Panasonic AY-NE2000E Service Manual

SPECIFICATIONS

Video

Video Input

[Analogue]

Input Connectors: 2 sources (selectable from Composite. Y/C, Y/PB/PR)

Composite: 1.0 V[p-p]/75 Ω (BNC)

Y /C: Y: 1.0V[p-p]/75 Ω

C: 0.3 V[p-p]/75 Ω (Y/C terminal)

Component: Y: 1.0V[p-p]/75 Ω (BNC)

P

B/PR

: 0.525V[p-p] or 0.7V[p-p]/75 Ω (BNC) (75% Colour Bar)

[SDI (Option)]

SMPTE259M 75 Ω (BNC) with active loop-through

Video Output

[Analogue]

Output Connector: 2 outputs (simultaneously from Composite, Y/C, Y/PB/PR)

Composite: 1.0V[p-p]/75 Ω

Y/C: Y: 1.0V[p-p]/75 Ω

C: 0.3V[p-p]/75 Ω (Y/C terminal)

Component: Y: 1.0V[p-p]/75 Ω (BNC)

P

B/PR

: 0.525V[p-p] or 0.7V[p-p]/75 Ω (BNC) (75% Colour Bar)

[SDI (Option)]

SMPTE259M 75 Ω (BNC)

Synchronization

Gen-Lock Input: 1.0V[p-p]/75 Ω (BNC), with loop-through output (x1)

ADV.REF output: Sync: 0.3V[p-p]/75 Ω

Burst: 0.3V[p-p]/75 Ω

Nonlinear Workstation Main Kit

AY-NE2000E

ORDER NO. BSD9903011C8

C 1999 Matsushita Communication Industrial Co., Ltd.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

This service information is designed for experienced repair technicians only and is not designed for use by the

general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to

service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any

attempt to service or repair the product or products dealt with in this service information by anyone else could

result in serious injury or death.

Y

WARNING

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION:

TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK). NO USER

SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user that uninsulated voltage within

the unit may have sufficient magnitude to cause electric

shock. Therefore, it is dangerous to make any kind of contact

with any inside part of this unit.

This symbol alerts the user that important literature concerning

the operation and maintenance of this has been included.

Therefore, it should be read carefully in order to avoid

any problems.

There are special components used in this equipment which are important for safety. These parts are indicated

by the ”

Y ” mark on the schematic diagram and the replacement parts list. It is essential that these critical

parts should be replaced with manufacturer's specified parts to prevent X-radiation, shock, fire, or other hazards.

Do not modify the original design without permission of manufacture.

IMPORTANT SAFETY NOTICE

Audio Input

[Analogue]

Selectable from 4 sources

Source 1/2: +4dBu, 0dBu, –20dBu selectable, Hi-Z balanced (3-pin XLR connector)

Source 3/4: –6dBs, 20 kΩ, unbalanced (RCA pin jack)

[AES/EBU (Option)]

SMPTE279M 75 Ω (BNC)

Audio Output

[Analogue]

4 outputs (simultaneous)

Ch. 1/2: +4dBu, 0dBu, –20dBu selectable, 47 Ω balanced (3-pin XLR connector)

Ch. 3/4: –6dBs, 75 Ω, unbalanced (RCA pin jack)

[AES/EBU (Option)]

SMPTE279M 75 Ω (BNC)

Other Inputs/Outputs

LTC time code Input: x1 (BNC)

LTC time code output: x1 (BNC)

SCSI connector: x4 (Audio, Video 1, Video 2, Video 3, SCSI-2 standard,

68-pin half pitch connector, pin type)

VTR control connector : RS-422, 9 pin x2 (D-sub)

Jog Pad connector: 9 pin x1 (D-sub)

PC

CPU : Pentium Processor, MMX 200 MHz

OS : Windows 95

Main Memory : 32 MB DIMM 168-pin SDRAM

Built-in Hard Disk Drive : 3.2 GB (E-IDE) x1

Floppy Disk Drive : 1.44MB x1

ZIP Drive : 100MB x1

CD-ROM Drive : x32 Speed

Card Slot : PCI x3 (supplied by Panasonic only)

SVGA connector : 15 pinx1 (D-Shell, female),

1024 x 768 dots, 256 colours,

Scanning: 48 kHz (horizontal),

60 Hz (vertical)

Parallel connector : 25 pin x1 (D-Shell, female)

Serial connector : 9 pin x2 (D-Shell, male)

Mouse : 6 pin x1 (Mini-Din, female)

Keyboard : 6 pin x1 (MIni-Din, female)

Video Performance

S/N Ratio * : 55 dB (Y/PB/PR), 53 dB (Y/C), 50 dB (Composite)

DG, DP * : 5%, 3°

Frequency Response * : 4.5 MHz, +0dB, –3dB (Y/C, Y/P

B/PR

)

Sampling Frequency : 13.5 MHz, 4:2:2, 8 bit component

Y/C Separation : 3 lines, digital logical comb filter

SC-H : ±30°

Compression : MOTION JPEG

Compression Quality : Q3, Q6, Q8, Q11, Q23

Recording Time : Approx. 3 min/GB (Q3)

Approx. 6 min/GB (Q6)

Approx. 7 min/GB (Q8)

Approx. 10 min/GB (Q11)

Approx. 15 min/GB (Q23)

Title Graphics

Resolution : 640 x 480 dots Y, U, V, α, 8 bit component each

Font : True type

Audio Performance

S/N Ratio : More than 67 dB (1 kHz, XLR OUT)

Dynamic Range : More than 85 dB

Total Harmonic Distortion : 0.05% (1 kHz)

Frequency Response : 20 kHz, +0, –3 dB, 20 Hz, +0, –3 dB

Sampling Frequency : 48 kHz, 16 bit

Mixing : Stereo 4 channels

Effector : EQ, Reverberation

Recording Time : Approx. 86 min/GB

Others

EDL Output : CMX3600, CMX340, GVG, BVE9000, AU-A950 Format

Graphic Conversion : TIFF, JPEG, TARGA, BMP, WMF, PCT

General

Power Supply : 220 ~ 240V AC, 50 Hz

Power Consumption : 135W (with optional Video Board)

Ambient Operating Temperature : 0°C ~ 35°C (32°F ~ 95°F)

Ambient Operating Humidity : 10% ~ 90%

Weight : Main unit: 27.0 kg (59.5 Ibs)

Jog pad: 1.2 kg (2.6 Ibs)

Dimensions :

Main unit (W x H x D) : 420 x 319 x 461 mm

Jog pad (W x H x D) : 340 x 45 x 193 mm

Weight and dimensions indicated above are approximate.

Specifications are subject to change without notice.

This product might be subject, to export control regulations.

* : Without Compression

Nonlinear Editing System Digital I/F Board AY-PB2002E

Video

Input Signal: Comply with the SMPTE259M standards,

BNC x 1 (with active loop-through)

Output Signal:

Comply with the SMPTE259M standards, BNC x 1

Audio

Input Signal:

Comply with the AES/EBU standards, BNC x 1

Output Signal:

Comply with the AES/EBU standards, BNC x 1

General

Power Supply: 5V DC, 12V, –12V

Ambient Operating Temperature: 5°C to 35°C

Ambient Operating Humidity: 10% to 90%

Dimensions (W x H x D): 236 x 35.5 x 67 mm

Weight: Approx. 340 g

CONTENTS

Major Operating Controls And Their Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

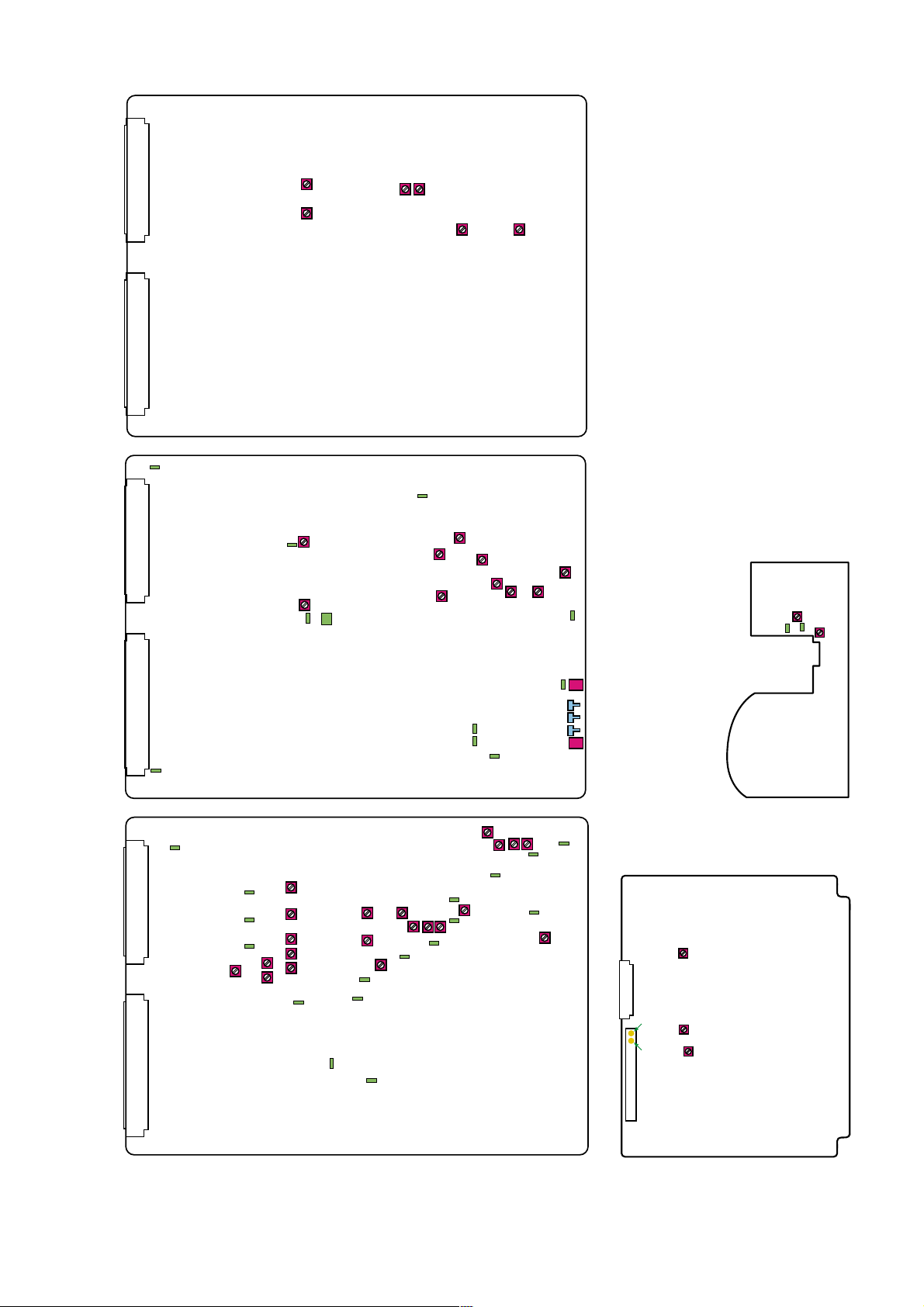

Location Of Test Points And Adjusting Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

