Page 1

®

Installation and Operating Instructions

ADVANTAGE SERVO FEED

Models SRF-5 / 8 / 12 / 16 / 20 / 24 / 28 / 32 / 36

(for Serial Numbers 7610697 and higher)

P/A INDUSTRIES INC.

522 Cottage Grove Road • Bloomfield, Connecticut 06002-3191 U.S.A.

Toll Free 1-800-243-8306 • Worldwide 1-860-243-8306 • Fax 1-860-242-4870

Website http://www.pa.com • E-Mail service@pa.com

Page 2

RECEIVING INSPECTION

Before removing unit from its packaging, check for

visual damage, especially if crate, skid, or carton has

been damaged in transit. Any damage caused by

shipping should be immediately reported to the

carrier. If unit appears in satisfactory condition,

remove all packing and wipe rust preventive from

rollers with mild solvent.

TABLE OF CONTENTS

DESCRIPTION PAGE

1. INTRODUCTION ................................... 2

2. HOW AN ADVANTAGE

SERVO FEED OPERATES ................... 2

2.1 MECHANICAL ASSEMBLY .............. 2

2.2 ELECTRICAL CONTROL

ENCLOSURE ASSEMBLY ............... 2

3. INSTALLING YOUR ADVANTAGE

SERVO FEED ........................................ 3

3.1 MECHANICAL INSTALLATION ........ 3

3.2 ELECTRICAL INSTALLATION .......... 3

3.3 ELECTRICAL CONNECTIONS ........ 3

3.4 ADVANTAGE MOUNTING HOLES ... 4

4. PROGRAMMING THE ADVANTAGE

SERVO FEED SYSTEM ........................ 4

4.1 PROGRAM A NEW FEED

LENGTH, COUNT, SPEED .............. 6

4.2 PROGRAM A NEW BATCH

COUNT ............................................. 6

4.3 PROGRAM A NEW SPEED

FOR THE FEED ............................... 6

5. OPERATING THE FEED ....................... 7

5.1 PRIORITY MODE .......... .................. 7

5.2 SET-UP MODE ................................. 7

5.3 AUTO/MANUAL MODE .................... 7

5.4 LOADING THE FEED ....................... 8

5.5 RUNNING THE FEED ....................... 8

6. TROUBLESHOOTING GUIDE ..............11

6.1 PRO-200 MOTION

CONTROL CARD ERRORS ............12

6.2 DDM DRIVE ERROR MESSAGES ..13

6.3 RUN TIME ERROR CODES ........... 13

6.4 POWER-UP ERROR CODES ......... 13

7. MAINTENANCE ................................... 13

8. ROLL FEED PARTS LIST

AND DIAGRAM ....................................14

WARNING .................................................... 16

SAFETY PROGRAM ................................... 16

WARRANTY ................................................ 16

1. INTRODUCTION

The P/A Industries Advantage Servo Roll Feed is

a state of the art AC Servo feed which eases operator

adjustments to feed pitch, feeder speed, and feed

acceleration. These operator adjustments are entered

into the control memory by key pad input. With the

use of positional limit switches, the press signals the

feeder when to begin moving the strip, when the

feed pitch must be completed, when the press has

completed its down stroke, and with optional pneumatic release, when to open the rolls for piloting.

The mechanical simplicity, accuracy, and ease of use of

the Advantage Servo Roll Feed should help to improve

your quality and production for years to come.

2. HOW AN ADVANTAGE

SERVO FEED OPERATES

The Advantage Servo Roll Feed consists of:

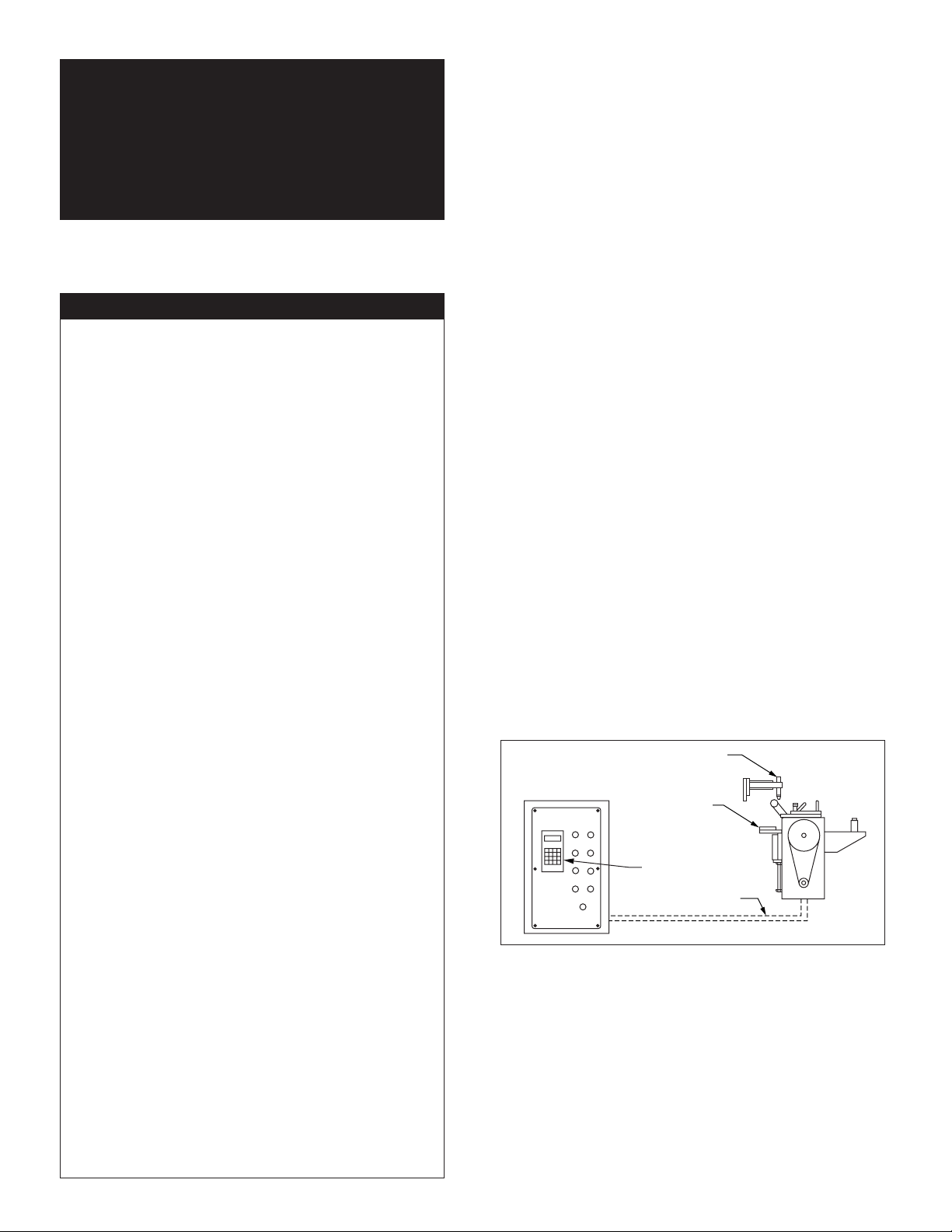

2.1 MECHANICAL ASSEMBLY

(Refer to Figure 1)

1) Adjustment/Mounting bracket

2) Feeder

3) Motor

4) Mechanical pilot release actuator

2.2 ELECTRICAL CONTROL

ENCLOSURE ASSEMBLY

(Refer to Figure 1)

1) Control switches/buttons

2) Power supply, 24 VDC (for controls)

3) Motor / Axis control module

(inside electrical enclosure)

4) Data entry terminal

5) Cabling

MECHANICAL PILOT

CONTROL

ENCLOSURE

Figure 1.

RELEASE ACTUATOR

ADJUSTABLE

MOUNTING

BRACKET

DATA

TERMINAL

CABLES

The introduction of servomotor technology to the

press roll feed has pushed the limits of accuracy,

adjustability, and performance to levels previously

unattainable.

