Page 1

Order No: PAPAMY1501049CE

/

MP

O

S

O

123

C

/

TEM P

O

TIMER

S

O

2

3

CHEC

K

OPERATION MANUAL

FAN

AUTO

SPEED

HEAT

AIR

COOL

SWING

DRY

FAN

AUTO

OFF/ON

FF/ON

ECONAVI

COMFORT

MODE

TEMP

TE

POWERFUL/

FANSPEED

QUIET

TIMER

TIMER

ON

123

FF

SETCHE CKCLOCK RESET

HECK

AUTO

HEAT

COOL

DRY

FAN

OFF/ON

FF/ON

ECONAVI

MODE

TEMP

POWERFUL/

FANSPEED

QUIET

TIMER

ON

123

1

FF

SETCHE CKCLOCK RESET

AIRSWING

ET

SET

CANCEL

CANCELONOFF

AC RC

FAN

SPEED

AIR

SWING

AUTO

COMFORT

AIRSWING

SET

ET

CANCELONOFF

CANCEL

AC RC

CS-E9RKUAW

CS-E12RKUAW

CS-E18RKUAW

CS-E24RKUAW

Destination

Indoor Unit

USA

Canada

Please file and use this manual together with the service manual for Model No. CU-2E18NBU and CU-5E36QBU, Order No.

PHAAM1111120A1 and PAPAMY1312037CE.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

© Panasonic Corporation 2015.

Page 2

13. Operation Control

13.1 Basic Function

Inverter control, which equipped with a microcomputer in determining the most suitable operation mode as time

passes, automatically adjusts output power for maximum comfort always. In order to achieve the suitable operation

mode, the microcomputer maintains the set temperature by measuring the temperature of the environment and

performing temperature shifting. The compressor at outdoor unit is operating following the frequency instructed by

the microcomputer at indoor unit that judging the condition according to internal setting temperature and intake air

temperature.

13.1.1 Internal Setting Temperature

Once the operation starts, remote control setting temperature will be taken as base value for temperature shifting

processes. These shifting processes are depending on the air conditioner settings and the operation environment.

The final shifted value will be used as internal setting temperature and it is updated continuously whenever the

electrical power is supplied to the unit.

Remote Control Setting Temperature

Outdoor Air Temperature Shifting

60.8°F - 86°F

Auto Operation Mode Shifting

Indoor Air Temperature Shifting

Powerful Mode Shifting

Setting Temperature Limit Checking

(Min: 60.8°F; Max 91.4°F)

Internal Setting Temperature

13.1.2 Cooling Operation

13.1.2.1 Thermostat control

Compressor is OFF when intake Air Temperature - Internal Setting Temperature < 2.7°F.

Compressor is ON after waiting for 3 minutes, if the Intake Temperature - Internal Setting Temperature >

Compressor OFF point.

13.1.3 Soft Dry Operation

13.1.3.1 Thermostat control

Compressor is OFF when Intake Temperature - Internal Setting Temperature < -3.6°F.

Compressor is ON after waiting for 3 minutes, if the Intake Air Temperature - Internal Setting Temperature >

Compressor OFF point.

13.1.4 Heating Operation

13.1.4.1 Thermostat control

Compressor is OFF when Intake Temperature - Internal Setting Temperature > 3.6°F.

Compressor is ON after waiting for 3 minutes, if the Intake Air Temperature - Internal Setting Temperature <

Compressor OFF point

49

Page 3

13.1.4.2 Automatic Operation (For Single Split Connection Only)

y

This mode can be set using remote control and the operation is decided by remote control setting temperature,

remote control operation mode and indoor intake air temperature.

During operation mode judgment, indoor fan motor (with speed of Lo-) is running for 30 seconds to detect the

indoor intake air temperature.

Every 10 minutes, the indoor temperature is judged.

