Page 1

Page 2

ULTRA EDGE SERVO ROLL FEED 2/09/2002

TABLE OF CONTENTS

DESCRIPTION PAGE

1 INTRODUCTION.......................................................................................................................................... 3

2 THEORY OF OPERATION ........................................................................................................................ 3

2.1 MECHANICAL ASSEMBLY.............................................................................................................. 3

2.2 ELECTRICAL CONTROL ENCLOSURE ASSEMBLY ......................................................................... 3

2.3 SERVOMOTOR/DRIVE OPERATION............................................................................................ 4

2 PROGRAMMING THE ULTRA EDGE SERVO ROLL FEED SYSTEM - OVERVIEW .................... 5

2.1 “OPER” KEY......................................................................................................................................... 6

2.2 “SETUP” KEY....................................................................................................................................... 7

4 HOW TO …................................................................................................................................................... 9

4.1 HOW TO EDIT “OPERATOR” PARAMETERS .......................................................................... 9

4.2 HOW TO EDIT “SETUP” PARAMETERS ................................................................................... 9

4.3 HOW TO MICRO ADJUST LENGTH USING LENGTH ADJUSTMENT................................. 10

5 OPERATING THE ULTRA EDGE SERVO FEED ................................................................................ 10

5.1 PROGRAMMING.............................................................................................................................. 10

5.2 PRIORITY MODE............................................................................................................................. 10

5.3 “JTL” (JOG TO LENGTH) MODE ................................................................................................. 10

5.4 “AUTO / MANUAL” MODE.............................................................................................................. 11

5.5 TROUBLESHOOTING GUIDE....................................................................................................... 13

5.6 ERROR CODES ............................................................................................................................... 14

WARNING ...................................................................................................................................................... 16

SAFETY PROGRAM .................................................................................................................................... 16

WARRANTY................................................................................................................................................... 16

2

Page 3

ULTRA EDGE SERVO ROLL FEED 2/09/2002

RECEIVING INSPECTION

BEFORE REMOVING UNIT FROM ITS PACKAGING, CHECK FOR VISUAL DAMAGE,

ESPECIALLY IF CRATE, SKID, OR CARTON HAS BEEN DAMAGED IN TRANSIT. ANY

DAMAGE CAUSED IN SHIPMENT SHOULD BE IMMEDIATELY REPORTED TO THE

CARRIER. IF UNIT APPEARS IN SATISFACTORY CONDITION, REMOVE ALL PACKING

AND WIPE RUST PREVENTIVE FROM ROLLERS WITH MILD SOLVENT.

1 INTRODUCTION

IMPORTANT

Before turning the system on for the first time, verify that installation has been completed according to

the Installation manual and the main input voltage is 110 VAC, single phase.

The P/A Industries Ultra Edge Servo Roll Feed is a state of the art AC Servo feed, which simplifies Operator

adjustments to feed parameters. These Operator adjustments are entered into the control memory through the keypad.

With the use of positional limit switches, the press signals the feeder when to begin moving the strip, when the feed

pitch must be completed, when the press has completed its down stroke, and with optional pneumatic pilot release,

when to open the rolls for piloting.

The mechanical simplicity, accuracy, and ease of use of the Ultra Edge Servo Roll Feed will help to improve your

quality and production for years to come.

