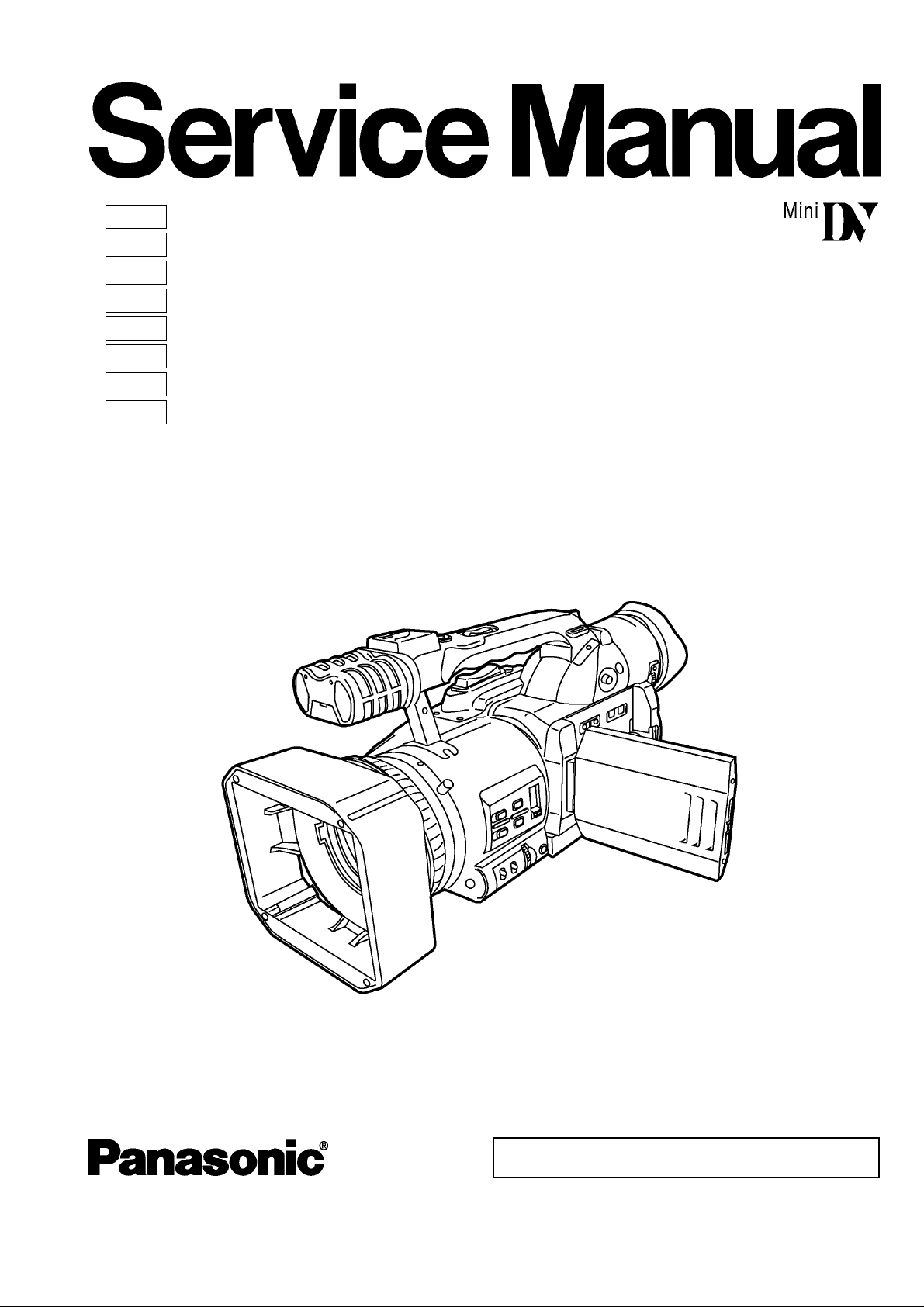

Panasonic AG-DVX100BP, AG-DVX100BE, AG-DVX100BAN, AG-DVC180BMC, AG-DVX102BEN Service Manual

.

Sec. 1 Service Information

Sec. 2 Disassembly Procedures

Sec. 3 Mechanical Adjustment

Sec. 4 Electrical Adjustment

Sec. 5 Block Diagrams

Sec. 6 Schematic Diagrams

Sec. 7 Circuit Board Diagrams

Sec. 8 Exploded Views &

Replacement Parts List

ORDER NO. BSD0510A25CE

D21

Camera-Recorder

AG-DVX100BP/E/AN

AG-DVX102BEN

AG-DVC180BMC

© 2005 Matsushita Electri c Industrial Co., Ltd. A l l ri ghts reserved.

Unauthorized copying and distribution i s a violation of law.

r

This service inform ation is desi gned for experienced repair technic ians only and is not designed for us e by the general publ ic. It does not

contain warnings or cautions to advi se non-technical individuals of potential dangers in attem pt i ng to service a product. Products powered

by electricity should be serviced or repai red only by experienced professional tec hnicians. A ny attempt to s ervice or repair the product o

products dealt with in this service information by anyone else could result in serious i nj ury or death.

WARNING

!

AG-DVX100BP

- 2 -

- 3 -

AG-DVX100BE

- 4 -

- 5 -

SAFETY PRECAUTIONS

GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a

short circuit is found, replace all parts, which have been

over-heated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

3. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohm meter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc. The

resistance value must be more than 5MΩ.

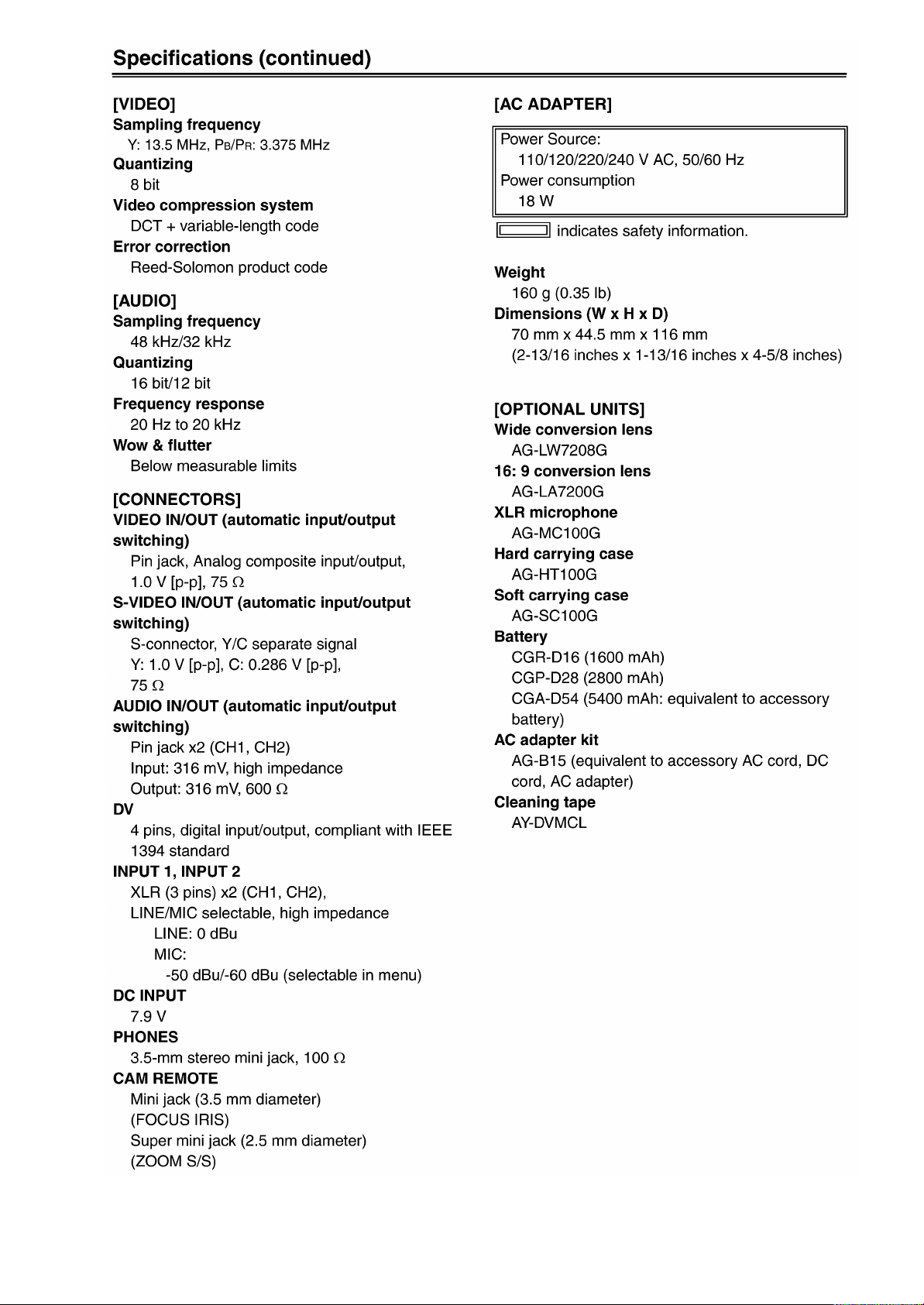

Figure1

LEAKAGE CURRENT HOT CHECK (See Figure 1)

1. Plug the AC cord directly into the AC outlet.

Do not use an isolation transformer for this check.

