Page 1

STD

MODE TEMP

OFF

CANCEL SET

FANSPEED

Order No. GMAC0504039C3

Air Conditioner

CS/CU-PC12DKD

CS/CU-PA12DKD

OFF/ON

ON

TIMER

AIRSWING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-techical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

CONTENTS

Page Page

WARNING

1 Features 2

2 Functions 3

3 Product Specifications 6

4 Dimensions 10

5 Refrigeration Cycle Diagram 12

6 Block Diagram 13

7 Wiring Diagram 15

8 Operation Details 17

Installation Insruction

9

--------------------------------------------------------

------------------------------------------------------

------------------------------------------

-----------------------------------------------------

-----------------------------------

--------------------------------------------------

-------------------------------------------------

-----------------------------------------------

---------------------------------------------------

10 2-way,3-way Valve

11

Disassembly of The Parts

12 Troubleshooting Guide

13 Technical Data

14 Exploded View

15 Replacement Parts List

16 Exploded View

17 Replacement Parts List

18 Electronic Circuit Diagram

31

-----------------------------------------------------

--------------------------------------

----------------------------------------

--------------------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------

41

48

51

53

55

56

57

58

59

C

R

R

Guangzhou Matsushita Air Conditioner Co., Ltd.

(GMAC) All rights reserved. Unauthorized copying

and distribution is violation of law.

Page 2

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

1 Features

High Efficiency

Air Quality Indicator

Auto Restart Control

Automatically restart after power failure

Comfort Environment

Air filter with function to reduce dust and smoke

12-hour Timer Setting

2

Page 3

2 Functions

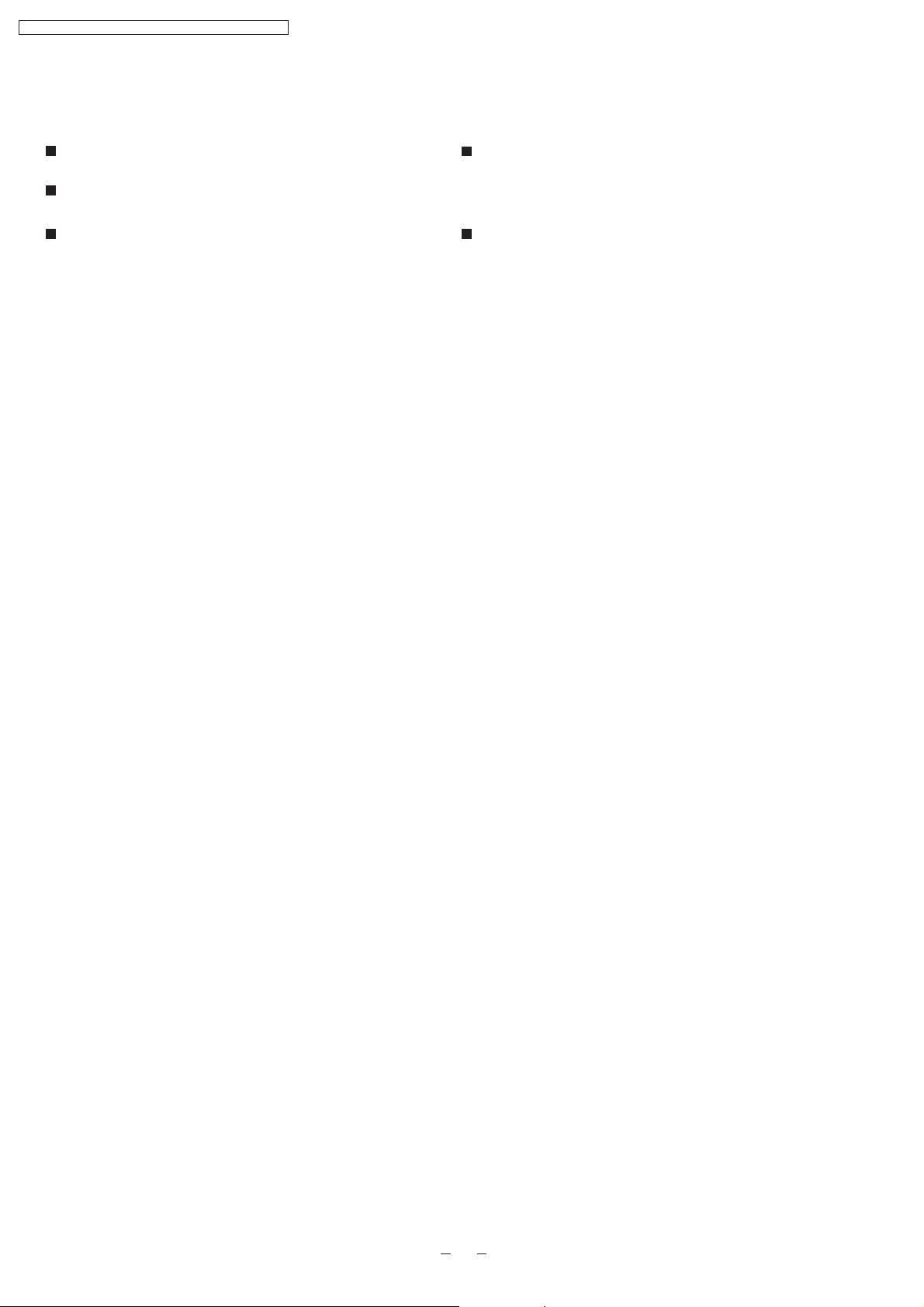

Remote Control

MODE TEMP

OFF

CANCEL

FANSPEED

OFF/ON

TIMER

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

STD

ON

SET

AIR SWING

OFF/ON

MODE

FAN

SPEED

Operation START/STOP

Turn on/off the air conditionor

When stop the operation by pressing

OFF/ON button,the cursor key points

to OFF.

Operation Mode Selection

Automatic Operation

Heating Mode Operation

(For PA12DKD)

Cooling Mode Operation

Soft Dry Mode Operation

Air Circulation Mode Operation

(For PC12DKD)

Mode

Indoor Fan Speed Selection

Low Speed

Medium Speed

High Speed

Automatic Speed

AIR

SWING

Airflow Direction Control

Horizontal Airflow Direction Control

-Auto Control

-Manual Control

Vertical Airflow Direction Manual Control

TEMP

Room Temperature Setting

Temperature Setting(16 to 30 )

Auto Operation

TIMER

OFF/ON

Timer Operation Selection

Stop/Start Operation Control

(set the ON/OFF Timer hourly later)

TIMER

SET/

CANCEL

Set /Cancel Timer Operation

Set timer/Cancel the set timer

By pressing SET button for 5seconds

continuously to switch to set the sensor

sensitivity.

3

Page 4

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Indoor Unit

Auto Switch

Button

Power Switch ON/OFF

National

Anti-freezing Control for the Evaporator

When the remote control cannot be used or

for repairing and testing ,please use this

button.

Demonstration Mode

Keep pressing this button for 15seconds to start

or end the Demonstration Mode.

Signal Receiving Sound Control

Keep pressing this button for 10seconds to turn

on or turn off the signal receiving sound.

Operation Indication Lamps

Power (green)

Timer(orange)

Air quality

Green

Orange

Red

Lights up in operation;

Blinks during Test

Run operation and

determining Auto

Operation mode

Timer in operation

Cooling or Soft Dry Operation

Warm Booting Control

(For PA12DKD only)

Indoor fan starts running when temperature

of evaporator reaches 30 or above.

When temperature of evaporator is between

30 and 34 ,indoor fan will run at Super Low

or Low speed.

When temperature of evaporator reaches 34 ,

Warm Booting Operation ends.

Indoor Fan Speed Control

High,Med,Low

Auto Fan Speed

Airflow Direction Control

Operation Mode

Cooling/Heating/Soft Dry /Auto Operation

/ Air circulation

Time Delay Safety Control

The unit will restart operation in 3-4

minutes after each pause.

7-Minutes Time Save Control

7-minutes automatic restarting at Cooling

Operation

Automatic Airflow Direction Control

The louver automatically swings up and down

Airflow Direction Manual Control

Delayed On-timer Control

For cooling or soft dry mode, the unit

starts 15 minutes before the set time with

the remote control, but for heating mode

30 minutes before the set time.

