Page 1

®

TRANSPORTER

Installation & Operating Instruction Manual

Page 2

P/A INDUSTRIES INC.

The Original Transporter.

The Transporter is a totally unique material handling device.

Protected under USA and foreign patents, these low profile,

beltless conveyors are pneumatically powered and have

become a cost effective alternative to conventional conveyors.

There are no belts or bearings to wear out or maintain.

The rhythmic vibrating or shaking motion moves parts or

scrap along a custom tray or chute designed to fit your tool or

application. Trays can be fabricated out of various materials

to suit any size opening and transport the pieces into the

parts bin or scrap container.

Contact our Sales Application Engineering Department for a

free video showing several different ways customers have

used the Transporter.

APPLICATIONS .................................................................... 3

INSTALLATION .................................................................... 4

MODEL TP-3 SERVICE ....................................................... 6

MODEL TP-10 SERVICE ................................................... 10

MODEL TP-40 SERVICE ................................................... 14

MODEL TP-70 SERVICE .................................................... 18

MODEL TP-140 SERVICE ................................................. 22

TECHNICAL DATA .............................................................. 26

RECOMMENDED TRAY SUPPORTS ................................ 27

2

Page 3

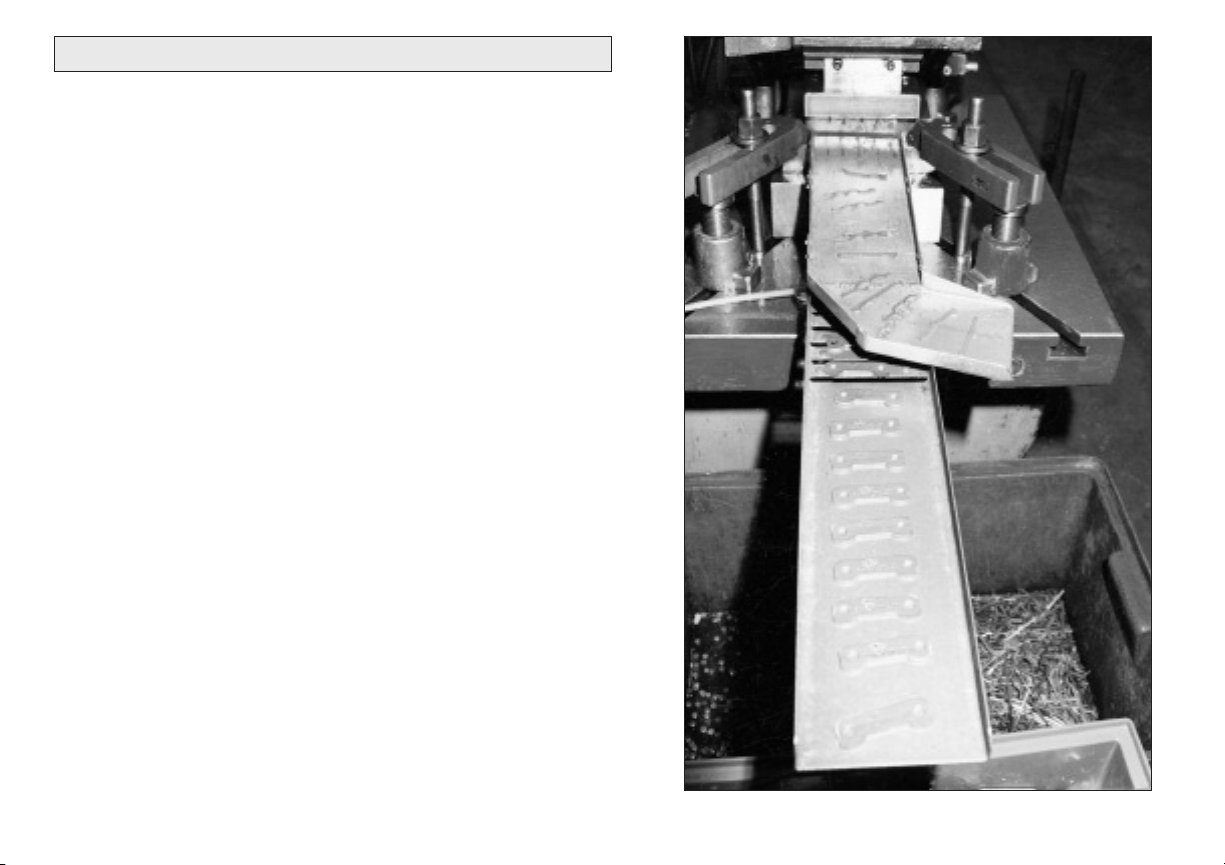

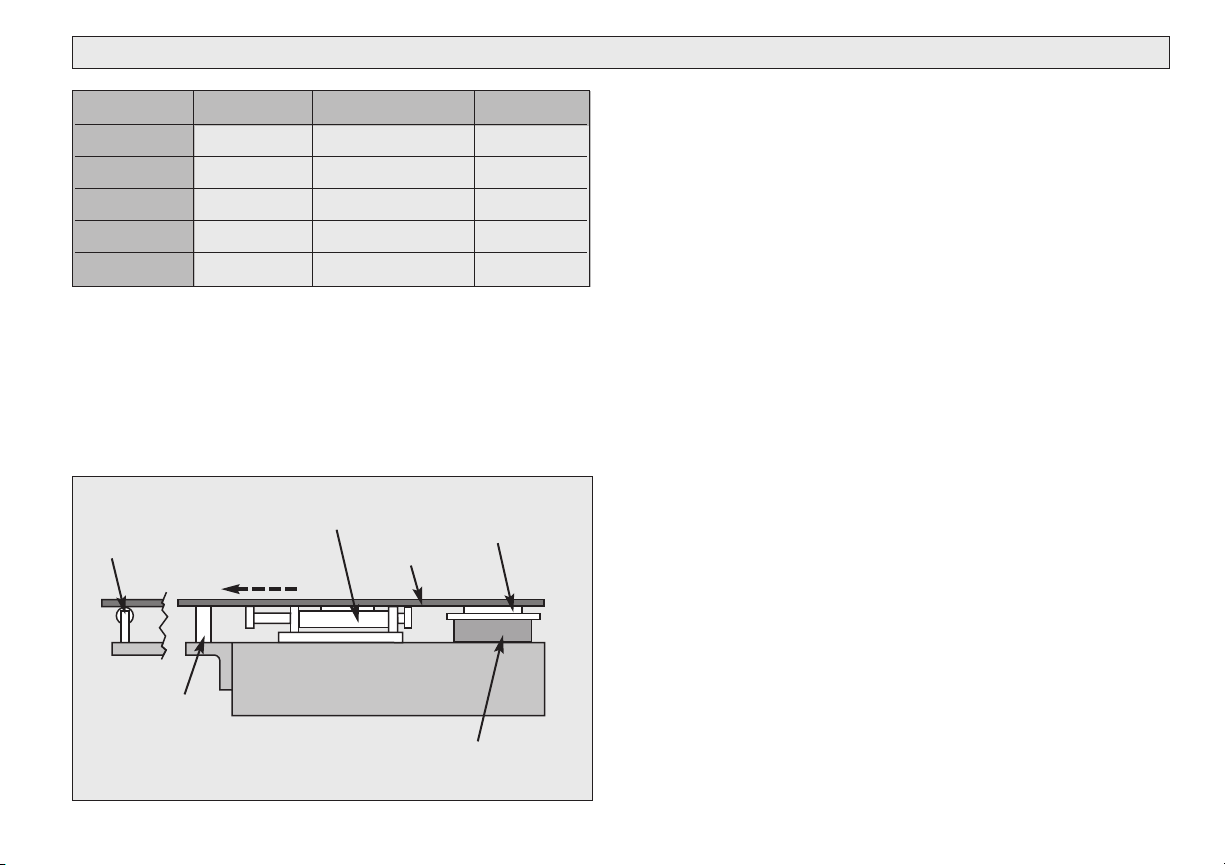

APPLICATIONS

Third Stage Blank

Second Stage Punch

First Stage

Pierce

U.S. PATENT NO.

4,444,346

Model TP-10

Transporter

Upper Tray for

Parts Removal

Model TP-10

Design the tray

configuration

to suit your application

Feed

Direction

Progressive Die

Lower Tray

Scrap

Slugs

Lower Tray for

Scrap Removal

Stamped Part

3

Page 4

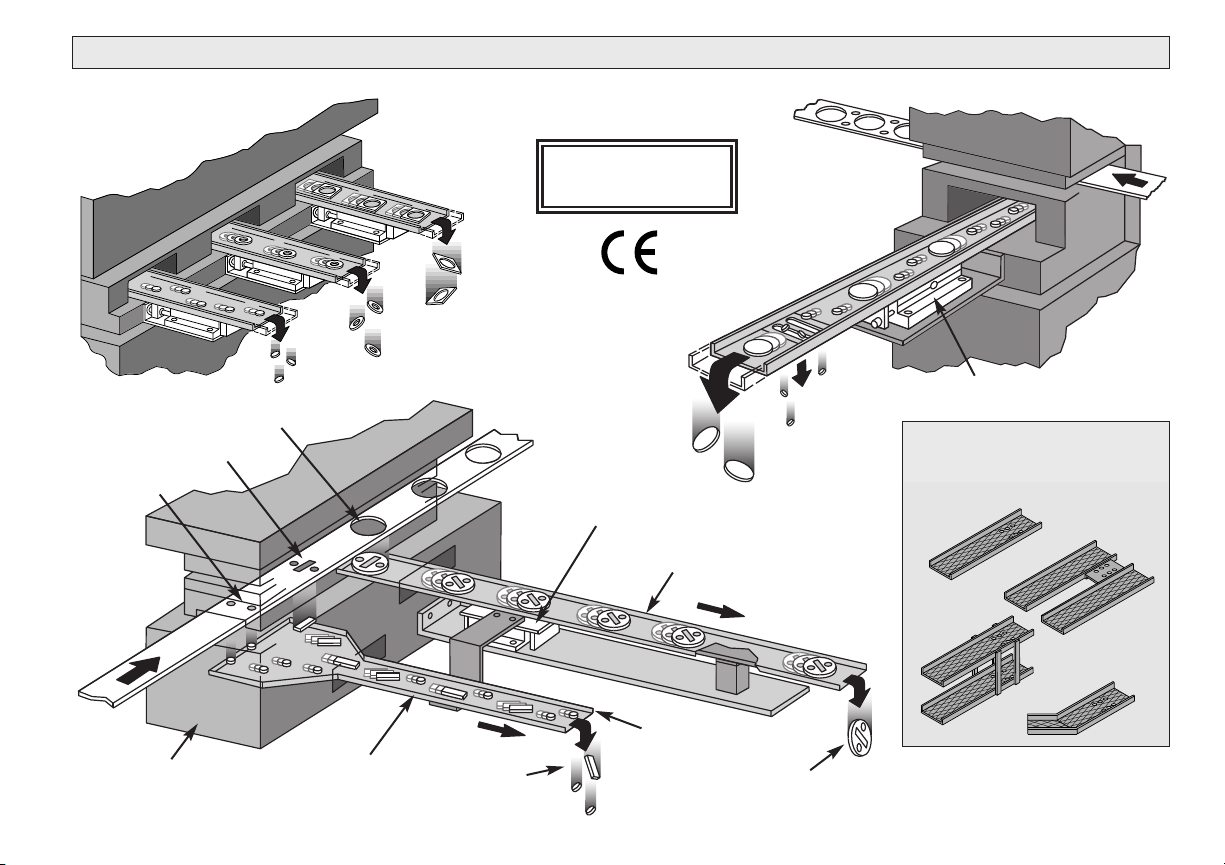

INSTALLATION

60

(4)

75

(5)

1. Rigidly Mount the Transporter to a solid surface using