2. Connect a 1.5KΩ, 10W resistor, in parallel with a 0.15µ F

capacitor, between each exposed metallic part on the set

an a good earth ground such as a water pipe, as shown

in Figure1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet repeat each of the

above measurements.

6. The potential at any point should not exceed 0.15 volts

RMS. A leakage current tester (Simpson Model 229

equivalent) may be used to make the hot checks,

leakage current must not exceed 0.1 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the

customer.

ABOU T LEAD FREE SOLDER (PbF)

Distinction of Pbf PCB:

PCBs (manufactured) using lead free solder will have a PbF

stamp on the PCB.

Caution:

1. Pb free solder has a higher melting point than standard

solder; Typically the melting point is 50–70

higher. Please use a high temperature soldering iron. In

case of the soldering iron with temperature control,

please set it to 700±20 (370±10 ).

2. Pb free solder will tend to splash when heated too high

(about 1100

/600 ).

(30-40 )

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically sensitive (ED) Devices. Examples of

typical ES devices are integrated circuits and some

field-effect transistors and semiconductor “chip” components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist trap device, which should be removed

for potent i al sh oc k re as o ns prio r t o app l yi ng powe r t o th e

unit under test.

2. After removing an e lectrical assembly eq uipped with E S

devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge

buildup or exposure of the assembly.

3. Use only a grounded tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static solder removal device classified

as “anti-static” can generate electrical charges sufficient

to damage ES devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it.

(most replacement ES devices are package with leads

electrically shorted together by conductive foam,

aluminum foil or comparable conductiv e material).

7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise hamless motion

such as the brushing together of your clothes fabric or

the lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ES device).

X-RADIATION

WARNING

1. The potential source of X-radiation in EVF sets is the

High Voltag e sect ion and the p ictur e tube.

2. When using a picture tube test jig for service, ensure

that jig is capable of handling 10kV without causing

X-Radiation.

Note: It is important to use an accurate periodically

calibrated high voltage meter.

3. Measure the High Voltage. The meter (electric type)

reading should indicate 2.5kV, ±0.15kV. If the meter

indication is out of tolerance, immediate service and

correction is required to prevent the possibility of

premature component failure. To prevent an X-Radiation

possibility, it is essential to use the specified picture

tube.

- 6 -

AG-DVX100BP

- 7 -

AG-DVX100BE

- 8 -

- 9 -

- 10 -

MHNK150/0123457F6S8P

MODEL:

SERVICE INFORMATION

AG-DVX100BP/E/AN,102BEN,DVC180BMC

CONTENTS

1. SERVICING FIXTURES AND TOOLS ........................................................................................INF-1

1-1. Summary Table of Servicing Fixtures and Tools ................................................................INF-1

2. MAINTENANCE ..........................................................................................................................INF-4

2-1. Maintenance Schedule........................................................................................................INF-4

2-2. Cleaning of Tape Transport Part .........................................................................................INF-4

3. MANUAL TAPE EJECT (EMERGENCY EJECT) .......................................................................INF-5

4. LITHIUM BATTERY ....................................................................................................................INF-6

4-1. Replacement Procedure .....................................................................................................INF-6

5. SERVICE MENU .........................................................................................................................INF-7

5-1. SERVICE MENU (CAMERA mode)....................................................................................INF-8

5-1-1. Audio Filter ...............................................................................................................INF-8

5-1-2. Software Version Display.........................................................................................INF-9

5-1-3. Hour Meter Display ..................................................................................................INF-9

5-1-4. Adjustment item for Video Level ..............................................................................INF-10

5-1-5. DIF Status Display ...................................................................................................INF-10

5-1-6. LCD/EVF Correction ................................................................................................INF-11

5-2. DIAGNOSTIC MENU (VCR mode) .....................................................................................INF-12

5-2-1. How to display the Error Rate ..................................................................................INF-12

5-2-2. Other item ................................................................................................................INF-13

5-3. ADJUST MENU (VCR mode) .............................................................................................INF-13

5-3-1. Setting item for LISTA Adjustment ...........................................................................INF-14

6. EEPROM .....................................................................................................................................INF-15

6-1. Each Menu Data .................................................................................................................INF-15

6-1-1. Setting menu data ....................................................................................................INF-15

6-1-2. Service menu data ...................................................................................................INF-15

6-1-3. DIAGNOSTIC menu data.........................................................................................INF-16

6-1-4. ADJUST menu data .................................................................................................INF-16

6-1-5. The other data..........................................................................................................INF-16

7. CAMERA REMOTE.....................................................................................................................INF-17

7-1. ZOOM S/S REMOTE ..........................................................................................................INF-17

7-1-1. Record start / stop input...........................................................................................INF-17

7-1-2. Zooming control input ..............................................................................................INF-17

7-2. FOCUS/IRIS REMOTE .......................................................................................................INF-18

7-2-1. Focus control input...................................................................................................INF-18

7-2-2. IRIS control input .....................................................................................................INF-19

8. CAUTION WHEN INSTALLING AUDIO CONTROL KNOB .......................................................INF-20

9. INTERCONNECTION .................................................................................................................INF-21

10. CIRCUIT BOARD LAYOUT ........................................................................................................INF-22

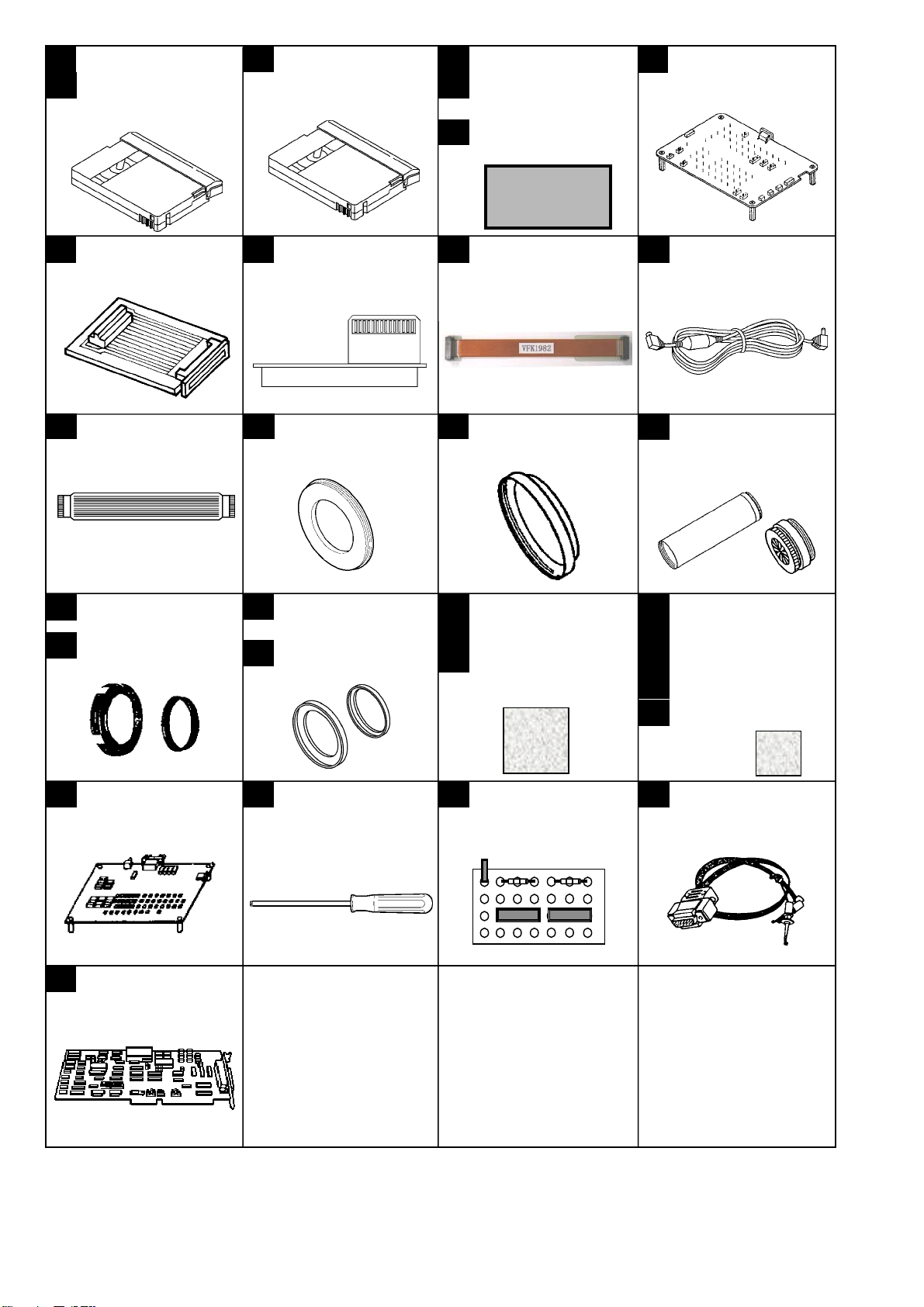

1. SERVICING FIXTURES AND TOOLS

The following servicing tools are required for mechanical and electrical servicing and alignment.

