Panasonic CS-FZ25UKE, CS-FZ35UKE, CS-FZ50UKE, CS-FZ60UKE, CU-FZ25UKE Operating Instructions

...

Operating Instructions

Air Conditioner

Model No.

Indoor Unit Outdoor Unit

CS-FZ25UKE

CS-FZ35UKE

CS-FZ50UKE

CS-FZ60UKE

CU-FZ25UKE

CU-FZ35UKE

CU-FZ50UKE

CU-FZ60UKE

Operating Instructions

Air Conditioner

Before operating the unit, please read these operating

instructions thoroughly and keep them for future reference.

The included Installation Instructions should be kept and read

by the installer before installation.

Remote control is packaged in the indoor unit and removed

by the installer before installation.

2-23

Comment utiliser l’appareil

Climatiseur

Avant d’utiliser l’appareil, veuillez lire ce mode d’emploi dans

son intégralité et conservez-le pour toute référence ultérieure.

Le manuel d’installation inclus doit être conservé et lu par

l’installateur avant l’installation.

La télécommande est emballée dans l’unité intérieure et

retirée par l’installateur avant l’installation.

Instrucciones de funcionamiento

Climatizador de aire

Antes de utilizar la unidad, sírvase leer atentamente estas

instrucciones de funcionamiento y conservarlas para futuras

consultas.

El instalador debe guardar y leer las Instrucciones de

instalación incluidas antes de la instalación.

El mando a distancia viene embalado en la unidad interior y

debe ser retirado por el instalador antes de la instalación.

24-45

46-67

Español Français English

ACXF55-18840

Provides maximum comfort with optimal

FAN SPEED

FAN SPEED

energy saving methods.

Use remote

control within 8 m

from the remote

control receiver of

the indoor unit.

* Remote control display

and functions may

vary depending on the

model.

Quick Guide

Inserting the batteries

B

Pull out the back cover

1

A

of remote control.

Insert AAA or R03

2

batteries.

Close the cover.

3

1

2

3

2

A

Clock setting

Press

1

time .

and

• Press and hold

for approximately

5 seconds to show

time in 12-hour

(am/pm) or 24 hour

indication.

Confi rm .

2

set the

Thank you for purchasing

Panasonic Air Conditioner.

Table of contents

Safety precautions

How to use

To learn more

Cleaning instructions

Troubleshooting

Information

..........

4-15

.........................

......................

...............

............................

.....

16-17

18

19-20

21-23

68

Accessories

• Remote control

• AAA or R03 batteries × 2

• Remote control holder

• Screws for remote control

holder × 2

The illustrations in this manual are for

explanation purposes only and may differ

from the actual unit. They are subject

to change without notice for future

improvement.

English

B

Basic operation

Press

1

to select

the desired mode.

AUTO HEAT

DRY

COOL

Press

2

to start/

stop the operation.

POWER

• Please note that

the

indication

is on display to

start the unit.

Select the desired

3

temperature.

Up

Down

Selection range:

16.0 °C ~ 30.0 °C /

60 °F ~ 86 °F.

• Press and hold

approximately 10 seconds

to switch the temperature

indication in °C or °F.

for

3

Safety precautions

Air inlet

Air inlet

Air outlet

Air outlet

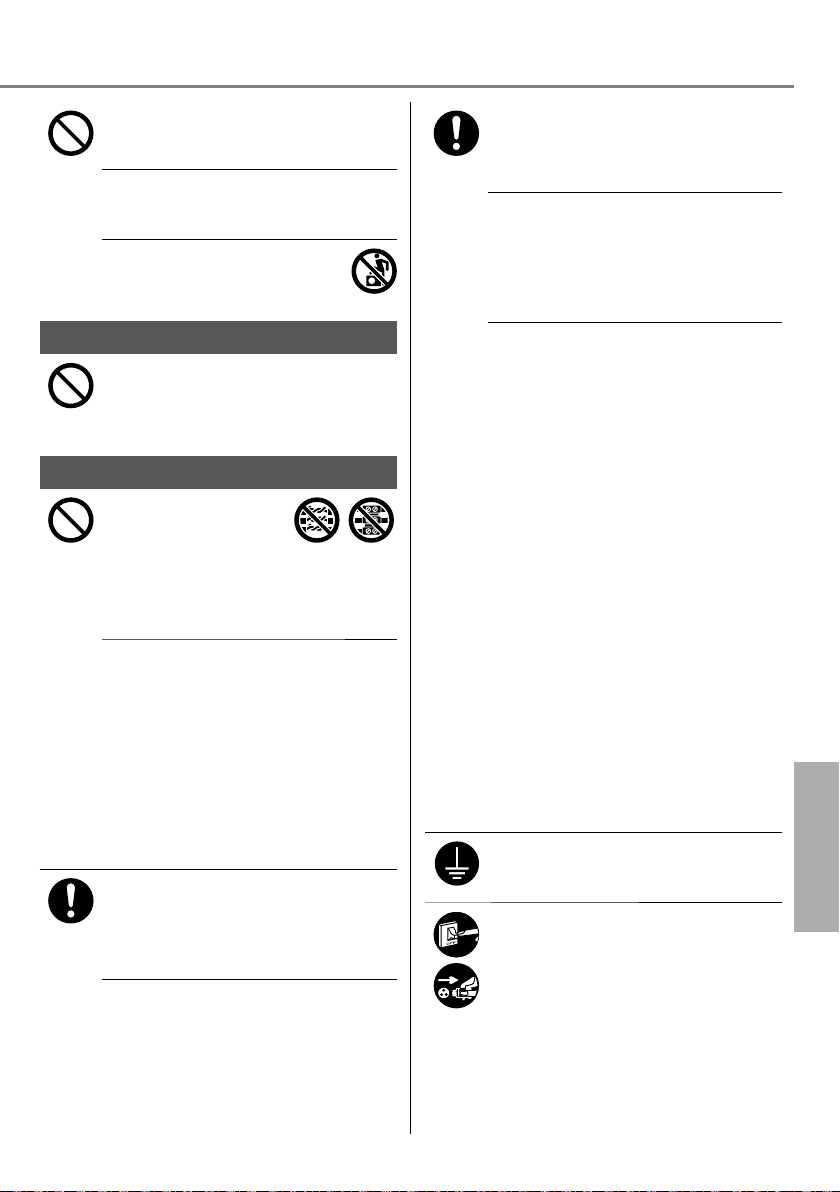

To prevent personal injury, injury to others

or property damage, please comply with the

following:

Incorrect operation due to failure to follow

instructions below may cause harm or

damage, the seriousness of which is

classifi ed as below:

This appliances is not intended for

accessibility by the general public.

This sign

Air inlet

warns of

death or

serious injury.

This sign

warns of

injury or

damage to

property.

Power supply

Air outlet

WARNING

CAUTION

The instructions to be followed are classifi ed

by the following symbols:

This symbol denotes an

action that is PROHIBITED.

These symbols denote

actions COMPULSORY.

Indoor unit

Air outlet

Remote control

Outdoor unit

Air inlet

WARNING

Indoor unit and outdoor unit

This appliance can be used by

children aged from 8 years and

above and persons with reduced

physical, sensory or mental

capabilities or lack of experience

and knowledge if they have been

given supervision or instruction

concerning use of the appliance

in a safe way and understand the

hazards involved.

Children shall not play with the

appliance. Cleaning and user

maintenance shall not be made by

children without supervision.

Please consult authorised dealer or

specialist to clean the internal parts,

repair, install, remove and reinstall

the unit. Improper installation and

handling will cause leakage, electric

shock or fi re.

Confi rm with authorised dealer or

specialist on usage of any specifi ed

refrigerant type. Using refrigerant

type other than the specifi ed may

cause product damage, burst and

injury etc.

Do not use means to accelerate

the defrosting process or to clean,

other than those recommended by

manufacturer.

Any unfi t method or using

incompatible material may cause

product damage, burst and serious

injury.

Do not install the unit in a potentially

explosive or fl ammable atmosphere.

Failure to do so could result in fi re.

4

Do not insert your fi ngers

or other objects into the air

conditioner indoor or outdoor

unit, rotating parts may cause

injury.

Do not touch the outdoor unit during

lightning, it may cause electric

shock.

Do not expose yourself directly to

cold air for a long period to avoid

excess cooling.

Do not sit or step on the unit,

you may fall down accidentally.

Remote control

Do not allow infants and small

children to play with the remote

control to prevent them from

accidentally swallowing the batteries.

Power supply

Do not use a modifi ed

cord, joint cord,

extension cord or

unspecifi ed cord to

prevent overheating

and fi re.

To prevent overheating, fi re or

electric shock:

•

Do not share the same power outlet

with other equipment.

•

Do not operate with wet hands.

•

Do not over bend the power supply

cord.

•

Do not operate or stop the unit by

inserting or pulling out the power

plug.

If the supply cord is damaged,

it must be replaced by the

manufacturer, service agent or

similarly qualifi ed persons in order to

avoid a hazard.

It is strongly recommended to be

installed with Earth Leakage Circuit

Breaker (ELCB) or Residual Current

Device (RCD) to prevent electric

shock or fi re.

To prevent overheating, fi re or

electric shock:

•

Insert the power plug properly.

•

Dust on the power plug should be

periodically wiped with a dry cloth.

Stop using the product if any

abnormality/failure occurs and

disconnect the power plug or turn off

the power switch and breaker.

(Risk of smoke/fi re/electric shock)

Examples of abnormality/failure

•

The ELCB trips frequently.

•

Burning smell is observed.

•

Abnormal noise or vibration of the

unit is observed.

•

Water leaks from the indoor unit.

•

Power cord or plug becomes

abnormally hot.

•

Fan speed cannot be controlled.

•

The unit stops running immediately

even if it is switched on for

operation.

•

The fan does not stop even if the

operation is stopped.

Contact your local dealer

immediately for maintenance/repair.

This equipment must be earthed to

prevent electrical shock or fi re.

Prevent electric shock by switching

off the power supply and unplug:

-Before cleaning or servicing,

-When extended non-use, or

-During abnormally strong

lightning activity.

EnglishSafety precautions

5

Safety precautions

CAUTION

Indoor unit and outdoor unit

Do not wash the indoor unit with

water, benzine, thinner or scouring

powder to avoid damage or

corrosion at the unit.

Do not use for preservation of

precise equipment, food, animals,

plants, artwork or other objects. This

may cause quality deterioration, etc.

Do not use any combustible

equipment in front of the airfl ow

outlet to avoid fi re propagation.

Do not expose plants or pet directly

to airfl ow to avoid injury, etc.

Do not touch the sharp

aluminium fi n, sharp parts may

cause injury.

Do not switch ON the indoor unit

when waxing the fl oor. After waxing,

aerate the room properly before

operating the unit.

Do not install the unit in oily and

smoky areas to prevent damage to

the unit.

Do not dismantle the unit for

cleaning purpose to avoid injury.

Do not step onto an unstable bench

when cleaning the unit to avoid

injury.

Do not place a vase or water

container on the unit. Water may

enter the unit and degrade the

insulation. This may cause an

electric shock.

Do not open window or door for

long time during operation, it may

lead to ineffi cient power usage and

uncomfortable temperature changes.

Prevent water leakage by ensuring

drainage pipe is:

-Connected properly,

-Kept clear of gutters and containers,

or

-Not immersed in water

After a long period of use or use with

any combustible equipment, aerate

the room regularly.

After a long period of use, make

sure the installation rack does not

deteriorate to prevent the unit from

falling down.

Remote control

Do not use rechargeable (Ni-Cd)

batteries. It may damage the remote

control.

To prevent malfunction or damage of

the remote control:

•

Remove the batteries if the unit

is not going to be used for a long

period of time.

•

New batteries of the same type

must be inserted following the

polarity stated.

Power supply

Do not disconnect the plug by pulling

the cord to prevent electric shock.

6

WARNING

This appliance is fi lled with

R32

(mild fl ammable refrigerant).

If the refrigerant is leaked and

exposed to an external ignition

source, there is a risk of fi re.

Indoor unit and outdoor unit

The appliance shall be installed,

and/or operated in a room with fl oor

area larger than Amin (m²) and

keep away from ignition sources,

such as heat/sparks/open fl ame

or hazardous areas such as gas

appliances, gas cooking, reticulated

gas supply systems or electric

cooking appliances, etc.(Refer to

Table A of Installation instructions

table for Amin (m²))

Be aware that refrigerant may

not contain an odour, highly

recommended to ensure suitable

fl ammable refrigerant gas detectors

are present, operating and able to

warn of a leak.

Keep any required ventilation

openings clear of obstruction.

Do not pierce or burn as the

appliance is pressurized. Do not

expose the appliance to heat, fl ame,

sparks, or other sources of ignition.

Else it may explode and cause injury

or death.

Precaution for using R32

refrigerant

The basic installation work procedures

are the same as conventional refrigerant

(R410A, R22) models.

Since the working pressure is

higher than that of refrigerant R22

models, some of the piping and

installation and service tools are

special. Especially, when replacing

a refrigerant R22 model with a

new refrigerant R32 model, always

replace the conventional piping and

fl are nuts with the R32 and R410A

piping and fl are nuts on the outdoor

unit side.

For R32 and R410A, the same fl are

nut on the outdoor unit side and pipe

can be used.

The mixing of different refrigerants

within a system is prohibited. Models

that use refrigerant R32 and R410A

have a different charging port thread

diameter to prevent erroneous

charging with refrigerant R22 and for

safety.

Therefore, check beforehand. [The

charging port thread diameter for

R32 and R410A is 1/2 inch.]

Must always ensure that foreign

matter (oil, water, etc.) does not

enter the piping. Also, when storing

the piping, securely seal the opening

by pinching, taping, etc. (Handling of

R32 is similar to R410A.)

