PA Industries SRF-M12, SRF-18, SRF-24, SRF-32, SRF-36 Installation Manual

...

®

Installation and Operating Instructions

MAGNUM SERVO FEED

MODELS SRF-M12 / 18 / 24 / 32 / 36 / 48

P/A INDUSTRIES INC.

522 Cottage Grove Road • Bloomfield, Connecticut 06002-3191 U.S.A.

Toll Free 1-800-243-8306 • Worldwide 1-860-243-8306 • Fax 1-860-242-4870

Website http://www.pa.com • E-Mail service@pa.com

RECEIVING INSPECTION

Before removing unit from its packaging, check for

visual damage, especially if crate, skid, or carton has

been damaged in transit. Any damage caused by

shipping should be immediately reported to the

carrier. If unit appears in satisfactory condition,

remove all packing and wipe rust preventive from

rollers with mild solvent.

TABLE OF CONTENTS

DESCRIPTION PAGE

1. INTRODUCTION .................................... 2

2. HOW A MAGNUM

SERVO FEED OPERATES .................... 2

3. INSTALLING YOUR MAGNUM

SERVO FEED ........................................ 3

3.1 MECHANICAL INSTALLATION ......... 3

3.2 ELECTRICAL INSTALLATION .......... 3

3.3 ELECTRICAL CONNECTIONS ........ 3

3.4 MAGNUM MOUNTING HOLES ........ 4

4. PROGRAMMING THE MAGNUM

SERVO FEED SYSTEM ........................ 4

4.1 PROGRAM A NEW FEED

LENGTH, COUNT, SPEED ............... 5

4.2 PROGRAM A NEW BATCH

COUNT ............................................. 6

4.3 PROGRAM A NEW SPEED

FOR THE FEED ................................ 6

5. OPERATING THE FEED ....................... 6

5.1 PRIORITY MODE .............................. 7

5.2 SET-UP MODE .................................. 7

5.3 AUTO/MANUAL MODE ..................... 7

5.4 LOADING THE FEED ........................ 7

5.5 RUNNING THE FEED ....................... 9

6. TROUBLESHOOTING GUIDE ..............11

6.1 PRO-200 MOTION

CONTROL CARD ERRORS ............12

6.2 DDM DRIVE ERROR MESSAGES ..13

6.3 RUN TIME ERROR CODES ............13

6.4 POWER-UP ERROR CODES ..........13

7. MAINTENANCE ....................................13

8. MAGNUM MECHANICAL

PARTS LIST AND DIAGRAM................14

9. CASCADE WITHOUT ENCODER

PARTS LIST AND DIAGRAM................17

1. INTRODUCTION

The P/A Industries Magnum Heavy Duty Servo

Roll Feed combines the latest servo roll feed design

technology with the latest servo drive control

technology. Years of testing and experience has led to

many of the design features found in the Magnum.

A high strength cast iron frame forms the core of

the Magnum. Large diameter textured feed rolls

with driven upper and lower rolls assure positive

feeding of the strip without slipping. A precision

worm-gear reducer provides the torque

multiplication necessary for optimum pulling

capacity required on heavier material.

A brand new high performance digital servo drive is

the heart of the Magnum. The new drive incorporates

all the latest motor control, tuning, and protection

features available. Standard features of the Magnum

controller include: Jog-To-Feed Length; Press Or

Feed Priority Selection, Press/Feeder Synchronous

Checking; Hand Held Jog Pendant with Roll

Release Selector; and many more.

The mechanical simplicity, accuracy, and ease of use

of your new Magnum Heavy Duty Servo Roll

Feeder should help you improve your quality and

production for years to come.

2. HOW A MAGNUM SERVO

FEED OPERATES

The Magnum Servo Roll Feed consists of:

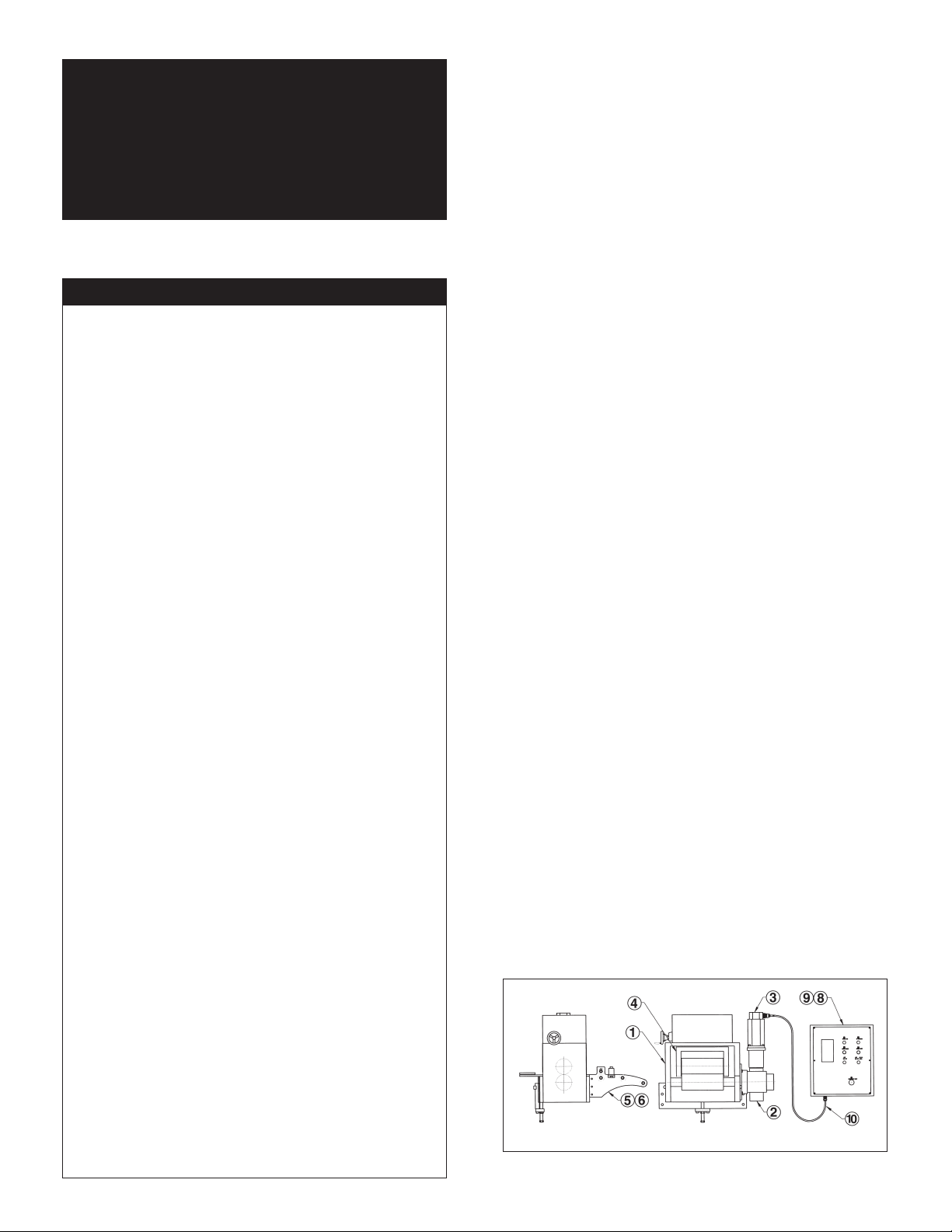

2.1 THE MECHANICAL COMPONENTS

(Refer to Figure 1)

1) Feeder Housing & Feed Rolls

2) Worm-Gear Speed Reducer

3) Servo Motor

4) Air Actuated Roll Release

5) Cascade Guide Rolls

6) OPTIONAL-Cascade Guide Rolls

With Strip Encoder

2.2 THE ELECTRICAL CONTROL

ENCLOSURE ASSEMBLY

(Refer to Figure 1)

7) Operators Control Panel & Data Entry Terminal

8) 24 VDC Logic Power Supply (For Controls)

9) Cabling

10. CASCADE WITH ENCODER

PARTS LIST AND DIAGRAM .............. 18

WARNING .....................................................20

SAFETY PROGRAM ....................................20

WARRANTY .................................................20

DRAWING 17573-01

Figure 1.

2

When a new feed pitch is entered into the system,

the built in computer calculates the correct number

of electronic “pulses” it must receive from the motor

mounted encoder in order to rotate the feed rolls

the correct amount. This will accurately position

the strip.