The items marked “NEW” in the following list are necessary for the AG-DVX100B/102B/DVC180B.

Please refer to “Y” and “N” in column of table below, which tools required for servicing the NTSC and PAL model.

Please refer to “Y” in column of table below, these tools were also use for servicing the AG-DVX100A/DVC180A.

1-1. Summary Table of Servicing Fixtures and Tools

No

1 VFM3010EDS DV Alignment Tape (Color bar) Y N Y

2 VFM3110EDS DV Alignment Tape (Color bar) N Y Y

3 VFM3000LS DV Alignment Tape (Linearity) Y Y Y

4 *VVS0026 EVR Adjustment Software Y N N NEW

5 *VVS0027 EVR Adjustment Software N Y N NEW

6 *VFK1481N LISTA Software Y Y Y Download from the WEB site.

7 VFK1308P Measuring Board Y Y Y

8 VFK1309A EVR Connector Board Y Y Y Enable to use with VFK1309

9 VFK1763 Connector Adapter Y Y N 60-30pin.

10 VFK1982 Extension Cable Y Y N NEW

11 VJA0941 DC Cable Y Y Y 2 pieces Required

12 VFK1317 30pin Flat Cable Y Y Y 2 pieces Required

13 VFK1809 72mm Attachment Ring Y Y Y

14 VFK1164TAR43 43mm Attachment Ring Y Y Y

15 VFK1164TCM01 Collimator Set (Infinity Lens) Y Y Y

16 VFK1345 CC Filter Holder Y Y Y

17 VFK1346 Step Down Ring Y Y Y

18 VFK1659 Step-Up Ring (43mm-49mm) Y Y Y

19 VFK1660 Step-Up Ring (49mm-62mm) Y Y Y

20 VFK1341 CC Filter (LB40) Y N Y

21 VFK1342 CC Filter (LB80) N Y Y

22 VFK1347 CC Filter (LB120) Y Y Y

23 VFK1884 CC Filter (LBA2) Y Y Y

24 VFK1888 CC Filter (LBB6) Y Y Y

25 VFK1885 CC Filter (LBB2) Y N Y

26 VFK1886 CC Filter (CC C10) N Y Y

27 VFK1887 CC Filter (CC C20) N Y Y

28 VFK1409A Measuring Board Y Y Y NOTE 1

29 VFK1899 Post Driver Y Y N NOTE 2

30 VFK1810 LISTA Measuring Board Y Y Y NOTE 1

31 VFK1186 LISTA Cable Y Y Y

32 VFK1300 A/D Converter Board Y Y Y ISA PC Board.

Parts No. NAME

NTSC

Model

PAL

Model

AG-DVX100A/

DVC180A

REMARK

Download from the WEB site.

Download from the WEB site.

It uses with AG-DVC30/32/33

and AG-DVC60/62/63.

It uses with AG-DVC30/32/33

and AG-DVC60/62/63.

NOTE:

1. If you already have VFK1409S, it can be used for LISTA adjustment with VFK1810 instead of VFK1409A.

(Refer to item “1-5. Connection of LISTA Adjustment system” on page MECH-4 in section 3.)

2. This Post Driver use for servicing the “A” mechanism of consumer model.

INF-1

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

VFM3010EDS

1

VFM3110EDS

2

DV Alignment Tape

(Color bar)

FM3000EDS

3 4

DV Alignment Tape

(Linearity)

5

6

VS0026

VS0027

EVR Adjustment Software

VFK1481N

LISTA Software

DOWN LOAD

FK1309A

8 9 10 11

EVR Connector Board

VFK1763

Connector Adapter

VFK1982

Extension Cable

12 13 14

FK1317

30pin Flat Cable

FK1809

72 mm Attachment Ring

FK1164TAR43

43 mm Attachment Ring

(In case of using VFK1308P,

required 2pcs. of this cable)

VFK1345

16

CC Filter Holder

VFK1346

17

Step Down Ring

VFK1659

18

Step-up Ring (43mm - 49mm)

VFK1660

19

Step-up Ring (49mm - 62mm)

VFK1341 (LB40)

20

VFK1342 (LB80)

21

VFK1347 (LB120)

22

CC Filter

VFK1345

28 29 30

FK1409A

Measuring Board

VFK1346

VFK1660

FK1899

Post Driver

VFK1659

FK1810

LISTA Measuring Board

32

FK1300

A/D Converter Board

FK1308P

7

Measuring Board

JA0941

DC Cable

15

FK1164TCM01

Collimator Set

(Infinity Lens)

VFK1884 (LBA2)

23

VFK1888 (LBB6)

24

VFK1885 (LBB2)

25

VFK1886 (CC C10)

26

VFK1887 (CC C20)

27

CC Filter

FK1186

31

LISTA Cable

INF-2

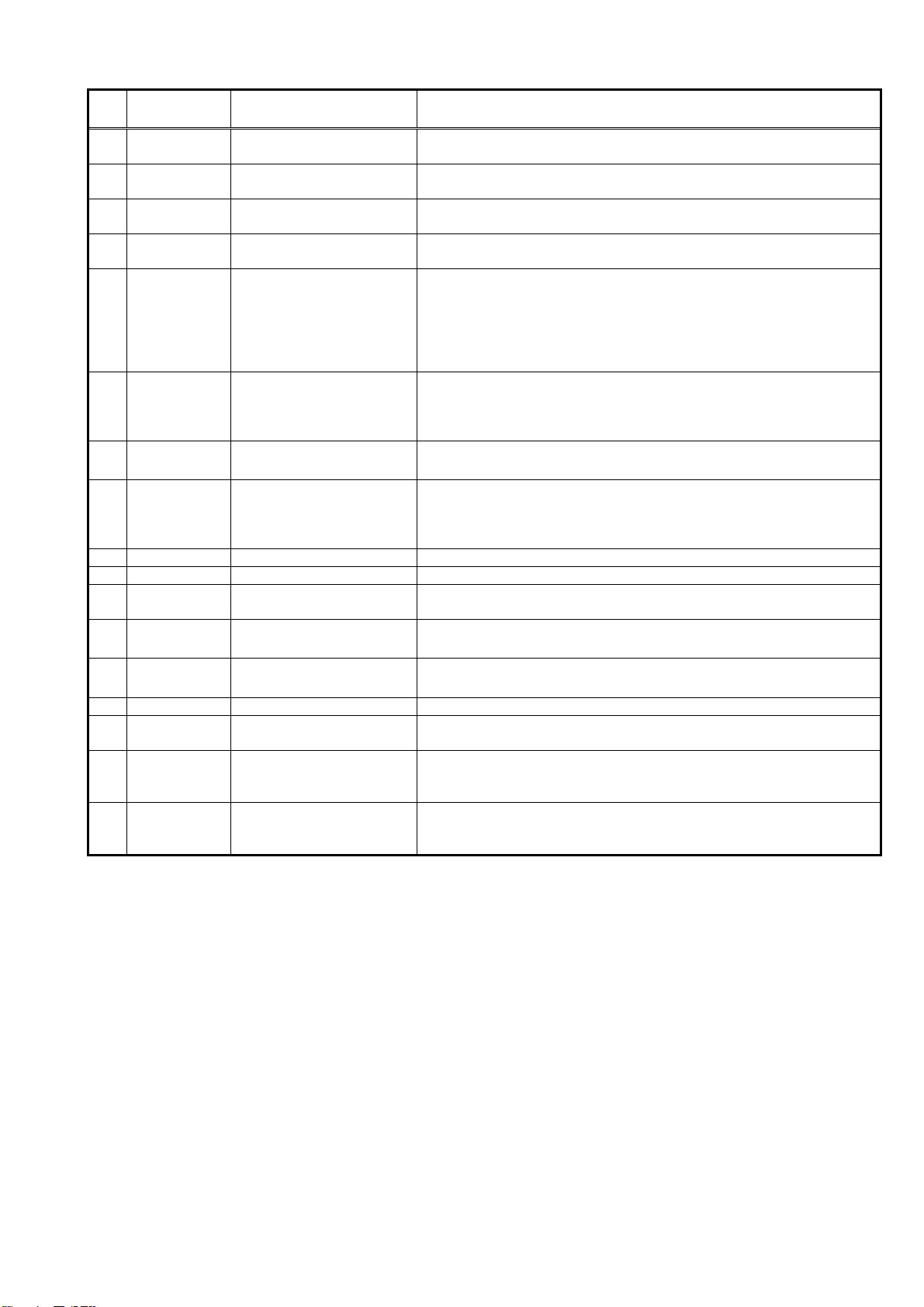

To determine which servicing fixtures and tools are required for each adjustment, refer to the following table.