2 THEORY OF OPERATION

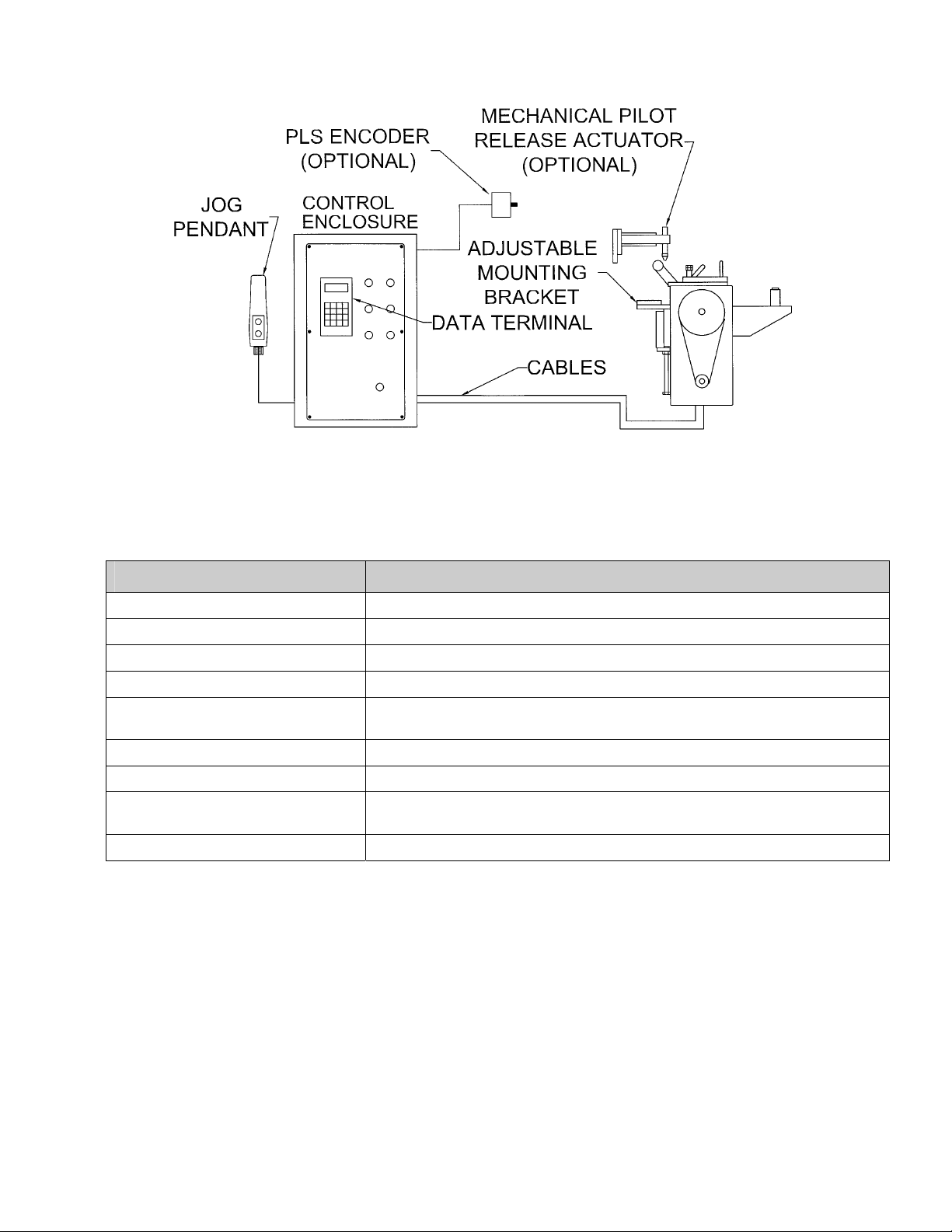

2.1 MECHANICAL ASSEMBLY

Mechanical assembly consists of:

1) Adjustment/Mounting bracket

2) Feeder

3) Servomotor

4) Mechanical pilot release actuator (optional)

5) PLS – Programmable Limit Switch (not available with SFI models)

2.2 ELECTRICAL CONTROL ENCLOSURE ASSEMBLY

Electrical control enclosure consists of:

1) Control switches/buttons/relays

2) Power supply, 24 VDC/5 VDC

3) Servo drive

4) Data entry terminal Cabling

5) Jog Pendant

3

Page 4

ULTRA EDGE SERVO ROLL FEED 2/09/2002

ALL ULTRA ADVENTAGE SERVO ROLL FEED CONTROLS ARE CONVENIENTLY

LOCATED ON THE FRONT SIDE OF THE ELECTRICAL ENCLOSURE

CONTROL/DEVICE DESCRIPTION

Power On/Reset button Turns controller on, resets the servo drive.

In Position indicator light, white Turns on when move is complete and motor is holding position.

Cycle Start illuminated button, green Turns controller into “Auto” mode from “Manual” mode, starts cycling.

Cycle Stop button, red: Stops cycling and returns the controller into “Manual” mode.

“JTL / Manual-Auto” mode selector

switch:

Emergency Stop mushroom button, red Shuts controller off

Operator terminal Displays controller’s data and enters data into controller.

“Programming Locked / Unlocked” keyswitch

Forward / Reverse remote jog pendant Pendant is attached to the enclosure through retractile cable.

Turns controller into “Manual” or “JTL” (Jog To Length) mode.

Locks access to programming.

2.3 SERVOMOTOR/DRIVE OPERATION

The introduction of servomotor technology to the press roll feed has pushed the limits of accuracy, adjustability,

and performance to levels previously unattainable.

