Panasonic CS-A181KE, CS-A241KE, CU-A241KE, CU-A181KE Service Manual

ORDER NO. MAC9811041C2

Service Manual

Room Air Conditioners

CS-A181KE / CU-A181KE

CS-A241KE / CU-A241KE

Contents

● Features ..........................................................1

● Functions ...................................................2 – 4

● Product Specifications ...............................5 – 8

● Dimensions ..............................................9 – 10

● Refrigeration Cycle Diagram .........................10

● Block Diagram ...............................................11

● Wiring Diagram .............................................. 12

● Operation Details ...................................13 – 22

● Installation Information ..........................23 – 24

● 3-way Valves .........................................25 – 31

● Servicing Information .............................32 – 35

● Troubleshooting Guide ..........................36 – 37

● Technical Data.......................................38 – 40

● Exploded View .........................................41, 43

● Replacement Parts List ...........................42, 44

● Electronic Parts List ............................... 45 – 46

1999 Matsushita Air-Conditioning Corp. Sdn. Bhd.

(183914D)

All rights reserved. Unauthorized copying and distribution is a violation of law.

CS-A181KE

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not contain

warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products powered by electricity

should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the product or products dealt with

in this service information by anyone else could result in serious injury or death.

Features

WARNING

!

!

PRECAUTION OF LOW TEMPERATURE

In order to avoid frostbite, be assured of no refrigerant leakage during the installation or repairing of refrigeration circuit.

• High Efficiency

• High Efficiency Airflow Circuit

• Compact Design

• Removable and Washable

Front Panel

• Auto Restart after Power Failure

• Long Piping up to 25m

• Deodorizing Air Filter

• Deodorizing Control during

operation

– 1 –

Functions

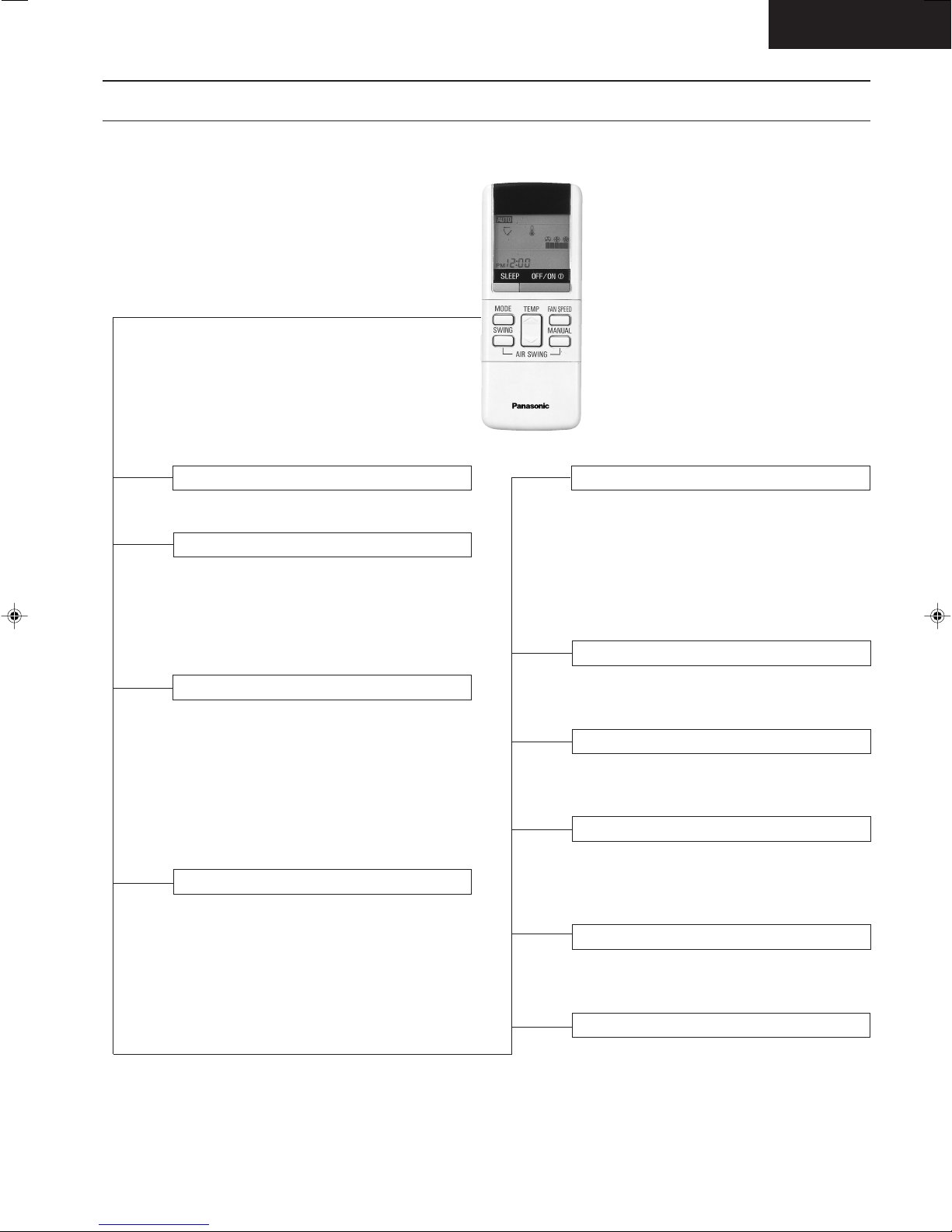

Remote Control

CS-A181KE

OFF / ON I

MODE

FAN SPEED

AIR SWING

Operation OFF / ON

Operation Mode Selection

• AUTO Automatic Operation Mode

• HEAT Heating Operation Mode

• COOL Cooling Operation Mode

• DRY Soft Dry Operation Mode

Indoor Fan Speed Selection

• h j k Low Speed

l

• h j k Medium Speed

lll

• h j k High Speed

lllll

• AUTOFAN Automatic Fan Speed

Airflow Direction Control

• SWING Automatic Airflow Direction

Control

• MANUAL Airflow Direction Manual Control

TEMP.

ON-TIMER

OFF-TIMER

TIME

SET

CANCEL

CLOCK

(q)

Room Temperature Setting

• Temperature Setting (16˚C to 30˚C)

• Automatic Operation

m / n 2˚C lower than standard

n Standard

n - o 2˚C higher than standard

Timer Operation Selection

• 24-hour, OFF / ON Real Timer Setting.

Time / Timer Setting

• Hours and minutes setting.

Timer Operation Set / Cancel

• ON Timer and OFF Timer setting and

cancellation.

Clock Setting

• Current time setting.

