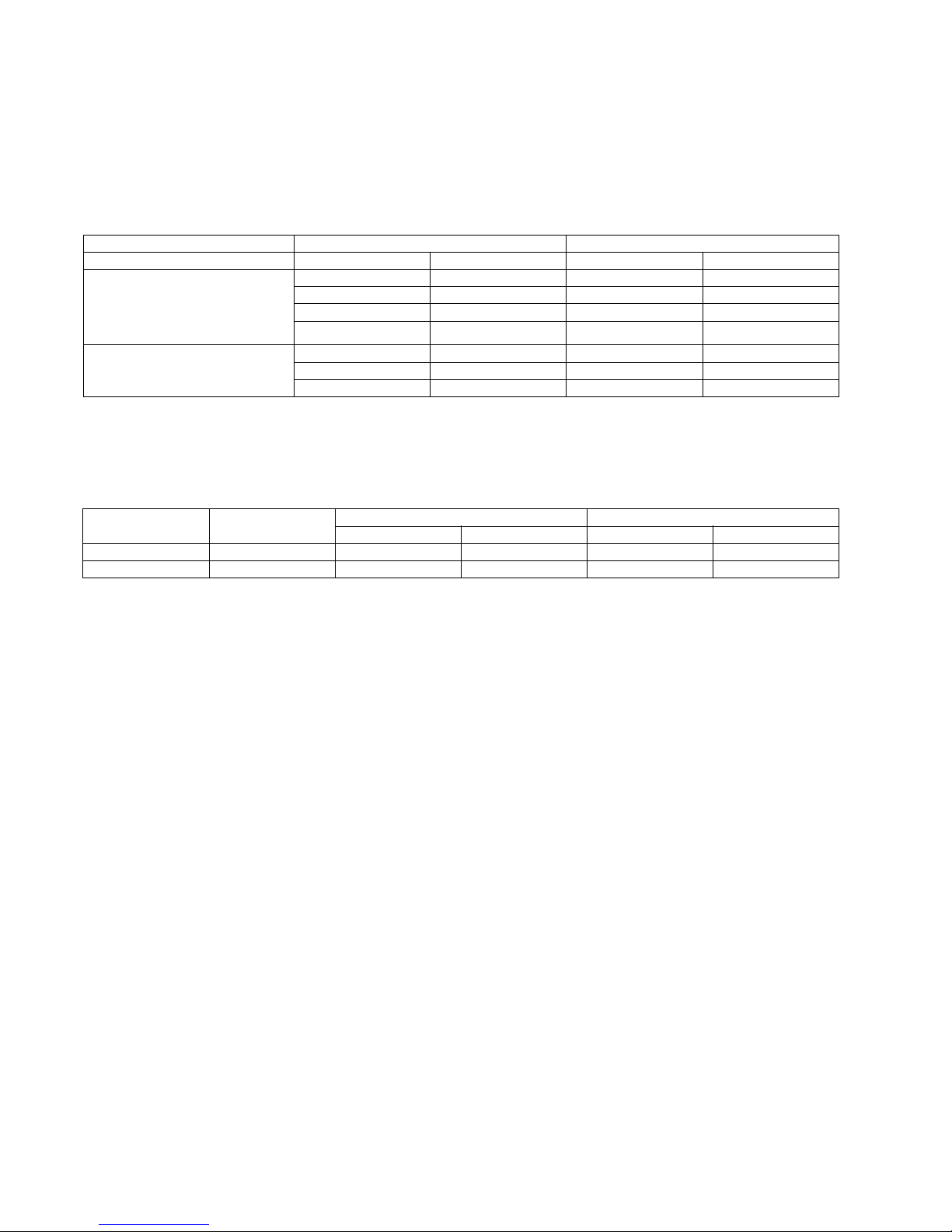

1.1. Operation range

1.1.1. Power supply

The applicable voltage range for each unit is given in the following table. The working voltage among the three phases must be

balanced within a 3% deviation from each voltage at the compressor terminals. The starting voltage must be higher than 85% of the

rated voltage.