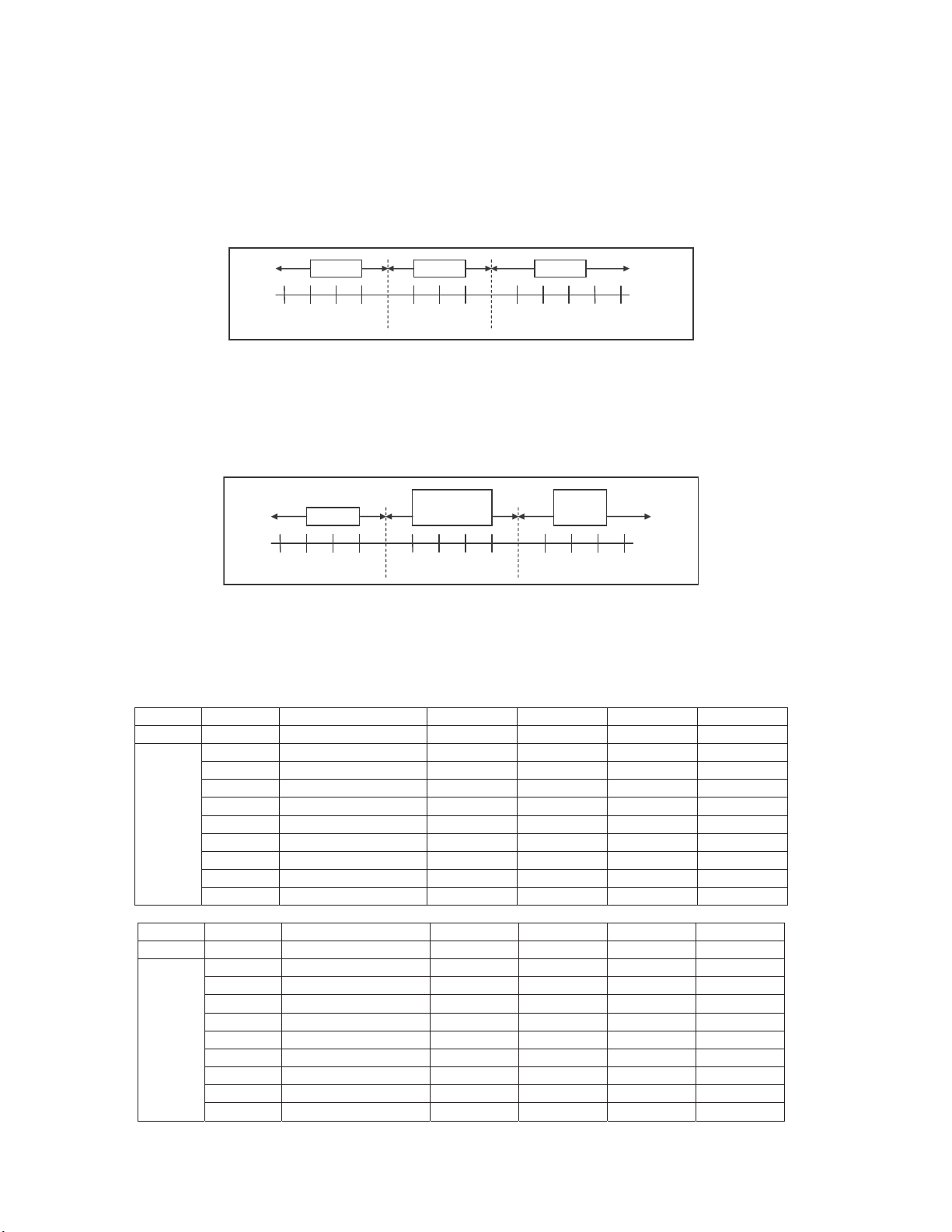

For the 1st judgment

o If indoor intake temperature - remote control setting temperature 3.6°F, COOL mode is decided.

o If -3.6°F indoor intake temperature - remote control setting temperature < 3.6°F, DRY mode is decided.

o If indoor intake temperature - remote control setting temperature < -3.6°F , HEAT mode is decided.

Heat Dr

-10.8 -9.0 -7.2 -5.4 -3.6 -1.8 1.8 3.6 5.4 7.2 9.0 10.80

Cool

For the 2nd judgment onwards

o If indoor intake temperature - remote control setting temperature 5.4°F, if previous operate in DRY mode,

then continue in DRY mode. otherwise COOL mode is decided.

o If -3.6°F indoor intake temperature - remote control setting temperature < 5.4°F, maintain with previous

mode.

o If indoor intake temperature - remote control setting temperature < -3.6°F, HEAT mode is decided.

Heat

-10.8 -9.0 -7.2 -5.4 -3.6 -1.8 1.8 3.6 5.4 7.2 9.0 10.80

current mode

Maintain

Cool

/Dry

13.2 Indoor Fan Speed Control

Indoor Fan Speed can be set using remote control.

