Page 1

Order No. GMAC0504036C3

Room Air Conditioners

CS/CU-PA7DKD

CS/CU-PC7DKD

STD

MODE TEMP

OFF

CANCEL SET

FANSPEED

OFF/ON

ON

TIMER

AIRSWING

CS/CU-PA9DKD

CS/CU-PC9DKD

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-techical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

CONTENTS

1 Features 2

2 Functions 3

3 Product Specifications 6

4 Dimensions 14

5 Refrigeration Cycle Diagram 16

6 Block Diagram 17

7 Wiring Diagram 19

8 Operation Details 21

Installation

9

--------------------------------------------------------

------------------------------------------------------

------------------------------------------

-----------------------------------------------------

-----------------------------------

--------------------------------------------------

-------------------------------------------------

-----------------------------------------------

---------------------------------------------------

WARNING

Page Page

10 2-way,3-way Valve

11

Disassembly of The Parts

12 Troubleshooting Guide

13 Technical Data

14 Exploded View

15 Replacement Parts List

16 Exploded View

17 Replacement Parts List

18 Electronic Circuit Diagram

35

-----------------------------------------------------

--------------------------------------

----------------------------------------

--------------------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------------------

-----------------------------------------

--------------------------------------

49

56

59

61

64

65

66

67

68

C

R

R

Guangzhou Matsushita Air Conditioner Co., Ltd.

(GMAC) All rights reserved. Unauthorized copying

and distribution is violation of law.

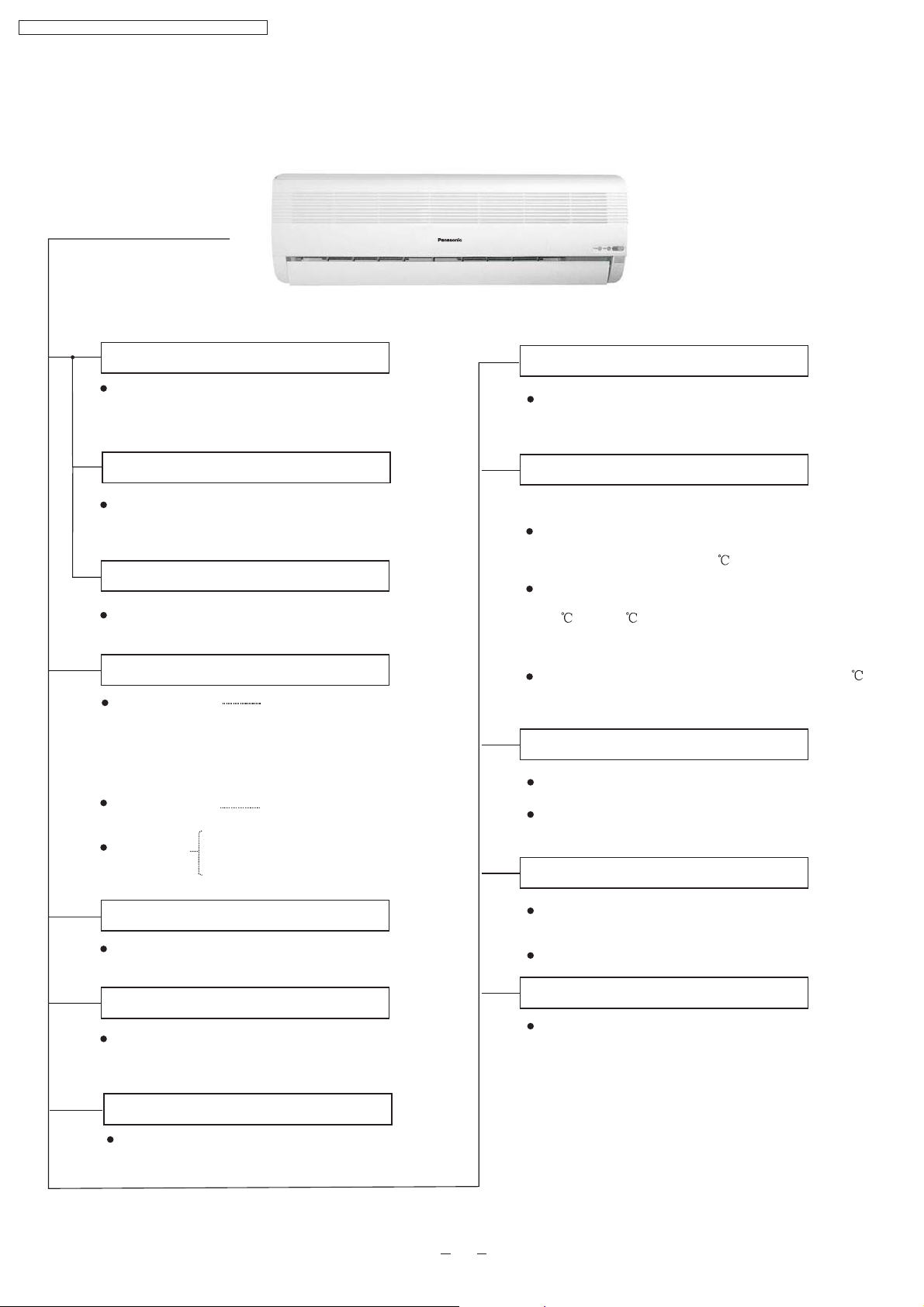

Page 2

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

1 Features

High Efficiency

Air Quality Indicator

Auto Restart Control

Automatically restart after power failure

Comfort Environment

Air filter with function to reduce dust and smoke

12-hour Timer Setting

2

Page 3

2 Functions

Remote Control

STD

MODE TEMP

OFF/ON

OFF

CANCEL SET

TIMER

FANSPEED

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

ON

AIR SWING

OFF/ON

MODE

FAN

SPEED

Operation START/STOP

Turn on/off the air conditionor

When stop the operation by pressing

OFF/ON button,the cursor key points

to OFF.

Operation Mode Selection

Automatic Operation

Heating Mode Operation

(For PA7DKD,PA9DKD)

Cooling Mode Operation

Soft Dry Mode Operation

Air Circulation Mode Operation

(For PC7DKD,PC9DKD)

Mode

Indoor Fan Speed Selection

Low Speed

Medium Speed

High Speed

Automatic Speed

Air

SWING

Airflow Direction Control

Horizontal Airflow Direction Control

-Auto Control

-Manual Control

Vertical Airflow Direction Manual Control

TEMP

Room Temperature Setting

Temperature Setting(16 to 30 )

Auto Operation

TIMER

OFF/ON

Timer Operation Selection

Stop/Start Operation Control

(set the ON/OFF Timer hourly later)

TIMER

SET/

CANCEL

Set /Cancel Timer Operation

Set timer/Cancel the set timer

By pressing SET button for 5seconds

continuously to switch to set the sensor

sensitivity.

3

Page 4

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Indoor Unit

Auto Switch

Button

Power Switch ON/OFF

National

Anti-freezing Control for the Evaporator

When the remote control cannot be used or

for repairing and testing ,please use this

button.

Demonstration Mode

Keep pressing this button for 15seconds to start

or end the Demonstration Mode.

Signal Receiving Sound Control

Keep pressing this button for 10seconds to turn

on or turn off the signal receiving sound.

Operation Indication Lamps

Power (green)

Timer(orange)

Air quality

Green

Orange

Red

Lights up in operation;

Blinks during Test

Run operation and

determining Auto

Operation mode

Timer in operation

Cooling or Soft Dry Operation

Warm Booting Control

(For PA7DKD, PA9DKD only)

Indoor fan starts running when temperature

of evaporator reaches 30 or above.

When temperature of evaporator is between

30 and 34 ,indoor fan will run at Super Low

or Low speed.

When temperature of evaporator reaches 34 ,

Warm Booting Operation ends.

Indoor Fan Speed Control

High,Med,Low

Auto Fan Speed

Airflow Direction Control

Operation Mode

Cooling/Heating/Soft Dry /Auto Operation

/ Air circulation

Time Delay Safety Control

The unit will restart operation in 3-4

minutes after each pause.

7-Minutes Time Save Control

7-minutes automatic restarting at Cooling

Operation

Automatic Airflow Direction Control

The louver automatically swings up and down

Airflow Direction Manual Control

Delayed On-timer Control

For cooling or soft dry mode, the unit

starts 15 minutes before the set time with

the remote control, but for heating mode

30 minutes before the set time.

4

Page 5

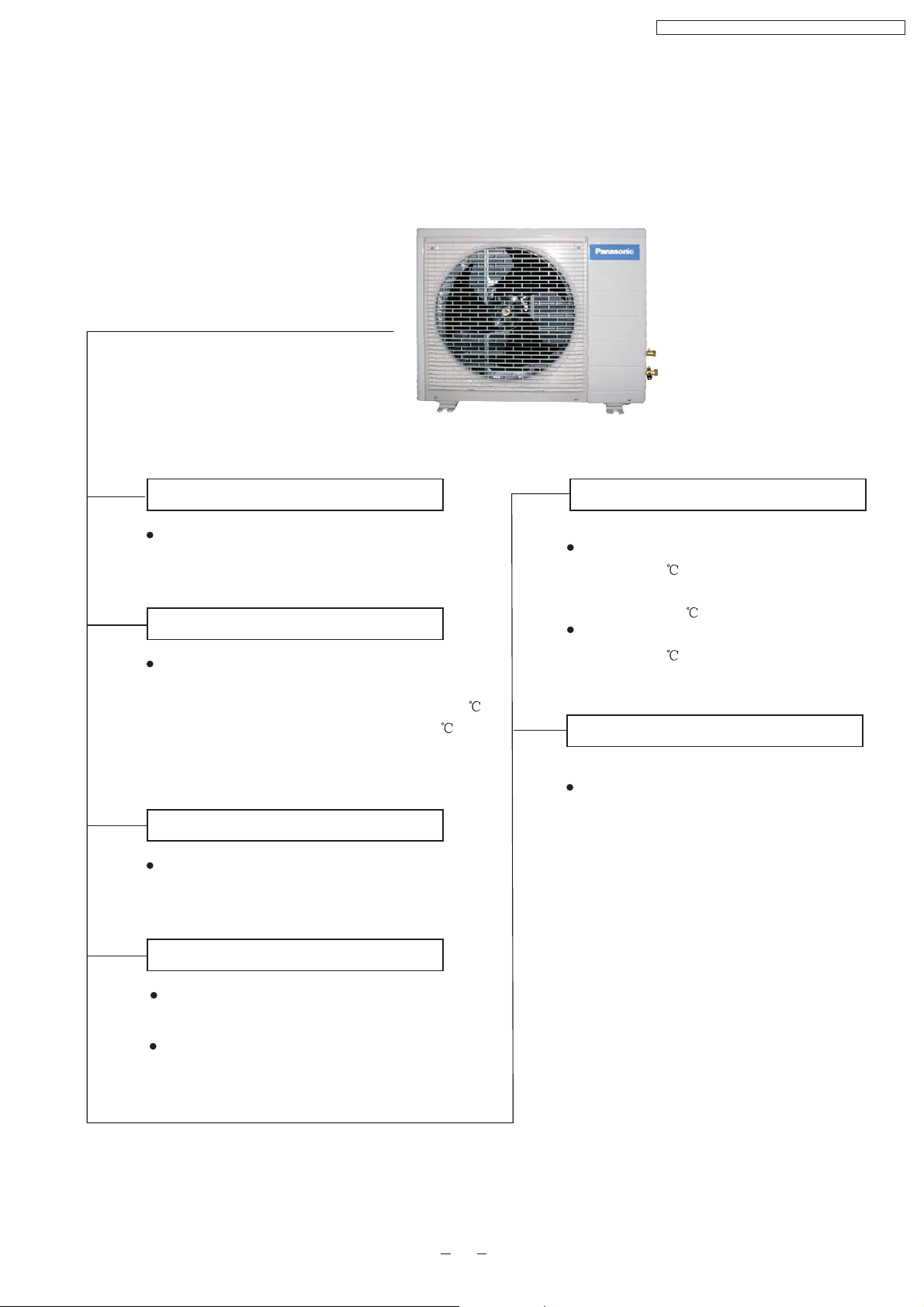

Outdoor Unit

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Panasonic

Anti-reverse Protection

To protect the compressor from reverse

rotation when power off suddenly.

Overload Protector

The 2-step Overload Protector is to protect

the compressor when

1)Temperature of compressor reaches 150

(PA7DKD,PC7DKD,PA9DKD) or

(PC9DKD)

2)High temperature or current enters into the

compressor

145

60-seconds Test Operation Control

Once the compressor is activated, it does not

stop for 60 seconds. It stops immediately with

remote control ON/OFF button.

Overload Protection Control

(For PA7DKD,PA9DKD only)

When the temperature of evaporator

reaches 51 ,outdoor fan stops,and will

restart when the temperature of evaporator

declines to 49 .

When the temperature of evaporator

reaches 65 ,compressor will stop.

4-way Valve Control

(Only for PA7DKD,PA9DKD)

If the unit is stopped during Heating

Operation,the 4-way valve will remain in

heating mode operation for 5 minutes.

Deicing Control

Anti-freezing operation for outdoor unit(during

Heating Mode Operation only)

Temperature of the condenser is tested by TRS.