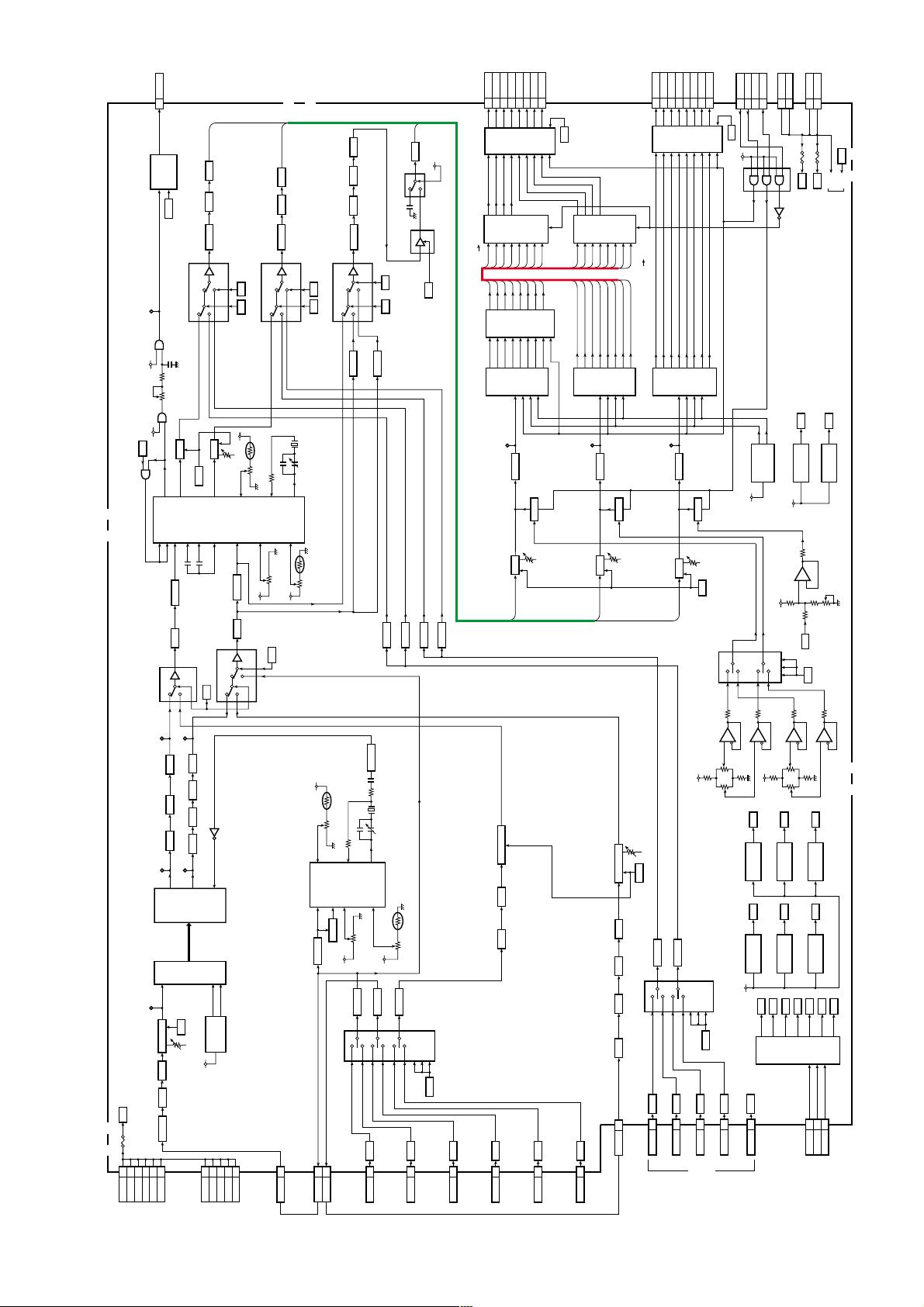

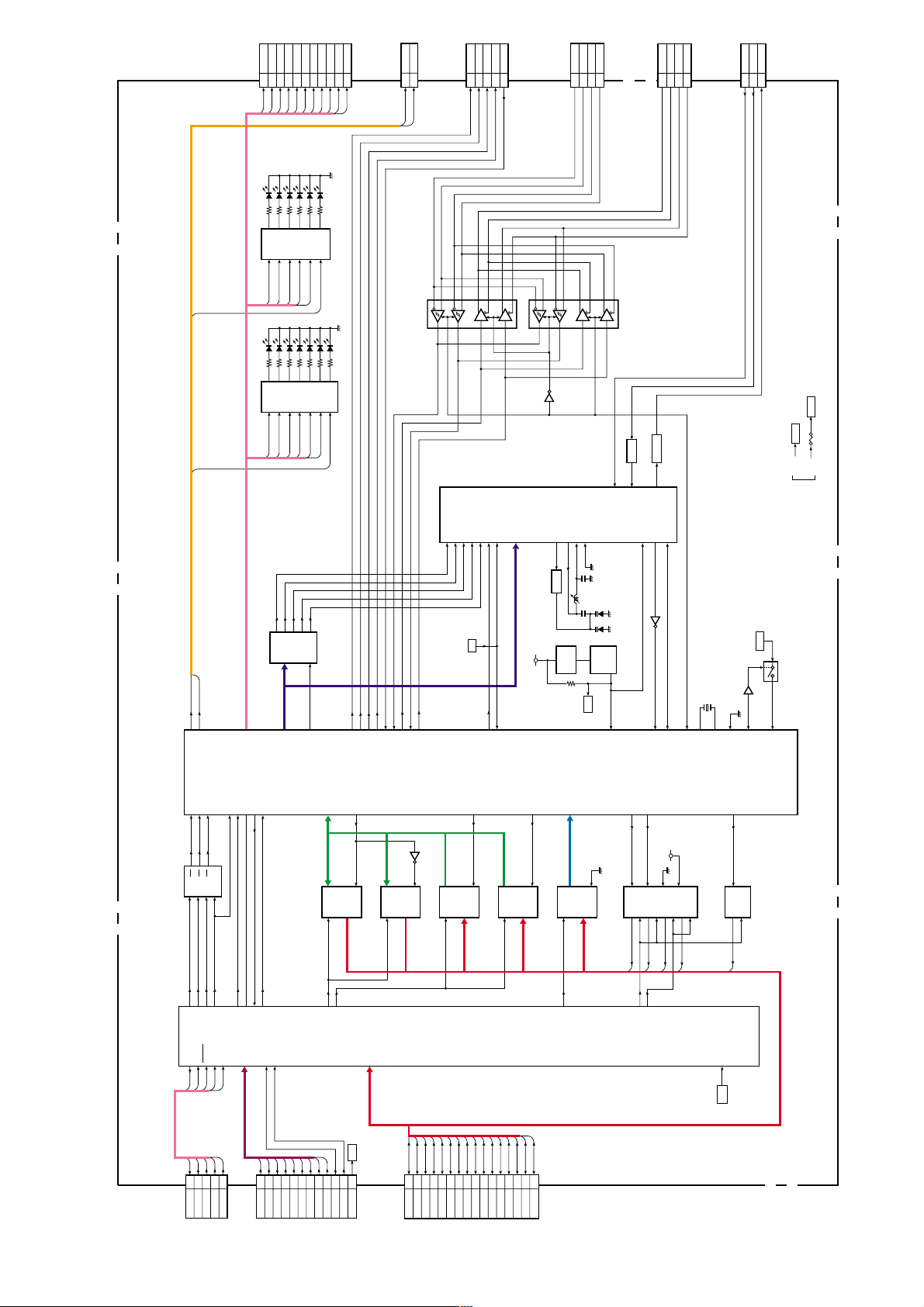

Block Diagram

Input Board (1/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Input Board (2/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

JPEG/SCSI Board (SCSI Section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

JPEG/SCSI Board (JPEG Section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Audio Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

CG Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Mixer Board (1/4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Mixer Board (2/4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Mixer Board (3/4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Mixer Board (4/4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

AY-PB2002E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Schematic Diagram

JPEG/SCSI Board (JPEG Section) (1/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

JPEG/SCSI Board (JPEG Section) (2/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

JPEG/SCSI Board (SCSI Section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Input Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Mixer Board (1/3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Mixer Board (2/3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Mixer Board (3/3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

CG Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

AY-PB2002E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

PCI Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Power Board/Power Switch Board/LED Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Mother Board (1/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Mother Board (2/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Audio Board (1/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Audio Board (2/2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Rear Board-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Rear Board-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Conductor View

JPEG/SCSI Board (JPEG Section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

JPEG/SCSI Board (SCSI Section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Input Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Mixer Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

CG Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

AY-PB2002E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

PCI Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Power Board/Power Switch Board/LED Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Mother Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Audio Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Rear Board-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Rear Board-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Exploded View

AY-NE2000E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

AY-PB2002E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

1

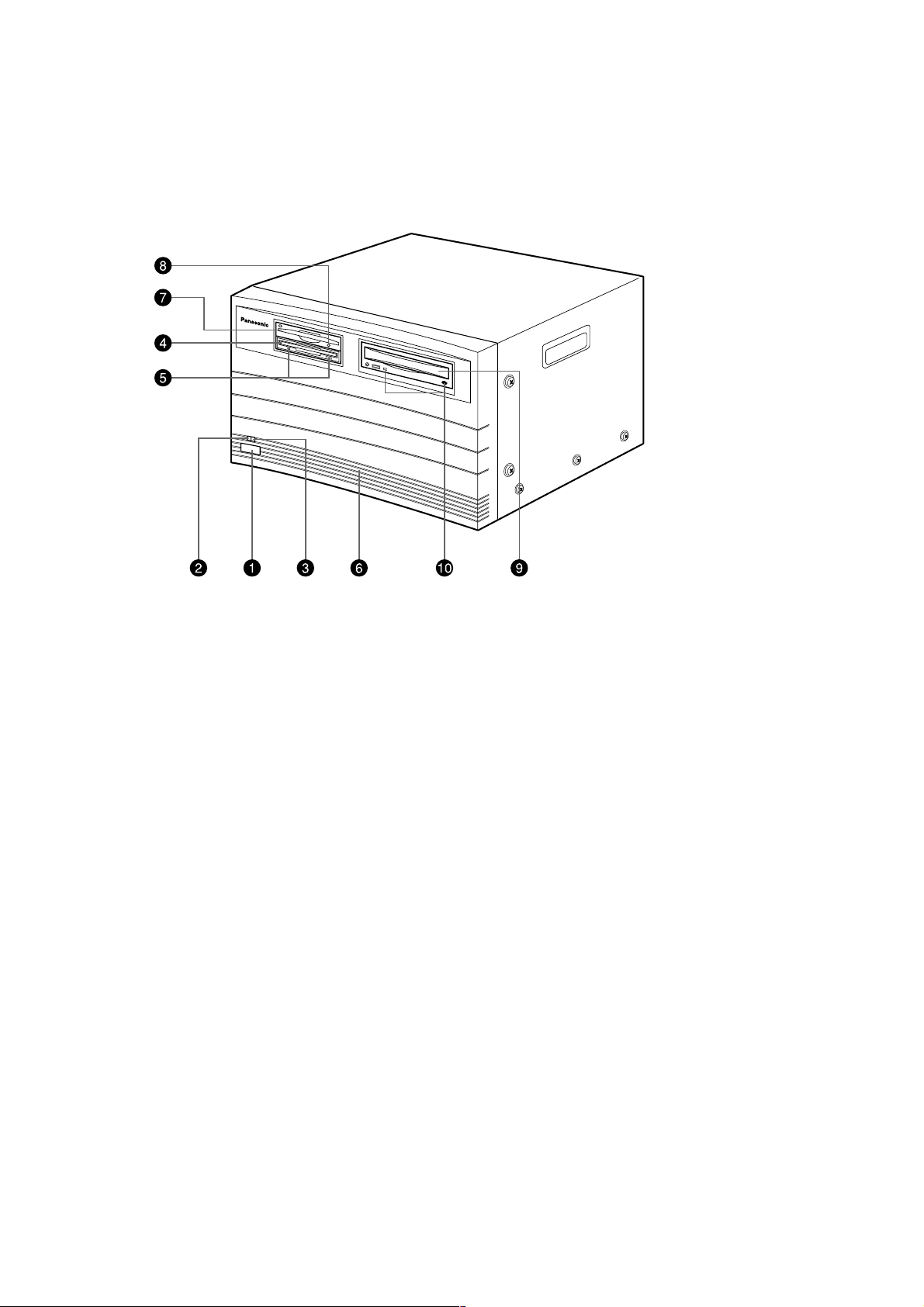

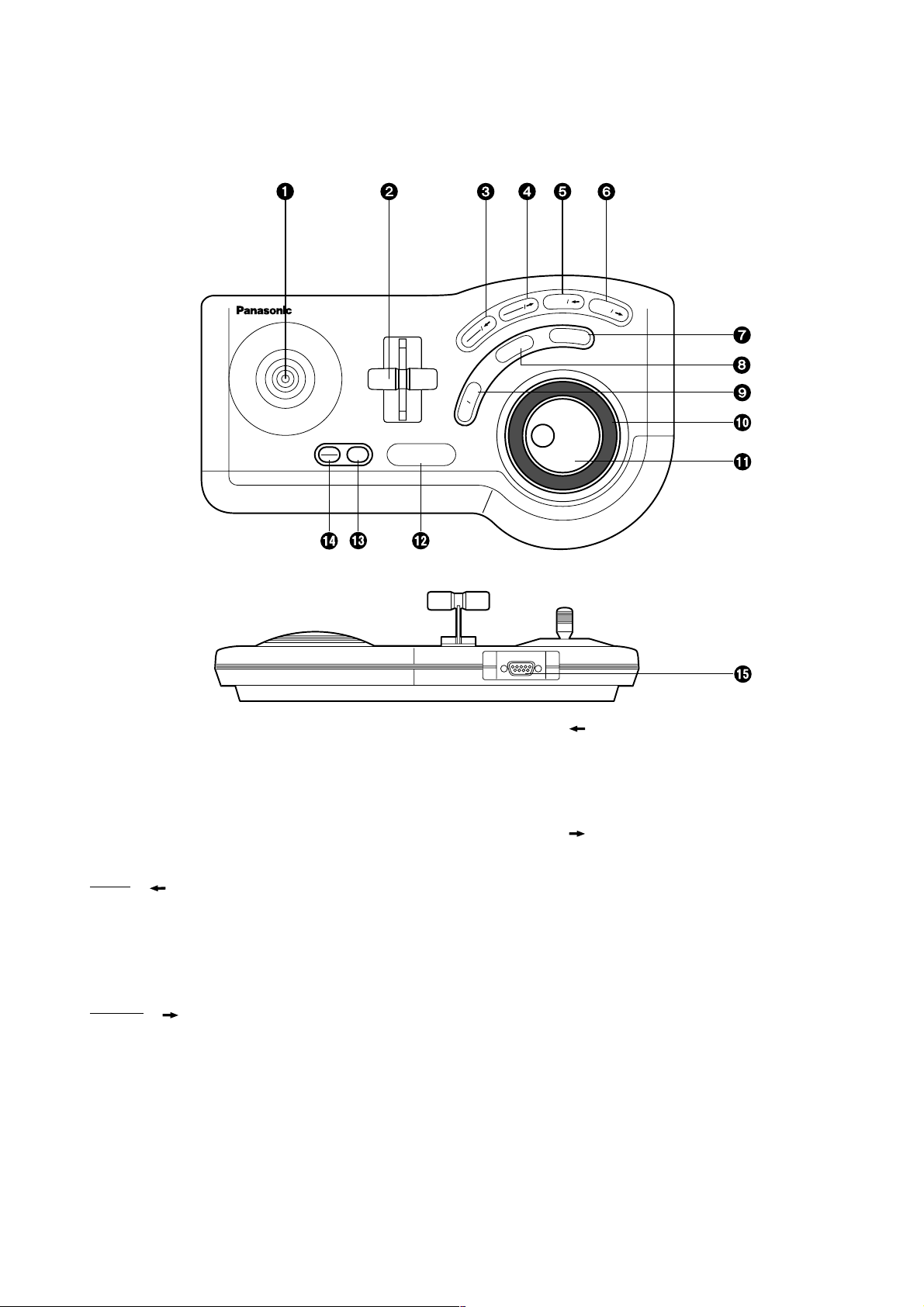

MAJOR OPERATING CONTROLS AND THEIR FUNCTION

■ FRONT PANEL

1. Power On/Off Switch

Turns the power of this unit on and off.