13.2.1 Fan Speed Rotation Chart

E9RKUAW E12RKUAW E18RKUAW E24RKUAW

Mode Fan Tap Application rpm rpm rpm rpm

SHi Pwr Me+ 1210 1350 1480 1500

Hi Fc, RC 1120 1230 1380 1400

Me+ RC 1010 1110 1300 1320

Me RC 910 1000 1220 1240

COOL

Mode Fan Tap Application rpm rpm rpm rpm

HEAT

Me- RC 810 890 1140 1160

Lo Fcmin, RC 710 780 1060 1090

Lo- QuietLo 610 620 970 1000

SLo Dry 550 560 690 690

SSLo Auto Cut 540 550 580 580

E9RKUAW E12RKUAW E18RKUAW E24RKUAW

SSHi Pwr Me+ 1340 1450 1500 1600

SHi Fh, RC 1250 1380 1410 1500

Me+ RC 1140 1290 1330 1430

Me RC 1040 1210 1260 1360

Me- RC 930 1120 1190 1290

Lo Fhmin, RC 830 1040 1120 1220

Lo- QuietLo 730 940 1030 1110

SLo Thermo Off, Hot start 570 570 430 430

SSLo Thermo Off 560 560 330 330

50

Page 4

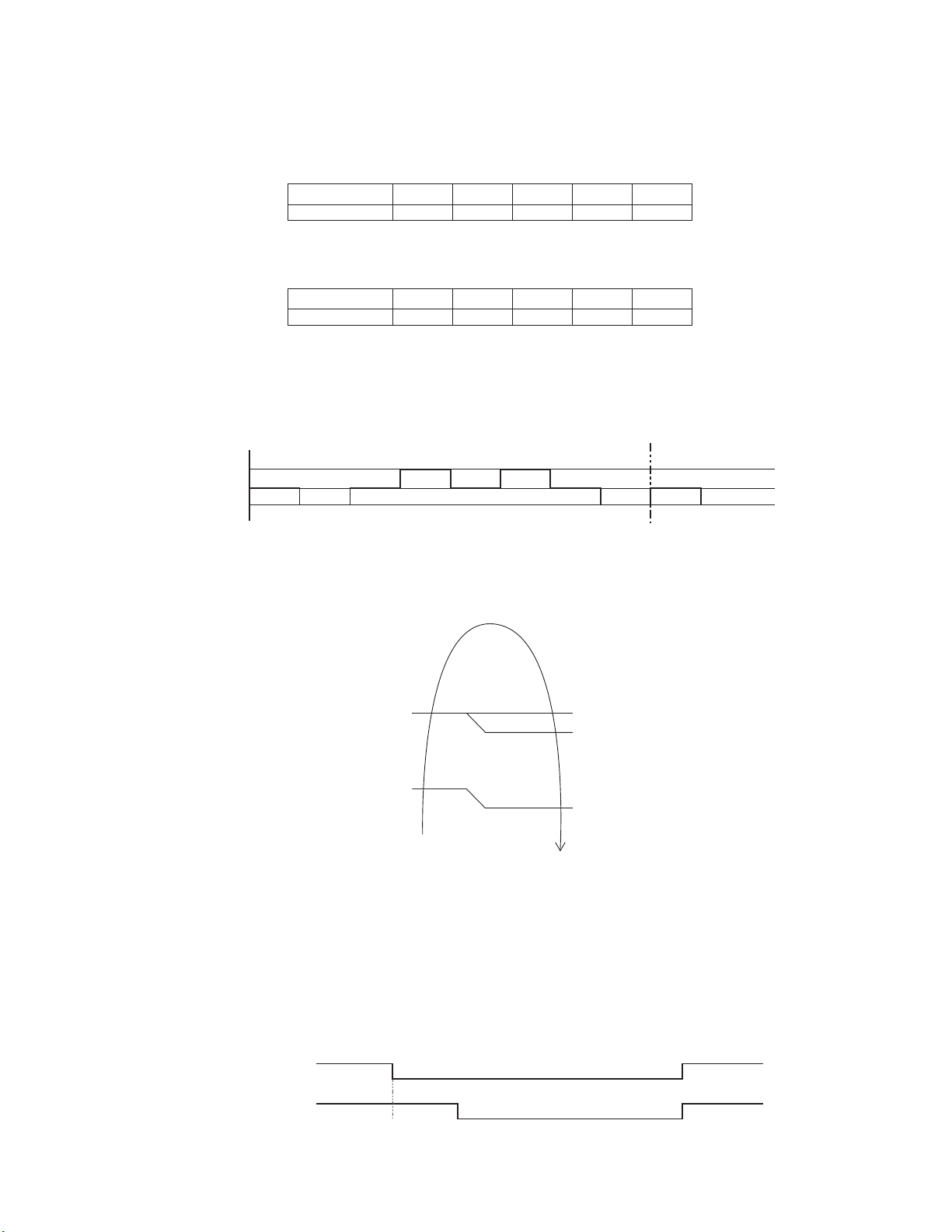

13.3 Indoor Fan Motor Operation

H

F

S

M

13.3.1 Basic Rotation Speed (rpm)

Manual Fan Speed

[Cooling, Dry]

o Fan motor’s number of rotation is determined according to remote control setting.

[Heating]

o Fan motor’s number of rotation is determined according to remote control setting.

Auto Fan Speed

[Cooling, Dry]

o According to room temperature and setting temperature, indoor fan speed is determined automatically.

o The indoor fan will operate according to pattern below.

an

peed

igher

edium

Lower

o During operation, indoor fan motor may stop due to odor prevention.

[Heating]

o According to indoor pipe temperature, automatic heating fan speed is determined as follows.

Remote control ż ż ż ż ż

Tab Hi Me+ Me Me- Lo

Remote control ż ż ż ż ż

Tab Shi Me+ Me Me- Lo

[1 pattern : 10 s]

abc def gh

ab

RPM Increased

o

F

102.2

o

F

66.2

Indoor Pipe Temp.

RPM Maintain

RPM Reduced

OFF

95oC

60.8oF

Feedback control

o Immediately after the fan motor started, feedback control is performed once every second.

o During fan motor on, if fan motor feedback 2550 rpm or < 50 rpm continue for 10 seconds, then fan motor