these recommended bolts sizes:

Model Quantity Metric Inch

TP-3 4 M 8 5/16

TP-10 4 M 8 5/16

TP-40 2 M10 3/8

TP-70 6 M 8 5/16

TP-140 6 M 8 5/16

2. Air line requires use of an oil mist-type combination

Filter/Regulator/Lubricator, and Pressure Gauge. Set

pressure to 4-5 Bar (60 to 75 psi). Do not exceed 5.5 Bar

(80 psi) as excess pressure will damage the Transporter.

Recommended Air Line

Connection to Eliminate Moisture

and Particles from Main Line

Main Air Line

Drain

To Transporter

4. Connect the Air Line with flexible poly-flow tubing into

the threaded inlet. On Model TP-3 use 1/4” tubing for

1/8” NPT. Models TP-10, TP-40, TP-70 and TP-140 use

3/8” tubing for 1/4” NPT.

5. A custom “U” profile tray or chute

must be designed to handle each

specific application or tool. Any

material can be used, but we

recommend aluminum or any light

gauge material to reduce tray weight.

Maximum tray weight should not

exceed the following table data:

Max. Weight Max. Weight

Tray & Scrap

Model

Tray Only of Parts

Kg Lbs. Kg Lbs.

TP-3 1,5 3.3 3 6.6

TP-10 3 6.6 10 20

TP-40 15 33 40 80

TP-70 50 110 70 140

TP-140 100 200 140 300

Filter/Regulator/Lubricator

3. Fill the Lubricator with a good grade of hydraulic oil

such as Shell Tellus 32 or equivalent. Set the Lubricator

for one (1) drop per minute.

4

6. Fasten the tray or chute to the Transporter with metric

screws at all holes. Be sure to use spacers or washers

between the Transporter and the tray to reduce contact

friction between the moving tray and the Transporter

body. Refer to the following table.

Page 5

INSTALLATION

Model Quantity Screw size Depth

TP-3 6 M6 8mm

TP-10 6 M6 8mm

TP-40 6 M8 9mm

TP-70 6 M8 8mm

TP-140 6 M8 8mm

7. The Conveyor tray or chute must be supported at

both ends to minimize vibration and deflection. A block of

Delrin GP-500 or Nylon, low friction material can be used

for the tray to slide. For optimum installation, use P/A

Roller Slides to rigidly control the tray movement and

provide trouble-free operation. See page 27.