Each revolution of the servo motor produces 8000

encoder pulses. Every 10.24 revolutions of the servo

motor shaft produce 1 revolution of the feed rollers.

The circumference of the lower roll is approximately

11.142 inches.

DRAWING 17415

2

Page 3

When a new feed pitch is entered into the system,

the built in computer calculates the correct number

of electronic “pulses” it must receive from the motor

mounted encoder in order to rotate the feed rolls

the correct distance.

Example: If a feed pitch/length of 11.142 inches is

entered into the feeder, this will result in exactly

one revolution of the feed rolls. The motor will

accelerate and turn 2.909 turns. This will produce

(2.909 x 8000 = 23,272) pulses of the encoder.

The feeder will decelerate and stop when 23,272

pulses are detected. The feeder is now on position.

The end result is an accurately positioned strip

exactly 11.142 inches from its starting point. This

entire process happens in milliseconds.

3. INSTALLING YOUR

ADVANTAGE SERVO FEED

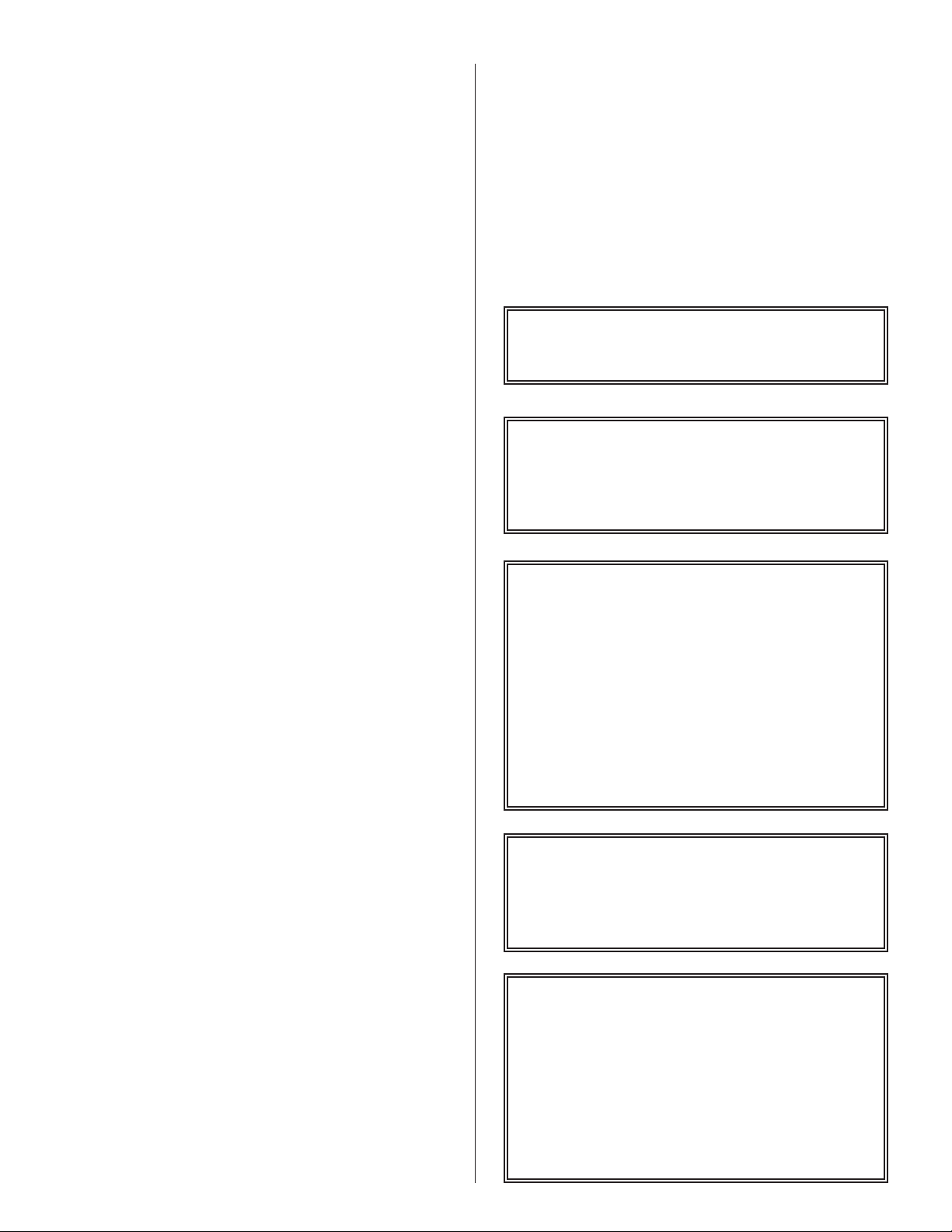

3.1 MECHANICAL INSTALLATION

The Advantage Servo Roll Feed is supplied with an

adjustable mounting bracket. The feed should be

securely mounted to the press frame. (A transition

bracket is sometimes required in certain

applications.) The feed should be centered, square,

and perpendicular to the pass line of the press.

It should be mounted at a height that will

accommodate the appropriate die sets. The feed has

a pass line height adjustment of ±1.2 inches.

(Note: The centerline of the Feeder is NOT the

centerline of the rolls.) Refer to Figure 2 on

Page 4 for dimensioning.

The feeder may be used to push or pull strip stock

through the die.

If pilot locating pins are used in your die sets, the

optional mechanical roll release bracket should be

attached to the press ram. It must be mounted in

such a way as to provide roll release at the proper

time and be adjustable for different die sets.

If the optional electro-pneumatic piloting is

used, another cam switch will be necessary for

controlling feed roll opening and closing.

3.3 ELECTRICAL CONNECTIONS

For more detailed wiring information refer to

Electrical Schematic A-17556-01 for 220 VAC and

Electrical Schematic A-17556-02 for 440 VAC.

The main power for the feed system requires a

"clean" 220 VAC single phase 20 ampere source.