Notes:

1. Be sure to turn on the power of this unit after turning

on the Hard Disk Box.

2. Do not turn off the power of this unit while the

Nonlinear AV Workstation System software is running.

2. Power Indicator (RED)

Lights by turning on the power.

3. HDD Indicator (GREEN)

Lights up while the HDD operates.

4. 3.5” Floppy Disk Drive

5. Floppy Disk Indicator/Eject Button

Indicator.......Lights during an access of the floppy disk.

Eject button..Ejects the Floppy Disk.

6. Front Panel

Caution: Do not interrupt the Vent Hole on this panel.

7. ZIP Drive

8. ZIP Indicator/Eject Button

Lights during an access of the ZIP.

Ejects the ZIP.

9. CD-ROM Drive

10. CD-ROM Indicator/Eject Button

Indicator.......Lights during an access of the

CD-ROM.

Eject button..Ejects the CD-ROM.

2

AC IN

IN1

IN2

LR

RL

OUT1

OUT2

AUDIO

OUT

LR

OUT1

LR

OUT2

BALANCED

AUDIO OUT

L

IN1 IN2

BALANCED

AUDIO IN

LRR

CONTROL 1 CONTROL 2 JOG PAD

Y/C

COMPOSITE

Y

P

B PR

IN1

IN2

G/L IN

LOOP

75Ω

Y/C COMPOSITE Y P

B PR

ADV REF

OUT

OUT1

OUT2

TC IN

VIDEO

IN

AUTO

VIDEO

OUT

TC OUT

AUDIO

IN

SEE MANUAL

KB MOUSE SEPIAL 1

SEPIAL 2 PRINTER

S-VGA

SCSI AUDIO SCSI VIDEO 1 SCSI VIDEO 2 SCSI VIDEO 3

VIDEO(DIGITAL)

IN

OUT

AUDIO(AES/EBU)

IN OUT

VIDEO(DIGITAL)

IN

OUT

AUDIO(AES/EBU)

IN OUT

~

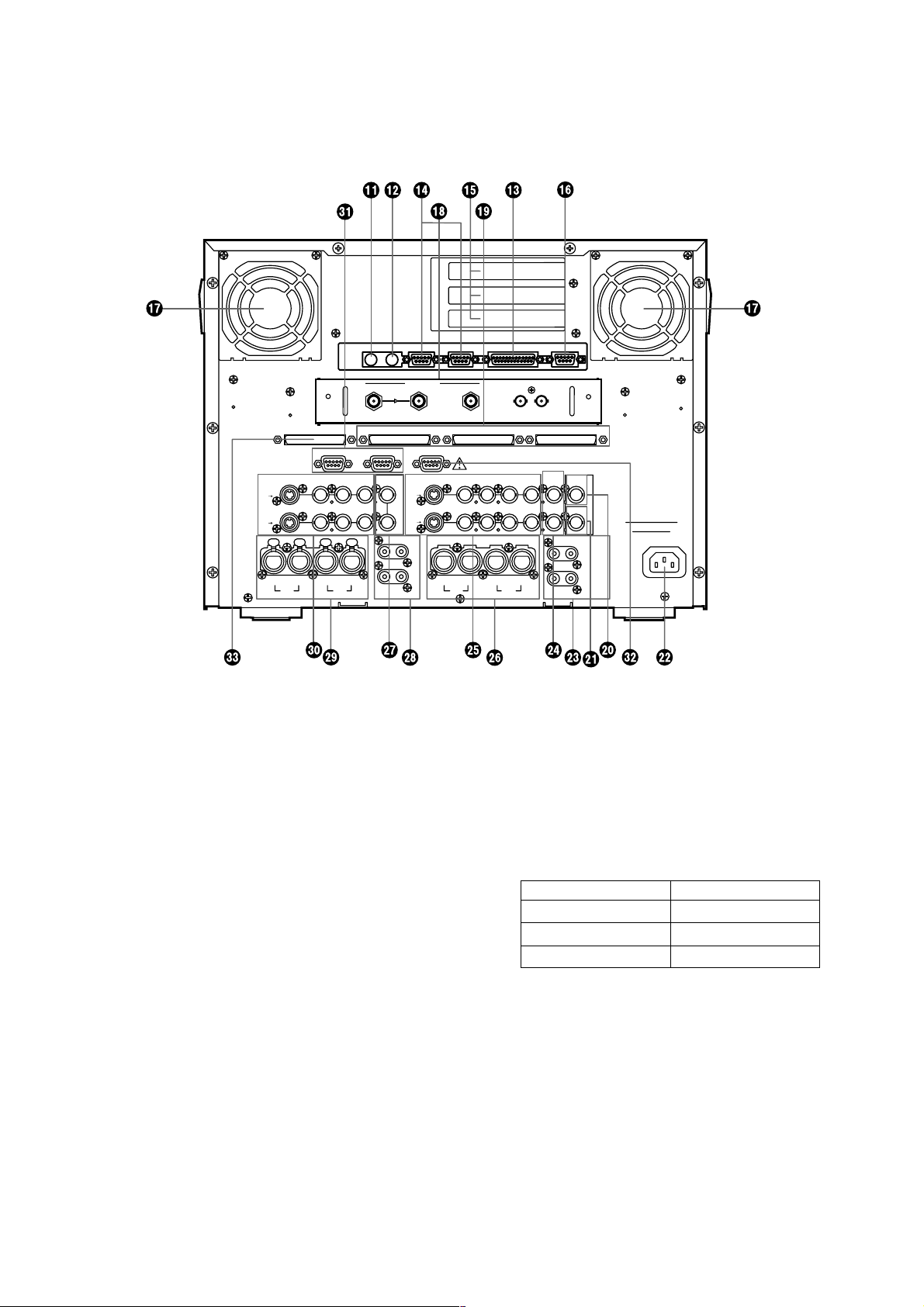

■ REAR PANEL

11. KEYBOARD Connector (KB)

Connects with the keyboard (locally purchase).

If the cable is too short to connect, use the Key Board

Extension Cable (accessory).

12. MOUSE Connector (MOUSE)

Connects with the Mouse (locally purchase).

When the cable is too short to connect, use the Mouse

Extension Cable (accessory).

13. PRINTER Connector (PRINTER)

Connects with the printer.

14. SERIAL1/2 Connectors (SERIAL 1/SERIAL 2)

Connects with equipment having RS-232C Interface

Connectors.

15. PCI Slots

Refer to qualified service personnel.

16. S-VGA Connector (S-VGA)

Connects with the computer display.

The applicable display parameters are shown below.

Resolution: 1024 x 768

Horizontal Scanning Frequency: 48 kHz

Vertical Scanning Frequency: 60 Hz

17. Fan

Supplies steady forced air through intake and filter.

Note: After extensive use the fans need to be replaced

periodically.

18. SDI Board Slots

Operating Time Operating Life

8-hour everyday use 6-year

12-hour everyday use 4-year

24-hour everyday use 2-year

3

19. SCSI VIDEO Connectors (SCSI VIDEO 1-3)

Connects with the SCSI Video Connector of the Hard

Disk Box AY-EB2000 or WJ-EB1000 via the optional

SCSI Cable AY-CA68SR3 for AY-EB2000 or

AY-CA50SR3 for WJ-EB1000.

20. TC (Time Code) IN Connector (TC IN)

Connects with a VTR having LTC time code signal

output connector to improve editing accuracy.

21. TC (Time Code) OUT Connector (TC OUT)

Connects with a VTR having LTC time code signal input

connector.

The signal supplied from this connector is not looped

through.

22. AC Inlet

Connect the AC Power Cord (provided).

23. AUDIO OUT 1/2 Jacks

(AUDIO OUT OUT1, OUT2 L/R)

Supply the audio signals.

24. ADV-REF OUT Connector (ADV-REF OUT)

Supplies the Advance Reference Signal to the VTR

having the time base corrector inside (or AUX video

source).

25. Video Output Connectors

(VIDEO OUT1/OUT2 Y/C, COMPOSITE, Y, P

B

, PR)

Supplies the video signal to the monitor or VTR.

26. AUDIO OUT 1/2 Connectors

(BALANCED AUDIO OUT, OUT1/OUT2)

Supply the audio signals.

27. G/L IN / AUTO Connectors (G/L, IN/AUTO)

The gen-lock signal is supplied to these connectors (Be

sure to terminate the video signal output from these

connectors).

By connecting with the G/L AUTO Connector, the video

signal is automatically unterminated.

Caution:

If a gen-lock signal is supplied to the G/L connector

during playback or recording, it may cause the video

to roll or cause other system malfunction.

Stop the playback or recording, then make a

connection to the G/L connector again.

28. AUDIO IN 1/2 Jacks (IN1, IN2 L/R) (Unbalanced)

Accepts the audio signal.

The audio signal supplied to these jacks can be saved in

the Hard Disk Box.

When the audio signal is supplied to the L side only, a

monaural audio signal is made.

29. AUDIO IN 1/2 Connectors

(BALANCED AUDIO IN IN1 L/R, IN2 L/R)

Accepts the audio signal.

The audio signal supplied to these connectors can be

saved in the Hard Disk Box.

30. Video 1/2 Input Connectors

(VIDEO IN1/IN2 Y/C, COMPOSITE, Y, P

B

, PR)

Accepts the video signals to be saved in the Hard Disk

Box.

Select the connector, either Composite, Y/C or

Component, according to the type of video signal.

The selection of either Video 1/Video 2 is available on

the PC monitor screen.

31. CONTROL 1/2 Connectors

(CONTROL 1/CONTROL 2) (9-pin)

Supplies the control signal (for the recording or play

back mode) to equipment having an RS-422 Interface

Connector.

Be sure to supply the video signal of the VTR connected

with CONTROL 1 to VIDEO IN 1, and likewise with the

VTR connected to CONTROL 2.

32. JOGPAD Connector (JOGPAD)

Connects with the Jogpad (provided).

33. SCSI AUDIO Connector (SCSI AUDIO)

Supplies the audio signal to the SCSI Audio Connector

of the optional Hard Disk Box via the optional SCSI

Cable AY-CA68SR3 for AY-EB2000 or AY-CA50SR3 for

WJ-EB1000.

4

OPEN

OK

UNDO SHIFT

TRIM

MODE

DIVIDE

DELETE

ZOOM

G

OTO

PLAY STOP

MARK IN

M

A

R

K

O

UT

■ JOG PAD

1. Positioner

Moves the selection cursor (when selection is

confirmed).

2. Wipe Lever

Controls Wipe, Key Size, and Audio Level.

3. TRIM

/

MODE

Switches edit modes (Insert - Replace - Cover)

(SHIFT + TRIM/MODE)

Turns Trim mode On/Off. (during transition)

4. DIVIDE

/

DELETE

Deletes a clip.

(SHIFT + DIVIDE / DELETE)

Divides a clip.

5. ZOOM /

Zooms in the time line.

(SHIFT + ZOOM)

Zooms out the time line.

6. GOTO /

Jumps to the starting or editing mark.

(SHIFT + GOTO)

Jumps to the beginning or end of a sequence.

7. MARK OUT

Sets or cancels the ending mark.

(SHIFT + MARK OUT)

Selects the grip of the OUT point.