(For PA7DKD,PA9DKD only)

5

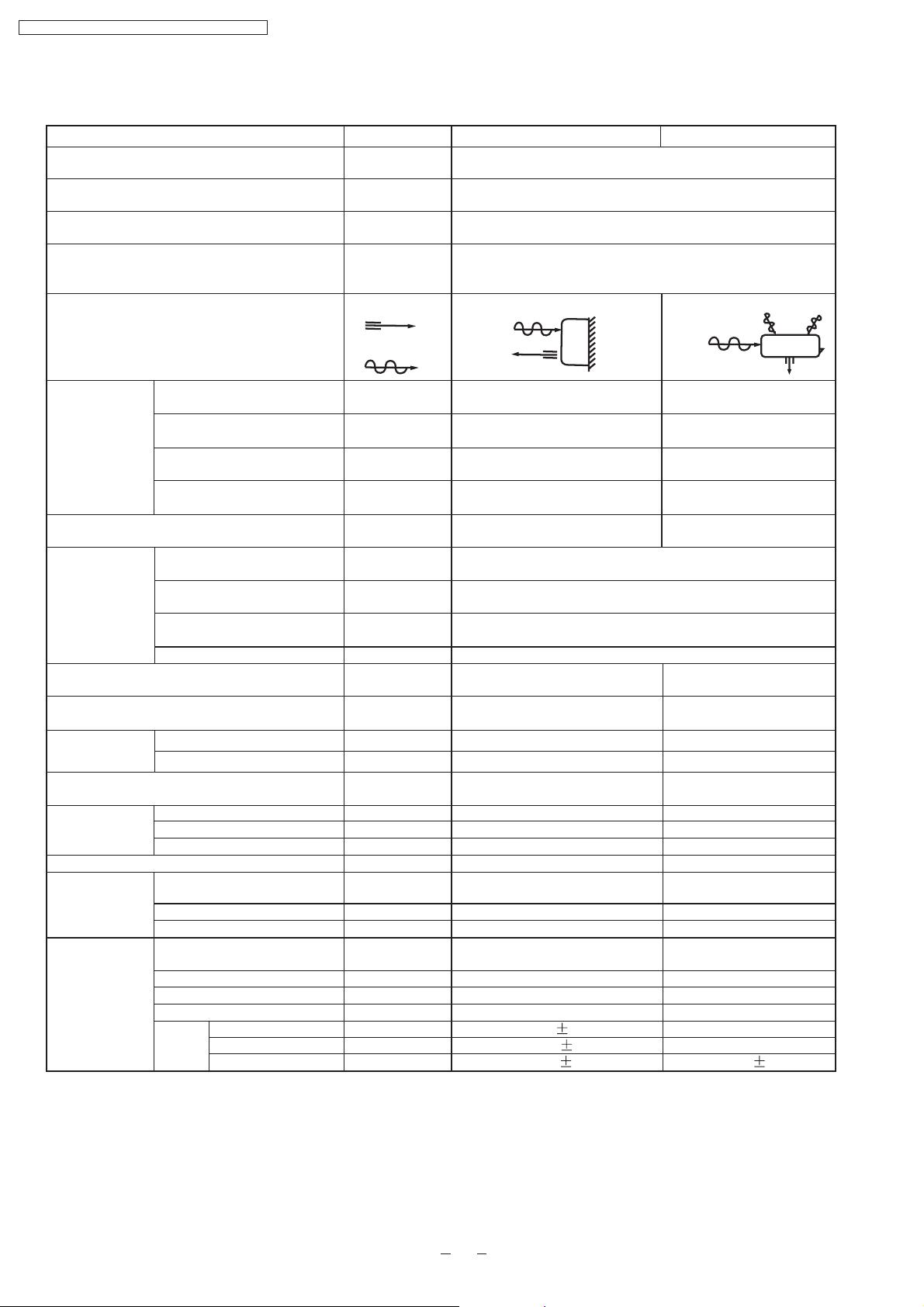

Page 6

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

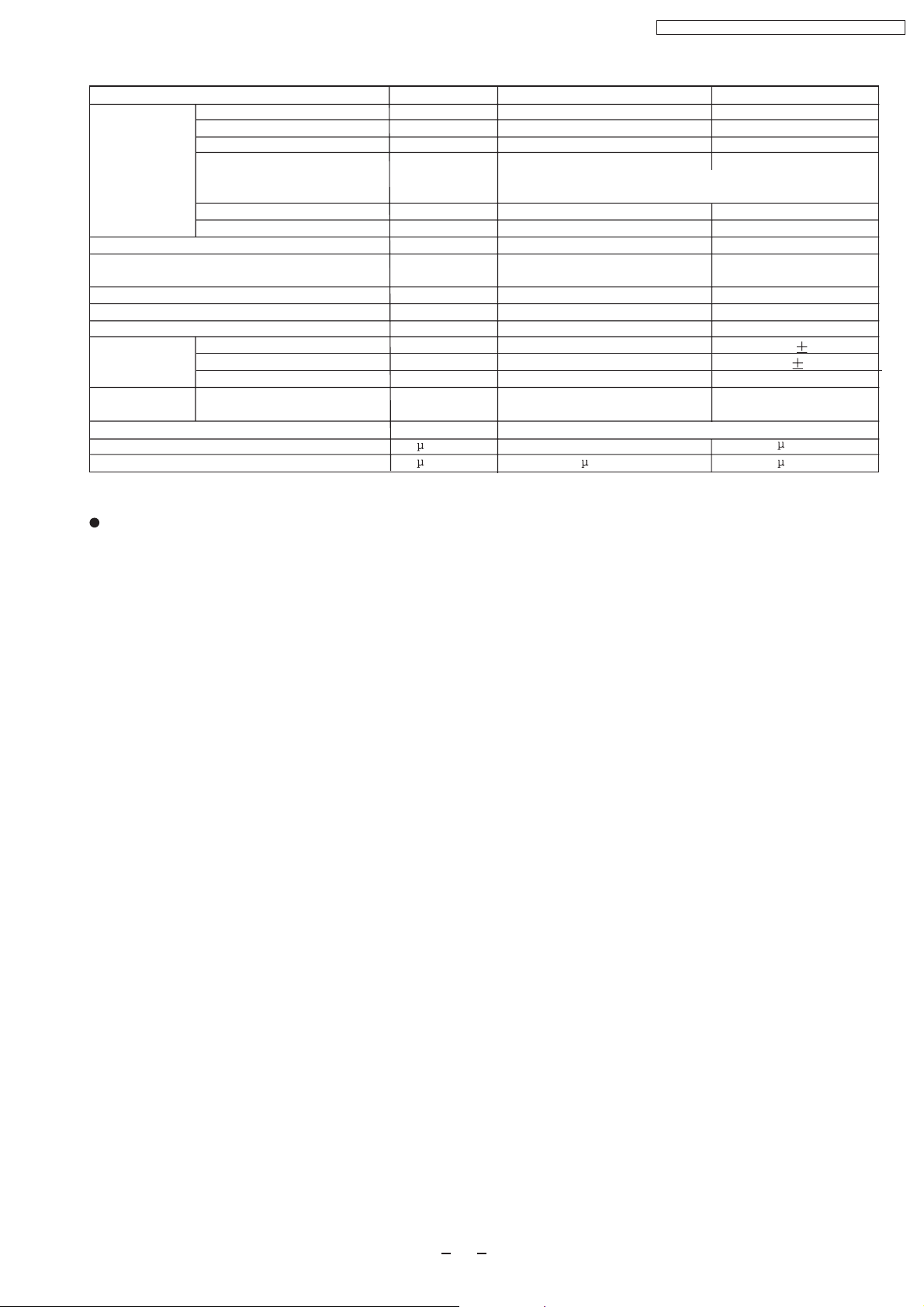

3 Product Specifications

Cooling Capacity

Heating Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Input

Data

Running Current

EER/COP

Starting Current

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Inner Diameter

Length

Power Supply Cord Length

(Number of core-wire)

Dimensions

Height

Width

Depth

Net Weight

Compressor

Type

Motor Type

Rated output

Air Circulation

type

Motor type

Input

Rated Output

Fan

Speed

Low

Med

High

Unit

kW

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

3

m /min

3

m /min

3

m /min

3

m /min

dB(A)

W

A

W/W

A

Inch

Inch

Inch

Inch

mm

m

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

CS-PA7DKD CU-PA7DKD

2.10

2.30

1.2

Single

220

50

SIDE VIEW

TOP VIEW

7.40

8.66

9.50

-

Cooling:high37,Low29

Heating:high37,Low29

Cooling:high47

Heating:high48

Cooling:695

Heating:620

Cooling:3.40

Heating:3.00

Cooling:3.02

Heating:3.71

18

G:half union3/8"

L:half union1/4"

G:gas side3/8"

L:liquid side1/4"

G:3-way valve3/8"

L:2-way valve1/4"

G:gas side3/8"

L:liquid side1/4"

14

0.5

3 core-wire/1.0mm

1.3

250

770

205

2

530

650

230

7.5

-

-

-

-

-

-

Cross-flow fan

Induction(4 pole)

Rotary(1 cylinder)

Rolling piston type

Induction(2 pole)

600

Propeller fan

Induction(6 pole)

-

13

880 60

1030 60

1130 50

800 60

-

-

-

-

-

-

-

-

23

-

28

-

-

6

Page 7

Heat

Exchanger

Description

Tube Material

Fin Type

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Unit CS-PA7DKD CU-PA7DKD

Evaporator

Copper

Slot type

Condenser

Copper

Corrugation type

Rows/Stage

(Plate fin configuration,forced draft)

2x12

FPI

Dimensions

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Length

Capillary

Circulation

Inner Diameter

Air Filter

mm

(c.c)

g

Electronic Control

mm

L/min

mm

P.P. Honeycomb

18

610x252x25.4

-

-

-

-

-

-

-

Refrigerant Circulation Control Device

Compressor Capacitor

Fan Motor Capacitor

F,V

F,V

1.5

-

F , 400V

* 60g for air purging is not included.

Specifications are subject to change without notice for further improvement.

1X24

17

269.1x504x18.19

Capillary Tube

SUNISO 4GDID or ATMOS

M60 or ATMOS 56M

530(*)

-

O.L.P.(230V,30A)

655 20

9.5 0.2

1.4

Capillary

20 370V

F,

F,2.0 400V

7

Page 8

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

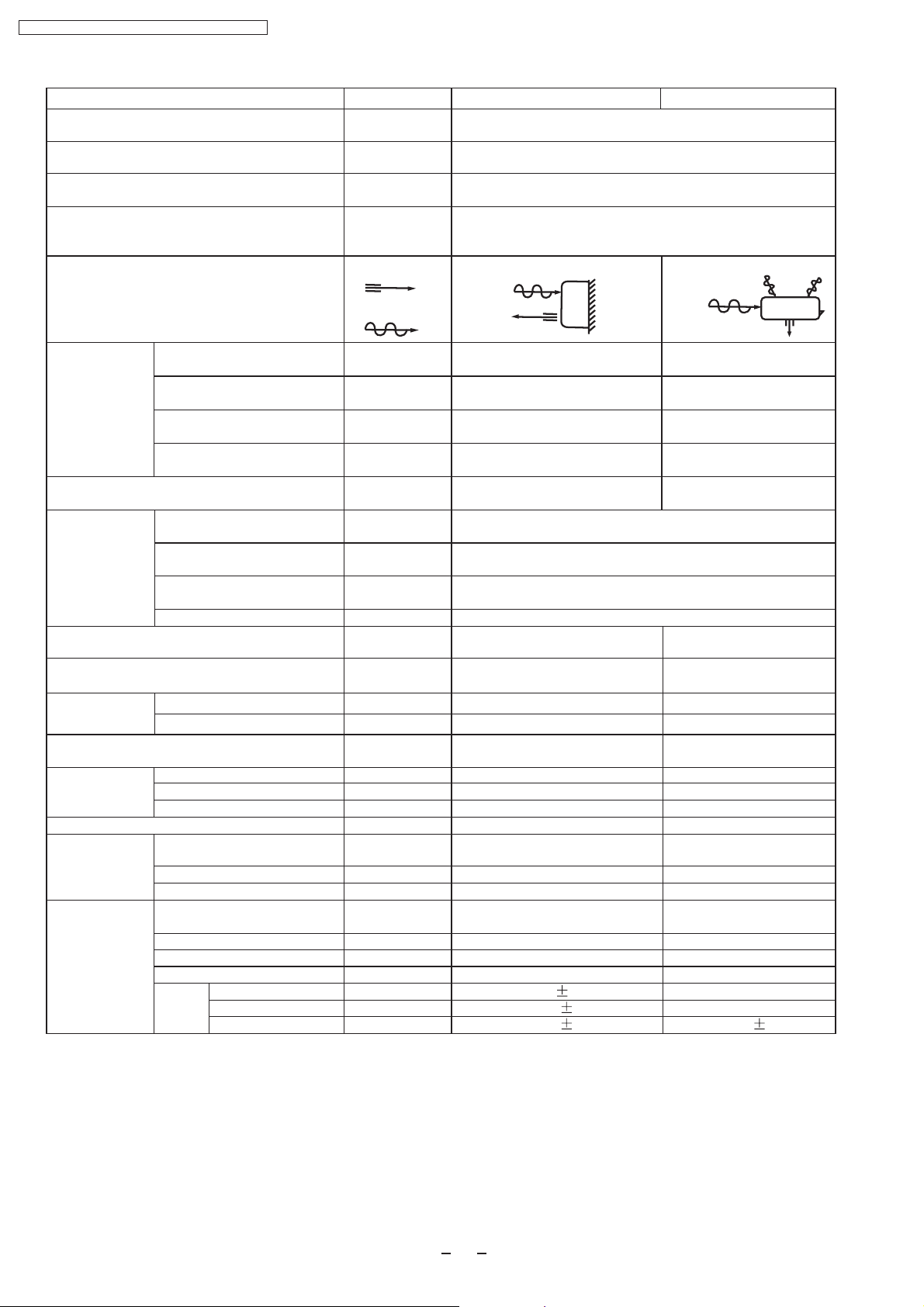

Cooling Capacity

Heating Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Input

Data

Running Current

EER/COP

Starting Current

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Inner Diameter

Length

Power Supply Cord Length

(Number of core-wire)

Dimensions

Height

Width

Depth

Net Weight

Compressor

Type

Motor Type

Rated output

Air Circulation

type

Motor type

Input

Rated Output

Fan

Speed

Low

Med

High

Unit

kW

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

3

m /min

3

m /min

3

m /min

3

m /min

dB(A)

W

A

W/W

A

Inch

Inch

Inch

Inch

mm

m

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

CS-PA9DKD CU-PA9DKD

2.60-2.65

3.00-3.05

1.40

Single

220/230

50

SIDE VIEW

TOP VIEW

7.72

8.54

10.10

-

Cooling:high38,Low29

Heating:high38,Low29

Cooling:high47

Heating:high48

Cooling:830-850

Heating:790-820

Cooling:3.90-3.80

Heating:3.65-3.65

Cooling:3.13-3.12

Heating:3.80-3.72

16

G:half union3/8"

L:half union1/4"

G:gas side3/8"

L:liquid side1/4"

G:3-way valve3/8"

L:2-way valve1/4"

G:gas side3/8"

L:liquid side1/4"

14

0.5

3 core-wire/1.0mm

1.3

250

770

205

2

530

650

230

7.5

-

-

-

-

-

-

Cross-flow fan

Induction(4 pole)

Rotary(1 cylinder)

Rolling piston type

Induction(2 pole)

700

Propeller fan

Induction(6 pole)

-

13

940 60

1090 60

1230 60

800 60

-

-

-

-

-

-

-

-

27

-

28

-

-

8

Page 9

Heat

Exchanger

Description

Tube Material

Fin Type

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Unit CS-PA9DKD CU-PA9DKD

Evaporator

Copper

Slot type

Condenser

Copper

Corrugation type

Rows/Stage

(Plate fin configuration,forced draft)

2x12

FPI

Dimensions

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Length

Capillary

Circulation

Inner Diameter

Air Filter

mm

(c.c)

g

Electronic Control

mm

L/min

mm

P.P. Honeycomb

18

610x252x25.4

-

-

-

-

-

-

-

Refrigerant Circulation Control Device

Compressor Capacitor

Fan Motor Capacitor

F,V

F,V

1.5

-

F , 400V

* 60g for air purging is not included.

Specifications are subject to change without notice for further improvement.