4

Page 5

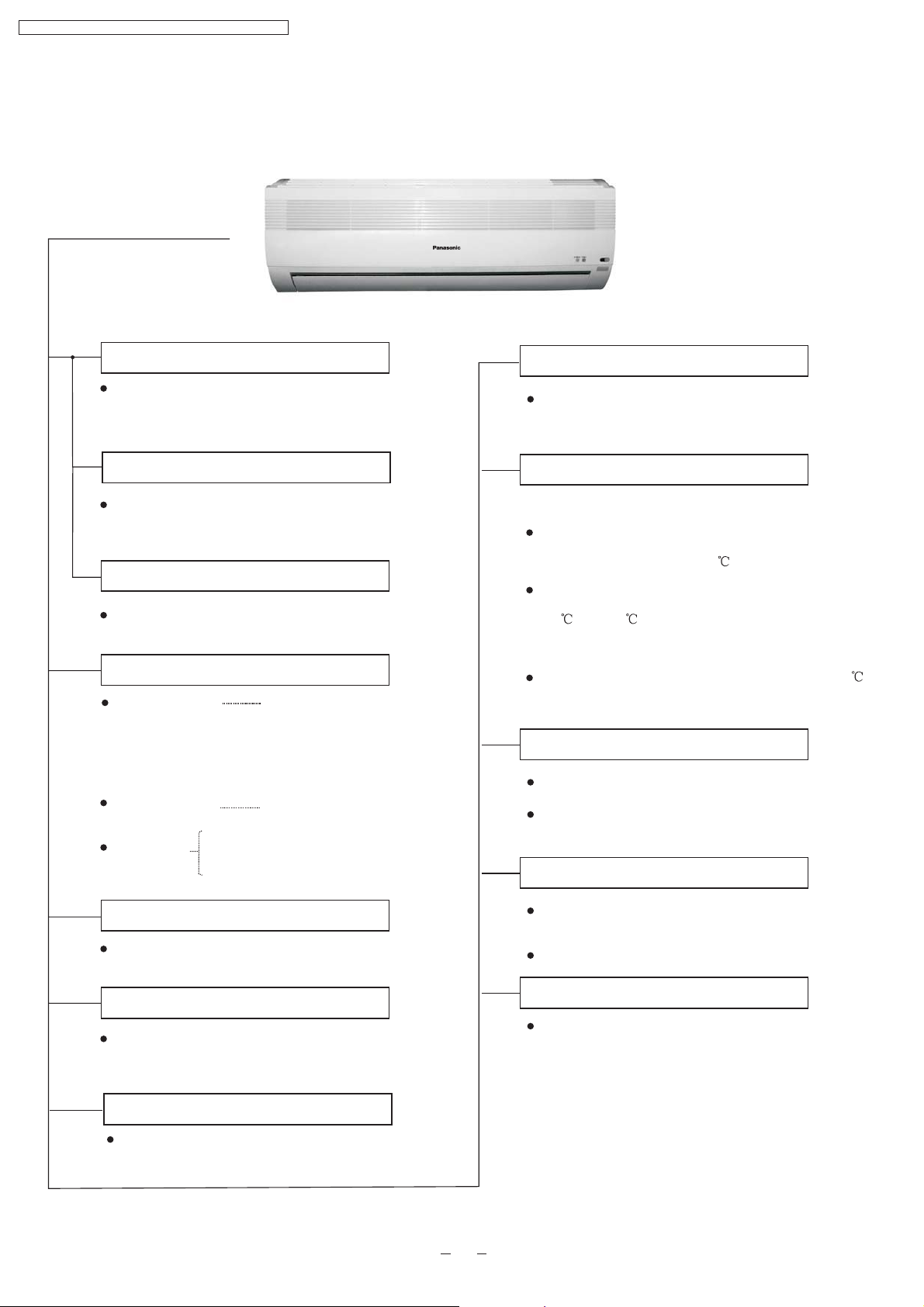

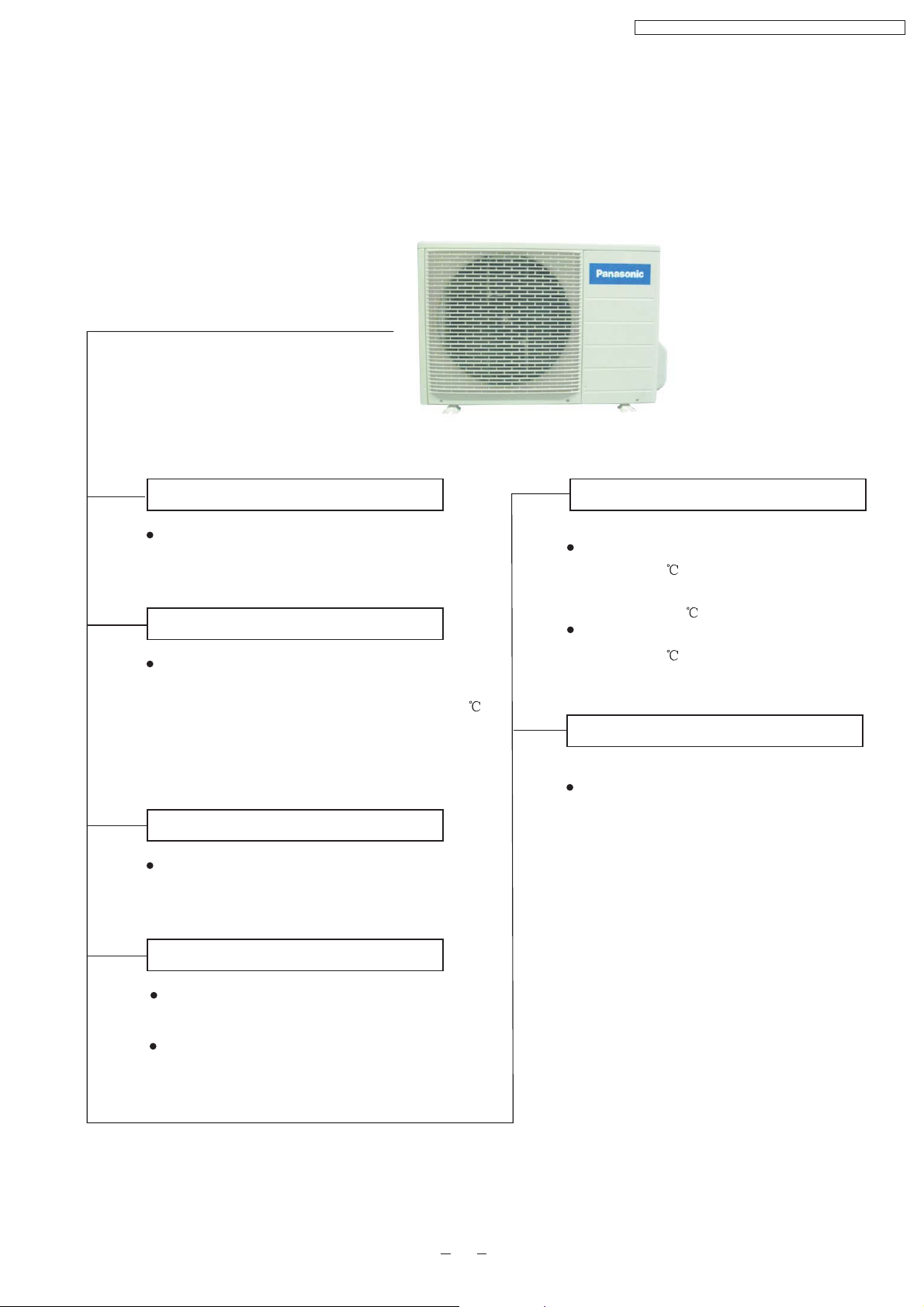

Outdoor Unit

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Panasonic

Anti-reverse Protection

To protect the compressor from reverse

rotation when power off suddenly.

Overload Protector

The 2-step Overload Protector is to protect

the compressor when

1)Temperature of compressor reaches

2)High temperature or current enters into the

compressor

145

60-seconds Test Operation Control

Once the compressor is activated, it does not

stop for 60 seconds. It stops immediately with

remote control ON/OFF button.

Overload Protection Control

(For PA12DKD only)

When the temperature of evaporator

reaches 51 ,outdoor fan stops,and will

restart when the temperature of evaporator

declines to 49 .

When the temperature of evaporator

reaches 65 ,compressor will stop.

4-way Valve Control

(For PA12DKDonly)

If the unit is stopped during Heating

Operation,the 4-way valve will remain in

heating mode operation for 5 minutes.

Deicing Control

Anti-freezing operation for outdoor unit(during

Heating Mode Operation only)

Temperature of the condenser is tested by TRS.

(For PA12DKD only)

5

Page 6

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

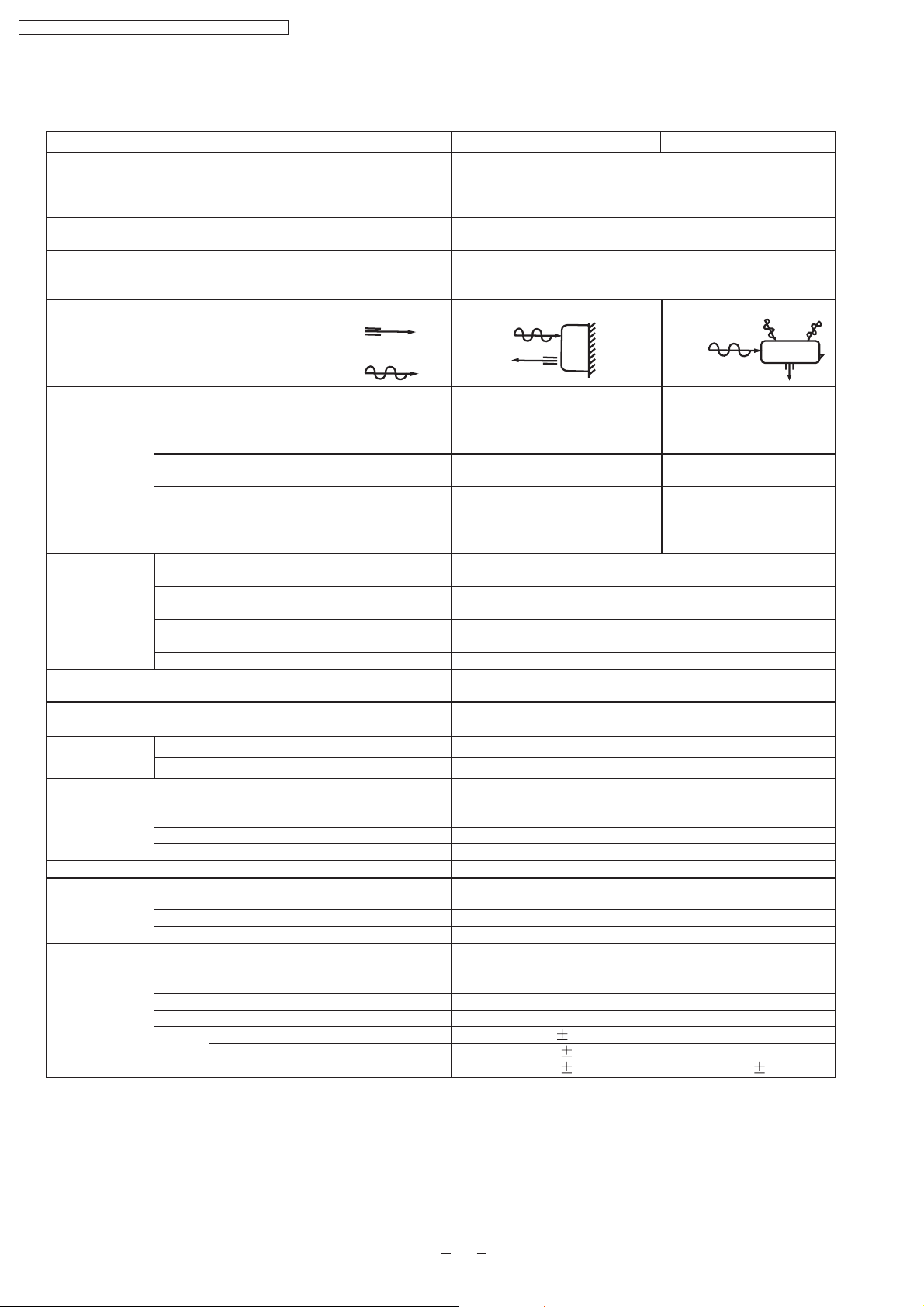

3 Product Specifications

Cooling Capacity

Heating Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Input

Data

Running Current

EER/COP

Starting Current

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Inner Diameter

Length

Power Supply Cord Length

(Number of core-wire)

Dimensions

Height

Width

Depth

Net Weight

Compressor

Type

Motor Type

Rated output

Air Circulation

type

Motor type

Input

Rated Output

Fan

Speed

Low

Med

High

Unit

kW

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

3

m /min

3

m /min

3

m /min

3

m /min

dB(A)

W

A

W/W

A

Inch

Inch

Inch

Inch

mm

m

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

CS-PA12DKD CU-PA12DKD

3.35-3.40

3.80-3.85

1.80

Single

220/230

50

SIDE VIEW

7.62

8.48

9.8

-

Cooling:high39,Low32

Heating:high39,Low31

TOP VIEW

-

-

-

-

Cooling:high48

Heating:high49

Cooling:1020-1050

Heating:1000-1030

Cooling:4.80-4.80

Heating:4.80-4.80

Cooling:3.28-3.24

Heating:3.80-3.74

22

G:half union1/2"

L:half union1/4"

G:gas side1/2"

L:liquid side1/4"

14

0.65

1.3

3 core-wire/1.0mm

280

799

183

9

-

-

-

-

-

-

Cross-flow fan

Induction(4 pole)

-

18

980 60

1090 60

1260 60

2

G:3-way valve1/2"

L:2-way valve1/4"

G:gas side1/2"

L:liquid side1/4"

-

-

-

540

780

289

34

Rotary(1 cylinder)

Rolling piston type

Induction(2 pole)

900

Propeller fan

Induction(6 pole)

-

25

-

-

760 50

6

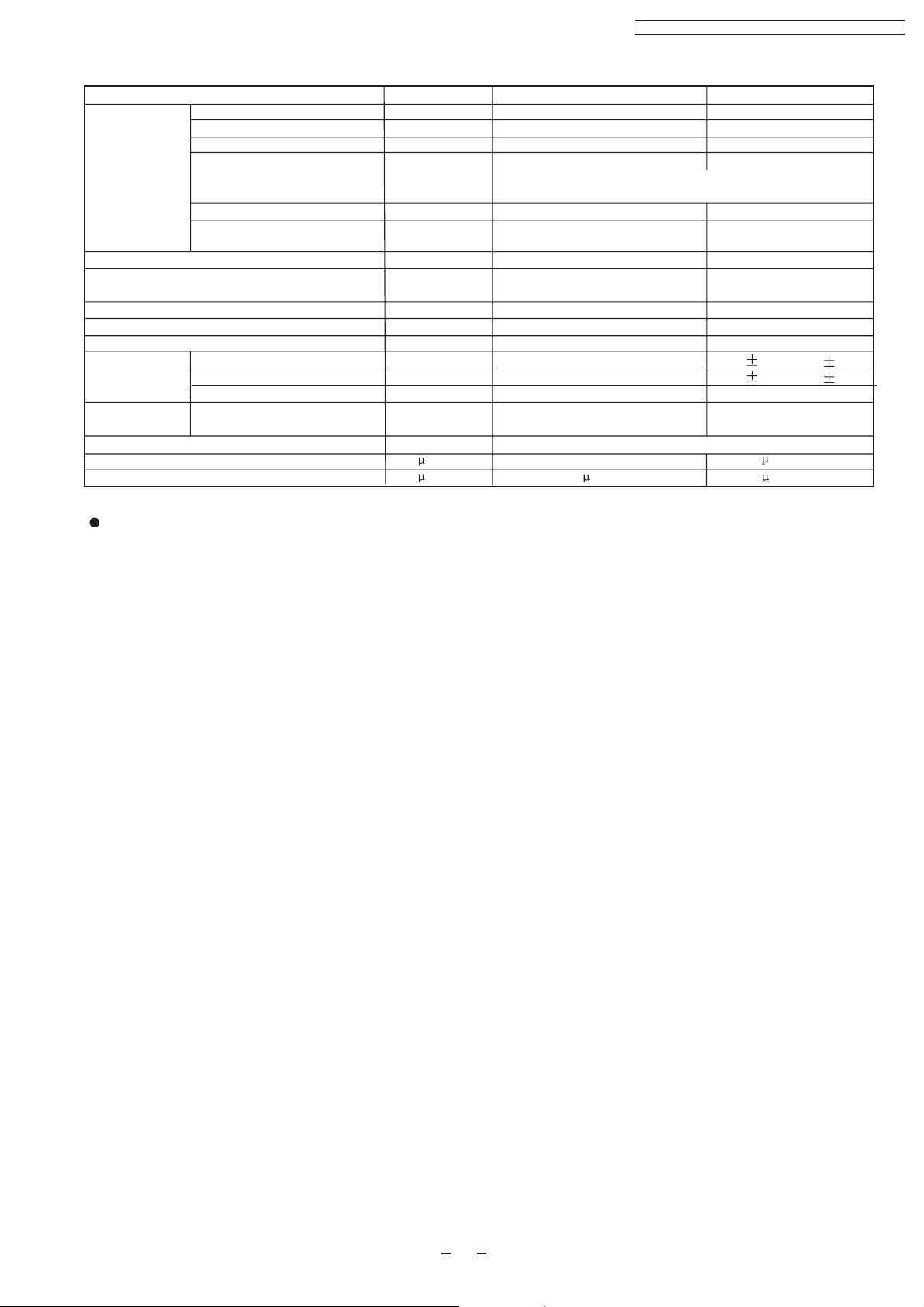

Page 7

Heat

Exchanger

Description

Tube Material

Fin Type

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Unit CS-PA12DKD CU-PA12DKD

Evaporator

Copper

Slot type

Condenser

Copper

Corrugation type

Rows/Stage

(Plate fin configuration,forced draft)

2x15

FPI

Dimensions

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Length

Capillary

Circulation

Inner Diameter

Air Filter

mm

(c.c)

g

Electronic Control

mm

L/min

mm

P.P. Honeycomb

21

610x252x25.4

-

-

-

-

-

-

-

Refrigerant Circulation Control Device

Compressor Capacitor

Fan Motor Capacitor

F,V

F,V

-

1.5

* 60g for air purging is not included.

Specifications are subject to change without notice for further improvement.