Ball Bearing

Roller

Solid Slide Low Friction

Material

Transporter

Chute

or Tray

Feed Direction

Press Bolster

Roller Slide

Spacer

8. The Speed Adjustment is preset at the factory with

the correct frequency for a light weight tray or chute.

The speed can be adjusted by turning the screw or knob

clockwise to decrease the movement on the Models

TP-3, TP-10, and TP-40. The TP-70 and TP-140 are

adjusted by turning the screw or knob counter-clockwise

to decrease the movement. Maximum speed is not

required to move parts or scrap efficiently.

9. If the TP-40 Speed Frequency is inadequate, release

the Air Regulator Rod T40-029 and gently push forward

to increase speed or backward to decrease.

10. The TP-10 may require a slight adjustment to

maintain proper speed frequency after a period of

operation. If Speed Adjustment Screw T10-405 does not

slow the unit sufficiently, it may be necessary to slightly

snug the two screws at the Air Regulator Valve T10-401.

This reduces the air being released from the valve and

decreases speed. Snugging the screws too tightly will

cause bending of the Air Regulator Rod and poor

performance.

11. Spray the same Tellus oil used in lubrication on the

pistons each week.

12. If there is a build-up of sticky oil on the conveyor tray

or if the parts or scrap are very oily, they may stick to the

surface and reduce movement. To reduce the coefficient

of friction, try dimpling the surface of the conveyor chute

with a ballpeen hammer or use a different material like

expanded metal or profiled, roll formed material.

5

Page 6

MODEL TP-3 SERVICE

Factory Repair & Rebuild Service

Return the Transporter by UPS Prepaid to our repair center.

After teardown and inspection, P/A Industries will notify you

of the recommended cost for spare parts and labor.

Disassembly Reassembly

1. Remove both Snap Rings and push the Front and

Rear Pistons inside Body.

2. Remove the Screws from the Rear Guide Holder

T3-204. Pull out together with Speed Adjustment

Knob T3-401.

3. Remove the Front Guide Holder T3-203.

4. Remove both Guide Holders (L & R) T3-201 and the

twelve (12) Ball Bearings.

5. Back out the Locking Screw T3-406 and remove the

Speed Adjustment Valve T3-603.

6. With both T3-701 Tools provided in the kit, remove the

Valve Discs and the Rod.

7. Check all “O” Rings, Springs, Discs, and Seals for

damage and replace as needed.

6

1. Install the Speed Adjustment Valve T3-603 and align

with the groove for the Locking Screw T3-406.

2. Insert the Front Piston T3-302 into the Body with the

Bumper Ring.

3. Mount the Bumper Ring and insert the Rear Piston

T3-303 into the Body.

4. Grease both Guide Holders T3-201 and put twelve (12)

Ball Bearings into both Bearing Plates T3-210. Hold

the Bearing Plates by hand while attaching Front and

Rear Holders. The Guide Holder assembly must run

smoothly in both directions without side-to-side

play.

5. Pull both Pistons T3-302 and T3-303 back into position

and secure the Snap Rings.

Page 7

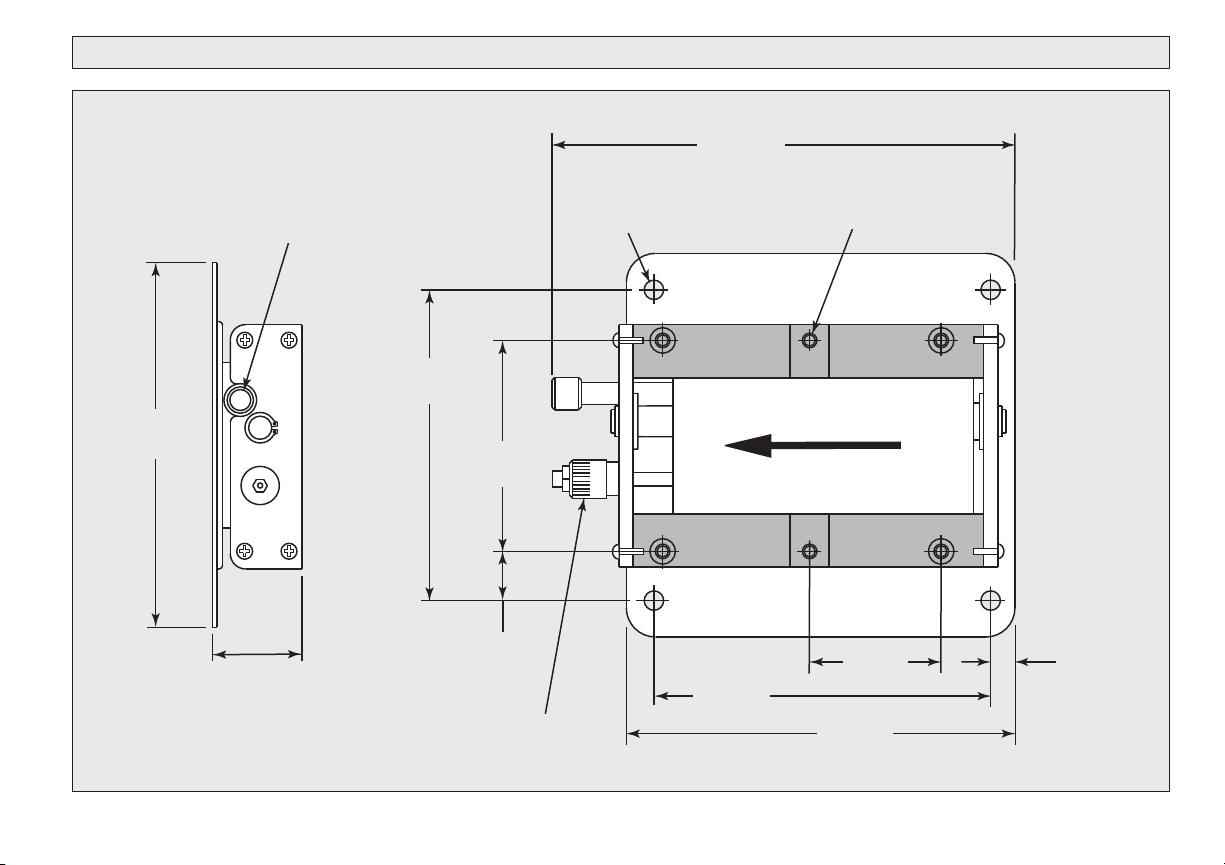

MODEL TP-3 DIMENSIONAL DRAWING

1/8” NPT

4.7”

120mm

5.5”

140mm

1.3”

34mm

Speed Adjustment Knob

3.3”

83mm

.75”

19mm

Use Four

M8 Bolts for

Mounting

7”

178mm

5.1”

130mm

Use Six M6 Screws

8mm Deep Thread

for Tray Mounting

2”

51mm

5.9”

150mm

.4”