1.1.2. Indoor and outdoor temperature

• Model 50Hz CU-L24DBE5, CU-L28DBE5, CU-L34DBE5, CU-L43DBE5, CU-L50DBE5, CU-L50DBE8

MODEL Unit Main Power Applicable Voltage

CU- Phase, Volts Hz Max Min

L24DBE5

L28DBE5

L34DBE5

L43DBE5

L50DBE5

1~240 50 264 216

1~220 50 242 198

1~230 50 253 207

1~240 50 264 216

L50DBE8 3N~380 50 418 342

3N~400 50 440 360

3N~415 50 457 374

Operating Hz Indoor Temp. (D.B./W.B.) (°C) Outdoor Temp. (D.B./W.B.) (°C)

MaxMinMaxMin

Cooling 50 32/23 21/15 43/- -15/Heating 50 27/- 16/- 24/18 -20/-

3

2 Specifications

2.1. Product Specification

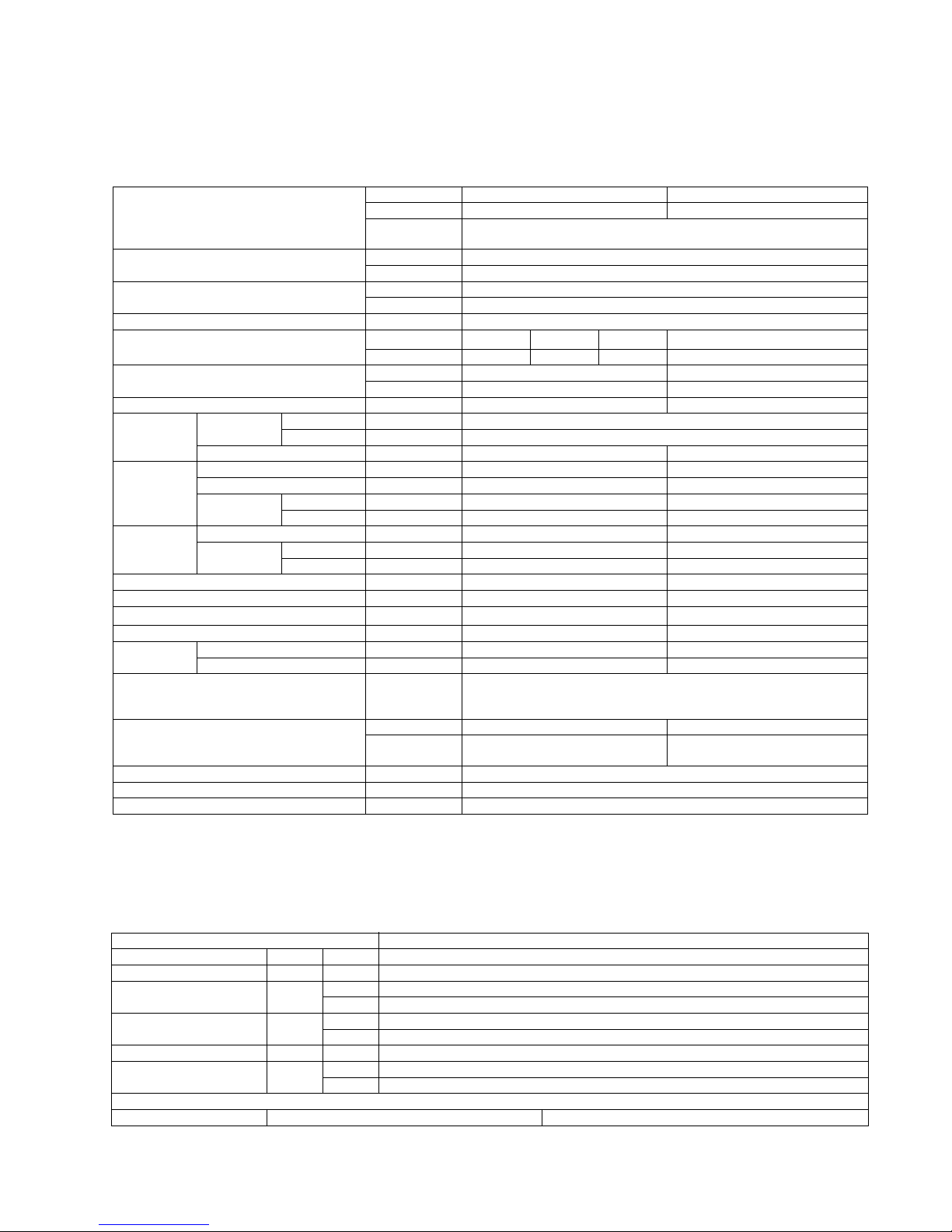

2.1.1. CS-F28DTE5 CU-L50DBE5 (For Australia only)

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50 Hz)

ITEM / MODEL

Indoor Unit Outdoor Unit

Main Body CS-F28DTE5 x 2 CU-L50DBE5

Remote

Control

CZ-RD513C (Wired)

CZ-RL513T (Wireless)

Cooling Capacity kW 14.0

BTU/h 47,700

Heating Capacity kW 16.0

BTU/h 54,600

Refrigerant Charge-less m 30

Standard Air Volume for High,

m

3

/min

Hi 18 x 2 Me 16 Lo 14 Hi 98

Medium and Low Speed cfm 636 x 2 565 495 3460

Outside Dimension (H x W x D) mm 210 x 1245 x 700 1340 x 900 x 320

inch 8-9/32 x 49-1/64 x 27-9/16 52-7/8 x 35-7/16 x 12-19/32