The following example is based on the Ultra Edge Servo Roll Feed Standard, US (SRF-125, 200, 300, 400, 500,

600) models. The actual numbers for SRF-100 or metric models are different.

Each revolution of the servomotor produces 1048576 encoder pulses. Every 2.909 revolutions of the servo motor shaft

produce 1 revolution of the feed rollers. The circumference of the lower roll is approximately 11.138 inches.

When a new feed pitch is entered into the system, the built in computer calculates the correct number of electronic

“pulses” it must receive from the motor mounted encoder in order to rotate the feed rolls the correct distance.

4

Page 5

ULTRA EDGE SERVO ROLL FEED 2/09/2002

Example: If a feed pitch/length of 11.138 inches is entered into the feeder, this will result in exactly one revolution of

the feed rolls. The motor will accelerate and turn 2.909 turns. This will produce (2.909 x 1048576 = 3050307) pulses

of the encoder. The feeder will decelerate and stop, when 3050307 pulses are detected. The feeder is now in position.

The result is an accurately positioned strip exactly 11.138 inches from its starting point. This entire process happens

in milliseconds.

2 PROGRAMMING THE ULTRA EDGE SERVO ROLL FEED SYSTEM OVERVIEW

NOTE: Before attempting any programming, make sure that the “PROGRAMMING LOCKED /

UNLOCKED” key switch is in the “Unlocked” position.

NOTE: After power shutdown, WAIT for 5 seconds before powering up the Feed.

Press the green Power On push-button. The button will illuminate and the OPERATOR terminal display will be

visible.

Wait for the IN POSITION light to illuminate.

Press any key to begin.

P/A Ind u s tri e s

R eal l y Co o l Fe e d

V ers i o n 1 . 1 6 S F I

H i t a n y k e y t o c ont .

NOTE: The OPERATOR terminal has three mode keys, they are:

● “OPER”

● “TOOLS” – disabled on SFI model.

● “SETUP”

NOTE: ▓ The flashing cursor is waiting for the value to be entered.

NOTE: < The pointer prompts to press the “ENTER” key.

NOTE: To confirm any value, press “ENTER”.

5

Page 6

ULTRA EDGE SERVO ROLL FEED 2/09/2002

2.1 “OPER” KEY

“OPER” key controls appearance of four screens: STATUS screen and three OPERATOR screens.

STATUS screen shows

:

P/A Ind u s tri e s

Ma n u a l M o d e

3 0 / C ont . R u n

P res s a M o d e Ke y

• Current mode of the feed

• Batch count, current and commanded

OPERATOR screens show and allow editing the following parameters:

L e ngt h 1 . 0 00

C o unt Con t . R uN

L e ngt h Adj u s tme n t <

P r ess O PER f or n e x t

Length is a distance in inches (or millimeters) of the “Feed Length”. It is a numeric entry with a range of 0 to the

Maximum Length.

Count is the number of feed indexes that should be performed. It is a numeric entry with a range of 0 to 9999999.

Entering “0” will result in a continuous run.

Length Adjustment is not a parameter but a feature that allows micro adjusting of the Length parameter. The

Length parameter can be micro adjusted even while feed is feeding material.

S p eed 72

A c cel 4 0 0 .0

D e cel 4 0 0 .0

P r ess O PER f or n e x t

6

Page 7

ULTRA EDGE SERVO ROLL FEED 2/09/2002

Speed is the maximum velocity of the material in in/sec (or mm/sec). It is a numeric entry with a range of 0 to 72

in/sec (1828 mm/sec) for Standard model and 0 to 41 in/sec (1041 mm/sec) for Heavy Duty models.

2

Accel is the rate of acceleration in in/sec

mm/sec

Decel is the rate of deceleration in in/sec

mm/sec

2

). Normally set to 400 in/sec2 (10160 mm/sec2).

2

). Normally set to 400-in/ sec2 (10160 mm/sec2). Enter “0” to duplicate Accel rate.

(or mm/sec2). It is a numeric entry with a range of 0-to 1000 in/sec2 (25400

2

(or mm/sec2). It is a numeric entry with a range of 0-to 1000 in/sec2 (25400

D w ell 50

P r ess O PER f or n e x t

Dwell controls the “On” duration of the “Permit Press” output while the control is in Single Stroke mode. The next

feed length will not be started until Dwell time is expired. It is a numeric entry with a range of 0 to 100000 msec.

