Panasonic cs-e9nkuw installation

Order No: PHAAM1111084C1

Installation Manual

Indoor Unit Outdoor Unit

CS-S9NKUW-1

CS-S12NKUW-1

CS-S18NKU-1

CS-S22NKU-1

CU-S9NKU-1

CU-S12NKU-1

CU-S18NKU-1

CU-S22NKU-1

Please file and use this manual together with the service manual for Model No. CU-2S18NBU, Order No. PHAAM1111121C1.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to

service or repair the products dealt with in this service information by anyone else could result in serious injury or death.

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigerant circuit.

© Panasonic HA Air-Conditioning (M) Sdn. Bhd. 2011.

Unauthorized copying and distribution is a violation of law.

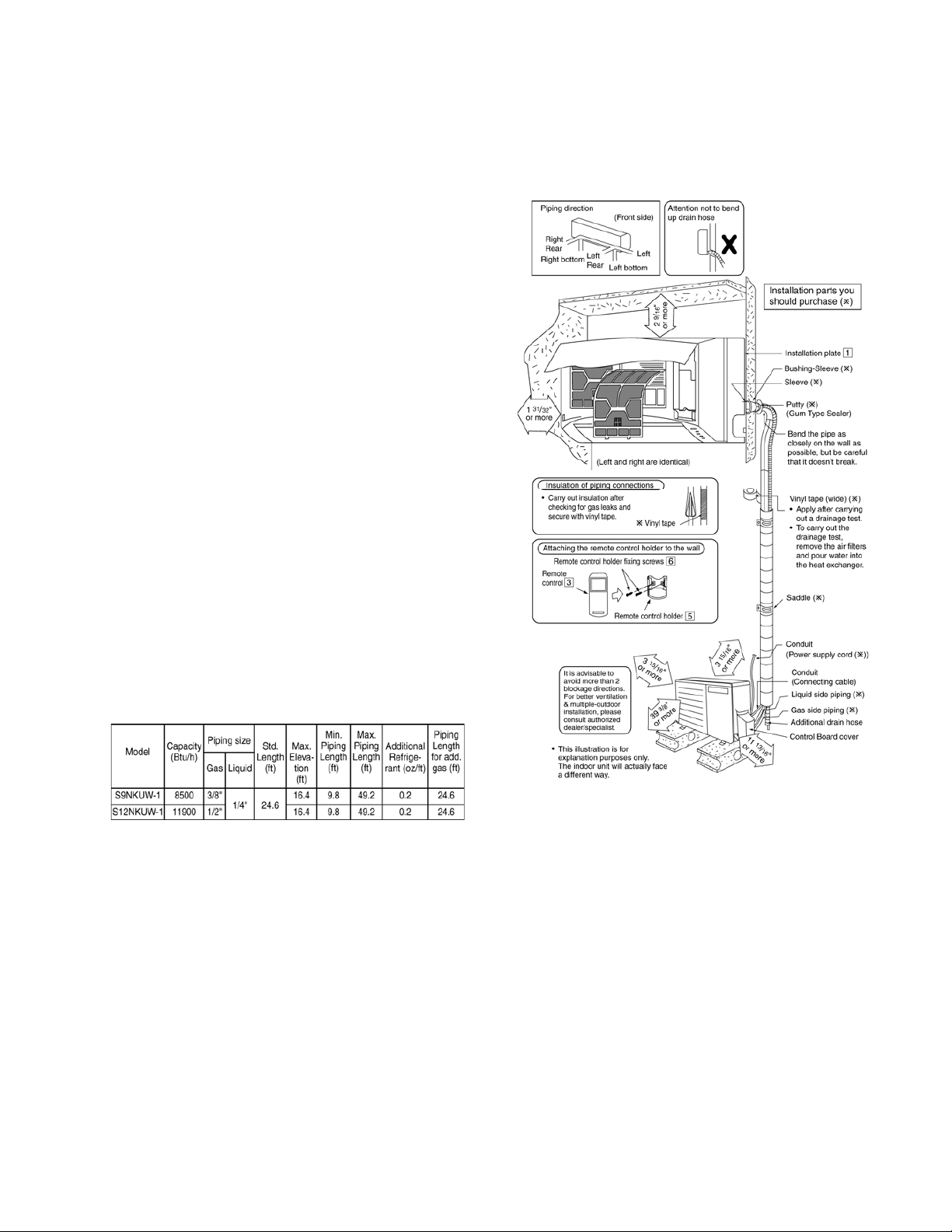

10. Installation Instruction

10.1 S9NKUW-1 S12NKUW-1

10.1.1 Select the Best Location

10.1.1.1 Indoor Unit

x Do not install the unit in excessive oil fume area

such as kitchen, workshop

There should not be any heat source or

x

near the unit.

x

There should not be any obstacles blocki

circulation.

x

A place where air circulation in the room

x

A place where drainage can be ea

A place where noise prevention is taken

x

c

onsiderat

Do not install the unit near a door

x

x Ensure the spaces indicated by arrows from the

wall, ceili

Recommended installation height for ind

x

shall be at least 8.2 ft.

ion.

ng, fence or other obstacles

and etc.

steam

ng the air

is good.

sily done.

into

way.

.

oor unit

10.1.1.2 Outdoor Unit

x If an awning is built over the unit to prevent direct

sunli

ght or rain, be careful that heat radiat

the con

x There should not be any animal or plant which

coul

Keep the spaces indicated by arrows from

x

ceiling, fence or other obstacles.

x

Do not place any obstacles

sho

x

If piping length is over the [piping length

addition

adde

denser is not obstru

d be affected by hot air discharg

rt circuit of the discharg

al gas], additional refrigerant sh

d as shown in the tabl

cted.

which may cause a

ed air.

e.

ion from

ed.

wall,

for

ould be

10.1.2 Indoor/Outdoor Unit Installation

Diagram

Example: For S9NKUW-1

If the unit is installe

additional refrigerant should be 1.64 oz .... (32.8 - 24.6)

ft x 0.2 oz/ft = 1.64 oz.