Net Weight kg (lbs) 33 (73) 110 (242)

Piping

Connection

Refrigerant

Gas mm (inch) O.D Ø 15.88 (5/8) Flared Type

Liquid mm (inch) O.D Ø 9.53 (3/8) Flared Type

Drain mm O.D Ø 20 I.D Ø 20 x 1

Compressor Type, Number of Set - Hermetic - 2P (Rotary), 1

Starting Method - DC - INV control

Motor

Type - 4-pole single phase brushless motor

Rated Output kW - 3.8

Fan Type, Number of Set Sirocco fan-4 Mix flow fan - 1

Motor

Type 4-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.04 x 2 0.07 x 2

Air-heat Exchanger (Row x Stage x FPI) Slit-fin type (2 x 12 x 18) Corrugate-fin type (2 x 51 x 18)

Refrigerant Control - Exp. Valve

Refrigerant Oil (Charged)

cm

3

- F V50S (1200)

Refrigerant (Charged) R410A kg (oz) - 3.50 (123)

Running

Adjustment

Control Switch Wireless or Wired Remote Control Room Temperature Thermostat -

Safety Devices Temperature, current and pressure protection control for compressor,

Internal thermostat for FM, High pressure switch,

Current trans, Crankcase heater

Noise Level dB (A) Hi 45 Lo 41 Cooling 55, Heating 57

Power level dB

Cooling : Hi 62 Lo 58

Heating : Hi 62 Lo 58

Cooling 69, Heating 71

Moisture Removal L/h (Pt/h) 9.0 (19.0)