•

Operation, maintenance, repairing

and refrigerant recovery should be

carried out by trained and certifi ed

personnel in the use of fl ammable

refrigerants and as recommended

by the manufacturer. Any personnel

conducting an operation, servicing

or maintenance on a system or

associated parts of the equipment

should be trained and certifi ed.

English

Safety precautions

7

Safety precautions

•

Any part of refrigerating circuit

(evaporators, air coolers, AHU,

condensers or liquid receivers) or

piping should not be located in the

proximity of heat sources, open

fl ames, operating gas appliance or

an operating electric heater.

•

The user/owner or their authorised

representative shall regularly check

the alarms, mechanical ventilation

and detectors, at least once a

year, where as required by national

regulations, to ensure their correct

functioning.

•

A logbook shall be maintained. The

results of these checks shall be

recorded in the logbook.

•

In case of ventilations in occupied

spaces shall be checked to confi rm

no obstruction.

•

Before a new refrigerating system

is put into service, the person

responsible for placing the system

in operation should ensure that

trained and certifi ed operating

personnel are instructed on the

basis of the instruction manual

about the construction, supervision,

operation and maintenance of the

refrigerating system, as well as the

safety measures to be observed,

and the properties and handling of

the refrigerant used.

•

The general requirement of

trained and certifi ed personnel are

indicated as below:

a) Knowledge of legislation,

regulations and standards

relating to fl ammable

refrigerants; and,

b) Detailed knowledge of and

skills in handling fl ammable

refrigerants, personal protective

equipment, refrigerant

leakage prevention, handling

of cylinders, charging, leak

detection, recovery and

disposal; and,

c) Able to understand and to apply

in practice the requirements

in the national legislation,

regulations and Standards; and,

d) Continuously undergo regular

and further training to maintain

this expertise.

1. Installation (Space)

•

Product with fl ammable

refrigerants, shall not be installed in

an unventilated space, if that space

is smaller than Amin (m²).

•

In case of fi eld charge, the effect

on refrigerant charge caused by

the different pipe length has to be

quantifi ed, measured and labelled.

•

Must ensure the installation of pipework shall be kept to a minimum.

Avoid use dented pipe and do not

allow acute bending.

•

Must ensure that pipe-work shall be

protected from physical damage.

•

Must comply with national gas

regulations, state municipal rules

and legislation. Notify relevant

authorities in accordance with all

applicable regulations.

•

Must ensure mechanical

connections be accessible for

maintenance purposes.

•

In cases that require mechanical

ventilation, ventilation openings

shall be kept clear of obstruction.

•

When disposal of the product, do

follow to the precautions in #12 and

comply with national regulations.

Always contact to local municipal

offi ces for proper handling.

8

2. Servicing

2-1. Service personnel

•

The system is inspected, regularly

supervised and maintained by

a trained and certifi ed service

personnel who is employed by the

person user or party responsible.

•

Ensure the actual refrigerant

charge size is in accordance with

the room size within which the

refrigerant containing parts are

installed.

•

Ensure refrigerant charge not to

leak.

•

Any qualifi ed person who is

involved with working on or

breaking into a refrigerant circuit

should hold a current valid

certifi cate from an industry-

accredited assessment authority,

which authorizes their competence

to handle refrigerants safely in

accordance with an industry

recognised assessment

specifi cation.

•

Servicing shall only be performed

as recommended by the equipment

manufacturer. Maintenance and

repair requiring the assistance of

other skilled personnel shall be

carried out under the supervision of

the person competent in the use of

fl ammable refrigerants.

•

Servicing shall be performed

only as recommended by the

manufacturer.

2-2. Work

•

Prior to beginning work on

systems containing fl ammable

refrigerants, safety checks are

necessary to ensure that the risk

of ignition is minimised. For repair

to the refrigerating system, the

precautions in #2-2 to #2-8 must

be followed before conducting

work on the system.

•

Work shall be undertaken under

a controlled procedure so as to

minimize the risk of a fl ammable

gas or vapour being present while

the work is being performed.

•

All maintenance staff and others

working in the local area shall be

instructed and supervised on the

nature of work being carried out.

•

Avoid working in confi ned spaces.

Always ensure away from source,

at least 2 meter of safety distance,

or zoning of free space area of at

least 2 meter in radius.

•

Wear appropriate protective

equipment, including respiratory

protection, as conditions warrant.

•

Ensure that the conditions within

the area have been made safe

by limit of use of any fl ammable

material. Keep all sources of

ignition and hot metal surfaces

away.

English

Safety precautions

9

Safety precautions

2-3. Checking for presence of

refrigerant

•

The area shall be checked with an

appropriate refrigerant detector

prior to and during work, to

ensure the technician is aware of

potentially fl ammable atmospheres.

•

Ensure that the leak detection

equipment being used is suitable

for use with fl ammable refrigerants,

i.e. non sparking, adequately

sealed or intrinsically safe.

•

In case of leakage/spillage

happened, immediately ventilate

area and stay upwind and away

from spill/release.

•

In case of leakage/spillage

happened, do notify persons down

wind of the leaking/spill, isolate

immediate hazard area and keep

unauthorized personnel out.

2-4. Presence of fi re extinguisher

•

If any hot work is to be conducted

on the refrigeration equipment or

any associated parts, appropriate

fi re extinguishing equipment shall

be available at hand.

•

Have a dry powder or CO2 fi re

extinguisher adjacent to the

charging area.

2-5. No ignition sources

•

No person carrying out work in

relation to a refrigeration system

which involves exposing any pipe

work that contains or has contained

fl ammable refrigerant shall use

any sources of ignition in such a

manner that it may lead to the risk

of fi re or explosion. He/She must

not be smoking when carrying out

such work.

•

All possible ignition sources,

including cigarette smoking, should

be kept suffi ciently far away from

the site of installation, repairing,

removing and disposal, during

which fl ammable refrigerant

can possibly be released to the

surrounding space.

•

Prior to work taking place, the

area around the equipment is to

be surveyed to make sure that

there are no fl ammable hazards or

ignition risks.

•

“No Smoking” signs shall be

displayed.

2-6. Ventilated area

•

Ensure that the area is in the open

or that it is adequately ventilated

before breaking into the system or

conducting any hot work.

•

A degree of ventilation shall

continue during the period that the

work is carried out.

•

The ventilation should safely

disperse any released refrigerant

and preferably expel it externally

into the atmosphere.

10

2-7. Checks to the refrigeration

equipment

•

Where electrical components are

being changed, they shall be fi t

for the purpose and to the correct

specifi cation.

•

At all times the manufacturer’s

maintenance and service

guidelines shall be followed.

•

If in doubt consult the

manufacturer’s technical

department for assistance.

•

The following checks shall be

applied to installations using

fl ammable refrigerants.

-

The charge size is in accordance

with the room size within which

the refrigerant containing parts

are installed.

-

The ventilation machinery and

outlets are operating adequately

and are not obstructed.

-

If an indirect refrigerating circuit is

being used, the secondary circuit

shall be checked for the presence

of refrigerant.

-

Marking to the equipment

continues to be visible and

legible. Markings and signs that

are illegible shall be corrected.

-

Refrigeration pipe or components

are installed in a position where

they are unlikely to be exposed

to any substance which may

corrode refrigerant containing

components, unless the

components are constructed of

materials which are inherently

resistant to being corroded or are

properly protected against being

so corroded.

2-8. Checks to electrical devices

•

Repair and maintenance to

electrical components shall include

initial safety checks and component

inspection procedures.

•

Initial safety checks shall include

but not limit to:-

-

That capacitors are discharged:

this shall be done in a safe

manner to avoid possibility of

sparking.

-

That there no live electrical

components and wiring are

exposed while charging,

recovering or purging the system.

-

That there is continuity of earth

bonding.

•

At all times the manufacturer’s

maintenance and service guidelines

shall be followed.

•

If in doubt consult the

English

manufacturer’s technical

department for assistance.

•

If a fault exists that could

compromise safety, then no

electrical supply shall be connected

to the circuit until it is satisfactorily

dealt with.

•

If the fault cannot be corrected

immediately but it is necessary to

continue operation, an adequate

Safety precautions

temporary solution shall be used.

•

The owner of the equipment must

be informed or reported so all

parties are advised thereinafter.

11

Safety precautions

3. Repairs to sealed components

•

During repairs to sealed

components, all electrical supplies

shall be disconnected from the

equipment being worked upon prior

to any removal of sealed covers,

etc.

•

If it is absolutely necessary to

have an electrical supply to

equipment during servicing, then

a permanently operating form of

leak detection shall be located at

the most critical point to warn of a

potentially hazardous situation.

•

Particular attention shall be paid

to the following to ensure that by

working on electrical components,

the casing is not altered in such a

way that the level of protection is

affected.This shall include damage

to cables, excessive number of

connections, terminals not made

to original specifi cation, damage to

seals, incorrect fi tting of glands, etc.

•

Ensure that apparatus is mounted

securely.

•

Ensure that seals or sealing

materials have not degraded such

that they no longer serve the

purpose of preventing the ingress

of fl ammable atmospheres.

•

Replacement parts shall be in

accordance with the manufacturer’s

specifi cations.

NOTE: The use of silicon sealant

may inhibit the effectiveness of some

types of leak detection equipment.

Intrinsically safe components do not

have to be isolated prior to working

on them.

4. Repair to intrinsically safe

components

•

Do not apply any permanent

inductive or capacitance loads to

the circuit without ensuring that

this will not exceed the permissible

voltage and current permitted for

the equipment in use.

•

Intrinsically safe components are

the only types that can be worked

on while live in the presence of a

fl ammable atmosphere.

•

The test apparatus shall be at the

correct rating.

•

Replace components only with

parts specifi ed by the manufacturer.

Unspecifi ed parts by manufacturer

may result ignition of refrigerant in

the atmosphere from a leak.

5. Cabling

•

Check that cabling will not be

subject to wear, corrosion,

excessive pressure, vibration,

sharp edges or any other adverse

environmental effects.

•

The check shall also take into

account the effects of aging or

continual vibration from sources

such as compressors or fans.

6. Detection of fl ammable

refrigerants

•

Under no circumstances shall

potential sources of ignition be

used in the searching or detection

of refrigerant leaks.

•

A halide torch (or any other detector

using a naked fl ame) shall not be

used.

12

7. Leak detection methods

The following leak detection

methods are deemed acceptable for

all refrigerant systems.

•

No leaks shall be detected when

using detection equipment with a

capability of 10−6 Pa·m3/s or better,

for example, a helium sniffer.

•

Electronic leak detectors may

be used to detect fl ammable

refrigerants, but the sensitivity may

not be adequate, or may need recalibration.

(Detection equipment shall be

calibrated in a refrigerant-free

area.)

•

Ensure that the detector is not a

potential source of ignition and is

suitable for the refrigerant used.

•

Leak detection equipment shall

be set at a percentage of the

LFL of the refrigerant and shall

be calibrated to the refrigerant

employed and the appropriate

percentage of gas (25 % maximum)

is confi rmed.

•

Leak detection fl uids are suitable

for use with most refrigerants but

the use of detergents containing

chlorine shall be avoided as

the chlorine may react with the

refrigerant and corrode the copper

pipe-work.

•

If a leak is suspected, all naked

fl ames shall be removed/

extinguished.

•

If a leakage of refrigerant is found

which requires brazing, all of the

refrigerant shall be recovered from

the system, or isolated (by means

of shut off valves) in a part of the

system remote from the leak.

Oxygen free nitrogen (OFN) shall

then be purged through the system

both before and during the brazing

process.

OFN = oxygen free nitrogen,

type of inert gas.

8. Removal and evacuation

•

When breaking into the refrigerant

circuit to make repairs – or for

any other purpose – conventional

procedures shall be used. However,

it is important that best practice

is followed since fl ammability is

a consideration. The following

procedure shall be adhered to:

remove refrigerant -> purge the

circuit with inert gas -> evacuate ->

purge again with inert gas -> open

the circuit by cutting or brazing

•

The refrigerant charge shall be

recovered into the correct recovery

cylinders.

•

The system shall be “fl ushed” with

OFN to render the unit safe.

•

This process may need to be

repeated several times.

•

Compressed air or oxygen shall not

English

be used for this task.

•

Flushing shall be achieved by

breaking the vacuum in the system

with OFN and continuing to fi ll until

the working pressure is achieved,

then venting to atmosphere, and

fi nally pulling down to a vacuum.

•

This process shall be repeated until

no refrigerant is within the system.

•

When the fi nal OFN charge is used,

Safety precautions

the system shall be vented down

to atmospheric pressure to enable

work to take place.

•

This operation is absolutely vital if

brazing operations on the pipe work

are to take place.

•

Ensure that the outlet for the

vacuum pump is not close to

any ignition sources and there is

ventilation available.

13

Safety precautions

9. Charging procedures

•

In addition to conventional

charging procedures, the following

requirements shall be followed.

-

Ensure that contamination of

different refrigerants does not

occur when using charging

equipment.

-

Hoses or lines shall be as short

as possible to minimize the

amount of refrigerant contained

in them.

-

Cylinders shall be kept upright.

-

Ensure that the refrigeration

system is earthed prior to

charging the system with

refrigerant.

-

Label the system when charging

is complete (if not already).

-

Extreme care shall be taken

not to over fi ll the refrigeration

system.

•

Prior to recharging the system it

shall be pressure tested with OFN

(refer to #7).

•

The system shall be leak tested on

completion of charging but prior to

commissioning.

•

A follow up leak test shall be carried

out prior to leaving the site.

•

Electrostatic charge may

accumulate and create a hazardous

condition when charging and

discharging the refrigerant.To

avoid fi re or explosion, dissipate

static electricity during transfer by

grounding and bonding containers

and equipment before charging/

discharging.