d at 32.8 ft distance, the quantity of

31

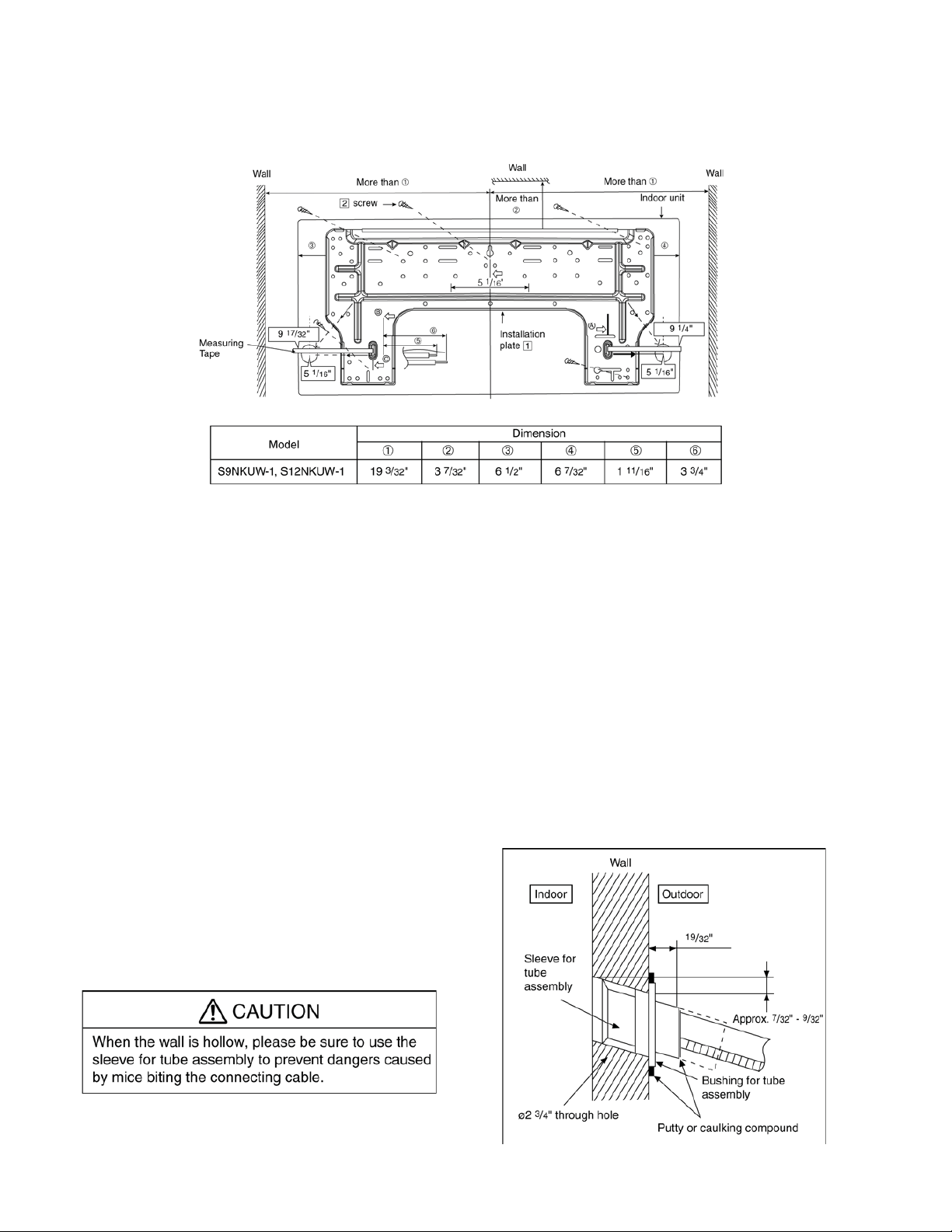

10.1.3 Indoor Unit

10.1.3.1 How to Fix Installation Plate

The mounting wall shall be strong and solid enough to prevent if from the vibration.

The ce

ntre of installation plate should be at more than c at right and left of the wall.

The distance from installation plate edge to ceiling should more than d.

From installation plate left edge to unit’s left side is e.

From installation plate right edge to unit’s right side is f.

B : For left side piping, piping connection for liquid should be about g from this line.

ƻ

: For left side piping, piping connection for gas should be about h from this line.

1 Mount the installation plate on the wall with 5 screws or more (at least 5 screws).

(If mounting the unit on the concrete wall, consider using anchor bolts.)

o Always mount the installation plate horizontally by aligning the marking-off line with the thread and us

a level gaug

2 Drill the piping plate hole with ø2 ¾” hole-core drill.

o Line according to the left and right side of the installation plate. The meeting point of the extended lin

the cente

above. The h

r

espec

o

Drill the piping hole at either the right or the left and the hole should be slightly slanting to the outdoo

side.

e.

r of the hole. Another method is by putting measuring tape at position as sh

ole center is obtained by measuring the distance namely 5 1/16” for left and righ

tively.

10.1.3.2 To Drill a Hole in the Wall and

Install a Sleeve of Piping

1 Insert the piping sleeve to the hole.

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 19/32”

from the wall.

ing

e is

own in the diagram

t hole

r

4

Finish by sealing the sleeve with putty or

caulking compound at the final stage.