– 2 –

SLEEP

Sleep Mode Operation OFF / ON

CS-A181KE

Functions

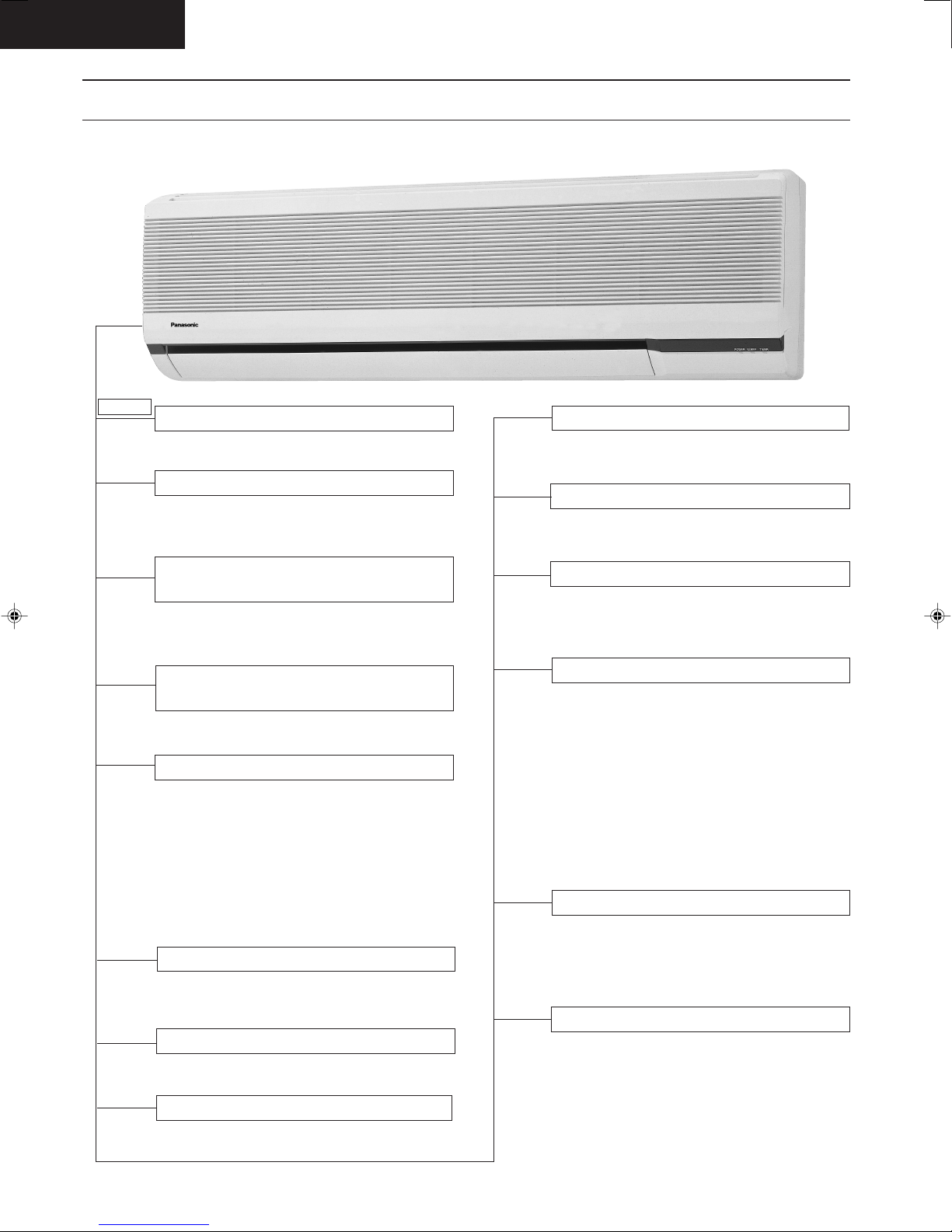

Indoor Unit

POWER I

AUTO

OFF / ON

TEST RUN

OFF / ON

Power Switch OFF / ON

Auto Operation Switch

• Used when the remote control cannot be

used.

Remote Control Signal Receiving

Sound Control

• It can be controlled by pressing Auto

Operation Switch for 10 seconds.

Operation Test Running / Pump

Down Switch

• Used when test running or servicing.

Operation Indication Lamps (LED)

• POWER (Red)...... Lights up in operation,

blinks in Automatic

Operation Mode judging

and Hot Start operation.

• SLEEP (Orange)..... Lights up in Sleep

Mode Operation.

• TIMER (Orange)..... Lights up in Timer

Setting.

Operation Mode

• Heating, Cooling, Soft Dry, and Automatic

Mode.

Time Delay Safety Control

• Restarting is inhibited for appro. 3 minutes.

7 Minutes Time Save Control

• Cooling Operation only.

Auto Restart Control

• Operation is restarted after power failure

at previous setting mode.

Anti-Freezing Control

• Anti-Freezing control for indoor heat

exchanger. (Cooling and Soft Dry)

Sleep Mode Auto Control

• Indoor Fan operates at Super Low fan

speed.

• Operation stops after 8 hours.

Indoor Fan Speed Control

• High, Medium and Low.

• Automatic Fan Speed Mode

– Heating : Fan speed varies from Me

SLo in accordance with indoor

heat exchanger.

– Cooling : Fan rotates at Hi and Me

speed. Deodorizing control is

available.

– Soft Dry : Fan rotates at SLo speed.

Deodorizing control is

available.

Airflow Direction Control

• Automatic air swing and manual adjusted

by remote control for vertical airflow.

• Manually adjusted by hand for horizontal

airflow.

Hot-Start Control

• The indoor fan stops until the indoor heat

exchanger temperature over 30°C.

• The indoor fan operates at SLo and Lo

when indoor heat exchanger temperature

reaches 30°C ~ 42°C.

• Hot start is completed when indoor heat

exchanger reaches 42°C.

–

➝

– 3 –

Functions

Outdoor Unit

CS-A181KE

4-Way Valve Control

• When the unit is switched to "OFF" during

Heating operation, 4-way valve stays at

Heating Position for 5 minutes.

Overload Protector

• Inner protector (Compressor, Fan Motor).

60 Secs. Forced Operation Control

• Once the compressor is activated, it does

not stop for 60 secs. (Stops immediately

with remote control stop signal.)

Outdoor Fan Operation Control

•

4-pole induction motor (2-speed)

• For Cooling or Soft Dry Operation

Hi-speed … when outdoor temperature

reaches to 31°C

Lo-speed … when outdoor temperature

reaches to 29°C

• For Heating Operation

Hi-speed ... when outdoor temperature

reaches to 13.5°C.

Lo-speed ... when outdoor temperature

reaches to 15.5°C.

• For Over-heating Protection, the Fan is

switched ON or OFF depending on the

piping temperature and the outdoor temperature.

2-Way Valve Control

• 2-way valve is ON for 1 minutes after

compressor start. Other than this, 2-way

valve is OFF. (A241K only)

Deice Control

•

To prevent frosting at outdoor heat

exchanger during Heating Operation.