10. Decommissioning

•

Before carrying out this procedure,

it is essential that the technician

is completely familiar with the

equipment and all its details.

•

It is recommended good practice

that all refrigerants are recovered

safely.

•

Prior to the task being carried

out, an oil and refrigerant sample

shall be taken in case analysis is

required prior to re-use of reclaimed

refrigerant.

•

It is essential that electrical power

is available before the task is

commenced.

a) Become familiar with the

equipment and its operation.

b) Isolate system electrically.

c) Before attempting the procedure

ensure that:

•

mechanical handling equipment

is available, if required, for

handling refrigerant cylinders;

•

all personal protective equipment

is available and being used

correctly;

•

the recovery process is

supervised at all times by a

competent person;

•

recovery equipment and

cylinders conform to the

appropriate standards.

d) Pump down refrigerant system,

if possible.

e) If a vacuum is not possible,

make a manifold so that

refrigerant can be removed from

various parts of the system.

f) Make sure that cylinder is

situated on the scales before

recovery takes place.

g) Start the recovery machine and

operate in accordance with

manufacturer’s instructions.

h) Do not over fi ll cylinders. (No

more than 80 % volume liquid

charge).

14

i) Do not exceed the maximum

working pressure of the cylinder,

even temporarily.

j) When the cylinders have been

fi lled correctly and the process

completed, make sure that the

cylinders and the equipment

are removed from site promptly

and all isolation valves on the

equipment are closed off.

k) Recovered refrigerant shall

not be charged into another

refrigeration system unless it has

been cleaned and checked.

•

Electrostatic charge may accumulate

and create a hazardous condition

when charging or discharging the

refrigerant.To avoid fi re or explosion,

dissipate static electricity during

transfer by grounding and bonding

containers and equipment before

charging/discharging.

11. Labelling

•

Equipment shall be labelled stating

that it has been de-commissioned

and emptied of refrigerant.

•

The label shall be dated and signed.

•

Ensure that there are labels on the

equipment stating the equipment

contains fl ammable refrigerant.

12. Recovery

•

When removing refrigerant from

a system, either for servicing

or decommissioning, it is

recommended good practice that all

refrigerants are removed safely.

•

When transferring refrigerant

into cylinders, ensure that only

appropriate refrigerant recovery

cylinders are employed.

•

Ensure that the correct number

of cylinders for holding the total

system charge are available.

•

All cylinders to be used are

designated for the recovered

refrigerant and labelled for that

refrigerant (i.e. special cylinders for

the recovery of refrigerant).

•

Cylinders shall be complete

with pressure relief valve and

associated shut-off valves in good

working order.

•

Recovery cylinders are evacuated

and, if possible, cooled before

recovery occurs.

•

The recovery equipment shall

be in good working order with a

set of instructions concerning the

equipment that is at hand and

shall be suitable for the recovery of

fl ammable refrigerants.

•

In addition, a set of calibrated

weighing scales shall be available

and in good working order.

•

Hoses shall be complete with leakfree disconnect couplings and in

good condition.

•

Before using the recovery machine,

check that it is in satisfactory

working order, has been properly

maintained and that any associated

electrical components are sealed

to prevent ignition in the event

of a refrigerant release.Consult

manufacturer if in doubt.

•

The recovered refrigerant shall be

returned to the refrigerant supplier

in the correct recovery cylinder, and

the relevant Waste Transfer Note

arranged.

•

Do not mix refrigerants in recovery

units and especially not in cylinders.

•

If compressors or compressor oils

are to be removed, ensure that

they have been evacuated to an

acceptable level to make certain

that fl ammable refrigerant does not

remain within the lubricant.

•

The evacuation process shall be

carried out prior to returning the

compressor to the suppliers.

•

Only electric heating to the

compressor body shall be

employed to accelerate this

process.

•

When oil is drained from a system,

it shall be carried out safely.

