Page 1

AXJ4

Compliance with RoHS Directive

ORDERING INFORMATION

AXJ 4 1 110G

4: Mini USB connectors

<Receptacle>

Interface connectors

1: 5 contacts receptacle

(Compliant with the Mini USB standard)

<Composition>

3: Mini B right angle type

6: Mini AB right angle type

<Mounting type>

1: Standard, with suction tape

<Terminal and Retention fitting>

1: Terminal portion: SMD,

Retention fitting portion: SMD,

Positioning bosses: Provided

<Flange shape>

0: Without flange

<Package>

G: Embossed tape packaging

MINIATURE INTERFACE

CONNECTOR COMPLIANT

WITH USB 2.0/ON-THE-GO

FEATURES

1. Compliant with USB 2.0-OTG

(Transmission speed: 480 Mbps)

2. 7.7 mm deep space-saving size

Since the depth is 7.7 mm, the occupied

space is approx.

15% smaller than competing standard

connectors (depth: approx 9.0 mm).

3. Reinforced fixing strength between

the body and shell

The high strength allows for the forcible

insertion of a plug.

Mini USB (AXJ4)

CONNECTORS

APPLICATIONS

1. DSC, PMP, DVC, IC recorders

2. Mobile phones, PDA, smart phones

3. Compact PC peripherals (e.g.

external HDD, memory card readers)

4. Game machines

PRODUCT TYPES

Type Te r minal shape

5 contacts receptacle

(Compliant with the

Mini USB standard)

Mini B

Right angle type

Mini AB

Right angle type

Te r minal position: SMD

Clips (retention fitting): SMD

Positioning

bosses

Provided Without flange

Flange Part number

AXJ413110G

AXJ416110G

Packing quantity

Inner carton

(Embossed)

1,200 6,000

http://www.mew.co.jp/ac/e/Matsushita Electric Works, Ltd.