2X24

21

735.8

X504x36.38

715.1

Capillary Tube

SUNISO 4GDID or ATMOS

M60 or ATMOS 56M

1060(*)

-

O.L.P.(230V,37A)

545 10

12.5 0.2

609 10

10.0 0.2

1.5

Capillary

F,30 370V

F,1.8 400VF , 400V

1.5

7

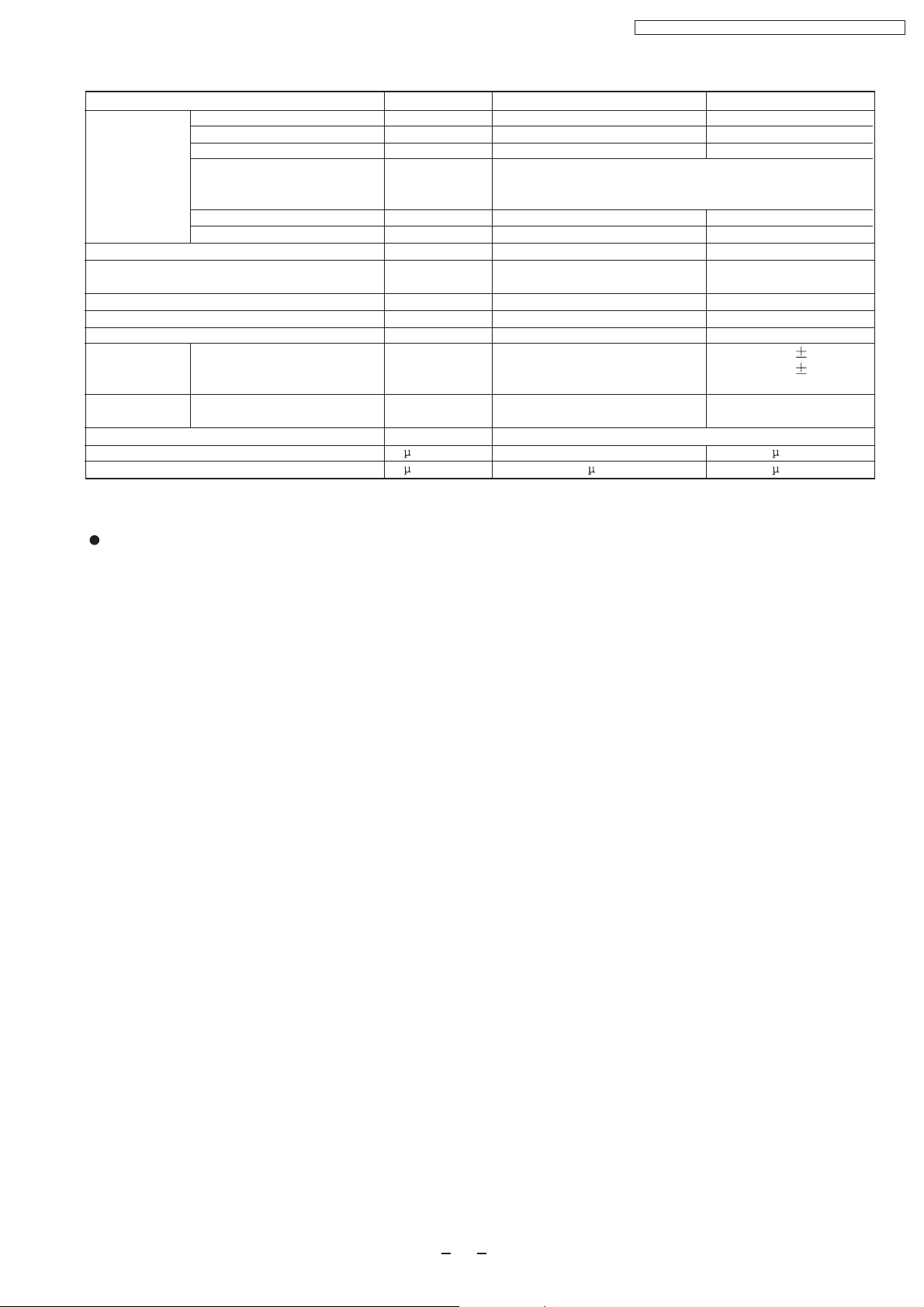

Page 8

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Cooling Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Input

Data

Running Current

Unit

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

3

m /min

3

m /min

3

m /min

3

m /min

dB(A)

W

A

CS-PC12DKD CU-PC12DKD

3.50-3.55

1.80

Single

220/230

50

SIDE VIEW

7.65

8.26

9.7

-

High39,Low32

TOP VIEW

-

-

-

-

High48

1020-1050

4.80-4.80

EER

Starting Current

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Inner Diameter

Length

Power Supply Cord Length

(Number of core-wire)

Dimensions

Height

Width

Depth

Net Weight

Compressor

Type

Motor Type

Rated Output

Air Circulation

Type

Motor Type

Input

Rated Output

Fan

Speed

Low

Med

High

W/W

A

Inch

inch

Inch

inch

mm

m

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

G:half union1/2"

L:half union1/4"

G:gas side1/2"

L:liquid side1/4"

14

0.5

1.3

3 core-wire/1.0mm

280

799

183

9

-

-

-

-

-

-

Cross-flow fan

Induction(4 pole)

-

18

1010 60

1090 60

1280 60

3.43-3.38

23

2

G:3-way valve1/2"

L:2-way valve1/4"

G:gas side1/2"

L:liquid side1/4"

-

-

-

540

780

289

32

Rotary(1 cylinder)

Rolling piston type

Induction(2 pole)

900

Propeller fan

Induction(6pole)

-

25

-

-

760 60

8

Page 9

Heat

Exchanger

Description

Tube Material

Fin Type

Rows/Stage

FPI

Dimensions

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Length

Capillary

Circulation

Inner Diameter

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Unit CS-PC12DKD CU-PC12DKD

Evaporator

copper

slot type

Condenser

copper

Corrugation type

(Plate fin configuration,forced draft)

2x15 2x24

mm

(c.c)

g

21

610x252x25.4

-

-

-

Electronic Control

Capillary Tube

SUNISO 4GDID or

ATMOS M60(M56)

O.L.P.(37A/230V)

21

735.8x504x25.4

760(*)

mm

L/min

mm

-

-

-

350 10

15.0 0.2

1.5

Air Filter

P.P Honeycomb

Refrigerant Circulation Control Device

Compressor Capacitor

Fan Motor Capacitor

F, V

F, V

-

* 60g for air purging is not included.

Specifications are subject to change without notice for further improvement.

Capillary

30

F,

F,1.8 440VF,1.5 400V

-

370V

9

Page 10

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

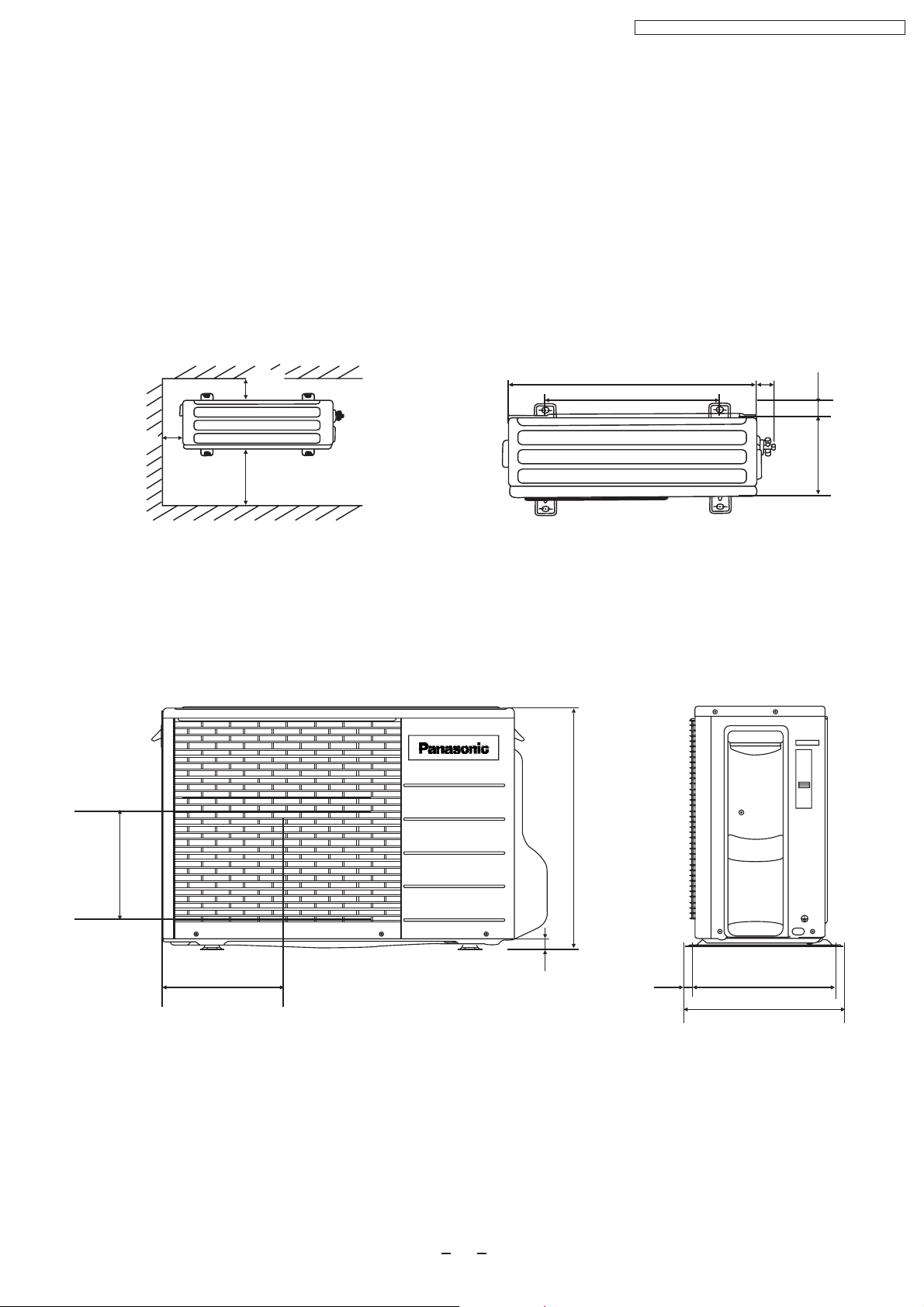

4 Dimensions

Indoor Unit

Unit : mm

Side view

Left Piping

Hole

Air intake

Air outlet

Front View

280

<Back View>

790

Installation Plate Hook

61

Gas Side

165

Liquid

Side

49

183

49

MODE

OFF

CANCEL

FANSPEED

TIMER

STD

TEMP

OFF/ON

ON

SET

AIRSWING

Right Piping

Hole

61

5

125

(100)

(420)

Drain Port

Installation plate (Front View)

254

95

(131)

B

(50)

56

16.5

A

(382) (118)

(631)

10

Page 11

Outdoor Unit

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Unit : mm

<Top View>

More

than 10cm

More

than 10cm

More than 100 cm

<Front View>

INVERTER

780

570

48

34.5

289

<Side View>

291

274

11

18

540

16

320

352

Page 12

INTAKE AIR

SENSOR

PIPING

SENSOR

PIPING

SENSOR

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

5 Refrigeration Cycle Diagram

CS/CU-PA12DKD

AIR QUALITY

SENSOR

INTAKE AIR

SENSOR

PIPING

SENSOR

PIPING

SENSOR

4-way valve

Cooling

Heating

CS/CU-PC12DKD

INTAKE AIR

AIR QUALITY

SENSOR

SENSOR

PIPING

SENSOR

PIPING

SENSOR

12

Page 13

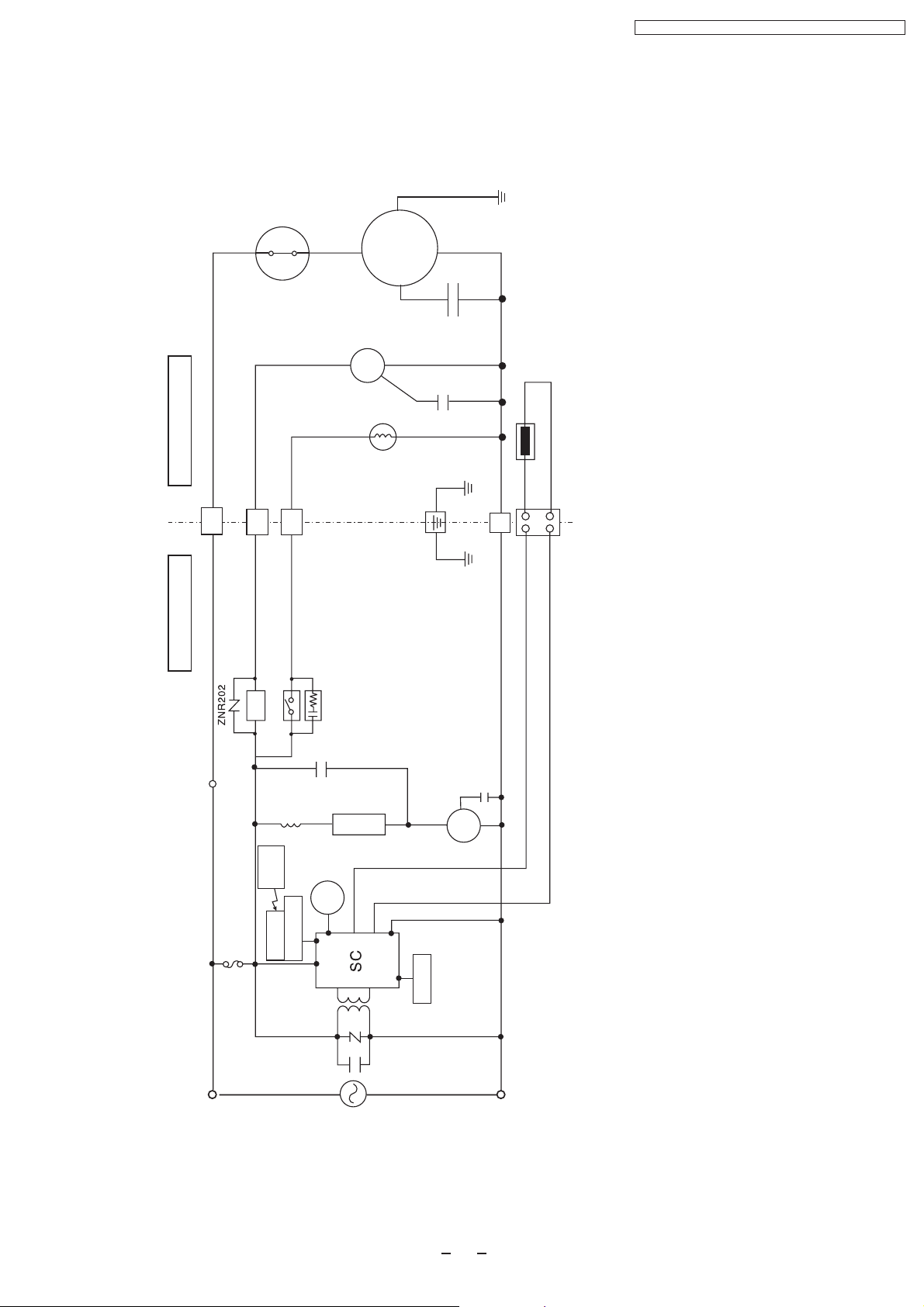

6 Block Diagram

CS-PA12DKD/CU-PA12DKD

O.L.P.