2.2 “SETUP” KEY

“SETUP” key controls the appearance of setup screens. Six screens contain parameters of the feed that are not

changed often or are never changed. Press “SETUP” key three times to open the first screen. Position the cursor on

the desired line, using “↑” and “↓” keys , enter in desired value and press the “ENTER” key. Press “SETUP” key to

open the next screen or “ BKSP” – the previous.

J o g S p e ed % 5

J o gAc c e l 10 . 0

J o gDe c e l 1 0 .0

S E TUP - N ext B KSP - P r ev

Jog speed is the maximum jogging speed. It is a numeric entry with a range of 0 to 99 percent of the Speed

parameter. Normally set between 1-5%.

2

JogAccel is the rate of jogging acceleration. It is a numeric entry with a range of 0-to 300-in/sec

2

.

in/sec

JogDecel is the rate of jogging deceleration. It is a numeric entry with a range of 0-to 300-in/sec

2

in/sec

.

. Normally set 10

2

. Normally set 10-

I n Pos i t ion 0 . 0 2 00

P r ior i t y ( 1 / 0) F BP

A d jus t m ent S t ep 0 . 0 01

S E TUP - N ext B KSP - P r ev

InPosition is a tolerance window around the final position. This is used to verify the feed index accuracy is within

acceptable limits before continuing onto the next function. It is a numeric entry with a range of 0 to 100 inch.

Normally set 0.02 inch.

Priority is a parameter that selects whether the feeder indexes before the press starts “FBP” or the press starts before

the feeder indexes “PBF”. Entering a “0” selects “PBF” mode and a “1” selects “FBP” mode.

AdjustmentStep is an increment of the Length adjustment. It is a numeric entry with a range of 0 to 1 inch.

Normally set 0.001 inch.

7

Page 8

ULTRA EDGE SERVO ROLL FEED 2/09/2002

S c ale 73 5 5 . 00

D i rec t i on ( 1/ 0 ) C W

D e bou n c e(m S ) 1

S E TUP - N ext B KSP - P r ev

Scale is the encoder scaling parameter used to define the number of encoder counts/inch (or mm). It is a numeric

entry. Its value is 273809 cnts/inch (10780 cnts/mm) for SRF200, 300, 400, 500, 600 models and 339214 cnts/inch

(13355 cnts/mm) for SRF100.

Direction controls the direction of positive motor rotation. Entering “0” selects CW and a “1” selects CCW.

Debounce is the amount of time each input should stay HI or LOW, in order to be recognized. It is a numeric entry,

with a range of 0 to 999 msec. It is normally set to 1.

K p 2 00

P g ain 1 2 00

I g ain 1

S E TUP - N ext B KSP - P r ev

Kp is proportional gain of the position loop. This is a tuning parameter, in order to change its value consult P/A

Industries Service Department.

Pgain is proportional gain of the velocity loop. This is a tuning parameter, in order to change its value consult P/A

Industries Service Department.

Igain is integral gain of the velocity loop. This is a tuning parameter, in order to change its value consult P/A

Industries Service Department.

F F 1 .0

K f f 1 .0

C u rre n t Li m i t 30

S E TUP - N ext B KSP - P r ev

FF is an acceleration feedforward gain of the velocity loop. This is a tuning parameter, in order to change its value

consult P/A Service Department.

Kff is a feedforward gain of the position loop. This is a tuning parameter, in order to change its value consult P/A

Service Department.

Current Limit is a maximum positive and negative current the drive may output to the motor. This is a tuning

parameter, in order to change its value consult P/A Service Department.

B a ck L e ngt h 0 . 0 00

K e rf 0 . 0 00

M a xLe n g th 6 0 . 0 00

S E TUP - E xit B KSP - P r ev

Back Length is used for Cut-to-Length application to protect the material against bending up by the blade. If any

value is assigned for this parameter, the feed will move material back for the distance that equals Back Length when

Reset Cam input is turned “On” by the blade bottom position sensor. The Back Length is compensated on the next

move, so it has no affect on the Length parameter. It is a numeric entry, with a range of 0 to 1 inch.

Kerf is a cutting tool width and used for Cut-to-Length application to compensate for a loss of the Length caused by

width of the tool. It is a numeric entry, with a range of 0 to 10 inches.