English

Safety precautions

15

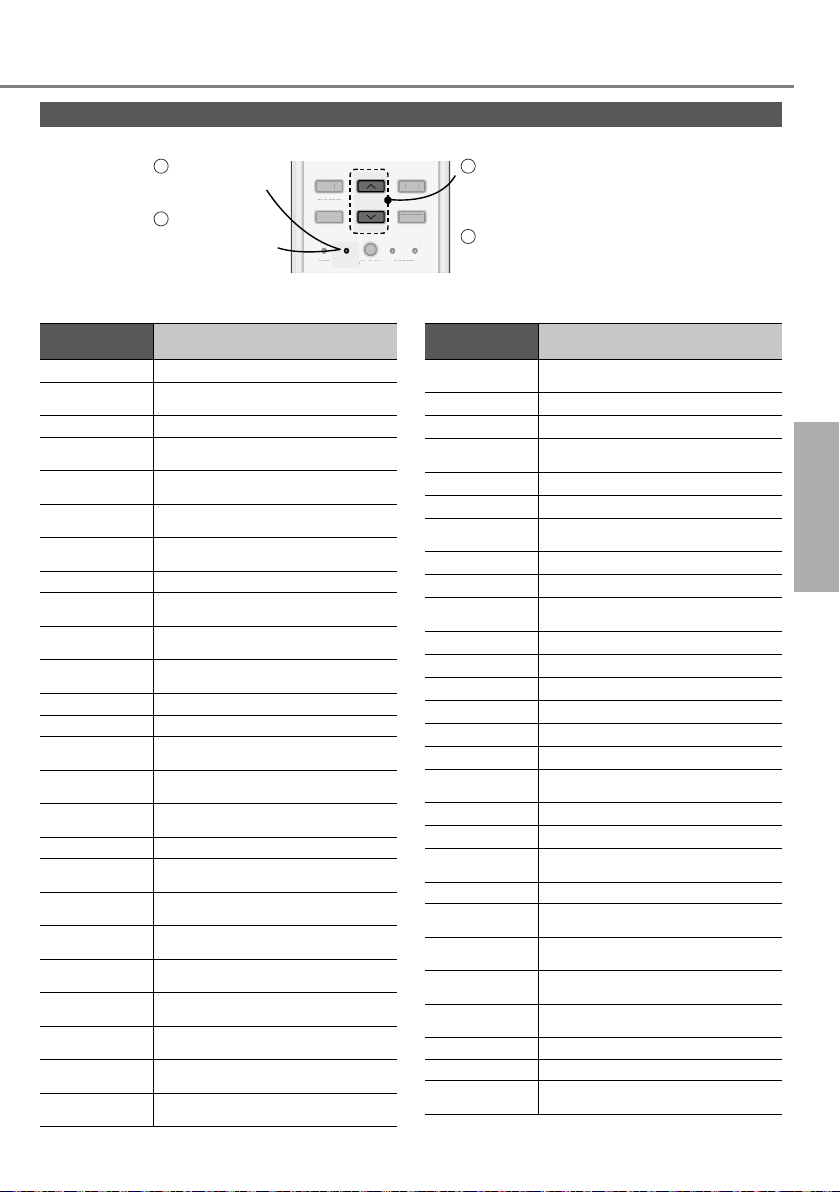

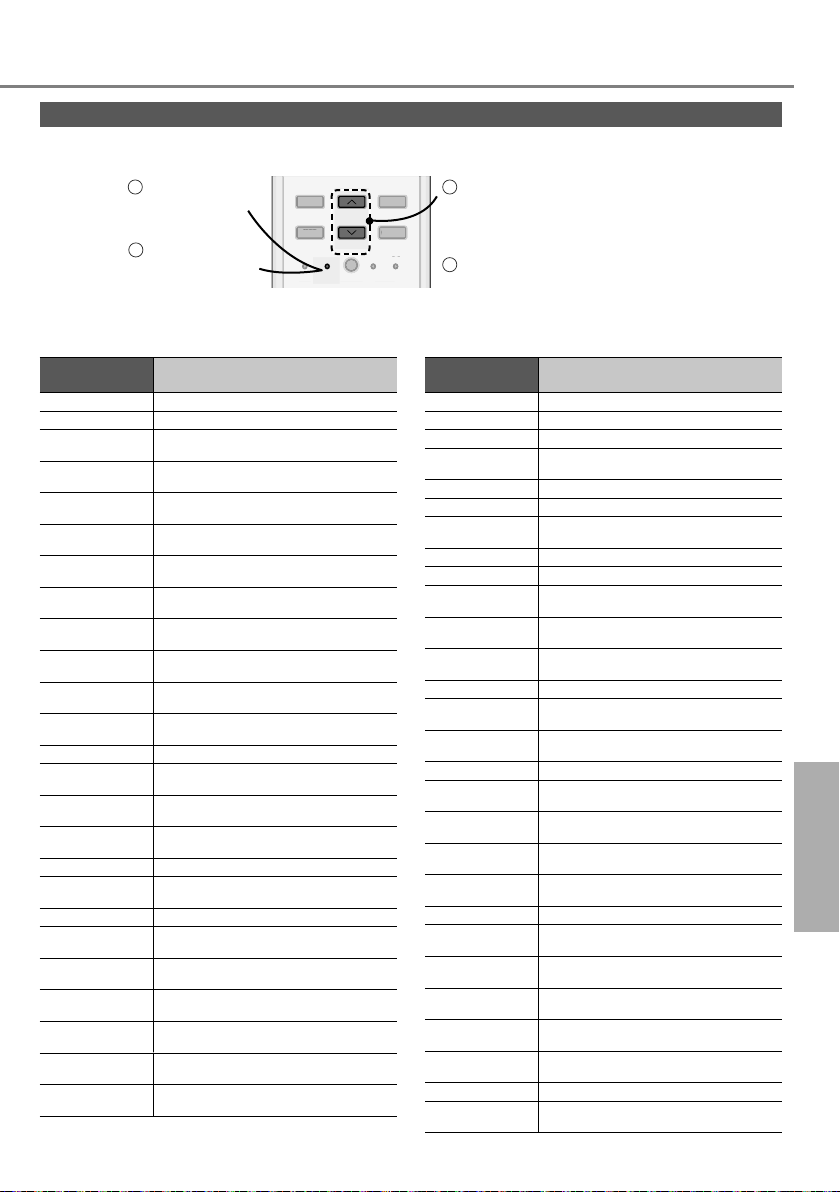

How to use

FAN SPEEDFAN SPEED

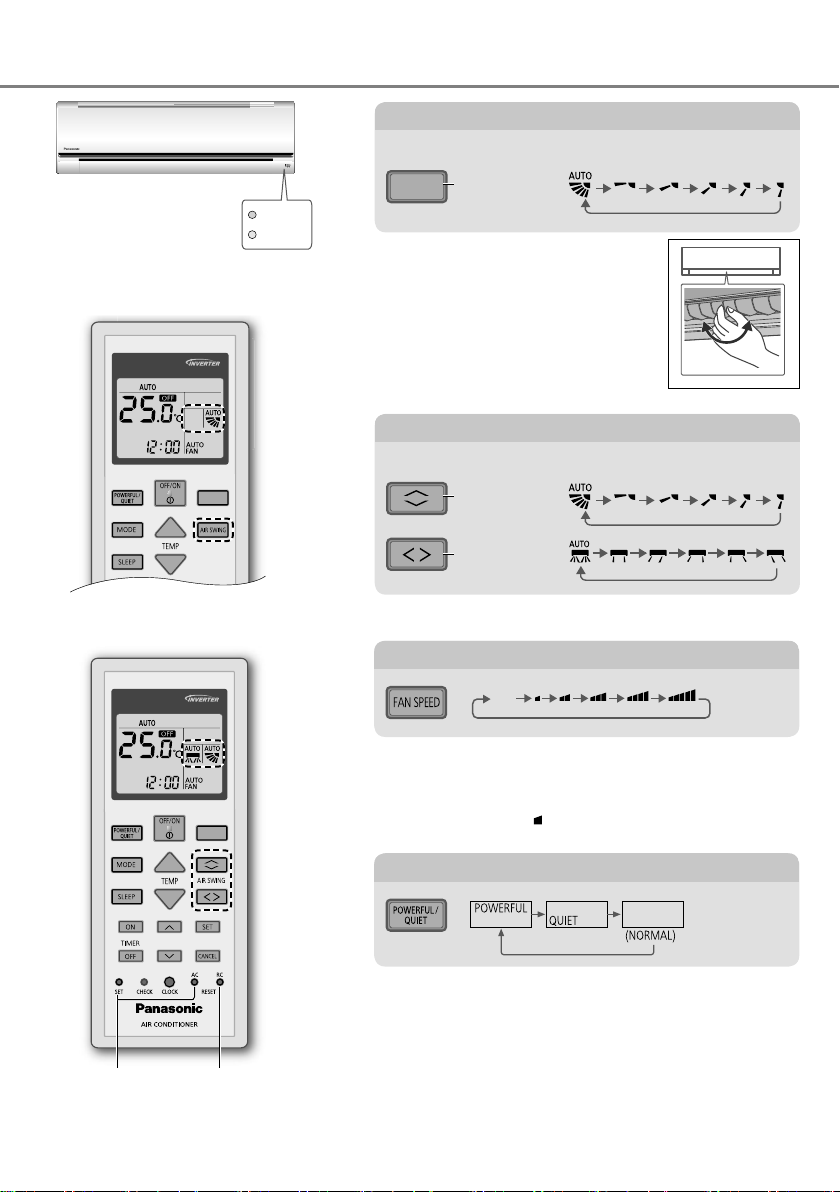

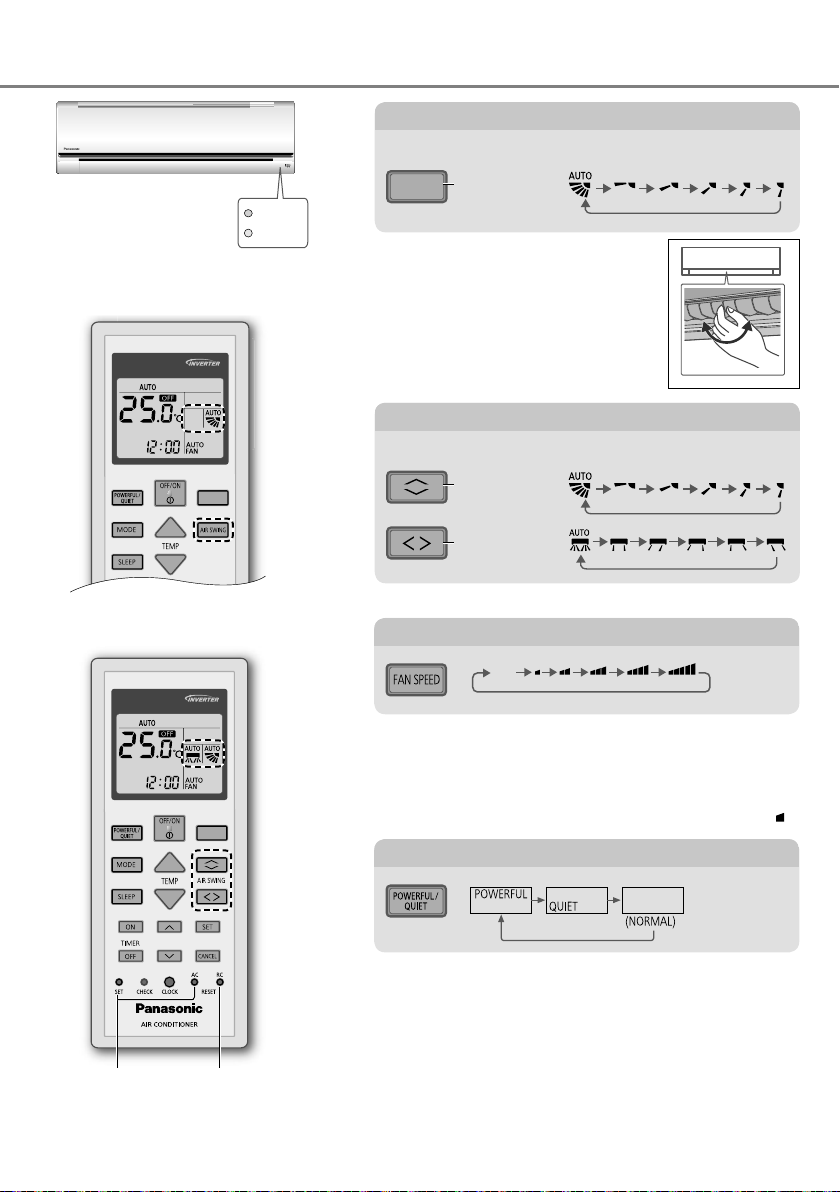

To adjust airfl ow direction

To adjust airfl ow direction

(CS-FZ25/35/50UKE)

Indicator

CS-FZ25/35/50UKE

CS-FZ60UKE

FAN SPEED

POWER

TIMER

AIR SWING

Upper direction

• Do not adjust the fl ap by hand.

• For lateral direction, it is manually

adjustable as shown.

To adjust airfl ow direction

To adjust airfl ow direction

(CS-FZ60UKE)

Upper direction

AIR SWING

Lateral direction

• Do not adjust the fl ap by hand.

To adjust fan speed

AUTO

FAN

• For AUTO, the indoor fan speed is automatically

adjusted according to the operation mode.

• To have low noise priority operation, select the

lowest fan speed (

).

Not used

in normal

operations.

16

Press to restore

the remote

control to default

setting.

To switch between powerful/quiet

POWERFUL:

To reach the preset temperature quickly

• This operation stops automatically after 20 minutes.

QUIET:

To enjoy quiet operation

• This operation reduces airfl ow noise.

See "To learn more..." for details.

CANCEL

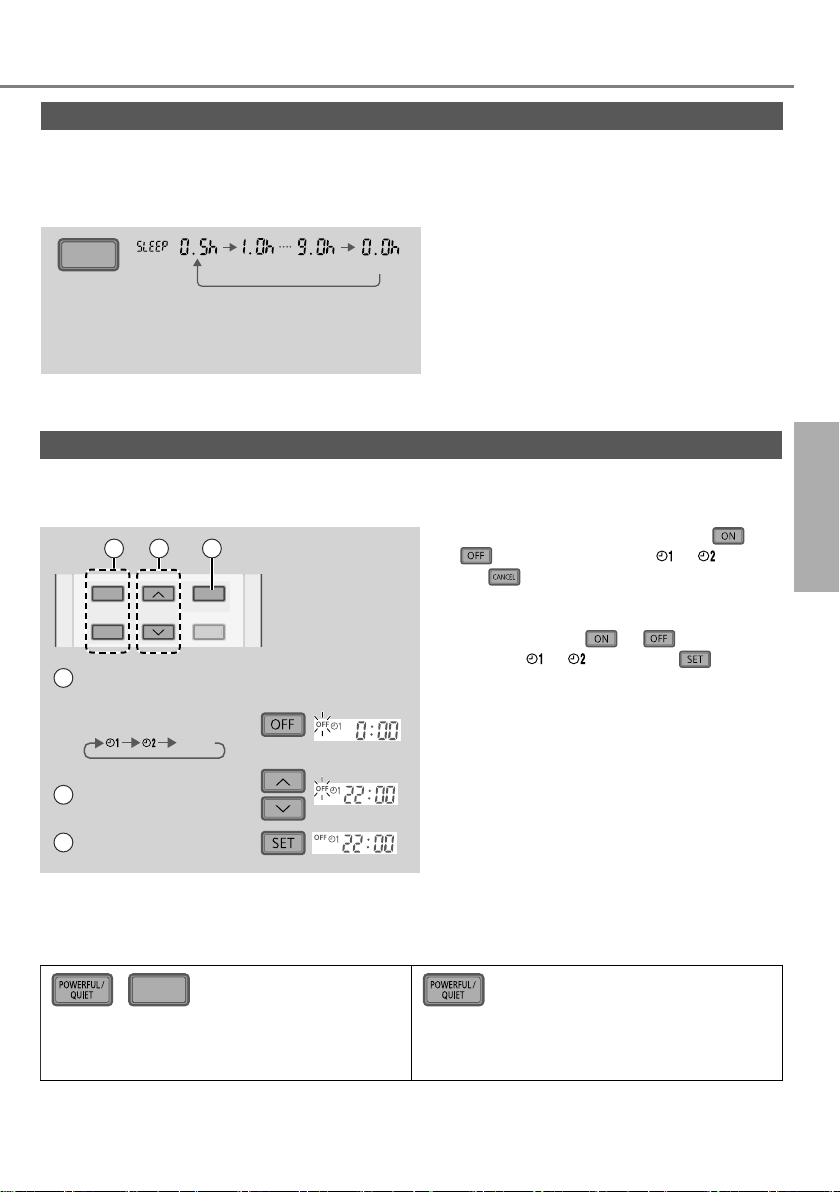

To maximise comfort while sleeping

This operation provides you with a comfortable environment while sleeping. It will

automatically adjust the sleep pattern temperature during the activation period. The indoor

unit indicator will dim when this operation is activated. This is not applicable if the indicator

brightness has been manually dimmed.

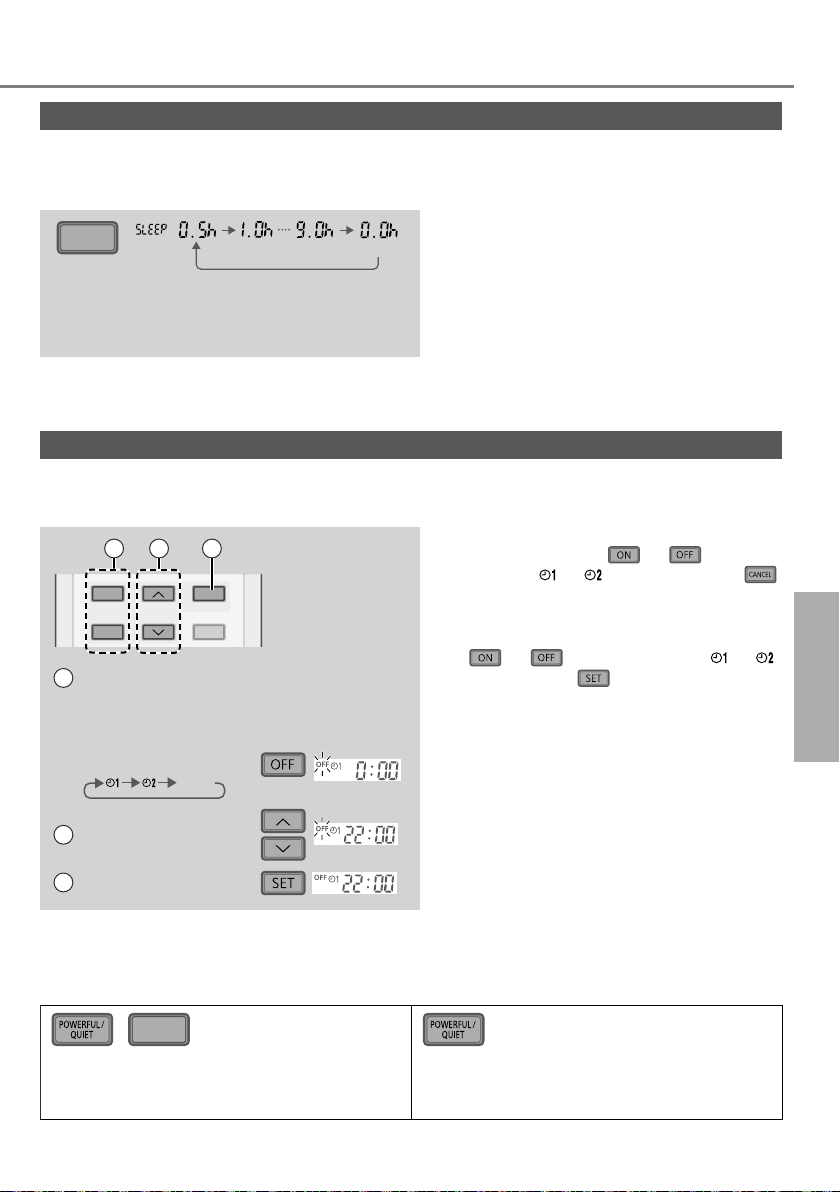

•

SLEEP

(Cancel)

This operation is incorporated with the

activation timer (0.5, 1, 2, 3, 4, 5, 6, 7, 8 or 9

hours).

This operation can be set together with timer.

Sleep operation has the priority over OFF

timer.

•

This operation can be cancelled by pressing

the respective button when the sleep timer

reaches 0.0h.