5

8. MARK IN

Sets or cancels the starting mark.

(SHIFT + MARK IN)

Selects the grip of the IN point.

9. PLAY/STOP

Plays back or stops.

(SHIFT + PLAY /STOP)

Plays back between the starting and ending marks.

10. Shuttle Ring

Plays back video and audio forward (clockwise) or in

reverse (counterclockwise) with variable speed.

11. Jog Dial

Plays back video and audio forward (clockwise) or in

reverse (counterclockwise) frame by frame.

12. SHIFT

Switches button functions.

13. UNDO

Cancels the immediately previous operation.

14. OPEN

OK

Opens the selected panel or selects a panel and closes

the previous panel.

15. Jog Pad Connector

Connects with the Main Unit by using the Jog Pad Cable

(accessory).

6

ADJUSTMENT PROCEDURE

1. Test Equipment Required

8

The following test Equipments are required for

adjustment of the Nonlinear AV Workstation Main Kit

AY-NE2000E.

8

Oscilloscope

8

Frequency Counter

8

Digital Voltmeter

8

Waveform Monitor

8

Vectorscope (with SC-H Function)

8

Underscanned Colour Video Monitor

8

Test Signal Generator (Colour Bar signal, Ramp signal

and etc.)

8

Extension Board (YWVOEA0356AN) for AY-NE2000E

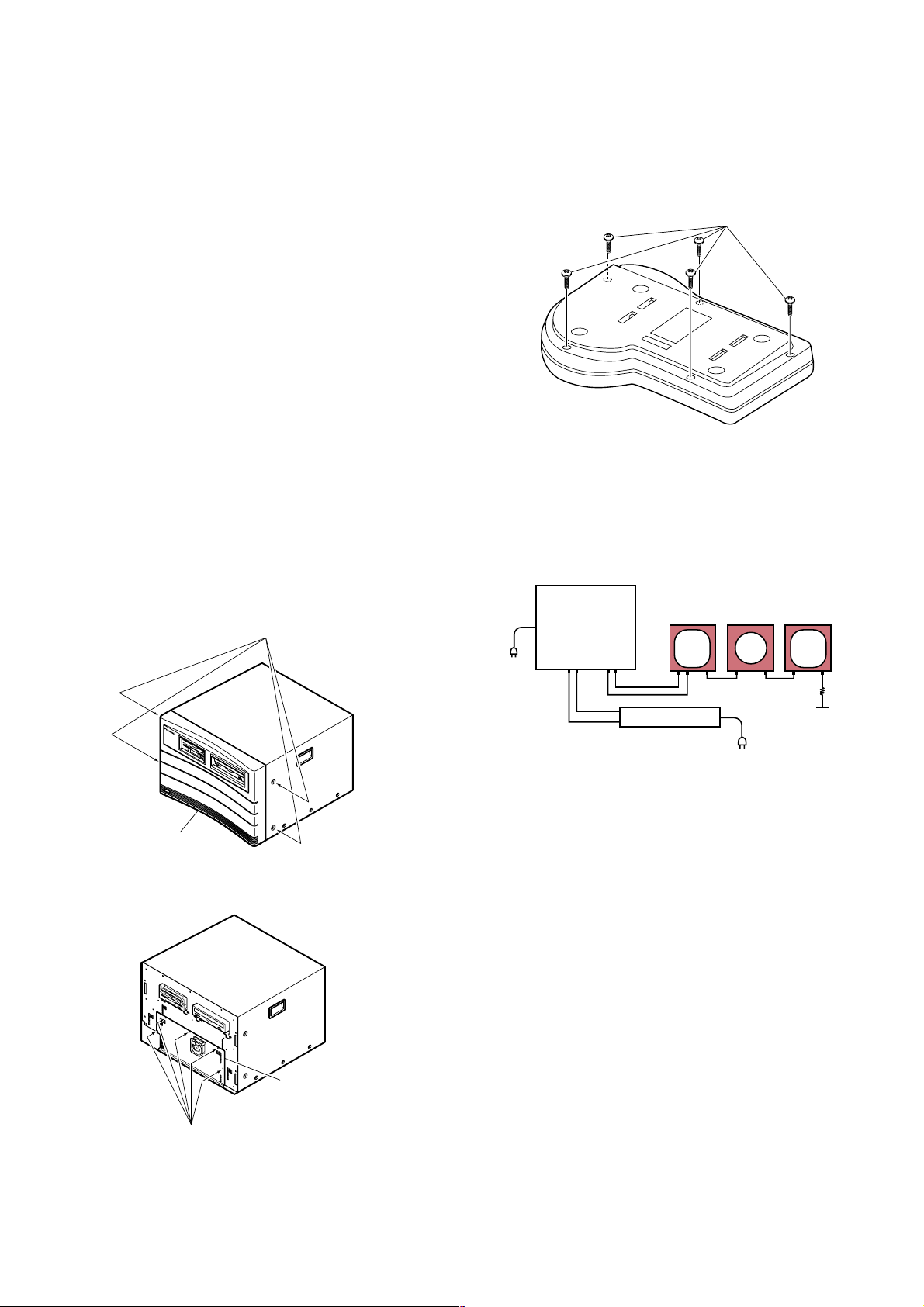

2. Disassembling Procedure for

Adjustment

■ AY-NE2000E

Referring to Fig. 2-1, rremove four screws that secure the

Front Panel and remove the Front Panel.

Fig. 2-1

8

Referring to Fig.2-2, remove five screws fixing the Front

Chassis and remove the Front Chassis.

Fig. 2-2

■ Jog Pad

8

Referring to Fig. 2-3, remove five screws that secure the

Bottom Cover and remove the Bottom Cover.

Fig. 2-3

3. Connection for Adjustment

8

The Fig. 3-1 shows the connection diagram for the

adjustment procedure.

Fig. 3-1

8

Connect the Underscanned Color Video Monitor through

the Waveform Monitor and Vectorscope to either Y/C

Video Output Connector or Composite Video Output

Connector on the Rear Panel of the AY-NE2000E.

8

Terminate the input terminal of the Underscanned Colour

Video Monitor with 75 Ω.

8

Connect the probe of the Digital Voltmeter, Oscilloscope

or Frequency Counter at the desired Test Point in each

adjustment step.

8

The adjustment should be done after 10 minutes warm-up.

Remove four screws.

Front Panel

AY-NE2000E

Waveform

Monitor

Vectorscope

Underscanned

Colour Video

Monitor

75

Ω

Signal Generator

Remove five screws.

Remove five screws.

Front Chassis

7

4. Adjustment Procedure

8

Refer to the Location of the Test Points and

Adjusting Controls on page 14.

■ Power Board

(1). Power Good Signal Adjustment

Test Point: Pin 2 of CN3 (5V) Power Board

Pin 1 of CN3 (P-GOOD) Power Board

Adjust: VR1 (4.85V) Power Board

VR3 (P-GOOD) Power Board

8

Connect the Digital Voltmeter to the pin 2 of CN3.

8

Adjust VR1 to obtain 4.85 ± 0.5 V DC.

8

Change the connection of the Digital Voltmeter to the pin 1

of CN3.

8

Adjust VR3 so that the Power Good Signal level just

changes from Low level to High level.

8

Confirm that the changing point should be between 4.8V

DC and 4.9V DC by adjusting of VR1.

(2). 5V Adjustment

Test Point: L202 (5V) Mixer Board

Adjust: VR1 (5V) Power Board

8

Connect the Digital Voltmeter to L202 on the Mixer Board.

8

Adjust VR1 to obtain 5.05 ± 0.02V DC.

(3). 12V Adjustment

Test Point: TP3 (12V) Mixer Board

Adjust: VR2 (12V) Power Board

8

Connect the Digital Voltmeter to TP3 on the Mixer Board.

8

Adjust VR2 to obtain 12 ± 0.05V DC.

■ Mixer Board

(4). Subcarrier Frequency Adjustment

Test Point: TP6 (FSC) Mixer Board

Adjust: VR202 (FSC) Mixer Board

8

Connect the Frequency Counter to TP6.

8

Adjust VR202 to obtain 17.734525 MHz ± 5 Hz.

(5). Ach VCO Adjustment

Test Point: Land between R997 and L742 (Ach VCO)

Mixer Board

Adjust: L742 (Ach VCO) Mixer Board

8

Executes the Manual Digitizer and set the Record mode.

8

Select the CH1-Y/C Input by the Device setting, and

supply the Colour Bar signal to the Y/C Video Input

Connector of CH1.

8

Connect the Digital Voltmeter to the land between R997

and L742.

8

Adjust L742 to obtain 2.1 ± 0.1V DC.

(6). Bch VCO Adjustment

Test Point: Land between R98 and L743 (Bch VCO)

Mixer Board

Adjust: L743 (Bch VCO) Mixer Board

8

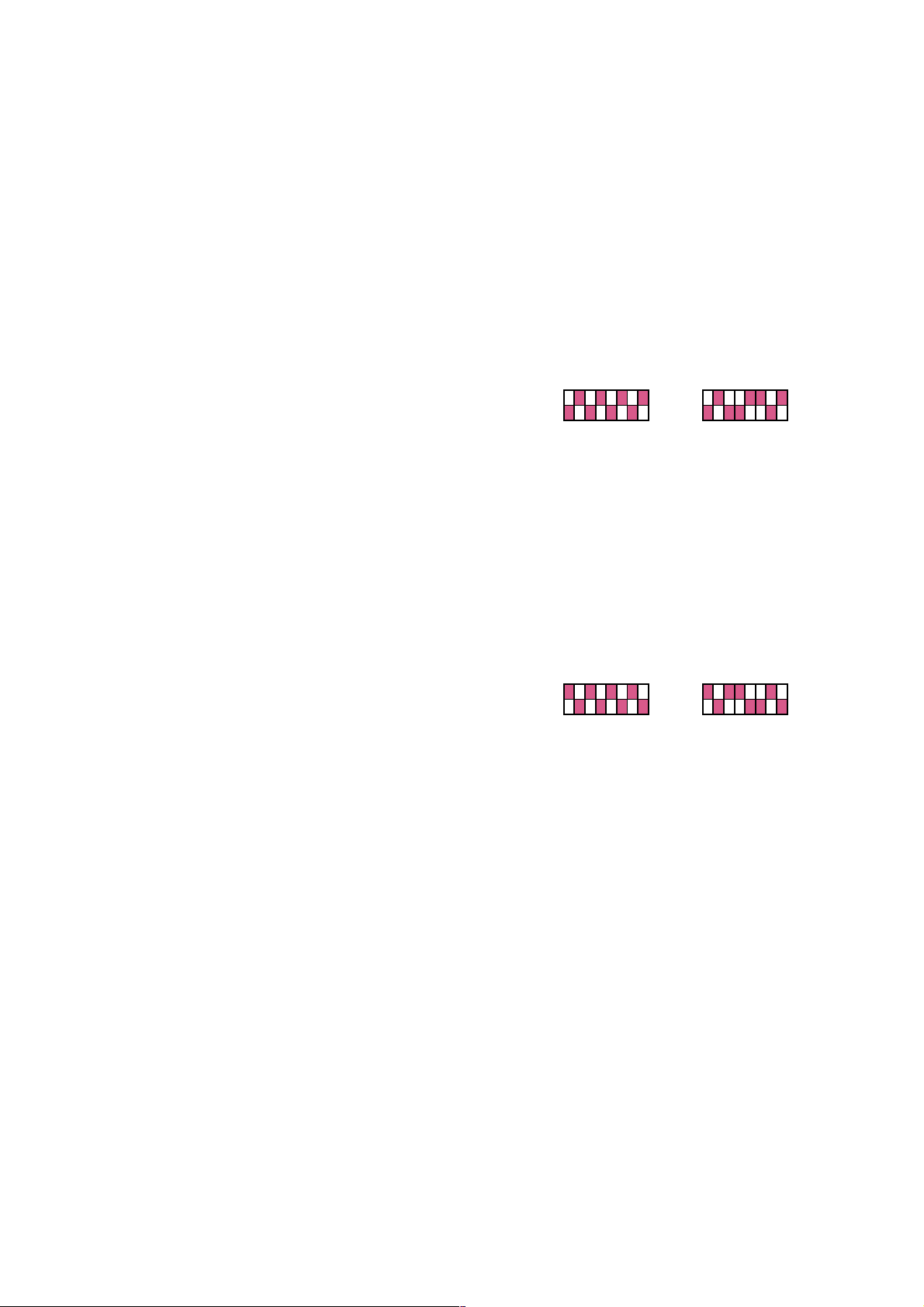

Set the SW1 and SW2 on the Pattern Side of the MIxer

Board are as shown in Fig. 3-1.

Fig. 3-1

8

Executes the Manual Digitizer and set the Record mode.

8

Select the CH1-Y/C Input by the Device setting, and

supply the Colour Bar signal to the Y/C Video Input

Connector of CH1.

8

Connect the Digital Voltmeter to the land between R98

and L743.

8

Adjust L743 to obtain 2.1 ± 0.1V DC.

