Page 1

AJ9 (J9)

VDE

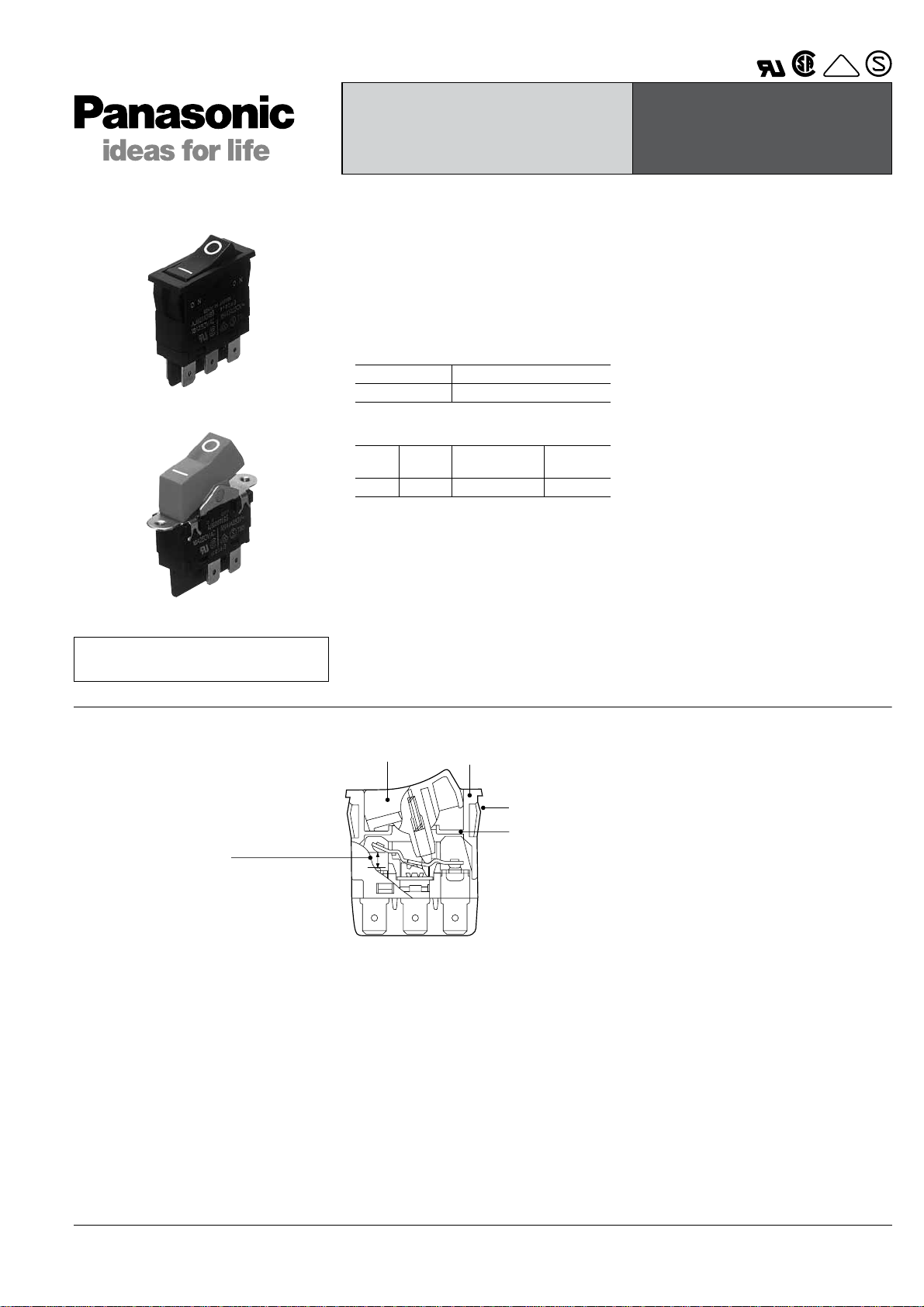

AJ9 switch snap-in mounting type

AJ9 switch screw mounting type

POWER ROCKER SWITCH

FEATURES

1. Power rocker switches for safety

requirements.

• All versions comply with ClassII

EN61058-1 insulation grade.

Insulation distance: 8mm Min.

Contact gap: 3mm Min.

• International Standard-approved

status

Already approved

AJ9 switch UL, CSA, VDE, SEMKO

2. High inrush current resistance is

ideal for office automation equipment.