– 4 –

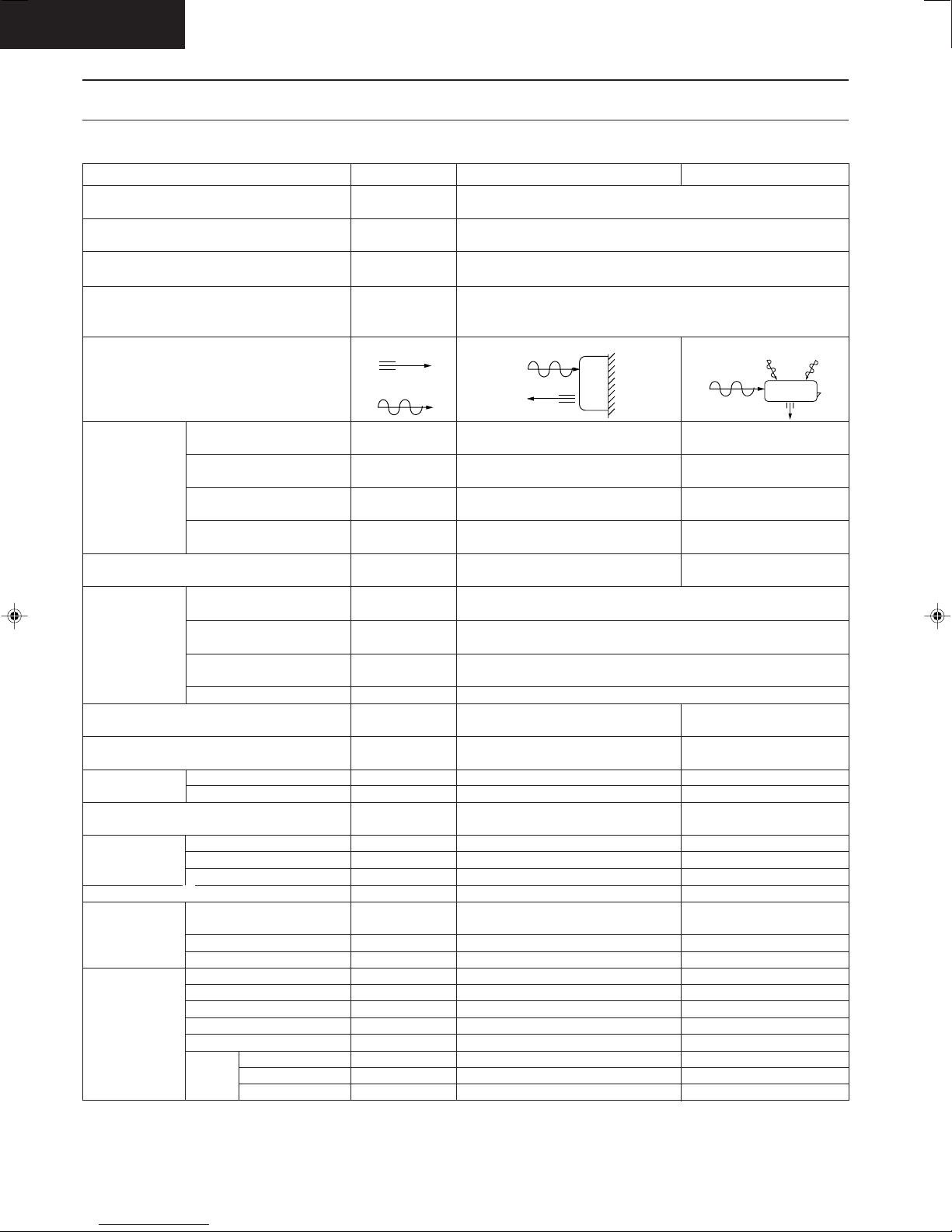

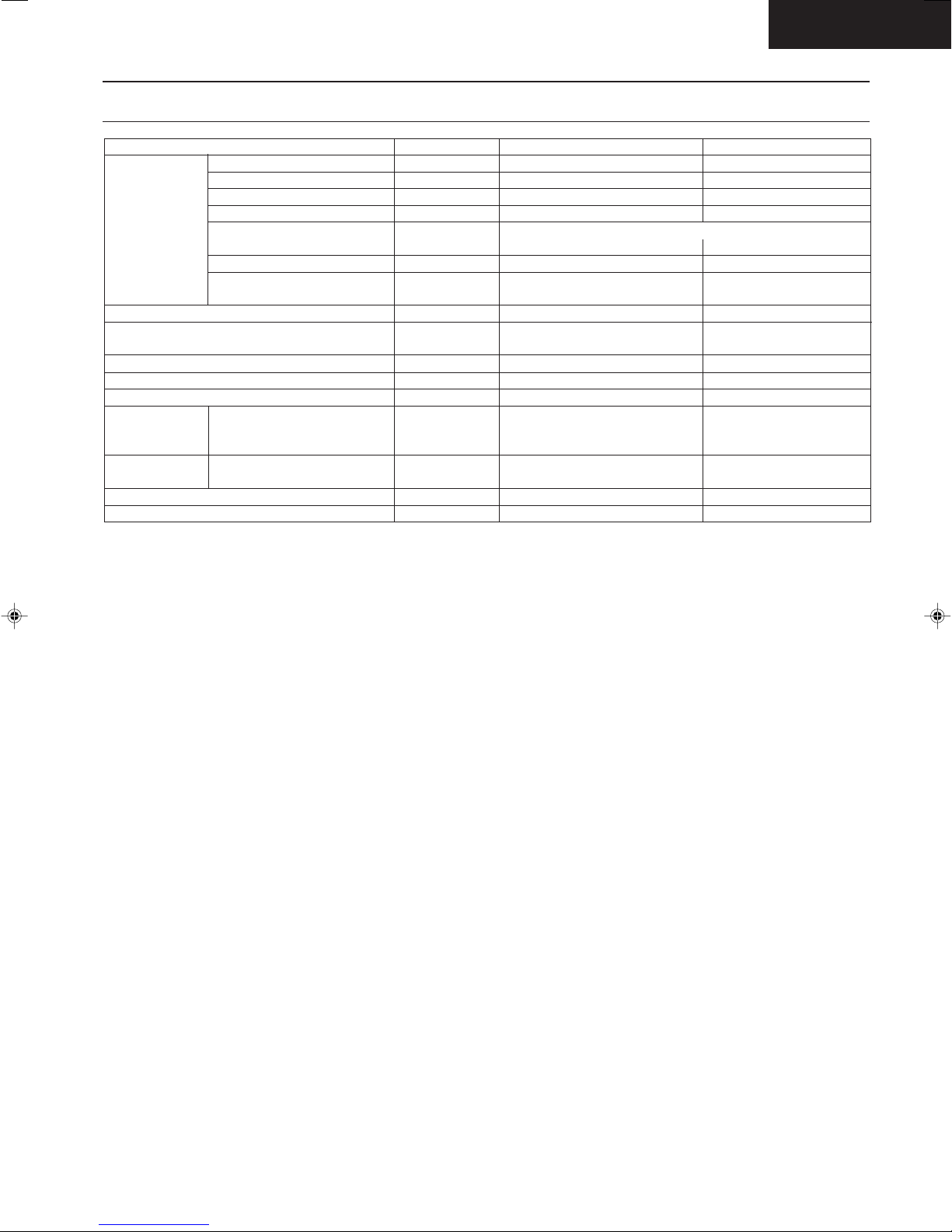

CS-A181KE

Product Specifications

Cooling Capacity

Heating Capacity

Moisture Removal

Power Source

Airflow Method

Air Volume

Noise Level

Electrical

Data

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Power Cord Length

Dimensions

Net Weight

Compressor

Air Circulation

Indoor Air (Lo)

Indoor Air (Me)

Indoor Air (Hi)

Outdoor Air

Input

Running Current

COP

Starting Current

Inner diameter

Length

Number of core-wire

Motor Type

Rated Output

Motor Type

Fan Low

Speed Medium

Height

Width

Depth

Type

Type

Material

Input

Rated Output

High

Unit

kW

Btu/h

kW

Btu/h

s/h

Pint/h

Phase

V

Cycle

OUTLET

INTAKE

3

m

/min (cfm)