8

After completion of adjustment, set the SW1 and SW2 as

shown in Fig. 3-2.

Fig. 3-2

■ Before start to next steps, executes the Sequence

Editor, then plays the Still Image of the Colour Bar

(Setup = 0) by drag & drop the Colour Bar Icon to the

Sequence Editor.

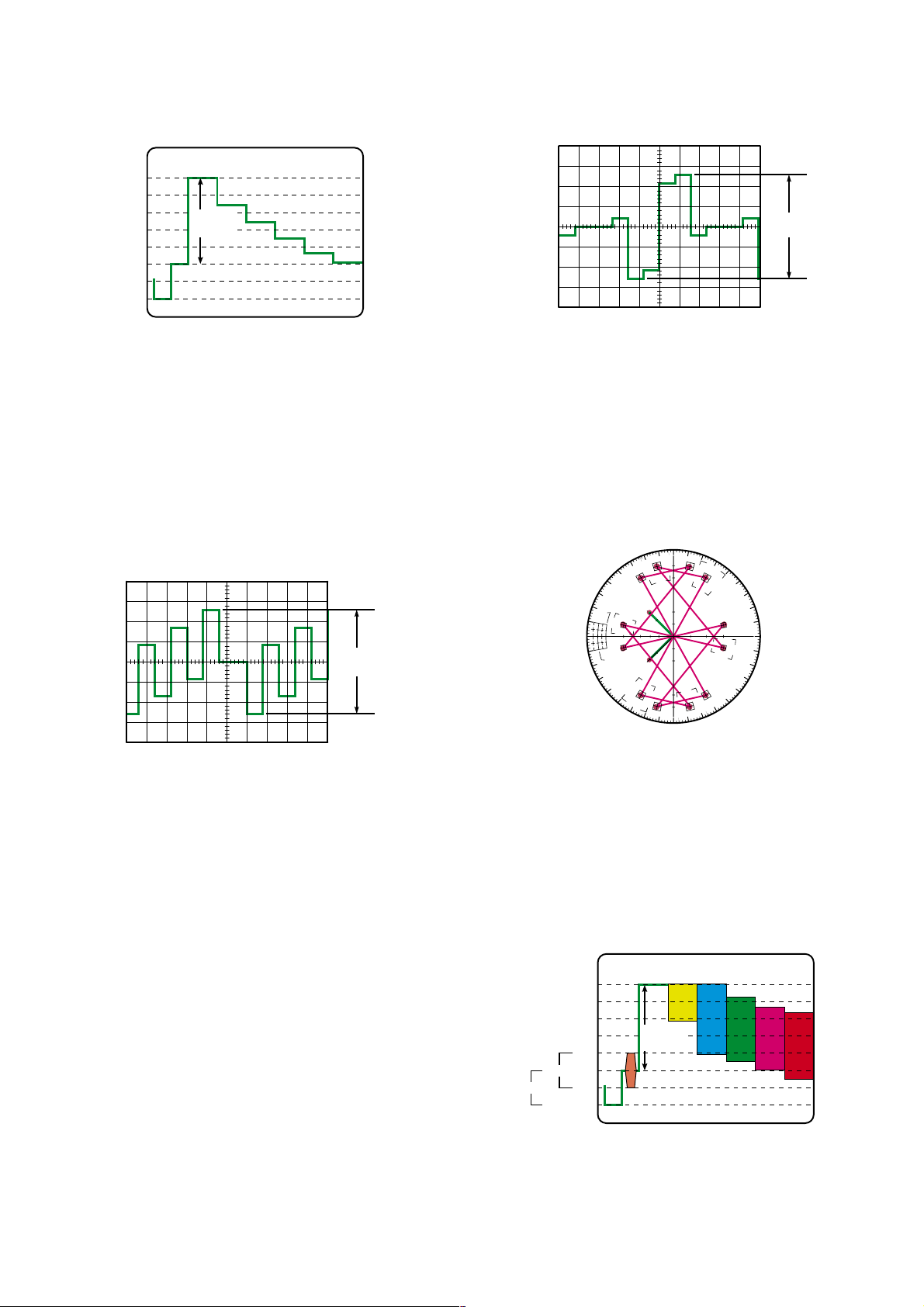

(7). Output Y Gain Adjustment

Test Point: Video Out Y Connector Rear Panel

Adjust: R439 (Y GAIN) Mixer Board

8

Connect the Waveform Monitor to the Video Out Y

Connector.

8

Adjust R439 so that the Y Level of the Y Reference signal

becomes 700 ± 7 mV as shown in Fig. 3-3.

ONON

8

7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

SW1 SW2

ONON

8

7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

SW1 SW2

8

Fig. 3-3

(8). Output PB Gain Adjustment

Test Point: Video Out PB Connector Rear Panel

Adjust: R442 (P

B GAIN) Mixer Board

8

Set the Video Out to MII Component by the Device

Setting.

8

Connect the terminated Oscilloscope with 75Ω to the

Video Out P

B Connector.

8

Adjust VR442 so that the PB signal level of the build-in

Colour Bar signal (Setup = 0) becomes 525 mV as shown

in Fig. 3-4.

Fig. 3-4

Note: When using the β Component for the adjustment,

adjust it to 756 mV (106 ± 1 IRE).

(9). Output PR Gain Adjustment

Test Point: Video Out PR Connector Rear Panel

Adjust: R443 (P

R GAIN) Mixer Board

8

Set the Video Out to MII Component by the Device

Setting.

8

Connect the terminated Oscilloscope with 75Ω to the

Video Out P

R Connector.

8

Adjust R443 so that the PR signal level (p-p) of the build-in

Colour Bar signal (Setup = 0) becomes 525 mV as shown

in Fig. 3-5.

100

20

–20

–40

700 ± 7

mV

Fig. 3-5

Note: When using the β Component for the adjustment,

adjust it to 756 mV (106 ± 1 IRE).

(10). Output C Gain Adjustment

Test Point: Video Out Y/C Connector Rear Panel

Adjust: R441 (C GAIN) Mixer Board

8

Connect the Vectorscope to the Video Out Y/C Connector.

8

Adjust VR441 so that the Chrominance Gain and Phase

are adjusted to proper position (± 3%, 3%) as shown in

Fig. 3-6.

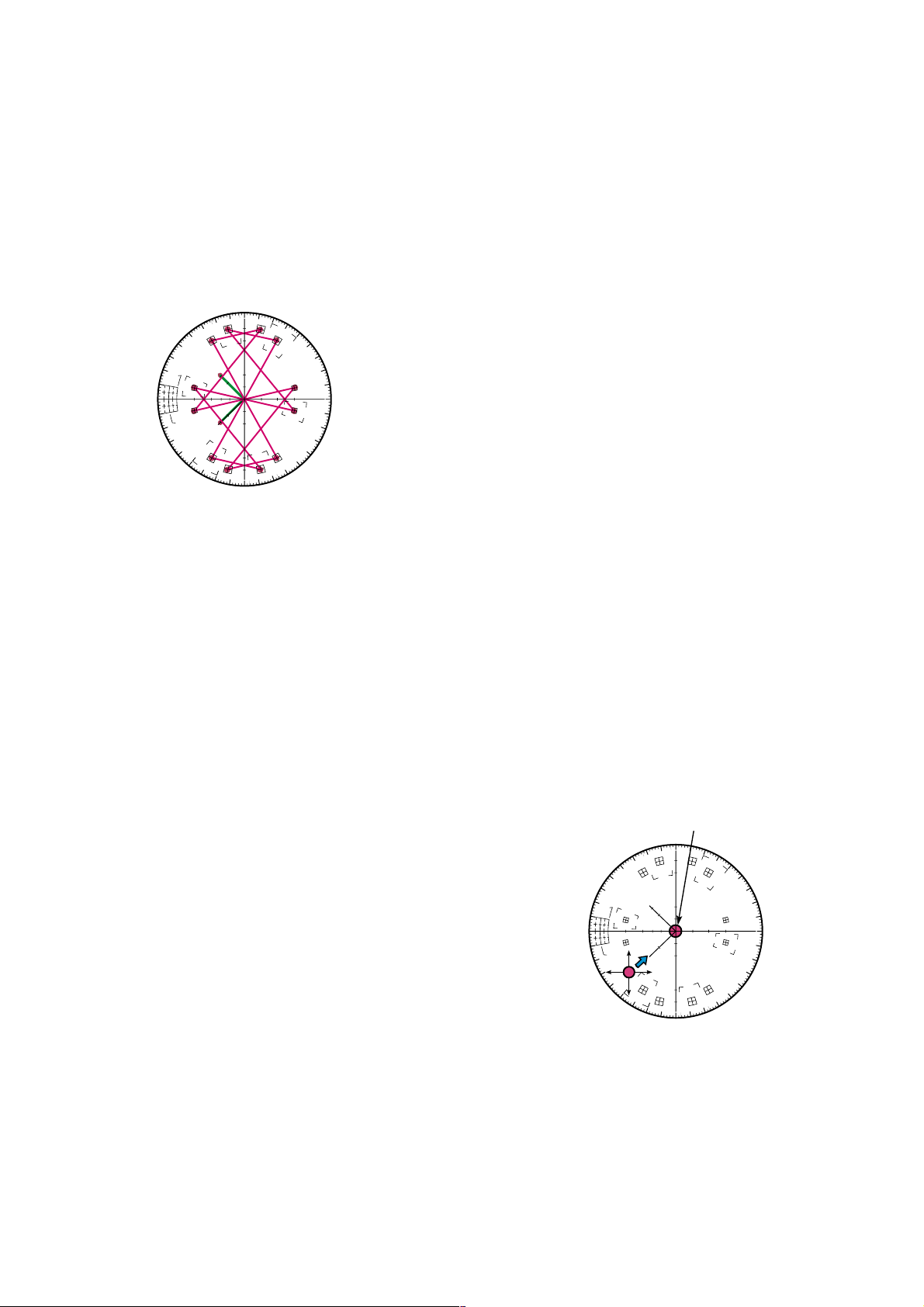

Fig. 3-6

(11). Composite Y Gain Adjustment

Test Point: Video Out Composite Connector

Rear Panel

Adjust: R440 (COMP Y) Mixer Board

8

Connect the Waveform Monitor to the Video Out

Composite Connector.

8

Adjust VR440 so that the Y signal level becomes 700 ± 7

mV as shown in Fig. 3-7.

Fig. 3-7

525 mV

525 mV

cy

g

MG

YL

yl

B

b

G

C

Y

dG

10°

0°

10°

dø

100%

75%

R

V

U

mg

r

20%

20%

dG

100

20

–20

–40

BURST

SYNC

700 ± 7

mV

9

(12). Output C Gain Adjustment

Test Point: Video Out Composite Connector

Rear Panel

Adjust: R444 (COMP C) Mixer Board

8

Connect the Vectorscope to the Video Out Y/C Connector.

8

Adjust R444 so that the Chrominance Gain and Phase are

adjusted to proper position (± 3%, 3%) as shown in Fig. 3-

8.

Fig. 3-8

(13). Output SC-H Adjustment

Test Point: Video Out Composite Connector

Rear Panel

Adjust: R445 (SC-H) Mixer Board

8

Connect the Vectorscope to the Video Out Y/C Connector.

8

Adjust R445 so that the SC-H Phase becomes 0 ± 5°.

(14). ADV. REF. SC-H Adjustment

Test Point: ADV. REF. Out Connector Rear Panel

Adjust: R446 (ADV.REF.) Mixer Board

8

Connect the Vectorscope to the ADV. REF. Output

Connector.

8

Adjust R446 so that the SC-H Phase becomes 0 ± 5°.

(15). Gen/Lock Colour Phase Adjustment

Test Point: Video Out Composite Connector

Rear Panel

Adjust: R438 (C-PHASE) Mixer Board

8

Supply the Video signal to the Gen/Lock Input Connector.

8

Adjust the Colour Phase roughly 0° by Switch SW201.

8

Adjust R438 so that the Colour Phase becomes 0 ± 10 °.

(16). Gen/Lock Horizontal Phase Adjustment

Test Point: Video Out Composite Connector

Rear Panel

Adjust: R436 (H-PHASE) Mixer Board

8

Supply the Video signal to the Gen/Lock Input Connector.

8

Adjust the Horizontal Phase roughly 0° by Switch SW203.

8

Adjust the Horizontal Phase 0° by Switch SW202.

8

Adjust R436 so that the Horizontal Phase becomes 0 ± 70

nS.

■ Input Board

■ Before start to adjust the Input Board, executes the

executes Manual Digitizer, set the Record mode.

(17). FVCXO1 Frequency Adjustment

Test Point: TP202 (FVCXO1) Input Board

Adjust: C601 (FVCXO1) Input Board

8

Disconnect all input from the AY-NE2000E.

8

Connect the Frequency Counter to TP202.

8

Adjust C601 to obtain 4.433624 MHz ± 5 Hz.