32

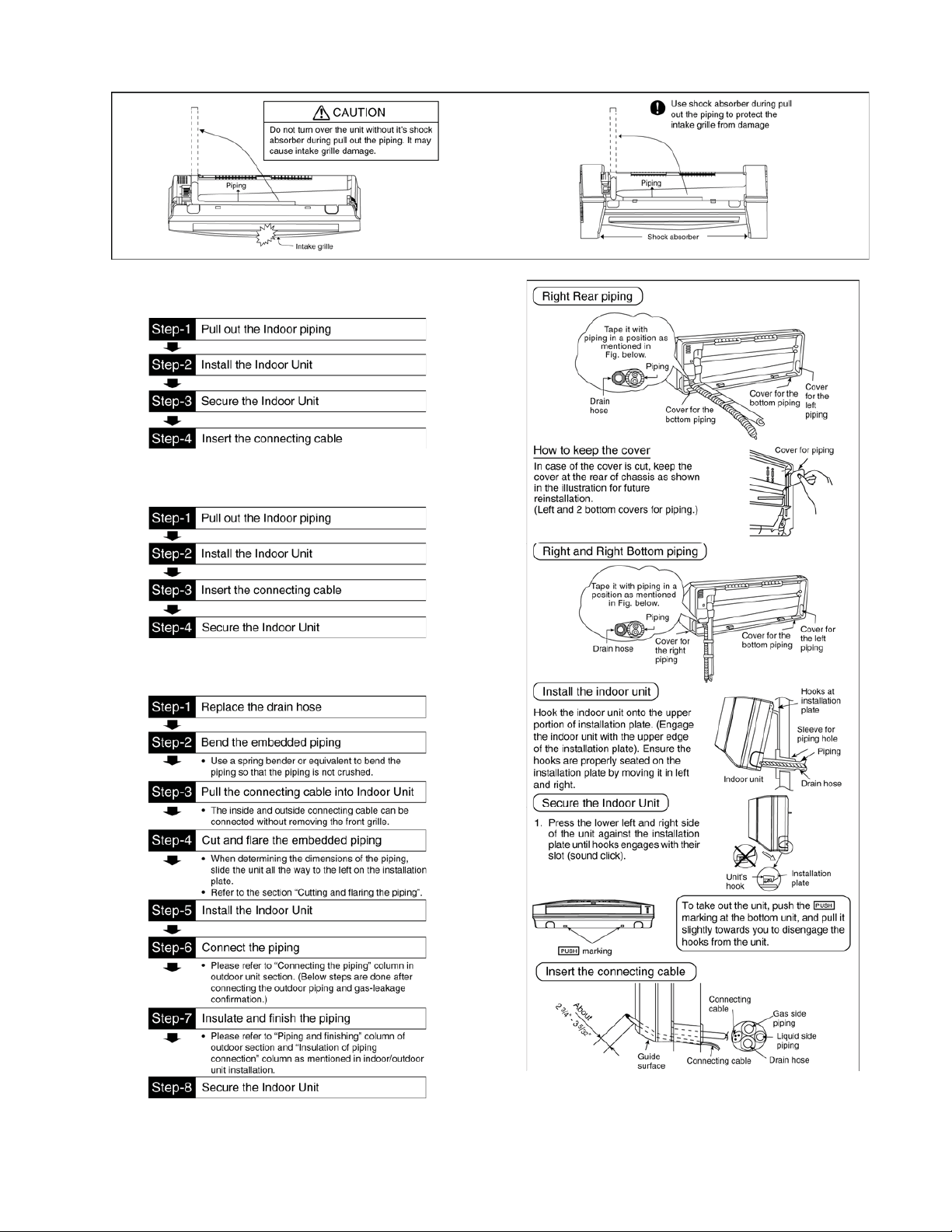

10.1.3.3 Indoor Unit Installation

10.1.3.4 For the right rear piping

10.1.3.5 For the right bottom piping

10.1.3.6 For the embedded piping

(Thi

s can be used for left rear piping and bottom

piping also.)