3

/min (cfm)

m

m3/min (cfm)

3

m

/min (cfm)

dB (A)

kW

A

W/W

A

inch

inch

inch

inch

mm

m

m

inch (mm)

inch (mm)

inch (mm)

lb (kg)

kW

W

W

rpm

rpm

rpm

CS-A181KE

5.20 - 5.15

17,700 - 17,600

6.20 - 6.05

21,100 - 20,600

2.9

6.1

Single

240 - 220

50

SIDE VIEW

Cooling ; 11.2 (395)

Heating ; 11.6 (409)

Cooling ; 12.4 (437)

Heating ; 12.9 (455)

Cooling ; 13.7 (480)

Heating ; 14.2 (500)

Cooling ; 11.8 (416)

Heating ; 12.2 (430)

Cooling ; High 43 - 43, Low 38 - 38 Cooling ; High 56 - 54

Heating ; High 42 - 42, Low 38 - 38 Heating ; High 57 - 55

G ; Half Union 1/2"

L ; Half Union 1/4"

G (gas side) ; 1/2"

L (liquid side) ; 1/4"

AS + Glass Fiber 30%

Transistor (4-poles)

Cooling ; 980 Heating ; 980

Cooling ; 1,090 Heating ; 1,090

Cooling ; 1,200 Heating ; 1,240

–

Cooling ; 2.12 - 1.98

Heating ; 2.19 - 2.04

Cooling ; 10.9 - 10.0

Heating ; 11.2 - 10.2

Cooling ; 2.45 - 2.60

Heating ; 2.83 - 2.97

16

0.75

2.1

2

3 (1.5 mm

11-7/16 (290)

38-19/32 (980)

7-11/16 (195)

29 (13)

Cross-flow Fan

)

–

–

–

–

20

51

CU-A181KE

TOP VIEW

–

–

–

G ; 3-way valve 1/2"

L ; 3-way valve 1/4"

G (gas side) ; 1/2"

L (liquid side) ; 1/4"

–

–

–

–

26-31/32 (685)

31-1/2 (800)

11-13/16 (300)

137 (62)

Rotary (1 cylinder)

rolling piston type

Induction (2-poles)

1.7

Propeller Fan

PC + AES + Glass Fiber 15%

Induction (4-poles)

136.3

72

670 - 600

–

1,030 - 950

– 5 –

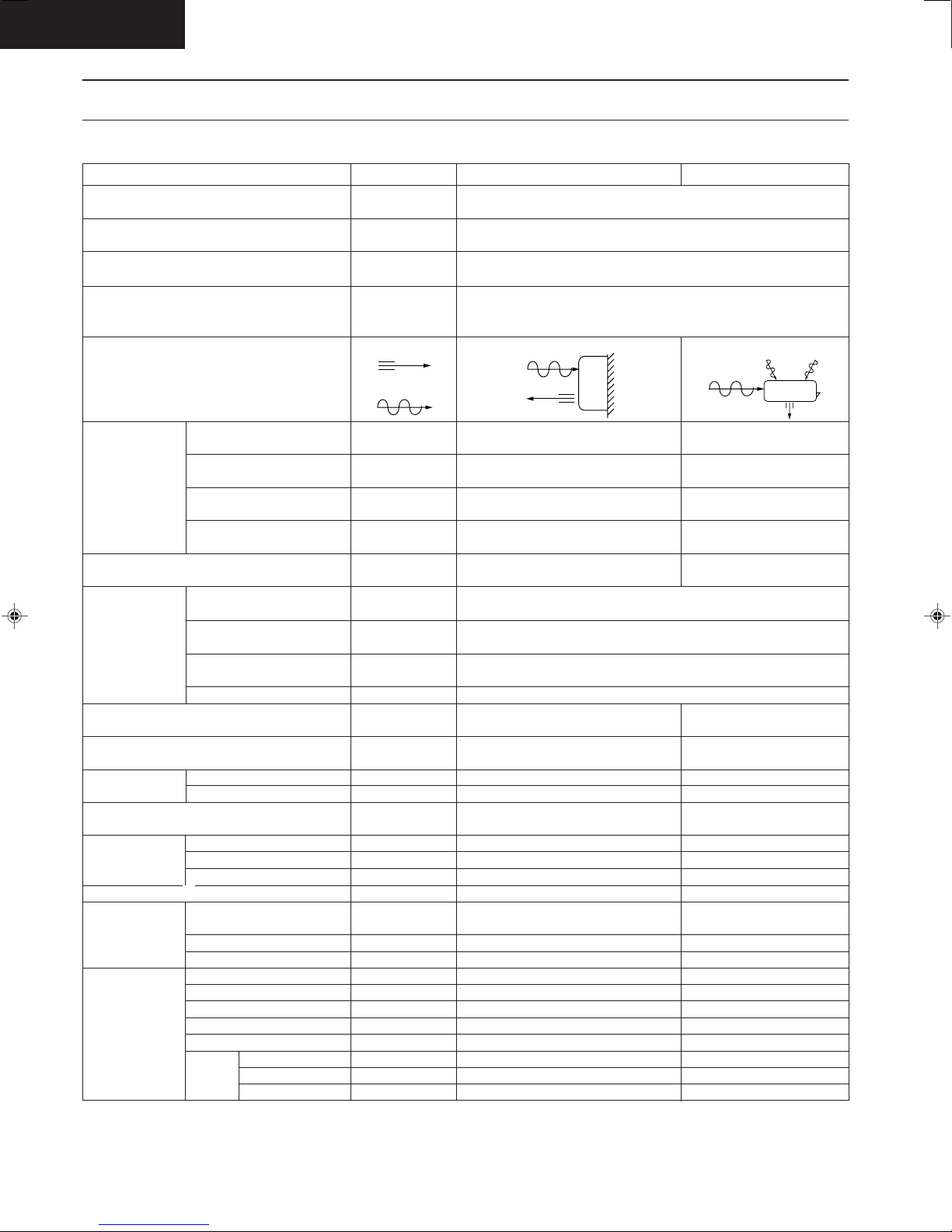

Product Specifications

CS-A181KE

Unit

Heat

Exchanger

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Capillary Tube

Air Filter

Compressor Capacitor

Fan Motor Capacitor

• Specifications are subject to change without notice for further improvement.

Description

Tube material

Fin material

Fin Type

Row / Stage

FPI

Size (W × H × L)

Length

Flow Rate

Inner Diameter

Material

Style

mm

(cm3)

g (oz)

mm

s/min

mm

µF, VAC

µF, VAC

CS-A181KE

Evaporator

Copper

Aluminium

Slot Fin

(Plate fin configuration, forced draft)

2 × 14

21

732 × 294 × 25.4

–

–

–

Electronic Control

–

–

–

–

P.P.