(18). FVCXO2 Frequency Adjustment

Test Point: TP206 (FVCXO2) Input Board

Adjust: C602 (FVCXO2) Input Board

8

Disconnect all input from the AY-NE2000E.

8

Connect the Frequency Counter to TP206.

8

Adjust C602 to obtain 4.433624 MHz ± 5 Hz.

(19). Component Carrier Balance Adjustment

Test Point: Video Out Y/C Connector Rear Panel

Adjust: R805 (COMP CAR BAL-1) Input Board

R806 (COMP CAR BAL-2) Input Board

8

Select the CH1-Component Input by the Device setting,

and supply the Colour Bar signal to the Component Input

Connector of CH1.

8

Connect the Vectorscope to the Video Out Y/C Connector.

8

Set the Gain Control of the Vectorscope to the maximum.

8

Adjust R805 and R806 so that the vector positions at the

center of the Vectorscope as shown in Fig. 3-9.

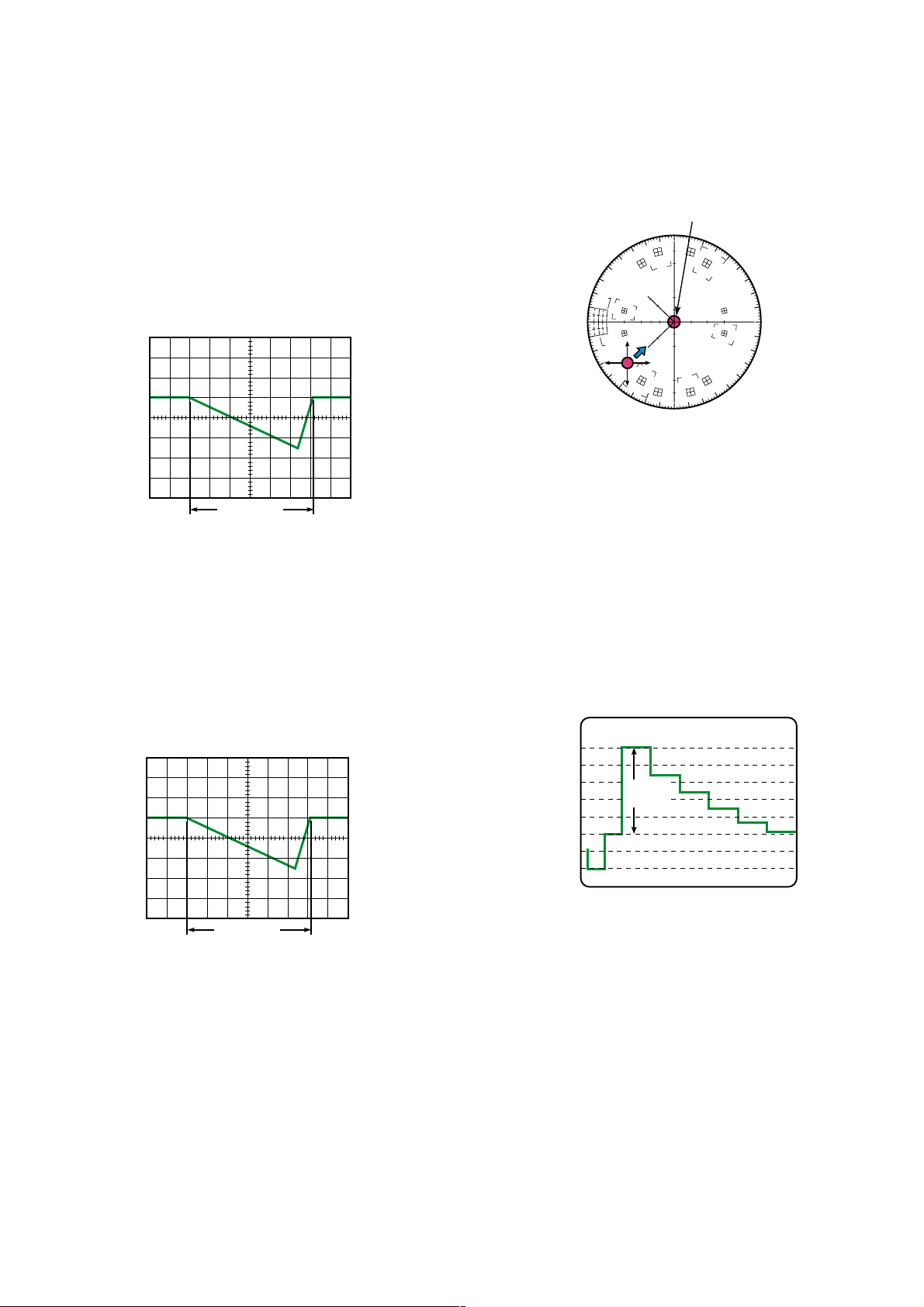

Fig. 3-9

8

Set the Gain Control of the Vectorscope to the normal.

cy

g

MG

YL

yl

B

b

G

C

Y

dG

10°

0°

10°

dø

100%

75%

R

V

U

mg

r

20%

20%

dG

Positions at center.

cy

g

MG

YL

yl

B

b

G

C

Y

dG

10°

0°

10°

dø

100%

75%

R

V

U

mg

r

20%

20%

dG

10

(20). Pedestal Level Adjustment

Test Point: Video Out Y/C Connector Rear Panel

Adjust: R812 (PED) Input Board

8

Select the CH1-Component Input by the Device setting,

and supply the Ramp signal to the Component Input

Connector of CH1.

8

Connect the Terminated Oscilloscope with 75Ω to the

Video Out Y/C Connector.

8

Adjust R812 so that the Pedestal signal level becomes 0

IRE as shown in Fig. 3-10.

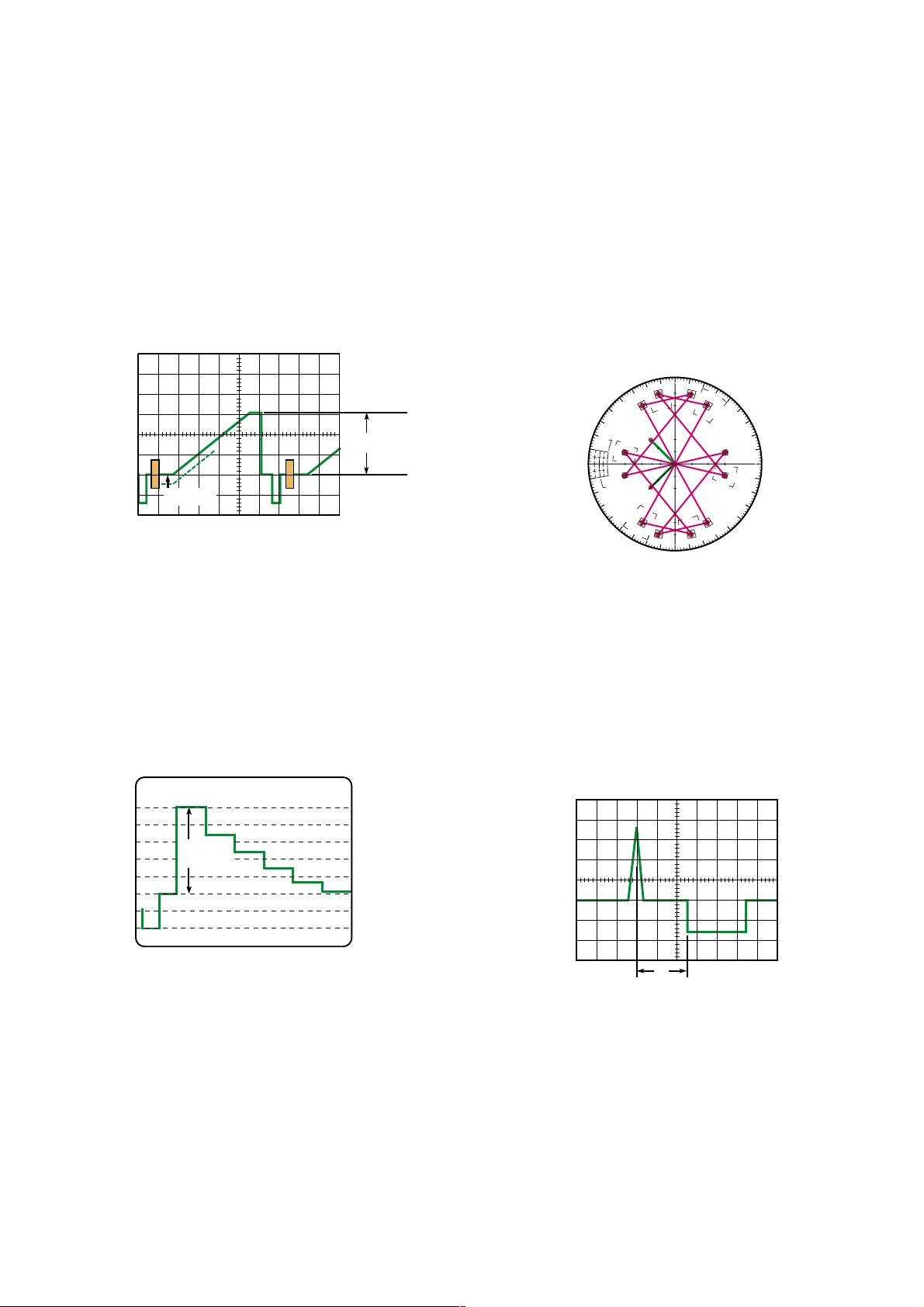

Fig. 3-10

(21). Component Y Gain Adjustment

Test Point: Video Out Y/C Connector Rear Panel

Adjust: R811 (COMP Y GAIN) Input Board

8

Select the CH1-Component Input by the Device setting,

and supply the Ramp signal to the Component Input

Connector of CH1.

8

Connect the Waveform Monitor to the Video Out Y/C

Connector.

8

Adjust R811 so that the Y signal level becomes 700 ± 1 4

mV as shown in Fig. 3-11.

Fig. 3-11

8

Confirm that the Pedestal level stays same level,

8

If not,

repeat steps 20 and 21 until satisfactory.

+ 1

– 0

700 ± 7 mV

NG

0 mV

+ 7

– 0

(22). Component C Gain Adjustment

Test Point: Video Out Y/C Connector Rear Panel

Adjust: R809 (COMP C GAIN-1) Input Board

R810 (COMP C GAIN-2) Input Board

8

Select the β Component Input by the Device setting, and

supply the P

B = 0.7V Component Colour Bar signal to the

Component Input Connector of CH1.

8

Connect the Vectorscope to the Video Out Y/C Connector.

8

Adjust R809 and R810 so that the Chrominance Gain and

Phase are adjusted to proper position (± 3%, 3%) as

shown in Fig. 3-12.

Fig. 3-12

(23). Horizontal Phase Adjustment

Test Point: Video Out Y/C Connector Rear Panel

Adjust: R804 (H-PHASE) Input Board

8

Select the CH1-Y/C Input by the Device setting, and

supply the Cross-hatch signal to the Y/C Video Input

Connector of CH1.

8

Connect the Oscilloscope to the Video Output terminal of

the Signal Generator, then measure the Horizontal Phase

” t ” as shown in the Fig. 3-13.

Fig. 3-13

8

Change the connection of the Oscilloscope to the Y

terminal of the Video Out Y/C Connector.

8

Adjust R804 so that the Horizontal Phase becomes t ± 70

nS.

cy

g

MG

YL

yl

B

b

G

C

Y

dG

10°

0°

10°

dø

100%

75%

R

V

U

mg

r

20%

20%

dG

100

20

–20

–40

700 ± 14

mV

t

11

(24). Burst Gate Pulse Width 1 Adjustment

Test Point: TP211 (BGP-1) Input Board

Adjust: R794 (BGP-1) Input Board

8

Select the CH1-Composite Input by the Device setting,

and supply the Colour Bar signal to the Composite Video

Input Connector of CH1.

8

Connect the Oscilloscope to TP211.

8

Adjust R794 so that the Burst Gate Pulse Width becomes

8.4 µS as shown in Fig. 3-14.

Fig. 3-14

(25). Burst Gate Pulse Width 2 Adjustment

Test Point: TP205 (BGP-2) Input Board

Adjust: R799 (BGP-2) Input Board

8

Select the CH1-Y/C Input by the Device setting, and

supply the Colour Bar signal to the Y/C Video Input

Connector of CH1.

8

Connect the Oscilloscope to TP205.

8

Adjust R799 so that the Burst Gate Pulse Width becomes

8.4 µS as shown in Fig. 3-15.

Fig. 3-15

(26). Y/C Carrier Balance Adjustment

Test Point: Video Out Y/C Connector Rear Panel

Adjust: R807 (Y/C CAR BAL-1) Input Board

R808 (Y/C CAR BAL-2) Input Board

8

Select the CH1-Y/C Input by the Device setting, and

supply the Colour Bar signal to the Y/C Video Input

Connector of CH1.

8

Connect the Vectorscope to the Video Out Y/C Connector.

t = 8.4 µS

8

Set the Gain Control of the Vectorscope to the maximum.