Fifteen and one-half revolutions of the servo motor

shaft produce 1 revolution of the feed rollers. The

motor-mounted optical encoder produces 8000

"pulses" for each revolution of the motor. The

circumference of the lower roll is 14.842 inches.

Example: If a feed pitch/length of 14.842 inches is

entered into the feeder, this will result in exactly

one revolution of the feed rolls. The motor will

accelerate and turn 15.5 turns. This will produce

(15.5 x 8000) =124,000 pulses of the encoder.

The feeder will decelerate and stop when 124,000

pulses are detected. The feeder is now on position.

This entire process happens very quickly, the end

result is an accurately positioned strip exactly

14.842 inches from its starting point. This entire

process happens in milliseconds.

Quick connectors. The electrical Control Enclosure

is supplied with a stand/support which may be

placed in any convenient location. The enclosure

may also be mounted in any fixed location as long

as cabling is adequate to reach the feeder. It is not

recommended that the Electrical Enclosure be

mounted directly to the press. The vibrations

caused by the press may result in damage to the

control system.

3.3 ELECTRICAL CONNECTIONS

For more detailed wiring information, refer to

Electrical Schematic A-17514-01 for 220 VAC

or 440 VAC

The main power for the feed system requires a

“clean” 220 VAC single phase 20 ampere source.

A terminal strip is provided in the main control

enclosure to facilitate wiring connections. It is

recommended that #12 MTW (Machine Tool Wire)

be used for the primary power supply input.

3. INSTALLING YOUR

MAGNUM SERVO FEED

3.1 MECHANICAL INSTALLATION

The Magnum Servo Roll Feed is supplied with

a height adjustable mounting bracket for the feeder.

The adjustment is (±2.0 inch) from middle

position. The feeder should be securely mounted to

the press frame. A transition bracket is sometimes

required in certain applications requiring more

adjustment.

The feeder should be centered, square, and

perpendicular to the pass line of the press. Use the

24 millimeter square keys on the front mounting

plate for alignment and leveling the feeder. The

feeder should be mounted at a height that will

accommodate the appropriate die sets. Refer to

Figure 2 on Page 4.

The feeder can be used to push or pull stock.

3.2 ELECTRICAL INSTALLATION

The Magnum Servo Roll Feed has been designed

to make electrical connections quickly and easily.

A clean 220 VAC single phase 20 ampere source is

required for trouble free operation. The inputs and

outputs to your press control (i.e. Emergency stop,

Feed advance cam contact, Continue cam contact,

Pilot Release Cam Contact (if used), and Taut

or No Loop Input) must be connected according

to the electrical schematic instructions included

with machine. The motor connects by a factory

installed "Amphenol" (Military Specifications)

IMPORTANT!

A #12 MTW grounding conductor must be

installed for proper machine grounding.

NOTE:

All connections should be made in accordance

with National Electrical Code (NEC)

requirements and must comply with all local

ordinances.

NOTE:

A word about electrical “noise”. Most pressroom

environments contain considerable electrical noise.

It is emitted from electro-mechanical press relays,

contacts, and solenoids. While The Magnum

Servo Roll Feed has been designed to minimize

"self generated" electrical noise, it is difficult to

provide protection for all applications. If erratic

system behavior is experienced, then the source

of the "noise" must be suppressed with either a

resistive/capacitive type of suppressor on AC

coils, or “Avalanche” type diodes on DC coils.

NOTE:

The Magnum Servo Roll Feed is fully protected

by a disconnect switch and line fuses. If it

becomes necessary to replace the fuses, use only

exact equivalent fuse types to prevent serious

damage to the system.