error counter increase, fan motor is then stop and restart. If the fan motor counter becomes 7 times, then

H19 - fan motor error is detected. Operation stops and cannot on back.

13.4 Outdoor Fan Motor Operation

Outdoor fan motor is operated with fan speed number of rotation. It starts when compressor starts operation and it

stops 30 seconds after compressor stops operation.

ON ON

Compressor OFF

ON Fan Speed ON

Outdoor Fan 30 sec OFF

51

Page 5

13.5 Airflow Direction

0

1

There are two types of airflow, vertical airflow (directed by horizontal vane) and horizontal airflow (directed by

vertical vanes).

Control of airflow direction can be automatic (angles of direction is determined by operation mode, heat

exchanger temperature and intake air temperature) and manual (angles of direction can be adjusted using

remote control).

13.5.1 Vertical Airflow

13.5.1.1 CU-E9RKUA CU-E12RKUA

Operation Mode Airflow Direction

Auto with Heat Exchanger

Heating

Cooling

Soft Dry

Temperature

Manual 20 32 45 57 68

Auto 20 ~ 45

Manual 20 26 32 37 45

Auto 20 ~ 45

Manual 20 26 32 37 45

A 20

B 57

C 32

1 2 3 4 5

13.5.1.2 CU-E18RKUA CU-E24RKUA

Operation Mode Airflow Direction

A 20

B 45

C 32

Heating

Cooling

Soft Dry

Auto with Heat Exchanger

Temperature

Manual 20 32 45 57 68

Auto 20 ~ 45

Manual 20 26 32 37 45

Auto (Anti-Dew Control) 20 ~ 45

Manual (Anti-Dew Control) 20 26 32 37 45

Automatic vertical airflow direction can be set using remote control; the vane swings up and down within the

angles as stated above. For heating mode operation, the angle of the vane depends on the indoor heat

exchanger temperature as Figure 1 below. When the air conditioner is stopped using remote control, the vane

will shift to close position.

Manual vertical airflow direction can be set using remote control; the angles of the vane are as stated above and

the positions of the vane are as Figure 2 below. When the air conditioner is stopped using remote control, the

vane will shift to close position.