10mm

7

Page 8

TP-3 Parts Description

TP-3 Assemblies

Part No. Description Qty

T3-105 Screw 8

T3-107 Air inlet 1

T3-110 Mounting plate 1

T3-111 Mounting plate screw 4

T3-112 Spring pin 4

T3-201 Guide holder (L&R) 2

T3-203 Front guide holder 1

T3-204 Rear guide holder 1

T3-210 Sleeve retainer 2

T3-211 Stainless Steel Ball 12

T3-302 Front piston 1

T3-303 Rear piston 1

T3-307 Grease O-ring 1

*

T3-308 Grease ring 1

T3-311 Valve seal 2

*

T3-322 Rear cup seal 1

*

T3-323 Front cup seal 1

*

T3-327 Bumper ring 2

*

T3-401 Speed adjustment knob 1

T3-402 Speed adjustment rod 1

T3-404 Threaded bushing 1

T3-405 Plug 1

T3-406 Locking screw 1

T3-407 Speed valve O-ring 2

*

T3-309 Knob locking nut 1

T3-412 Speed valve O-ring 1

*

T3-601 Valverod assembly 1

T3-602 Spring assembly 2

T3-603 Valve assembly 1

T3-701 Assembly tool 2

*

T10-209 Snap ring 2

T10-313 Spring 1

T70-306 Knob O-ring (*14208-011) 1

*

Included in Repair Kit 3-001 (17269)

*

8

T3-601 Valve Rod Assembly Qty

T3-310 Valve rod 1

T3-325 O-ring 1

T3-602 Spring Assembly Qty

T3-315 Spring holder 1

T3-407 O-ring 1

T10-313 Spring 1

T3-603 Valve Assembly Qty

T3-402 Valve bar 1

T3-407 O-ring 1

T3-411 Valve 1

T3-412 O-ring 1

Page 9

TP-3 PARTS DRAWING

T3-105

T3-203

*T3-327

T3-110

T3-111

T3-323

*T3-602

T3-601

T3-325

*T3-311

*T3-602

*T3-307

T3-308

*T3-322

T3-303

T3-201

*T3-327

T3-107

* Included in Repair Kit 3-001 (17269)

T10-209

T3-302

T3-112

T3-405

T3-210

T3-211

*T3-407

T3-406

*T3-412

T3-603

T3-402

T3-204

T3-404

*T70-306 (*14208-011)

T3-401

T3-309

9

Page 10

MODEL TP-10 SERVICE

Sample

tray

shown

Disassembly

Factory Repair & Rebuild Service

Return the Transporter by UPS Prepaid to our repair center.

After teardown and inspection, P/A Industries will notify you

of the recommended cost for spare parts and labor.

1. Remove the Guide Column Locking Nuts T10-214

and the Tray Holder Screws T10-210 for the Front

Holder T10-202.

2. Pull out the Front Holder T10-202 together with the Air

Regulator Rod and Nut T10-604 and Threaded Guide

Columns T10-203.

3. Pull out the Rear Holder T10-201 together with the

Rear Pistons T10-303.

4. Remove the Air Inlet T10-601 and O-Ring 14208-119

with an 8 mm hex wrench.

5. Remove the Nut T10-305 from the Piston T10-302.

6. Remove the disc from the Valve Rod using a Phillips

head screwdriver at the T10-325, and a 13 mm socket

at the opposite end.

7. Remove the Piston Valve Assembly T10-606.

10

8. Carefully Disassemble the Piston Valve Assembly.

9. Examine all Springs, “O” Rings, and Valve Discs for

damage and replace as necessary.

Reassembly

1. Verify that the Extension, Inner Disc, and Valve Rod

must be very straight and not overtightened.

2. Assemble all components of the Piston Valve Assembly

T10-606, install in the Transporter Body, and add the

Outer Disc, noting the .015” (.38mm) movement for

proper operation.

3. If many parts have been replaced, the Transporter may

need a brief run-in period before final adjustments are

made.

Page 11

MODEL TP-10 DIMENSIONAL DRAWING

1.8”

45mm

.78”

20mm

4.9”

125mm

1/4” NPT

8.5”

216mm

4.52”

115mm

1.8”

45mm

1.2”

30mm

4.1”

105mm

2.3”

58mm

Speed

Adjustment

Screw

2.6”

67mm

Use Six M6 Screws

8mm Deep Thread for Tray Mounting

2.4”

60mm

Use Four M8 Bolts

for Mounting

11

Page 12

TP-10 Parts Description

TP-10 Assemblies

Part No. Description Qty

T10-106 Guide column sleeve 4

*

T10-201 Rear holder 1

T10-202 Front holder 1

T10-203 Threaded guide column 2

T10-204 Tray holder set (L & R) 2

T10-209 Snap ring 2

T10-210 Tray holder screw 4

T10-212 Urethane washer 4

*

T10-213 Guide column spacer 2

T10-214 Guide column locking nut 4

T10-302 Piston 1

T10-303 Rear piston 2

T10-305 Nut, piston 1

T10-311 Valve disk 2

T10-313 Spring, long 1

T10-314 Spring, short 1

T10-316 Gasket 1

*

T10-318 Valve O-ring (14208-107) 1

T10-319 Rear piston O-ring 2

*

T10-320 Plug O-ring 2

T10-324 Extension 1

T10-325 Spring retaining screw 1

T10-413 Felt 1

T10-414 Snap ring 1

T10-601 Air inlet 1

T10-602 Valve rod assembly 1

T10-603 Air regulator assembly 1

*

T10-604 Air regulator rod & nut 1

*

T10-605 Speed adjustment screw 1

T10-606 Piston assembly 1

*

T40-035 O-Ring (*14208-119) 1

*

Included in Repair Kit 10-001 (17270)

*

T10-601 Air Inlet Assembly Qty

T10-102 Air inlet 1

T40-035 O-ring 1

T10-602 Valve Rod Assembly Qty

T3-325 O-ring 1

T10-310 Valve rod 1

T10-603 Air Regulator Assembly Qty

T10-318 O-ring 1

T10-401 Air regulator 1

T10-403 Urethane washer 1

T10-404 Washer 1

T10-408 Screw 2

T10-604 Air Regulator Rod & Nut Qty

T10-321 Nut 1

T10-402 Air regulator 1

T10-605 Speed Adjustment Screw Qty

T10-405 Speed adjustment screw 1

T10-407 O-ring 1

T10-606 Piston Assembly Qty

T3-325 O-ring 1

T10-302 Piston 1

T10-310 Valve rod 1

T10-311 Disc 2

T10-313 Spring 1

T10-314 Spring 1

T10-320 O-ring 2

T10-324 Extension 1

T10-325 Screw 1

T10-327 Gasket, disc 2

12

Page 13

TP-10 PARTS DRAWING

T10-214

T10-202

*T10-213

T10-212

T10-414

T10-413

T10-605

T10-203

T10-106

*T10-319

T10-303

*T10-212

T10-201

T10-209

T10-210

T10-204

T10-305

*T10-316

T10-325

*T10-602

T10-313

T10-324

T10-320

T10-302

T10-314

T10-311

T10-318 (14208-107)

*T10-603

T10-602

T10-311

*T40-035(*14208-119)

T10-601

*Included in Repair Kit 10-001 (17270)

*T10-606

T3-325

Use 8 mm

Hex

Wrench

13

Page 14

MODEL TP-40 SERVICE

Disassembly

Factory Repair & Rebuild Service

Return the Transporter by UPS Prepaid to our repair center.