8

Page 9

ULTRA EDGE SERVO ROLL FEED 2/09/2002

Max length is a Length limit and protects against accidental entering extra digits, for example: 100 inch instead of 10

inch. It is a numeric entry, with a range of 0 to 999999. (This value is factory set to 20.000.)

NOTE: To exit setup editing at any time, press the “OPER” key. Changes will be saved.

4 HOW TO …

4.1 HOW TO EDIT “OPERATOR” PARAMETERS

Position cursor next to desired parameter, enter appropriate value, and press the “ENTER” key.

Locate the OPERATOR screen, position cursor next to desired parameter, enter appropriate value, and press the

“ENTER” key.

L e ngt h 1 . 0 00

C o unt Con t . R un

L e ngt h Adj u s tme n t <

P r ess O PER f or n e x t

Press “OPER” key to open next screen. Position cursor next to desired parameter, enter appropriate value, and press

the “ENTER” key. Enter “0” for Decel to use Accel value or an actual desired value.

S p eed 72

A c cel 4 0 0 .0

D e cel 4 0 0 .0

P r ess O PER f or n e x t

Press “OPER” key to open next screen. Position cursor next to desired parameter, enter the appropriate value, and

press the “ENTER” key.

D w ell 0

P r ess O PER f or n e x t

4.2 HOW TO EDIT “SETUP” PARAMETERS

NOTE: Make sure that the PROGRAMMING “LOCKED / UNLOCKED” key switch is in “Unlocked”

position and OPERATOR screen is displayed. If the current screen is not OPERATOR one then press the

“OPER” key to bring it up.

Press “SETUP” key three times, position cursor next to desired parameter, enter in new value, and press the

“ENTER” key.

9

Page 10

ULTRA EDGE SERVO ROLL FEED 2/09/2002

J o g S p e ed % 5

J o gAc c e l 10 . 0

J o gDe c e l 1 0 .0

P r ess S ETU P for n e xt

Press “OPER” key if editing is done or press “SETUP” key to open next screen.

4.3 HOW TO MICRO ADJUST LENGTH USING LENGTH ADJUSTMENT

Locate the OPERATOR screen, position pointer next to the Length Adjustment and press the “ENTER” key.

L e ngt h 1 . 0 00

C o unt Con t . R un

L e ngt h Adj u s tme n t <

P r ess O PER f or n e x t

L e ngt h 1 . 0 00

U se A r row K eys t o

Ad j u st L e ngt h

P res s OPE R to e x i t

Adjust Length using “↑” and “↓” keys and then press “OPER” to exit adjusting.

5 OPERATING THE ULTRA EDGE SERVO FEED

5.1 PROGRAMMING

OPERATOR screens are only screens that are Operator editable. These screens display Length, Count, Length

Adjustment, Speed, Accel, Decel and Dwell. Length and Count can be changed only when cycling is stopped,

although Length can be adjusted by using the LENGTH ADJUSTMENT command even while the feed is running.

Access to the SET UP parameters can be locked by “Programming Locked/Ulocked” keyswitch.

5.2 PRIORITY MODE

The Ultra Edge Servo Roll Feed has two modes of automatic cycle starting. The choice can be made between “Press –

Before – Feed” (“PBF”) and “Feed – Before – Press” (“FBP”) operating mode.

When “PBF” mode is selected and the Cycle Start button is pressed on the control panel, the feeder causes the “Auto”

and “Permit Press” relays to turn on thus enabling the start of continuous cycling on the press.

When “FBP” is selected and Cycle Start button is pressed on the feed control, the material/strip will be fed forward

before the press is started. The Operator may verify that the strip is in position before starting the press.

The Ultra Edge Servo Roll Feed will now follow the press until it is stopped by the Operator, counter, emergency stop,

or feed error.

5.3 “JTL” (JOG TO LENGTH) MODE

“JTL” mode is used primarily during the threading of the strip through the die. This mode allows the Jog – To –

“Feed Length” operations to be performed. While in the “JTL” mode, the strip may be moved using the remote Jog

Pendant.

If the “Jog Forward” is stopped before the “Feed Length” is reached, then either the “Jog Forward” or the “Jog

Reverse” Operator buttons will work. The “Jog Reverse” will not allow the strip to go backwards beyond the initial

“Feed Length” starting point.

10

Page 11

ULTRA EDGE SERVO ROLL FEED 2/09/2002

The “Jog Forward” Operator button will function until the end of the “Feed Length” is reached. During “JTL”

mode, the bottom line on the display will show “Waiting for Jog”. When the “Feed Length” is reached, the jog

buttons become inactive and the message on display will show “Waiting for Press”. The jog buttons will not become

active again until after the press has made a cycle.