36.4°F

96.8°F

Indoor Heat Exchanger

Temperature

C

B

A

122°F

86°F

°

1

2

3

4

1 2 3 4 5

140°

5

Vane angle (°)

Vane angle (°)

Side View

Close position

Figure 2Figure 1

13.5.2 Horizontal Airflow (CU-E9RKUA CU-E12RKUA)

The horizontal airflow direction louvers can be adjusted manually by hand.

52

Page 6

13.5.3 Horizontal Airflow (CU-E18RKUA CU-E24RKUA)

Automatic horizontal airflow direction can be set using remote control; the vane swings left and right within the

angles as stated below. For heating mode operation, the angle of the vane depends on the indoor heat

exchanger temperature as Figure 1 below.

Operation Mode Vane Angle (°)

Heating with heat exchanger temperature

Cooling and Soft Sry 68 ~ 112

A 68 ~ 112

B 90

109.4°F

Indoor Heat Exc hanger

Tem p e ra t u r e

A: swin g

B: fi x front

Figure 1

104.0°F

0°

1

2

3

Figure 2

Top Vi e w

5

4

Manual vertical airflow direction can be set using remote control; the angles of the vane are as stated below and

the positions of the vane are as figure below:

54321nrettaP

Airflow Direction

Patterns at Remote

Control

Vane Angle (° ) 90 68 78 102 112

13.6 Quiet Operation (Cooling Mode/Cooling Area of Dry Mode)

Purpose

o To provide quiet cooling operation compare to normal operation.

Control condition

o Quiet operation start condition

When “Quiet” button at remote control is pressed.

Quiet LED illuminates.

o Quiet operation stop condition

When one of the following conditions is satisfied, quiet operation stops:

POWERFUL/QUIET button is pressed.

Stop by OFF/ON button.

OFF Timer activates.

POWERFUL/QUIET button is pressed again.

When quiet operation is stopped, operation is shifted to normal operation with previous setting.

When fan speed is changed, quiet operation is shifted to quiet operation of the new fan speed.

When operation mode is changed, quiet operation is shifted to quiet operation of the new mode.

During quiet operation, if ON timer activates, quiet operation maintains.

After off, when on back, quiet operation is not memorised.

Control contents

o Auto fan speed is change from normal setting to quiet setting of respective fan speed. This is to reduce

sound of Hi, Me, Lo for 3dB.

o Manual fan speed for quiet operation is -1 step from setting fan speed.

53

Page 7

13.7 Quiet Operation (Heating)

e

air

e

air

Purpose

o To provide quiet heating operation compare to normal operation.

Control condition

o Quiet operation start condition

When “POWERFUL/QUIET” button at remote control is pressed.

Quiet LED illuminates.

o Quiet operation stop condition

When one of the following conditions is satisfied, quiet operation stops:

Stop by OFF/ON button.

Timer “off” activates.

POWERFUL/QUIET button is pressed again.

When quiet operation is stopped, operation is shifted to normal operation with previous setting.

When fan speed is changed, quiet operation is shifted to quiet operation of the new fan speed.

When operation mode is changed, quiet operation is shifted to quiet operation of the new mode.

During quiet operation, if timer “on” activates, quiet operation maintains.

After off, when on back, quiet operation is not memorised.

Control contents

o Fan speed auto

Indoor FM RPM depends on pipe temperature sensor of indoor heat exchanger. Auto fan speed is

changed from normal setting to quiet setting of respective fan speed. This is to reduce sound of Hi, Me,

Lo for 3dB.

o Fan speed manual

Manual fan speed for quiet operation is -1 step from setting fan speed.

13.8 Powerful Mode Operation

When the powerful mode is selected, the internal setting temperature will shift lower up to 3.6°F (for Cooling/Soft

Dry) or higher up to 6.3°F (for Heating) than remote control setting temperature for 20 minutes to achieve the

setting temperature quickly.

13.9 Timer Control

13.9.1 ON Timer Control

ON Timer can be set using remote control, where the unit with timer set will start operation earlier than the setting

time. This is to provide a comfortable environment when reaching the set ON time.

60 minutes before the set ON time, indoor (at fan speed of Lo-) and outdoor fan motor start operation for 30

seconds to determine the indoor intake air temperature and outdoor air temperature in order to judge the

operation starting time.

From the above judgment, the decided operation will start operation earlier than the set time as shown below.