A terminal strip is provided in the main control

enclosure to facilitate wiring connections. It is

recommended that #12 MTW (Machine Tool Wire)

be used for the primary power supply input.

IMPORTANT!

A #12 MTW grounding conductor must be

installed for proper machine grounding.

NOTE:

All connections should be made in accordance

with National Electrical Code (NEC)

requirements and must comply with all local

ordinances.

NOTE:

A word about electrical “noise”. Most pressroom

environments contain considerable electrical noise.

It is emitted from electro-mechanical press relays,

contacts, and solenoids. While the Advantage

Servo Roll Feed has been designed to minimize

“self generated” electrical noise, it is difficult to

provide protection for all applications. If erratic

system behavior is experienced, then the source

of the "noise" must be suppressed with either a

resistive/capacitive type of suppressor on AC

coils, or “Avalanche” type diodes on DC coils.

NOTE:

The Advantage Servo Roll Feed is fully

protected by line fuses. If it becomes necessary

to replace the fuses, use only exact equivalent fuse

types to prevent serious damage to the system.

3.2 ELECTRICAL INSTALLATION

The Advantage Servo Roll Feed has been designed

to make electrical connections quickly and easily. All

that is required is a "clean" 220 VAC single phase

20 ampere source. The inputs and outputs to your

press control (i.e. Emergency Stop, Feed Advance

Cam Contact, Pilot Release Cam Contact,

Continue Cam Contact, End of Strip Input) must

also be connected for proper operation. The motor

connects by factory installed "Amphenol" (Military

Specifications) Quick connectors.

NOTE:

The electrical control enclosure is supplied with

a stand/support which may be placed in any

convenient location. The enclosure may also be

mounted in any fixed location as long as the

cabling is adequate to reach the feed. It is not

recommended that the electrical enclosure be

mounted directly to the press. The vibrations

caused by the punch press can result In

damage to the control system.

3

Page 4

3.4 ADVANTAGE

MOUNTING HOLES

4. PROGRAMMING THE

ADVANTAGE SERVO FEED

SYSTEM

PASS LINE

CENTER LINE OF RAM

D

TAP X 1”(25mm) DEEP

TYPICAL MOUNTING ON GAP FRAME PRESS

E REF

A REF

BOLSTER

C

L

C

B

D

PASS LINE

BOLSTER

ADJUSTABLE

CAM BAR

DRAWING 17147-03

PASS LINE

ADJUSTMENT

E

A

IMPORTANT !