Outer carton

Page 2

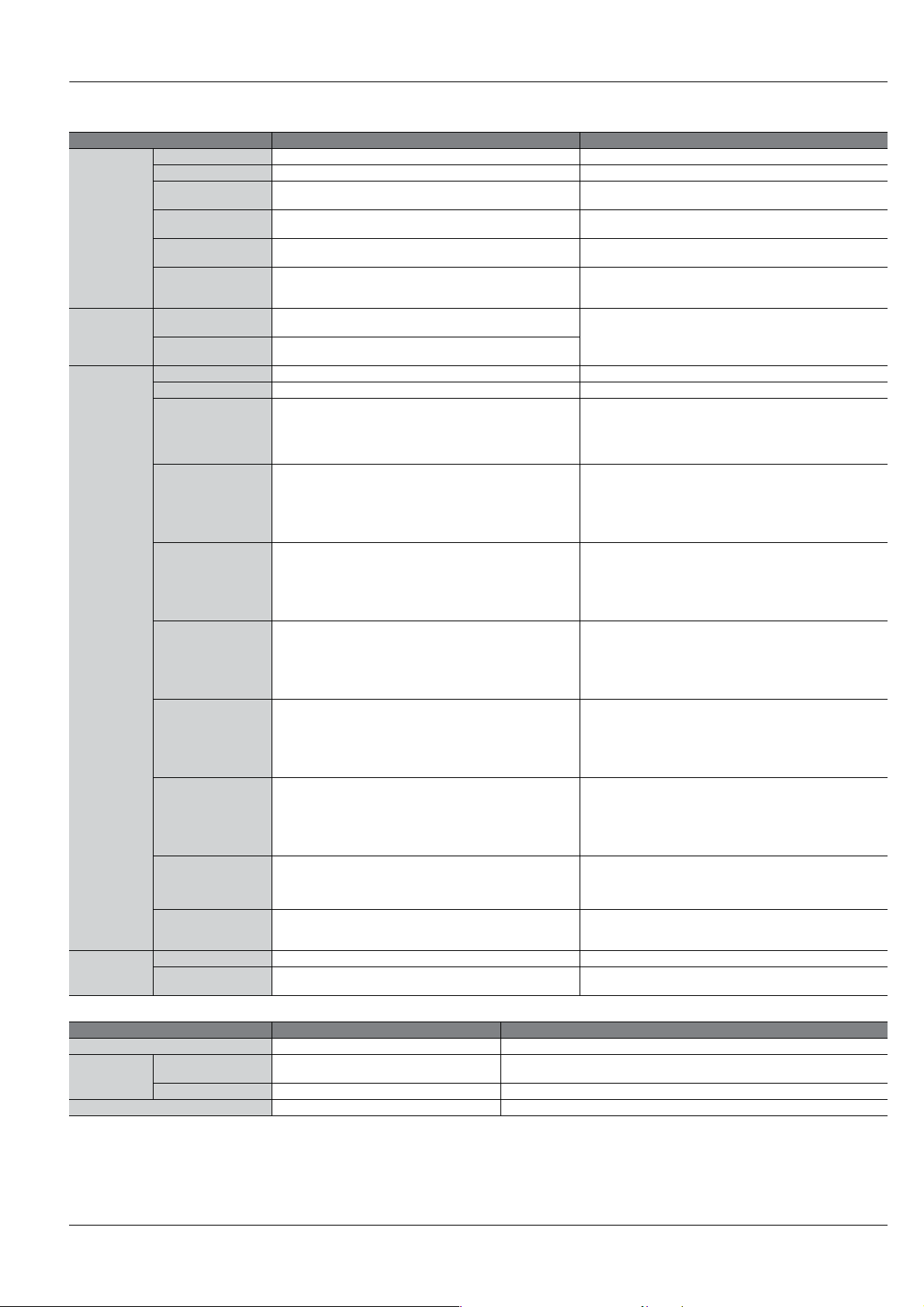

SPECIFICATIONS

1. Characteristics

Item Specifications Conditions

Rated current 1.0A

Rated voltage 30V DC/AC

Contact resistance Max. 50mΩ

Electrical

characteristics

Mechanical

characteristics

Environmental

characteristics

Soldering

temperature

resistance

Insulation resistance Min. 100MΩ

Breakdown voltage

Electrostatic capacity Max. 2pF

Composite insertion

force (initial)

Composite removal

force (initial)

Ambient temperature –55°C to 85°C No freezing or condensation in low temperatures

Storage temperature –55°C to 85°C (–40°C to 50°C for packaging materials) No freezing or condensation in low temperatures

Vibration resistance

Impact resistance

Heat resistance

(mated)

Low temperature

resistance (mated)

Humidity resistance

(mated)

Temperature cycle test

(mated)

Saltwater spray

resistance (mated)

Hydrogen sulfide

Reflow soldering Peak temperature: Max. 260°C

Manual soldering

100V AC (Dielectric breakdown must not occur during a 1 min.

application)

Max. 35N

{3.57kgf}

Min. 7N {0.714kgf}

Discontinuity: Max. 1µs

Contact resistance: Max. 50mΩ

Appearance: No abnormality

Discontinuity: Max. 1µs

Contact resistance: Max. 50mΩ

Appearance: No abnormality

250 hours

Contact resistance: Max. 50mΩ

Withstand voltage: 100V AC dielectric breakdown must not

occur during a one-minute application.

Insulation resistance: Min. 100MΩ

Appearance: No abnormality

96 hours

Contact resistance: Max. 50mΩ

Withstand voltage: 100V AC dielectric breakdown must not

occur during a one-minute application.

Insulation resistance: Min. 100MΩ

Appearance: No abnormality

7 cycles

Contact resistance: Max. 50mΩ

Withstand voltage: 100V AC dielectric breakdown must not

occur during a one-minute application.

Insulation resistance: Min. 100MΩ

Appearance: No abnormality

10 cycles

Contact resistance: Max. 50mΩ

Withstand voltage: 100V AC dielectric breakdown must not

occur during a one-minute application.

Insulation resistance: Min. 100MΩ

Appearance: No abnormality

48 hours

Contact resistance: Max. 100mΩ

Appearance: No abnormality

96 hours

Contact resistance: Max. 100mΩ

Appearance: No abnormality

300±10°C: Max. 5 s

350±10°C: Max. 3 s

2. Material and surface treatment

Part name Material Surface treatment

Resin-molding portion Heat-resistant resin (UL94V-0) —

Metal parts

Pickup tape Heat-resistant resin —

Contact Copper alloy

Shell Copper alloy Ni plating on base, Sn plating on surface

Contact portion: Ni plating on base, Au plating on surface

Te r minal portion: Ni plating on base, Sn plating on surface

EIA-364-23

(Inductive resistance to wire is not included)

EIA-364-21

Using 100V DC megger

EIA-364-20

Detection current: 1mA

EIA-364-30

(Measure it between the adjacent terminals of the unmated

connector at a frequency of 1 kHz.)

EIA-364-13

Insert and remove a plug at a speed of 12.5 mm/min.

EIA-364-28

Apply vibration in three directions including the mating axis

that are perpendicular to one another for 15 minutes

respectively with a 100 mA DC current applied.

Cord length: 100mm Fix the cord end.

EIA-364-27

Acceleration: 294m/s

Duration: 11 ms,

Application directions: 6 surfaces (X, Y, and Z directions)

Number of applications: 3 times respectively (Total: 18 times)

Cord length: 100mm Fix the cord end.

EIA-364-17

Temperature: 85±2°C

Temperature: –55±2°C

EIA-364-31 Method III

Sequence

1. –55±3°C, 30 minutes

2. ~, Max. 5 minutes

3. 85±2°C, 30 minutes

4. ~, Max. 5 minutes

Bath temperature: 35±2°C

Saltwater concentration: 5±1%

Wash the connector with water at room temperature after the

test, and then dry it at room temperature.

Temperature :40±2°C

Humidity: 75 to 80%

Gas concentration: 3±1ppm

2

(30G)

AXJ4

Interface connectors

http://www.mew.co.jp/ac/e/Matsushita Electric Works, Ltd.