EER W/W 2.91

COP W/W 3.34

ITEM / MODEL Condition by JIS-B8615

Volts V 240

Phase Single

Power Consumption kW Cool 4.81

Heat 4.79

Running Current A Cool 21.0

Heat 20.9

Starting Current A 21.0

Power Factor % Cool 95

Heat 95

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 1~240V 50Hz

4

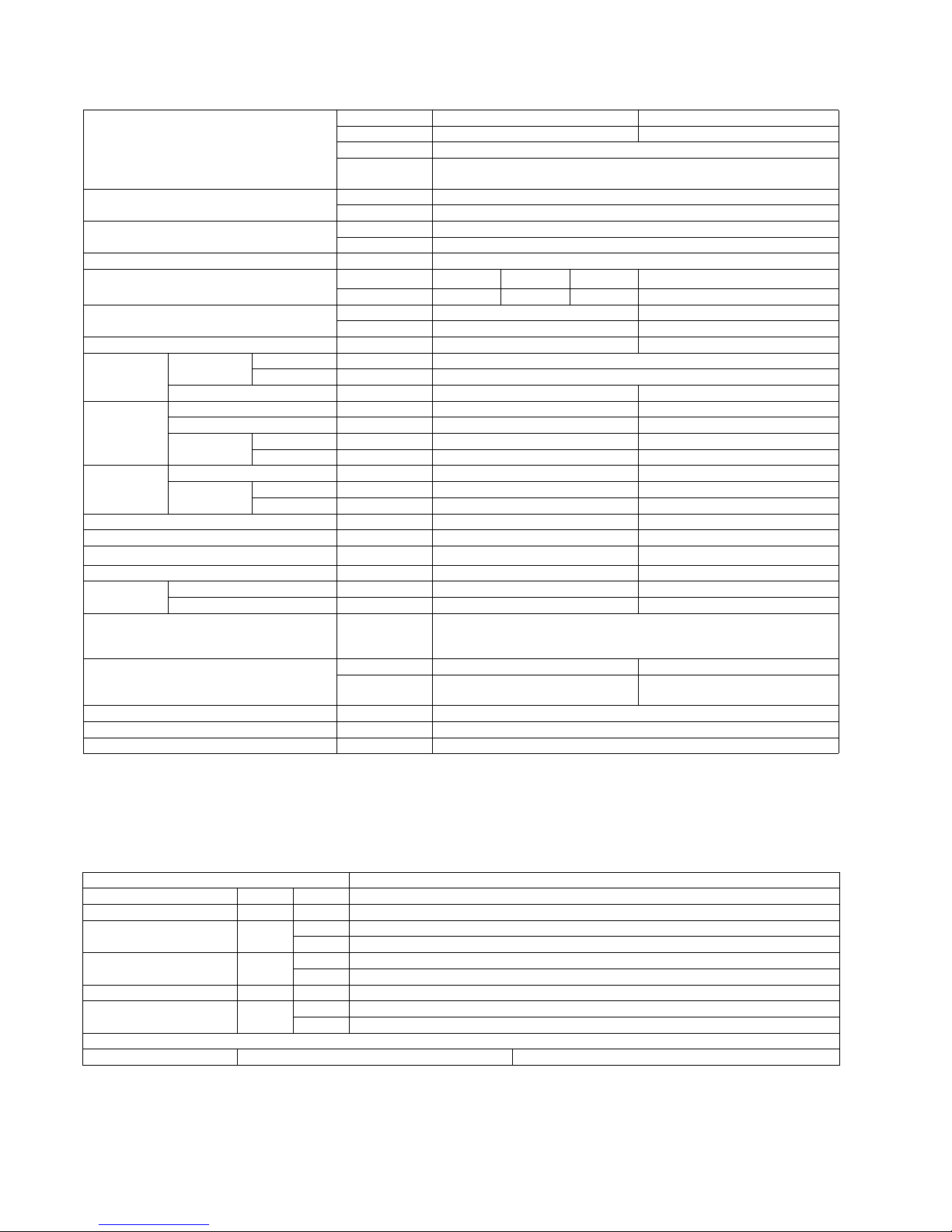

2.1.2. CS-F50DTE5 CU-L50DBE5 (For Australia only)

1. Cooling capacities are based on indoor temperature of 27°C D.B. (80.6°F D.B.), 19.0°C W.B. (66.2°F W.B.) and outdoor air

temperature of 35°C D.B. (95°F D.B.), 24°C W.B. (75.2°F W.B.)

2. Heating capacities are based on indoor temperature of 20°C D.B. (68°F D.B.) and outdoor air temperature of 7°C D.B. (44.6°F

D.B.), 6°C W.B. (42.8°F W.B.)