Before turning the system on for the first time,

verify that the main input voltage is correct

(220 VAC single phase) and inspect all

connections for tightness, shorts, etc.

STEP #1:

Turn on the main power disconnect switch. This

applies power to the control power supply. Press the

amber ‘

POWER ON’ push-button. The button will

illuminate and the data input display will be visible:

☞

STEP #2:

P/A INDUSTRIES

SERVO ROLL FEED

VERSION 1.00

HIT KEY TO CONT__

Press any key on the terminal, the display will show:

☞

LENGTH 00008.000

COUNT 100000

SPEED 0062/SEC

ENCODER FAULT

Figure 2.

ADVANTAGE MOUNTING HOLES

for drawing 17147-03

ENGLISH

DIMENSION SRF-5 SRF-8 SRF-12 SRF-16/20/24/28/32/36

A 1.97 1.97 1.97 1.97

B 3.15 3.94 3.94 3.94

C 6.30 7.87 7.87 7.87

D – – – 5.91

TAP M14 M16 M16 M16

E MIN. 2.2 2.2 2.4 2.4

PASS LINE +2.4 +2.4 +2.4 +2.4

ADJUSTMENT -0.0 -0.0 -0.0 -0.0

METRIC

DIMENSION SRF-5 SRF-8 SRF-12 SRF-16/20/24/28/32/36

A505050 50

B 80 100 100 100

C 160 200 200 200

D – – – 150

TAP M14 M16 M16 M16

E MIN. 56 56 60 60

PASS LINE +60 +60 +60 +60

ADJUSTMENT -00.0 -00.0 -00.0 -00.0

STEP #3:

The ‘POWER ON’ push-button has a ‘FAULT

RESET

POWER ON’ button to clear the ‘ENCODER

‘

FAULT

’ function built into the button. Press the

’ message at the bottom line of the display.

The feed may now be jogged forward by pressing

JOG FORWARD’ button, or jogged in reverse

the ‘

by pressing the ‘

JOG REVERSE’ button.

The Advantage Servo Roll Feed has six viewable

screens. Only the first operator screen (shown

above) will be operator editable/program-mable.

This screen displays the length, count, and speed

parameters. These parameters may only be changed

while the program is stopped (indicated by lack

CYCLE START’ or set up light). The other

of ‘

viewable screens are shown on the following page.

These five other screens will be viewable at all times,

but are "locked" out of programming via run/prog

switch located on the electrical panel inside the

electrical enclosure. The factory set parameter

values for the Advantage Servo Roll Feed are printed

on the operator panel below the operator terminal.

4

Page 5

These parameters are set from the factory for

average feeding applications and they seldom

require any changes. The five screens and a brief

explanation of the parameters are described below:

• CNTS/UNIT: This is the encoder scaling

parameter used to define the number encoder

counts/inch (or counts/millimeter).

• LENGTH: Distance in inches (or millimeters) of

the feed length. Maximum value of 1140 inches.

• COUNT: The number of pieces required to run

in the batch. Maximum value of 999,999 pieces.

• SPEED: The maximum velocity of the material in

inches/second (or millimeters/second). Maximum

value of 72 inches/second. (Maximum value of

54 inches/second for SRF-28/32/36).

ACCEL 000402/SEC^2

☞

• ACCEL: The rate of acceleration in

inches/second

Maximum value of 1000 inches/second

• DWELL: The time delay, which controls the ‘ON’

duration of the cut output relay. The dwell is used

when the press or shear, lacks a continue Bottom

Dead Center (

controlled by the dwell parameter.

• DBNC: This is the debounce parameter, which

is used to ignore contact bounce on the feed

signals.

☞

• PRIORITY: This parameter selects whether the

feeder indexes before the press starts ‘

(Feed-Before-Press), or the press starts before

the feeder indexes ‘

Entering a ‘

‘

FBP’ mode.

DWELL 00.00

DBNC 1 X 3.75MS

2

(or millimeters/second2).