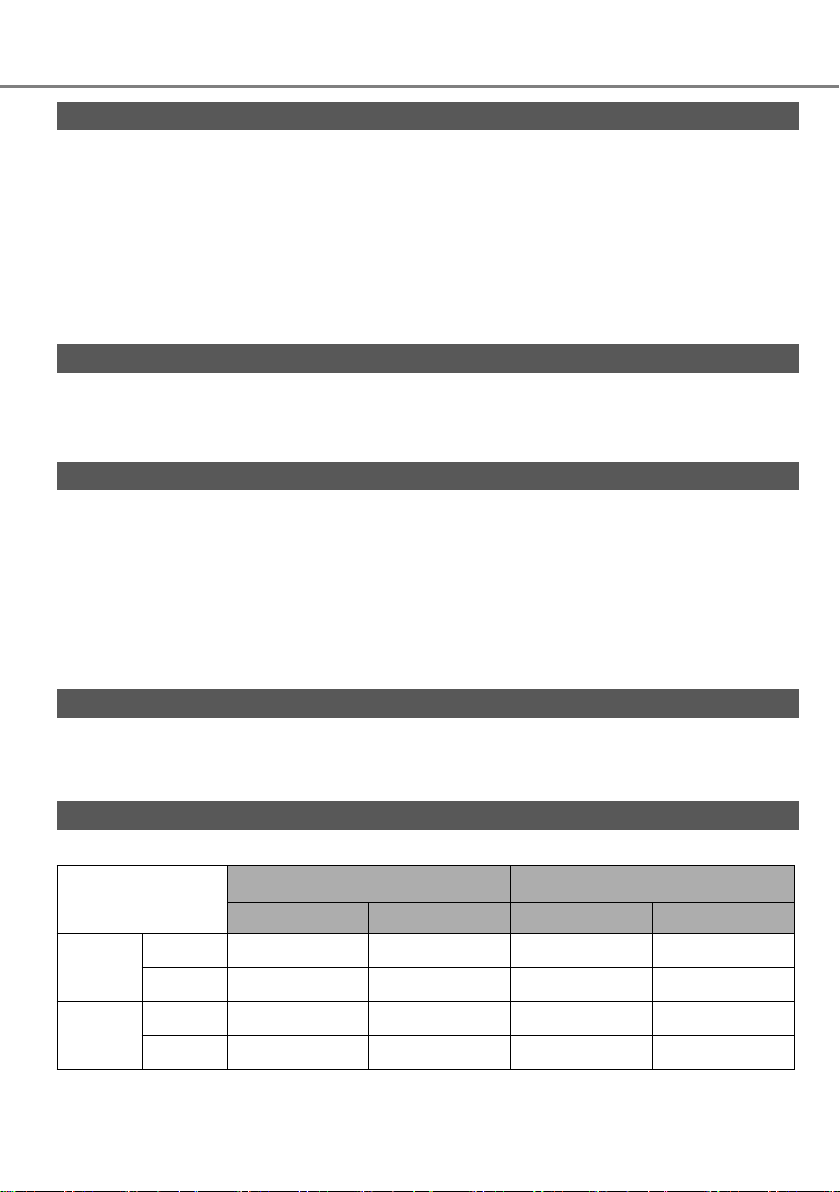

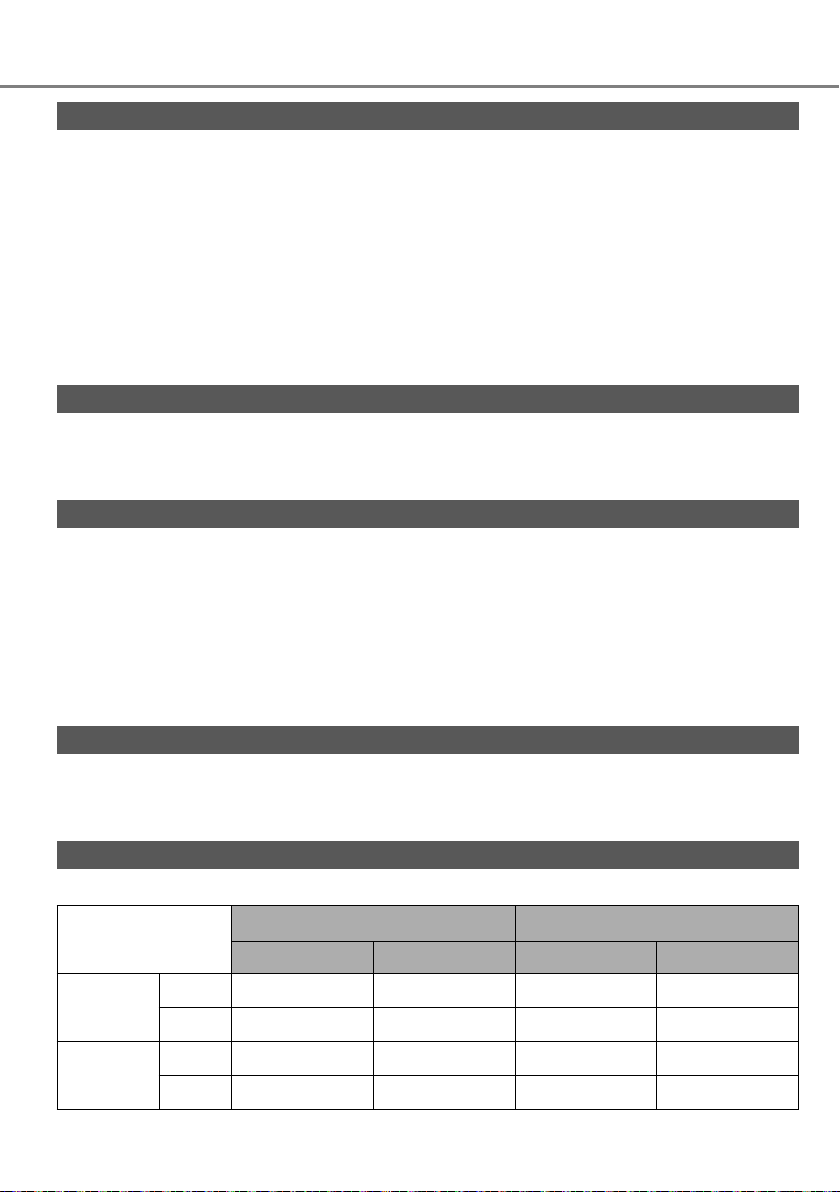

To set the timer

2 sets of ON and OFF timers are available to turn ON or OFF the unit at different preset

times.

21 3

ON

TIMER

OFF

Select ON or OFF

1

timer

• Each time pressed:

Cancel

SET

CANCEL

Example:

OFF at 22:00

• To cancel ON or OFF timer, press

or

to select respective or then

press

.

• If timer is cancelled manually or due to

power failure, you can restore the timer

again by pressing

respective

or then press .

or to select

• The nearest timer setting will be displayed

and will activate in sequence.

• Timer operation is based on the clock set

in the remote control and repeats daily

once set. For clock setting, please refer to

2 Set the time

Quick Guide.

English

How to use

3 Confi rm

Note

SLEEP

,

• Can be activated in all modes and can be

cancelled by pressing the respective button

again.

• Cannot be selected at the same time.

17

To learn more...

Operation mode

AUTO : During operation, the POWER indicator will blinks at initial.

HEAT : The POWER indicator blinks at the initial stage of this operation. Unit takes a while

COOL : Provides effi cient comfort cooling to suit your needs.

DRY : Unit operates at low fan speed to give a gentle cooling operation.

Energy saving temperature setting

Operating the unit within the recommended temperature range may save energy.

HEAT : 20.0 °C ~ 24.0 °C /

COOL: 26.0 °C ~ 28.0 °C /

Air fl ow direction

In COOL/DRY mode:

(CS-FZ25/35/50UKE)

If AUTO is set, the fl ap swings up/down automatically.

(CS-FZ60UKE)

If

AUTO is set, the fl ap swings left/right and up/down automatically.

In HEAT mode:

If AUTO is set, the horizontal fl ap is fi xed at the predetermined position. The vertical fl ap

swings left/right after the temperature rises.

Unit selects operation mode every 10 minutes according to the setting and room

temperatures.

to warm up.

• For system which HEAT mode has been locked, if operation mode other than

HEAT is selected, the indoor unit stops and the POWER indicator blinks.

68 °F ~ 75 °F.

79 °F ~ 82 °F.

Auto restart control

If power is resumed after a power failure, the operation will restart automatically after a

period of time with previous operation mode and airfl ow direction.

• This control is not applicable when TIMER is set.

Operating conditions

Use this air conditioner in the temperature range indicated in the table.

Temperature

COOL

HEAT

DBT: Dry bulb temperature, WBT: Wet bulb temperature

°C (°F)

DBT WBT DBT WBT

Max. 32 (89.6) 23 (73.4) 43 (109.4) 26 (78.8)

Min. 16 (60.8) 11 (51.8) -10 (14.0) -

Max. 30 (86.0) - 24 (75.2) 18 (64.4)

Min. 16 (60.8) - -15 (5.0) -16 (3.2)

Indoor Outdoor

18

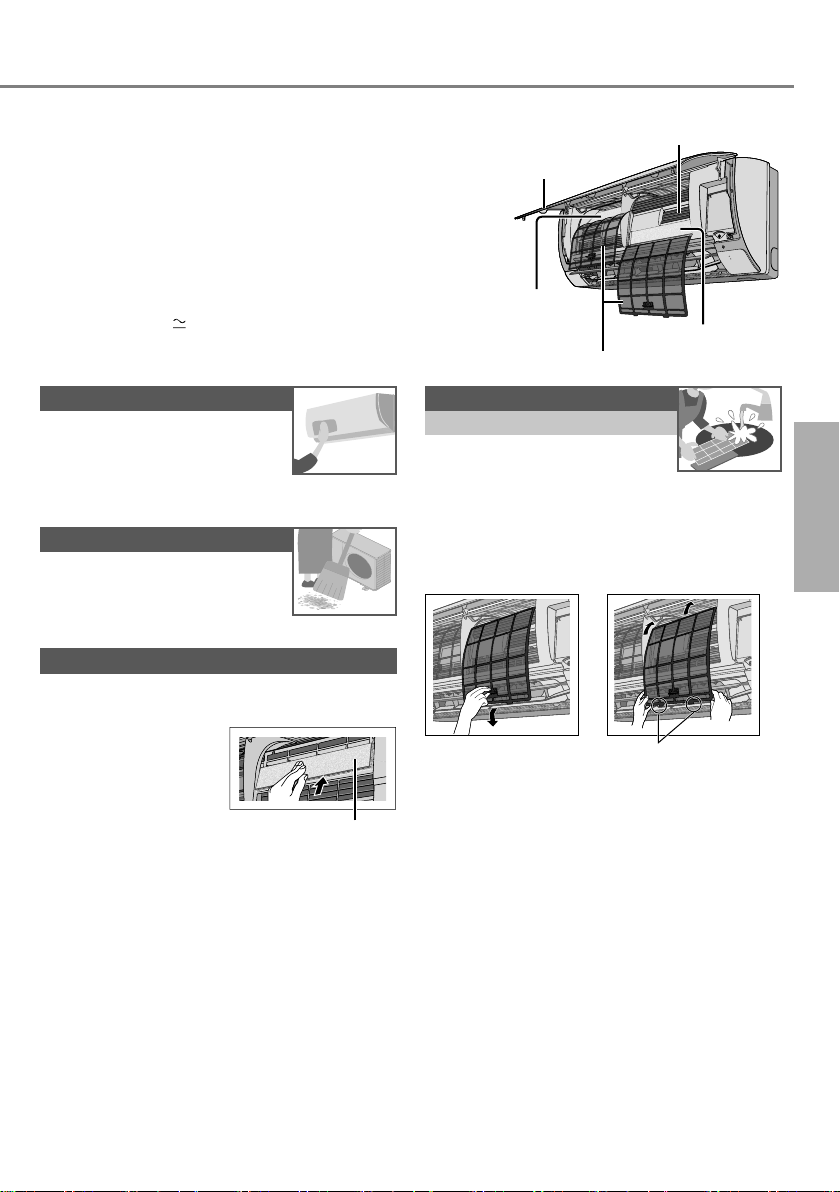

Cleaning instructions

To ensure optimal performance of the unit,

cleaning has to be carried out at regular intervals.

Dirty unit may cause malfunction and you may

see error code “H 99”. Please consult authorised

dealer.

• Switch off the power supply and unplug before

cleaning.

• Do not touch the aluminium fi n, sharp parts may

cause injury.

• Do not use benzine, thinner or scouring powder.

• Use only soap (

pH 7) or neutral household

detergent.

• Do not use water hotter than 40 °C / 104 °F.

Indoor unit

Wipe the unit gently with a soft,

dry cloth.

Coils and fans should be clean

for at least every 6 months by

authorised dealer.

Outdoor unit

Clear debris that surround the

unit.

Air fi lters

Once every 2 weeks

• Wash/rinse the fi lters gently

with water to avoid damage to

the fi lter surface.

• Dry the fi lters thoroughly under shade,

away from fi re or direct sunlight.

• Replace any damaged fi lters.

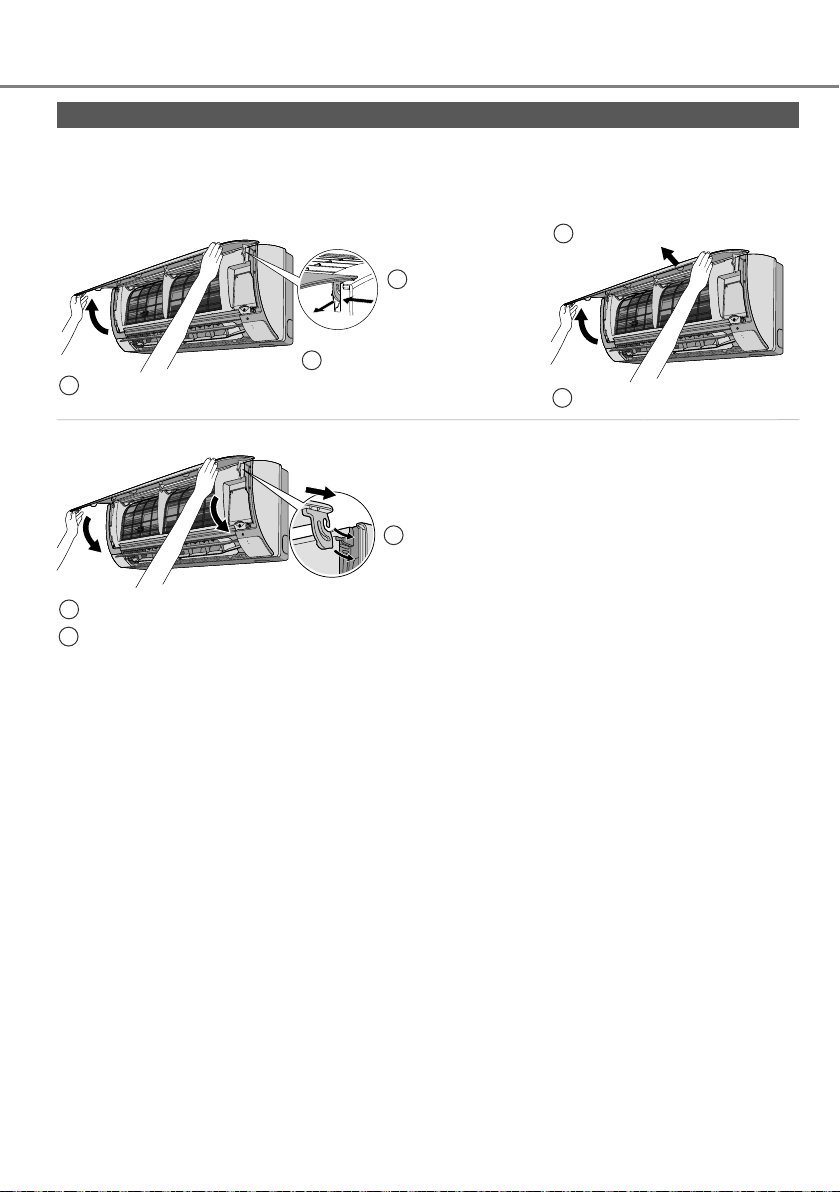

Remove air fi lter Attach air fi lter

Clear any blockage from the

drain pipe.

Air Purifying Filter

• Do not wash/rinse the fi lter with water.

• Replace the fi lter every 2 years or replace

any damaged fi lter.