No. Parts No. NAME

1 2 VFM3010EDS

VFM3110EDS

3 VFM3000LS DV Alignment Tape (Linearity) 1-8. LISTA Sensitivity Detection (SEC.3)

4 5 VVS0026

VVS0027

6 VFK1481N LISTA Software 1-8. LISTA Sensitivity Detection (SEC.3)

VFK1308P

7

VFK1309A

8

VFK1763

9

VFK1982

10

VJA0941

11

VFK1317

12

13 VFK1809 72mm Attachment Ring 4-5. Zoom tracking adjustment (SEC.4)

14

VFK1164TAR43

15

VFK1164TCM01

16

VFK1345

17

VFK1346

18

VFK1659

19

VFK1660

20 VFK1341 CC Filter (LB40) 4-6-4. White balance adjustment (3600K) (SEC.4)

21 VFK1342 CC Filter (LB80) 4-6-3. White balance adjustment (4500K) (SEC.4)

22 VFK1347 CC Filter (LB120) 4-6-2. White balance adjustment (5100K) (SEC.4)

23

VFK1884

24

VFK1888

25

VFK1885

26

VFK1886

27 VFK1887 CC Filter (CC C20) 4-6-3. White balance adjustment (4500K) (SEC.4)

28 VFK1409A Measuring Board 1-8. LISTA Sensitivity Detection (SEC.3)

29 VFK1899 Post Driver 1-9. LISTA Linearity Adjustment (SEC.3)

30

VFK1810

31

VFK1186

32

VFK1300

DV Alignment Tape (Color bar)

DV Alignment Tape (Color bar)

EVR Adjustment Software 4. ADJUSTMENT PROCEDURE (CAMERA SECTION) (SEC.4)

Measuring Board

EVR Connector Board

Connection Adapter

Extension Cable

DC Cable

30pin Flat Cable

43mm Attachment Ring

Collimator Set (Infinity Lens)

CC Filter Holder

Step Down Ring

Step-Up Ring (43mm-49mm)

Step-Up Ring (49mm-62mm)

CC Filter (LBA2)

CC Filter (LBB6)

CC Filter (LBB2)

CC Filter (CC C10)

LISTA Measuring Board

LISTA Cable

A/D Converter Board

5-2. PG shifter adjustment (SEC.4)

1-9. LISTA Linearity Adjustment (SEC.3)

5. ADJUSTMENT PROCEDURE (VTR SECTION) (SEC.4)

1-9. LISTA Linearity Adjustment (SEC.3)

1-8. LISTA Sensitivity Detection (SEC.3)

1-9. LISTA Linearity Adjustment (SEC.3)

1-11. Self-REC/PLAY Envelope Waveform Confirmation (SEC.3)

4. ADJUSTMENT PROCEDURE (CAMERA SECTION) (SEC.4)

5. ADJUSTMENT PROCEDURE (VTR SECTION) (SEC.4)

4-6-2. White balance adjustment (5100K) (SEC.4)

4-6-3. White balance adjustment (4500K) (SEC.4)

4-6-4. White balance adjustment (3600K) (SEC.4)

4-5. Zoom tracking adjustment (SEC.4)

4-6-2. White balance adjustment (5100K) (SEC.4)

4-6-3. White balance adjustment (4500K) (SEC.4)

4-6-4. White balance adjustment (3600K) (SEC.4)

4-6-3. White balance adjustment (4500K) (SEC.4)

4-6-2. White balance adjustment (5100K) (SEC.4)

4-6-4. White balance adjustment (3600K) (SEC.4)

1-9. LISTA Linearity Adjustment (SEC.3)

1-10. Tape Path Confirmation (SEC.3)

1-11. Self-REC/PLAY Envelope Waveform Confirmation (SEC.3)

1-8. LISTA Sensitivity Detection (SEC.3)

1-9. LISTA Linearity Adjustment (SEC.3)

ADJUSTMENT ITEM

INF-3

2. MAINTENANCE

r

Maintenance is done by periodically performing suitable maintenance servicing in order to maintain the best

condition, so that the user can use the equipment safely. Video equipment with mounted mechanisms have parts

which will wear, and their wear and deterioration cause troubles. Dust and dirt also can impair stable operation. For

this reason it is important not to just perform repair at the time of trouble, but also to perform suitable maintenance

at regular intervals.

The maintenance schedule requires replacement of mechanism unit, which contains a cylinder unit and so on.

2-1. Maintenance Schedule

No. Part Name Part No. Cleaning Replacement Remark

--- Tape Transport Part ------ 100 hours ------ *1

1 Mechanism Chassis Unit VXY1903Z1 ------ Every 2000 hours *2

2 Zoom Motor Unit L6DABBHC0001 ------ Every 4000 hours *2

Note:

Hours of use are based on the head rotation hours. (Head rotation hours can be confirm on item HOUR METER in

OTHER FUNCTION menu.)

Hours of use are recommendation. It may depend on temperature, humidity, quality of tape or dust condition.

Hours of use are listed as the reference of maintenance. They do not mean guarantee hours.

*1. Tape Transport part is cleaned by cleaning liquid.

*2. Please refer to the most recent execution outline, as the maintenance specifications and the part numbers may

change.

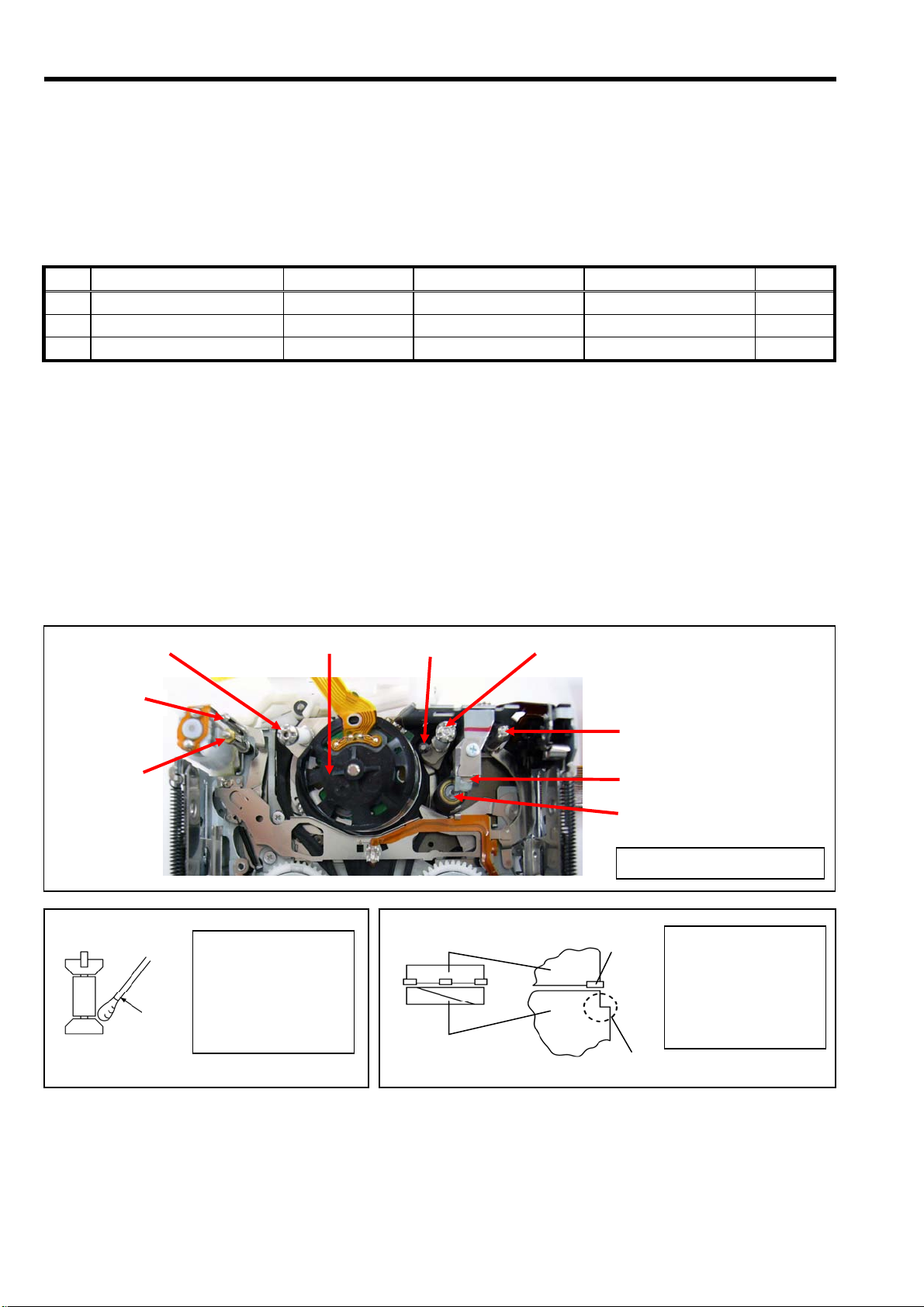

2-2. Cleaning of Tape Transport Part

Please clean the below indicated tape transport p arts with cleaning liquid when needed.