2X24

17

569.1

X504x36.38

540.5

Capillary Tube

SUNISO 4GDID or ATMOS

M60 or ATMOS 56M

860(*)

-

O.L.P.(230V,37A)

609 10

10.0 0.2

495 20

9.0 0.2

1.4

Capillary

F,30 370V

F,2.0 400V

1.3

9

Page 10

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

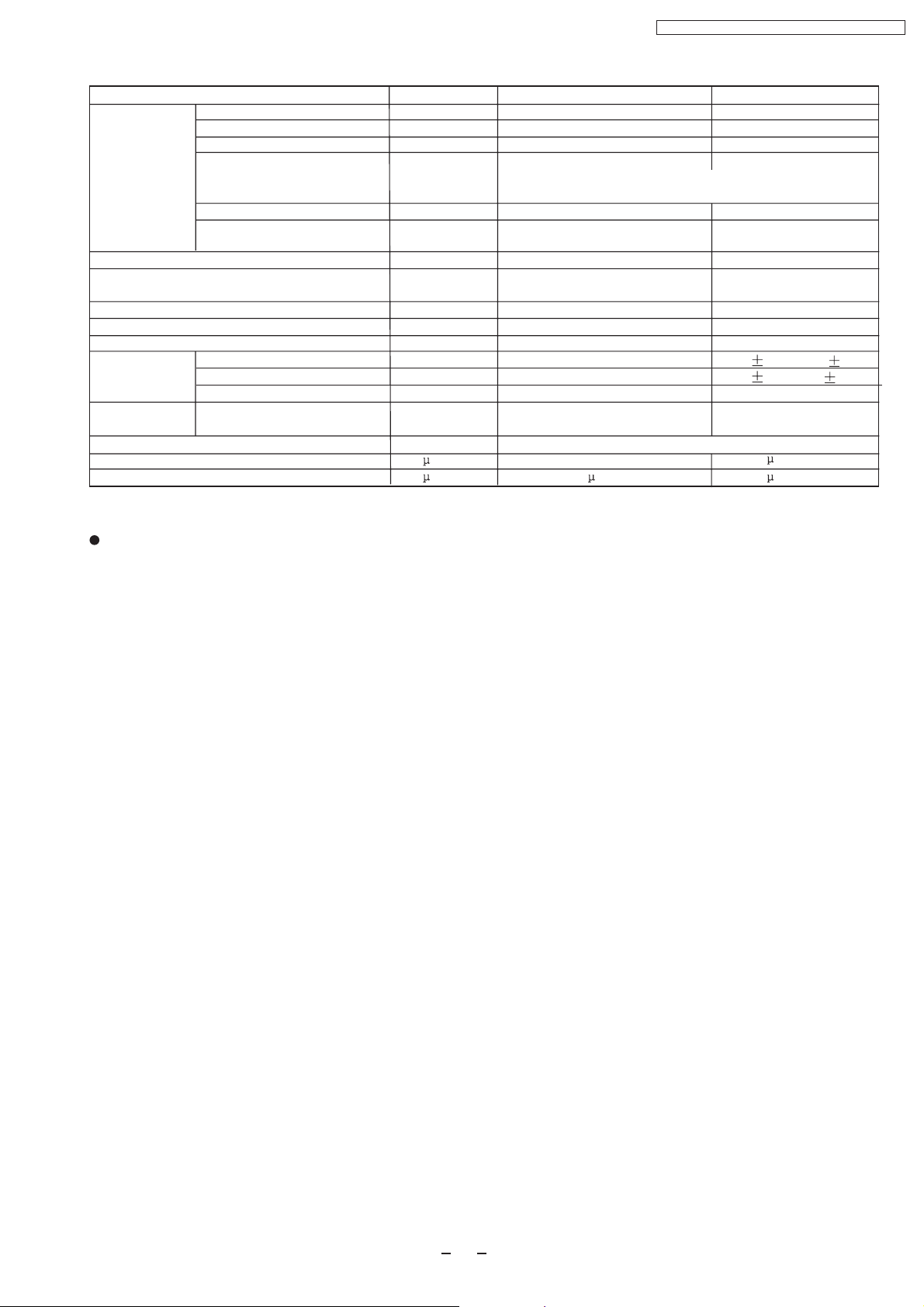

Cooling Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Input

Data

Running Current

EER

Starting Current

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Inner Diameter

Length

Power Supply Cord Length

(Number of core-wire)

Dimensions

Height

Width

Depth

Net Weight

Compressor

Type

Motor Type

Rated Output

Air Circulation

Type

Motor Type

Input

Rated Output

Fan

Speed

Low

Med

High

Unit

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

3

m /min

3

m /min

3

m /min

3

m /min

dB(A)

W

A

W/W

A

Inch

inch

Inch

inch

mm

m

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

CS-PC7DKD CU-PC7DKD

2.10

1.20

Single

220

50

SIDE VIEW

TOP VIEW

4.9

5.7

6.8

-

High36,Low28

High47

680

3.20

3.09

15

G:half union3/8"

L:half union1/4"

G:gas side3/8"

L:liquid side1/4"

G:3-way valve3/8"

L:2-way valve1/4"

G:gas side3/8"

L:liquid side1/4"

14

0.5

1.3

3 core-wire/1.0mm

250

770

205

2

530

650

230

7.5

-

-

-

-

-

-

Cross-flow fan

Induction(4 pole)

Rotary(1 cylinder)

Rolling piston type

Induction(2 pole)

660

Propeller fan

Induction(6pole)

-

13

810 60

940 60

1130 60

800 60

-

-

-

-

-

-

-

-

21

-

28

-

-

10

Page 11

Heat

Exchanger

Description

Tube Material

Fin Type

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Unit CS-PC7DKD CU-PC7DKD

Evaporator

copper

slot type

Condenser

copper

Corrugation type

Rows/Stage

(Plate fin configuration,forced draft)

2x8 1x24

FPI

Dimensions

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Length

Capillary

Circulation

Inner Diameter

Air Filter

mm

(c.c)

g

Electronic Control

mm

L/min

mm

P.P Honeycomb

18

610x168x25.4

-

-

-

-

-

-

-

Refrigerant Circulation Control Device

Compressor Capacitor

Fan Motor Capacitor

F, V

F, V

-

* 60g for air purging is not included.

Specifications are subject to change without notice for further improvement.

17

575.8x504x12.7

Capillary Tube

SUNISO 4GDID or

ATMOS M60(M56)

450(*)

O.L.P.(25A/230V)

810 10

7.0 0.2

1.3

-

Capillary

F,20 400V

F,2.0 400VF,1.5 400V

11

Page 12

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

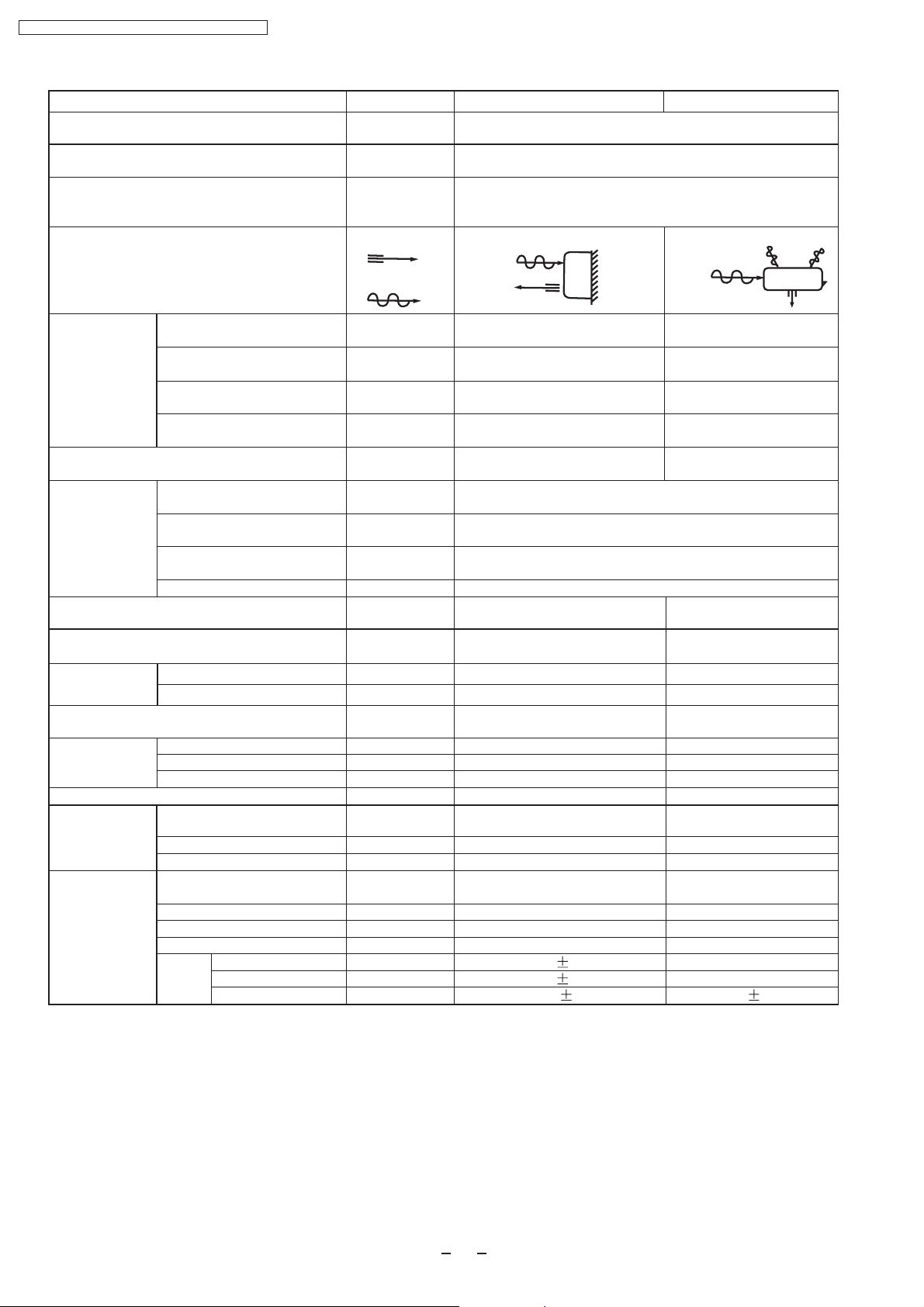

Cooling Capacity

Moisture Removal

Power Source

Airflow Method

Air Circulation

Indoor Air (low)

Indoor Air (medium)

Indoor Air (high)

Outdoor Air

Noise Level

Electrical

Input

Data

Running Current

Unit

kW

L/h

Phase

V

Cycle

OUTLET

INTAKE

3

m /min

3

m /min

3

m /min

3

m /min

dB(A)

W

A

CS-PC9DKD CU-PC9DKD

2.50

1.40

Single

220 / 230

50

SIDE VIEW

TOP VIEW

6.5

7.4

8.5

-

High30,Low28

High48

860

4.00

-

-

-

-

EER

Starting Current

Piping Connection Port(Flare piping)

Piping Size(Flare piping)

Drain Hose

Inner Diameter

Length

Power Supply Cord Length

(Number of core-wire)

Dimensions

Height

Width

Depth

Net Weight

Compressor

Type

Motor Type

Rated Output

Air Circulation

Type

Motor Type

Input

Rated Output

Fan

Speed

Low

Med

High

W/W

A

Inch

inch

Inch

inch

mm

m

m

mm

mm

mm

kg

W

W

W

rpm

rpm

rpm

G:half union3/8"

L:half union1/4"

G:gas side3/8"

L:liquid side1/4"

14

0.5

1.3

3 core-wire/1.0mm

250

770

205

7.5

-

-

-

-

-

-

Cross-flow fan

Induction(4 pole)

-

13

870 60

980 60

1130 60

2.91

20.0

2

G:3-way valve3/8"

L:2-way valve1/4"

G:gas side3/8"

L:liquid side1/4"

-

-

-

530

650

230

23

Rotary(1 cylinder)

Rolling piston type

Induction(2 pole)

750

Propeller fan

Induction(6pole)

-

28

-

-

800 60

12

Page 13

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Unit CS-PC9DKD CU-PC9DKD

Heat

Exchanger

Description

Tube Material

Fin Type

Rows/Stage

FPI

Dimensions

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Length

Capillary

Circulation

Inner Diameter

Air Filter

(Plate fin configuration,forced draft)

mm

(c.c)

g

mm

L/min

mm

Evaporator

copper

slot type

2x12

18

610x252x25.4

-

-

-

Electronic Control

-

-

-

-

P.P Honeycomb

Refrigerant Circulation Control Device

Compressor Capacitor

Fan Motor Capacitor

F, V

F, V

-

* 60g for air purging is not included.

Specifications are subject to change without notice for further improvement.

Condenser

copper

Corrugation type

1x24

17

575.8x504x12.7

Capillary Tube

SUNISO 4GDID or

ATMOS M60(M56)

430(*)

O.L.P.(30A/230V)

590 20

10.1 0.2

1.4

-

Capillary

F,25 370V

F,2.0 400VF,1.5 400V

13

Page 14

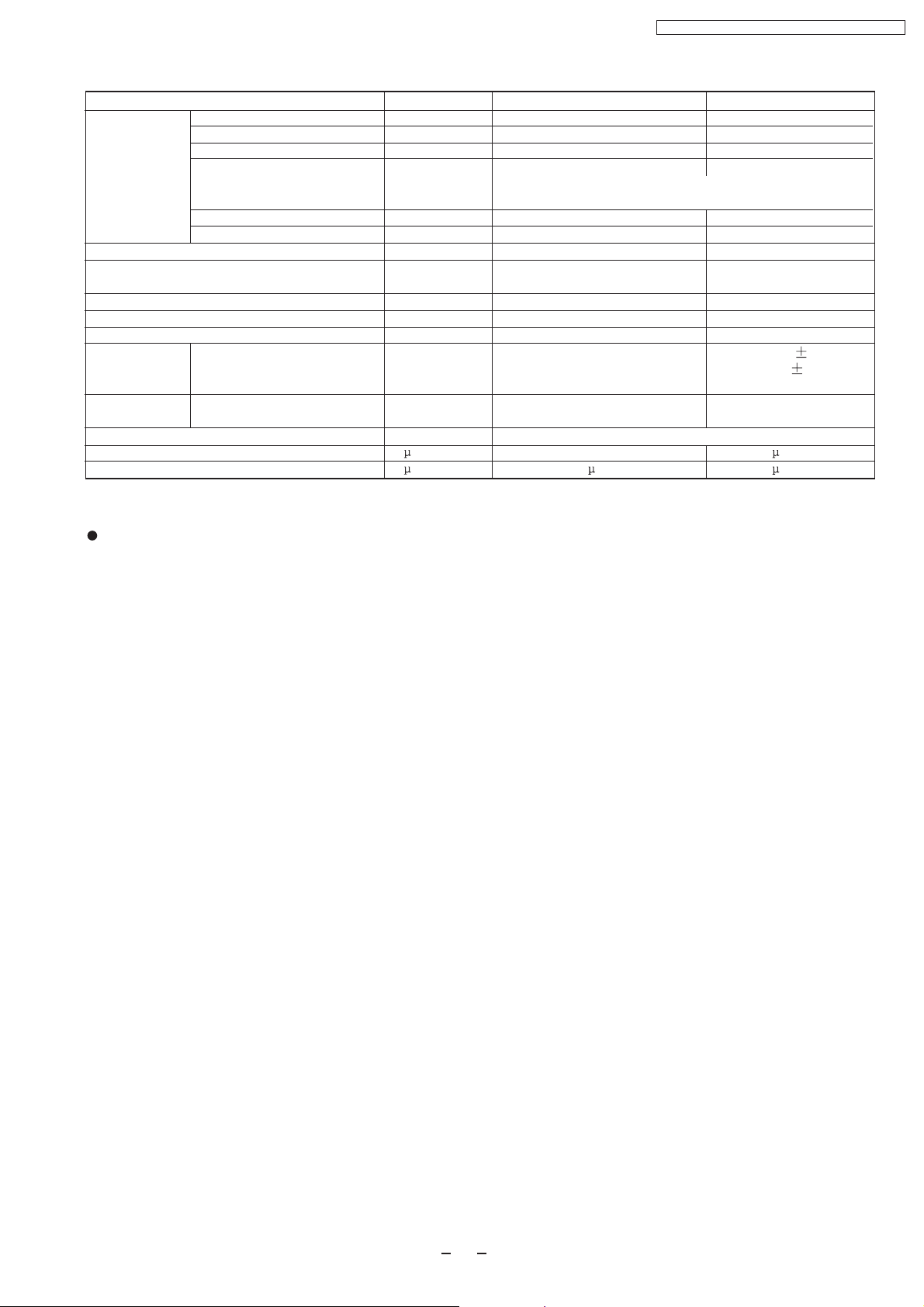

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

4 Dimensions

Indoor Unit

Unit : mm

Side view

Left Piping

Hole

Air intake

Air outlet

Front View

250

<Back View>

770

Installation Plate Hook

61

Gas Side

165

Liquid

Side

49

205

49

CANCEL

FANSPEED

Right Piping

Hole

61

5

STD

TEMP

MODE

OFF/ON

ON

OFF

TIMER

AIRSWING

125

SET

(79)