After teardown and inspection, P/A Industries will notify you

of the recommended cost for spare parts and labor.

1. Remove the Air Regulator Rod T40-029 by loosening

the set screw in the top of the Slide Frame and slide the

rod out. If the slide is deformed, it must be replaced.

2. Remove the two (2) Flathead Screws, which secure the

Stop Washer T40-027 to the Slide Frame. Remove Nut

T40-072 from back of Piston. Remove the Slide Frame.

3. Remove the Top Plate T40-006 which holds the Air

Regulator T40-608 and Felt Cover T40-009. Check

the Regulator O-Ring T3-407 (14208-008) for damage.

4. Remove the Air Line from Fitting T40-605. Remove the

Plug T40-601 and check the Plug O-Ring T40-037.

5. Remove Air Inlet Cap. Check O-Ring for damage.

6. Remove the eight (8) Flathead Screws T10-210 from

the bottom mounting plate and slide the Piston

Housing away from the body.

14

7. Remove the Valve Disk T40-010 by unscrewing the

Valve Disc Screw. Hold a 3mm hex wrench at the

Valve Rod Washer T40-017 to prevent rotation. It is

now possible to take out the Piston T40-019.

8. To remove the Valve Rod and Disk Assembly T40-603

from the Piston, hold the exposed Valve Disc gently in

a vise. Use the 3mm Hex Wrench and remove the

screw.

9. Replace the Long Valve Spring T40-047 and the

Short Valve Spring T40-046.

Reassembly

Reassemble in reverse order, using caution not to bend

the Valve Disc Assembly.

Page 15

MODEL TP-40 DIMENSIONAL DRAWING

3.5”

89mm

6.3”

160mm

1/4” NPT

Speed Adjustment Screw

Use Six M8 Screws

9mm Deep Thread

for Tray Mounting

9.8”

250mm

Use Two M10 Bolts

for Mounting

2.7”

68mm

3.4”

87mm

3.6”

92mm

1.3”

32mm

.4”

10mm

3.6”

92mm

5.12”

130mm

15

Page 16

TP-40 Parts Description

TP-40 Assemblies

Part No. Description Qty

T3-407 Regulator O-ring (14208-008) 1

T10-210 Flat head screw (6mm) 10

T10-605 Speed adjustment screw 1

T40-001 Foot 1

T40-006 Top plate 1

T40-008 Valve bar 1

T40-009 Felt cover 1

T40-010 Valve disk 1

*

T40-011 Valve seat 1

T40-013 Disc 1

T40-017 Valve rod washer 1

T40-019 Piston 1

T40-026 Slide frame sleeve 4

*

T40-027 Stop washer 2

T40-028 Air inlet 1

T40-029 Air regulator rod 1

T40-031 Small urethane washer 2

*

T40-035 Piston O-ring (*14208-119) 2

*

T40-036 Large O-ring (*14208-325) 1

*

T40-037 Plug O-ring 1

*

T40-038 Guide pin 2

T40-039 Valve rod cup seal 2

*

T40-041 Piston cup seal 2

*

T40-045 Compression spring 1

*

T40-046 Short valve spring 1

*

T40-047 Long valve spring 1

*

T40-049 Washer 2

T40-050 Large urethane washer 4

*

T40-051 Air connection 2

T40-052 Tube 1

T40-055 Flat head screw (5mm) 3

T40-057 Slide frame set screw 1

T40-065 Felt 2

T40-068 Bushing, long 1

T40-069 Bushing, short 1

T40-071 Threaded mounting insert (8mm) 6

T40-072 Plug nut 1

T40-073 Threaded valve seat 1

T40-074 Air inlet O-ring 1

*

T40-601 Plug assembly 1

T40-602 Cylinder front assembly 1

T40-603 Valve rod assembly 1

*

T40-604 Slide frame assembly 1

T40-605 Air tube assembly 1

T40-606 Silencer assembly 1

T40-607 Speed adjustment assembly 1

T40-608 Air regulator rod assembly 1

*

Included in Repair Kit 40-001 (17271)

*

T40-601 Plug Assembly Qty

T40-018 Plug 1

T40-037 O-ring 1

T40-049 Washer 2

T40-050 Damper 2

T40-602 Front Cylinder Assembly Qty

T40-002 Front cylinder 1

T40-016 Sleeve 1

T40-024 Spacer 2

T40-026 Bearing 4

T40-036 O-ring 1

T40-603 Valve Rod Assembly Qty

T40-008 Valve bar 1

T40-013 Disc 1

T40-070 Extension 1

T40-030 Gasket, disc 1

T40-604 Slide Frame Assembly Qty

T40-014 Slide frame 1

T40-031 Damper 2

T40-038 Guide column 2

T40-042 Snap ring 2

T40-054 Screw 2

T40-057 Screw 1

T40-071 Mounting insert 6

T40-605 Air Tube Assembly Qty

T40-051 Air connection 2

T70-052 Tube 1

T40-606 Silencer Assembly Qty

T40-059 Mantel 1

T70-067 Washer 1

T40-607 Speed Adjustment Assembly Qty

T10-407 O-ring 1

T10-405 Screw 1

T40-060 Valve 1

T40-608 Air Regulator Rod Assembly Qty

T3-407 O-ring 1

T40-029 Air regulator rod 1

T40-058 Air regulator 1

16

Page 17

TP-40 PARTS DRAWING

T40-028

*T40-074

*T40-010

*T40-045

T40-011

*T40-039

T40-073

T40-029

T40-006

T40-058

*T40-608

T3-407

T40-009

T10-605

*T40-603

*T40-041

T40-001

*T40-035

T40-019

*T40-036

T40-047

T40-068

T40-017

T10-210

T40-055

T40-601

*T40-037

T40-072

T40-065

T40-069

*T40-046

T40-602

T40-055

T40-071

T40-604

T40-057

*Included in Repair Kit 40-101 (17271)

T40-607

T40-606

T40-027

*T40-050

*T40-026

T40-038

*T40-031

17

Page 18

MODEL TP-70 SERVICE

Disassembly

Factory Repair & Rebuild Service

Return the Transporter by UPS Prepaid to our repair center.

After teardown and inspection, P/A Industries will notify you

of the recommended cost for spare parts and labor.

1. Remove the Spanner Nut T70-216 from the Rear

Piston T70-601 and push the Piston inside the Cylinder.

2. Remove the eight (8) holder screws with a T40 Torx

wrench. Loosen the eight (8) Set Screws T70-436.

There is no need to remove the set screws.