(Tension Post, S1 Post, Cylinder & Heads, T1 Post, T2 Post, T3 Post, Capst an Shaft and Pinch Roller)

Tension Post

S2 Post

S1 Post

Thin

stick

When cleaning the

post, wrap a cloth on a

pick. Wipe each post

with a cloth dipped in

cleaning liquid. And

wipe it again with dry

cloth.

Cylinder

Upper Cylinder

Lower Cylinder

T2 Post T1 Post

T3 Post

Capstan Shaft

Pinch Roller

LOADING condition

Head

Lead

Do not forget cleaning

the upper Cylinder,

Head, tape transport

part of Lower Cylinde

and Lead, when

cleaning the Cylinder.

INF-4

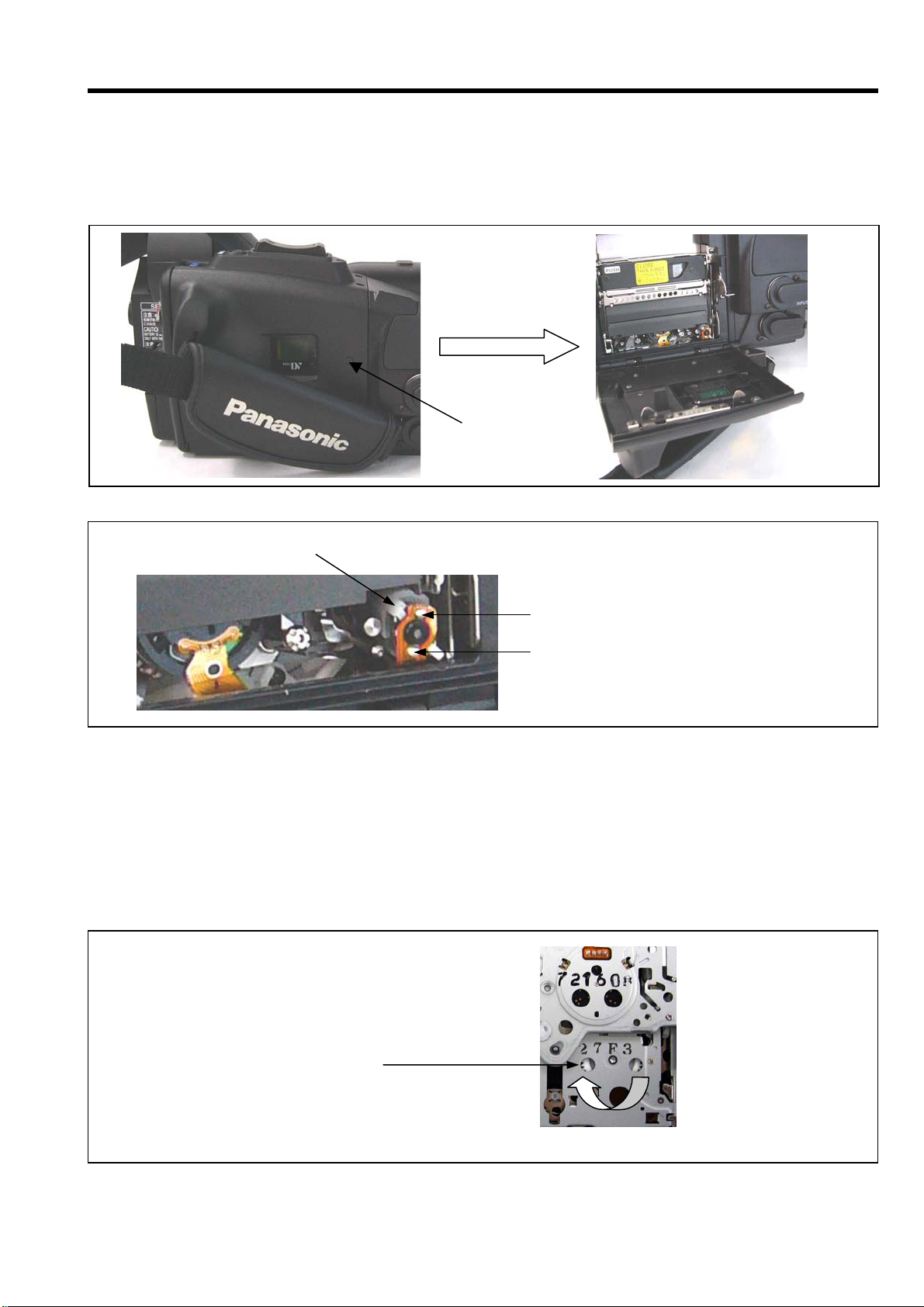

3. MANUAL TAPE EJECT (EMERGENCY EJECT)

When the tape cannot be ejected by norm al operation because of trouble in the elec trical system or mechanical

system, the tape can be removed from the unit manually by using the following method.

NOTE: By below indicated m ethod, the unit will not tak e up tape slack. Be careful when r emoving the tape f rom

Cassette Holder.

1. Unscrew the screw (A) and open the cassette cover as shown in figure.

2. Supply 4.5 Volts using 3 AA batteries in series to unload the posts using the motor.

3. Stop supplying the power when the tape is ejected and remove the tape from Cassette Holder.

<How to rolls up tape>

Be sure to take up the tape slack so that tape does not become damaged.

1. Remove the Mechanism Unit.

2. Supply 4.5 Volts to unload the posts using the motor.

3. Stop supplying the power at unloading complete position.

NOTE: If power is supplied too long, then the Cassette tape will be ejected prematurely.

4. Turn the Gear of Supply Reel as shown in figure, and this will take up the slack in the tape.

5. Supply 4.5 Volts again to eject the tape using the motor and remove the tape from Cassette Holder.

LOADING MOTOR

Turn this Gear with the tip of

a tweezers.

SCREW (A)

UNLOADING ............A: +4.5 V B: GND

LOADING ................. A: GND B: +4.5V

(B)

(A)

(Bottom side of Mechanism)

INF-5

4. LITHIUM BATTERY

4-1. Replacement Procedure

1. There is a Lithium battery on the BACK CONNECT C.B.A.

2. Unsolder the Lithium battery a nd then r eplace with the new one. Please refer to item “16. Remov al of BACK

CONNECT C.B.A.” in section 2(Disassembly Procedure) about how removal of BACK CONNECT C.B.A..

NOTE:

The lithium battery is a critical component.

It must never be subjected to excessive heat of discharge.

It must therefore only be fitted in equipment designed specifically for its use.

Replacement batteries must be of the same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts

observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

VTR C.B.A.

(LI-BATT)

IC2002<3>

(REAL TIME CLOCK)

P2002 P53

11

RTC_3V 60B 60A

B51

BACK_CONNECT C.B.A.

BACK CONNECT C.B.A.

LITHIUM BATTERY

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the equipment manufacturer.

Discard used batteries according to manufacture’s instructions.