5.4 “AUTO / MANUAL” MODE

“Auto” Mode is used for production running of the UltraEdge Servo Roll Feed. When “Manual” mode is selected via

the 2-position selector switch, the control can be put in “Auto” mode by pressing Cycle Start button.

During “Manual” mode, the feeder can be jogged infinitely in either direction. After the Cycle Start button is

pressed, the jog buttons are inactive, and the feeding of the strip follows the cam signals from the press.

During “Auto” mode, the control keeps check on synchronization of the feeder and the press. If the feeder does not

complete the index within the feed cam window, the message “SYNC FAULT” displays.

The Ultra Edge Servo Roll Feed has 2 modes of automatic cycling. The feeder can operate with Single Stroke or

Continuous modes. The mode is selected through an input to the feed controller. The Press single stroke/continuous

mode switch should be interfaced to that input for proper operation. During single stroke mode operation, the “Permit

Press” relay is activated upon the completion of each feed index.

The “Permit Press” relay remains activated until the reset cam signal turns on, or for the duration of the Dwell, if the

Dwell parameter is programmed. The “Permit Press” relay may be used to signal the press when to initiate the single

stroke cycle. The automatic cycling of the press and feeder will continue until the batch is completed, or the cycle is

stopped by the Operator, or an error occurs.

During “Continuous Press” mode, the “Permit Press” relay turns on at the beginning of the indexing.

The “Permit Press” relay remains activated until the automatic cycling is stopped by either “Cycle Stop” button,

“Batch Complete” internal command, “Sync Fault” or any other drive related error. Under “Cycle Stop” or “Batch

Complete” stopping, the output will turn off at the beginning of the Feed Cam Signal. This should allow the press to

stop near the top of the stroke. Under “Sync Fault” or other drive fault conditions, the “Permit Press” relay will turn

off immediately upon detection of the error.

NOTE: The following speed performance charts represent theoretical calculations based on parameter values

most commonly used. Higher performance for specific applications can be reached by custom tuning the

control.

11

Page 12

ULTRA EDGE SERVO ROLL FEED 2/09/2002

Figure 6 SPEED PERFORMANCE CHART

Velocity (in/sec) 72.00 Feed Window (degrees)

Accel (in/sec2) 400.00 Strokes per minute

Feed(in) Feed Time(sec)

0.25 0.070 214 429 643

0.50 0.091 165 331 496

0.75 0.107 141 281 422

1.00 0.120 125 250 375

2.00 0.161 93 186 279

3.00 0.193 78 155 233

4.00 0.220 68 136 205

5.00 0.244 62 123 185

6.00 0.265 57 113 170

7.00 0.285 53 105 158

8.00 0.303 50 99 149

9.00 0.320 47 94 141

10.00 0.336 45 89 134

12.00 0.366 41 82 123

14.00 0.394 38 76 114

16.00 0.422 36 71 107

18.00 0.450 33 67 100

20.00 0.478 31 63 94

22.00 0.506 30 59 89

24.00 0.533 28 56 84

26.00 0.561 27 53 80

28.00 0.589 25 51 76

30.00 0.617 24 49 73

35.00 0.686 22 44 66

40.00 0.756 20 40 60

45.00 0.825 18 36 55

50.00 0.894 17 34 50

55.00 0.964 16 31 47

60.00 1.033 15 29 44

90 180 270

12

Page 13

ULTRA EDGE SERVO ROLL FEED 2/09/2002

5.5 TROUBLESHOOTING GUIDE

The chart that follows contains the most frequently encountered issues.

Symptom Cause or Remedy

No power indication when

Power On button is pressed

No display on power up 6. Check the cabling connection between display and the servo drive.

Feed will not jog 8. Check if the Feed is in “JTL” mode. Waiting for press?

Power On indicator is lit. Feed

will not operate.

Feed will not accept new “Feed

Length” or other parameters

Inaccurate feeding 16. Adjust the rolls for the correct material thickness; the tip of the roll release lever

Feed runs backwards 21. Verify that the direction parameter has been set properly (CW or CCW).

Drive Fault This is a generic display prompt indicating a fault on the Servo Drive.