(410)

(43)

Drain Port

Relative position between the unit and the installation plate (Front View)

229

118.8

15.5

20

6

26.5

E

B

C

D

B

(382)

(452)

(680)

15.5

20

6

26.5

109.2

D

B

144.2

56

16.5

14

Page 15

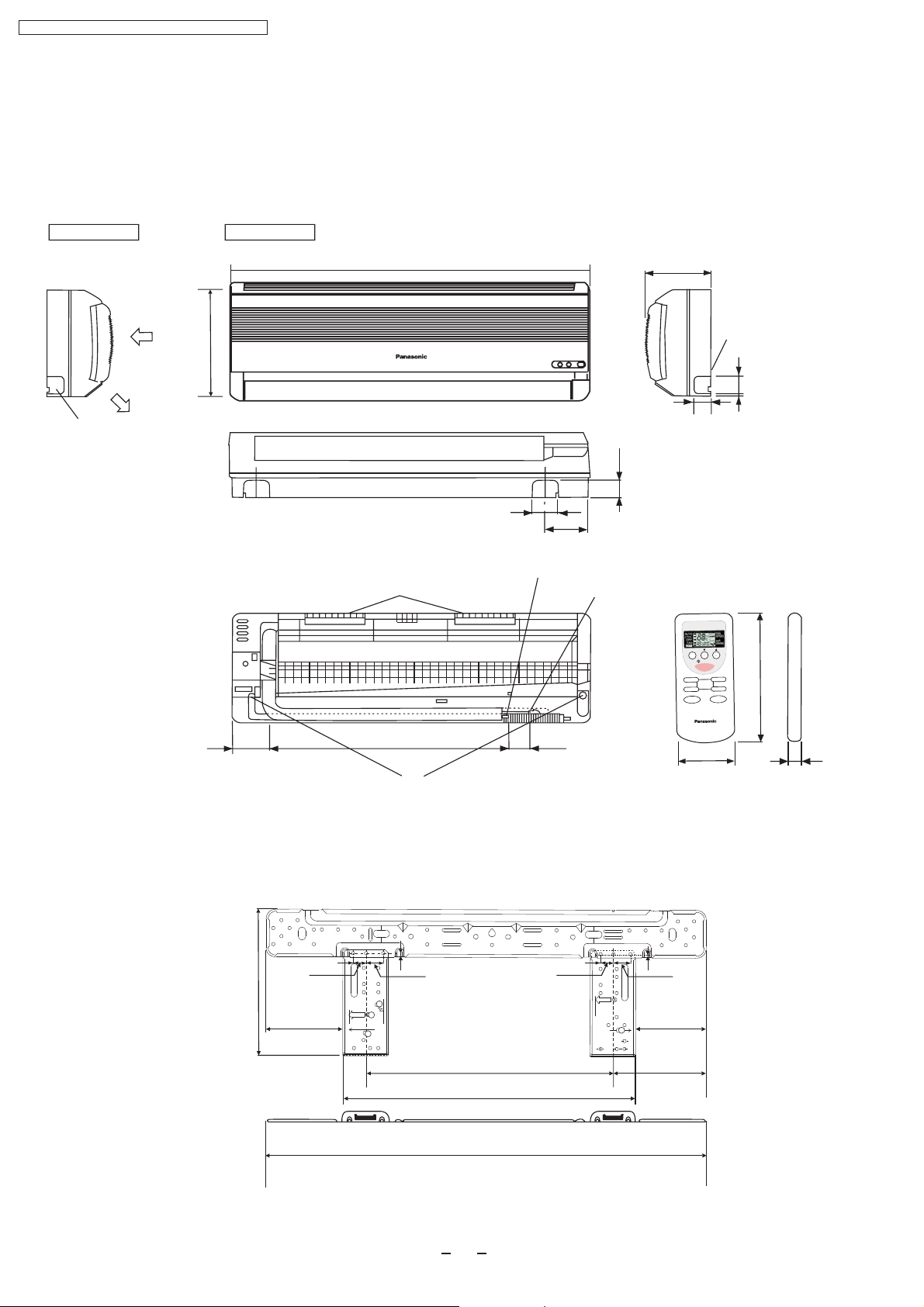

Outdoor Unit

CU-PA7DKD

CU-PA9DKD

CU-PC7DKD

CU-PC9DKD

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Unit : mm

<Top View>

Required space for installation

10cm

10cm

100cm

<Front View>

668

650

Air intake

Air outlet

<Side View>

61.6

250

230

88 88

650

15

61.6

62.2

123.8

530

55.8

293

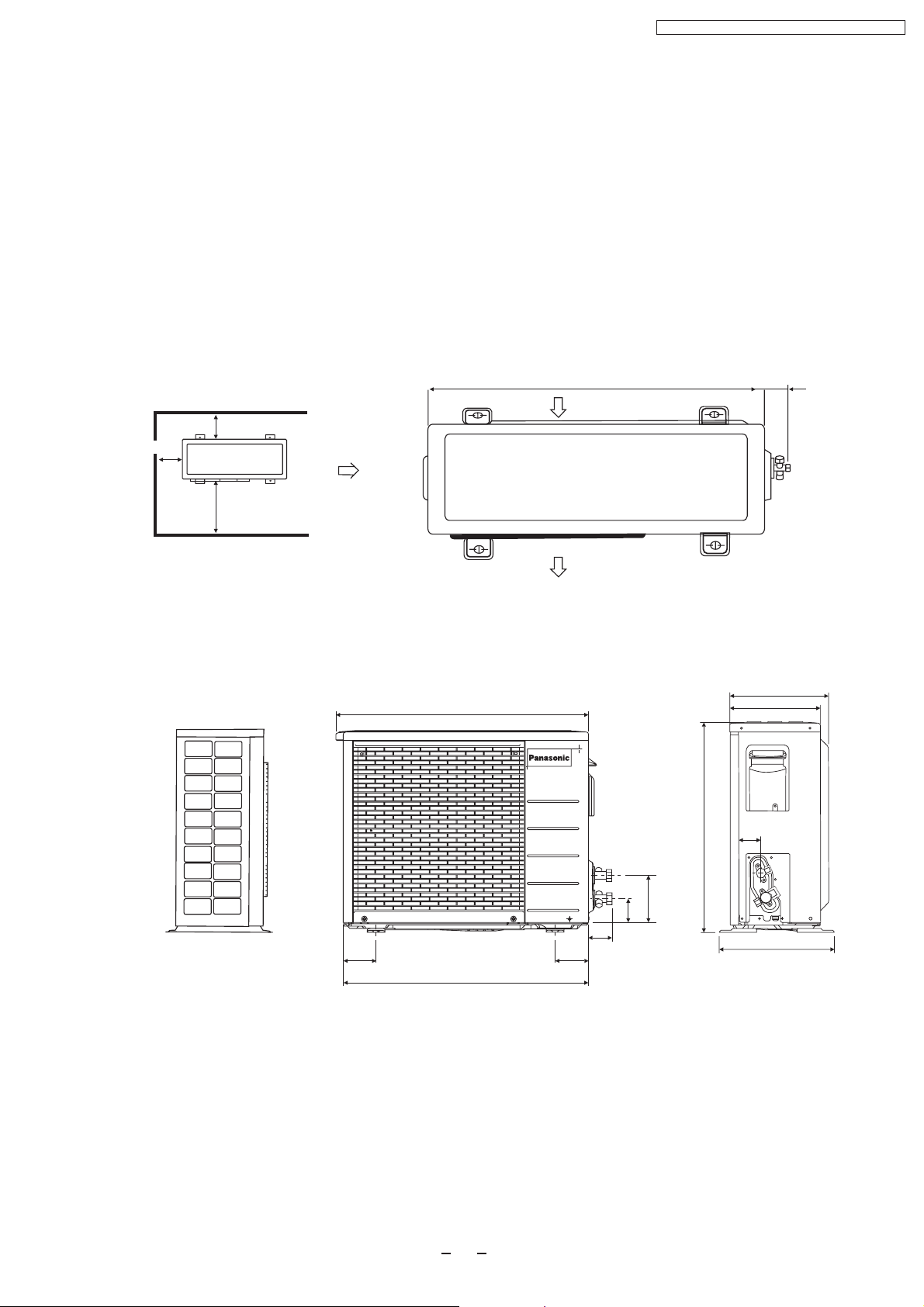

Page 16

INTAKE AIR

SENSOR

PIPING

SENSOR

PIPING

SENSOR

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

5 Refrigeration Cycle Diagram

CS/CU-PA7DKD

CS/CU-PA9DKD

AIR QUALITY

SENSOR

INTAKE AIR

SENSOR

PIPING

SENSOR

PIPING

SENSOR

4-way valve

Cooling

Heating

CS/CU-PC7DKD

CS/CU-PC9DKD

INTAKE AIR

AIR QUALITY

SENSOR

SENSOR

PIPING

SENSOR

PIPING

SENSOR

16

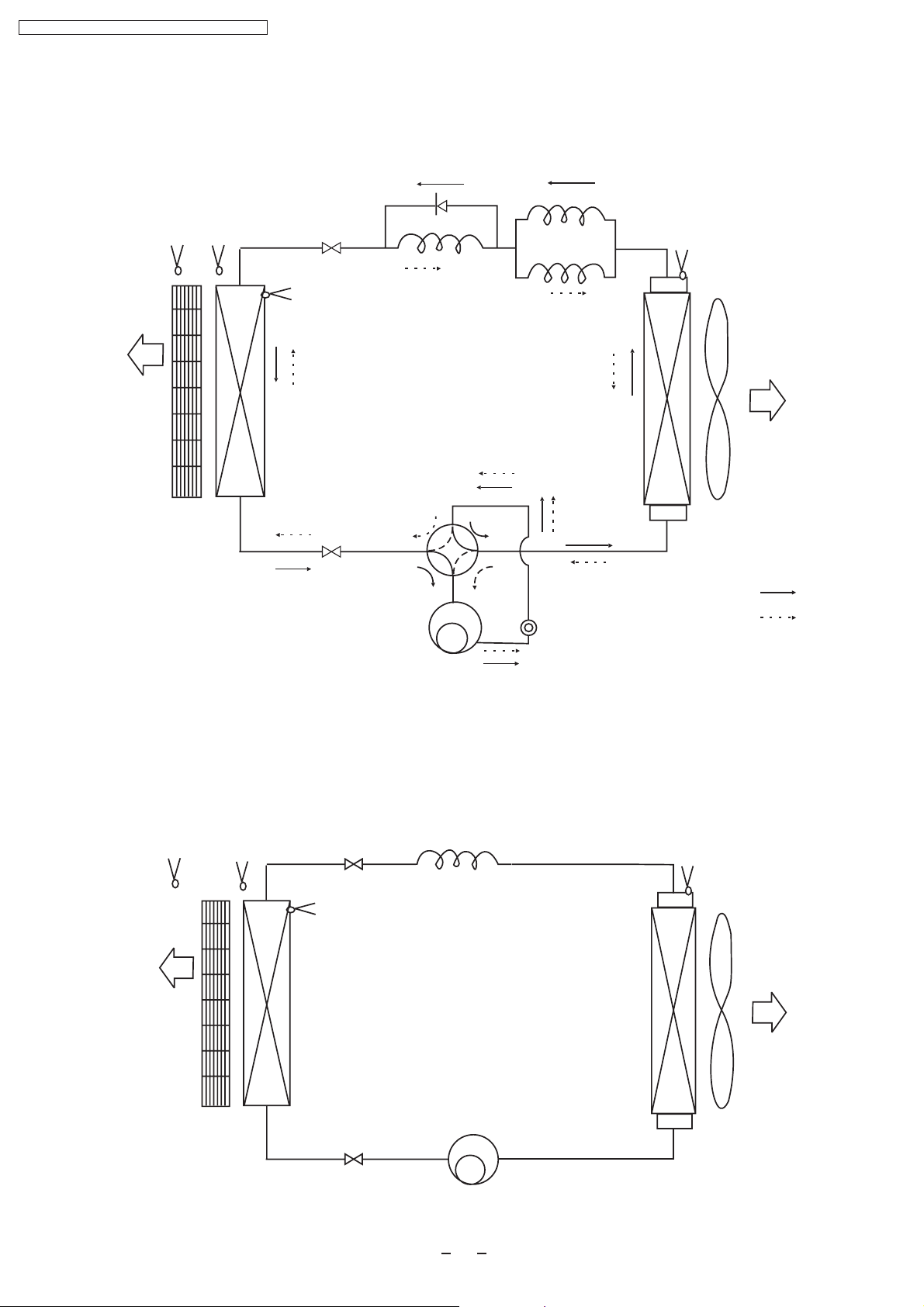

Page 17

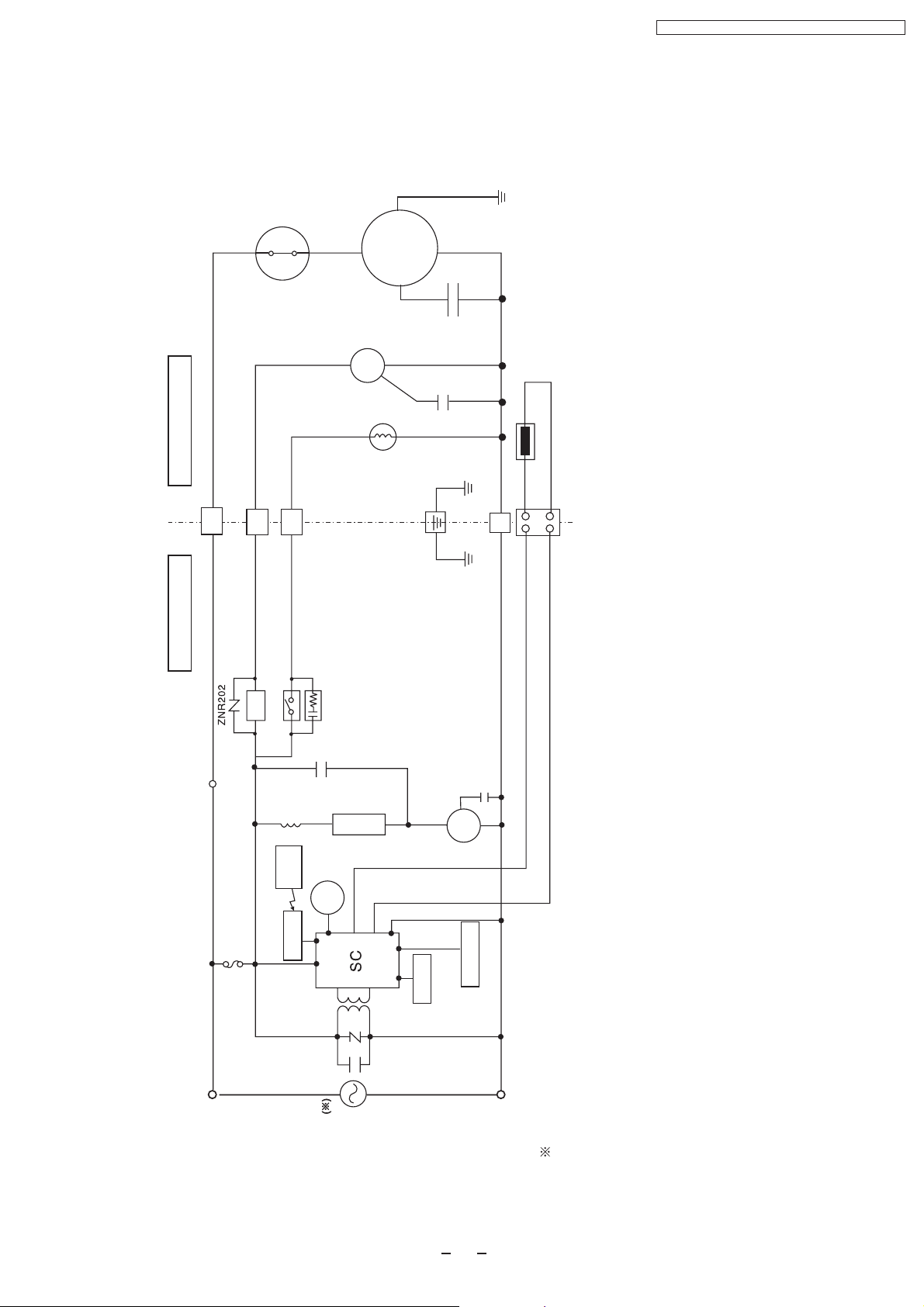

6 Block Diagram

CS-PA7DKD/CU-PA7DKD

CS-PA9DKD/CU-PA9DKD

O.L.P.