INF-6

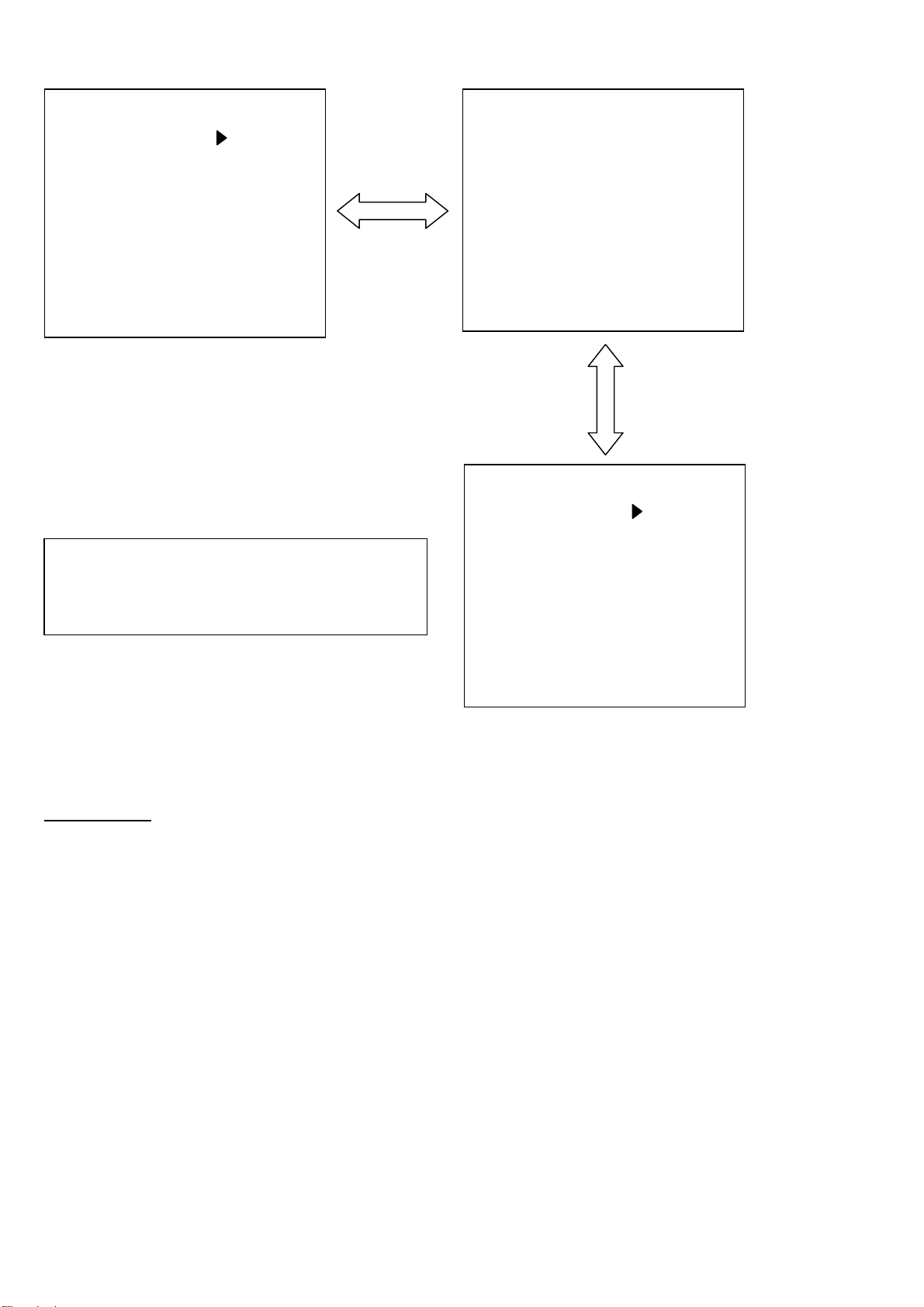

5. SERVICE MENU

The SERVICE(CAMERA mode), DIAGNOSTIC(VCR mode) and ADJUST(VCR mode) menu can be displayed as

follows.

Press the button in order of “ADUB button” → “STOP button” → “MODE CHK button” → “MENU button”,

SERVICE menu in CAMERA mode, DIAGNOSTIC and the ADJUST menu in VCR mode can be displayed in

addition to a setup menus.

■

Next, Tilt the OPERATION lever in the UP( ► :PLAY) or DOWN (

ADJUST menu, press SET(STILL) of the OPERATION lever to open the DIAGNOSTIC or ADJUST menu.

Normal Screen

(CAMERA mode)

Press the button in order of “ADUB

button” → “STOP button” → “MODE

CHK button” → “MENU button”.

1. SCENE FILE

2. CAMERA SETUP

3. SW MODE

4. AUTO SW

5. RECORDING SETUP

6. DISPLAY SETUP

7. OTHER FUNCTIONS

SERVICE MENU

CAMERA MENU

PUSH MENU TO EXIT

1. PLAYBACK FUNCTIONS

2. RECORDING SETUP

3. AV IN/OUT SETUP

4. DISPLAY SETUP

5. OTHER FUNCTIONS

DIAGNOSTIC MENU

ADJUST MENU

:STOP) direction, select the DIAGNOSTIC or

Normal Screen

(VCR mode)

VCR FUNCTIONS

PUSH MENU TO EXIT

INF-7

5-1. SERVICE MENU (CAMERA mode)

DEFFECT COMP OFF

AUDIO FILTER ON

VTR SUB MICON 1.001

VTR MAIN MICON 1.77-P-F

VTR EEPRPM 0.007

VTR EEPROM SUM D7EF

CAM MICON 0.D0

CAM EEPROM 0.CA

SERVICE MENU

CYLINDER 10000H

TAPE RUN 10000H

THREADING 10000T

Y LEVEL 1B

C LEVEL 27

DIF INFO OFF

DEBUG DISP OFF

DEBUG MODE OFF

PUSH MENU TO RETURN

NOTE: Please do not change the setting of the

items of “DEFFECT COMP”, “DEBUG

DISP” and “DEBUG M ODE”. These items

are for factory use only.

Factory default setting is “OFF”.

LCD OFFSET OFF

EVF OFFSET OFF

5-1-1. Audio Filter

AUDIO F ILTER

ON: The mechanism noise cancellation function operates by IC3001(DUO).

OFF: The mechanism noise cancellation function does not operates by IC3001(DUO).

Factory default setting is “ON”.

SERVICE MENU

PUSH MENU TO RETURN

SERVICE MENU

PUSH MENU TO RETURN

INF-8

5-1-2. Software Version Display.

This unit have three pieces of microprocessor and two pieces of EEPROM.

--- CAMERA board VTR board

Microprocessor IC301 IC2001(VTR MAIN MICON) IC3001(VTR SUB MICON)

EEPROM IC307 IC2006 ---

VTR C.B.A.(Foil side)

CAMERA C.B.A.(Foil side)

IC3001

IC2001

IC2006

IC301

IC307

This indicates the

value of the chec k sum

value of the VTR

EEPROM displayed in

hexadecimal.

DEFFECT COMP OFF

AUDIO FILTER ON

VTR SUB MICON 1.001

VTR MAIN MICON 1.77-P-F

VTR EEPRPM 0.007

VTR EEPROM SUM D7EF

CAM MICON 0.D0

CAM EEPROM 0.CA

SERVICE MENU

PUSH MENU TO RETURN

The version of VTR, and the

CAMERA microprocessor,

VTR and CAMERA EEPROM

are displayed.

(In case of VTR MAIN MICON)

- P - F

*.**

Version Number

F = FLASH

M = MASK

N = NTSC

P = PAL

5-1-3. Hour Meter Display.

CYLINDER 10000H

TAPE RUN 10000H

THREADING 10000T

Y LEVEL 1B

C LEVEL 27

DIF INFO OFF

DEBUG DISP OFF

DEBUG MODE OFF

ITEM Display Data Description

TAPE RUN 00000H – 99999H It displays the time that the tape is running in units of hours.

THREADING 00000T – 99999T It displays the number of times the tape is inserted.

CYLINDER 00000H – 99999H

SERVICE MENU

TAPE RUN, THREADING are

displayed in addition to the rotating

time of the Cylinder (CYLINDER).

PUSH MENU TO RETURN

It displays the t ime that the c ylinder is r otating in units of hours.

It displays same tim e as in the item HOUR METER of OT HER

FUNCTION menu.

INF-9

5-1-4. Adjustment item for Video Level

Y LEVEL

Y level of VIDEO OUT and S-VIDEO OUTPUT signal can be adjusted on this item.

The displayed value is the same as value for Luminance level adjustment in EVR adjustment.

C LEVEL

C level of VIDEO OUT and S-VIDEO OUTPUT signal can be adjusted on this item.

The displayed value is the same as value for Chroma level adjustment in EVR adjustment.

5-1-5. DIF Status Display.

CYLINDER 10000H

TAPE RUN 10000H

THREADING 10000T

Y LEVEL 1B

C LEVEL 27

DIF INFO OFF

DEBUG DISP OFF

DEBUG MODE OFF

NORMAL: The DIF STATUS display is updated every five frames.

FAST: The DIF STATUS display is updated every frame.

Factory default setting is “OFF”.

Items Description Remark

NODECNT Number of NODE connections.

MY_ID NODE ID of this unit.

ROOT_ID ROOT ID

IRM_ID PHY ID of IRM IRM(Isochronous Resonance Manager)

IN_CH Input channel number of Isochronous data.

OUT_CH Output channel number of Isochronous data.

DIFMODE DIF mode

RX_IN Received condition of Isochronous data.

O_BCC Transmitted condition of Isochronous data.

STYPE Type of VIDEO signal

FIELD NTSC/PAL

SPEED Speed of Isochronous data. IN_SPD in VCR MODE

UID USER ID of 1394 equipment

AS Source pack of AUDIO

ASC Source control pack of AUDIO

VS Source pack of VIDEO

VSC Source control pack of VIDEO

HEADER HEADER pack

SERVICE MENU

PUSH MENU TO RETURN

OFF

NORMAL

FAST

Set the item “DIF INFO” to NORMAL

or FAST and it does ON/OFF of the

DIF STATUS display b y pressing the

MODE CHECK button on normal

screen.

INF-10

5-1-6. LCD/EVF Correction

LCD OFFSET

LCD OFFSET OFF

EVF OFFSET OFF

EVF OFFSET

LCD OFFSET OFF

EVF OFFSET OFF

SERVICE MENU

PUSH MENU TO RETURN

SERVICE MENU

PUSH MENU TO RETURN

R signal output to LCD is corrected.