Indoorintak

temperature (oF)

86

77

5min

15 min

10 min

86 95

Cooling/Soft Dry

o

F)

(

Outdoor air

temperature (

Indoorintak

temperature (oF)

59

41

35 min

o

F)

25 min

30 min

32 41

Heating

o

F)

(

Outdoor air

temperature (

o

F)

13.9.2 OFF Timer Control

OFF Timer can be set using remote control, the unit with timer set will stop at set time.

54

Page 8

13.10 Auto Restart Control

When the power supply is cut off during the operation of air conditioner, the compressor will re-operate within

three to four minutes (there are 10 patterns between 2 minutes 58 seconds and 3 minutes 52 seconds to be

selected randomly) after power supply resumes.

This type of control is not applicable during ON/OFF Timer setting.

13.11 Indication Panel

LED POWER TIMER QUIET POWERFUL AUTO COMFORT ECONAVI

Color Green Orange Orange Orange Green Green

Light ON Operation ON Timer Setting ON Quiet Mode ON Powerful Mode ON Auto Comfort ON Econavi Mode ON

Light OFF Operation OFF Timer Setting OFF Quiet Mode OFF Powerful Mode OFF Auto Comfort OFF Econavi Mode OFF

Note:

If POWER LED is blinking, the possible operation of the unit are Hot Start, during Deice operation, operation

mode judgment, or ON timer sampling.

If Timer LED is blinking, there is an abnormality operation occurs.

13.12 ECONAVI and AUTO COMFORT Operation

A Pyoelectric infrared sensor is used to detect injection strength variation of infrared at setting area to determine

the presence or absence of human and its activity level. Human detection area is shown in figure below:

Top Vi ew

90°

2m

Angle of detection

7m

Area of detection

ECONAVI and AUTO COMFORT operation – Human presence/absence detection outlined flow

Process infrared sensor output signal

Human detection (movement) every 3 seconds.

ź

Human detection records

Records human detection (movement) result for 30 seconds and determine its activity level i.e. Hi/Lo.

ź

Presence / absence detection

Compares current and previous human detection result every 30 seconds to determine the presence

or absence of human.

ź

Presence / absence determination

Based on human presence / absence detection, if human presence detection showed within

30 minutes, it is recognised that human is present. If human absence detection showed continuously

for more than 30 minutes, it is recognised that no human is present.

ECONAVI and AUTO COMFORT Sensor abnormality detection

1. Connector pulled out (disconnected), Wire cut Abnormality (Fix Output at Hi)

a. Abnormal judgment start condition.

Start from ECONAVI and AUTO COMFORT Sensor power ON, and end after 30 seconds.

b. Control content.

Judge ECONAVI and AUTO COMFORT Sensor power level every 100ms.

c. Abnormal Judgment condition.

When ECONAVI and AUTO COMFORT Sensor has continues for 25 seconds Hi level.

55

Page 9

2. Circuit Abnormal (Fix Output Lo)

a. Abnormal judgment start condition.

After ECONAVI and AUTO COMFORT Sensor unit power ON, and after pressed 70 seconds.

b. Control content.

Judge ECONAVI and AUTO COMFORT Sensor power level every 100ms.

c. Abnormal Judgment condition.

When ECONAVI and AUTO COMFORT Sensor has continues at Lo level for 25 seconds.

3. Abnormal treatment

Any one of the above self-diagnosis result is abnormal

Abnormal counter +1 and ECONAVI and AUTO COMFORT Sensor power supply OFF.

After ECONAVI and AUTO COMFORT Sensor unit power is OFF for 5 seconds, Retry the ECONAVI and

AUTO COMFORT operation.

When Abnormal counter reach 4 counts, ECONAVI and AUTO COMFORT sensor abnormality is

confirmed.

(Abnormal counter is cleared when sensor power ON and maintain normal for 120 seconds and above or

Clear Abnormal counter by power reset)

Save ECONAVI and AUTO COMFORT Sensor Abnormality H59 (no Timer LED blinking).

ECONAVI & AUTO COMFORT Sensor operation OFF, but ECONAVI and AUTO COMFORT LED

maintain ON.

The unit still operate as normal.

Sensor error counter can be cleared only after power supply reset or AC Reset button on the remote

control is pressed.

ECONAVI and AUTO COMFORT Demo Mode

To enable ECO DEMO mode, during unit is OFF (power standby):

Remote control normal mode

Press continously for 5s

SET

SET

Transmit ECO demo code

and after 30 seconds return to normal

mode.