3

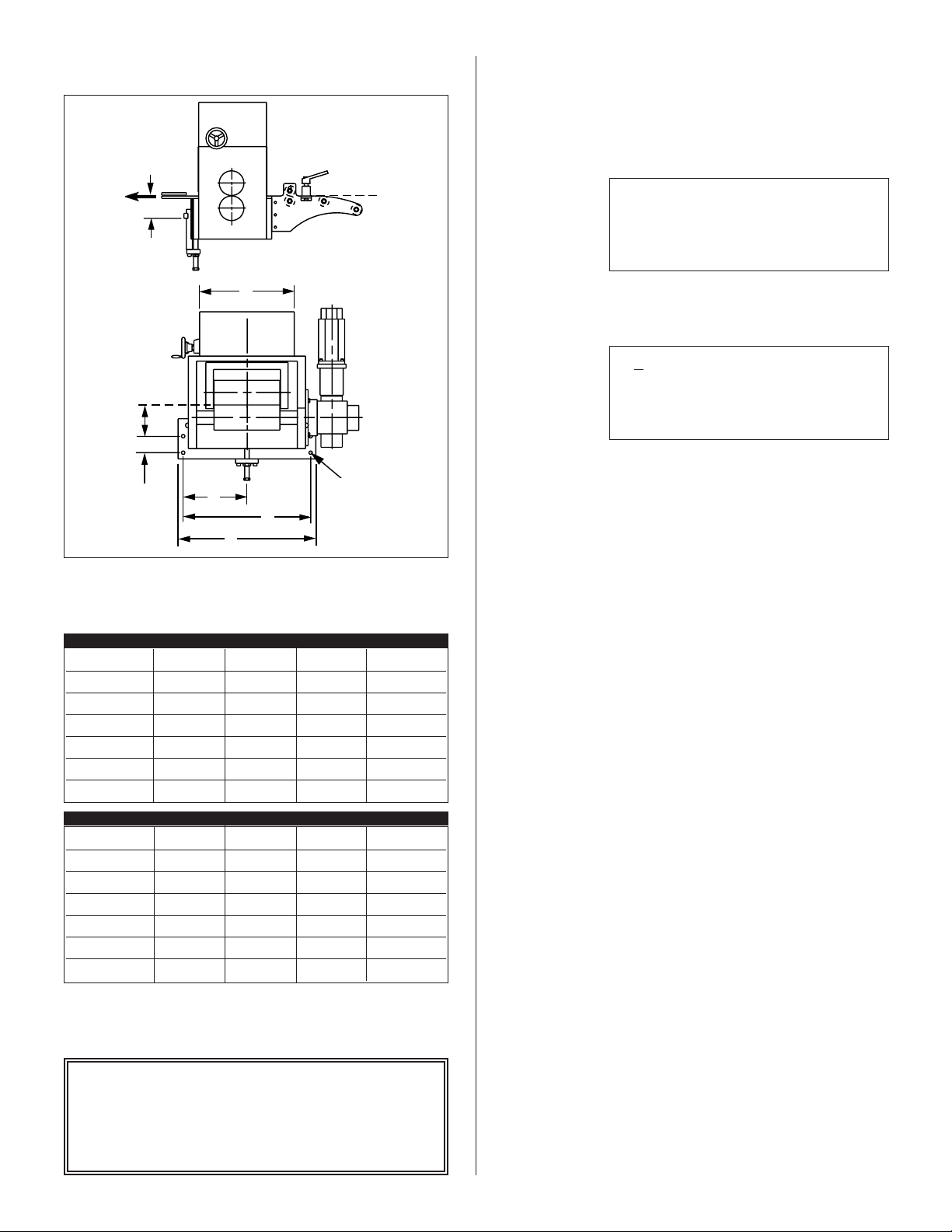

3.4 MAGNUM MOUNTING HOLES

PASS LINE

HEIGHT

ADJUSTMENT

±

2.0”

4.3” (109mm)

DRAWING 17573-02

D

PASS LINE

5.9”

(150mm)

3.1” (80mm)

STEP #1:

Turn on the main power disconnect switch. This

applies power to the control power supply. Press the

amber ‘

POWER ON’ push-button. The button will

illuminate and the data input display will be visible:

☞

STEP #2:

P/A INDUSTRIES

SERVO ROLL FEED

VERSION 1.00

HIT KEY TO CONT__

Press any key on the terminal, the display

will show:

LENGTH 00008.000

☞

COUNT 100000

SPEED 0060/SEC

ENCODER FAULT

A

B

C

ø0.67” (ø17mm)

(4) MOUNTING

HOLES

Figure 2.