3. Pull the Front and Rear Holders away from the Body

while holding the Outer Guide Assemblies to prevent

the Bearings from being lost. The Front Piston

T70-602 and Shock Absorber T70-407 will come out

with the Front Holder. The Speed Adjustment

Assembly will come out with the Rear Holder.

4. Now remove the Front and Rear Retaining Plates.

The Rear Piston can now be removed from the Body.

5. Back out the Speed Adjustment Valve Locking

Screw T70-311 and remove the Speed Adjustment

Valve T70-604.

18

6. Unscrew Valve Seals T40-010 and pull the seals

out. Check all seals and O-rings for wear, make

sure valve seals are flat, and Valve Rod T70-603

is straight.

Reassembly

When reassembling, take care with the following:

1. Install Speed Adjustment Valve and align indent

for the Speed Adjustment Valve Locking Screw.

2. Remember to install the Front and Rear Cylinder

Urethane Washers T70-257 and T70-259.

3. Use the T70-436 Set Screws to adjust out any

play or looseness in the Slide Assembly before

tightening the Holder Screws.

Page 19

MODEL TP-70 DIMENSIONAL DRAWING

1.8”

46mm

3.0”

77mm

5.5”

140mm

3.9”

99mm

5.0”

127mm

2.8”

70mm

1.6”

41mm

12.8”

325mm

2.5”

64mm

Typ.

Use Six M8 Bolts

for Mounting

Speed

Adjustment

Knob

1.5”

38mm

1.2”

30mm

Typ.

1/4” NPT

1.1”

28mm

.28”

7mm

.94”

24mm

2.0”

51mm Typ.

Use Six M8 Screws

8mm Deep Thread

for Tray Mounting

19

Page 20

TP-70 Parts Description

TP-70 Assemblies

Part No. Description Qty

T3-407 Cylinder rod O-ring (14208-008) 2

T10-319 Speed adjustment knob O-ring 1

*

T10-320 Plug O-ring 1

*

T40-010 Valve seals 2

*

T40-037 O-ring 1

*

T40-045 Compression spring 1

*

T40-047 Compression spring long assembly 2

*

T70-105 Threaded mounting insert (8mm) 6

T70-153 Bearing retainer (5mm) 2

T70-154 Ball bearing (5mm) 56

T70-215 Cup seal (front & rear) 2

*

T70-216 Spanner nut (front & rear) 2

T70-217 Snap ring 2

T70-220 Piston urethane washer 2

*

T70-253 Rear spring guide 1

T70-254 Front spring guide 1

T70-257 Front cylinder urethane washer 1

*

T70-259 Rear cylinder urethane washer 1

*

T70-302 Speed adjustment rod 1

T70-303 Speed adjustment knob 1

T70-306 Speed adjustment valve O-ring, small (*14208-011) 1

*

T70-310 Knob locking nut 1

T70-311 Speed adjustment valve lock screw 1

T70-320 Washer 1

T70-321 Rear threaded bushing 1

T70-322 Silencer 1

T70-403 Rear retaining plate 1

T70-404 Front retaining plate 1

T70-406 Front threaded bushing 1

T70-407 Shock absorber 1

T70-408 Shock absorber locking nut 1

T70-410 Holder screw 8

T70-411 Retaining plate screw 12

T70-413 Shock absorber plug 1

T70-433 Rear holder 1

T70-434 Front holder 1

T70-436 Screw 8

T70-601 Front piston assembly 1

T70-602 Rear piston assembly 1

T70-603 Valve Rod assembly 1

*

T70-604 Valve assembly 1

T70-605 Ball guide assembly 1

Included in Repair Kit 70-001 (17272)