TEMP

TEMP

SET

Transmit sunlight sensor check code

and after 30 seconds return to normal

mode.

TEMP

TEMP

SET

Transmit check code

and after 30 seconds return to normal

mode.

To disable ECO Demo MODE:

Transmit ECO Demo signal again.

Control details:

During ECONAVI and AUTO COMFORT Demo mode, operation LED ON and horizontal vane will set to Auto

Swing.

When Hi activity judge, Fan speed change to Hi Fan and ECONAVI and AUTO COMFORT LED ON.

When Lo activity judge, Fan speed change to Lo Fan and ECONAVI and AUTO COMFORT LED OFF.

No setting temperature adjustment.

During ECONAVI and AUTO COMFORT operation, the internal setting temperature and fan speed are adjusted

in order to provide comfort and energy saving.

56

Page 10

ECONAVI Start condition.

V

Press ECONAVI button.

ECONAVI Stop condition.

Press ECONAVI button again.

OFF Timer activates.

Press OFF/ON button to turn off the air conditioner.

Press AUTO OFF/ON button to turn off the air conditioner.

Press POWERFUL/QUIET button.

AUTO COMFORT Start condition.

Press AUTO COMFORT button.

AUTO COMFORT Stop condition.

Press AUTO COMFORT button again.

OFF Timer activates.

Press OFF/ON button to turn off the air conditioner.

Press AUTO OFF/ON button to turn off the air conditioner.

Press POWERFUL/QUIET button.

ECONAVI and AUTO COMFORT operation could ON when any of the following conditions is fulfilled:

During forced cooling or forced heating operation.

Power Failure

ECONAVI and AUTO COMFORT operation will be resuming after recovered from power failure.

Timer Operation

When unit is turn on by ON Timer and ECONAVI and AUTO COMFORT operation is ON during previous

operation before OFF, ECONAVI and AUTO COMFORT operation will not be ON automatically.

When unit is turn on by ON Timer and ECONAVI and AUTO COMFORT operation is OFF during

previous operation before OFF, ECONAVI and AUTO COMFORT operation will not be ON automatically.

Other Information

ECONAVI and AUTO COMFORT, Powerful, Quiet and Mild Dry Cooling cannot be operated at the same

time.

ECONAVI and AUTO COMFORT sensor initialized time is 70 seconds from power supplied to ECONAVI

and AUTO COMFORT sensor, or 70 seconds from the operation start.

Setting Temperature and Fan Speed Shift

Mono Sensor

I ; Detecting human presence and activity, the unit controls room temperature to save energy.

ECONA

Mode

COOL/DRY

HEAT

AUTO COMFORT ; Detecting human presence and activity, the unit controls room temperature to keep human

comfortable consistently.

Mode

COOL/DRY

HEAT

* During low activity, fan speed 1 tap up for first 15 minutes or until set temperature is reached.

** During human absence, maximum fan speed for COOL/DRY mode is medium fan.

Human

Set

temperature

Human

Set

temperature

Set

Fan Speed

Low activity Normal activity

+2°F / +1 °C

Low activity Normal activity

+2°F / +1 °C

+0.5°F / +0. 3°C

+1 tap*

High activity Absent

-4°F / -2°C

High activity Absent

-2°F / -1°C

-4°F / -2°C

+1 tap

+4°F /

+2°C

-4°F /

-2°C

+4°F /

+2°C

-4°F /

-2°C

57

Page 11

13.12.1 Human Activity Sensor Check Mode

To enable Human Activity sensor abnormality check mode, during ECONAVI operation ON:

Remote control normal mode

Press continously for 5s

SET

SET

Tra nsmit ECO de mo code

and after 30 seconds return to normal

mode.

TEMP

TEMP

SET

Transmit sunlight sensor check code

and after 30 seconds return to normal

mode.

TEMP

TEMP

SET

Transmit check code

and after 30 seconds return to normal

mode.

During ECONAVI is ON, when CHECK signal received, if either sensors has abnormality, the 4 times abnormality

counter is ignored, ECONAVI Indicator will blink immediately and error code is memorized.

The unit could operate without ECONAVI or AUTO COMFORT.

The ECONAVI indicator blinking could be cancelled by pressing ECONAVI button again.

If the human activity sensor has no abnormality, the CHECK process will end and continue with normal operation.