Part no.: CZ-SA31P

Indoor unit

Front panel

Air Purifying Filter

(CS-FZ25/35UKE)

Air fi lters

Aluminium fi n

Air Purifying Filter

(CS-FZ50/60UKE)

Insert into the unit

POWER

TIMER

EnglishTo learn more... / Cleaning instructions

Air Purifying Filter

19

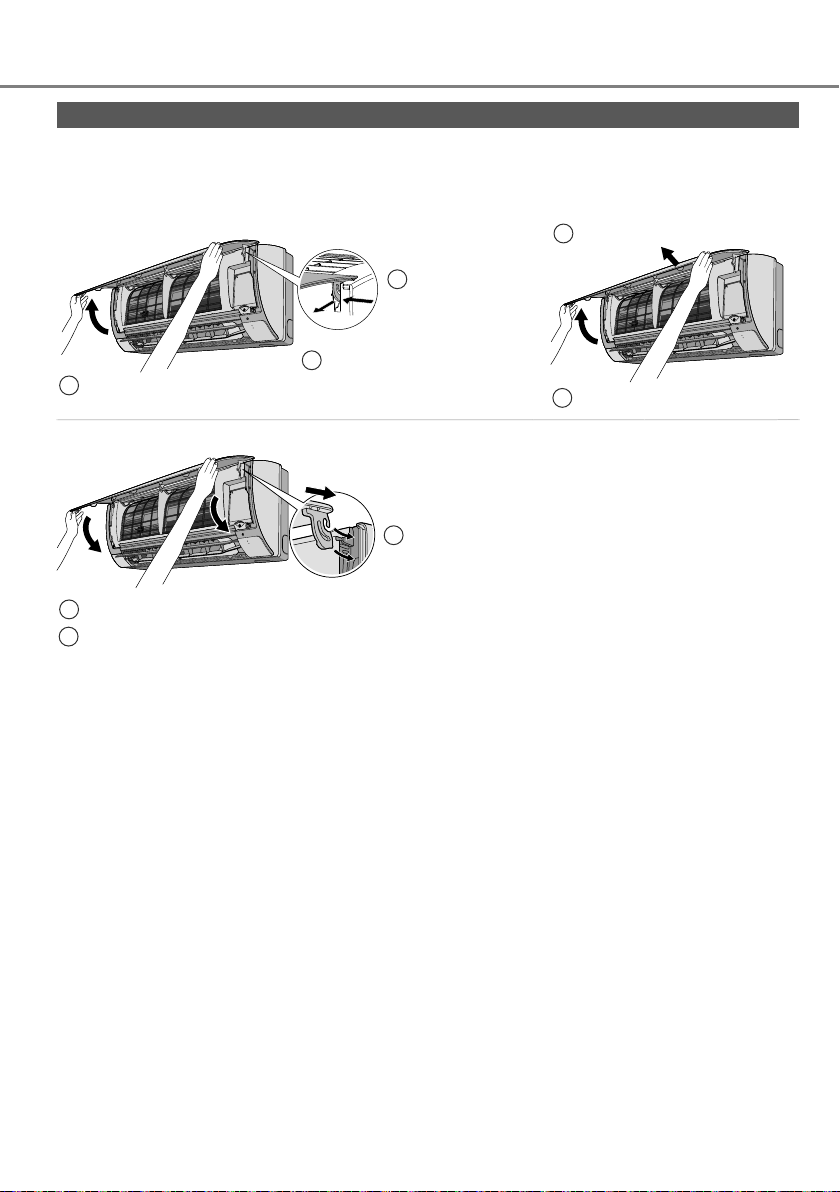

Cleaning instructions

Front panel

Wash gently and dry.

Remove the front panel

(For CS-FZ25/35/50UKE) (For CS-FZ60UKE)

Raise.

1

Close it securely

For both sides

POWER

TIMER

Pull out.

3

Slide to the

2

right or left.

Pull out.

2

Raise.

1

POWER

TIMER

POWER

TIMER

Close down.

2

Press both ends of the front panel.

3

Insert at

1

both sides.

20

Troubleshooting

The following symptoms do not indicate malfunction.

Symptom Cause

POWER indicator blinks before the unit is

switched on.

POWER indicator blinks during HEAT mode

with no warm air supply (and fl ap is closed).

POWER indicator blinks and stops when

operate COOL/DRY mode.

TIMER indicator is always on. • The timer setting repeats daily once set.

Operation is delayed a few minutes after

restarting.

Cooling/heating capacity reduced during the

lowest fan speed setting.

Indoor fan stops occasionally during heating

operation.

Indoor fan stops occasionally during automatic

fan speed setting.

Airfl ow continues even after operation has

stopped.

The room has a peculiar odour. • This may be due to damp smell emitted by the wall,

Cracking sound during operation. • Changes of temperature caused the expansion/

Water fl owing sound during operation. • Refrigerant fl ow inside the unit.

Mist emerges from indoor unit. • Condensation effect due to cooling process.

Outdoor unit emits water/steam. • Condensation or evaporation occurs on pipes.

Dusts accumulated on the wall. • Due to air circulation or static electricity generated

Discoloration of some plastic parts. • Discoloration is subject to material types used in plastic

• This is a preliminary step in preparation for the

operation when the ON timer has been set.

When ON Timer is set, the unit may start earlier (up

to 35 minutes) before the actual set time in order to

achieve the desired temperature on time.

• The unit is in defrost mode (and AIR SWING is set to

AUTO).

• The system has locked to operate in HEAT mode only.

• The delay is a protection to the unit’s compressor.

• The low fan speed is low noise priority operation, so

cooling/heating capacity may be reduced (depending

on the condition). Increase the Fan Speed to increase

the capacity.

• To avoid unintended cooling effect.

• This helps to remove the surrounding odour.

• Extraction of remaining heat from the indoor unit

(maximum 30 seconds).

carpet, furniture or clothing.

contraction of the unit.

by the air conditioner. Some types of wall paper may

collect dusts easily (recommended to clean the area

around the air conditioner frequently).

parts, accelerated when exposed to heat, sun light, UV

light or environmental factor.

English

Check the following before calling for servicing.

Symptom Check

Operation in HEAT/COOL mode is not working

effi ciently.

Noisy during operation. • Check if the unit has been installed at an incline.

Remote control does not work.

(Display is dim or transmission signal is weak.)

The unit does not work. • Check if the circuit breaker is tripped.

The unit does not receive the signal from the

remote control.

• Set the temperature correctly.

• Close all doors and windows.

• Clean or replace the fi lters.

• Clear any obstruction at the air inlet and air outlet

vents.

• Close the front panel properly.

• Insert the batteries correctly.

• Replace weak batteries.

• Check if timers have been set.

• Make sure the receiver is not obstructed.

• Certain fl uorescent lights may interfere with signal

transmitter. Please consult authorised dealer.

Cleaning instructions / Troubleshooting

21

Troubleshooting

When...

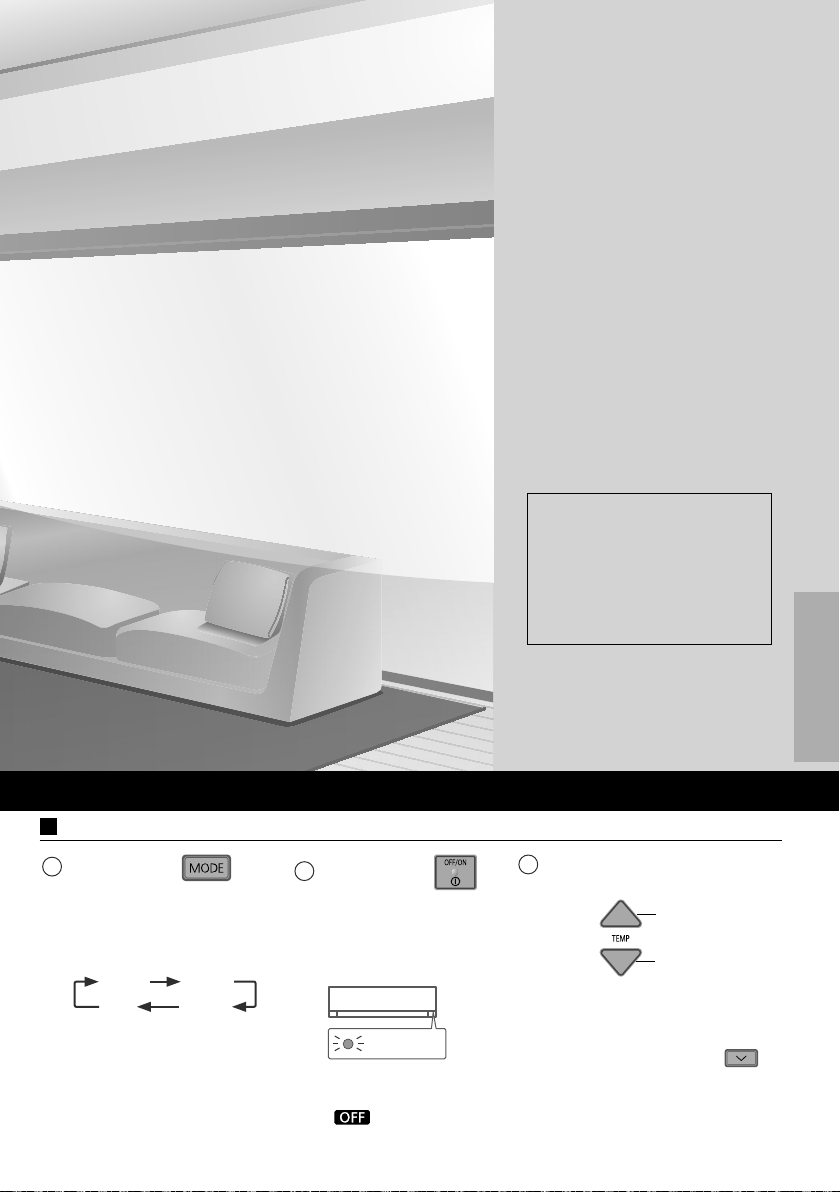

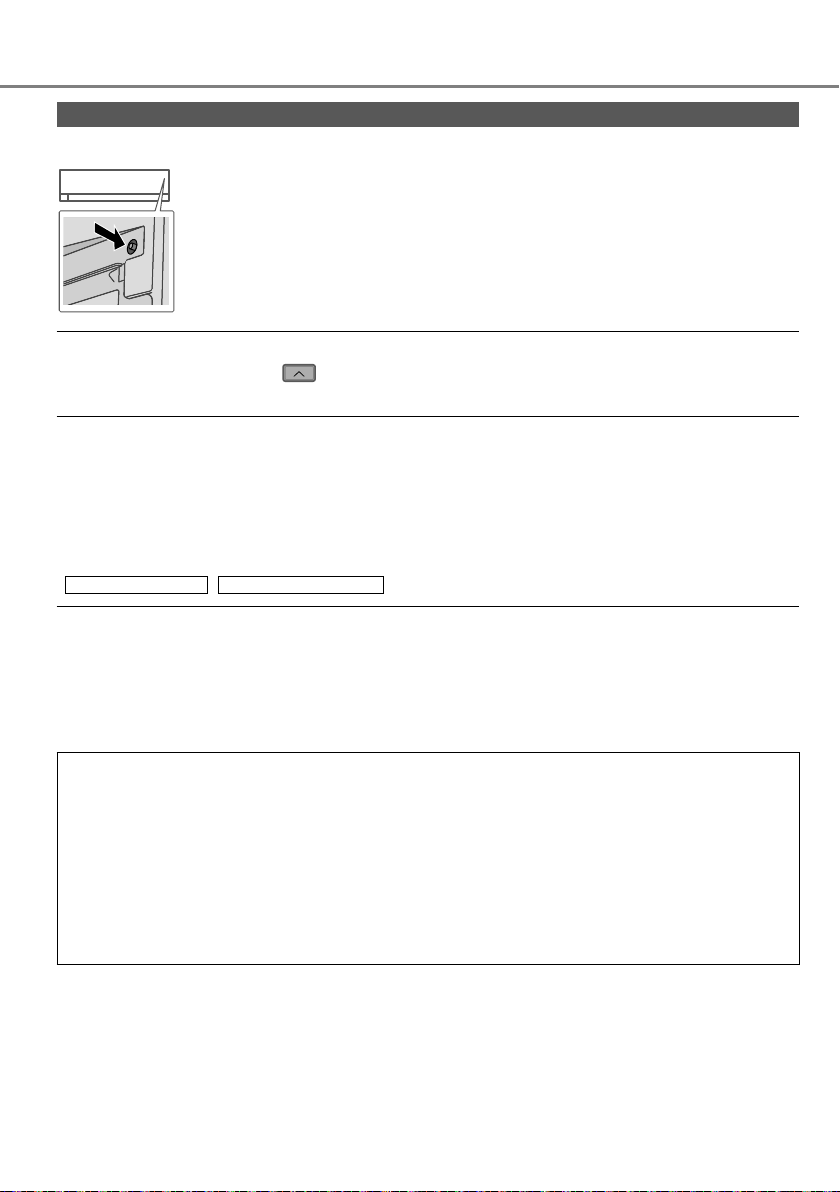

■ The remote control is missing or a malfunction has occurred

1.Raise the front panel.

2.Press the button once to use in AUTO mode.

3. Press and hold the button until you hear 1 beep, then release to use in

forced COOL mode.

4. Repeat step 3. Press and hold the button until you hear 2 beeps, then

release to use in forced HEAT mode.

5.Press the button again to turn off.

■ The indicators are too bright

• To dim or restore the unit’s indicator brightness, press

■ Conducting a seasonal inspection after extended non-use

• Check the remote control batteries.

• Check that there is no obstruction around the air inlet and outlet vents.