FM

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Compressor

OUTDOOR UNIT

INDOOR UNIT

4-Valve

4

SSR202

RY-HOT

Remote

3

CR201

SSR201

FM

Control

1

RY-PWR

Piping Sensor

2

FM

FUSE

Receiver

POWER SUPPLY

Indicator

Sensor

For PA7DKD, the power source is 220V.

For PA9DKD, the power source is 220V-230V .

AC220V-230V 50Hz

17

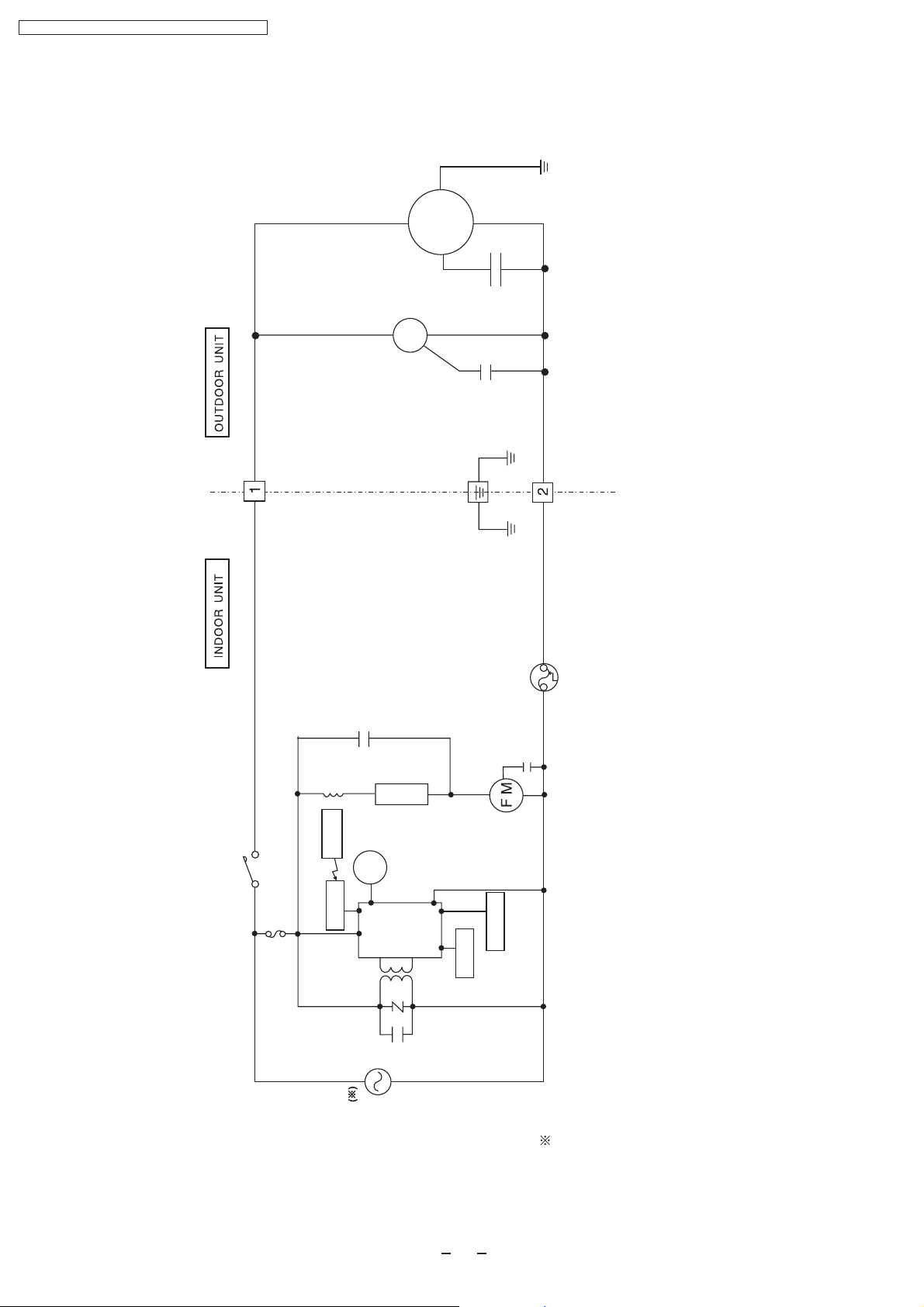

Page 18

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

CS-PC7DKD/CU-PC7DKD

CS-PC9DKD/CU-PC9DKD

Compressor

FM

RY-PWR

FUSE

Remote

Control

Receiver

POWER SUPPLY

FM

AC220V-230V 50Hz

SC

SSR201

Indicator

Sensor

For PC7DKD, the power source is 220V.

For PC9DKD, the power source is 220V-230V .

18

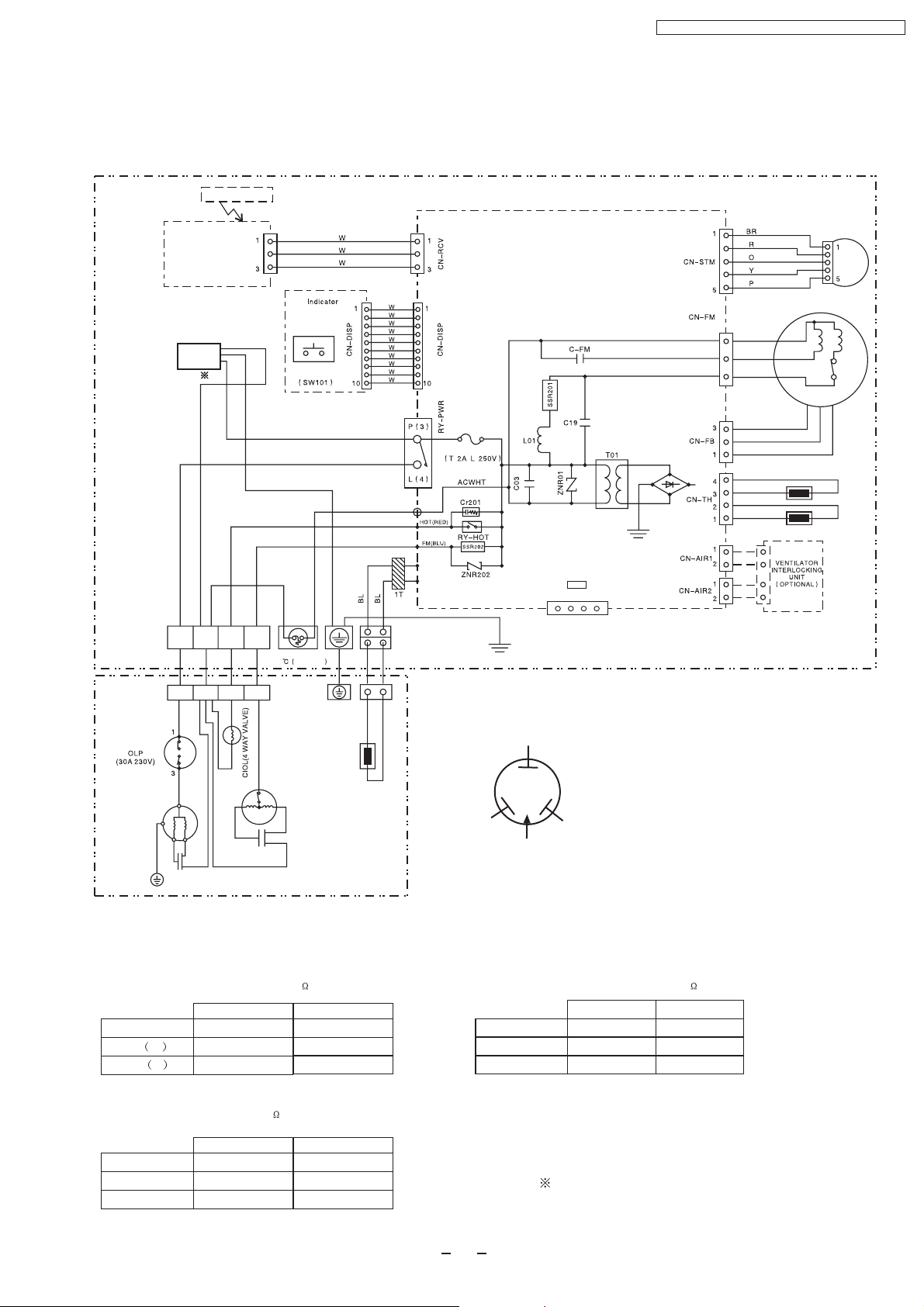

Page 19

POWER SUPPLY

CORD

AC 220V-230 50Hz( )

7 Wiring Diagram

CS-PA7DKD/CU-PA7DKD

CS-PA9DKD/CU-PA9DKD

Remote Control

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

POWER SUPPLY

AC 220V-230 50Hz( )

INDOOR UNIT

TERMINAL BOARD

Signal Receiver

CORD

B

1(L) 2(N) 3 4

CN-RCV

Y/G

102 250V 3A

AUTO SWITCH

BR

BL

FUSE

ELECTRONIC CONTROLLER

STEPPING

MOTOR

1

B

3

R

5

Y

FAN MOTOR

W

FUSE

W

R

B

HA

1234

Y/G

BR

BL

SENSOR(PIPING TEMP.)

SENSOR(INTAKETEMP.)

INDOOR UNIT

OUTDOOR UNIT

TERMINAL BOARD

COMPRESSOR

1(L) 2(N) 3 4

YW

Y

Y/G

R

CAPACITOR

Y

FAN MOTOR

R

B

B

CAPACITOR

B

OUTDOOR UNIT

INDOOR FAN MOTOR RESISTANCE( )

CS-PA7DKD CS-PA9DKD

CONNECTING

Y-B M

Y-R A

COMPRESSOR RESISTANCE( )

CWA921308 CWA921329

395

325

390

390

R : RED

BL : BLACK

YELLOW

C

B : BLUE

BR : BROWN

O : ORANGE

SENSOR(PIPING TEMP.)

R

BLUE

TRADE MARK

S

RED

COMPRESSOR TERMINAL

OUTDOOR FAN MOTOR RESISTANCE( )

GRY : GREY

G : GREEN

Y : YELLOW

W : WHITE

Y/G : YELLOW/GREEN

P : PINK

CU-PA7DKD CU-PA9DKD

CONNECTING

Y-B

Y-R

CWA951419 CWA951419

275

260

275

260

CONNECTING

C-R

C-S

CU-PA7DKD CU-PA9DKD

CWB092128

3.678

7.240

CWB092312

3.466

3.843

For PA7DKD, the power source is 220V.

For PA9DKD, the power source is 220V-230V .

19

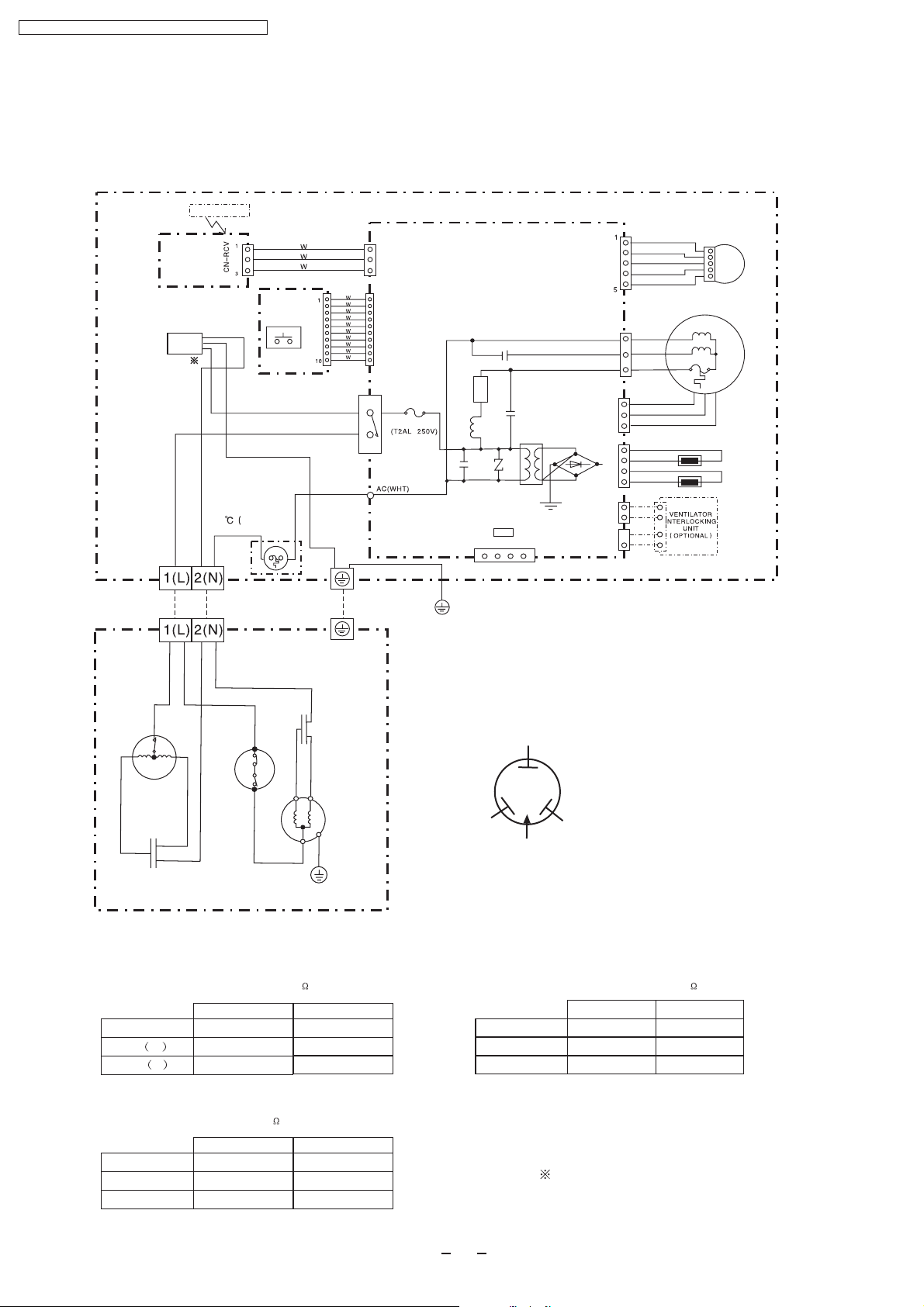

Page 20

POWER SUPPLY

CORD

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

AC 220V-230 50Hz( )

CS-PC7DKD/CU-PC7DKD

CS-PC9DKD/CU-PC9DKD

REMOTE CONTROL

SIGNALRECEIVER

POWER SUPPLY

CORD

AC 220V-230 50Hz( )

INDOOR UNIT

TERMINAL BOARD

OUTDOOR UNIT

TERMINAL BOARD

Y

FAN MOTOR

R

B

CAPACITOR

B

FUSE

102 250V 3A)

OUTDOOR UNIT

B

Y

O.L.P

INDICATOR

CN-DISP

AUTO SWITCH

(SW 01)

BR

BL

Y/G

W

B

Capacitor

1

R

B

3

Y

COMPRESSOR

Y/G

OUTDOOR UNIT

ELECTRONIC CONTROLLER

1

CN-RCV

3

1

P(3)

L(4)

CN-DISP

10

RY-PWR

FUSE

Y/G

L01

C03

C-FM

SSR01

C19

ZNR01

HA

1234

YELLOW

R

BLUE

TRADE MARK

T01

COMPRESSOR TERMINAL

BR

R

CN-FM

CN-STM

1

3

5

3

CN-FB

1

4

3

2

1

1

CN-AIR1 CN-TH

2

1

2

CN-AIR2

O

Y

P

B

R

Y

W

BR

BL

SENSOR(PIPING TEMP.)