33

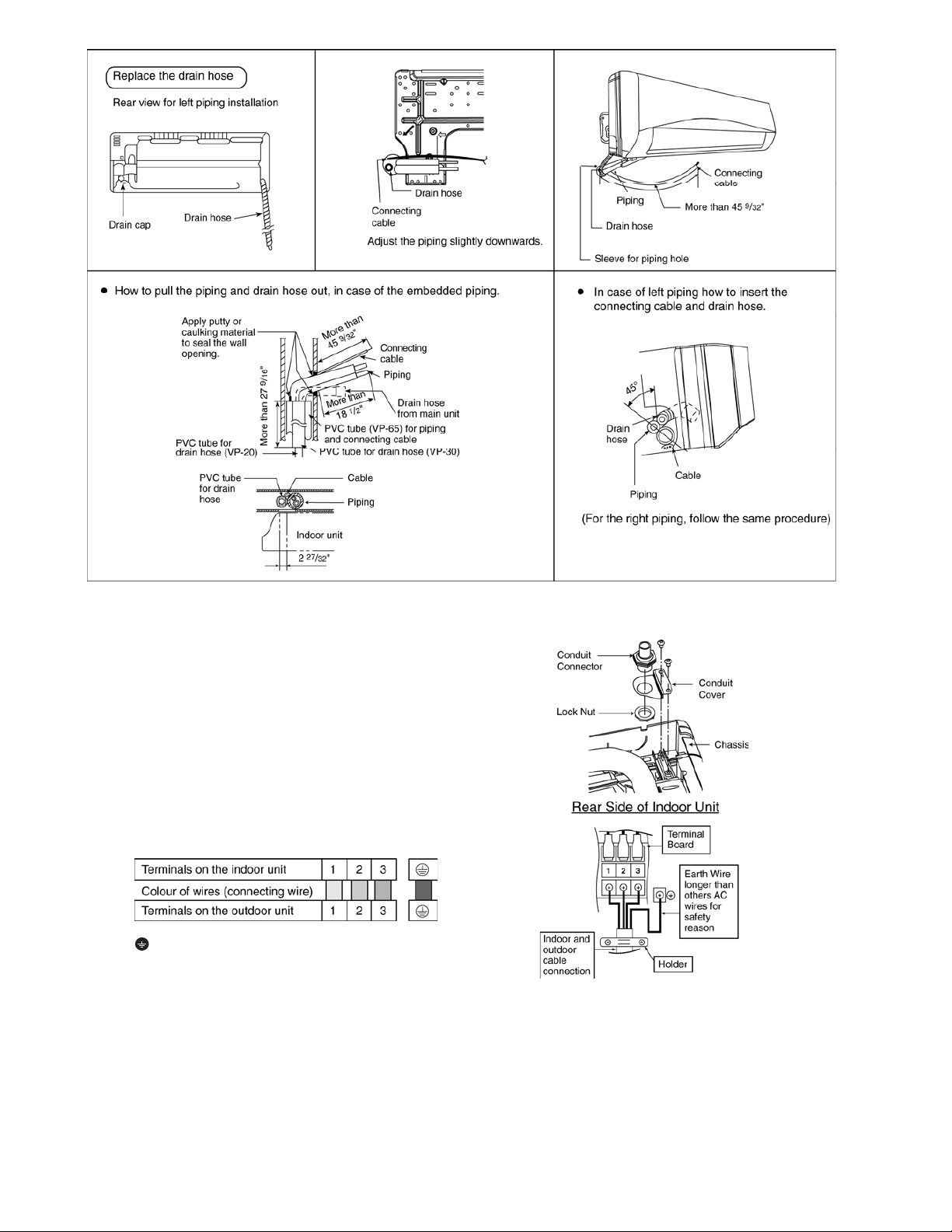

10.1.3.7 Connect the Cable to the Indoor Unit

1. The inside and outside connecting cable can

be co

nnected without remo

Unscrew the conduit cove

2.

nector to conduit cove

con

se

cure it against chassi

3.

Connecting wire between indoor unit an

r unit should be UL listed or

outdoo

approved 4 condu

in accordan

Ensure the colour of wires of outdoor un

o

and terminal number are the same as the

indoo

r's resp

This equipment must be properly earthed.

o Earth lead wire shall be

(Y/G) in colou

other lead wires as shown in the figure fo

electri

cal safety in case of the slip

ctor wires minimum AWG1

ce with local electric code

ectively.

r and shall be longer than

ving the front grille.

r and fix the conduit

r with lock nut, then

s.

d

CSA

6

s.

it

Yellow/Green

r

ping.