Honeycomb

–

–

Cooling ; 690 Heating ; 650

Cooling ; 13.0 Heating ; 20.9

Cooling ; 1.6 Heating ; 1.9

CU-A181KE

Condenser

Copper

Aluminium

Corrugated Fin

2 × 26

14

769.2

× 660.4 × 44

732.9

Capillary Tube

SUNISO 4GDID or

ATMOS M60 (700)

1,590 (56.1)

–

Inner Protector

–

35 µF, 370VAC

3.0 µF, 400VAC

– 6 –

CS-A181KE

Product Specifications

Cooling Capacity

Heating Capacity

Moisture Removal

Power Source

Airflow Method

Air Volume

Noise Level

Electrical

Data

Piping Connection Port

(Flare piping)

Pipe Size

(Flare piping)

Drain

Hose

Power Cord Length

Dimensions

Net Weight

Compressor

Air Circulation

Indoor Air (Lo)

Indoor Air (Me)

Indoor Air (Hi)

Outdoor Air

Input

Running Current

COP

Starting Current

Inner diameter

Length

Number of core-wire

Motor Type

Rated Output

Motor Type

Fan Low

Speed Medium

Height

Width

Depth

Type

Type

Material

Input

Rated Output

High

Unit

kW

Btu/h

kW

Btu/h

s/h

Pint/h

Phase

V

Cycle

OUTLET

INTAKE

3

m

/min (cfm)

3

/min (cfm)

m

m3/min (cfm)

3

m

/min (cfm)

dB (A)

kW

A

W/W

A

inch

inch

inch

inch

mm

m

m

inch (mm)

inch (mm)

inch (mm)

lb (kg)

kW

W

W

rpm

rpm

rpm

CS-A241KE

6.45 - 6.40

22,000 - 21,800

7.80 - 7.55

26,600 - 25,700

3.8

8.0

Single

240 - 220

50

SIDE VIEW

Cooling ; 13.1 (462)

Heating ; 14.1 (497)

Cooling ; 14.3 (504)

Heating ; 15.4 (542)

Cooling ; 15.7 (550)

Heating ; 16.9 (600)

Cooling ; 14.3 (504)

Heating ; 15.4 (542)

Cooling ; High 47 - 47, Low 41 - 41 Cooling ; High 61 - 59

Heating ; High 46 - 46, Low 41 - 41 Heating ; High 62 - 60

G ; Half Union 5/8"

L ; Half Union 1/4"

G (gas side) ; 5/8"

L (liquid side) ; 1/4"

AS + Glass Fiber 30%

Transistor (4-poles)

Cooling ; 1,100 Heating ; 1,200

Cooling ; 1,200 Heating ; 1,320

Cooling ; 1,320 Heating ; 1,410

–

Cooling ; 2.86 - 2.67

Heating ; 2.96 - 2.74

Cooling ; 14.0 - 13.2

Heating ; 14.3 - 13.5

Cooling ; 2.26 - 2.40

Heating ; 2.64 - 2.76

16

0.75

2.1

29 (13)

–

–

–

–

40

2

)

3 (2.5 mm

11-7/16 (290)

38-19/32 (980)

7-11/16 (195)

Cross-flow Fan

66

CU-A241KE

TOP VIEW

–

–

–

G ; 3-way valve 5/8"

L ; 3-way valve 1/4"

G (gas side) ; 5/8"

L (liquid side) ; 1/4"

–

–

–

–

26-31/32 (685)

31-1/2 (800)

11-13/16 (300)

146 (66)

Rotary (1 cylinder)

rolling piston type

Induction (2-poles)

2.2

Propeller Fan

PC + AES + Glass Fiber 15%

Induction (4-poles)

179.0

108

720 - 635

–

1,200 - 1,140

– 7 –

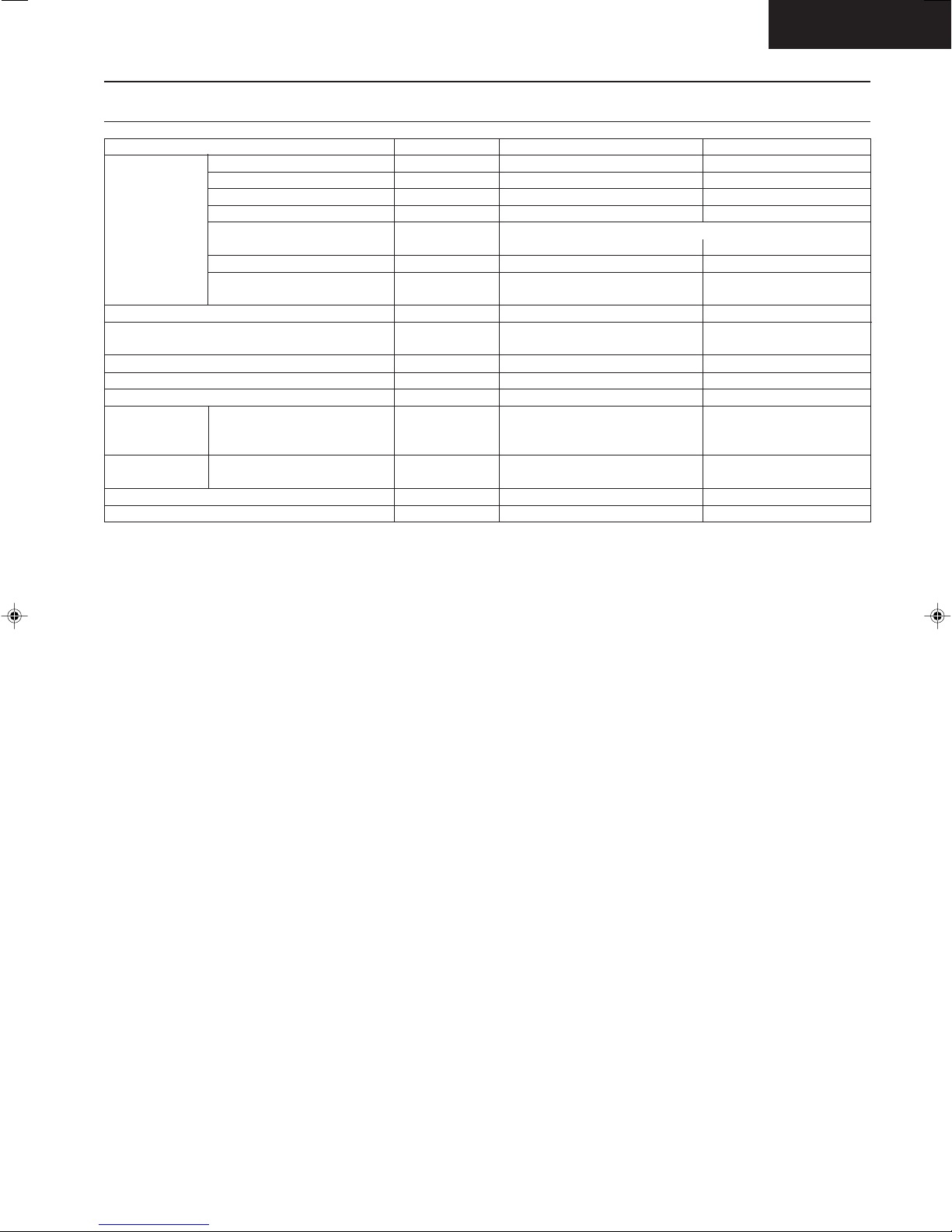

Product Specifications

CS-A181KE

Unit

Heat

Exchanger

Refrigerant Control Device

Refrigeration Oil

Refrigerant (R-22)

Thermostat

Protection Device

Capillary Tube

Air Filter

Compressor Capacitor

Fan Motor Capacitor

• Specifications are subject to change without notice for further improvement.