SENSOR(INTAKETEMP.)

FAN MOTOR

STEPPING

MOTOR

INDOOR UNIT

R : RED

BL : BLACK

B : BLUE

C

S

RED

BR : BROWN

O : ORANGE

GRY : GREY

G : GREEN

Y : YELLOW

W : WHITE

Y/G : YELLOW/GREEN

P : PINK

INDOOR FAN MOTOR RESISTANCE( )

CS-PC7DKD CS-PC9DKD

CONNECTING

Y-B M

Y-R A

COMPRESSOR RESISTANCE( )

CWA921308

395

325

CU-PC7DKD CU-PC9DKD

CONNECTING

C-R

C-S

CWB092129

4.307

7.668

CWA921329

390

390

CWB092279

3.072

5.216

OUTDOOR FAN MOTOR RESISTANCE( )

CU-PC7DKD CU-PC9DKD

CONNECTING

Y-B

Y-R

CWA951427

275

260

For PC7DKD, the power source is 220V.

For PC9DKD, the power source is 220V-230V .

20

CWA951427

275

260

Page 21

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

8 Operation Details

8.1 .Cooling Mode Operation

When selecting the Cooling Mode Operation, the unit will operate according to the setting by the Remote Controller or

the control panel on the indoor unit and the operation is as the following.

Time Delay Safety Control

3 min.----If the compressor stops, it will not restart within 3 minutes.(Protection of compressor).

7 Minutes Time Save Control

7 min.----The unit will automatically operate in 7 minutes even if the room temperature is not reached.

(Prevention of raising the humidity)

Anti-Freezing Control

If temperature of evaporator is lower than 2 continuously

Evaporator

Temperature

()

for 4 minutes, the compressor will cease to prevent the

evaporator from freezing. Fan speed setting will not be

changed.

When temperature of evaporator reaches 10 ,compressor

will restart.

During Cooling Mode Operation, the Time Delay Safety

Control is available.

Time

Automatic Fan Speed Mode

During Cooling Mode Operation, use remote controller to select Automatic Fan Speed.

Fan speed will be at the point between "High speed" and "Medium speed".

Deodorization control.

1

Indoor Fan

STOP

Slow

Slow

STOP STOP

Slow Slow

10

4 minutes

2

Compressor ceases

2

Restart

40 30 40 3020 160

Compressor

ON

STOP

1 Fan speed will be at Hi till the compressor ceases (set temperature reached).

2 Fan speed will be at Me when the compressor restarts.

21

ON

Page 22

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

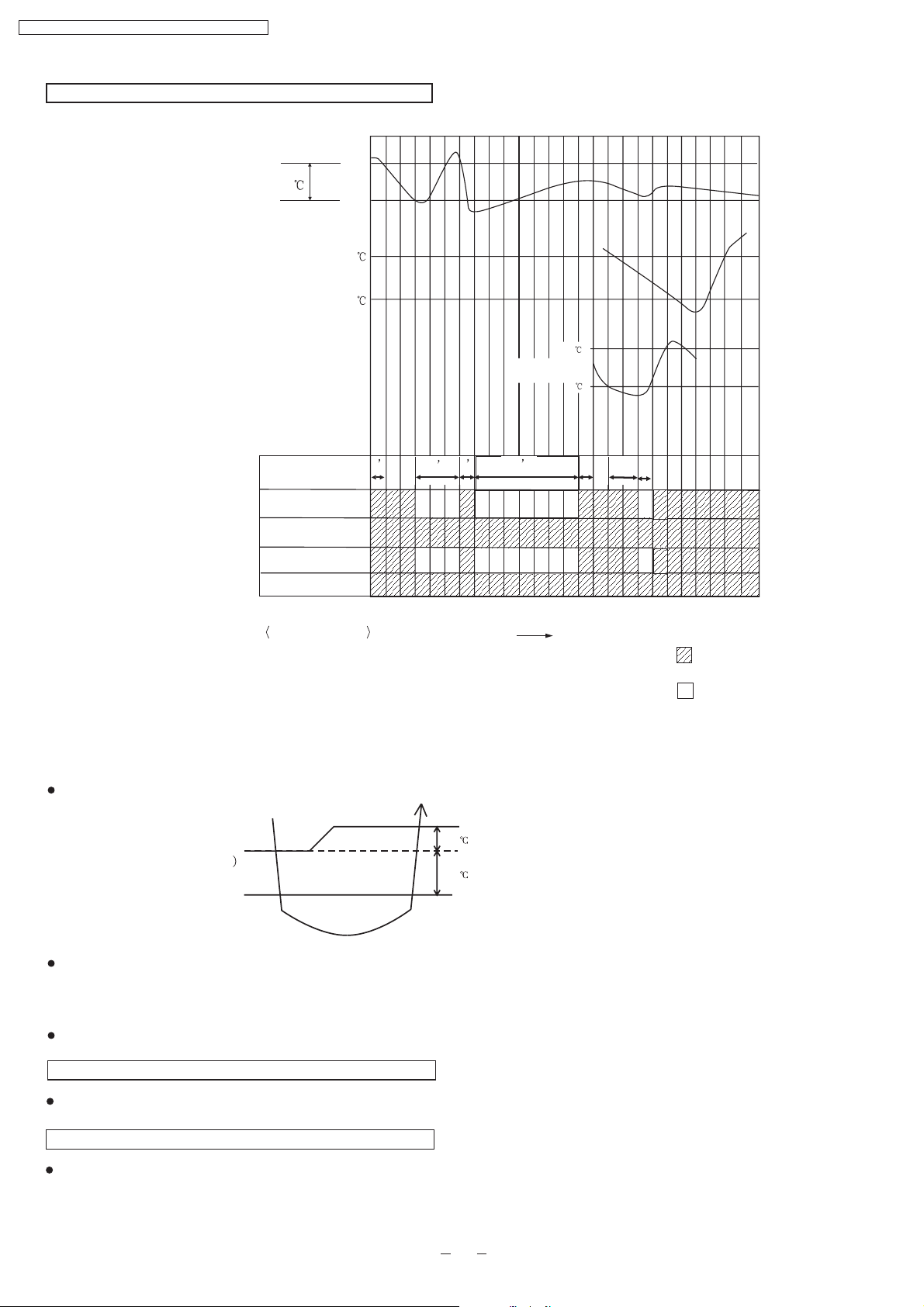

Time Graph for Cooling Operation

Intake air temperature

Set temperature

1.5

Basic Time

Comp.

Indoor Fan

Outdoor Fan

abcdefghi j klmnopqrstuvwxyz

Start

Stop

31

29

10

2

1’

3

4’

1 1

3

Evaporater

temperature

7

Operation Indicator

Operation status

d-g

g-h

h-o

q-t

:

Time delay safety control

:

Compressor Test control

:

Auto restart control

:

Anti-freezing Control

Time

Operate

Stop

8.2. Soft Dry Mode Operation

Operation area

COOLING

COOLING(OFF)

DRY(ON

DRY

DRY(OFF)

DRY(OFF)

When selecting Soft Dry mode operation, the operation will be cooling until the room temperature reaches the set temp on

remote control, and then Soft Dry will be activated. (During Soft Dry Mode the fan of indoor unit will operate at super low

speed. The soft dry mode will run for less than 10 minutes.)

Once Soft Dry mode operation is turned off, indoor fan, compressor and outdoor fan will stop for 6 minutes.

COOLING(ON)

1.5

1.0

DRY(ON)

Time Delay Safety Protection

During cooling mode operation, if the compressor ceased, it will not restart within 3 minutes.

Anti Freezing Control

Same as the denotation in Cooling Operation.( )

P21

(During Soft Dry Mode Operation, compressor will stop for at least 6 min.)

22

Page 23

Automatic Fan Speed

During Soft Dry Operation, use remote controller to select Auto Fan Speed mode.

Indoor Fan Speed is at “Lo-”

CS-PA7DKD/CU-PC7DKD / CS-PC7DKD/CU-PC7DKD

Lo-

Slo

Indoor

fan

OFF

T1

40

T2

70

10

Compressor

ON

Time Graph for soft dry operation

Intake Air temp

Cooling mode operation activated

1.5

1.0

Cooling mode operation stopped

Soft mode operation activated

Soft dry mode operation stop

Lo-

Slo Slo

OFF OFF OFF

T1

40

6

T2

70

10

ON

OFF

abcdef g hi jklmnopq rst u

Basic Time

Comp.

Indoor Fan

Outdoor Fan

Operation Indicator

4-way Valve

Operation status

a-c,p-r

c-p,r-u

e-f

j-l

q-t

:

Cooling Mode Operation

Soft Dry Mode Operation

:

:

Soft Dry Mode Operation Stopped

Compressor Test Operation Control

:

:

Anti Freezing Control

Evaporator

temperature

61 1 4

1

Super

Super

Super

Slo Slo Slo Slo

Low

Low

Low

Super

Low

Low

Slo Slo

Slo Slo Slo

Time

o

10 C

o

2C

666

Slo

Slo

Cooling mode operation

Soft Dry Mode operation

Operate

Stop

23

Page 24

Super Low

Indoor Fan

Stop

Indoor Heat

Exchanger

()

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

8.3. Heating Mode Operation(Only for PA7DKD,PA9DKD)

When selecting the Heating Mode Operation, the unit will operate according to the setting by the Remote Controller and

the operation is as the following.

Time Delay Safety Control

If the compressor stopped by switching off, turning off by remote controller, or power off, it will not restart within 3 minutes.

When room temperature reaches the set temperature on the remote controller, compressor stops and will not restart within

4 minutes.

3 minutes after the compressor stopped, indoor fan will stop for 1 minute. Then indoor fan will resume operation with the

speed at ”super low”

Over Load protection Control

When temperature of indoor heat exchanger rises to 51 , outdoor fan will stop

when temperature of indoor heat exchanger falls to 49 , outdoor fan will restart.

When temperature of indoor heat exchanger rises to 65 or above, compressor stops, and will restart 4 minutes later.

.

Compressor

Indoor Heat Exchanger 65

Anti-reversing Control

If the compressor has been continuously running for 5 minutes or longer, and the difference of temperature between

intake air and evaporator is continuously lower than 5.0 or below for 2 minutes, the compressor will stop , and then

restart 3 minutes later.(Time Delay Protection Control is effective.)

Compressor runs 5 min

T 5 last for 2 min

T= intake air temperature - evaporator temperature

4-way valve control

During heating mode operation,4-way valve is at open mode.

During heating mode operation,if the unit turned off, the 4-way valve will remain

at open mode for 5 minutes.

Stops

Compressor

Stops

Compressor Restarts

4 minutes later

Compressor Restarts

3 minutes later

Warm Booting Control

When turning on the unit by heating mode operation,indoor fan

will be activated when temperature of indoor heat exchanger

reaches 30 . (See the figure on the right)

Warm boot operation ends when temperature of indoor heat

exchanger reaches 34 .

24

Indoor Heat

Exchanger

()

34

30

Low

Super Low

Indoor Fan

Stop

Page 25

Automatic Fan Speed

S Lo

()

()

45

41

34

30

38

30

28

15

Temperature of heat exchanger

During Heating Operation, use remote controller to select Auto Fan Speed mode.

Indoor Fan Speed is between “Me” and “Slo”.

()

SLo

Me

Lo

Lo-

()

38

30

28

45

41

34

30

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Temperature of heat exchanger

Time Graph for Heating Operation

abcdefghi jk

42

Indoor heat

exchanget

Temp.

Intake Temp.

34

32

30

OFF

2

ON

Basic Time

Compressor

Indoor Fan

Outdoor Fan

Operation Indicator

4-way valve

<Operation status>

a-b

c-d

h-k,o-r

:

Warm booting control(indoor fan Off)

:

Warm booting control(indoor fan Super Slo)

:

Prevent cool airEORZLQJRXW

Stop

30'

58''

1'

Tim e

15

l

nop qr

m

30

Manual fan speed

Blink

Operate

Stop

150'

25

Page 26

Deicing Operation Time(T)

3

min

3min T 7min

7

min T 9min

T 9min

Td(s)

0

60

120

180

<Operation status>

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Deice Control

Deice operation is to protect the outdoor unit from freezing.

Normal Deice Operation

Deicing starts 30 minutes after heating mode operation or 60 minutes after the latest deicing operation. If temperature of

outdoor piping, tested by TRS, falls to -3 (TRS OFF) or below for continuously 50 seconds, deicing operation starts.

Overload Deicing Operation

During heating operation, if the accumulative stopping time of outdoor fan reaches 60 minutes,

deicing operation will start 1 minute after compressor starts.

Deicing operation ends under conditions below

(a) After 12 minutes.

(b) Temperature of outdoor unit rises to 4 .

(c) As the illustration showed bellow and due to Time Delay (Td), deicing won’t ends immediately.

Deicing Operation Time(T)

3min

3min T 7min

7 min T 9min

T 9min

Td(s)

0

60

120

180

Once deicing operation starts, it won’t end until 60 seconds later.

When deicing operation ends, compressor will stop for 30 seconds, and 4-way valve remains at cooling mode operation

for 10 seconds.

Time Graph for Normal Deicing Operation

Lo

max60'

l

nopq r s t uvwxy z

m

max12'

Slo

or

Blink

Operat io n

Stop

max60'

Lo

42

34

30

Indoor Piping Temp.