MAGNUM MOUNTING HOLES

for drawing 17573-02

INCHES

MODEL A B C D

SRF-M12 12.2 24.4 26.4 18.4

SRF-M18 15.3 30.5 32.5 24.4

SRF-M24 18.2 36.4 38.4 30.4

SRF-M32 22.3 44.5 46.5 38.3

SRF-M36 24.2 48.4 50.4 42.4

SRF-M48 30.1 60.2 62.2 54.2

MILLIMETERS

MODEL A B C D

SRF-M12 310 620 670 467

SRF-M18 387 775 825 619

SRF-M24 462 925 975 772

SRF-M32 565 1130 1181 972

SRF-M36 615 1230 1280 1076

SRF-M48 765 1529 1580 1377

4. PROGRAMMING THE MAGNUM

SERVO FEED SYSTEM

IMPORTANT !

Before turning the system on for the first time,

verify that the main input voltage is correct

(220vac single phase) and inspect all connections

for tightness, shorts, etc.

STEP #3:

The ‘POWER ON’ push-button has a ‘FAULT

RESET

‘

POWER ON’ button to clear the ‘ENCODER

FAULT

’ function built into the button. Press the

’ message at the bottom line of the display.

The feed may now be jogged forward by pressing

the ‘

JOG FORWARD’ button, or jogged in reverse

by pressing the ‘

JOG REVERSE’ button.

The Magnum Servo Roll Feed has six viewable

screens. Only the first operator screen (shown

above) will be operator editable/programmable.

This screen displays the length, count, and speed

parameters. These parameters may only be changed

while the program is stopped (indicated by lack of

‘

CYCLE START’ or set up light). The other

viewable screens are shown on the following page.

These five other screens will be viewable at all times,

but are “locked” out of programming via run/prog

switch located on the electrical panel inside the

electrical enclosure. The factory set parameter

values for the Magnum Servo Roll Feed are printed

on the operator panel below the operator terminal.

These parameters are set from the factory for

average feeding applications and they seldom

require any changes. The five screens and a brief

explanation of the parameters are described below:

• LENGTH: Distance in inches (or millimeters) of

the feed length. Maximum value of 999.750

inches.

• COUNT: The number of pieces required to run

in the batch. Maximum value of 999,999 pieces.

4

• SPEED: The maximum velocity of the material

in inches/second (or millimeter/second).

Maximum value of 60 inches/second.

ACCEL 000402/SEC^2

☞

• ACCEL: The rate of acceleration in

inches/second2(or millimeter/second2).

Maximum value of 1000 inches/second2.

• DWELL: The time delay which controls the ‘ON’

duration of the cut output relay. The dwell is used

when the press or shear, lacks a continue Bottom

Dead Center (

controlled by the dwell parameter.

• DBNC: This is the debounce parameter, which

is used to ignore contact bounce on the feed

signals.

DWELL 00.00

DBNC 1 X 3.75MS

BDC) switch and the cycle can be

PRIORITY PBF

BACKLIGHT ON

☞

• KP: Proportional gain parameter for the motion

control. It controls the transitions between the

starting and stopping of the rolls. A lower value

provides a smoother (slower) transition.

• KD: This parameter is not used.

• KFF: Velocity feed forward gain. This is used to

reduce following error of the system.

• AUTO OFFSET: This parameter turns the

automatic offset on. Turn this feature on by

entering ‘

☞

• INPOSN: In-position parameter is a tolerance

window around the final position. This is used to

verify the feed index accuracy is within acceptable

limits before continuing onto the next function.

1’.

INPOSN 000.0200

FELIM 5.000

FETIM 0.500

SYSTEM RESET

• PRIORITY: This parameter selects whether the

feeder indexes before the press starts ‘FBP’

(Feed-Before-Press), or the press starts before

the feeder indexes ‘PBF’ (Press-Before-Feed).

Entering a ‘0’ selects ‘PBF’ mode or a ‘1’ selects

‘FBP’ mode.

• BACKLIGHT: This turns on the backlight in the

display, which enhances the viewing.

CNTS/UNIT 8396

TIME BASE /SEC

☞

• CNTS/UNIT: This is the encoder scaling

parameter used to define the number encoder

counts/inch (or counts/millimeter).

• TIME BASE: Time scaling parameter for various

parameters. This is always set to ‘/SEC’ by

entering ‘0’.

• JOG SPEED: The rate of jogging speed in

percent of the SPEED parameter. Normally set

between 1 - 5%.