OFF

1

2

1: Correction level 1

2: Correction level 2

R signal output to EVF is corrected.

OFF

1

2

1: Correction level 1

2: Correction level 2

INF-11

5-2. DIAGNOSTIC MENU (VCR mode)

y

f

A

5-2-1. How to display the Error Rate.

This unit can be displayed Error Rate and it shows the playing condition of the VCR.

In case of the error rate is displayed, BER DISPLAY and SAMPLE SPEED mode is select on DIAGNOSTIC menu.

BER DISPLAY OFF

SAMPLE SPEED SLOW

DIF INFO OFF

CYLINDER 10000H

TAPE RUN 10000H

THREADING 10000T

BER DISPLAY TOTAL

SAMPLE SPEED SLOW

DIF INFO OFF

CYLINDER 10000H

TAPE RUN 10000H

THREADING 10000T

When selecting TOTAL in BER DISPLAY

mode, it is displayed “TOT” and if select

VIDEO, it is displayed “VID” and if select

AUDIO, it is displayed “AUD”.

TOT

TOT

DIAGNOSTIC MENU

PUSH MENU TO EXIT

DIAGNOSTIC MENU

PUSH MENU TO EXIT

CH1

CH2

CH1

CH2

OFF

VIDEO

AUDIO

TOTAL

SLOW

FAST

Select the item BER DISPLAY and press

SET(STILL) of OPERATION LEVER.

Select VIDEO, AUDIO or TOTAL b

OPERATION LEVER and press SET(STILL) o

OPERATION LEVER.

Factory default setting is “OFF”.

fter selecting BER DISPLAY mode, move to

item of SAMPLE SPEED by tilt the

■

OPERATION LEVER in the DOWN (

direction.

Select SLOW or FAST by OPERATION LEVER

and press SET(STILL) of OPERATION LEVER.

Factory default setting is “SLOW”.

The Audio Level Meter is change to error rate

display, when returning to the normal screen.

NOTE:

The display screen is changed only in the VCR

mode.

The color of the bar

In case of green display: Error rate is good

In case of red display: Error rate is bad

:STOP)

How to confirm the Error rate.

1. Select the TOTAL in item of BER DISPLAY.

2. Record the color bar signal on LP mode and playback the recorded portion. Confirm that the number of bar on

display within 10 bars or less. The less bars displayed the better the error rate.

INF-12

5-2-2. Other item.

A

y

BER DISPLAY OFF

SAMPLE SPEED SLOW

DIF INFO OFF

CYLINDER 10000H

TAPE RUN 10000H

THREADING 10000T

DIAGNOSTIC MENU

These items are displayed even by the CAMER

SERVICE menu. (refer to item 5-1-3 and 5-1-5. )

PUSH MENU TO EXIT

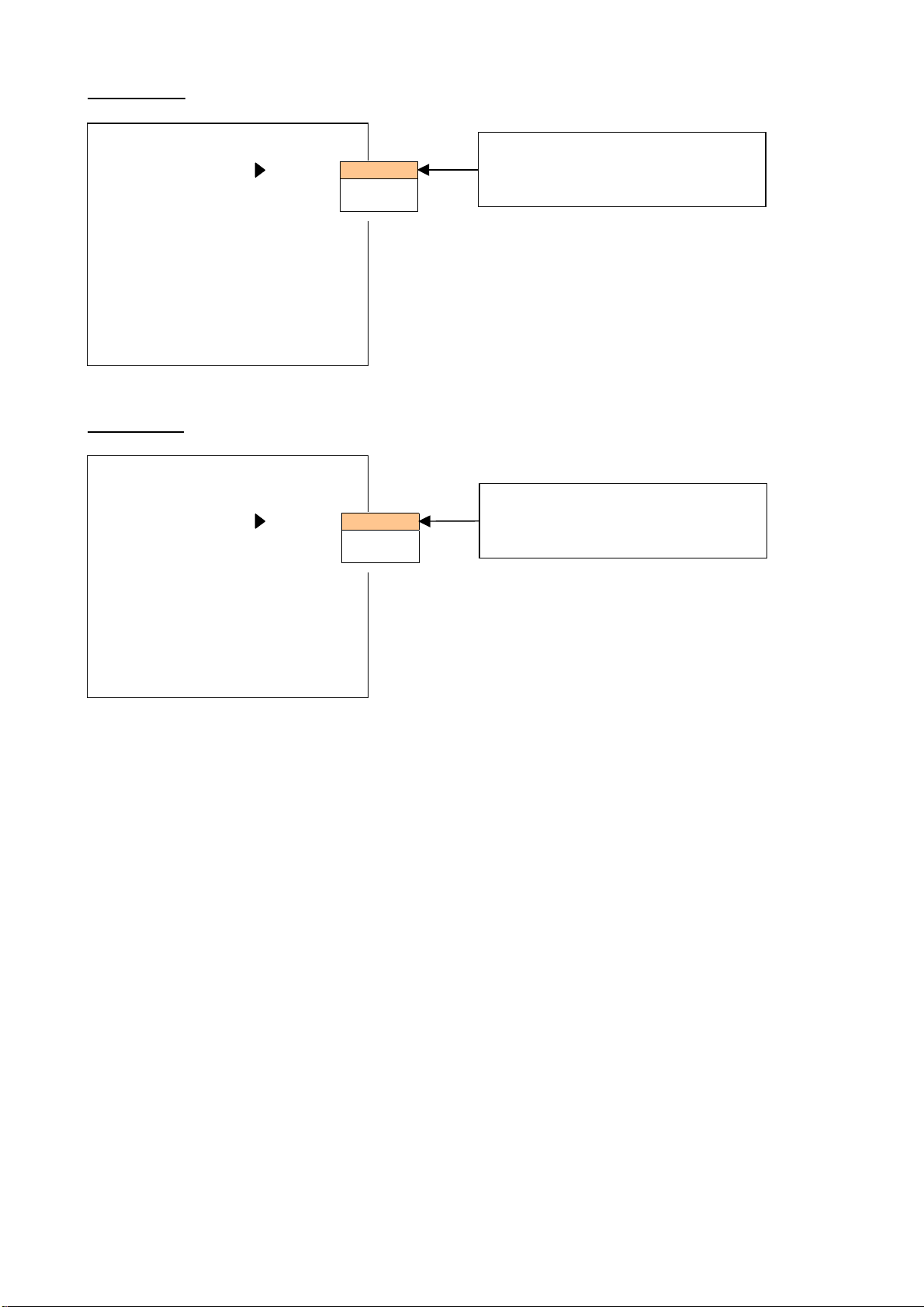

5-3. ADJUST MENU (VCR mode)

ATF GAIN OFF

LINEARITY OFF

AUDIO FILTER ON

Y LEVEL 1B

C LEVEL 27

DEBUG DISP OFF

DEBUG MODE OFF

LCD OFFSET OFF

EVF OFFSET OFF

NOTE: Please do not change th e setting of t he items of “ DEBUG DISP” and “DEBUG MODE”. T hese items

are for factory use only.

ADJUST MENU

Setting item for LISTA Measurement

These items are d ispl ayed even by

the CAMERA SERVICE menu.

(refer to item 5-1-1 and 5-1-4. )

PUSH MENU TO EXIT

These items are d ispl ayed even b

the CAMERA SERVICE menu.

(refer to item 5-1-6. )