1. Check the main power supply for proper voltage.

2. Check the supply circuit breakers.

3. Verify that the main disconnect switch is on.

4. Verify that the E-Stop is not engaged (E-Stop Loop closed.)

5. Check the bulb in Power On push button.

7. Check 5 VDC power supply.

9. Check if IN POSITION indicator is off. Check parameters. Check drive for

Error Codes.

10. Check the FAULT in display i.e. DRIVE FAULT # ABC. Check for Error

descriptions. See Section 5.2 of the “Ultra 5000 Intelligent Positioning Drives”

Installation Manual.

11. Check that the IN POSITION indicator is lit. If not, check parameters.

12. Check that the Error message is in the Display. If so, check error description in

Section 7.2

13. Move selector switch to “Manual”, press the Power On button, release the Power

On button, and then try to jog feeder.

14. Make sure that the feed is not in “Auto” Mode.

15. Reset the Feed.

must have a small amount of play/wobble – approx. 1/16’’.

17. Adjust the spring pressure (Do not bottom springs. Catastrophic damage can

occur.)

18. Confirm if the rolls are slipping on the strip. Remove oil from the feed rolls,

reduce acceleration, check the tool for binding/slugs, etc.

19. Adjust the upstream equipment if the upstream equipment not providing

adequate/consistent free loop.

20. Check the roll release for the proper settings

22. Look at the diagnostic display on the Servo Drive. The cause of the fault can be

determined by reading the Error Code.

23. Refer to Sections 7.2. This fault condition can be caused by any one of the errors

in the lists.

24. Check the Error Code first, then reset the Servo Drive by turning the power off,

waiting 10 seconds, and then powering the Servo Drive back on.

25. Verify that the fault will not reset. Call the factory for assistance.

If the problem you are having does not appear in the above chart, or does appear in the chart, and you have questions

about it, call the P/A Service Department for assistance. Please have your Model Number and Serial Number ready.

However, it is advisable to check the basics before calling to be sure the problem is not something simple that may

have been overlooked.

13

Page 14

ULTRA EDGE SERVO ROLL FEED 2/09/2002

5.6 ERROR CODES

Error

Code

Problem or

Symptom

Possible Cause(s) Action/Solution

04 Motor Over

Temperature

05 IPM Fault

10 Bus Over Voltage

20 Motor Encoder

State Error

Motor thermostat trips due to:

High motor ambient

temperature, and/or

Excessive RMS torque.

Bad encoder cable or

connection.

Motor cables shorted. Verify continuity of motor power cable and connector.

Motor winding shorted

internally.

Ultra5000 Servo drive

temperature too high.

Operation above continuous

power rating.

Ultra5000 has a bad IPM,

output short circuit, or over

current.

Low AC line/AC power input. Verify voltage level of the incoming AC power. 09 Bus Under Voltage

100 VAC minimum for safe

Ultra5000 operation.

Excessive regeneration of

power.

When the motor is driven by an

external mechanical power

source, it may regenerate too

much peak energy through the

Ultra5000's power supply. The

system faults to save itself from

an overload.

Excessive AC input voltage. Verify input is below 264V AC.

Output short circuit. Check for shorts.

Motor cabling wires shorted

together.

Internal motor winding short

circuit.

Incorrect phasing. Check cables and connections. 11 Illegal Hall State

Bad connections.

The motor encoder encountered

an illegal transition.

Bad encoder. Replace motor.

Operate within (not above) the continuous torque rating

for the ambient temperature (40'C maximum).

Lower the ambient temperature to increase motor

cooling.

Check the encoder cable connections. Check the

encoder cable for continuity.

Check for short on U,V,W and Gnd windings of the

motor.

Check for clogged vents or defective fan.

Ensure cooling is not restricted by insufficient space

around the unit.

Verify ambient temperature is not too high (above 60'

C). Operate within the continuous power rating.

Replace Ultra5000.

Check AC power source for glitches or line drop (below

90V AC).

Install an uninterruptible power supply (UPS) of the

proper size on your AC input.

Lower the deceleration rate.

Check for shorts.

Check for shorts.

Replace the motor. Check the Pilot Release settings.

Route the cables away from potential noise sources.

Check the system grounds.

14

Page 15

ULTRA EDGE SERVO ROLL FEED 2/09/2002

Error

Code

21 Auxiliary Encoder

Problem or

Symptom

state Error

Possible Cause(s) Action/Solution

The auxiliary encoder

encountered an illegal

transition.

Use shielded cables with twisted pair wires.