58

Page 12

14. Operation Control (For Multi Split Connection)

During multi split connection, indoor unit’s operation controls are same with single split connection unless specified in

this chapter.

14.1 Cooling operation

14.1.1 Thermostat control

Capability supply to indoor unit is OFF (Expansion valve closed) when Intake Air Temperature — Internal setting

temperature < 28.4°F.

Capability resume supply to indoor unit after waiting for 3 minutes, if the Intake Air temperature — Internal setting

temperature > Capability supply OFF point.

14.2 Soft Dry Operation

14.2.1 Thermostat control

Capability supply to indoor unit is OFF (Expansion valve closed) when Intake Air Temperature Ϋ Internal setting

temperature < 26.6°F.

Capability resume to indoor unit after waiting for 3 minutes, if the Intake Air temperature Ϋ Internal setting

temperature > Capability supply OFF point.

14.3 Heating Operation

14.3.1 Thermostat control

Capability supply to indoor unit is OFF (Expansion valve closed) when Intake Air Temperature Ϋ Internal setting

temperature > 33.8°F.

During this condition, the indoor fan is stopped if compressor is ON.

Capability resume supply to indoor unit after waiting for 3 minutes, if the Intake Air Temperature Ϋ Internal

setting temperature < Capability supply OFF point.

14.3.2 Temperature Sampling Control

Temperature sampling is controlled by outdoor unit where room temperature for all power supply ON indoor unit

could be obtained.

When capability supply to the indoor unit is OFF and the compressor is ON during heating operation, the indoor

fan motor is stopped. During this condition, 15 seconds after sampling signal from outdoor unit is received, the

indoor fan start operation at low fan speed.

However, within first 4 minutes of capability stopped supply to the indoor unit, even sampling signal is received,

the sampling control is cancelled.

59

Page 13

14.4 Automatic Operation (For Multi Split Connection Only)

This mode can be set using remote control and the operation is decided by remote control setting temperature,

remote control operation mode, indoor intake and outdoor air temperature.

During operation mode judgment, indoor fan motor (with speed of -Lo) and outdoor fan motor are running for

30 seconds to detect the indoor intake and outdoor air temperature. The operation mode is decided based on

below chart.

Indoor intake air

temperature (F)

96.8

60.8

Heating Mode

Soft Dry Mode

T1

T2

T3

66.255.4 69.8 73.4 77

Outdoor air

temperature (F)

Cooling Mode

Remote Control

setting temperature

Every 180 minutes, the indoor and outdoor temperature is judge. Based on remote control setting temperature,

the value of T1 will increase up to 50°F, T2 will decrease by 37.4°F and T3 will decrease up to 46.4°F.

14.5 Indoor Fan Motor Operation

14.5.1 Residual Heat Removal Control

To prevent high pressure at indoor unit, when heating mode thermostat-off condition or power supply OFF,

indoor fan continue to operate at controlled fan speed for maximum 30 seconds then stop.

14.6 Powerful Mode Operation

When the power mode is selected, the internal setting temperature will shift lower up to 39.2F for Cooling/Soft

Dry or higher up to 42.8°F for heating than remote control setting temperature, the powerful operation continue

until user cancel the Powerful operation by pressing powerful button again.

14.7 Auto restart control

When the power supply is cut off during the operation of air conditioner, the compressor will re-operate between

three to four minutes (10 patterns to be selected randomly) after power resume.

During multi split connection, Indoor unit will resume previous mode, include unit standby mode.

14.8 Indication Panel

LED POWER TIMER QUIET POWERFUL AUTO COMFORT ECONAVI

Color Green Orange Orange Orange Green Green

Light ON Operation ON Timer Setting ON Quiet Mode ON Powerful Mode ON Auto Comfort ON Econavi Mode ON

Light OFF Operation OFF Timer Setting OFF Quiet Mode OFF Powerful Mode OFF Auto Comfort OFF Econavi Mode OFF

Note:

If POWER LED is blinking (0.5 second ON, 0.5 second OFF), the possible operation of the unit are during Indoor

Residual Heat Removal, Hot Start, during Deice operation, operation mode judgment, or ON timer sampling.

If POWER LED is blinking (2.5 seconds ON, 0.5 second OFF), the unit is in standby mode.

If TIMER LED is blinking, there is an abnormality operation occurs.

60

Loading...

Loading...