• Use Auto OFF/ON button to select COOL/HEAT operation. After 15 minutes of operation, it

is normal to have the following temperature difference between the air inlet and outlet vents:

COOL: ≥ 8 °C / 14.4 °F

■ The units are not going to be used for a long period of time

Activate HEAT mode for 2~3 hours to remove moisture left in the internal parts thoroughly to

•

prevent mould growth.

• Turn off the power supply and unplug.

• Remove the remote control batteries.

HEAT: ≥ 14 °C / 25.2 °F

and hold for 5 seconds.

NON SERVICEABLE CRITERIAS

TURN OFF THE POWER SUPPLY AND UNPLUG then please consult an authorised

dealer when in following conditions:

• Abnormal noise during operation.

• Water/foreign particles have entered the remote control.

• Water leaks from Indoor unit.

• Circuit breaker switches off frequently.

• Power cord becomes unnaturally warm.

• Switches or buttons are not functioning properly.

22

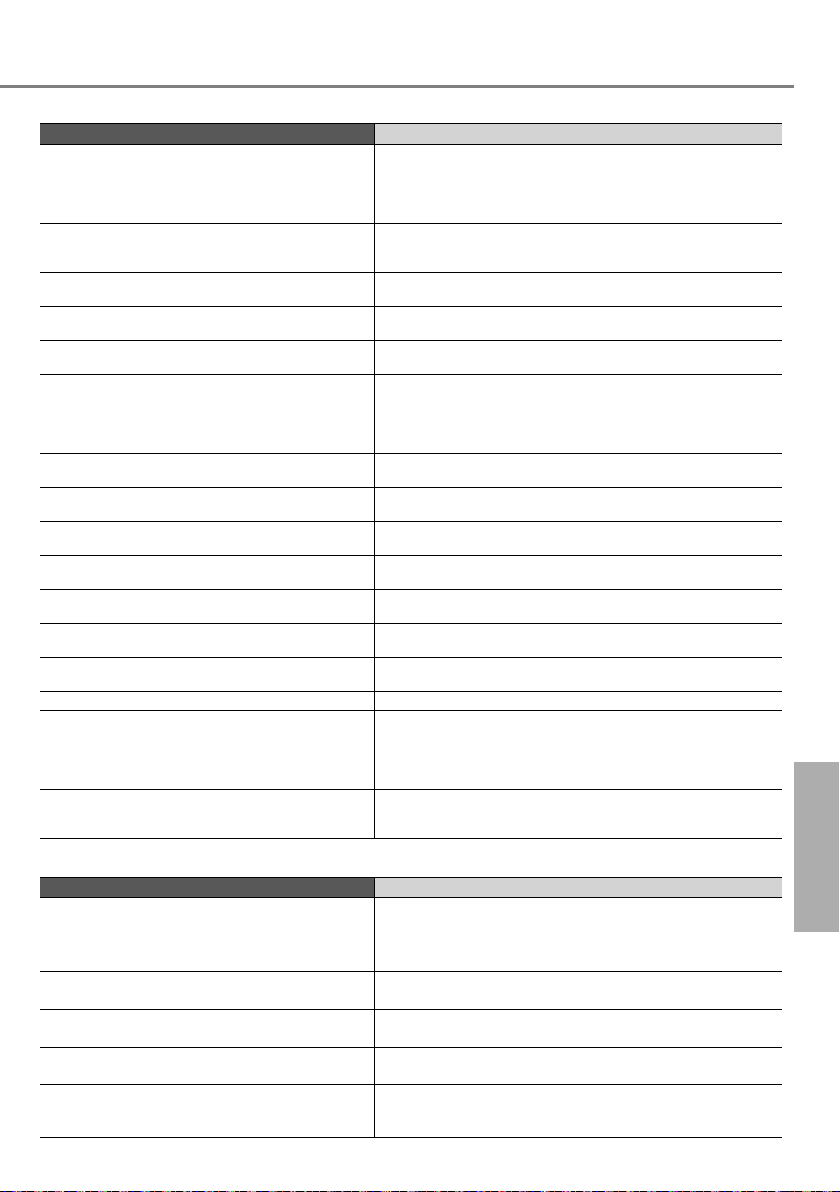

How to retrieve error codes

TIMER

S

CANCEL

ON

O

S

K

RES

C

RC

If the unit stops and the TIMER indicator blinks, use the remote control to retrieve the error code.

Press for

5 seconds

Press for 5

3

seconds to quit

checking

•

For certain errors, you may restart the unit for limited operation if there are 4 beeps when operation starts.

Diagnostic

display

Abnormality/Protection control

ON

TIMER

OFF

FF

A

SET CHECK CLOCK RESET

ET CLOC

AC

CANCEL

H 00 No memory of failure

H 11

Indoor/outdoor abnormal

communication

H 12 Indoor unit capacity unmatched

H 14

H 15

H 16

H 17

Indoor intake air temperature sensor

abnormality

Outdoor compressor temperature

sensor abnormality

Outdoor current transformer (CT)

abnormality

Outdoor suction temperature sensor

abnormality

H 19 Indoor fan motor mechanism lock

H 21

H 23

H 24

H 25

Indoor fl oat switch operation

abnormality

Indoor heat exchanger temperature

sensor 1 abnormality

Indoor heat exchanger temperature

sensor 2 abnormality

Indoor ion device abnormality

H 26 Minus ION abnormality

H 27

H 28

H 30

Outdoor air temperature sensor

abnormality

Outdoor heat exchanger temperature

sensor 1 abnormality

Outdoor discharge pipe temperature

sensor abnormality

H 31 Abnormal swimming pool sensor

H 32

H 33

H 34

H 35

H 36

H 37

H 38

H 39

Outdoor heat exchanger

temperature sensor 2 abnormality

Indoor/outdoor misconnection

abnormality

Outdoor heat sink temperature sensor

abnormality

Indoor/outdoor water adverse current

abnormality

Outdoor gas pipe temperature

sensor abnormality

Outdoor liquid pipe temperature

sensor abnormality

Indoor/outdoor mismatch

(brand code)

Abnormal indoor operating unit or

standby units

21

SET

ET

Press until you hear beep

sound, then write down the

error code

Turn the unit off and

4

RC

ET

reveal the error code to

authorised dealer

Diagnostic

display

H 41

H 50 Ventilation fan motor locked

H 51 Ventilation fan motor locked

H 52

H 58 Indoor gas sensor abnormality

H 59 Eco sensor

H 64

H 67 nanoe abnormality

H 70 Light sensor

H 71

H 72 Abnormality tank temperature sensor

H 97 Outdoor fan motor mechanism lock

H 98 Indoor high pressure protection

H 99 Indoor operating unit freeze protection

F 11 4-way valve switching abnormality

F 16 Total running current protection

F 17

F 18 Dry circuit blocked abnormality

F 87 Control box overheat protection

F 90

F 91 Refrigeration cycle abnormality

F 93

F 94

F 95

F 96

F 97 Compressor overheating protection

F 98 Total running current protection

F 99

Abnormality/Protection control

Abnormal wiring or piping

connection

Left-right limit switch fi xing

abnormality

abnormality

Outdoor high pressure sensor

abnormality

abnormality

DC cooling fan inside control board

abnormality

Indoor standby units freezing

abnormality

Power factor correction (PFC)

circuit protection

Outdoor compressor abnormal

revolution

Compressor discharge pressure

overshoot protection

Outdoor cooling high pressure

protection

Power transistor module overheating

protection

Outdoor direct current (DC) peak

detection

English

Troubleshooting

* Some error code may not be applicable to your model. Consult authorised dealer for clarifi cation.

23

Fournit un confort maximum avec des méthodes

FAN SPEED

FAN SPEED

d’économie d’énergie optimales.

Utilisez la

télécommande

dans les 8 m du

récepteur de la

télécommande de

l’unité intérieure.

24

* L’affi chage et les

fonctions de la

télécommande peuvent

varier selon le modèle.

Guide Rapide

Insertion des piles

B

Retirez le couvercle

1

A

arrière de la

télécommande.

Placez des piles AAA ou

2

R03.

Fermez le couvercle.

3

1

2

3

A

Réglage de l’horloge

Appuyez sur et

1

réglez l’heure time

•

Maintenez la touche

enfoncée pendant environ

5 secondes pour passer du

mode d’affi chage 12 heures

(am/pm) ou au mode 24

heures et inversement.

Confi rmez

2

.

.

Nous vous remercions d’avoir

porté votre choix sur un climatiseur

Panasonic.

Table des matières

Consignes de sécurité

Consignes d’utilisation

Pour en savoir plus

Instructions de nettoyage

Dépannage

Informations

......................................

...............................................

......

26-37

.....

38-39

..........................

.........

40

41-42

43-45

69

Accessoires

•

Télécommande

•

Piles AAA ou R03 × 2

•

Support de la télécommande

•

Vis pour le support de la

télécommande × 2

Les illustrations de ce mode d’emploi

sont fournies à titre d’exemple

uniquement et peuvent présenter des

différences par rapport à l’appareil

proprement dit. Celui-ci peut être modifi é

sans préavis à des fi ns d’amélioration.

Français

B

Fonctionnement de base

Appuyez sur

1

pour sélectionner le

mode souhaité.

AUTO HEAT

DRY

COOL

Appuyez sur

2

pour mettre le

fonctionnement en

marche/arrêt.

POWER

• Veuillez noter

que l’indication

se trouve sur

l’affi cheur pour

démarrer l’unité.

Sélectionnez la

3

température souhaitée.

Haut

Bas

Plage de sélection:

16.0 °C ~ 30.0 °C /

60 °F ~ 86 °F.

• Maintenez la touche

enfoncée pendant environ

10 secondes passer

l’indication de température

en °C ou en °F.

25

Consignes de sécurité

Entrée d’air

Entrée d’air

Sortie d’air

Sortie d’air

Pour éviter des blessures corporelles sur vousmême et sur les autres ou des dégâts matériels,

respectez les instructions ci-dessous :

Tout dysfonctionnement dû au non-respect des

instructions peut occasionner des nuisances ou

des dégâts dont la gravité est classée comme

décrit ci-après :

Ces appareils ne sont pas conçus pour être

accessibles du grand public.

Ce symbole signale

la présence d’un

AVERTISSEMENT

ATTENTION

Les instructions à respecter sont classées

d’après les symboles suivants :

Ce symbole désigne une

action INTERDITE.

Ces symboles désignent des

actions OBLIGATOIRES.

Unité

intérieure

Sortie d’air

Télécommande

Unité

extérieure

danger pouvant

provoquer des

blessures graves

ou mortelles.

Ce symbole signale

la présence d’un

danger pouvant

provoquer

des blessures

corporelles ou des

dégâts matériels.

Alimentation électrique

Entrée d’air

Entrée d’air

Sortie d’air

AVERTISSEMENT

Unité intérieure et unité extérieure

Cet appareil peut être utilisé par des

enfants âgés de 8 ans et plus et par

des personnes ayant des capacités

physiques, sensorielles ou mentales

réduites, ou dénuées d’expérience

et de connaissances si elles ont été

formées et encadrées pour l’utilisation

de cet appareil en toute sécurité et

comprennent bien les dangers auxquels

ils s’exposent.

Les enfants ne doivent pas jouer avec

l’appareil. Le nettoyage et l’entretien par

l’utilisateur ne doivent pas être effectués

par des enfants sans surveillance.

Veuillez consulter un revendeur agréé

ou un spécialiste pour le nettoyage des

pièces internes et pour la réparation,

l’installation, le retrait et la réinstallation

de l’unité. Une installation et une

manipulation incorrectes pourraient

occasionner des fuites, un choc

électrique ou un incendie.

Validez auprès du revendeur agréé ou

du spécialiste l’usage de tout type de

réfrigérant spécifi é. L’utilisation d’un

type de réfrigérant autre que le type

spécifi é peut endommager le produit ou

provoquer des explosions, des brûlures,

etc.

N'utilisez pas de moyens d'accélérer le

processus de dégivrage ou de nettoyer,

autres que ceux qui sont conseillés par

le fabricant.

Toute méthode inappropriée ou

utilisation de matériel incompatible peut

occasionner une détérioration du produit,

une explosion et de graves blessures.

N’installez pas l’appareil dans une

atmosphère potentiellement explosive ou

infl ammable.

Sinon, il y a un risque d’incendie.

26

N’insérez jamais vos doigts ou

des objets dans l’unité intérieure

ou extérieure du climatiseur, les

parties tournantes peuvent causer

des blessures.

Ne touchez pas l’unité extérieure

au cours d’un orage, cela pourrait

provoquer un choc électrique.

Ne vous exposez pas directement à de

l’air froid pendant une période prolongée

afi n d’éviter un refroidissement excessif.

Ne vous asseyez pas et

ne montez pas sur l’unité,

vous risquez de tomber

accidentellement.

Télécommande

Maintenez la télécommande hors de

portée des bébés et des enfants pour

éviter qu’ils n’avalent accidentellement

les piles.

Alimentation

N’utilisez pas de cordon

modifi é, de raccords, de

rallonge ou de cordon non

spécifi é afi n d’éviter une

surchauffe et un incendie.

Pour éviter une surchauffe, un incendie

ou un choc électrique :

•

Ne partagez pas la prise d’alimentation

avec un autre appareil.

•

N’utilisez pas l’unité avec des mains

mouillées.

•

Ne pas plier excessivement la fi che

électrique.

•

Ne pas opérer ou arrêter l’unité en

insérant ou en tirant sur la fi che

électrique.

Si le cordon d’alimentation est

endommagé, il doit être remplacé par

le fabriquant, par un de ses techniciens

ou par une personne qui possède des

qualifi cations équivalentes afi n d’éviter

tout risque.