Compressor

FM

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

OUTDOOR UNIT

INDOOR UNIT

4-Valve

4

SSR202

RY-HOT

Remote

Control

3

CR201

SSR201

FM

1

RY-PWR

Piping Sensor

2

FM

FUSE

Receiver

Indicator

POWER SUPPLY

Sensor

AC220V-230V 50Hz

13

Page 14

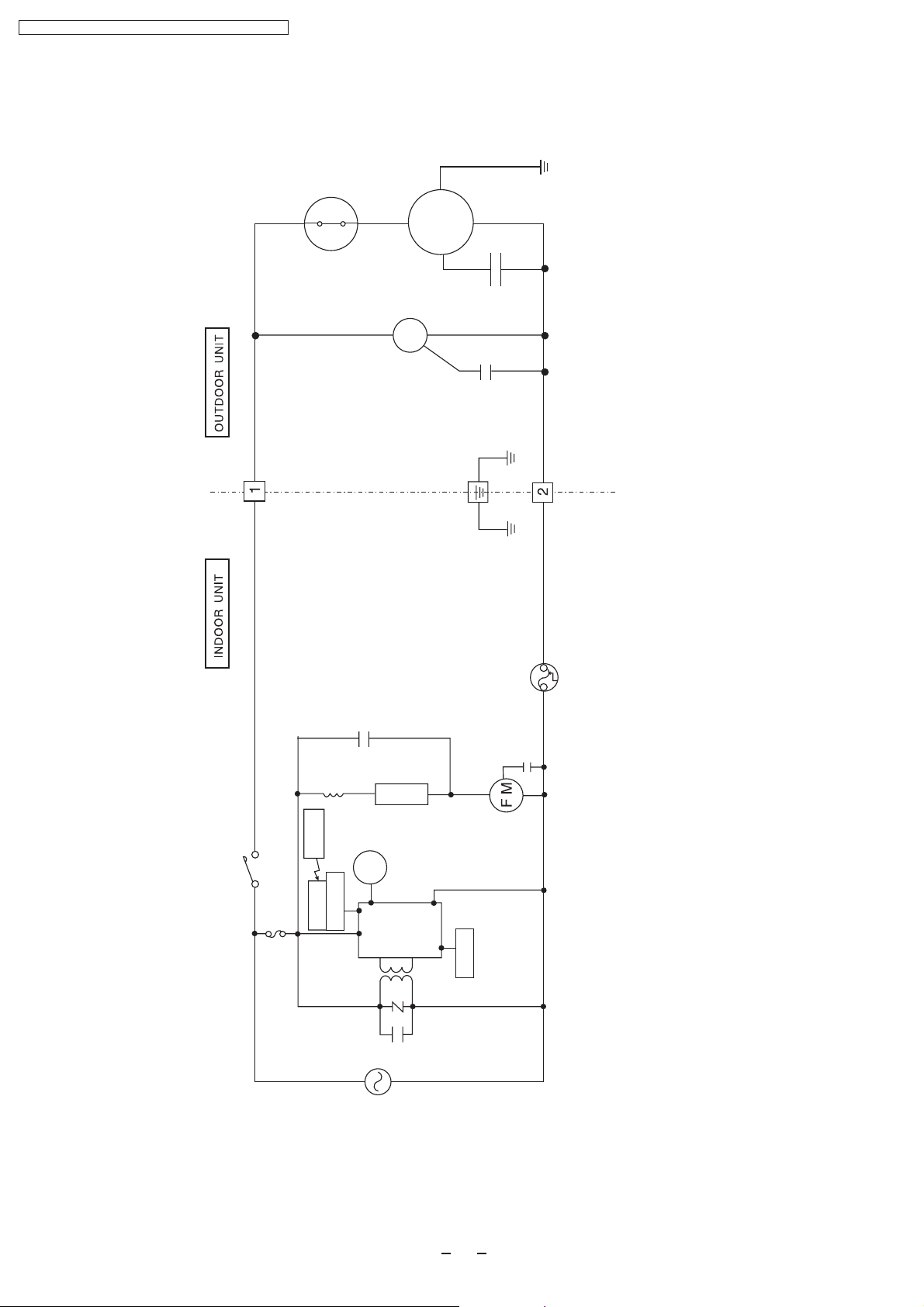

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

CS-PC127DKD/CU-PC12DKD

O.L.P.

Compressor

FM

RY-PWR

FUSE

Remote

Control

Receiver

FM

Indicator

POWER SUPPLY

AC220V-230V 50Hz

SSR201

SC

Sensor

14

Page 15

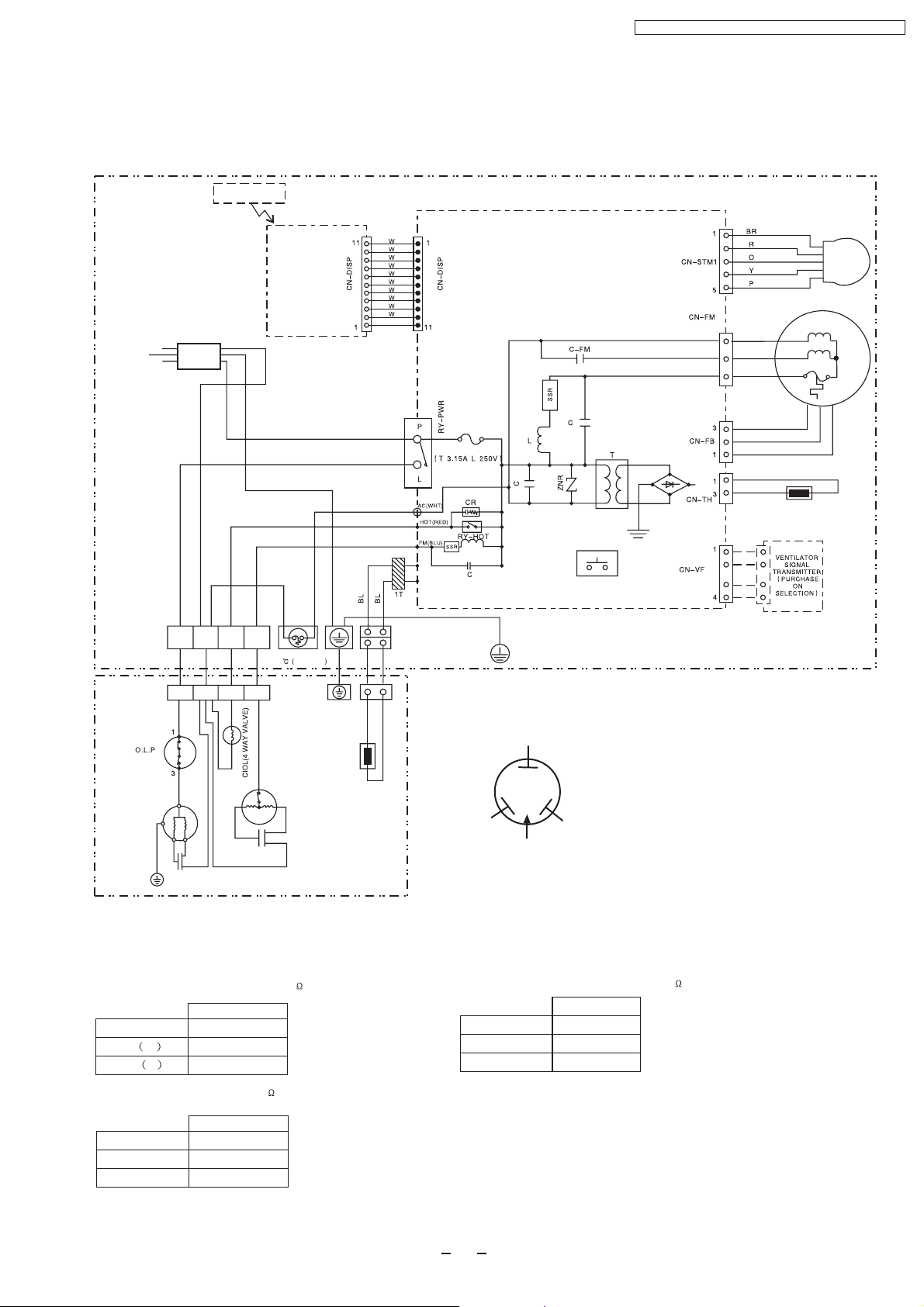

7 Wiring Diagram

POWER SUPPLY

CORD

AC 220V/230V, 50Hz

CS-PA12DKD/CU-PA12DKD

Wireless

Remote Control

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

AC 220V/230V, 50Hz

INDOOR UNIT

TERMINAL BOARD

POWER SUPPLY

CORD

B

1(L) 2(N) 3 4

Indicator

Complete

BR

BL

Y/G

FUSE

102 250V 3A

ELECTRONIC CONTROLLER

STEPPING

MOTOR

1

B

3

R

5

Y

W

FUSE

W

R

B

AUTO SWITCH

Y/G

BR

BL

SENSOR(PIPING TEMP.)

FAN MOTOR

INDOOR UNIT

OUTDOOR UNIT

TERMINAL BOARD

COMPRESSOR

1(L) 2(N) 3 4

YW

Y

Y/G

R

CAPACITOR

Y

FAN MOTOR

R

B

B

CAPACITOR

B

OUTDOOR UNIT

INDOOR FAN MOTOR RESISTANCE( )

CS-PA12DKD

CONNECTING

Y-B M

Y-R A

COMPRESSOR RESISTANCE( )

CWA921098

324

290.5

CU-PA21DKD

CONNECTING

C-R

C-S

CWB092281

2.803

4.420

R : RED

BL : BLACK

YELLOW

C

B : BLUE

BR : BROWN

O : ORANGE

SENSOR(PIPING TEMP.)

R

BLUE

TRADE MARK

S

RED

COMPRESSOR TERMINAL

OUTDOOR FAN MOTOR RESISTANCE( )

GRY : GREY

G : GREEN

Y : YELLOW

W : WHITE

Y/G : YELLOW/GREEN

P : PINK

CU-PA21DKD

CONNECTING

Y-B

Y-R

CWA951440

272

248

15

Page 16

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

POWER SUPPLY

CORD

AC 220V/230V 50Hz

CS-PC12DKD/CU-PC12DKD

Wireless

Remote Control

POWER SUPPLY

CORD

AC 220V/230V 50Hz

B

Indicator

Complete

Y/G

THERMAL FUSE

102 (250V 3A)

W

W

W

W

W

W

W

W

W

W

W

W

ELECTRONIC CONTROLLER

AC(WHT)

AUTO SWITCH

BR

R

O

Y

P

B

R

Y

W

BR

BL

SENSOR(PIPING TEMP.)

STEPPING

FAN MOTOR

MOTOR

Y/G

VENTILATION SIGNAL

TRANSMITTER(PURCHASE

ON SELECTION)

INDOOR UNIT

Y

Y

FAN

MOTOR

R

B

CAPACOTOR

B

B

CAPACOTOR

Y

R

INDOOR FAN MOTOR RESISTANCE( )

CS-PC12DKD

CONNECTING

Y-B M

Y-R A

COMPRESSOR RESISTANCE( )

CWA921098

324

290.5

CU-PC21DKD

CONNECTING

C-R

C-S

CWB092281

2.803

4.420

O.L.P

COMPRESSOR

Y/G

OUTDOOR

UNIT

YELLOW

C

R

BLUE

TRADE MARK

S

RED

COMPRESSOR TERMINAL

OUTDOOR FAN MOTOR RESISTANCE( )

CU-PC21DKD

CONNECTING

Y-B

Y-R

CWA951423

272

248

R : RED

BL : BLACK

B : BLUE

BR : BROWN

O : ORANGE

GRY : GREY

G : GREEN

Y : YELLOW

W : WHITE

Y/G : YELLOW/GREEN

P : PINK

16

Page 17

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

8 Operation Details

8.1 .Cooling Mode Operation

When selecting the Cooling Mode Operation, the unit will operate according to the setting by the Remote Controller or

the control panel on the indoor unit and the operation is as the following.