Page 3

AXJ4

DIMENSIONS

1. Mini B Right angle type

AXJ413110G

7.70

Terminal No.1

3.702.90

4×1.20

0.80

3.10

3.20

7.70

9.90

6.90

4.40

5.87

0.80±0.15

0.25

Terminal No.5

0.80 dia.

3.95

0.07

3.95

5.95

PC board edge

With a plug inserted:

Including the projection of the spring

4.40

in the shell contact section

mm General tolerance: ±0.3

Recommended PC board pattern

(TOP VIEW)

8.9±0.1

0.95±0.05 dia. (hole)

2.0±0.1

2.7±0.1

2.5±0.1

1.00±0.1

7.5±0.1

1.40±0.1

5.3±0.1

3.2±0.05

0.8±0.05

0.4±0.05

4.4±0.05

7.50±0.1

2. Mini AB Right angle type

mm General tolerance: ±0.3

AXJ416110G

Interface connectors

3.702.90

7.70

4×1.20

Terminal No.1

3.10

0.80

1.93

3.20

7.70

9.90

6.90

4.40

5.32

0.80±0.15

0.25

Terminal No.5

0.80 dia.

3.95

0.07

3.95

5.95

With a plug inserted:

Including the projection of the spring

4.40

in the shell contact section

Recommended PC board pattern

(TOP VIEW)

3.2±0.05

0.8±0.05

0.4±0.05

7.5±0.1

1.40±0.1

5.3±0.1

PC board edge

4.4±0.05

8.9±0.1

EMBOSSED TAPE DIMENSIONS (unit: mm)

• Tape dimensions (Conforming to JIS C 0806-3 1999) • Reel dimensions (Conforming to EIAJ ET-7200B)

24.0±0.3

11.5

1.75

4.0

2.0

380 dia.

25.4±1

Taping reel

Top cover tape

Embossed carrier tape

0.95±0.05 dia. (hole)

2.0±0.1

2.7±0.1

2.5±0.1

7.50±0.1

1.00±0.1

Pull out direction

12.0

1.5 dia.

Embossed mounting-hole

http://www.mew.co.jp/ac/e/Matsushita Electric Works, Ltd.

Page 4

NOTES

1. Use of a cover is recommended

when using this device in order to

prevent scraps, dust, dirt, etc., from

getting inside of the receptacle.

2. PC board design

Please refer to the recommended PC

board pattern to ensure the strength of

soldered portion of terminals.

3. Soldering

1) Manual soldering

• Please set up temperature and applied

time of soldering iron as indicated in

specification sheet.

• Please use soldering iron after

confirming removal of dispersed solder

flux on the contact surface by use of

magnifying glass after each soldering.

• Please properly clean soldeing iron.

2) Reflow soldering

• Screen printing is recommended for

cream solder printing.

• Screen thickness of 0.15mm is

recommended for cream solder printing.

• When applying different thickness of

screen, please consult us.

• Depending upon size of connector, self

alignments may not be expected.

Please pay attention to align terminals

and soldered pads.

• The following diagram shows the

recommended reflow soldering

temperature profile.

Temperature

Max. 260°C

150 to 175°C

• The temperature measured on the PC

board surface near connector terminals.

• After reflow soldering, in case of PC

board surface the reverse side using

reflow soldering, for example an adhesive

and so on connector of fixed disposition.

3) Rework of soldering portion

• Rework is one time.

• In case of soldering rework of bridges.

Please use a flat-head soldering iron and

don’t use supplementary solder flux.

• Please use the soldering iron under

specification’s temperature

Maximum temperature

Pre-heating

60 to 120 second

200°C

Max. 70 sec

Time

4. Since excessive force on the

terminals will cause deformation and

the integrity of the soldering will be

lost during reflow soldering, avoid

dropping or rough handling of the

product.

5. PC board warpage should be

controlled less than 0.03mm to entire

length of the connector.

6. Repeated bending of terminals and

holding parts can result in terminals

breaking.

7. Regarding after soldering

connectors on PC boards

• After mounting connectors on PC

boards, do not apply excessive loads to

the connector by piling up the boards.

• Please do not add the force to the

connector during assembled connector

on PC board.

8. This connector has metal shell for

preventing EMI, when designing an

enclosure the followings should be

considered. Guide for plug entrance

should be arranged in order to prevent

distorted insertions. Provide a cover

to reinforce the metal shell portions of

the receptacle.

9. We recommend the use of a

purified-water-based solution for

cleaning the PC board. If you use an

alcohol-based solution, the surface of

the molded part may be whitened. In

addition, please carefully monitor the

contamination degree of the solution

to prevent the solution from recontaminating the connector

contacts.

10. Others

To prevent insulation deterioration of PC

board after soldering, please avoid

adhesion coating agent to terminals in

case of coating.

For other details, please verify with

the product specification sheets.

AXJ4

Interface connectors

http://www.mew.co.jp/ac/e/Matsushita Electric Works, Ltd.

Loading...

Loading...