ELECTRICAL DATA (50 Hz)

ITEM / MODEL

Indoor Unit Outdoor Unit

Main Body CS-F50DTE5 CU-L50DBE5

Panel CZ-BT03P

Remote

Control

CZ-RD513C (Wired)

CZ-RL513T (Wireless)

Cooling Capacity kW 14.0

BTU/h 47,700

Heating Capacity kW 16.0

BTU/h 54,600

Refrigerant Charge-less m 30

Standard Air Volume for High,

m

3

/min

Hi 32 Me 28 Lo 26 Hi 98

Medium and Low Speed cfm 1130 1040 960 3460

Outside Dimension (H x W x D) mm 250 x 1600 x 700 1340 x 900 x 320

inch 9-27/32 x 62-31/32 x 27-9/16 52-7/8 x 35-7/16 x 12-19/32

Net Weight kg (lbs) 47 (104) 105 (231)

Piping

Connection

Refrigerant

Gas mm (inch) O.D Ø 15.88 (5/8) Flared Type

Liquid mm (inch) O.D Ø 9.53 (3/8) Flared Type

Drain mm O.D Ø 20 I.D Ø 20 x 1

Compressor Type, Number of Set - Hermetic - 2P (Rotary), 1

Starting Method - DC - INV control

Motor

Type - 4-pole single phase brushless motor

Rated Output kW - 3.8

Fan Type, Number of Set Sirocco fan-4 Mix flow fan - 2

Motor

Type 4-pole single phase induction motor 6-pole single phase induction motor

Rated Output kW 0.14 0.07 x 2

Air-heat Exchanger (Row x Stage x FPI) Slit-fin type (3 x 14 x 18) Corrugate-fin type (2 x 51 x 18)

Refrigerant Control - Exp. Valve

Refrigerant Oil (Charged)

cm

3

- FV50S (1200)

Refrigerant (Charged) R410A kg (oz) - 3.50 (123)

Running

Adjustment

Control Switch Wireless or Wired Remote Control Room Temperature Thermostat -

Safety Devices Temperature, current and pressure protection control for compressor,

Internal thermostat for FM, High pressure switch,

Current trans, Crankcase heater

Noise Level dB (A) Hi 50 Lo 46 Cooling 55, Heating 57

Power level dB

Cooling : Hi 67 Lo 63

Heating : Hi 67 Lo 63

Cooling 69, Heating 71

Moisture Removal L/h 9.0

EER W/W 2.91

COP W/W 3.34

ITEM / MODEL Condition by JIS-B8615

Volts V 240

Phase Single

Power Consumption kW Cool 4.81

Heat 4.79

Running Current A Cool 21.0

Heat 20.9

Starting Current A 21.0

Power Factor % Cool 95

Heat 95

*Power Factor means total figure of compressor, indoor fan motor and outdoor fan motor.