Time Delay Safety Control

3 min.----If the compressor stops, it will not restart within 3 minutes.(Protection of compressor).

7 Minutes Time Save Control

7 min.----The unit will automatically operate in 7 minutes even if the room temperature is not reached.

(Prevention of raising the humidity)

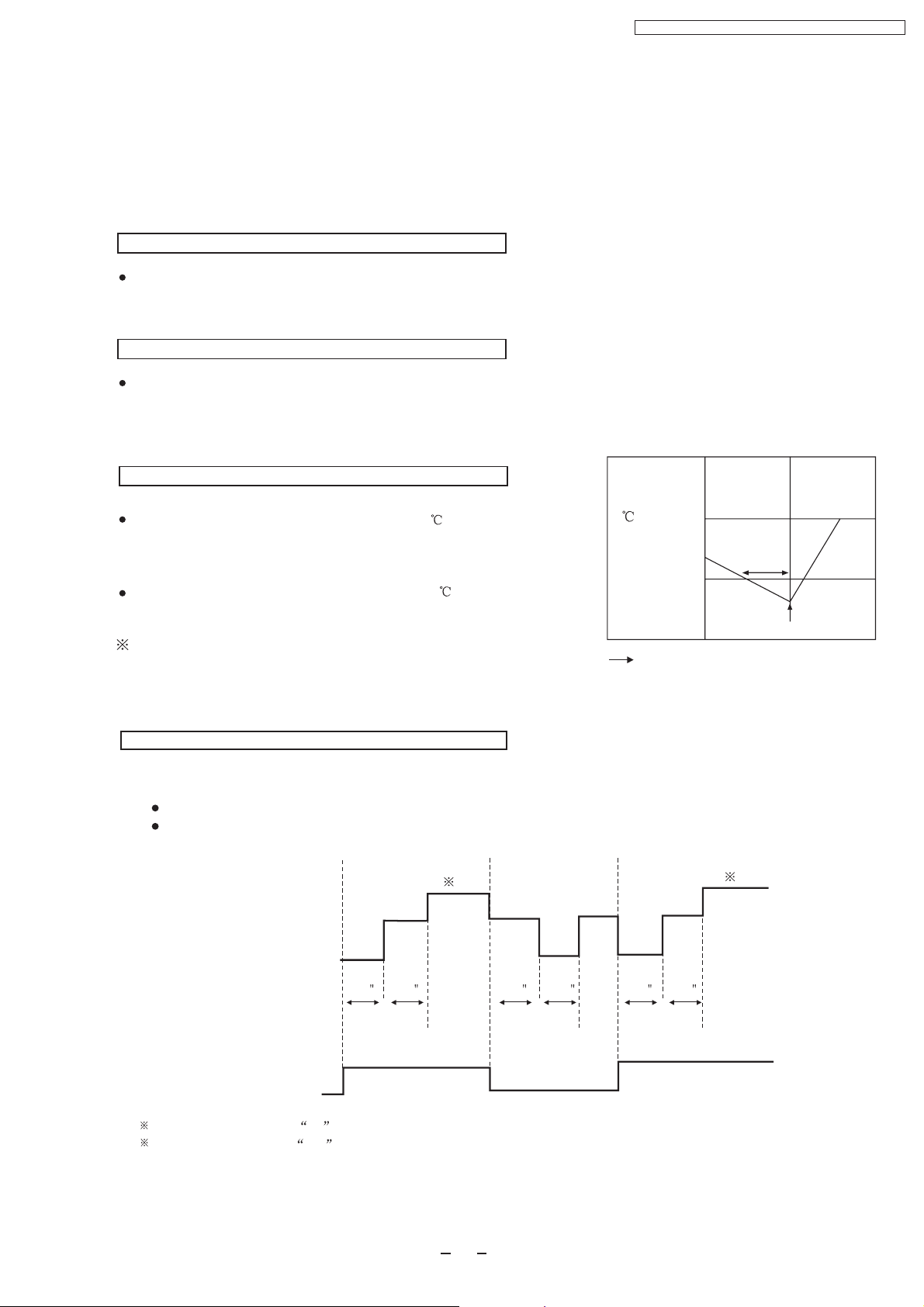

Anti-Freezing Control

If temperature of evaporator is lower than 2 continuously

Evaporator

Temperature

()

for 4 minutes, the compressor will cease to prevent the

evaporator from freezing. Fan speed setting will not be

changed.

When temperature of evaporator reaches 10 ,compressor

will restart.

During Cooling Mode Operation, the Time Delay Safety

Control is available.

Time

Automatic Fan Speed Mode

During Cooling Mode Operation, use remote controller to select Automatic Fan Speed.

Fan speed will be at the point between "High speed" and "Medium speed".

Deodorization control.

1

Indoor Fan

STOP

Slow

Slow

STOP STOP

Slow Slow

10

4 minutes

2

Compressor ceases

2

Restart

40 30 40 3020 160

Compressor

ON

STOP

1 Fan speed will be at Hi till the compressor ceases (set temperature reached).

2 Fan speed will be at Me when the compressor restarts.

17

ON

Page 18

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

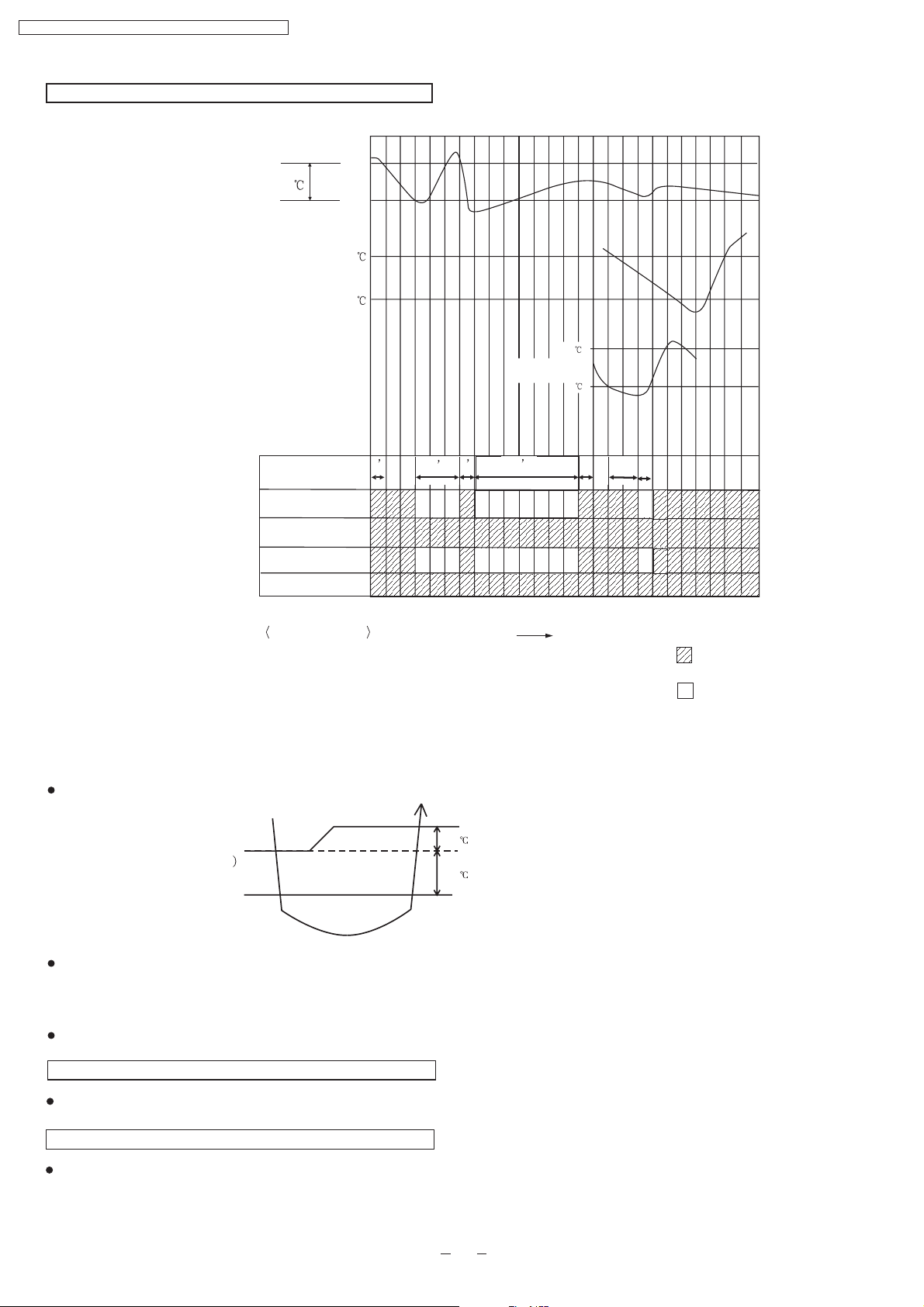

Time Graph for Cooling Operation

Intake air temperature

Set temperature

1.5

Basic Time

Comp.

Indoor Fan

Outdoor Fan

abcdefghi j k lmnopqrstuvwxyz

Start

Stop

31

29

10

2

1’

3

4’

1 1

3

Evaporater

temperature

7

Operation Indicator

Operation status

d-g

g-h

h-o

q-t

:

Time delay safety control

:

Compressor Test control

:

Auto restart control

:

Anti-freezing Control

Time

Operate

Stop

8.2. Soft Dry Mode Operation

Operation area

COOLING

COOLING(OFF)

DRY(ON

DRY

DRY(OFF)

DRY(OFF)

When selecting Soft Dry mode operation, the operation will be cooling until the room temperature reaches the set temp on

remote control, and then Soft Dry will be activated. (During Soft Dry Mode the fan of indoor unit will operate at super low

speed. The soft dry mode will run for less than 10 minutes.)

Once Soft Dry mode operation is turned off, indoor fan, compressor and outdoor fan will stop for 6 minutes.

COOLING(ON)

1.5

1.0

DRY(ON)

Time Delay Safety Protection

During cooling mode operation, if the compressor ceased, it will not restart within 3 minutes.

Anti Freezing Control

Same as the denotation in Cooling Operation.( )

P21

(During Soft Dry Mode Operation, compressor will stop for at least 6 min.)

18

Page 19

Automatic Fan Speed

During Soft Dry Operation, use remote controller to select Auto Fan Speed mode.

Indoor Fan Speed is at “Lo-”

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Lo-

Slo

Indoor

fan

OFF

T1

40

T2

70

10

Compressor

ON

Time Graph for soft dry operation

Intake Air temp

Cooling mode operation activated

1.5

1.0

Cooling mode operation stopped

Soft mode operation activated

Soft dry mode operation stop

Lo-

Slo Slo

OFF OFF OFF

T1

40

6

T2

70

10

ON

OFF

abcdef g hi jklmnopq rst u

Basic Time

Comp.

Indoor Fan

Outdoor Fan

Operation Indicator

4-way Valve

Operation status

a-c,p-r

c-p,r-u

e-f

j-l

q-t

:

Cooling Mode Operation

Soft Dry Mode Operation

:

:

Soft Dry Mode Operation Stopped

Compressor Test Operation Control

:

:

Anti Freezing Control

Evaporator

temperature

61 1 4

1

Super

Super

Super

Slo Slo Slo Slo

Low

Low

Low

Super

Low

Low

Slo Slo

Slo Slo Slo

Time

o

10 C

o

2C

666

Slo

Slo

Cooling mode operation

Soft Dry Mode operation

Operate

Stop

19

Page 20

Super Low

Indoor Fan

Stop

Indoor Heat

Exchanger

()

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

8.3. Heating Mode Operation(Only for PA12DKD)

When selecting the Heating Mode Operation, the unit will operate according to the setting by the Remote Controller and

the operation is as the following.

Time Delay Safety Control

If the compressor stopped by switching off, turning off by remote controller, or power off, it will not restart within 3 minutes.

When room temperature reaches the set temperature on the remote controller, compressor stops and will not restart within

4 minutes.

3 minutes after the compressor stopped, indoor fan will stop for 1 minute. Then indoor fan will resume operation with the

speed at ”super low”

Over Load protection Control

When temperature of indoor heat exchanger rises to 51 , outdoor fan will stop

when temperature of indoor heat exchanger falls to 49 , outdoor fan will restart.

When temperature of indoor heat exchanger rises to 65 or above, compressor stops, and will restart 4 minutes later.

.

Compressor

Indoor Heat Exchanger 65

Anti-reversing Control

If the compressor has been continuously running for 5 minutes or longer, and the difference of temperature between

intake air and evaporator is continuously lower than 5.0 or below for 2 minutes, the compressor will stop , and then

restart 3 minutes later.(Time Delay Protection Control is effective.)

Compressor runs 5 min

T 5 last for 2 min

T= intake air temperature - evaporator temperature

4-way valve control

During heating mode operation,4-way valve is at open mode.

During heating mode operation,if the unit turned off, the 4-way valve will remain

at open mode for 5 minutes.

Stops

Compressor

Stops

Compressor Restarts

4 minutes later

Compressor Restarts

3 minutes later

Warm Booting Control

When turning on the unit by heating mode operation,indoor fan

will be activated when temperature of indoor heat exchanger

reaches 30 . (See the figure on the right)

Warm boot operation ends when temperature of indoor heat

exchanger reaches 34 .

20

Indoor Heat

Exchanger

()

34

30

Low

Super Low

Indoor Fan

Stop

Page 21

Automatic Fan Speed

S Lo

()

()

45

41

34

30

38

30

28

15

Temperature of heat exchanger

During Heating Operation, use remote controller to select Auto Fan Speed mode.