Type Inrush Contact rating

AJ9 100A 16A 250V AC Min.10

3. Eight standard actuator colors

White, black, red, dark gray, light gray,

blue, green, yellow

Expected

life

4

AJ9 (J9)

SWITCHES

PRECAUTIONS WHEN

USING CADMIUM-FREE

CONTACT TYPE

Models with cadmium-free contacts have

been introduced in order to reduce

environmentally harmful substances. (“F”

is affixed to the end of the part number.)

We ask customers who are currently

using products with cadmium-containing

contacts (no “F” at the end of the part

number) to please make the switch to

models with cadmium-free contacts.

When switching, operating life may differ

depending on the load. Please be sure to

verify this by conducting an evaluation

using actual equipment.

RoHS Directive compatibility information

http://www.nais-e.com/

CONSTRUCTION

Contact gap (more than 3mm)

The EN60950 (intended for office automation

equipment) conforms with a 3mm gap.

When directly opening or closing the primary power

supply side, a contact gap of at least 3mm is required

in order to ensure safety.

Actuator

Case

Snap-in Clip

Dustproof construction

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 2

AJ9 (J9)

ORDERING INFORMATION

AJ 9 F

9: AJ9 switch

Poles

1: 1-pole 2: 2-pole

Mounting type

1: Snap-in mounting (16A)

2: Screw mounting (16A)

Operating type

0: ON-OFF 1: ON-ON

Terminal shape

0: .250 Quick-connect terminal

1: Soldering compatible with .250 Quick-connect terminal

2: PC board terminal

Actuator indication

0: No indication

1: indication

2: indication

Actuator color

W: White B: Black R: Red Z: Dark gray H: Light gray L: Blue G: Green Y: Yellow

Flang color

Nil: Black (standard color)

(Custom ordered color: W: White, R: Red, Z: Dark gray, H: Light gray, L: Blue, G: Green, Y: Yellow)

Approved standard

3: UL, CSA, VDE, SEMKO

9: UL, CSA

F: Cadmium-free product

Remarks: 1. Please consult us for details concerning different flange colors.

Remark 2)

Remark 3)

2. The color of “I O” indication on the actuator:

• White actuator: black

• Others: white

3. The ON-OFF type with no indications on the actuator have received UL and CSA certifications.

Remark 1)

PRODUCT TYPES

1. Snap-in mounting type

(1) Without indication on actuators

Te r minal shape Poles Operating types

1-pole

.250 Quick-connect terminal

2-pole

Soldering compatible with

.250 Quick-connect terminal

PC board terminal

(Standard flange color is black. For other colors type, they are custom ordered.)

Remarks: 1. A letter indicating the actuator color is entered in place of ∗ symbol. (W: White B: Black R: Red Z: Dark gray H: Light gray L: Blue G: Green Y: Yellow)

For requests of other flange color, please suffix following letter. (W: White R: Red Z: Dark gray H: Light gray L: Blue G: Green Y: Yellow)

2. The color of I O indication on the actuator:

White actuator: black, Others: white

3. The ON-OFF type with no indications on the actuator have received UL and CSA certifications.

All other types come with a stamp indicating international standards without your request.

1-pole

2-pole

1-pole

2-pole

ON-OFF AJ911000∗9F

ON-ON AJ911100∗3F

ON-OFF AJ921000∗9F

ON-ON AJ921100∗3F

ON-OFF AJ911010∗9F

ON-ON AJ911110∗3F

ON-OFF AJ921010∗9F

ON-ON AJ921110∗3F

ON-OFF AJ911020∗9F

ON-ON AJ911120∗3F

ON-OFF AJ921020∗9F

ON-ON AJ921120∗3F

Part number

(Without indication)

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 3

AJ9 (J9)

(2) With indication on actuators

Te r minal shape Poles Operating types

1-pole

.250 Quick-connect terminal

2-pole

Soldering compatible with

.250 Quick-connect terminal

PC board terminal

(Standard flange color is black. For other colors type, they are custom ordered.)

Remarks: 1. A letter indicating the actuator color is entered in place of ∗ symbol. (W: White B: Black R: Red Z: Dark gray H: Light gray L: Blue G: Green Y: Yellow)

For requests of other flange color, please suffix following letter. (W: White R: Red Z: Dark gray H: Light gray L: Blue G: Green Y: Yellow)

2. The color of I O indication on the actuator:

White actuator: black, Others: white

3. The ON-OFF type with no indications on the actuator have received UL and CSA certifications.

All other types come with a stamp indicating international standards without your request.