*

20

T70-601 Front Piston Assembly Qty

T40-047 Spring, long 1

T70-211 Front piston 1

T70-215 Cup seal 1

T70-217 Snap ring 1

T70-253 Spring guide 1

T70-602 Rear Piston Assembly Qty

T40-047 Spring, long 1

T70-212 Rear piston 1

T70-215 Cup seal 1

T70-217 Snap ring 1

T70-254 Spring guide 1

T70-603 Valve Rod Assembly Qty

T3-407 O-ring 2

T70-251 Valve rod 1

T70-604 Valve Assembly Qty

T40-037 O-ring 1

T70-302 Valve rod 1

T70-306 O-ring 1

T70-308 Valve 1

T70-605 Ball Guide Assembly Qty

T70-153 Ball retainer (5mm) 1

T70-154 Ball (5mm) 28

T70-426 Ball guide 1

T70-428 Screw 7

T70-435 Guide column 1

T70-437 Ball guide 1

Page 21

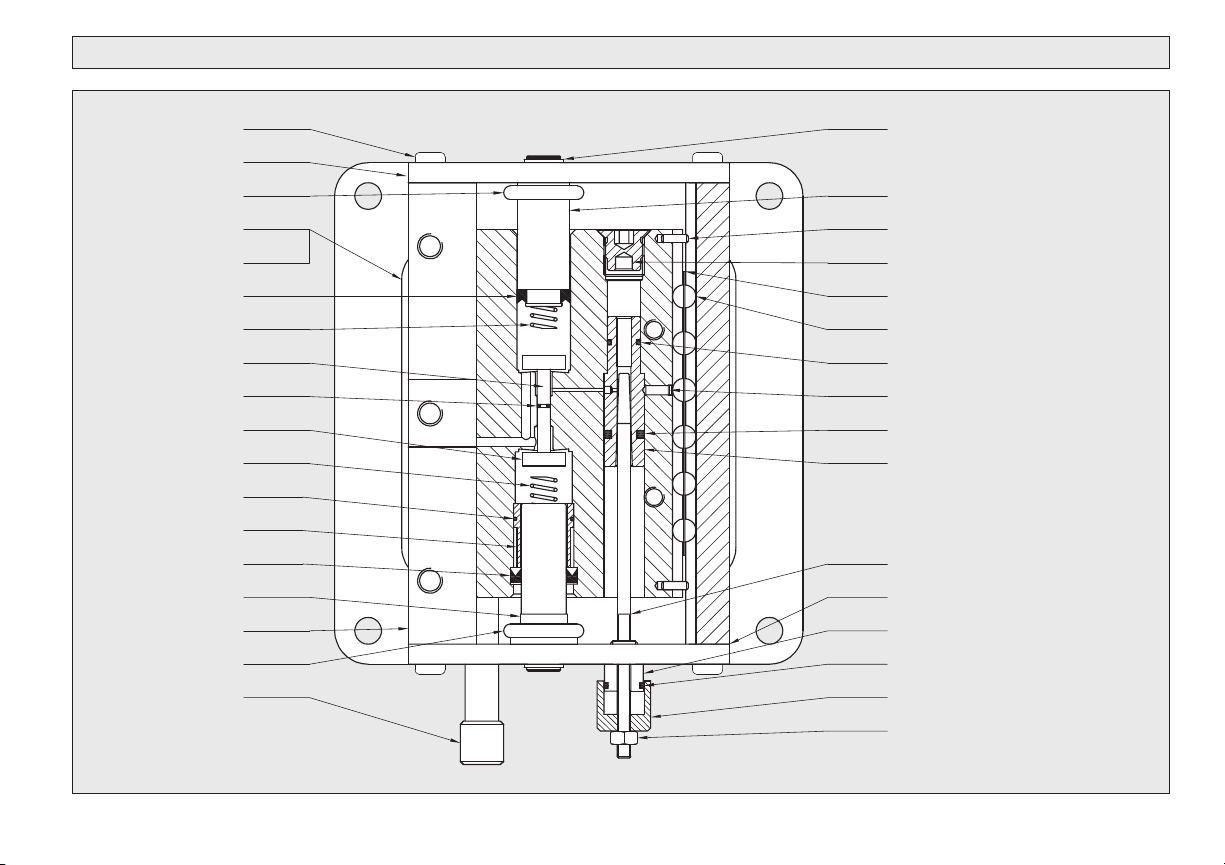

TP-70 PARTS DRAWING

T70-216

T70-434

T70-410

T70-220

T70-602

T70-411

T70-404

*T70-215

*T40-047

T70-153

T70-154

T70-257

T40-010

T70-605

T70-105

*T40-010

T70-259

T70-217

*T70-215

T70-601

T70-253

T70-403

*T40-047

T70-436

T70-433

T70-216

T70-408

T70-320

T70-406

T70-407

T70-217

T70-254

T70-413

T10-320

*T40-045

*T70-603

*T3-407

*T70-306

T70-311

T40-037

T70-604

T70-322

T70-302

T70-321

*T10-319

T70-303

T70-310

*Included in Repair Kit 70-001 (17272)

21

Page 22

MODEL TP-140 SERVICE

Disassembly

Factory Repair & Rebuild Service

Return the Transporter by UPS Prepaid to our repair center.

After teardown and inspection, P/A Industries will notify you

of the recommended cost for spare parts and labor.

1. Remove the two (2) Spanner Nuts T70-216 from the

Rear Piston assembly T70-601 and T140-211 and

push the Pistons inside the Cylinder.

2. Remove the eight (8) holder screws with a T40 Torx

wrench. Loosen the eight (8) Set Screws T70-436.

(No need to remove).

3. Pull the Front and Rear Holders away from the Body

while holding the Outer Guide Assemblies to prevent

the Bearings from being lost. Remove the Front Piston

assembly T70-602 and Rear Piston T140-212.

Together, with the two (2) Shock Absorbers T70-407,

they will come out with the Front Holder. The Speed

Adjustment Assembly will come out with the Rear

Holder.

4. Now remove the Front Retaining Plate T140-404.

The Rear Piston can now be removed from the Body.

22

5. Unscrew Sleeve T140-326 using an 8 mm Hexagon

Wrench. Then pull out the Speed Adjustment Valve

T140-308.

6. Unscrew Valve Seals T40-010 and pull out. Check all

seals and o-rings for wear, make sure Valve Seals are

flat, and Valve Rod T70-603 is straight.

Reassembly

When reassembling, take care with the following:

1. Install the Speed Adjustment Valve T140-308 and

tighten Sleeve T140-326 using an 8 mm Hexagon

Wrench. Do not overtighten.

2. Don’t forget to install the Front and Rear Cylinder

Urethane Washers T70-257 and T70-259.

3. Use the T70-436 Set Screws to adjust out any play or loose

ness in the Slide Assembly before tightening the Holder Screws.

Page 23

MODEL TP-140 DIMENSIONAL DRAWING

3.0”

77mm

7.6”

192mm

2.9”

75mm

1/4” NPT

5.8”

148mm

4.8”

122mm

7”

179mm

1.1”

28.5mm

2.5”

63.5mm

Typ.

51mm

12.8”

325mm

2.0”

Typ.

Use Six M8 Bolts

for Mounting

Speed

Adjustment

Knob

Use Six M8 Screws

8mm Deep Thread

for Tray Mounting

23

Page 24

TP-140 Parts Description

TP-140 Assemblies

Part No. Description Qty

T3-407 Cylinder rod O-Ring (14208-008) 2

T10-319 Speed adjustment knob O-Ring 1

*

T10-320 Plug O-ring 2

*

T40-010 Valve seals 2

*

T40-045 Compression spring 2

*

T40-047 Valve spring 2

*

T70-153 Bearing retainer (5mm) 2

T70-215 Cup seal (front & rear) 4

*

T70-216 Spanner nut (front & rear) 4

T70-217 Snap ring 2

T70-220 Piston urethane washer 4

*

T70-253 Rear spring guide 1

T70-254 Front spring guide 1

T70-303 Speed adjustment knob 1

T70-310 Knob locking nut 1

T70-320 Washer 2

T70-406 Front threaded bushing 2

T70-407 Shock absorber 2

T70-408 Shock absorber locking nut 2

T70-411 Retaining plate screw 8

T70-413 Shock absorber plug 2

T70-436 Screw 8

T70-601 Front piston assembly 1

T70-602 Rear piston assembly 1

T70-603 Valve rod assembly 1

*

T70-605 Ball guide assembly 1

T140-105 Threaded mounting insert (8mm) 6

T140-211 Front piston 1

T140-212 Rear piston 1

T140-302 Speed adjustment Rod 1

T140-308 Speed adjustment valve 1

T140-326 Sleeve 1

T140-401 Rear holder 1

T140-402 Front holder 1

T140-404 Front retaining plate 1

T140-601 Front piston assembly 1

T140-602 Rear piston assembly 1

T140-603 Silencer assembly 1

Included in Repair Kit 140-001 (18914)

*

T140-601 Front Piston Assembly Qty

T140-211 Piston 1

T70-215 Cup seal 1

T140-602 Rear Piston Assembly Qty

T140-212 Rear piston 1

T70-215 Cup seal 1

T140-603 Silencer Assembly Qty

T140-324 Damp bushing 1

T140-502 Lock 1

T140-503 Silencer 1

T140-504 Felt 1

T40-045 Spring 1

T70-601 Front Piston Assembly Qty

T40-047 Spring, long 1

T70-211 Front piston 1

T70-215 Cup seal 1

T70-217 Snap ring 1

T70-253 Spring guide 1

T70-602 Rear Piston Assembly Qty

T40-047 Spring, long 1

T70-212 Rear piston 1

T70-215 Cup seal 1

T70-217 Snap ring 1

T70-254 Spring guide 1

T70-603 Valve Rod Assembly Qty

T3-407 O-ring 2

T70-251 Valve rod 1

T70-605 Ball Guide Assembly Qty

T70-153 Ball retainer (5mm) 1

T70-154 Ball (5mm) 28

T70-426 Ball guide 1

T70-428 Screw 7

T70-435 Guide column 1

T70-437 Ball guide 1

24

Page 25

TP-140 PARTS DRAWING

T140-402

T140-410

*T70-220

T70-602

T140-404

T70-411

*T70-215

T40-047

T70-153

T70-154

*T70-257

T40-010

*T70-603

*T3-407 (*14208-008)