Indoor Fan Speed is between “Me” and “Slo”.

()

SLo

Me

Lo

Lo-

()

38

30

28

45

41

34

30

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Temperature of heat exchanger

Time Graph for Heating Operation

abcdefghi jk

42

Indoor heat

exchanget

Temp.

Intake Temp.

34

32

30

OFF

2

ON

Basic Time

Compressor

Indoor Fan

Outdoor Fan

Operation Indicator

4-way valve

Stop

30'

58''

15

l

nop qr

m

Manual fan speed

Blink

Operate

Stop

150'

1'

30

<Operation status>

a-b

c-d

h-k,o-r

:

Warm booting control(indoor fan Off)

:

Warm booting control(indoor fan Super Slo)

:

Prevent cool air blowing out

Tim e

21

Page 22

Deicing Operation Time(T)

3

min

3min T 7min

7

min T 9min

T 9min

Td(s)

0

60

120

180

<Operation status>

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Deice Control

Deice operation is to protect the outdoor unit from freezing.

Normal Deice Operation

Deicing starts 30 minutes after heating mode operation or 60 minutes after the latest deicing operation. If temperature of

outdoor piping, tested by TRS, falls to -3 (TRS OFF) or below for continuously 50 seconds, deicing operation starts.

Overload Deicing Operation

During heating operation, if the accumulative stopping time of outdoor fan reaches 60 minutes,

deicing operation will start 1 minute after compressor starts.

Deicing operation ends under conditions below

(a) After 12 minutes.

(b) Temperature of outdoor unit rises to 4 .

(c) As the illustration showed bellow and due to Time Delay (Td), deicing won’t ends immediately.

Deicing Operation Time(T)

3min

3min T 7min

7 min T 9min

T 9min

Td(s)

0

60

120

180

Once deicing operation starts, it won’t end until 60 seconds later.

When deicing operation ends, compressor will stop for 30 seconds, and 4-way valve remains at cooling mode operation

for 10 seconds.

Time Graph for Normal Deicing Operation

Lo

max60'

l

nopq r s t uvwxy z

m

max12'

Slo

or

Blink

Operat io n

Stop

max60'

Lo

42

34

30

Indoor Piping Temp.

Basic Time

Compressor

Indoor Fan

Outdoor Fan

Operation LED

4-way valve

abcd ef gh i j k

60'

max12'

10S20S 20S 20S 20S 20S 10S 20STd

Slo

Time

<Operation status>

a-c Deicing confirmation

c-g Deicing operation(time reset)

h-j,u-w Warm Booting

o-r Deicing(TRS )

22

Page 23

Time Graph for Overload Deicing

Outdoor Heat

Exchanger

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Outdoor Heat

Exchanger

Basic time

Compressor

abcdef ghi j k

51

49

Out door fan stop for 60' accumulatively

20’’ 20’’

Max

12’

l

m

10’’ 20’’

nopq

Indoor fan

Outdoor fan

Operation Indicator

4-way valve

<Operation status>

Overload controla-i

i-l Overload deicing(timer)

l-m: Warm booting control

m-r Overload control

Time

Blin k

Oper ati on

Stop

23

Page 24

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

8.4 Automatic Mode Operation

Standard for Determining Operation Mode

First Determination:

Setting Temperature (Standard)

25

22

21

Intake Air

temperature

23

20

Cooling mode

Soft Dry mode

Heating mode

Cooling mode

Soft Dry mode

Heating mode

Second Determination:

One hour after the above determination, the unit will operate according to the table below.

Second Determination

Cooling

Cooling

First

determination

A)

Indoor fan operates at super low speed for 25 seconds.

B)

After judging indoor air temperature, the operation is determined and operation continued at the mode determined.

C)

If indoor temperature is less than 16 , heating operation will immediately operate.

D)

After the operation mode has been determined, the mode does not change. However,Soft Dry mode operation

includes cooling mode operation.

E)

If automatic mode operation is started while the unit is operating,operation will continue.

If current operation is in cooling mode (including the cooling mode operation when is a part of Soft Dry mode

operation) it will be maintained, and if current operation is not cooling mode, the appropriate operation mode is

determined for 25seconds at super slow fan speed.Then the selected mode will continue.

F)

Room temperature adjustment

Dry

Heating

Higher

23 or above

25 or above

2

Dry

20 or above

Heating

23 below

20 below

25 below

Standard

Lower

0

2

8.5. Air Circulation Mode Operation(Only for PC12DKD)

1. An additional heater may make the warm air evenly covering each corner of the room.

2. When the temperature near the ceiling reaches the setting temperature, Air Circulation Mode Operation commences

at low airflow volume. It stops when the temperature drops to 2 below the setting temperature.

3. The vertical airflow direction louver will not swing.

24

Page 25

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

8.6 Air Quality Sensor Control

Resistance of air quality sensor: Rs(air)=10k ~50k ( The worse the air quality, the smaller the resistance.)

Basic Operation

Detecting and indicating of the air quality will not stop during the operation of the air conditioner.

The power of the air quality sensor is always on during the operation of the air conditioner. When the air

conditioner stops (The air conditioner is on standby.), the air conditioner will provide power to the air quality

sensor intermittently (It will be on for 3 minutes after each 109 minutes.) for the purpose of air quality detecting.

Within 2 minutes after the air conditioner starts to operate, the air quality sensor is in the process of preheating

and the air quality indicator is red.

Resistance Reference

Detecting of air quality( During the operation of the air conditioner)

(a) The measuring period is 20 minutes; The air conditioner will measure the resistance (Rs) of the air quality

sensor once each 2 seconds and record the data. The maximum Rs within the 20 minutes will be selected as

Rs(MAX) for this measuring period.

(b) Suppose the current Rs(MAX) as MAX and the resistance reference of the previous measuring period is as

MAXR1.; If MAX>MAXR1, the resistance reference of the current measuring period is MAXR=MAX; If

MAX<MAXR1, MAXR=MAXR1;

(c) Within 2 minutes after the power of the air quality sensor is turned on, the resistance reference of this

measuring period is the maximum resistance of the sensor during this period.

Maximum of Rs

MAXR1 of previous

measuring period

Updating of MAXR

20minutes

MAX1 MAX2 MAX3

MAX0 MAX1 MAX2

MAX1 MAX0 MAX0

MAX1 MAX0 MAX1

MAX2 MAX1 MAX1

MAX2 MAX1 MAX2

20minutes20minutes

MAX3 MAX2 MAX2

MAX3 MAX2 MAX3

The following conditions should be fulfilled

(d)

The initial MAXR after the preheating of the air quality sensor when the air conditioner is turned on:

The air conditioner will compare the maximum value of the current measuring period (MAX) with the

resistance reference 109 minutes before ( MAXR0) and select the bigger one as the current resistance

(e)

reference(MAXR).

When the air conditioner determines the air quality is getting worse: Air quality level 1 Air quality level 2,

MAXR will not be updated; When the air quality gets better (air quality level 0), Rs detected at this time will be

(f)

MAX and MAXR.

The air conditioner will not detect the air quality during deicing operation. The indication prior to the deicing

operation will be held during the deicing operation.

25

Page 26

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Detecting of air quality( When the air conditioner is on standby.)

(a) After the air conditioner stops operation, it will provides power to the air quality sensor intermittently to detect

the air quality and update the resistance reference (MAXR). The power of the air quality sensor will be on for 3

minutes after each 109 minutes.

(b)

During these 3 minutes, the air quality sensor will be in preheating process for 2 minutes and the other time is

for measuring the resistance. The air conditioner will compare the maximum resistance measured in this period

with the maximum value in the previous 109 minutes and the bigger one will be selected as resistance

Air Quality Control

Detecting of air quality(When the air conditioner is on standby.)

Rs/MAXR will be calculated automatically every 2 seconds and the air quality level will be determined in

accordance with the value below,

Air Quality

Getting Worse

Air Quality

Getting Better

*G1=0.85

*G2=0.60

Signal of Air Quality Sensor

Air quality

becomes better

Rs/MAXR G1

Rs/MAXR G2

Rs/MAXR G3

Rs/MAXR G4

Air Quality Level

(0) (1)

(2) (1)

(1) (0)

Air quality

(0)

becomes worse

(1)

(2)

(2)(1)

Set the sensitivity number of the air quality sensor as 2 (Standard)

Air Quality Level and Indicator

During preheating of the air quality sensor the air quality indicator is red.

The color of the air quality indicator varies with the air quality level:

Air Pollution Level 0: Green

Air Pollution Level 1:Orange

Air Pollution Level 2:Red

26

Page 27

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Forced Resetting

Forced Resetting Time (The added operation time mentioned later not included.)

(a) Air Pollution Level 2: Red: 5 minutes Orange: 8 minutes Green

(B) Air Pollution Level 1: Red: 5 minutes Orange: 8 minutes Green

Timer Resetting

When the forced resetting mode is determined and the following conditions are fulfilled, the timer is reset.

1) The air quality changes which results in the changing of the color of the air quality indicator.

2) Compare Rs detected in current 2 seconds with R1 detected in previous 2 seconds and Rs/R1<0.95.

3) Suppose Rs detected in previous 3 minutes is R2 and Rs/R2 0.87.

Added Operation of Air Quality Sensor

When the air quality getting worse

If the air pollution level changes from 0 to 2, the color of the air quality indicator changes as below,

Green Orange (2 Sec.) Red

When the air quality getting better (added operation )

If the air pollution level changes from 2 to o, the color of the air quality indicator changes as below,

Red (60 Sec. ) Orange( 60Sec.) Green

Judgment during added operation

During added operation, if the air quality sensor judges that the air quality is getting worse, the added operation will

be stopped immediately and the air quality indicator will shift to normal indication. If the air quality getting better,

the air conditioner will judge the air quality until the added operation is finished.

Sensitivity Control of Air Quality Sensor

The sensitivity number can be changed through the following procedure

<Setting Sensitivity Number>

1.Keep the SET button on the remote control depressed continuously for 5 seconds to select sensitivity control

m ode.

2.The previous sensitivity setting will be displayed in the temperature display.

“0”=Turn off the air quality indicator

“1”= Low Sensitivity

“2”=Standard Sensitivity

“3”=High Sensitivity................

…………....G1=0.70, G2=0.45, G3=0.48, G4=0.73

………G1=0.85, G2=0.60, G3=0.63, G4=0.88

G1=0.90, G2=0.65, G3=0.68, G4=0.93

3.Press or button on the remote control to change the sensitivity

Within 10 seconds after the sensitivity setting is finished, other settings are not available. The display of the remote

control will change back to normal without pressing any button.

27

Page 28

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

8.7Demo Mode ( Outdoor unit not needed)

Activate the demo mode:

Keep the AUTO button on the indoor

unit depressed continuously for 15

seconds until 3 beeps are heard and

the demo mode is activated.

In demo mode, the air conditioner can be operated(if the outdoor unit is connected to the indoor unit); Whenever

you turned off the air conditioner, it will restart automatically into demo mode opertion.

Cancel the demo mode:

Keep the AUTO button on the indoor unit depressed continuously for 15 seconds until 3 beeps are heard.

Turn off the air

conditioner

Demo mode operation will be

restarted automatically in 1

minute.

ON

5seconds 10seconds 15seconds

AUTO TEST RUN SOUND DEMO

1“BEEP”

Demo operation control( Air quality indicator and Ventilator Interlocking Unit signal)

5 seconds 5 seconds 5 seconds 5 seconds 5 seconds 5 seconds 5 seconds

Color of air quality indicator

Red Orange green Orange Green Orange Red

Ventilator Interlocking

Unit ON/OFF

ON

OFF

10 seconds 20 seconds

2“BEEP”

3“BEEP”

8.8Ventilator Interlocking Unit Control (Optional)

Purpose: The air conditioner will control the operation of the ventilator (optional) according to the signal of

the air quality sensor when displaying the air quality.

Devices: Ventilator, Ventilator Interlocking Unit (wireless)

To use this function, a ventilator and a ventilator interlocking unit should be purchased.

Power supply:220V-240V~50/60Hz

Control Specification:

Air quality getting worse Air quality getting better

Green

OFF

Oriange

ON

Red

ON

Green

OFF

Oriange

ON

Red

ON

15 minutes after the air conditioner is

Turned on:

Ventilator ON: Air quality indicator is red or

orange.

Ventilator OFF: Air quality indicator is green

or the air conditioner is turned off.

Within 15 minutes after the air conditioner is

turned on, the ventilator will not operate even

though the air quality indicator is red.

28

Page 29

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

8.9 About Cursor Key Which Points To “OFF” On Remote Control

When the ON/OFF button on the remote control is pressed, the cursor key which points to “OFF” will appear or

disappear to indicate the ON/OFF status of the air conditioner.

AUTO

HEAT

STD

COOL

DRY

OFF

For some reason (Ex. The signal of the remote control does not reach the signal receiver of the indoor unit.), the

display of the remote control will not correspond with the actual ON/OFF status of the indoor unit:

The air conditioner is running but the cursor key which points to “OFF” appears. The air conditioner can be

1.

stopped with any button (Except for “ON/OFF”, “TIMER SET”, “TIMER ON”) pressed.

The air conditioner is on standby, but the cursor key which points to “OFF” disappears. The air conditioner can

2.

be started with any button(Except for “ON/OFF”, “TIMER SET”, “TIMER OFF”) pressed.

AUTO

AUTO

FAN

SPEED

AIR

SWING

PRESS "OFF/ON" BUTTON

AUTO

HEAT

COOL

DRY

OFF

STD

AUTO

AUTO

FAN

SPEED

AIR

SWING

8.10. Indoor Fan Motor Control

Automatic fan speed control

When automatic fan speed set, the available range for fan speed is from Hi to Slo.