Panasonic Power source AC, 1~240V 50Hz

5

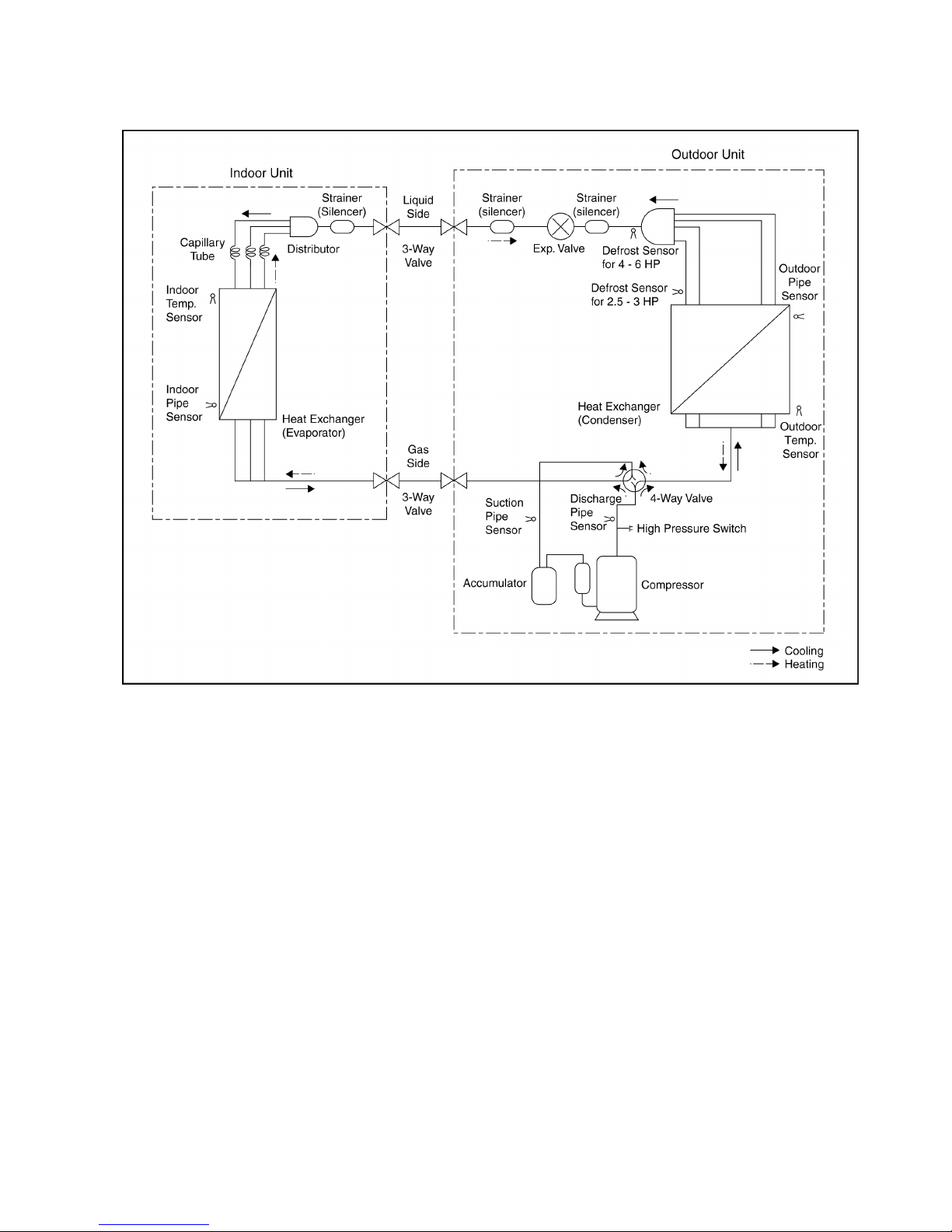

3 Refrigeration Cycle

6

4 Block Diagram

4.1. CU-L50DBE5

7

5 Wiring Diagram

5.1. CU-L50DBE5

8

6 Electronic Circuit Diagram

6.1. CU-L50DBE5

9

7 Installation Instruction

7.1. Outdoor Unit Installation

• As to indications with illustration

• After installation work has been completed, do not only make sure that the unit is free from any abnormal condition through the

execution of trial run but also explain how to use and how to perform maintenance of this unit to the customer according to the

instruction manual.

• In addition, request the customer to keep this manual for installation work together with instruction manual.

AIR CONDITIONERS OUTDOOR UNIT INSTALLATION INSTRUCTIONS

Precautions in terms of safety

Carry out installation work with reliability after through reading of this “Precautions in terms of safety”.

•

Precautions shown here are differentiated between and . Those that have much chances for

leading to significant result such as fatality or serious injury if wrong installation would have been carried out are listed compiling

them especially into the column of

.

However, even in the case of items which are listed in the column of , such items also have a chance for leading

to significant result depending on the situations.

In either case, important descriptions regarding the safety are listed, then observe them without fail.

This mark means “Caution” or “Warning”. This mark means “Earth”.

Warnings

▲ The appliance must be installed by technician, who takes into

account the requirements given by ISO5149 or eventual

equivalent requirements.

▲ If installing inside a small room, measures should be taken to

prevent refrigerant levels from building up to critical

concentrations in the event of a refrigerant leak occurring.