34

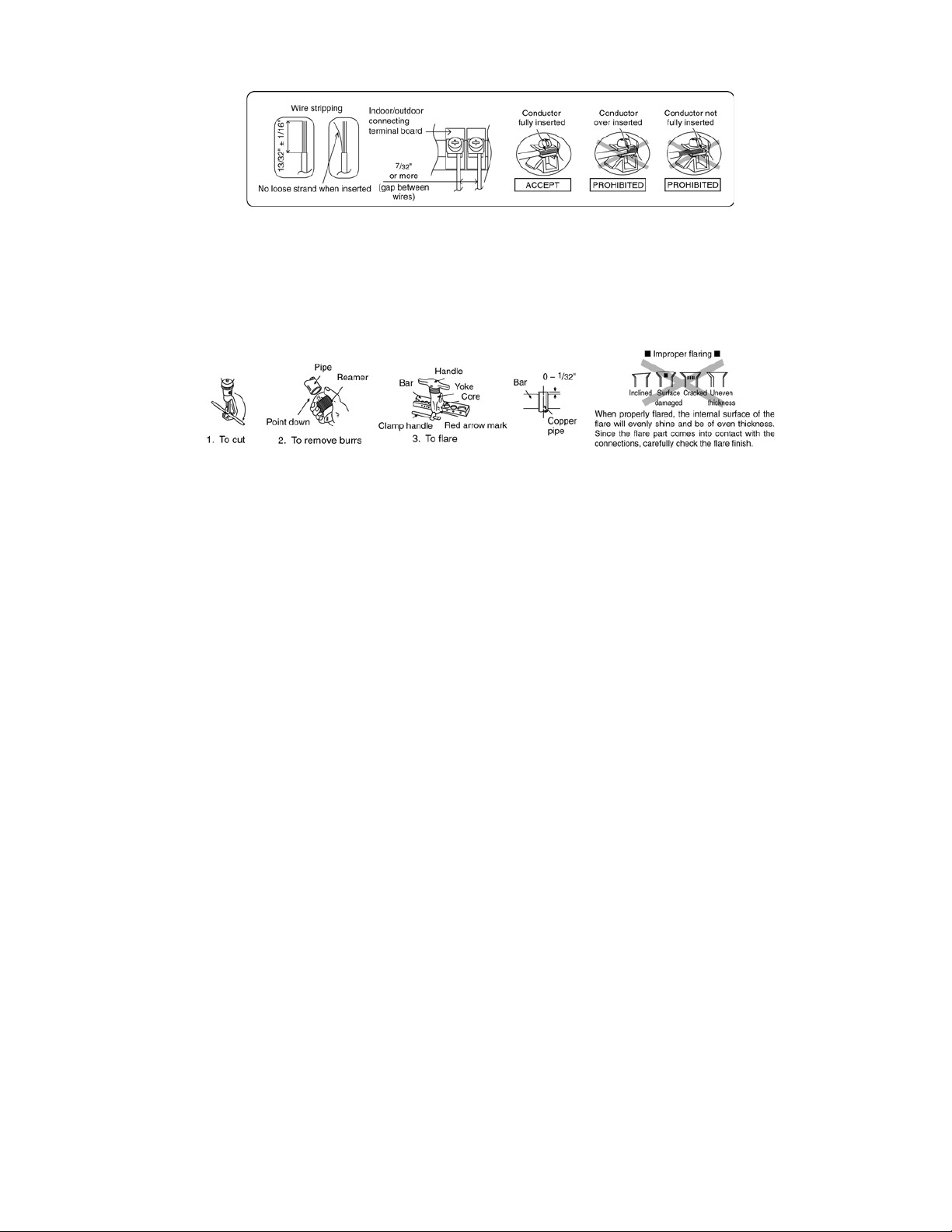

10.1.3.8 Wire Stripping and connecting requirement

10.1.3.9 Cutting and flaring the piping

1 Please cut using pipe cutter and then remove the burrs.

2 Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end

down to avoid the metal powder entering the pipe.

3 Please make flare after inserting the flare nut onto the copper pipes.

35

Loading...

Loading...