Manual Fan Speed Control

Basic fan speed can be manually adjusted (Lo, Med, Hi) by using the fan speed selection button.

Basic Fan Speed

Category

Cooling Mode

Operation

Soft Dry

Operation

Heating Mode

Operation

Manual

Auto

Manual

Auto

Manual

Auto

8.11. Auto restart control

If the operation is stopped due to a power failure u , it will restart automatically

un der the previous operation mode when the power supply is resumed.

Hi Me

SLo

Lo-

Lo

nder any operation mode

SSLo

29

Page 30

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

8.12. Airflow Direction Control

Airflow Direction Auto-control

When set at airflow direction auto-control with remote control,the louver swings up and down as shown in the table below.

The louver does not swing when the indoor fan stops during operation.

When stop the unit with remote control,the discharge vent is closed with the louver.

When temperature of indoor heat exchanger reaches 38 during heating mode operation, if temperature falls to 35 ,airflow

direction will change from the lower limit to horizontal.

The left and right airflow direction louver can be adjusted manually.

Airflow direction manual control

When the airflow direction set button is pressed,the automatic airflow is released and the

airflow direction louver moves up and down as shown in thetable below. The louver can

be stopped by releasing the button at the desired position.

When the remote control is used to stop the operation,the discharge vent is closed with

airflow direction louver.

Angles Of Airflow Direction Louver

12 34 5

Operating Mode

Cooling

Manual

Soft dry

Auto

Manua

Heating

Auto

Determining operation

mode

oo o o o

12 17 26 32 36

oo

12 ~36

oo o o o

921 29 44 55

oo

9 ~55

o

9

Notes:

In heating mode operation

1.

Airflow direction automatic control:

Airflow direction is automatically adjusted to horizontal direction when the temperature of indoor heat exchanger is low and it will

be automatically adjusted downward while the indoor temperature rises.

2.

Airflow direction manual control:

The airflow direction is automatically adjusted to horizontal direction when temperature of indoor heat exchanger is low .While

temperature of indoor heat temperature rises ,the airflow direction is automatically adjusted to the place set by the remote control.

In cooling or soft dry mode operation

If the compressor continues to operate for 60 minutes ,and the louver direction is at No 5,the fan speed is below Med, the intake

air temperature is below 29 and continues to change between 2 for 30 minutes ,the louver direction will be at No 2 in order

to prevent dew around the discharge vent.

30

Page 31

CS-PC12DKD/ CU-PC12DKD/ CS-PA12DKD / CU-PA12DKD

9 Installation Instructions

Required tools for Installation Works

1. Philips screw driver 5. Spanner 9. Gas leak detector 13. Multimeter

2. Level gauge 6. Pipe cutter 10. Measuring tape 14. Torque wrench

3. Electric drill, hole core drill

(ø70 mm)

4. Hexagonal wrench (4 mm) 8. Knife 12. Megameter 16. Gauge manifold

7. Reamer 11. Thermometer 15. Vacuum pump

9.1. Safety Precautions

Read the following "SAFETY PRECAUTIONS" carefully before installation.

Electrical work must be installed by a licensed electrician.

The caution items stated here must be followed because these important contents are related to safety. The meaning of each

indication used is as below. Incorrect installation due to ignoring of the instruction will cause harm or damage, and the

seriousness is classified by the following indications.

This indication shows the possibility of causing death or serious injury.

18 N.m (1.8 kgf.m)

42 N.m (4.2 kgf.m)

55 N.m (5.5 kgf.m)

This indication shows the possibility of causing injury or damage to properties only.

The items to be followed are classified by the symbols:

Symbol with background white denotes item that is PROHIBITED from doing.

Carry out test running to confirm that no abnormality occurs after the installation. Then, explain to user the operation, care and

maintenance as stated in instructions. Please remind the customer to keep the operating instructions for future reference.

1. Engage dealer or specialist for installation. If installation done by the user is defective, it will cause water leakage, electrical shock or fire.

2. Install according to this installation instruction strictly. If installation is defective, it will cause water leakage, electrical shock or fire.

3. Use the attached accessories parts and specified parts for installation. Otherwise, it will cause the set to fall, water leakage, fire or

electrical shock.

4. Install at a strong and firm location which is able to withstand the set• sweight. If the strength is not enough or installation is not properly

done, the set will drop and cause injury.

5. For electrical work, follow the local national wiring standard, regulation and this installation instruction. An independent circuit and single

outlet must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.

6. Use the specified cable (1.5 mm2) and connect tightly for indoor/outdoor connection. Connect tightly and clamp the cable so that no

external force will be acted on the terminal. If connection or fixing is not perfect, it will cause heat-up or fire at the connection.

7. Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed perfectly, it will

cause heat-up at connection point of terminal, fire or electrical shock.

8. When carrying out piping connection, take care not to let air substances other than the specified refrigerant go into refrigeration cycle.

Otherwise, it will cause lower capacity, abnormal high pressure in the refrigeration cycle, explosion and injury.

9. When connecting the piping, do not allow air or any substances other than the specified refrigerant ( R22 ) to enter the

refrigeration cycle. Otherwise, this may lower the capacity, cause abnormally high pressure in the refrigeration cycle, and

possibly result in explosion and injury.

10.Do not modify the length of the power supply cord or use of the extension cord, and do not share the single outlet with

other electrical appliances. Otherwise, it will cause fire or electrical shock. if the power supply cord is damaged, engage an

authorized dealer to replace it.

31

Page 32

CS-PC12DKD/ CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

1. The equipment must be earthed. It may cause electrical shock if grounding is not perfect.

2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at

surrounding of the unit, it may cause fire.

3. Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage the

furniture.

1. Selection of the installation location.

Select a installation location which is rigid and strong enough to support or hold the unit, and select a location for easy maintenance.

2. Power supply connection to the room air conditioner.

Connect the power supply cord of the room air conditioner to the mains using one of the following method.

Power supply point shall be the place where there is ease for access for the power disconnection in case of emergency.

In some countries, permanent connection of this room air conditioner to the power supply is prohibited.

1. Power supply connection to the receptacle using a power plug.

Use an approved 10A power plug with earth pin for the connection to the socket.

2. Power supply connection to a circuit breaker for the permanent connection. Use an approved 10A circuit breaker for the permanent

connection. It must be a double pole switch with a minimum 3 mm contact gap.

3. Do not release refrigerant.

Do not release refrigerant during piping work for installation, reinstallation and during repairing a refrigeration parts. Take care of the

liquid refrigerant, it may cause frostbite.

4. Installation work.

It may need two people to carry out the installation work.

5. Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.

32

Page 33

Attach ed access ories

Attached accessories.

No. Accessories part Qty. No. Accessories part Qty.

Installation plate

1

Installation plate fixing

screw

2

Remote control

3

C

A

N

F

C

A

NS

P

EE

D

1

5

A

UTO

C

O

O

DRY

L

F

A

O

N

F

F

MO

D

ET

h

S

r

T

DEL

*

O

D

A

FF

UT

A

O

Y

AU

O

N

T

O

F

O

A

S

F

E

N

P

F

M

O

E

A

E

P

F

IR

SW

D

F

/

O

I

N

N

E

G

L

TI

M

E

R

1

O

N

SE

A

T

I

RS

W

I

N

G

Battery

4

2

SELECT THE BEST LOCATION

INDOOR UNIT

There should not be any heat source or steam near the

unit.

There should not be any obstacles blocking the air

circulation.

A place where air circulation in the room is good.

ı

A place where drainage can be easily done.

ı

A place where noise prevention is taken into

consideration.

ı

Do not install the unit near the door way.

ı

Ensure the spaces indicated by arrows from the wall,

ceiling, fence or other obstacles.

ı

Recommended installation height for indoor unit shall be

at least 2.5 m.

OUTDOOR UNIT

ı

If an awning is built over the unit to prevent direct

sunlight or rain, be careful that heat radiation from the

condenser is not obstructed.

There should not be any animal or plant which could be

affected by hot air discharged.

Keep the spaces indicated by arrows from wall, ceiling,

fence or other obstacles.

Do not place any obstacles which may cause a short

circuit of the discharged air.

If piping length is over the common length, additional

refrigerant should be added as shown in the table.

Model

PC12DK

PA12DKD

Piping size

Liquid

Gas

1/2"

1/2"

1/4"

1/4"

Drain elbow

(Only for PA12DKD)

5

Connecting Wire (Connector)

(Only for PA12DKD)

6

Max. Piping

Max.

Elevation

Length

(m)

5

5

(m)

7

7

Additional

Refrigerant

(g/m)

-

-

CS-PC12DKD/ CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Indoor /Outdo or Unit Installa tion Diagra m

1

Indoor/Outdoor Unit Installation Diagram

Length of power supply cord

About 1.1 m

<

<

About 1.8 m

<

Piping direction Attention not to

Right

Right Rear

<

Right Bottom

Left

Rear

(Front side)

Left Bottom

bend up drain hose

Left

1

Installation parts you

should purchase ( )

5cm

or more

(Left and right are identical)

Insulation of piping connections

Carry out insulation

after checking for

gas leaks and

secure with vinyl

tape.

Vinyl tape

10 ZZ

or

more

100 cm

more

or

ı

ıı

5cm

or more

m

10 c

more

or

or mo

30

cm

r

Installation plate

Sleeve ( )

e

Bushing Sleeve ( )

This illustration is for explanation purposes only.

The indoor unit will actually face a different way.

1

Putty (Gum type sealer) ( )

Bend the pipe as closely on

the wall as possible, but be

careful that it doesn't break.

Vinyl tape (Wide) ( )

Apply after carrying out a

drainage test.

To carry out the drainage

test, remove the air filters

and pour water into the heat

exchanger.

Saddle ( )

Connecting cable

(3-CORE WIRE/1.5mm2)

PC12DKD

(5-CORE WIRE/1.5mm

2

+2X0.5mm )Typedesignation 245 IEC 57

or heavier cord

PA12DKD

Additional drain hose ( )

1/4" Liquid side piping ( )

Gas side piping ( ) 1/2"

( )-

2

( )

33

Page 34

CS-PC12DKD/ CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

9.2. INDOOR UNIT

9.2.1. SELECT THE BEST LOCATION

(Refer to “Select the best location”

section)

9.2.2. HOW TO FIX INSTALLATION

PLATE

The mounting wall is strong and solid enough to prevent it from

the vibration.

Wall

224mm

More than 450 mm

2

Screw

150 mm

B

Installation

plate

Measuring tape

1

More than 450 mm

A

125 mm

Wall

219 mm

9.2.3. TO DRILL A HOLE IN THE WALL

AND INSTALL A SLEEVE OF

PIPING

1. Insert the piping sleeve to the hole.

2. Fix the bushing to the sleeve.

3. Cut the sleeve until it extrudes about 15 mm from the wall.

Caution

When the wall is hollow, please be sure to use the

sleeve for tube ass’y to prevent dangers caused by

mice biting the connecting cable.

4. Finish by sealing the sleeve with putty or caulking

compound at the final stage.

The centre of installation plate should be at more than 450 mm

at right and left of the wall.

The distance from installation plate edge to ceiling should more

than 67 mm.

From installation plate left edge to unit’s left side is 74 mm.

From installation plate right edge to unit’s right is 94 mm.

B

:

For left side piping, piping connection for gas should be

about 45 mm from this line.

:

For left side piping, piping connecting cable should be

about 800 mm from this line.

1. Mount the installation plate on the wall with 5 screws or

more.

(If mounting the unit on the concrete wall consider using

anchor bolts.)

Always mount the installation plate horizontally by

aligning the marking-off line with the thread and using a

level gauge.

2. Drill the piping plate hole with ø70 mm hole-core drill.

Line according to the arrows marked on the lower left

and right side of the installation plate. The meeting point

of the extended line is the centre of the hole. Another

method is by putting measuring tape at position as

shown in the diagram above. The hole centre is

obtained by measuring the distance namely 105 mm

and 145 mm for left and right hole respectively.

Drill the piping hole at either the right or the left and the

hole should be slightly slanted to the outdoor side.

9.2.4. INDOOR UNIT INSTALLATION

For the right rear piping

1.

For the right and right bottom piping

2.

34

Page 35

CS-PC12DKD/ CU-PC12DKD/ CS-PA12DKD / CU-PA12DKD

35

Page 36

CS-PC12DKD/ CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

9.2.5. CONNECT THE CABLE TO THE

INDOOR UNIT

1. The inside and outside connecting cable can be connected

without removing the front grille.

2. Connecting cable between indoor unit and outdoor unit

shall be approved polychloroprene sheathed

(PA12DKD

x 1.5 mm ,

x 1.5 mm

)

2

type

2

flexible cord,

3 (PC12DKD)

designation 245 IEC 57 or heavier cord.

For PA12DKD, the attached wire 6 with two connectors

should be applied.

ııııˇ

Ensure the color of wires of outdoor unit and the

terminal Nos. are the same to the indoor’s respectively.

ı

Earth lead wire shall be longer than the other lead wires

ıı

as shown in the figure for the electrical safety in case of

the slipping out of the cord from the anchorage.

CS-PA12DKD

connector

CS-PC12DKD

Terminals on the indoor unit 1(L) 2(N)

Color of wires

Ter minals on the outdoor unit 1(L) 2(N)

(L) (N)

1 2 3 4

5

CS-PA12DKD

(L) (N)

ı

Secure the cable onto the control board with the holder

ıı

(clamper).