8

Adjust R807 and R808 so that the vector positions at the

center of the Vectorscope as shown in Fig. 3-16.

Fig. 3-16

8

Set the Gain Control of the Vectorscope to the normal.

(27). Y/C Y Gain Adjustment

Test Point: Video Out Y/C Connector Rear Panel

Adjust: R797 (Y/C Y GAIN) Input Board

8

Select the CH1-Y/C Input by the Device setting, and

supply the Colour Bar signal to the Y/C Video Input

Connector of CH1.

8

Connect the Waveform Monitor to the Video Out Y/C

Connector.

8

Adjust R797 so that the Y signal level becomes 700 ± 7

mV as shown in Fig. 3-18.

Fig. 3-18

(28). Y/C Chrominance Adjustment

Test Point: Video Out Y/C Connector Rear Panel

Adjust: R800 (Y/C R-Y GAIN) Input Board

R802 (Y/C B-Y GAIN) Input Board

R801 (TINT) Input Board

8

Select the CH1-Y/C Input by the Device setting, and

supply the Colour Bar signal to the Y/C Video Input

Connector of CH1.

8

Connect the Waveform Monitor to the Video Out Y/C

Connector.

t = 8.4 µS

Positions at center.

cy

g

MG

YL

yl

B

b

G

C

Y

dG

10°

0°

10°

dø

100%

75%

R

V

U

mg

r

20%

20%

dG

100

20

–20

–40

700 ± 7

mV

12

8

Aim the Red vector, adjust R800 so that the Red vector

becomes proper position.

8

Aim the Yellow vector, adjust R802 so that the Yellow

vector becomes proper position.

8

Aim the Red vector, adjust R801 so that the Red vector

becomes proper position.

8

Repeat adjustment R800, R802 and R801 so that the

Chrominance Gain and Phase are adjusted to proper

position as shown in Fig. 3-19.

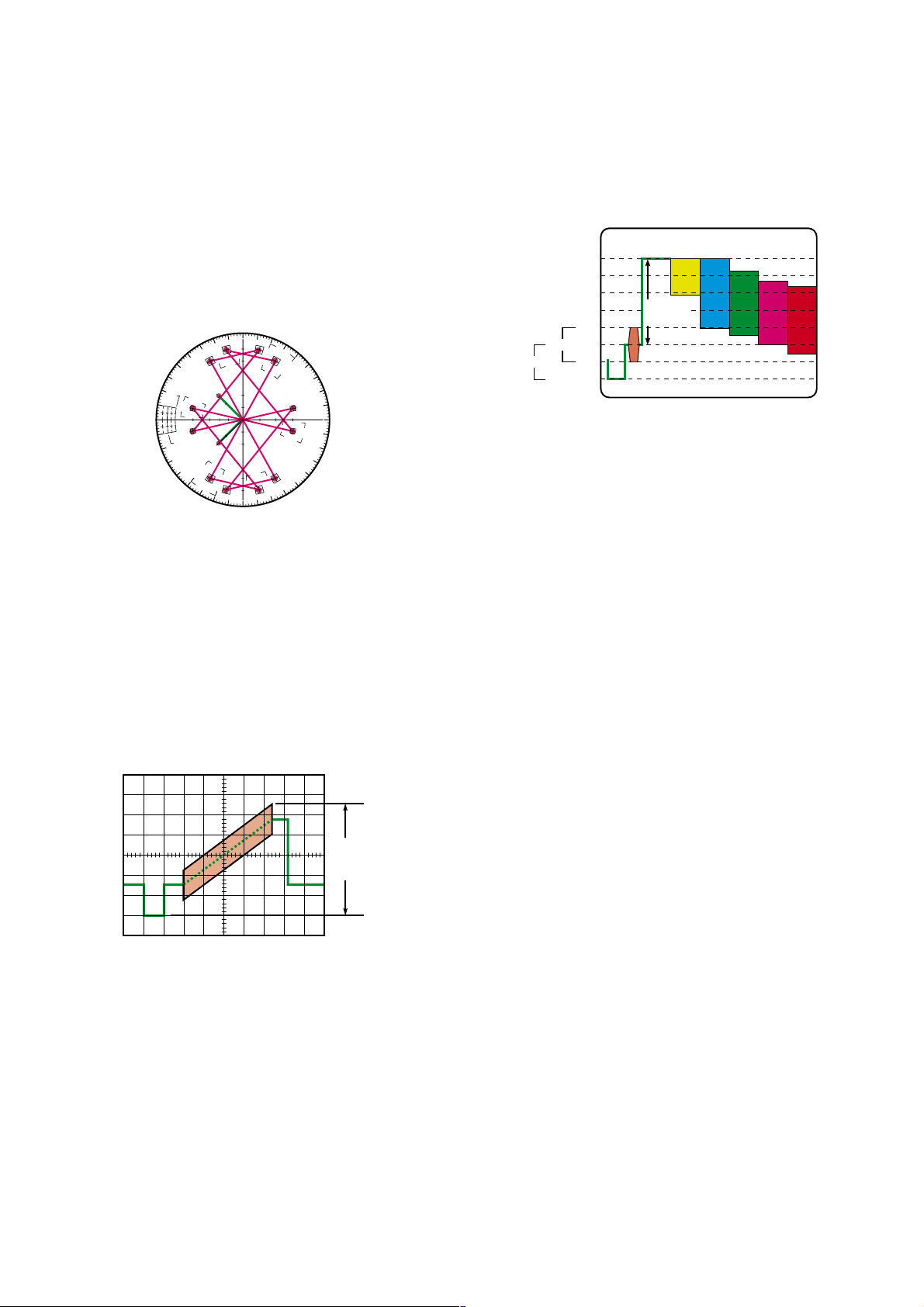

Fig. 3-19

(29). Y/C Separation Gain Adjustment

Test Point: Video Out Composite Connector

Rear Panel

Adjust: R793 (Y/C SEPA GAIN) Input Board

8

Select the CH1-Composite Input by the Device setting,

and supply the Ramp (Chroma 40 IRE (286 mV)) signal to

the Composite Input Connector of CH1.

8

Connect the Oscilloscope to TP201.

8

Adjust 793 so that the Y/C Separation signal becomes

maximum without saturation as shown in Fig. 3-20.

Fig. 3-20

(30). Composite Y Gain Adjustment

Test Point: Video Out Composite Connector

Rear Panel

Adjust: R798 (COMP Y-GAIN) Input Board

8

Select the CH1-Composite Input by the Device setting,

and supply the Colour Bar signal to the Composite Input

Connector of CH1.

cy

g

MG

YL

yl

B

b

G

C

Y

dG

10°

0°

10°

dø

100%

75%

R

V

U

mg

r

20%

20%

dG

8

Connect the Waveform Monitor to the Video Out Y/C

Connector.

8

Adjust R798 so that the Y signal level becomes 700 ± 7

mV as shown in Fig. 3-21.

Fig. 3-21

- Audio Board

(31). Balance Output Level Adjustment

Test Point: 1-CH Unbalanced Audio

Output Connector-L Rear Panel

1-CH Unbalanced Audio

Output Connector-R Rear Panel

Adjust: R759 (BAL-L) Audio Board

R762 (BAL-R) Audio Board

8

Supply 1 KHz Tone Clip to the Sequence Editor and

playback.

8

Connect the AC Voltmeter (with dB Measure) to the 1-CH

Balanced Audio Output Connector-L.

8

Adjust R759 so that the 1-CH Balanced Output level

becomes 0.00 ± 0.10 dBµ.

8

Change the connection of the AC Voltmeter (with dB

Measure) to the 1-CH Balanced Audio Output ConnectorR.

8

Adjust R762 so that the 1-CH Balanced Output level

becomes 0.00 ± 0.10 dBµ.

(32). Unbalance Output Level Adjustment

Test Point: 3-CH Unbalanced Audio

Output Connector-L Rear Panel

3-CH Unbalanced Audio

Output Connector-R Rear Panel

Adjust: R245 (UNBAL-L) Audio Board

R247 (UNBAL-R) Audio Board

8

Supply 1 KHz Tone Clip to the Sequence Editor and

playback.

8

Connect the AC Voltmeter (with dB Measure) to the 3-CH

Unbalanced Audio Output Connector-L.

Becomes maximum

without satiration

100

20

–20

–40

BURST

SYNC

700 ± 7

mV

13

■ Jog pad WJ-JP1000

■ Before start to adjust the Jog Pad, remove the

Bottom Cover, connect supplied cable between the

Jog Pad and AY-NE2000E.

(34). Wipe High Level Adjustment

Test Point: TP2 (WIPE H) Jog Pad Board

TP3 (WIPE L) Jog pad Board

Adjust: VR3 (WIPE H) Jog pad Board

8

Move the Wipe Level Controls and Audio Level Knob to +

side slightly.

8

Connect the Digital Voltmeter to TP3 and measure the

voltage at TP3 (this voltage is E).

8

Change the connection of the Digital Voltmeter to TP2.

8

Adjust VR3 so that the voltage at TP2 becomes E – (0.2 ±

0.05) V.

(35). Wipe Low Level Adjustment

Test Point: TP3 (WIPE L) Jog Pad Board

Adjust: VR4 (WIPE L) Jog pad Board

8

Move the Wipe Level Controls and Audio Level Knob to

the frontward slightly.

8

Connect the Digital Voltmeter to TP3.

8

Adjust VR4 to obtain –0.2 ± 0.05 V.

8

Adjust R245 so that the 3-CH Unbalanced Output level

becomes – 6.00 ± 0.10 dBs.

8

Change the connection of the AC Voltmeter (with dB

Measure) to the 3-CH Unbalanced Audio Output

Connector-R.

8

Adjust R247 so that the 3-CH Unbalanced Output level

becomes – 6.00 ± 0.10 dBs.

(33). Input Level Adjustment

Test Point: 1-CH Balanced Audio

Output Connector-L Rear Panel

1-CH Balanced Audio

Output Connector-R Rear Panel

Adjust: R263 (INPUT-L) Audio Board

R266 (INPUT-R) Audio Board

8

Supply 1 KHz (0.00 ± 0.10 dBµ) signal from the Audio

Analyzer to the 1-CH Balanced Input Connector-L.

8

Executes the Manual Digitizer and select 1-CH Balanced

Input Connector-L by the Device setting.

8

Connect the AC Voltmeter (with dB Measure) to the 1-CH

Balanced Audio Output Connector-L.

8

Adjust R263 so that the 1-CH Balanced Output level-L

becomes 0.00 ± 0.10 dBµ.

8

Supply 1 KHz (0.00 ± 0.10 dBµ) signal from the Audio

Analyzer to the 1-CH Balanced Input Connector-R.

8

Executes the Manual Digitizer and select 1-CH Balanced

Input Connector-R by the Device setting.

8

Change the connection of the AC Voltmeter (with dB

Measure) to the 1-CH Balanced Audio Output ConnectorR.

8

Adjust R266 so that the 1-CH Balanced Output level-R

becomes 0.00 ± 0.10 dBµ.

POWER BOARD (COMPONENT SIDE)

VR2

(12V)

VR1

(5V)

CN3-2

(5V)

CN3-1

(P-GOOD)

CN3

VR3

(WIPE H)

VR4 (WIPE L)

VR3

(P-GOOD)

CN2

WJ-JP1000

MAIN BOARD (PATTERN SIDE)

}{POIUYTREWQ

TP2 (WIPE H)

TP3 (WIPE L)

TP211

(BGP-1)

TP205

(BGP-2)

TP201

()

TP203 ()

TP202

(FVCXO1)

R795

()

R796

()

R794

(BGP-1)

R799 (BGP-2)

R800 (Y/C Y GAIN)

C602 (FVCXO2)

C601

(FVCXO1)

R801 (TINT)

R798

(COMP Y-GAIN)

R793

(Y/C SEPA GAIN)

R804

(H-PHASE)

R802 (Y/C B-Y GAIN)

R803

R811

(COMP Y GAIN)

R810 (COMP C GAIN-2)

R809 (COMP C GAIN-1)

R806 (COMP CAR BAL-2)

R812 (PED)

R805

(COMP CAR BAL-1)

R807

(Y/C CAR BAL-1)

R808

(Y/C CAR BAL-2)

TP219

()

TP206

(FVCXO2)

TP207

TP208 TP210

TP209

TP221

TP218

TP227

TP45

TP44

TP3 (12V)

L742

(Bch VCO)

R98

R977

L742 (Ach VCO)

L202 (5V)

TP11

TP4

TP6 (FSC)

R439 (Y GAIN)

R440 (COMP Y)

R444 (COMP C)

R441 (C GAIN)

R442 (P

B GAIN)

R443 (PR GAIN)

R446 (ADV.REF.)