JOG SPEED 5%

DIRECTION CCW

• FELim: Follower error limit. FELim is the

maximum allowed position error. When this limit

is exceeded for the amount of time specified by

the FETime, the control will execute an

emergency stop.

• FETime: Follower error time. FETime is the

maximum amount of time that the following error

limit may be exceeded before executing an

emergency stop.

• SYSTEM RESET: This function clears all

parameters to the factory default conditions. No

program may be running,

(press and hold the ‘

the ‘

PROG/RUN’ switch must be set to ‘PROG’

position. Pressing ‘

SYSTEM RESET line will result in a confirmation

screen being displayed. Pressing ‘

time will reset the parameters to the factory

default values and the power-up screen will be

displayed. Pressing any other key than ‘

result in aborting the system reset.

1’ while the cursor is on the

RESET must be active

POWER ON’ button), and

1’ a second

1’ will

• DIRECTION: This parameter controls the

direction of positive motor rotation. 0 = CCW,

and 1 = CW.

☞

KP 0.30

KD 0.00

KFF 0.30

AUTO OFFSET ON

4.1 PROGRAM A NEW FEED

LENGTH, COUNT, SPEED

To program a new feed pitch/length the program

must be stopped. This may be done by pressing the

‘

POWER ON’ or the ‘CYCLE STOP’ button

(if the press is running). Press the ‘

button to view the following screen:

5

OPERATOR’

LENGTH 00008.000

☞

STEP #1:

The ‘UNDERLINE’ type cursor is located under

the length display whenever this screen is called up.

This indicates that this entry is capable of being

modified.

STEP #2:

Enter a new feed length; for instance...1.253 inches.

Press the ‘

press the ‘

‘

ENTER’ key. The control will now take a moment

to clear the existing length value in its memory and

then "memorize" the new setting. The display

should now show the new feed length setting. The

maximum feed length is limited to 8,388,608

encoder counts or 999.750 inches.

1’ key, press the ‘.’ Key, press the ‘2’ key,

5’ key, press the ‘3’ key, and press the

COUNT 100000

SPEED 0060/SEC

After the first Index/Part is made, the display

will show:

LENGTH 00001.253

COUNT 001000

☞

S

PEED 0060/SEC

000001 / 001000

4.3 PROGRAM A NEW SPEED

FOR THE FEED

STEP#1:

Position the ‘UNDERLINE

PEED with the ◗ key.

S

LENGTH 00001.253

☞

STEP #2:

Enter a new speed value, 60 inches per second is the

maximum speed setting. 1 inch per second is the

minimum speed setting.

COUNT 001000

S

PEED 0060/SEC

’ type cursor under

☞

LENGTH 00001.253

COUNT 100000

SPEED 0060/SEC

4.2 PROGRAM A NEW

BATCH COUNT

STEP #1

Position the ‘UNDERLINE’ type cursor under

C

OUNT. Use the ◗ key.

☞

LENGTH 00001.253

C

OUNT 100000

SPEED 0060/SEC

STEP #2

Enter a new desired batch count. For instance....

1000 pieces. Press the ‘

buttons. The control takes a moment to clear the

existing batch count setting in memory, and then

"memorizes" the new value. Enter a value of ‘

disable the batch counter. The display should now

show:

1’, ‘0’, ‘0’, ‘0’, and ‘ENTER’

0’ to

We will use 50/inches per second as our

example... Press the ‘

The control clears the existing value and inserts

50/seconds into its memory.

The display should now show the new setting:

☞

These (3) parameters may be changed when the

running batch is stopped. All other feeder

parameters are locked out of the editing mode via

‘RUN/PROGRAM’ switch located inside the

electrical enclosure on the panel.

5’, ‘0’, and ‘ENTER’ buttons.

LENGTH 00001.253

COUNT 001000

S

PEED 0050/SEC

5. OPERATING THE FEED

NOTE:

It is very important to remember that the motor

on the Magnum Servo Feed System is only

for feeding material. It is not intended to be the

power source for a pull-through straightening

device, or the like. An adequate free loop must

be provided at all times. This will assure

consistent and accurate feeding.

☞

LENGTH 00001.253

C

OUNT 001000

SPEED 0060/SEC

5.1 PRIORITY MODE

The Magnum Servo Roll Feed has (2) modes of

automatic cycle starting. The Operator can

6

Loading...

Loading...