1-pole

2-pole

1-pole

2-pole

ON-OFF AJ911001∗3F AJ911002∗3F

ON-ON AJ911101∗3F AJ911102∗3F

ON-OFF AJ921001∗3F AJ921002∗3F

ON-ON AJ921101∗3F AJ921102∗3F

ON-OFF AJ911011∗3F AJ911012∗3F

ON-ON AJ911111∗3F AJ911112∗3F

ON-OFF AJ921011∗3F AJ921012∗3F

ON-ON AJ921111∗3F AJ921112∗3F

ON-OFF AJ911021∗3F AJ911022∗3F

ON-ON AJ911121∗3F AJ911122∗3F

ON-OFF AJ921021∗3F AJ921022∗3F

ON-ON AJ921121∗3F AJ921122∗3F

Part No.

(With I O indication)

2. Screw mounting type

(1) Without indication on actuators

Te r minal shape Poles Operating types

.250 Quick-connect terminal

Soldering compatible with

.250 Quick-connect terminal

PC board terminal

1-pole

2-pole

1-pole

2-pole

1-pole

2-pole

ON-OFF AJ912000∗9F

ON-ON AJ912100∗3F

ON-OFF AJ922000∗9F

ON-ON AJ922100∗3F

ON-OFF AJ912010∗9F

ON-ON AJ912110∗3F

ON-OFF AJ922010∗9F

ON-ON AJ922110∗3F

ON-OFF AJ912020∗9F

ON-ON AJ912120∗3F

ON-OFF AJ922020∗9F

ON-ON AJ922120∗3F

Part number

(Without indication)

(2) With indication on actuators

Te r minal shape Poles Operating types

1-pole

.250 Quick-connect terminal

2-pole

Soldering compatible with

.250 Quick-connect terminal

PC board terminal

Remarks: 1. A letter indicating the actuator color is entered in place of ∗ symbol. (W: White B: Black R: Red Z: Dark gray H: Light gray L: Blue G: Green Y: Yellow)

2. The color of I O indication on the actuator:

White actuator: black, Others: white

3. The ON-OFF type with no indications on the actuator have received UL and CSA certifications.

All other types come with a stamp indicating international standards without your request.

1-pole

2-pole

1-pole

2-pole

ON-OFF AJ912001∗3F AJ912002∗3F

ON-ON AJ912101∗3F AJ912102∗3F

ON-OFF AJ922001∗3F AJ922002∗3F

ON-ON AJ922101∗3F AJ922102∗3F

ON-OFF AJ912011∗3F AJ912012∗3F

ON-ON AJ912111∗3F AJ912112∗3F

ON-OFF AJ922011∗3F AJ922012∗3F

ON-ON AJ922111∗3F AJ922112∗3F

ON-OFF AJ912021∗3F AJ912022∗3F

ON-ON AJ912121∗3F AJ912122∗3F

ON-OFF AJ922021∗3F AJ922022∗3F

ON-ON AJ922121∗3F AJ922122∗3F

Part No.

(With I O indication)

Part No.

(With — O indication)

Part No.

(With — O indication)

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 4

AJ9 (J9)

R0.5 Max.

X

12.6

+0.1

0

SPECIFICATIONS

1. Contact rating

Type Voltage

Resistive load

(cos

φ

] 1.0)

AJ9 switch 250V AC 16A 4A

Remark: The motor load is in accordance with EN61058-1. Inrush current can be switched up to the value of 6 times the indicated rating.

2. Characteristics

Expected life

(Min. operations)

Initial insulation resistance (Between terminals) Min. 100 MΩ (at 500V DC measured by insulation resistive meter)

Initial breakdown voltage (Between terminals) 2,000 Vrms detection current: 10 mA

Initial contact resistance (By voltage drop at 1A, 2 to 4V DC) Max. 20mΩ

Temperature rise

Vibration resistance 10 to 55 Hz at double amplitude of 1.5mm

Shock resistance Min. 294m/s2{30 G}

Actuator strength 40 N {4.08kgf} for 1 minute (operating direction)

Tensile terminal strength 100 N {10.2kgf} for 1 minute or more (Pull & push direction)

Ambient temperature –25°C to +85°C (Not freezing below 0°C)

Flame retardancy UL94V-0

Tr acking resistance Min. 175

Operating force

(reference characteristics)

Contact material AgZnO alloy

Remark: Test conditions are in accordance with EN61058-1, UL1054 and JIS C 6571.