Please discuss with the place of purchase for advice on what

measures may be necessary to prevent critical concentrations

being exceeded. If the refrigerant leaks and reaches critical

concentration levels, there is the danger that death from

suffocation may result.

▲ As to installation, request the distributor or vendor to perform it.

Imperfection in installation caused by that having been carried

out by the customer himself may leads to water leakage, electric

shock, fire, etc.

▲ Securely attach the protective covers for the outdoor unit

connection cables and power cord so that they do not lift up

after installation. If the covers are not properly attached and

installed, the terminal connections may overheat, and fire or

electric shock may result.

▲ Carry out the installation work with reliability according to this

manual for installation work.

Imperfection in installation leads to water leakage, electric

shock, fire, etc.

▲ Switch off all supplies before accessing any electrical part.

▲ Carry out the installation work with reliability on the place that

can bear the weight of this unit sufficiently. Insufficient strength

leads to injury due to falling of the unit.

▲ If refrigerant gas escapes during installation, ventilate the

affected area. If the refrigerant gas comes into contact with

sparks or naked flames, it will cause toxic gases to be

generated.

10

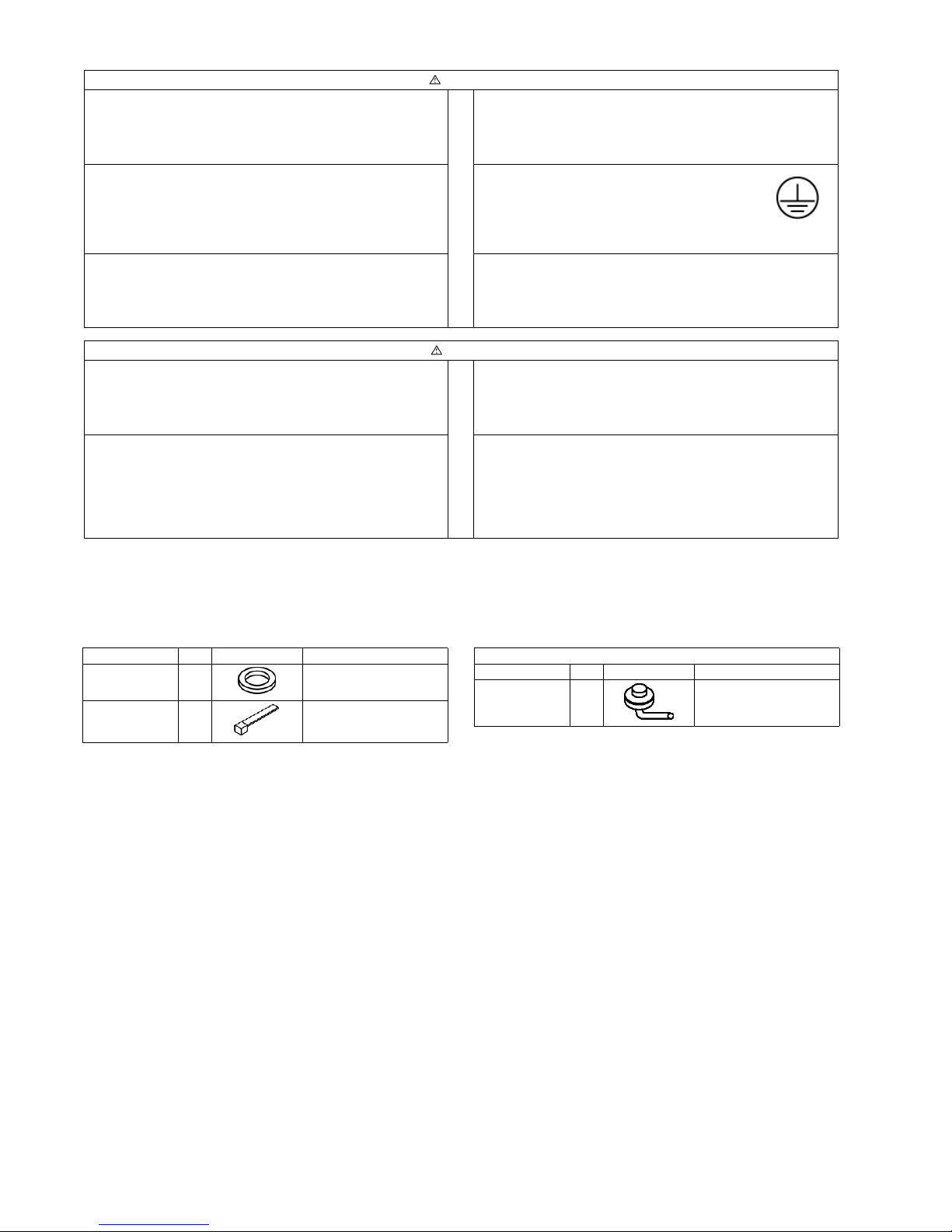

7.1.1. Accessories supplied with outdoor unit

• The following parts are supplied as accessories with each outdoor unit.

Check that all accessory parts are present before installing the outdoor unit.

7.1.2. Before installation work

• This product is using new refrigeration (R410A). The basic way of installation work is the same as usual, but water and impurities

should be controlled more strictly than before due to characteristic of refrigerating machine oil. Therefore, selection of materials

to use and processing, storing and brazing need appropriate construction and control.

1. Tools and materials

There are tools and materials for both new refrigeration and usual refrigeration you can use together and for either two of

them you can use. Use the below for new refrigeration.

• Vacuum pump (with back flow preventor system)

• Gas leakage detection warning device

• Gauge manifold

• Charge hose

2. Installation work

a. Brazing work

Brazing work needs replacing air inside pipe with nitrogen gas in order to prevent oxidization scale from occurring. This