Description

Tube material

Fin material

Fin Type

Row / Stage

FPI

Size (W × H × L)

Length

Flow Rate

Inner Diameter

Material

Style

mm

3

)

(cm

g (oz)

mm

s/min

mm

µF, VAC

µF, VAC

CS-A241KE

Evaporator

Copper

Aluminium

Slot Fin

(Plate fin configuration, forced draft)

2 × 14

21

732 × 294 × 25.4

–

–

–

Electronic Control

–

–

–

–

P.P.

Honeycomb

–

–

Cooling ; 700 Heating ; 649

Cooling ; 17.5 Heating ; 27.0

Cooling ; 1.8 Heating ; 2.4

CU-A241KE

Condenser

Copper

Aluminium

Corrugated Fin

2 × 26

16

769.2

× 660.4 × 44

732.9

Capillary Tube

SUNISO 4GDID or

ATMOS M60 (1,130)

1,770 (62.5)

–

Inner Protector

–

50 µF, 370VAC

3.0 µF, 450VAC

– 8 –

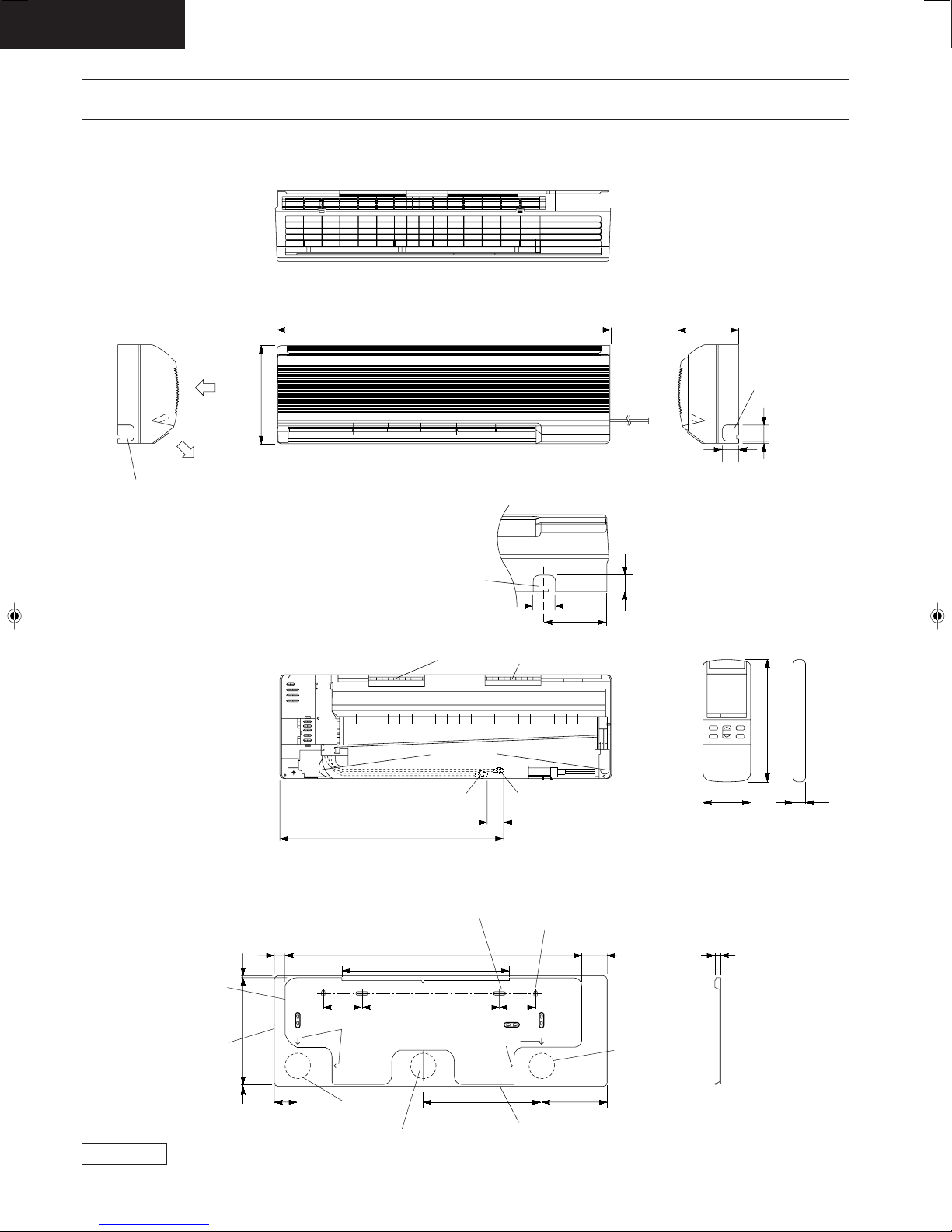

CS-A181KE

Dimensions

CS-A181K / CS-A241K

<Top View>

Air outlet direction

Left piping hole

Air intake

direction

<Front View>

290

980

Lower piping hole

Installation plate hooks

Drain ports

165

195

Approx

2,100

<Side View>

48.5

60

Remote control transmitter

Right piping hole

52

59

6

142

Relative position between the indoor unit and the installation plate <Front View>

(39)

Installation plate

Indoor unit external

dimensions line

7

276

7

(59.5)

Left piping hole

Unit : mm

Gas side Liquid side

55

Approx. 706

Slot (2 places)

892

561

100 100

Arrow

(Ø 70)

Centre

piping hole

350

Arrow

(335.5)

Installation plate positioning gauge

(Ø 70)

– 9 –

Slot (2 places)

(49)

(165)

Right piping hole

(Ø 70)