Basic Time

Compressor

Indoor Fan

Outdoor Fan

Operation LED

4-way valve

abcd ef gh i j k

60'

max12'

10S20S 20S 20S 20S 20S 10S 20STd

Slo

Time

<Operation status>

a-c Deicing confirmation

c-g Deicing operation(time reset)

h-j,u-w Warm Booting

o-r Deicing(TRS )

26

Page 27

Time Graph for Overload Deicing

Outdoor Heat

Exchanger

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Outdoor Heat

Exchanger

Basic time

Compressor

abcdefghi j k

51

49

Out door fan stop for 60' accumulatively

20’’ 20’’

Max

12’

l

m

10’’ 20’’

nopq

Indoor fan

Outdoor fan

Operation Indicator

4-way valve

<Operation status>

Overload controla-i

i-l Overload deicing(timer)

l-m: Warm booting control

m-r Overload control

Time

Blin k

Oper ati on

Stop

27

Page 28

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

8.4. Automatic Mode Operation

Standard for Determining Operation Mode

First Determination:

Setting Temperature (Standard)

25

22

21

Intake Air

temperature

23

20

Cooling mode

Soft Dry mode

Heating mode

Cooling mode

Soft Dry mode

Heating mode

Second Determination:

One hour after the above determination, the unit will operate according to the table below.

Second Determination

Cooling

Cooling

First

determination

A)

Indoor fan operates at super low speed for 25 seconds.

B)

After judging indoor air temperature, the operation is determined and operation continued at the mode determined.

C)

If indoor temperature is less than 16 , heating operation will immediately operate.

D)

After the operation mode has been determined, the mode does not change. However,Soft Dry mode operation

includes cooling mode operation.

E)

If automatic mode operation is started while the unit is operating,operation will continue.

If current operation is in cooling mode (including the cooling mode operation when is a part of Soft Dry mode

operation) it will be maintained, and if current operation is not cooling mode, the appropriate operation mode is

determined for 25seconds at super slow fan speed.Then the selected mode will continue.

F)

Room temperature adjustment

Dry

Heating

Higher

23 or above

25 or above

2

Dry

20 or above

Heating

23 below

20 below

25 below

Standard

Lower

0

2

8.5. Air Circulation Mode Operation(Only for PC7DKD,PC9DKD)

1. An additional heater may make the warm air evenly covering each corner of the room.

2. When the temperature near the ceiling reaches the setting temperature, Air Circulation Mode Operation commences

at low airflow volume. It stops when the temperature drops to 2 below the setting temperature.

3. The vertical airflow direction louver will not swing.

28

Page 29

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

8.6 Air Quality Sensor Control

Resistance of air quality sensor: Rs(air)=10k ~50k ( The worse the air quality, the smaller the resistance.)

Basic Operation

Detecting and indicating of the air quality will not stop during the operation of the air conditioner.

The power of the air quality sensor is always on during the operation of the air conditioner. When the air

conditioner stops (The air conditioner is on standby.), the air conditioner will provide power to the air quality

sensor intermittently (It will be on for 3 minutes after each 109 minutes.) for the purpose of air quality detecting.

Within 2 minutes after the air conditioner starts to operate, the air quality sensor is in the process of preheating

and the air quality indicator is red.

Resistance Reference

Detecting of air quality( During the operation of the air conditioner)

(a) The measuring period is 20 minutes; The air conditioner will measure the resistance (Rs) of the air quality

sensor once each 2 seconds and record the data. The maximum Rs within the 20 minutes will be selected as

Rs(MAX) for this measuring period.

(b) Suppose the current Rs(MAX) as MAX and the resistance reference of the previous measuring period is as

MAXR1.; If MAX>MAXR1, the resistance reference of the current measuring period is MAXR=MAX; If

MAX<MAXR1, MAXR=MAXR1;

(c) Within 2 minutes after the power of the air quality sensor is turned on, the resistance reference of this

measuring period is the maximum resistance of the sensor during this period.

Maximum of Rs

MAXR1 of previous

measuring period

Updating of MAXR

20minutes

MAX1 MAX2 MAX3

MAX0 MAX1 MAX2

MAX1 MAX0 MAX0

MAX1 MAX0 MAX1

MAX2 MAX1 MAX1

MAX2 MAX1 MAX2

20minutes20minutes

MAX3 MAX2 MAX2

MAX3 MAX2 MAX3

The following conditions should be fulfilled

(d)

The initial MAXR after the preheating of the air quality sensor when the air conditioner is turned on:

The air conditioner will compare the maximum value of the current measuring period (MAX) with the

resistance reference 109 minutes before ( MAXR0) and select the bigger one as the current resistance

(e)

reference(MAXR).

When the air conditioner determines the air quality is getting worse: Air quality level 1 Air quality level 2,

MAXR will not be updated; When the air quality gets better (air quality level 0), Rs detected at this time will be

(f)

MAX and MAXR.

The air conditioner will not detect the air quality during deicing operation. The indication prior to the deicing

operation will be held during the deicing operation.

29

Page 30

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Detecting of air quality( When the air conditioner is on standby.)

(a) After the air conditioner stops operation, it will provides power to the air quality sensor intermittently to detect

the air quality and update the resistance reference (MAXR). The power of the air quality sensor will be on for 3

minutes after each 109 minutes.

(b)

During these 3 minutes, the air quality sensor will be in preheating process for 2 minutes and the other time is

for measuring the resistance. The air conditioner will compare the maximum resistance measured in this period

with the maximum value in the previous 109 minutes and the bigger one will be selected as resistance

Air Quality Control

Detecting of air quality(When the air conditioner is on standby.)

Rs/MAXR will be calculated automatically every 2 seconds and the air quality level will be determined in

accordance with the value below,

Air Quality

Getting Worse

Air Quality

Getting Better

*G1=0.85

*G2=0.60

Signal of Air Quality Sensor

Air quality

becomes better

Rs/MAXR G1

Rs/MAXR G2

Rs/MAXR G3

Rs/MAXR G4

Air Quality Level

(0) (1)

(2) (1)

(1) (0)

Air quality

(0)

becomes worse

(1)

(2)

(2)(1)

Set the sensitivity number of the air quality sensor as 2 (Standard)

Air Quality Level and Indicator

During preheating of the air quality sensor the air quality indicator is red.

The color of the air quality indicator varies with the air quality level:

Air Pollution Level 0: Green

Air Pollution Level 1:Orange

Air Pollution Level 2:Red

30

Page 31

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Forced Resetting

Forced Resetting Time (The added operation time mentioned later not included.)

(a) Air Pollution Level 2: Red: 5 minutes Orange: 8 minutes Green

(B) Air Pollution Level 1: Red: 5 minutes Orange: 8 minutes Green

Timer Resetting

When the forced resetting mode is determined and the following conditions are fulfilled, the timer is reset.

1) The air quality changes which results in the changing of the color of the air quality indicator.

2) Compare Rs detected in current 2 seconds with R1 detected in previous 2 seconds and Rs/R1<0.95.

3) Suppose Rs detected in previous 3 minutes is R2 and Rs/R2 0.87.

Added Operation of Air Quality Sensor

When the air quality getting worse

If the air pollution level changes from 0 to 2, the color of the air quality indicator changes as below,

Green Orange (2 Sec.) Red

When the air quality getting better (added operation )

If the air pollution level changes from 2 to o, the color of the air quality indicator changes as below,

Red (60 Sec. ) Orange( 60Sec.) Green

Judgment during added operation

During added operation, if the air quality sensor judges that the air quality is getting worse, the added operation will

be stopped immediately and the air quality indicator will shift to normal indication. If the air quality getting better,

the air conditioner will judge the air quality until the added operation is finished.

Sensitivity Control of Air Quality Sensor

The sensitivity number can be changed through the following procedure

<Setting Sensitivity Number>

1.Keep the SET button on the remote control depressed continuously for 5 seconds to select sensitivity control

m ode.

2.The previous sensitivity setting will be displayed in the temperature display.

“0”=Turn off the air quality indicator

“1”= Low Sensitivity

“2”=Standard Sensitivity

“3”=High Sensitivity................

…………....G1=0.70, G2=0.45, G3=0.48, G4=0.73

………G1=0.85, G2=0.60, G3=0.63, G4=0.88

G1=0.90, G2=0.65, G3=0.68, G4=0.93

3.Press or button on the remote control to change the sensitivity

Within 10 seconds after the sensitivity setting is finished, other settings are not available. The display of the remote

control will change back to normal without pressing any button.

31

Page 32

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

8.7Demo Mode ( Outdoor unit not needed)

Activate the demo mode:

Keep the AUTO button on the indoor

unit depressed continuously for 15

seconds until 3 beeps are heard and

the demo mode is activated.

In demo mode, the air conditioner can be operated(if the outdoor unit is connected to the indoor unit); Whenever

you turned off the air conditioner, it will restart automatically into demo mode opertion.

Cancel the demo mode:

Keep the AUTO button on the indoor unit depressed continuously for 15 seconds until 3 beeps are heard.

Turn off the air

conditioner

Demo mode operation will be

restarted automatically in 1

minute.

ON

5seconds 10seconds 15seconds

AUTO TEST RUN SOUND DEMO

1“BEEP”

Demo operation control( Air quality indicator and Ventilator Interlocking Unit signal)

5 seconds 5 seconds 5 seconds 5 seconds 5 seconds 5 seconds 5 seconds

Color of air quality indicator

Red Orange green Orange Green Orange Red

Ventilator Interlocking

Unit ON/OFF

ON

OFF

10 seconds 20 seconds

2“BEEP”

3“BEEP”

8.8Ventilator Interlocking Unit Control (Optional)

Purpose: The air conditioner will control the operation of the ventilator (optional) according to the signal of

the air quality sensor when displaying the air quality.

Devices: Ventilator, Ventilator Interlocking Unit (wireless)

To use this function, a ventilator and a ventilator interlocking unit should be purchased.

Power supply:220V-240V~50/60Hz

Control Specification:

Air quality getting worse Air quality getting better

Green

OFF

Oriange

ON

Red

ON

Green

OFF

Oriange

ON

Red

ON

15 minutes after the air conditioner is

Turned on:

Ventilator ON: Air quality indicator is red or

orange.

Ventilator OFF: Air quality indicator is green

or the air conditioner is turned off.

Within 15 minutes after the air conditioner is

turned on, the ventilator will not operate even

though the air quality indicator is red.

32

Page 33

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

8.9 About Cursor Key Which Points To “OFF” On Remote Control

When the ON/OFF button on the remote control is pressed, the cursor key which points to “OFF” will appear or

disappear to indicate the ON/OFF status of the air conditioner.

AUTO

HEAT

STD

COOL

DRY

OFF

For some reason (Ex. The signal of the remote control does not reach the signal receiver of the indoor unit.), the

display of the remote control will not correspond with the actual ON/OFF status of the indoor unit:

The air conditioner is running but the cursor key which points to “OFF” appears. The air conditioner can be

1.

stopped with any button (Except for “ON/OFF”, “TIMER SET”, “TIMER ON”) pressed.

The air conditioner is on standby, but the cursor key which points to “OFF” disappears. The air conditioner can

2.

be started with any button(Except for “ON/OFF”, “TIMER SET”, “TIMER OFF”) pressed.

AUTO

AUTO

FAN

SPEED

AIR

SWING

PRESS "OFF/ON" BUTTON

AUTO

HEAT

COOL

DRY

OFF

STD

AUTO

AUTO

FAN

SPEED

AIR

SWING

8.10. Indoor Fan Motor Control

Automatic fan speed control

When automatic fan speed set, the available range for fan speed is from Hi to Slo.

Manual Fan Speed Control

Basic fan speed can be manually adjusted (Lo, Med, Hi) by using the fan speed selection button.

Basic Fan Speed

Category

Cooling Mode

Operation

Soft Dry

Operation

Heating Mode

Operation

Manual

Auto

Manual

Auto

Manual

Auto

8.11. Auto restart control

If the operation is stopped due to a power failure u , it will restart automatically

un der the previous operation mode when the power supply is resumed.

Hi Me

SLo

Lo-

Lo

nder any operation mode

SSLo

33

Page 34

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

8.12. Airflow Direction Control

Airflow Direction Auto-control

When set at airflow direction auto-control with remote control,the louver swings up and down as shown in the table below.

The louver does not swing when the indoor fan stops during operation.

When stop the unit with remote control,the discharge vent is closed with the louver.

When temperature of indoor heat exchanger reaches 38 during heating mode operation, if temperature falls to 35 ,airflow

direction will change from the lower limit to horizontal.

The left and right airflow direction louver can be adjusted manually.

Airflow direction manual control

When the airflow direction set button is pressed,the automatic airflow is released and the

airflow direction louver moves up and down as shown in thetable below. The louver can

be stopped by releasing the button at the desired position.

When the remote control is used to stop the operation,the discharge vent is closed with

airflow direction louver.

Angles Of Airflow Direction Louver

12 34 5

Operating Mode

Cooling

Manual

Soft dry

Auto

Manua

Heating

Auto

Determining operation

mode

oo o o o

12 17 26 32 36

oo

12 ~36

oo o o o

921 29 44 55

oo

9~55

o

9

Notes:

In heating mode operation

1.

Airflow direction automatic control:

Airflow direction is automatically adjusted to horizontal direction when the temperature of indoor heat exchanger is low and it will

be automatically adjusted downward while the indoor temperature rises.

2.

Airflow direction manual control:

The airflow direction is automatically adjusted to horizontal direction when temperature of indoor heat exchanger is low .While

temperature of indoor heat temperature rises ,the airflow direction is automatically adjusted to the place set by the remote control.

In cooling or soft dry mode operation

If the compressor continues to operate for 60 minutes ,and the louver direction is at No 5,the fan speed is below Med, the intake

air temperature is below 29 and continues to change between 2 for 30 minutes ,the louver direction will be at No 2 in order

to prevent dew around the discharge vent.

34

Page 35

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

9

Installation

9.1. Before Installation

WARNING

Engage dealer or specialist for installation. If installation done by the user is defective, it will cause water leakage, electrical

shock or fire.

Use the specified cable (1.5mm ) and connect tightly for indoor/outdoor connection.

Power supply connection to a circuit breaker for the permanent connection. Use an approved 10A circuit breaker for the

permanent connection. lt must be a double pole switch with a minimum 3 mm contact gap.

The unit must be earthed, or it will cause fire or electric shock.

.

Attached accessories.

2

No . Accessories parts

1

Installation plate

Installation plate fixing screw

2

Battery

3

4

Remote controller

AUTO

COOL

DRY

FAN

OFF

MODE

h

r

STD

DE

O

*

AUTO

FFON

LAY

AUTO

FAN

TEMP

OFF

SPEED

OFF/ON

AIR

CANCEL

SWING

FAN

S

PEED

TIMER

ON

SET

AIR

S

WING

Qty

1

5

2

1

Drain elbow

5

(Only for models:

PA7DKD,PA9DKD)

1

6

SELECT THE BEST LOCATION

INDOOR UNIT

There should not be any heat source or steam near the unit.

There should not be any obstacles blocking the air circulation.

A place where air circulation in the room is good.

A place where drainage can be easily done.

A place where noise prevention is taken into consideration.

Do not install the unit near the door way.

Ensure the spaces indicated by arrows from the wall, ceiling, fence or other obstacles.

Recommended installation height for indoor unit shall be at least 2.5m.

OUTDOOR UNIT

If an awning is built over the unit to prevent direct sunlight or rain, be careful that heat radiation from the condenser is

not obstructed.

There should not be any animal or plant which could be affected by hot air discharged.

Keep the spaces indicated by arrows from wall, ceiling, fence or other obstacles.