is called nitrogen replacement, and one of very important work in brazing refrigerant piping. (Oxidation preventive is

not possible to use)

▲ The unit must be installed in accordance with applicable national

and local regulations. Any electrical work should only be carried

out by qualified technician and use exclusive circuits without fail.

Presence of insufficient capacity in power circuit or imperfection

in execution leads to electric shock, fire, etc.

▲ When performing piping work do not mix air except for specified

refrigerant (R410A) in refrigeration cycle. It causes capacity

down, and risk of explosion and injury due to high tension inside

the refrigerant cycle.

▲ Wiring shall be connected securely using specified cables and

fix them securely so that external force of the cables may not

transfer to the terminal connection section.

Imperfect connection and fixing leads to fire, etc.

▲ Earth

This equipment must be properly earthed. Earth

line must not be connected to gas pipe, water

pipe, lightning rod and telephone. Otherwise, it

may cause electrical shock in case the

equipment breakdown or has leakage current.

▲ Installation of Earth Leakage Current Breaker

This equipment must be installed with earth leakage current

breaker.

Otherwise, it may cause electrical shock and fire in case the

equipment breakdown or has leakage current.

Cautions

▲ Do not install the unit at the place where the possibility of

inflammable gas leakage exists. If such gas leakages should

arise and the gas builds up around the unit, such situation may

lead to ignition.

▲ Drain piping should be made to ensure secure drainage

according to the manual for installation work and carry out the

thermal insulation to prevent the occurrence of condensation.

Imperfection in piping work leads to water leakage and may

cause the house and property, etc. to become wet.

▲ Position the indoor unit and outdoor unit, power cords and

indoor/outdoor unit connection cables in a way so that they are at

least 1 meter away from televisions and radios.

This is to avoid problem such as interference with picture and/or

sound. (However, note that depending on the electromagnetic

wave conditions, interference may still occur even if the

separation distance is more than 1 meter.)

Warnings

Part name Q’ty Diagram Application

Protective

bushing

2 For protecting electrical

wires

Banding

strap

3 For tying electrical wires

together

Heat pump-types only

Part name Q’ty Diagram Application

Drain elbow AS 1 For connecting the drain

pipe (with ring seat)

Loading...

Loading...