CS-PC12DKD

36

Page 37

HOW TO TAKE OUT FRONT GRILLE

Please follow the steps below to take out front grille if

necessary such as when servicing.

1. Set the vertical airflow direction louver to the horizontal

position.

2. Slide down the two caps on the front grille as shown in the

illustration at right, and then remove the two mounting

screws.

3. Pull the lower section of the front grille towards you to

remove the front grille.

When reinstalling the front grille, first set the vertical

airflow direction louvre to the horizontal position and

then carry out above steps 2 - 3 in the reverse order.

CS-PC12DKD/ CU-PC12DKD/ CS-PA12DKD / CU-PA12DKD

9.3. OUTDOOR UNIT

9.3.1. SELECT THE BEST LOCATION

(Refer to "Select the best location"

section)

9.3.2. INSTALL THE OUTDOOR UNIT

After selecting the best location, start installation according

to Indoor/Outdoor Unit Installation Diagram.

1. Fix the unit on concrete or rigid frame firmly and horizontally

by bolt nut. (ø10 mm).

2. When installing at roof, please consider strong wind and

earthquake. Please fasten the installation stand firmly with

bolt or nails.

A

B

C

D

Model

CU-PC12DKD

CU-PA12DKD

ABCD

570 103.9

Unit: mm

13.3 320

AUTO SWITCH OPERA TION

The below operations will be performed by pressing the

"AUTO" switch.

1. AUTO OPERATION MODE

The Auto operation will be activated immediately once the

Auto Switch is pressed.

2. TEST RUN OPERATION (FOR PUMP DOWN/SERVICING

PURPOSE)

The Test Run operation will be activated if the Auto Switch

is pressed continuously for more than 5 sec. to below 10

sec. A "pep" sound will occur at the fifth sec., in order to

identify the starting of Test Run operation

3. REMOTE CONTROLLER RECEIVING SOUND ON/OFF

The ON/OFF of Remote Controller receiving sound can be

changed over by pressing the "AUTO" Switch continuously

for 10 sec. and above. A "pep", "pep" sound will occur at the

tenth sec., in order to indicate the "ON/OFF" changed over

of remote control receiving sound.

9.3.3. CONNECTING THE PIPING

Connecting The Piping To Indoor Unit

Please make flare after inserting flare nut (locate at joint portion

of tube assembly) onto the copper pipe. (In case of using long

piping)

Connect the piping

Align the center of piping and sufficiently tighten the flare

nut with fingers.

Further tighten the flare nut with torque wrench in specified

torque as stated in the table.

Piping size (Torque)

Gas

1/2'' (55 N.m) 1/4'' (18 N.m)

Liquid

Connecting The Piping To Outdoor Unit

Decide piping length and then cut by using pipe cutter. Remove

burrs from cut edge. Make flare after inserting the flare nut

(located at valve) onto the copper pipe.

Align center of piping to valves and then tighten with torque

wrench to the specified torque as stated in the table.

37

Page 38

CS-PC12DKD/ CU-PC12DKD/ CS-PA12DKD / CU-PA12DKD

CUTTING AND FLARING THE PIPING

1. Please cut using pipe cutter and then remove the burrs.

2. Remove the burrs by using reamer. If burrs is not

removed, gas leakage may be caused.

Turn the piping end down to avoid the metal powder

entering the pipe.

3. Please make flare after inserting the flare nut onto the

copper pipes.

9.3.4. (a) EVACUA TION OF THE EQUIPMENT (FOR EUROPE & OCEANIA DESTINATION)

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND PIPES in the

following procedure.

1. Connect a charging hose with a push pin to the Low side of a charging set and the service port of the 3-way valve.

Be sure to connect the end of the charging hose with the push pin to the service port.

2. Connect the center hose of the charging set to a vacuum pump with check valve, or vacuum pump and vacuum pump adaptor.

3. Turn on the power switch of the vacuum pump and make sure that the needle in the gauge moves from 0 cmHg (0 MPa) to

-76 cmHg (-0.1 MPa). Then evacuate the air approximately ten minutes.

4. Close the Low side valve of the charging set and turn off the vacuum pump. Make sure that the needle in the gauge does not

move after approximately five minutes.

Note: BE SURE TO FOLLOW THIS PROCEDURE IN ORDER TO AVOID REFRIGERANT GAS LEAKAGE.

5. Disconnect the charging hose from the vacuum pump and from the service port of the 3-way valve.

6. Tighten the service port caps of the 3-way valve at torque of 18 N.m with a torque wrench.

7. Remove the valve caps of both of the 2-way valve and 3-way valve. Position both of the valves to • OPENŽusing a hexagonal

wrench (4 mm).

8. Mount valve caps onto the 2-way valve and the 3-way valve.

Be sure to check for gas leakage.

CAUTION

If gauge needle does not move from 0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa), in step 3 above take the following measure:

If the leak stops when the piping connections are tightened further, continue working from step 3.

If the leak does not stop when the connections are retightened, repair the location of leak.

Do not release refrigerant during piping work for installation and reinstallation. Take care of the liquid refrigerant, it may cause

frostbite.

38

Page 39

CS-PC12DKD/ CU-PC12DKD/ CS-PA12DKD / CU-PA12DKD

9.3.5. (b) AIR PURGING OF THE PIPING AND INDOOR UNIT

The remaining air in the Refrigeration cycle which contains moisture may cause malfunction on the compressor.

1. Remove the caps from the 2-way and 3-way valves.

2. Remove the service-port cap from the 3-way valves.

3. To open the valve, turn the valve stem of 2-way valve counter-clockwise approx. 90° and hold it there for ten seconds, then

close it.

4. Check gas-leakage of the connecting portion of the pipings.

For the left pipings, refer to item 4(A).

5. To open 2-way valve again, turn the valve stem counter-clockwise until it stops.

4(A). Checking gas leakage for the left piping.

(1) **Connect the manifold gauge to the service port of 3-way

valve.

Measure the pressure.

(2) **Keep it for 5-10 minutes.

Ensure that the pressure indicated on the gauge is the

same as that of measured during the first time.

9.3.6. CONNECT THE CABLE TO THE OUTDOOR UNIT

1. Remove the control board cover from the unit by loosening the screw.

2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 3 (PC12DKD) or

5 (PA12DKD)

x 1.5 mm2flexible cord,

type designation 245 IEC 57 or heavier cord. For PA12DKD, the attached wire

6 should be applied.

CS-PC12DKD

Terminals on the indoor unit 1(L) 2(N)

Color of wires

Terminals on the outdoor unit 1(L) 2(N)

CS-PA12DKD

connector

3. Secure the cable onto the control board with the holder (clamper).

4. Attach the control board cover back to the original position with the screw.

9.3.7. PIPE INSULA TION

1. Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation Diagram. Please wrap

the insulated piping end to prevent water from going inside the piping.

2. If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by using POLY-E FOAM

with thickness 6 mm or above.

39

Page 40

CS-PC12DKD/ CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

DISPOSAL OF OUTDOOR UNIT DRAIN WATER

ı

If a drain elbow is used, the unit should be placed on a

ıı

stand which is taller than 3 cm.

ı

If the unit is used in an area where temperature falls below

0°C for 2 or 3 days in succession, it is recommended not to

use a drain elbow, for the drain water freezes and the fan

will not rotate.

Only for CU-PA12DKD:

CHECK THE DRAINAGE

ı

Open front panel and remove air filters.

(Drainage checking can be carried out without removing the

front grille.)

ı

Pour a glass of water into the drain tray-styrofoam.

ıı

ı

Ensure that water flows out from drain hose of the indoor

ıı

unit.

CHECK ITEMS

Is there any gas leakage at flare nut connections?

Has the heat insulation been carried out at flare nut

connection?

Is the connecting cable being fixed to terminal board firmly?

Is the connecting cable being clamped firmly?

Is the drainage OK?

(Refer to “Check the drainage” section)

Is the earth wire connection properly done?

Is the indoor unit properly hooked to the installation plate?

Is the power supply voltage complied with rated value?

Is there any abnormal sound?

Is the cooling operation normal?

Is the thermostat operation normal?

Is the remote control’s LCD operation normal?

Is the air purifying filter installed?

EVALU ATION OF THE PERFORMANCE

ı

Operate the unit for fifteen

minutes or more.

Measure the temperature of the intake and discharge air.

ı

Ensure the difference between the intake temperature and

the discharge is more than 8°C during cooling operation or

14°C during heating operation.

NOTE:

These equipment shall be connected to a suitable

mains network with a main impendance less than:

0.27ohm.

40

Page 41

10 2-way,3-way Valve

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

Works Shaft Position Shaft Position

Shipping Close Closed Closed

Air purging(Installation and Re-

installation)

Operation Open Open Closed

2-way Valve (Liquid Side)

(With valve cap)

Open Closed Open

(Counter-clockwise) (clockwise)

(Counter-clockwise)

(With valve cap)`

(With valve cap)`

3-way Valve (Gas Side)

Service Port

(With cap)

(Push-pin)

(With cap)

Pumping down

(Transferring)

Evacuation

(Servicing)

Charging

(Servicing)

Pressure check

(Servicing)

Gas releasing

(Servicing)

Closed Open Open

(Clockwise) (Counter-clockwise) (Connected manifold

Open

Open Open Open

Open Open (Connected manifold

Open Open

Open Open

(

gauge)

(With vacuum pump)

With charging cylinder)

Open

gauge)

Open

(Connected manifold

gauge)

41

Page 42

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

10.1. Evacuation of Installation

When installing an air conditioner, be sure to evacuate the air inside the indoor unit and pipes in the following procedure.

Required tools:

Hexagonal wrench, adjustable wrench, torque wrench,

wrench to hold the joints, gas leak detector, charging set

and vacuum pump.

The air in the indoor unit and in the piping must be purged.

If air remains in the refrigeration piping, it will affect the

compressor , reduce cooling capacity, and could lead to a

malfunction.

Vacuum Pump

(Indoor unit)

Open

Low

(Liquid side)

(Gas side)

High

Closed

2-way

valve

3-way

valve

(Outdoor unit)

Open

Open

Service port cap

Be sure, using a torque wrench to tighten the service port cap(after using the service port),so that it prevents the gas leakage

from the refrigeration cycle.

Procedure:

.

1 Connect a charging hose with a push pin to the Low

side of a charging set and the service port of the 3-way

valve.

Be sure to connect the end of the charging hose with the

push pin to the service port.

2.Connect the centre hose of the charging set to a

vacuum pump.

3.Turn on the power switch of the vacuum pump and

make sure that the needle in the gauge moves from 0

cmHg (0 Mpa) to -76 cmHg (-0.1 Mpa). Then evacuate

the air for approximately 10 minutes.

4.Close the valve of the Low side of the charging set

and turn off the vacuum pump. Make sure that the

needle in the gauge does not move after approximately

5 minutes.

BE SURE TO TAKE THIS PROCEDURE IN ORDER TO

AVOID GAS REFRIGERANT LEAKAGE.

6.Tighten the service port caps of both the 3-way valve

and the 2-way valve at a torque of18 N.m with a torque

wrench.

7.Remove the valve caps of both the 3-way and the 2-way

valves.

Position both of the valves to using a hexagonal

“open”

wrench (4 mm).

8.Mount valve caps onto both of the 3-way valve and the

2-way valve.

Be sure to check for gas leakage.

Caution

If gauge needle does not move from 0 cmHg(0 Mpa) to -76cmHg

(-0.1MPa) in step (3) above, take the following measures:

If the leaks stop when the piping connections are tightened

further, continue working from step (3).

If the leaks do not stop when the connections are retightened,

repair the location of the leak.

5.Disconnect the charging hose from the vacuum pump

and from the service port of the 3-way valve.

42

Page 43

10.2. Pumping down

(For Re-Installation)

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

(Indoor unit)

Closed

Low

High

(Liquid side)

(Gas side)

Closed

2-way

valve

3-way

valve

(Outdoor unit)

Closed

Open

Procedure

1.Confirm that both 2-way and 3-way valves are set to open

positions.

Remove the valve stem cap and confirm that the valve

stems are in the open position.

Be sure using a hexagonal wrench to operate the valve

stems.

2.Operate the unit for 10-15 minutes.

3.Stop operation and wait for 3 minutes, then connect the

charge set to the service port of the 3-way valve.

Connect the charge hose with the push pin to the

service port.

4.Air purging of the charge hose.

Open the low-pressure valve of the charge set slightly

to purge air from the charge hose.

5.Set the 2-way valve to the close position.

6. Operate the air conditioner at the cooling cycle and stop it

when the gauge indicates 2 G (0.1Mpa).

kg/cm

2

If the unit cannot be operated at the cooling mode

operation (weather is rather cold), short the Pumping

Down pins on the Main Control P.C.B.

7. Immediately set 3-way valve to the closed position.

Do this quickly so that the gauge ends up indicating

2

kg/cm G (0.1 to 0.3 Mpa).

1to3

8. Use refrigerant reclaiming equipment to collect refrigerant

from indoor unit and pipes.

9. Disconnect the charge set, and mount the 2-way and 3-way

valve stem s nuts and service port cap.

’

Use torque wrench to tighten the service port cap to a

torque 1.8kgf.m (18N.m).

Be sure to check for gas leakage.

10. Disconnect pipes from indoor unit and outdoor unit.

.

43

Page 44

CS-PC12DKD / CU-PC12DKD / CS-PA12DKD / CU-PA12DKD

10.3.Re-air Purging

(Re-installation)

Vacuum Pump

(Indoor unit)

Open

Low

(Liquid side)

(Gas side)

High

Closed

2-way

valve

3-way

valve

(Outdoor unit)

Open

Open