Do not place any obstacles which may cause a short circuit of the discharged air.

If piping length is over the common length, additional refrigerant should be added.

35

Page 36

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Installation parts you

should purchase ( )

5cm

or more

(Left and right are identical)

Insulation of piping connections

Carry out insulation

after checking for

gas leaks and

secure with vinyl

tape.

Vinyl tape

5cm

or more

Installation plate

1

Sleeve ( )

Bushing Sleeve ( )

Putty (Gum type sealer) ( )

Bend the pipe as closely on

the wall as possible, but be

careful that it doesn t break.

Vinyl tape (Wide) ( )

Apply after carrying out a

drainage test.

To carr y out the drainage

test, remove the air filters

and pour water into the heat

exchanger.

10 cm

or more

100 cm

or more

Saddle ( )

Connecting cable ( )

(3-CORE WIRE/1.5 mm

PC7DKD,PC9DKD

10 cm

or more

(5-CORE WIRE/1.5 mm

CORE WIRE/0.50mm

+2

PA7DKD,PA9DKD

Type designation 245 IEC 57

or heavier cord

Additional drain hose ( )

Liquid side piping ( ) 1/4"

Gas side piping ( ) 3/8"

30 cm

or more

Fig 1

This illustration is for explanation purposes only.

The indoor unit will actually face a different way.

2

)-

2

2

)-

36

Page 37

9.2. Outline of installation

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Installation works

1. Installation of indoor, outdoor unit

1) Select the best location

2) Indoor unit installation

2. Piping and drainage of indoor unit

1) Prepare of piping

2) Connection of piping

For the right piping

For the left piping

3. In case of Embedded Piping

For the embedded piping

38

39

40

41

41

42

44

Installation parts Required tools

Installation plate

4 wooden screws

4 anchor bolts

Pipes: Gas side 3/8’’

Liquid side 1/4’’

Insulated drain hose

Insulation materials

Pipes:Gas side 3/8 ”

Liquid side 1/4”

Insulated drain hose

Insulation materials

A level gauge

Philips screw driver

Electric drill hole-core

drill( 70mm)

Side cutter or electrical pliers

Flaring tools set

Specified torque wrenches

18N.m

42N.m

Spanner

Flaring tools set

Specified torque wrenches

18N.m

42N.m

Spanner

Liquid side piping

Gas side piping

Half union

Liquid side piping

Gas side piping

Half union

4. Connecting piping and cable to

the outdoor unit

1) Connecting the piping to

the outdoor unit

2) Connecting the cable

5.Checking the drainage and connecting

the cable to inddor unit

1) Checking the drainage

2)Connect the cable to the

indoor unit

6. Test Running

1) Connect the power supply

2) Evaluation of the performance

45

45

46

47

48

48

Additional drain hose

(Outer diameter 1.5mm)

Connecting cable

(3-core wire/1.5mm2)

Locally approved cable

Connecting cable

(3-core wire/1.5mm2)

Locally approved cable

Specified torque wrenches

18N.m

42N.m

A glass of water

Phillips screw driver

Circuit breaker or time delay

fuse(consult an electrician)

Operating instructions

Thermometer

Liquid side

Gas side

37

Page 38

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

9.3. Outline of installation

9.3.1. Select the best location

1. Indoor unit

There should not be any heat source of steam near the

unit.

There should not be any obstacles to prevent the air

circulation.

A place where air circulation will be good.

A place where drainage can be easily obtained.

A place where noise prevention is taken into

consideration.

Do not install the unit near the doorway.

Ensure the spaces indicated by arrows from the wall,

ceiling, fence, or other obstacles.(Fig 2)

Recommended installation height for indoor unit shall be

at least 2.5m.

10cm

100cm

10cm

Fig.3

5cm

5cm

Height more than

2.5m

Fig.2

2. Outdoor unit

If an awning is built over the unit to prevent direct

sunlight or rain exposure, be careful that heat radiation

from the condenser is not restricted.

There should not any animals or plants which

could be affected by hot air discharged.

Ensure the spaces indicated by arrows from the wall,

ceiling, fence, or other obstacles.(Fig 3)

be

5cm

3. Piping length and elevation

Model

PA7DKD/PC7DKD

PA9DKD/PC9DKD

Piping size

Gas

3/8’’ 1/4’’

5m

Fig.4

Liquid

Max piping

length(m)

Max piping

elevation(m)

75

7m

38

Page 39

9.3.2. Indoor unit Installation

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

The mounting wall is strong and solid enough to prevent it from

vibration.

1. Mount the installation plate on the wall with four

installation plate fixing screws.

(If mounting the unit on the concrete wall,consider

using anchor bolts.)

Always mount the installation plate horizontally by

aligning the mark-off line with the thread and use a

level gauge.

Screw

105mm

2

C

B

E

Thread

Weight

Installation

1

plate

A

145mm

B

The lower left and right side of installation plate

Left rear piping

Center

70mm

7 0mm 7 0mm

Right rear piping

Center

70mm

Wall

Indoor

Outdoor

5-7mm

Fig.6

Fig.5

2. Drill the piping hole with 70mm

hole-core drill.

•

Line according to the arrows marked on the lower left and

right side of the installation plate.

To drill a hole in the wall and install a sleeve for tube ass’y

•

Drill a 70mm hole sloping downward toward the outside of

the wall.

•

Insert the sleeve for tube ass’y through the hole.

•

Fix the bushing to the sleeve.

•

Extrude 15mm of the sleeve then cut

.

Caution

When the wall is horrow please be sure to use the sleeve

for tube ass’y to prevent dangers caused by mice biting

the connecting cable.

Indoor

70mm

Outdoor

15mm

5-7mm

Fig.7

•

Finish by sealing the sleeve with putty or caulking

compound at the final stage.

39

Page 40

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

9.4. Piping and Drainage of Indoor Unit

9.4.1. Preparation of piping

1. Cut the pipes and the cable

Use the accessory piping kit or pipes purchased locally

Measure the distance between the indoor and the

outdoor unit.

Cut the pipes a little longer than the measured distance.

Cut the cable a little longer than the pipe length.

Pipe size

Model

PA7DKD/PC7DKD

PA9DKD/PC9DKD

Pipe cutter

Gas side Liquid side

3/8”

Slanted

1/4”

Rough

3. Flaring the pipe

Insert the flare nuts, mounted on the connection ports

of both indoor and outdoor unit, onto the copper pipes.

Fit the copper pipe end into the bar of flare tool about

0.5-1.5mm higher.(See Fig.10)

Flare the pipe ends.

Bar

Bar

Handle

Yoke

Cone

Copper pipe

Clamp handle

Fig.10

Fig.8

2. Remove burrs

Remove burrs from cut edges of pipes.

Turn the pipe end down to avoid the metal powder

entering the pipe.

Pipe

Reamer

Point down

4. Tape the flaring portion to protect it from dust or damage.

Improper flaring

Slanted

Surface

Damaged

Cracket

Uneven

Thickness

When properly flared,the internal surface of the

flare will evenly shine and be of even thickness.

Since the flare part come into contact with the

connectors, carefully check the flare finish.

Fig.11

Fig.9

Caution

If burrs are not removed, they may cause a gas leakage.

40

Page 41

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

9.4.2.

Remove the indoor piping

For the right piping

1. Pull the tube out of chassis.

2. Insert the tube and drain hose into the hole.

Connection of piping

Pull the tube out of chassis.

Fig.12

Indoor/Outdoor

Connecting cable

Gas side piping

Liquid side piping

Connecting

cable

Fig.14

5. Indoor unit installation

Hook the indoor unit onto the upper portion of

installation plate. (Engage the two hooks of the rear

top of the indoor unit with the upper edge of the

installation plate.)

Ensure the hooks are properly seated on the installation

plate by moving it left and right.

Drain hose

3. Insert the connecting cable into the indoor unit

through the hole.

Do not connect the unit to power supply.

Make a small loop with the cable for easy

connection later.

4. Tape the tube,drain hose and cable.

Indoor/Outdoor

Connecting cable

Fig.13

Drain hose

Connecting cable

Press the lower left and right side of the unit against the

installation plate until the hooks engages with their slots

(sound clicks)

Fig.15

6. Connecting the piping to the indoor unit

• Align the center of the piping and sufficiently tighten the

flare nut with fingers.

• Finally, tighten the flare nut with torque wrench until the

wrench clicks.

When tightening the flare nut with torque wrench,

ensure the direction for tightening follows arrow on the

wrench.

Model Piping side Torque

PA7DKD

Liquid side 1 4"

/

18N.m

PA9DKD

PC7DKD

PC9DKD

Gas side 3/8”

42N.m

41

Page 42

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Outdoor

Indoor unit piping

Flare Nut

Pipings

Spanner or

wrench

Fig.16

For the left piping

1. Route the indoor tubing with the drain hose to the

hole.

Pull out the drain hose.

Exchange the hose and cap.

Torque wrench

Piping

Indoor

3. Insert the connecting cable into the indoor unit

• Do not connect the cable to the indoor unit.

• Make a small loop with the cable for easy connection.

Connecting cable

Fig.18

Cap

Cap

2. Insert the piping and connecting cable to indoor side

through the hole.

Drain hose

Fig.17

Connecting cable

Fig.19

Gas side piping

Liquid side piping

42

Page 43

4. Indoor unit installation

• Hook the indoor unit onto the upper portion of

installation plate. (Engage the two hooks of the rear top

of the indoor unit with the upper edge of the installation

plate.)

• Ensure the hooks are properly seated on the installation

plate by moving it left and right.

Hook at

installation plate

Sleeve for

piping hole

Drain hose

Piping

Fig.21

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

Fig.23

7. Tape the piping, drain hose and connecting cable.

5. Connecting the piping to the indoor unit

• Align the center of the piping and sufficiently tighten the

flare nut with fingers.

• Finally, tighten the flare nut with torque wrench until the

wrench clicks.

When tightening the flare nut with torque wrench,

ensure the direction for tightening follows arrow on the

wrench.

Model Piping side Torque

PA7DKD

PA9DKD

PC7DKD

PC9DKD

Indoor unit piping

Liquid side 14"

Gas side 3/8”

Flare Nut

18N.m

42N.m

Pipings

Tape

Piping

Drain hose

Fig.24

Spanner or

wrench

Fig.22

6. Set the piping and the connecting cable to the back of

chassis with the clamping cover.

Torque wrench

43

Page 44

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

9.5. In case of embedded Piping

For the embedded piping

Follow the same procedure for left rear and left piping.

9.5.1. Replace the drain hose

9.5.6. Connecting the piping

• Refer to the section "connecting the piping" in the directions

for the indoor unit.

(Connecting the piping to the outdoor unit and checking the

gas leakage.)

Replace the drain hose and drain cap.

Figure from the back of the indoor unit after

installation.

(For the left and left rear piping)

Drain cap

Drain hose

Fig.25

9.5.2. Bend the embedded piping

• Use a spring bender or equivalent to bend the piping so

that the piping is not crushed.

In case of the embedded piping.

How to pull the piping and drain hose out.

Sealed with putty or

caulking compound

More than 95cm

PVC tube for

drain hose

More than 70cm

PVC tube for

drain hose

PVC tube for drain hose

(Be sure to insulate the

PVC tube for drain hose)

More than 30cm

PVC tube for drain hose

Connecting

cable

Piping

Fig.27

Connecting cable

Indoor unit

Drain hose from

main unit

Piping

5.5cm

9.5.7. Connecting the cable to the indoor

unit

• The cable can be connected without removing the front

grille.

Connecting

Connecting

cable

cable

Drain

Drain

hose

hose

Slightly pull down the drain hoseSlightly pull down the drain hose

Fig.26

9.5.3. Install the indoor unit.

9.5.4. Cut and flaring the embedded

piping

• When determining the dimensions of the piping, slide the

unit all the way to the left on the installation plate.

• Refer to the section “cut and flaring the piping” in the

directions for the outdoor unit. (Refer page 40)

9.5.5. Pull the connecting cable into the

indoor unit.

A

Insert the piping

B

through the sleeve

Drain hose

Piping

About 95cm or a bove

Fig.28

Connecting cable

9.5.8. Install the indoor unit fixly.

[REFERENCE Fig.28, Fig.29]

For left side piping,how to insert the connecting cable and drain hose

45

Drain hose

Piping

Connecting cable

(Same as the directions for right

side piping)

44

Fig.29

Page 45

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

9.6. Connecting piping and the cable to outdoor unit

9.6.1. Connecting the piping to outdoor unit

1. Align the center of the piping and sufficiently tighten the flare nut with fingers.

2. Finally tighten the flare nut with torque wrench until the wrench clicks.

When tightening the flare nut with torque wrench, ensure the direction for tightening follows the arrow of the wrench.

Piping side Torque

Liquid side 1/ 4"

Gas side 3/8”

18N.m

42N.m

Caution

When connecting the piping, always use a torque wrench.

Other tools may cause damage to the flare nut because

of improper force.

3. Ensure not to let the piping exposed to air.

9.6.2. Connecting the cable to the outdoor unit

1. Remove the control board cover of the outdoor unit from the unit by loosening the screw.

2. Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 3 (PC7DKD,

PC9DKD) or 5 (PA7DKD, PA9DKD)x 1.5 mm flexible cord, type designation 245 IEC 57 or heavier cord.

For PA7DKD, PA9DKD the attached wire 6 with two connectors should be applied.

CS/CU-PC7DKD,CS/CU-PC9DKD

2

Indoor Connecting Terminal

Colours of wires

Outdoor Connecting Terminal

CS/CU-PA7DKD,CS/CU-PA9DKD

Indoor Connecting Terminal

Colours of wires

Outdoor Connecting Terminal

1(L) 2(N)

1(L) 2(N)

1(L) 2(N)

1(L) 2(N)

3

3

4

4

Connector

3. Secure the cable onto the control board with the holder ( clamper ).

4. Attach the control board cover to the original position with the screws.

45

Page 46

CS-PA7DKD / CU-PA7DKD / CS-PC7DKD / CU-PC7DKD

9.7. Checking the drainage and connecting the cable to indoor unit

9.7.1. Checking the drainage

1. Remove the front grille from the cabinet

When removing the front grille for maintenance purposes

etc, carry out by the following procedures.

a. Set the vertical airflow direction louver to the

horizontal position.

b. Remove the two caps on the front grille as shown in the

illustration at right, and then remove the two mounting

screws.

c. Pull the lower section of the front grille toward you to

remove the front grille.

When reinstalling the front grille, first set the vertical airflow

direction louver to the horizontal position, and then carry out

by steps” c” and “b” in that order. At this time check to sure

that the fixing tabs on the top inside edge of the front grille

are securely inserted into the respective slots.

Traystyrofoam

Air filter

Horizontal airflow

direction louver

Cap

Front Grille

Manually adjust the

horizontal airflow

direction louver to

horizontal position

Fig.30

2. Checking the drainage

• Pour a glass of water into the drain train traystyroform.

• Ensure water flow out from drain hose of indoor unit.

Pull the lower section

of the front grille

toward you to remove

the front grille.

Fig.31

3. Drainage control for outdoor unit

(For heating pump models only)

If a drainage plug is applied,the outdoor unit

should at least be 3 centimeters high from the

floor.

If is better not to use the drainage plug if the

temperature is lower than 0 ,since icing of the

condensed water may block the water flow.

46

Drain plug

Page 47

9.7.2. Connect the cable to the indoor

unit

The inside and outside connecting cable can be

1.