13.5

57

16

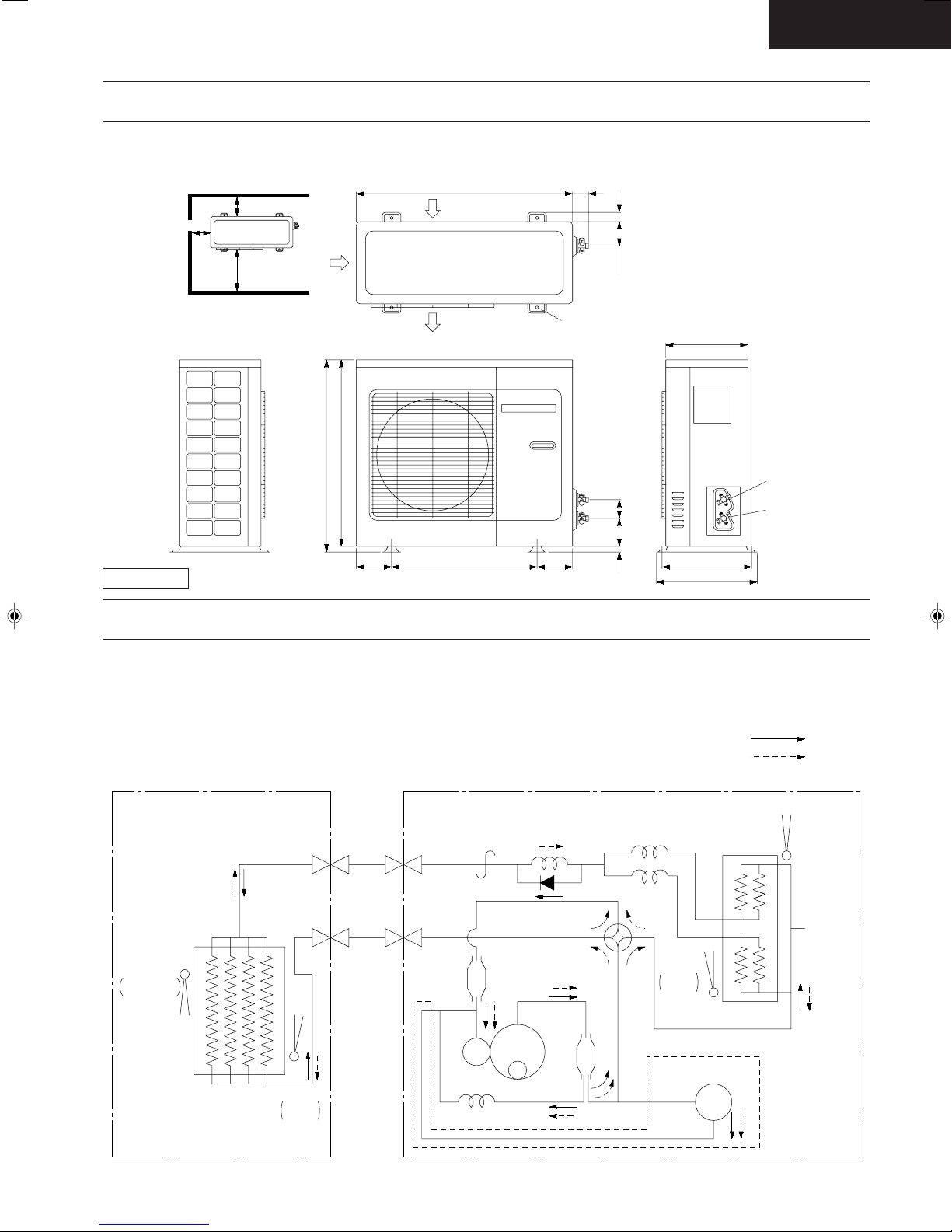

Dimensions

CU-A181K / CU-A241K

Required space for installation

10cm

10cm

Air intake direction

CS-A181KE

56.3800

35

100cm

Anchor bolt pitch 330 x 540

Air outlet direction Slots (12 x 17) Four places

663

685

Unit : mm

Refrigeration Cycle Diagram

CS/CU-A181K

CS/CU-A241K

106.5

300

3-way valve at

liquid side

7577.5

130130 540

22

330

370

3-way valve at

gas side

INDOOR UNIT OUTDOOR UNIT

HEAT EXCHANGER

(EVAPORATOR)

SENSOR

INTAKE

AIR TEMP.

SENSOR

PIPE

TEMP.

3-WAY VALVE

3-WAY VALVE

STRAINER

ACCUMULATOR

(SUB)

COMPRESSOR

CAPILLARY TUBE

CHECK VALVE

4-WAY

VALVE

OIL

SEPARATOR

CAPILLARY TUBE

ONLY OIL

SENSOR

PIPE

TEMP.

HEAT EXCHANGER

(CONDENSER)

CU-A241K ONLY

2-WAY VALVE

COOLING

HEATING

SENSOR

INTAKE

(AIR TEMP.)

PROCESS

TUBE

V

– 10 –

CS-A181KE

POWER

SWITCH

INDOOR UNIT OUTDOOR UNIT

SINGLE

PHASE

240-220V

50Hz

(113°C)

THERMAL FUSE

22

11

WIRELESS

REMOTE CONTROL

TRANSMITTER

LH

C

ZNR

RY-PWR

RY-HOT

ELECTRONIC CONTROLLER

4 4

33

TRANSFORMER2

FUSE

3.15A

FUSE

3.15A

ZNR2

RY-HOT

ZNR1

COMP

F/M

RY-V

RY-OFF

RY-DEICE

2-WAY

TRANSFORMER1

RY-H/L

TRANS-

FORMER

4-WAY VALVE

VALVE

CU-A241K

ONLY

O.L.P.

P.C.B.

RECEIVER

SENSOR

6C

S/M

INDICATORS

5C

4C

SENSOR

4C

ZNR3 ZNR4

3.15A

FUSE

3C

F/M

ELECTRONIC CONTROLLER

THERMAL

FUSE (102°C)

Indicates the number of core wires. (Example: 6C=6 core wires)

"C"

Indicates the electronic control unit.

MAIN

PC1

ZNR2

STEPPING

MOTOR

FAN MOTOR

INDOOR

Block Diagram

CS-A181KE / CU-A181KE

CS-A241KE / CU-A241KE

– 11 –

O

M

R

W

Wiring Diagram

CS-A181KE / CU-A181KE

CS-A241KE / CU-A241KE

CS-A181KE

240/220V, 50Hz

POWER SUPPLY CORD

YLW/GRN

BRW

2

1

MAIN SW

BRW

BLK

WHT

WHT

RED

CORE

BLU

THERMAL FUSE (102°C)

RED

4

3

BLU

(A241K ONLY)

RED

CN-FUSE1(BLU)

AC (BRW)

COMP(BLK)

THERMAL FUSE

(113°C)

CN-FUSE2

AC(WHT)

HOT(RED)

DEICE (BLU)

RED

CN-T(WHT)

1

3

P

L

1

2

BLK

T (BLK)

FUSE (3.15A)

ZNR

ZNR

RY-HOT

ELECTRONIC

CONTROLLER

RED

T (BLK)

TRANSFORMER

BLK

PUMP

DOWN SW

(SW1)

REMOTE

CONTROL No

BA

WIRELESS

REMOTE

CONTROL

AUTO SW

ELECTRONIC

CONTROLLER

RECEIVER+

()

DISPLAY LAMP

CN-DISP (WHT)

654

WHT

1

WHT

2

WHT

3

WHT

4

WHT

5

CN-DISP (WHT)

WHT

6

BRW

1

RED

2

ORG

3

MOTOR

YLW

CN-STMCN-TH (YLM)

4

PNK

5

(AIR TEMP.)

1324

SENSOR SENSOR

(PIPE TEMP.)

YLW

1

BLU

FAN

2

MOTOR

RED

3

CN-MTR (GRN)

321

REMARKS:

BLU : BLUE

BRW : BROWN

BLK : BLACK

WHT : WHITE

RED : RED

ORG : ORANGE

PNK : PINK

YLW : YELLOW

GRN : GREEN

GRY : GRAY

VLT : VIOLET

INDOOR UNIT TERMINAL

21

3

312

BLU

BLU

ELECTRONIC

CONTROLLER

TRANSFORMER1

TRANSFORMER2

COIL

(2-WAY VALVE)

FUSE

BLU BLU

CAPACITOR

RED

T 3.15A L 250V

YLW/GRN

4

4

VLT

COMP(VLT) AC(WHT)

ZNR2

BLU

OUTDOOR UNIT

TERMINAL

WHT

FUSE (3.15A)

RY-V

V(BLU)

RED

GRY

RY-DEICE

RY-OFF

ZNR4

RY-H/L

FM2(ORG) FM1(BRW)

(A241K ONLY)

ORG

BRW

FAN MOTOR

BLK

BLK

RY-HOT

HOT2(BLK)HOT1(RED) DEICE (GRY)

YLW

COIL

(4-WAY VALVE)

ZNR3

1

2

3

CN-TH(WHT)

4

WHT

SENSOR

SENSOR

O.L.P.