Route the encoder cable away from potential noise

sources.

Bad encoder - replace motor.

Check the ground connections.

22 Motor Thermal

Protection Fault

23 IPM Thermal

Protection Fault

The internal filter protecting the

motor from overheating has

tripped.

The internal filter protecting the

IPM at slow speed has tripped.

Reduce acceleration rates.

Reduce duty cycle (“On/Off”) of feed indexes.

Increase time permitted for motion. (Check cabling.)

Reduce acceleration rates.

Reduce duty cycle (“On/Off”) of feed indexes.

Increase time permitted for motion.

The servo drive module has built in diagnostics. The current status of the drive is always shown on the 7-segment

LED STATUS display, located on the front of the drive. The normal state of the LED is to actively cycle its edge

segments and an illuminated decimal point that indicates +5 volts. If an error occurs, the LED displays flashing letter

E followed by a two-digit error code, one digit at a time.

Errors can also be viewed on a Personal Computer screen using Ultraware software package available upon request.

15

Page 16

ULTRA EDGE SERVO ROLL FEED 2/09/2002

WARNING

This equipment offers various means of operating or controlling machines. The operator must not be in or near the point-ofoperation of the machine, or the operating parts of any equipment installed on the machine, or bodily injury could result. The

EMPLOYER must post adequate warning signs onto the machine with proper warnings for his machine and the specific

application to which the machine and equipment are being applied.

Occupational Safety and Health Act (OSHA) Sections 1910.211, 1910.212, and 1910.217 contain installation information on the

distance between danger points and point-of-operation guards and devices. No specific references have been made to which

paragraph of OSHA 1910.211, 1910.212, 1910.217 or any other applicable sections because the paragraphs may change with each

edition of the publication of OSHA provisions.

All equipment manufactured by us is designed to meet the construction standards of OSHA in effect at the time of sale, but the

EMPLOYER installs the equipment so the EMPLOYER is responsible for installation, use, application, training, and maintenance,

as well as adequate signs on the machine onto which this equipment will be installed.

Remember, OSHA says that the EMPLOYER must use operating methods designed to control or eliminate hazards to operating

personnel.

It shall be the responsibility of the EMPLOYER to establish and follow a program of periodic and regular inspections of his

machine to insure that all their parts, auxiliary equipment, and safeguards are in a safe operating condition and adjustment. Each

machine should be inspected and tested no less than weekly to determine the condition of the machine. Necessary maintenance or

repair of both shall be performed and completed before the machine is operated. The EMPLOYER shall maintain records of these

inspections and the maintenance work performed.

Our Company is not responsible to notify the user of this equipment of future changes in State or Federal laws, or construction

standards.

SAFETY PROGRAM

Accident free operation will result from a well developed, management sponsored and enforced safety program. Of vital

importance to any successful program is the proper selection of guards and devices. However, there is no safety device that will

bring “automatic” safety to your operation.

Of equal importance to this proper selection of the guard and the device is the training of your personnel. Each person must be

trained as to the operation of the guard or safety device, highlighting why they have been provided on the equipment. Rules for

safe operating should be written and enforced at all times. A final major concern of an effective safety program is regularly

scheduled inspection and maintenance of all of the equipment.

To ensure continued safety at all times, top management, line supervision, safety engineers and all employees must assume their

proper share of the responsibility in the program. Only as a group, one that knows your own operation and its problems, can you

carry out an effective safety program.

To assist you in the development of and continued use of safety programs, many safety minded groups have made guidelines

available to you. However, you must know when and how to apply these guidelines. The manufacturer provides information to

assist you in properly adjusting and maintaining your equipment. There is no short cut to proper safety; therefore, it is

recommended that you comply with their recommendations at all times.

WARRANTY

We warrant our new parts against defects under normal use and service for a period of 12 months after date of shipment. Our

obligation under this warranty is limited to replacing or repairing (at our option) the defective part without charge, F.O.B. our plant

in Bloomfield, Connecticut. The defective part must be forwarded to our plant, freight prepaid, for our inspection prior to

replacement or repair. EXCEPT AS EXPRESSLY PROVIDED HEREIN, THIS WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING A WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. Furthermore, the seller does not warrant or represent that the equipment

complies with the provisions of any law, particularly including the Occupational Safety and Health Act of 1970, and regulations

promulgated thereunder. In no

event shall we be liable for special, indirect incidental or consequential damages, however rising.

16

Loading...

Loading...