ADJUST MENU

PUSH MENU TO EXIT

INF-13

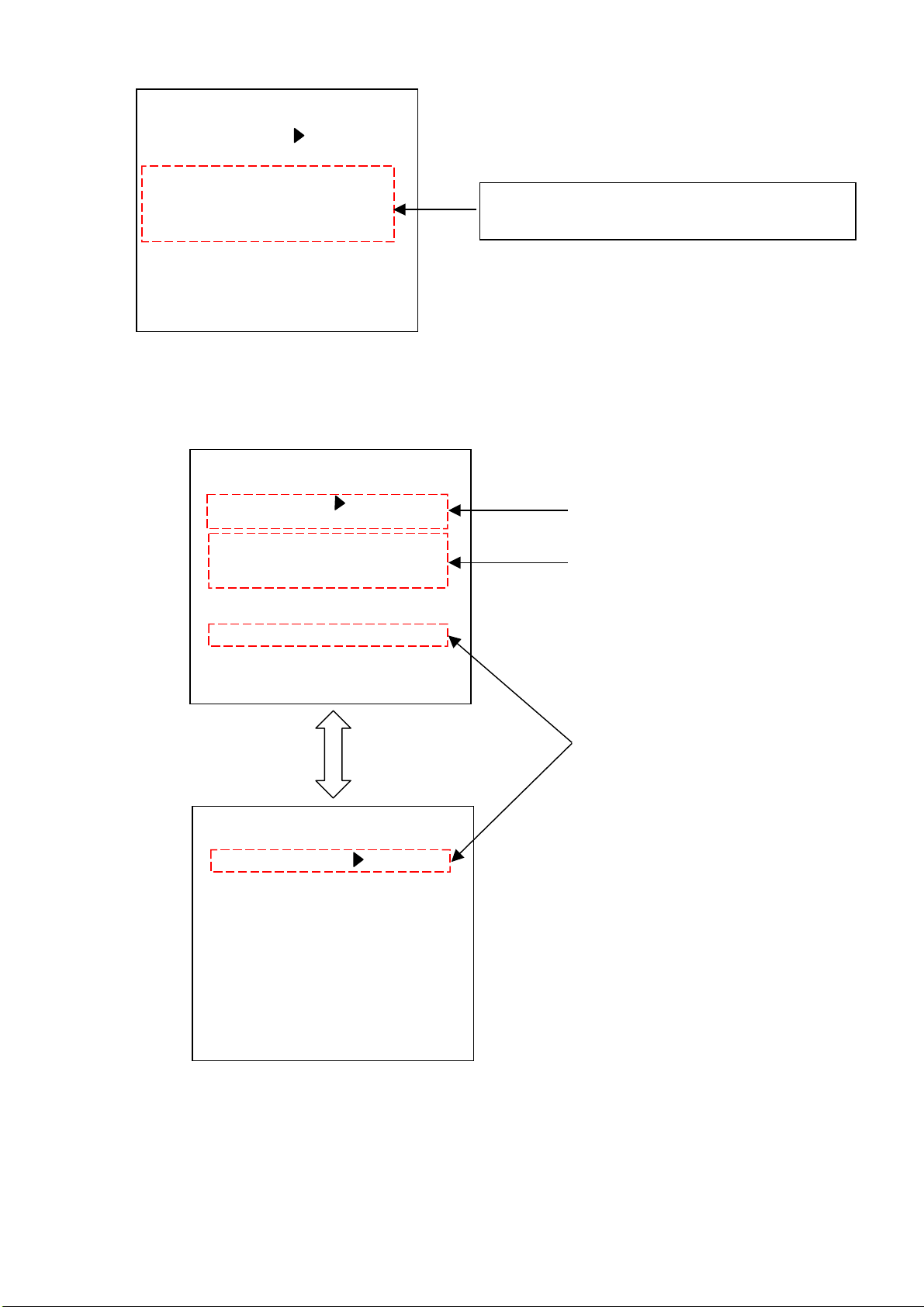

5-3-1. Setting item for LISTA Measurement

ATF GAIN

The speed of the tape changes if this item set to “ON” for the ATF sensitivity confirmation.

After selected “ON” , By pressing SET(STILL) of OPERATION LEVER, enter the adjustment mode an d t hen e x it th e

menu once. The VTR mode is operated when the menu mode is exited temporarily. The screen below is displayed.

NOW SERVO ADJUST

PUSH MENU TO RETURN

It will be returned to ADJUST MENU when the MENU button is pressed in this condition.

ATF GAIN OFF

LINEARITY OFF

AUDIO FILTER ON

Y LEVEL 1B

C LEVEL 27

DEBUG DISP OFF

DEBUG MODE OFF

LCD OFFSET OFF

LINEARITY

The ATF sensitivity changes if this item set to “ON” for the LINEARITY confirmation.

After selected “ON” , By pressing SET(STILL) of OPERATION LEVER, enter the adjustment mode an d t hen e x it th e

menu once. The VTR mode is operated when the menu mode is exited temporarily. The screen below is displayed.

PUSH MENU TO RETURN

It will be returned to ADJUST MENU when the MENU button is pressed in this condition.

ADJUST MENU

PUSH MENU TO EXIT

NOW SERVO ADJUST

After selected “ON”, By pressing SET(STILL) of OPERATION LEVER

OFF

ON

(Adjustment mode screen)

NOW SERVO ADJUST

PUSH MENU TO RETURN

Press MENU button.

INF-14

6. EEPROM

Several information are stored in EEPROM. Please refer to below explanation, which data stored in EEPROM.

6-1. Each Menu Data

6-1-1. Setting menu data

1. SCENE FILE

2. CAMERA SETUP

3. SW MODE

4. AUTO SW

5. RECORDING SETUP

6. DISPLAY SETUP

7. OTHER FUNCTIONS

CAMERA MENU

PUSH MENU TO EXIT

n : Each setting value are stored in VTR EEPROM.

▲ : Each setting value are stored in CAMERA EEPROM.

NOTE1: The item “PROGRESSIVE” and “NAME EDIT” in SCENE FILE screen, which is stored in VTR EEPROM.

NOTE2: The item “Aspect CONV” in CAMERA SETUP screen, which is stored in VTR EEPROM.

6-1-2. SERVICE menu data

Please refer to as follows.

ITEM STORED IN

DEFECT COMP X

AUDIO FILTER VTR EEPROM

VTR SUB MICON VTR SUB MICON (IC3001)

VTR MAIN MICON VTR MAIN MICON (IC2001)

VTR EEPROM VTR EEPROM

VTR EEPROM SUM VTR EEPROM

CAM MICON CAM MICON (IC301)

CAM EEPROM CAM EEPROM

CYLINDER VTR EEPROM

TAPE RUN VTR EEPROM

THREADING VTR EEPROM

Y LEVEL VTR EEPROM

C LEVEL VTR EEPROM

DIF INFO X

DEBUG DISP X

DEBUG MODE X

LCD OFFSET VTR EEPROM

EVF OFFSET VTR EEPROM

VCR FUNCTIONS

▲

▲

▲

▲

n

n

n

1. PLAYBACK FUNCTIONS

2. RECORDING SETUP

3. AV IN/OUT SETUP

4. DISPLAY SETUP

5. OTHER FUNCTIONS

PUSH MENU TO EXIT

n

n

n

n

n

Common display items

INF-15

6-1-3. DIAGNOSTIC menu data

Please refer to as follows.

ITEM STORED IN

BER DISPLAY X

SAMPLE SPEED X

DIF INFO X

CYLINDER VTR EEPROM

TAPE RUN VTR EEPROM

THREADING VTR EEPROM

6-1-4. ADJUST menu data

Please refer to as follows.

ITEM STORED IN

ATF GAIN X

LINEARITY X

AUDIO FILTER X

Y LEVEL VTR EEPROM

C LEVEL VTR EEPROM

DEBUG DISP X

DEBUG MODE X

LCD OFFSET VTR EEPROM

EVF OFFSET VTR EEPROM

6-1-5. The other data

Except setting menu data, below indicated information are stored in EEPROM.

EEPROM INFORMATION REMARK

CAMERA EEPROM

VTR EEPROM

CAMERA adjustment value Adjustment values are set by EVR software.

Control data ------------------

VTR adjustment Value

HOUR METER ------------------

Time code data -----------------Control data ------------------

Adjustment values are set by EVR software or

SERVCE/ADJUST menu.

INF-16

7. CAMERA REMOTE

The operation of zoom operation and record start/stop can be remotely controlled by connecting a remote controller

with ZOOM S/S remote jack.

The operation of focus and iris operation can be remotely controlled by connecting a remote controller with

FOCUS/IRIS remote jack.

NOTE: CAMERA remote control is only effective in the CAMERA mode.

7-1. ZOOM S/S REMOTE

Please refer to below indicated specification, When external remote is checked.

Terminal (refer to figure A) Contents

A Record start/stop input

B Zooming control input

C GND

7-1-1. Record start / stop input

Every time A terminal connects with the GND, it repeats recording and a recording stop.

7-1-2. Zooming control input

With the voltage to input to the B terminal, the zoom speed changes. As for the relation between the zoom control

voltage and the zoom speed, it is as shown in the following.

Relation between the zoom control voltage and zoom speed

Zoom speed (sec.)

Zoom control voltage (V)

Figure B

Equivalent circuit of ZOOM S/S REMOTE jack

Measuring point of zoom control voltage

Figure A

NOTE:

The control voltage and the

zoom speed, which are shown

below are a reference value.

Because there is a little

difference, see as t he reference

data.

INF-17

7-2. FOCUS/IRIS REMOTE

Please refer to below indicated specification, When external remote is checked.

Terminal (refer to figure A) Contents

A GND

B FOCUS control input

C IRIS control input

D IRIS(AUTO/MANU) switch input

Equivalent circuit of FOCUS/IRIS REMOTE jack

Figure C

7-2-1. Focus control input

With the voltage to input to the B terminal, the focus is changes. As for the relation between the focus control

voltage and the focus, it is as shown in the following.

Relation between the focus control voltage and focus

FOCUS

NEAR

When terminal B is open, the focus remote control becomes invalid.

0Ω 10kΩ 20kΩ

FAR

0 0.5

Focus control voltage (V)

1.0 1.5 2.0

NOTE:

The control voltage and the

focus, which are shown below

are a reference value . Because

there is a little difference, see

as the reference data.

Figure D

4-pole / 3.5mm diameter

INF-18

Loading...

Loading...