TP14

TP2

TP1

R436

(H-PHASE)

TP5

SW201

SW202

SW203

R438

(FSC)

R445 (SC-H)

MIXER BOARD (COMPONENT SIDE)INPUT BOARD (COMPONENT SIDE)

R762 (BAL-R)

R247 (UNBAL-R)

R266 (INPUT-R)R263 (INPUT-L)

R245 (UNBAL-L)

R759 (BAL-L)

AUDIO BOARD (COMPONENT SIDE)

LOCATION OF TEST POINTS AND ADJUSTING CONTROLS

– 14 –

AO9AO8

+5V

+5V

+5V

+5V

+5V

4852566064

+5V

+5V

+5V

+5V

+5V

+5V

100

104

108

112

116

120

P1

P2

P11

+5VD

SF1

FL202

AMP

+5V

BIAS

R193

Q208

REFERENCE

VOLTAGE

GENERATOR

Q209,Q210,U201

19

17

23

1

7

VRB

VRT

VIN

D0|D7

67-74

IYC1|IYC8

U205

Y/C SEPARATOR

AMP FL208

OCIO

TP213

AMP

TP201

AMP FL206

OYIO

TP212

AMP

TP203

TP204

38

27

80 4 2

Q219,Q220

Q217,Q218

Q222

Q223

U204

U203

A/D

CONVERTER

3-10

AMP

AMP

AMP

FL201

Q201

AMP

AMP

AMP

55

C.SYNC

P2

P2

P2

P2

P2

P2

P2

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARDTOMOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARDTOMOTHER

BOARDTOMOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

P12

2

153

12

13

U210 SELECTOR

BUFFER

Y0Y1Z0Z1X0

X1

15

BUFFER4BUFFER

14

BUFFER

Q290

Q291

Q215

11

10

9

ABC

AO3

AMP

Q213

P2

P2

P2

P2

P2

11

10

9

ABC

AO3

AMP

AMP

AMP

AMP

BUFFER

Q292

Y

Z

X

Q211

15

BUFFER

Q293

4

WHD

151617

LD

CLK

DI

125

3

Y0Y1Z0

Z1

Y

Z

AO1

AO3

AO5

AO6

AO7

AO8

AO9

U211 SELECTOR

AO1

AO3

AO5

AO6

AO7

AO8

AO9

U224

D/A CONVERTER

18245678

B.P.F.

5

2

+5V

4

+5V

R794

R795

25

YIN

CIN

BF GW

GAIN

TINT

VCXOI

VCXO

OUT

11

+5V

R796

(TINT)

10

12

BUFFER

Q212

IGCK

C601

Y201

U202

CHROMA DIFFERENCE EDECODER

Q202-Q207

FL205

AMP

AMP

FL203 FL204 AMP

BIAS

Q216

Q284

Q285-Q287

Q281-Q283

U207 SWITCH

231

231

7

54

AO8

AMP

AO7

Q224 Q236

25

AMP

Q225 Q237

2

+5V

R799

4

+5V

R800

5

16

14

3

23

24

BLKIN

HDIN

CIN

RYIN

BYIN

COUT

YIN

BPGW

GAIN

SYNC

AMP

Q244- Q247

BIAS

Q252

AMP

Q248-Q251

19

28

11

+5V

R801

R802

10

12

C602 Y202

RYO

BYO

TINT

VCXOI

VCXO

OUT

WHD

1

2

4

U212

+5VD

+5VD

+5V

REGULATOR

+5V

REGULATOR

+5V

REGULATOR

+5V

+5V

+5V

1

1

1

+5V

REGULATOR

+5V

REGULATOR

+5V

REGULATOR

+5V

+5V

+5V

1

1

1

+12

U242

U217

U213

U245

U232

U243

BUFFER

BUFFER

BUFFER

BUFFER

Q238

Q243

Q239

Q242

+5V

3

2

+

-

1

+

-

7

5

6

+5V

3

2

+

-

1

+

-

7

5

6

R806

R805

R807

R808

U233 (2/ 4)

U233 (1/4)

U218(1/ 4)

U218(2 /4)

U206

SWITCH

7

U234 SELECTOR

13

12

1

2

14

15

X1X0Y1

Y0

Y

X

CBA

9

11

10

AO8

24

1

3

5

7

U220 SWITCH

Q254

AO9

AO8

24

1

3

5

7

U221 SWITCH

Q262

AO9AO8

24

1

3

5

7

U222 SWITCH

Q270

Q240

Q241

FL209

AMP

A01

A3 Y3

8

9

OE3

a

a

b

c

b

c

Q255

AMP

Q256-Q259

FL210

AMP

Q263

AMP

Q264-Q267

FL211

AMP

Q272-Q275

AMP

Q271

FL212

1

2

AO6

1

3

U244 SWITCH

+5V

AMP

Q294

7

3

U223

VCA

BIAS

10

9

+

-

8

U218 (3/ 4)

+5V

A05

R809

R810

R811

Q253

1

2

4

U215

R804

U216

1

2

4

Q226

Q227

Q228

Q229

Q230

Q231

Q232

Q233

Q234

Q235

3

3

3

3

3

3

R797

AMP

Q214

FL207

R812

U214

CHROMA DIFFERENCE

DECODER

20

1

COMP IN

COMP2

109COMP1

111

Y2

115

Y1

113

C1

117

C2

119

YCY IN

1

WHD 75

U1

U2

V2

V1

114

116

119

120

STRV

SCK

SDATA

119

111

115

P1

Q277

Q261

Q269

CLAMP

Q260

CLAMP

Q268

CLAMP

Q276

D4D5D6D7D0D1D2

D3

VIN

CLK

VRT

VRB

Q3Q2Q1Q0Q7Q6Q5

Q4

D3D2D1D0D7D6D5D4CP

U226

A/ D CONVERTER

U252

D-FFs

D4D5D6D7D0D1D2

D3

VIN

CLK

VRT

VRB

D7D6D5D4D3D2D1

D0

VIN

CLK

VRT

VRB

U235 A/ D CONVERTER

U229 A/ D CONVERTER

REFERENCE

VOLTAGE

GENERATOR

+5V

1

7

Q288,Q289, U219

A0B0A1B1A2B2A3

B3

D0D1D2D3D4D5D6D7CP

Q0Q1Q2Q3Q4Q5Q6

Q7

OE

Y7A

Y6A

Y5A

Y4A

Y3A

Y2A

Y1A

Y0A

73747778818285

86

C7A

C6A

C5A

C4A

C3A

C2A

C1A

C0A

8990939497

98

101

102

676371

59

CADCLK

YADCLK

CSEL

CLAMP

24

28

+12V

+12V

36

40

+12V

+12V

2345678

9

11

19181716151413

12

D0D1D2D3D4D5D6D7CP

Q0Q1Q2Q3Q4Q5Q6

Q7

OE

2345678

9

11

19181716151413

12

1297

4

A0B0A1B1A2B2A3

B3

Y3Y2Y1

Y0

1

1

2

1

10913

12

3

8

11

42

+5V

U239

U238

U230

D-FFs

U227

D-FFs

U236

2 1 SELECTOR

U237

2 1

SELECTOR

78910345

6

5432987

6

11

16171819121314

15

235

6

111014

13

78910345

6

235

6

111014

13

abcdefg

h

i

jkl

m

nop

aib

j

c

k

d

efg

h

l

m

nop

P2

P2

P2

+12V

SF201

TO INPUT BOARD (2/2)

+12V

+12V

+5VD+5VD

SF2

1297

4

P2

P1

Y3Y2Y1

Y0

191217

23

191217

23

191217

23

10987654

3

S

S

BLOCK DIAGRAM OF INPUT BOARD (1/2)

INUPT BOARD

1

3

P10

COMP IN

YCY IN

BUFFER

BUFFER

TP207

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

+5V

REGULATOR

+5V

REGULATOR

+5V

+5V

1

1

+12

U246

U247

3

3

TP208

TP209

TP210

U250(a)

BUS BUFFER

BUFFER

A01

1

A01

1

– 15 –

SDO

SDI

ISPEN

MODE

SCLK

23468

SD15

SD14

SD13

SD12

SD11

SD10

SD9

SD8

SD7

SD6

SD5

SD4

SD3

SD2

SD1

SD0

818283848586878889909192939495

96

P1

SA1

SA2

SA3

SA4

SA5

SA6

SA7

SA8

SA9

IOR

IOW

VP

797877757473717069

102

106

107

P1

TO

MOTHER

BOARD

TO

MOTHER

BOARD

P13

U1 LOGIC CONTROL

PSDO

PSCLK

SLATCH

SCS

PSDI

12569

135

131

IRQ10

IRQ11

IRQ10

IRQ11

IRQMX

IRQJ1

IRQJ2

IRQJ3

IRQCG

IRQA

CMDMX

CMDJ1

CMDJ2

CMDJ3

CMDA

2711151923314735394351

P2

P1

P1

P1

P1

131721

25

RXA1

RXB1

RXA2

RXB2

181426

22

TXB1

TXA1

TXB2

TXA2

P1

992933

HD

TCIN

TCOUT

Q0Q1Q2Q3Q4

Q5

D0D1D2D3D4

D5

1918171615

14

CMDMX

CMDJ1

CMDJ2

CMDJ3

CMDA

23456

7

Q0Q1Q2Q3Q4Q5Q6

D0D1D2D3D4D5D6

1918171615

14

IRQMX

IRQJ1

IRQJ2

IRQJ3

IRQCG

IRQA

2345678

IRQ10

IRQ11

U240 D-LATCH

U241 D-LATCH

13

18

8

7

30

21

SDO

SDI

ISPEN

MODE

SCLK

A0A1A2

WR

10-16,19,20

SA1|SA9

IOR

IOW

21

9

HD15

HD14

HD13

HD12

HD11

HD10

HD9

HD8

HD7

HD6

HD5

HD4

HD3

HD2

HD1

HD0

HD0-HD3

VP

22-25

HD0|HD3

RES

RST

HD0-HD15

D0D1D2

CK

Q0Q1Q2

U18 D-FFs U10 MICROPROCESSOR

U19 D-FFs

U21 TIME CODE

U30

Q2

Q1

U20

U9

VOLTAGE DETECTOR

4

5129

3611

234

A0A1A2

IRQR/W

NMI

FACK

PA6

NMIMASK

IRQ10

IRQ11

Q4Q3Q2Q1Q0

1516171819

IRQ10

IRQ11

86-92,94-97

IRQJ1-IRQJ3

IRQMX

CMDJ1-CMDJ3

CMDMX

CMDA,IRQA

IRQCG

TDB0|TDB7

110

111

722467

68

108

OE

2-9

11

11-18

RDU/L

IDB0-IDB7

U4 D-FFs

Q0|Q7

D0|D7

CP

IDB0|IDB7

12-19

1

HD8-HD15

OE

2-9

IDB0-IDB7

U6 D-FFs

U3

Q0|Q7

D0|D7

CP

12-19

1

HD0-HD7

CP

12-19

IDB0-IDB7

U7 D-FFs

D0|D7

Q0|Q7

OE

2-9

11

HD8-HD15

CP

12-19

12-19

IDB0-IDB7

U8 D-FFs

D0|D7

Q0|Q7

OE

2-9

11

CP

U248 D-FFs

U14

BUS BUFFER

U250(b)

BUS BUFFER

FROM INPUT BOARD (1/2)

D0|D7

Q0|Q7

OE

11

HD0-HD7

2-9

HD0-HD7

Y1

OE1Y2OE2Y3OE3Y4OE4

2411

1

1

1

6

8

7

28-34

925212

35

38

37

RE

WE

3OBW

26

FDB0|FDB7

WRL

WRU

A1A2A3

A4

22

23

21

+5V

31648

101113

34

36

3OAR

WS

Y1

OE1

A1

FREQ

FERR

P31

D0|D7

CP

2-9

11

54

RLATCH

55

101

45-51

TDB0-TDB7

REG4

REG3

REG2

REG1

REG0

ST

VI

D0|D7

PCO

127

6

OSI

PAL

RST

HI

TCIN

TCO

OSO

RSYNC

TO3

21222324252015

6566626364

103

102

105

104

26-33

TDB0-TDB7

VP

L.P.F

U22

AMP

17 2

14

16

Q3-Q6

DRIVER

L10

14

131241

RIPPLE

FILTER

VCC

OUT

+5VD

71

109

56

1077574

6

42

40

34

6

RST

+5VD

+12V+12V

+5VD

SF202

+12V

7

FL1

U253(a)

Q7

PSDO

PSCLK

SLATCH

SCS

PSDI

VSDI1

VSDO1

VSDI2

VSDO2

TCSTB

VSYNC

RES

TCRSYNC

FIELD

XTAL

EXTAL

PAL/NTSC

12VON

VPP

N/S

57

25 21

19

141310

11

345

15

12

9

24

127

6

141310

11

345

15

12

9

U12 RS422A TRANSCEIVER

U25 RS422A TRANSCEIVER

INPUT BOARD

BLOCK DIAGRAM OF INPUT BOARD (2/2)

444342

41

31322

4

NMI(30D)

ACK(30C)

INT

NMIMASK

3

1

HD8

HD1

HD9

HD8

HD2

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

TO

MOTHER

BOARD

– 16 –

Loading...

Loading...