T70-605

*T40-010

T70-259

T70-217

T70-215

T70-601

T70-253

T140-112

*T40-047

T70-436

T70-408

T70-407

T70-320

T70-406

T140-212

T70-220

T70-254

T70-413

*T10-320

T140-105

*T40-045

T140-308

T140-326

T140-211

T140-302

T70-220

T140-401

T70-216

*Included in Repair Kit 140-001 (18914)

T140-603

*T10-319

T70-303

T70-310

25

Page 26

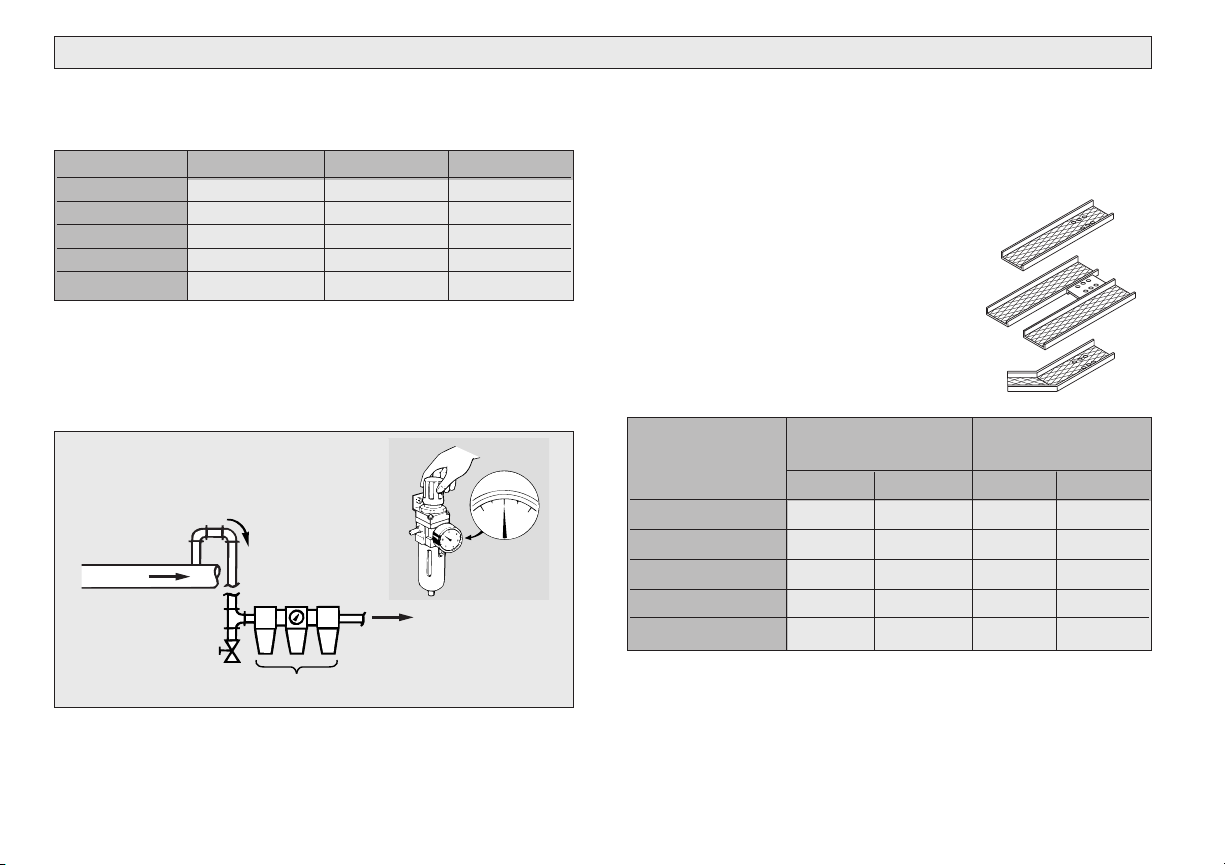

TECHNICAL DATA

Model Pressure Consumption Stroke Feed Chute Level Weight capacity Chute

TP-3

TP-10

TP-40

TP-70

Air Air of of of Feed Sound portation weight

60-80 psi 8.8 cfm .9 in. 29-33 fpm 8° 56 dB (A) 3 lbs 6.4 lbs 3.2 lbs

4–5,5 bar 5 l/min 23 mm 8–10 m/min 8° 56 dB (A) 1,4 kg 3 kg 1,5 kg

60-80 psi 19.4 cfm .9 in. 29-33 fpm 8° 60 dB (A) 6 lbs 21.4 lbs 6.4 lbs

4–5,5 bar 11 l/min 23 mm 8–10 m/min 8° 60 dB (A) 2,8 kg 10 kg 3 kgs

60-80 psi 55 cfm 1.1 in. 29-33 fpm 8° 70 dB (A) 15 lbs 85.6 lbs 32 lbs

4–5,5 bar 31 l/min 27 mm 8–10 m/min 8° 70 dB (A) 7,2 kg 40 kg 15 kg

60-80 psi 78 cfm 1.1 in. 29-33 fpm 8° 68 dB (A) 12 lbs 150 lbs 107 lbs

4–5,5 bar 44 l/min 27 mm 8–10 m/min 8° 68 dB (A) 5,5 kg 70 kg 50 kg

Length Rate incline Trans- Max.

Max.

26

TP-140

60-80 psi 74 cfm 1.1 in. 29-33 fpm 8° 62 dB (A) 17 lbs 300 lbs 214 lbs

4–5,5 bar 42 l/min 27 mm 8–10 m/min 8° 62 dB (A) 8 kg 140 kg 100 kg

Air consumption is measures at a pace of 120 strokes per minute and an air pressure of 4 bars (60psi).

Page 27

Roller Slide Tray Support Options

Model RS-1

#17918

Slide Rail

Stopper

Mounting Plate

Roller Slide Dimensions

Model RS-1

#17918

Tray

Mounting

Surface

Model RS-2 #17432-01

J

E

D

F

Tray Mounting

Surface

J

D

M

K

A

B

C

Ball Bearings

B

E

M4 THRU

H

Model RS-2

#17432-01

A

C

Bottom View

Note: Cut slide rail to desired length.

H

L

M

N

N

G

Slide Rail

K

1

/2K

Mounting Plate

Guide Plate

Stopper

Ball Bearings

METRIC - mm USA - inches

RS-1 RS-2 RS-1 RS-2

A 105 100 4.20 3.94

B 6.8 15 .27 0.59

C 86 70 3.38 2.76

D 35 60 1.375 2.36

E 35 5 .68 0.20

F– 50 – 1.97

G– 50 – 1.97

H–100 – 3.94

J 9.5 16.2 .375 0.64

K 24 37 .93 1.46

L–300 – 11.8

M 32 Max 2.3 1.25 Max 0.09

N 4.5 4.6 x 5.3 .175 0.18 x 0.21

SEAL

27

Page 28

P/A INDUSTRIES INC., 522 Cottage Grove Road, Bloomfield, CT 06002-3191 USA

®

www.pa.com

Toll-Free: 1-800-243-8306, Worldwide: 1-860-243-8306, Fax: 1-860-242-4870, E-mail: sales@pa.com FORM 1053 11-07

Loading...

Loading...