(TEMP.)

YLW

BLU

RED

CAPACITOR

(AIR TEMP.)

(PIPE TEMP.)

(BLU)

COMPRESSOR TERMINAL

COMPRESSOR

(YLW)

YELLOW

BLUE

(BLU)

COMPRESSO

TRADE MARK

(YL

YELL

TRADE

(RED)

Resistance of Outdoor Fan Motor Windings

CU-A181KE

CONNECTION

BLUE - BROWN

BROWN - ORANGE

RED - BROWN

CWA92294 (Ω)

79.5

65.1

70.8

Resistance of Compressor Windings

CU-A181KE

REDBLUE

CONNECTION

C-R

C-S

2JS350D3AA02 (Ω)

0.980

3.929

CU-A241KE

CWA92295 (Ω)

46.8

64.6

73.7

CU-A241KE

2JS464D3AA02 (Ω)

0.888

2.328

– 12 –

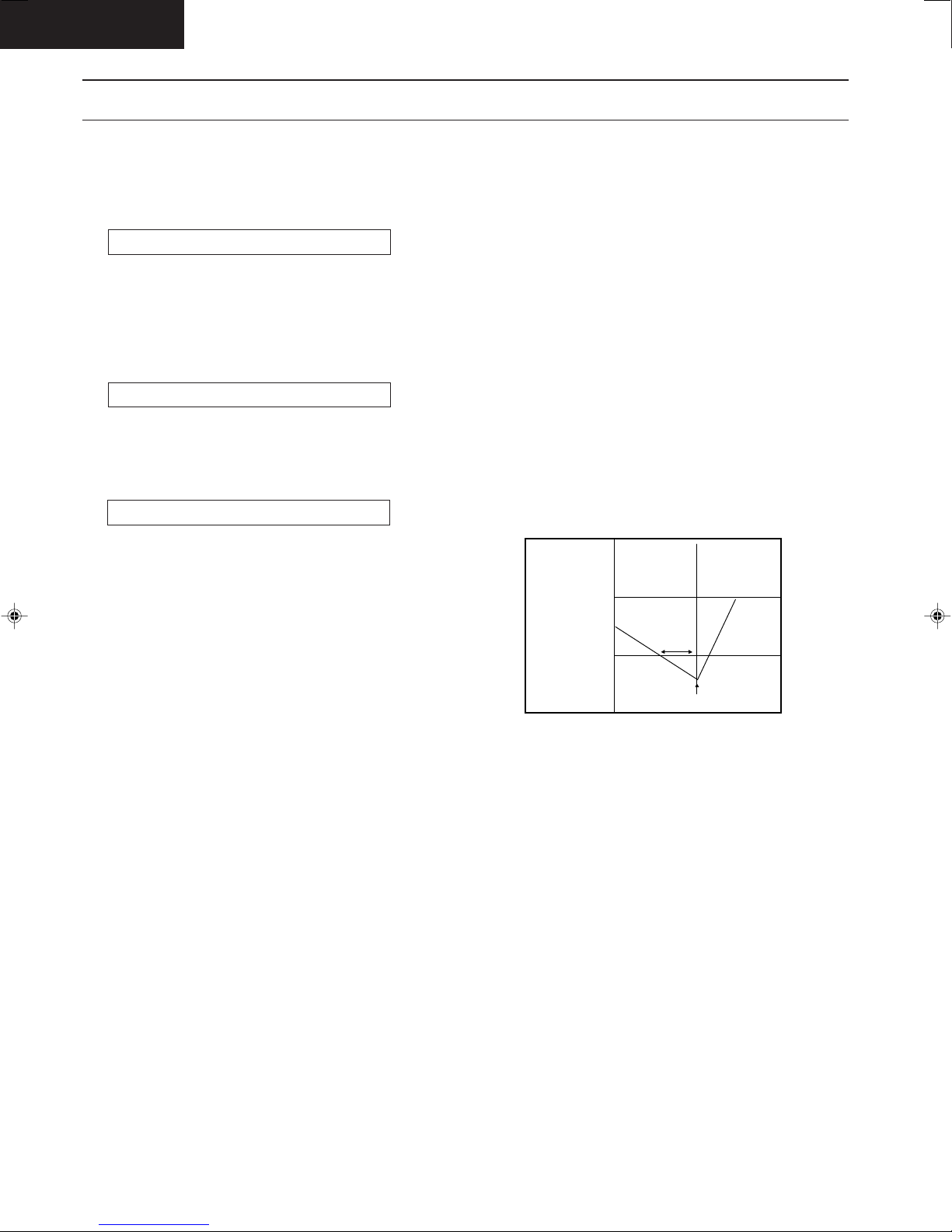

CS-A181KE

Operation Details

1) Cooling Mode Operation

Cooling in operation according to Remote Control setting.

Time Delay Safety Control (3 minutes)

• When the compressor is stopped by Power Switch, Remote Control or there is a power failure, it restarts after 3

minutes when the Power Switch, Remote Control is turned ON or the power supply is resumed.

• When the setting temperature is reached during cooling operation, the compressor stops and it will not start for 3

minutes.

7 minutes Time Saved Control

• The compressor will start automatically if it has stopped for 7 minutes even if the room temperature is below the

compressor ON temperature.

Anti-Freezing Control

• If the temperature of the indoor heat exchanger

falls continously below 2°C for 4 minutes, the

compressor turns off to protect the indoor heat

exchanger from freezing. The fan speed setting

remains the same.

• Compressor recommences when the indoor heat

exchanger temperature rises to 10°C (Recovery).

* 3 minutes waiting of Time Delay Safety Control

is valid for Cooling Operation.

Indoor Heat

Exchanger

Temperature

(°C)

10

2

Recovery

4 min

Compressor OFF

– 13 –

Operation Details

Automatic Fan Speed Mode

When Automatic Fan Speed is selected at Remote Control during cooling operation.

• Fan speed rotates in the range of Hi to Me.

• Deodorizing Control.

CS-A181KE

Indoor

SLo SLo SLo SLo

Fan

stop stop stop

stop

40"

30"

Comp.

* 1 Fan Speed is Hi until the compressor stops (when the room temperature reaches

setting temperature).

* 2 Fan Speed is Me after the compressor restarts.

Cooling Operation Time Diagram

Intake Air

Temperature

Comp.

ON

1.5˚C

Set Temp.

Outdoor Air

Temperature

Comp.

OFF

31˚C

29˚C

.

.

.

✕

.

1

20"

ON ONOFF

a

defghijklmnopqrstuvwxyz

b

c

Indoor

Heat

Exchanger

Temp.

10°C

2°C

40"

.

.

.

✕

.

2

30"160"

Operation

Stop

Basic Time

Compressor

Indoor Fan

Outdoor Fan

Operation LED

4 Way Valve

2 Way Valve (A241K)

<Description of operation>

d – g : Time Delay Safety Control (waiting for 3 minutes)

g – h : 60 sec. Forced Operation

h – o : 7 min. Time Saved Control

q – t : Anti Freezing Control

v – y : Outdoor Fan Control

1’ 3’ 1’ 7’ 1’

– 14 –

4’

HiHi Hi Lo Lo Lo Hi

Loading...

Loading...