Mechanical Min. 5 × 104 (at 20 cpm.)

Electrical Min. 104 (at 10 cpm., at rated load)

at 6 × 103 ope. or less Max. 30°C (UL1054)

from 6 × 103 ope. to 10

4

Max. 55°C (EN61058-1)

1-pole 3.92 ± 1.96N {400 ±200gf}

2-pole 5.88 ± 24.5N {600 ±250gf}

Motor load

(EN61058-1)

(cos φ ] 0.6)

DIMENSIONS

1) .250 Quick-connect terminal

1. Snap-in mounting type

Remark: For soldering compatible with .250 Quick-connect terminal and PC board terminal, only terminal shape is changed.

28°±4°

O N

1.75 dia.

mm General tolerance: ±0.5

Diagram of recommended locations

for panel mounting holes

37

2

7

2-pole 1-pole

15

10

Panel thickness X

O N

27

37

12.5

0.8

1.2

7

9.7

6.35

11

34

4.4

0.75 to 1.25 34.2

1.25 to 2 34.4

+0.1

−0

+0.1

−0

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 5

2. Screw mounting type

7.5

AJ9 (J9)

mm General tolerance: ±0.5

50

±0.2

42

2-pole 1-pole

33

30°

19.9

4

OFFON

0.8

19

29

15

10

9.7

4.4

1.75 dia.

6.35

11

34

Remark: For soldering compatible with .250 Quick-connect terminal and PC board terminal, only terminal shape is changed.

2) Soldering compatible with .250 Quick-connect terminal

R1.5

1

9.7

4.4

R0.9

6.35

11

34

Remark: Dimensions other than listed above are same as those of .250 Quick-connect terminal.

3) PC board terminal

6

11

3

34

12.4

15

0.8

1.2

7

PC board pattern (ON-ON)

2-pole 1-pole

±0.1

4.5

±0.1

1.2

7

11 11

3.5

11 11

4.5

±0.1

±0.1

1.2

Remark: Dimensions other than listed above are same as those of .250 Quick-connect terminal.

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 6

AJ9 (J9)

+5

0

NOTES

1. Switch mounting

Mount the switch with the recommended

panel mounting hole dimensions shown

in the dimensions.

Contact us if you are considering using a

panel of other than the recommended

size and shape.

2. Regarding fastening lead wires to

terminals

1) When connecting the tab terminals,

use a .250 Quick-connect and insert the

terminals straight in.

If they are skewed, the terminals will

require excessive insertion force.

In addition, there is some variation in the

insertion force required for different

receptacles from different manufacturers,

so confirm how much force is needed

REFERENCE

1. Outline of UL1054 test

Overload test AJ9: 20A 250V AC

(Power factor 0.75 to 0.8)

50 operation

Endurance test AJ9: 16A 250V AC

(Power factor 0.75 to 0.8)

3

6×10

operation

After testing, temperature rise of

terminals should be less than 30°C and

no abnormality should be observed in

characteristics.

under actual conditions.

Do not solder wires onto tab terminals.

2) With manual soldering: Complete the

soldering connection work within 3

seconds with the tip of the soldering iron

(60W soldering iron) at a temperature of

420°C or lower, and take care not to

apply any force to the terminal area.

Avoid touching the switch with soldering

iron.

3) The terminals should be connected in

such a way that they are not under

constant stress from the connecting

wires.

4) Terminal material is copper alloy which

may discolor due to finger’s oil or after a

long time. But that discoloration does not

effect actual performance.

2. Outline of EN61058-1 test

After switching 5 × 10

3

times on the

above load condition at both 85 °C and

25±10°C, temperature rise of terminals

should be less than 55°C and no

abnormality should be observed in

characteristics.

50 to 100ms

24A

2 sec.

J9: 16A

4 sec.

AC: 250V

(Power factor 0.6)

3. Resistance to chemicals

To clean the switch unit, use a neutral

detergent diluted with water.

Do not use acidic or alkaline solvents as

they may damage the switch.

Furthermore, be careful not to get any of

the detergent solution inside of the switch

while cleaning it.

4. Environment

Avoid using and storing these switches in

a location where they will be exposed to

corrosive gases, silicon, or high dust

levels, all of which can have an adverse

effect on the contacts.

5. Take care not to drop the product as

it may impair perfomance.

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Loading...

Loading...