Il est fortement conseillé d’installer

un disjoncteur-détecteur de fuite à la

terre (DDFT) ou un dispositif à courant

résiduel (DCR) afi n d’éviter un choc

électrique ou un incendie.

Pour éviter une surchauffe, un incendie

ou un choc électrique :

•

Insérez la fi che d’alimentation

correctement.

•

Il faut régulièrement essuyer la poussière

sur la fi che d’alimentation à l’aide d’un

chiffon sec.

Cesser d’utiliser le produit lorsqu’une

anomalie ou défaillance quelconque

se produit et débrancher la fi che

d’alimentation ou mettre hors tension

l’interrupteur et le disjoncteur.

(Risque de fumée / feu / choc électrique)

Exemples d’anomalie ou défaillance

•

L’ELCB se déclenche fréquemment.

•

Odeur de brûlé est observée.

•

Un bruit ou des vibrations anormales de

l’unité sont observés.

•

Fuite d’eau de l’unité intérieure.

•

Le cordon d’alimentation ou la prise

deviennent anormalement chaud.

•

La vitesse du ventilateur ne peut pas

être contrôlée.

•

L’unité s’arrête de fonctionner

immédiatement même si elle est

activée pour opérer.

•

Le ventilateur ne s’arrête pas même si

l’opération est arrêtée.

Contacter immédiatement votre

revendeur local pour l’entretien /

réparation.

Cet équipement doit être raccordé à la

terre afi n d’éviter un choc électrique ou

un incendie.

Prévenez les chocs électriques en

coupant l’alimentation et en débranchant

l’unité :

- Avant le nettoyage ou l’entretien.

- En cas de non utilisation prolongée, ou

- En période d’activité orageuse

anormalement forte.

Français Consignes de sécurité

27

Consignes de sécurité

ATTENTION

Unité intérieure et unité extérieure

Afi n d’éviter des dommages ou de la

corrosion sur l’unité, ne nettoyez pas

l’unité intérieure avec de l’eau, du

benzène, du solvant ou de la poudre à

récurer.

N’utilisez pas l’unité pour conserver des

appareils de précision, des aliments,

des plantes, des œuvres d’art ou autres

objets. Cela pourrait entraîner une

détérioration de la qualité, etc.

N’utiliser pas d’appareil à combustibles

dans la direction du fl ux d’air afi n d’éviter

toute propagation du feu.

N’exposez pas des plantes ou des

animaux de compagnie directement au

fl ux d’air pour éviter des blessures, etc.

Ne touchez pas l’ailette pointue

d’aluminium, les parties pointues

peuvent causer des dommages.

Ne mettez pas l’unité intérieure sous

tension lorsque vous cirez le sol. Après

le cirage, aérez suffi samment la pièce

avant de faire fonctionner l’unité.

Afi n d’éviter d’endommager l’unité, ne

l’installez pas dans des zones grasses et

enfumées.

Afi n d’éviter des blessures, ne démontez

pas l’unité pour la nettoyer.

Afi n d’éviter des blessures, ne marchez

pas sur un banc instable lors du

nettoyage de l’unité.

Ne placez pas de vas ou de récipient

d’eau sur l’unité. De l’eau peut pénétrer

à l’intérieur de l’unité et dégrader

l’isolation. Cela pourrait entraîner un

choc électrique.

N'ouvrez pas de fenêtre ou de porte

pendant longtemps lorsque l'appareil est

en marche, car cela peut compromettre

la consommation électrique et

provoquer des variations de température

inconfortables.

Prévenez les fuites d’eau en vous

assurant que le tuyau de vidange est :

- Correctement raccordé,

- Dégagé de toute gouttière et récipient, ou

- Non immergé dans l’eau

Après une longue période d’utilisation

ou après une utilisation avec un appareil

à combustibles, aérez régulièrement la

pièce.

Après une longue période d’utilisation,

assurez-vous que le support

d’installation n’est pas détérioré afi n

d’éviter une chute de l’unité.

Télécommande

N’utilisez pas de piles rechargeables

(Ni-Cd). Cela pourrait endommager la

télécommande.

Pour éviter tout dysfonctionnement ou

dommages à la télécommande :

•

Retirez les piles si vous envisagez de

ne pas utiliser l’appareil pendant une

période prolongée.

•

De nouvelles piles du même type

doivent être insérées en respectant la

polarité indiquée.

Alimentation

Ne débranchez pas la fi che en tirant sur

le cordon d’éviter un choc électrique.

28

AVERTISSEMENT

L'appareil est rempli de R32

(réfrigérant infl ammable doux).

Il existe un risque d'incendie

en cas de fuite du réfrigérant

et d'exposition à une source

d'infl ammation externe.

Unité intérieure et unité extérieure

L'appareil doit être installé et/ou utilisé

dans une pièce dont la surface au

sol dépasse Amin (m²) et maintenu à

distance des sources d'infl ammation,

comme la chaleur/les étincelles/

les fl ammes nues, ou des zones

dangereuses, comme les appareils à

gaz, les appareils de cuisson au gaz, les

systèmes d'approvisionnement en gaz

ou les appareils de cuisson électrique,

etc. (Référez-vous au Tableau A du

tableau des consignes d'installation pour

Amin (m²))

Sachez que le réfrigérant peut ne

pas comporter d'odeur. Il est très

recommandé de s'assurer que

les détecteurs appropriés de gaz

réfrigérants infl ammables sont utilisés,

fonctionnent bien et peuvent alerter en

cas de fuite.

Dégagez de toute obstruction toutes les

ouvertures de ventilation requises.

N'utilisez pas l'appareil pour percer ni

brûler pendant qu'il est sous pression.

N'exposez pas l'appareil à la chaleur,

aux fl ammes, aux étincelles ou à

d'autres sources d'infl ammation. Sinon

il peut exploser et provoquer des

blessures ou la mort.

Précautions pour l’utilisation

du réfrigérant R32

Les procédures d'installation de base sont les

mêmes que pour les modèles à réfrigérant

classiques (R410A, R22).

La pression de fonctionnement étant

supérieure à celle des modèles

à réfrigérant R22, certaines des

tuyauteries et certains outils d'installation

et d'entretien sont spécifi ques. En

particulier, lorsque vous remplacez

un modèle à réfrigérant R22 par un

nouveau modèle à réfrigérant R32,

remplacez toujours la tuyauterie

classique et les écrous d'évasement

avec la tuyauterie et les écrous

d'évasement R32 et R410A côté

extérieur de l'unité.

Pour le R32 et le R410A, le même écrou

d'évasement peut être utilisé sur le côté

et le tuyau de l'unité extérieure.

Il est interdit de mélanger des

réfrigérants différents dans un même

système. Les modèles qui utilisent le

réfrigérant R32 et R410A ont différents

diamètres de fi letage des ports de

charge, pour éviter les charges erronées

avec du réfrigérant R22 et pour la

sécurité.

Vérifi ez donc en amont. [Le diamètre de

fi letage du port de charge pour R32 et

R410A est de 12,7 mm (1/2 pouces).]

Vous devez toujours vous assurer que

les matières étrangères (huile, eau, etc.)

n’entrent pas dans le tuyau. Lorsque

vous stockerez la tuyauterie, scellez bien

l'ouverture en pinçant, tapant, etc. (La

manipulation du R32 est similaire à celle

du R410A.)

•

Le fonctionnement, la maintenance,

la réparation et la récupération du

réfrigérant doivent être effectués par

du personnel qualifi é et certifi é en ce

qui concerne l’utilisation de réfrigérants

infl ammables et conformément aux

recommandations du fabricant. Tout

personnel qui effectue une opération,

un entretien ou une maintenance sur

un système ou des pièces associées de

l’équipement doit être formé et certifi é.

Français Consignes de sécurité

29

Consignes de sécurité

30

•

Aucune partie du circuit de réfrigération

(évaporateurs, refroidisseurs d’air, AHU,

condensateurs ou réservoirs de liquide)

ou de la tuyauterie ne doit être située

à proximité de sources de chaleur, de

fl ammes ouvertes, d’un appareil à gaz

en fonctionnement ou d’un chauffage

électrique en fonctionnement.

•

L’utilisateur/propriétaire ou son

représentant autorisé doit vérifi er

régulièrement les alarmes, la ventilation

mécanique et les détecteurs, au

moins une fois par an, lorsque

les réglementations nationales

l’exigent, afi n d’en garantir le bon

fonctionnement.

•

Un journal de bord doit être tenu à jour.

Les résultats de ces contrôles doivent

être consignés dans le journal de bord.

•

En cas de ventilation dans des locaux

occupés, il convient de vérifi er qu’il n’y

a pas d’obstruction.

•

Avant la mise en service d’un nouveau

système de réfrigérant, la personne

responsable de la mise en service doit

s’assurer que le personnel opérateur

formé et certifi é est informé, sur la

base du manuel d’instructions, de

la construction, de la surveillance,

du fonctionnement et de l’entretien

du système de réfrigérant, ainsi que

des mesures de sécurité à respecter

ainsi que des propriétés et de la

manipulation du réfrigérant utilisé.

•

Les exigences générales relatives

au personnel formé et certifi é sont

indiquées ci-dessous :

a) Connaissance de la législation,

des règlements et des normes

concernant les réfrigérants

infl ammables ; et,

b) Connaissances et compétences

approfondies en matière de

manipulation des réfrigérants

infl ammables, d’équipement

de protection individuelle,

de prévention des fuites de

frigorigènes, de manutention des

bouteilles, de chargement, de

détection, de récupération et de

mise au rebut ; et,

c) Capacité de comprendre et

d’appliquer dans la pratique les

exigences de la législation, des

réglementations et des normes

nationales ; et,

d) Suivi d’une formation de base et

approfondie et afi n de maintenir

cette expertise.

1. Installation (Espace)

•

Le produit contenant des réfrigérants

infl ammables ne doit pas être installé

dans un local non ventilé si cet espace

est inférieur à Amin (m²).

•

En cas de charge sur site, l’effet sur la

charge de réfrigérant dû aux différentes

longueurs de tuyau doit être quantifi é,

mesuré et étiqueté.

•

Assurez-vous que la tuyauterie est

installée à sa longueur minimum. Évitez

d'utiliser des tuyaux cabossés et évitez

les courbures importantes.

•

Assurez-vous que la tuyauterie

est protégée de toute détérioration

physique.

•

Assurez-vous de vous conformer aux

réglementations nationales sur le gaz,

aux règles et à la législation d'état

et municipale. Notifi ez les autorités

compétentes conformément aux

réglementations en vigueur.

•

Assurez-vous que les raccords

mécaniques sont accessibles pour la

maintenance.

•

Dans les cas nécessitant une

ventilation mécanique, les ouvertures

de ventilation doivent être dégagées de

toute obstruction.

•

Lors de la mise au rebut du

produit, suivez les précautions du

paragraphe 12 et conformez-vous aux

réglementations nationales.

Contactez toujours les bureaux locaux

et municipaux pour une manipulation

correcte.

2. Entretien

2-1. Personnel de service

•

Le système est inspecté, régulièrement

surveillé et entretenu par un personnel

de maintenance formé et certifi é,

employé par la personne responsable

ou par l’utilisateur.

•

Assurez-vous que la quantité de charge

réelle de réfrigérant correspond à la

taille de la pièce dans laquelle sont

installées les pièces contenant du

réfrigérant.

•

Assurez-vous que la charge de

réfrigérant ne fuit pas.

•

Toute personne qualifi ée travaillant ou

pénétrant dans un circuit de réfrigérant

doit détenir un certifi cat en cours

de validité remis par une autorité

d'évaluation agréé par l'industrie, qui

valide sa compétence à manipuler

les réfrigérants en toute sécurité

conformément à une spécifi cation

d'évaluation reconnue par l'industrie.

•

L'entretien doit uniquement être

effectué conformément aux

recommandations du fabricant de

l'équipement. Toute maintenance et

réparation nécessitant l'aide d'autres

personnes qualifi ées doit être effectuée

sous la supervision de la personne

compétente dans l'utilisation des

réfrigérants infl ammables.

•

L'entretien doit uniquement être

effectué conformément aux

recommandations du fabricant.

2-2. Travail

•

Avant de commencer des travaux sur

les systèmes contenant des réfrigérants

infl ammables, des contrôles de sécurité

sont obligatoires pour s'assurer que

le risque d'infl ammation est minimisé.

Pour les réparations sur le système

de réfrigérant, les précautions des

paragraphes 2-2 à 2-8 doivent être

respectées avant d'entreprendre tout

travail sur le système.

•

Le travail doit être entrepris dans

le cadre d'une procédure contrôlée

de manière à minimiser le risque

de présence de gaz ou de vapeurs

infl ammables pendant la réalisation du

travail.

•

Tous les techniciens de maintenance

et autres personnels travaillant dans la

zone locale doivent être conseillés et

supervisés sur la nature du travail en

cours.

•

Évitez de travailler dans des espaces

confi nés. Assurez-vous toujours que

la distance de sécurité est d’au moins

2 mètres ou que la zone d’espace libre

est d’au moins 2 mètres de rayon.

•

Portez un équipement de protection

individuelle approprié, y compris une

protection respiratoire si la situation le

justifi e.

•

Assurez-vous que les conditions au

sein de la zone ont été sécurisées

en limitant l'usage de toute matière

infl ammable. Tenez toutes les sources

d'infl ammation et surfaces en métal

chaudes à distance.

Consignes de sécurité

Français

31

Consignes de sécurité

2-3. Vérifi cation de la présence de

réfrigérant

•

La zone doit être vérifi ée à l'aide d'un

détecteur de réfrigérant approprié

avant et pendant les travaux, afi n

de s'assurer que le technicien soit

informé de la présence d'atmosphères

potentiellement infl ammables.

•

Assurez-vous que l'équipement de

détection des fuites utilisé est adapté