2

.

BDC) switch and the cycle can be

PRIORTY PBF

BACKLIGHT ON

FBP’

PBF’ (Press-Before-Feed).

0’ selects ‘PBF’ mode or a ‘1’ selects

• TIME BASE: Time scaling parameter for various

parameters. This is always set to ‘

entering ‘

• JOG SPEED: The rate of jogging speed in

percent of the ‘

between 1 - 5%.

• DIRECTION: This parameter controls the

direction of positive motor rotation. 0 = CCW,

and 1 = CW.

☞

• KP: Proportional gain parameter for the motion

control. It controls the transitions between the

starting and stopping of the rolls. A lower value

provides a smoother (slower) transition.

• KD: This parameter is not used.

• KFF: Velocity feed forward gain. This is used to

reduce following error of the system.

• AUTO OFFSET: This parameter turns the

automatic offset on. Turn this feature on by

entering ‘

☞

• INPOSN: In-position parameter is a tolerance

window around the final position. This is used to

verify the feed index accuracy is within acceptable

limits before continuing onto the next function.

0’.

SPEED’ parameter. Normally set

KP 0.30

KD 0.00

KFF 0.50

AUTO OFFSET ON

1’.

INPOSN 000.0200

FELIM 5.000

FETIM 0.500

SYSTEM RESET

/SEC’ by

• BACKLIGHT: This turns on the backlight in the

display, which enhances the viewing.

CNTS/UNIT 7353

☞

TIME BASE /SEC

JOG SPEED 5%

DIRECTION CCW

• FELim: Follower error limit. FELim is the

maximum allowed position error. When this limit

is exceeded for the amount of time specified by

the FETime, the control will execute an

emergency stop.

• FETime: Follower error time. FETime is the

5

Page 6

maximum amount of time that the following error

limit may be exceeded before executing an

emergency stop.

• SYSTEM RESET: This function clears all

parameters to the factory default conditions. No

program may be running,

(press and hold the ‘POWER ON’ button), and

PROG/RUN’ switch must be set to ‘PROG’

the ‘

position. Pressing ‘1’ while the cursor is on the

SYSTEM RESET line will result in a confirmation

screen being displayed. Pressing ‘

time will reset the parameters to the factory

default values and the power-up screen will be

displayed. Pressing any other key than ‘

result in aborting the system reset.

RESET must be active

1’ a second

1’ will

4.1 PROGRAM A NEW FEED

LENGTH, COUNT, SPEED

To program a new feed pitch/length the program

must be stopped. This may be done by pressing the

‘POWER ON’ or the ‘CYCLE STOP’ button

(if the press is running). Press the ‘

button to view the following screen:

OPERATOR’

4.2 PROGRAM A NEW

BATCH COUNT

STEP #1

Position the ‘UNDERLINE’ type cursor under

COUNT. Use the ◗ key.

☞

STEP #2

Enter a new desired batch count. For instance....

1000 pieces. Press the ‘

buttons. The control takes a moment to clear the

existing batch count setting in memory, and then

“memorizes” the new value. Enter a value of ‘

disable the batch counter. The display should now

show:

☞

LENGTH 00001.253

C

OUNT 100000

SPEED 0062/SEC

1’, ‘0’, ‘0’, ‘0’, and ‘ENTER’

0’ to

LENGTH 00001.253

C

OUNT 001000

SPEED 0062/SEC

ENGTH 00008.000

L

☞

STEP #1:

The "UNDERLINE" type cursor is located under

the length display whenever this screen is called up.

This indicates that this entry is capable of being

modified.

STEP #2:

Enter a new feed length; for instance...1.253 inches.

Press the ‘1’ key, press the ‘.’ Key, press the ‘2’ key,

press the ‘

‘ENTER’ key. The control will now take a moment

to clear the existing length value in its memory and

then "memorize" the new setting. The display

should now show the new feed length setting. The

maximum feed length is limited to 8,388,608

encoder counts or 1,140 inches.

5’ key, press the ‘3’ key, and press the

COUNT 100000

SPEED 0062/SEC

4.3 PROGRAM A NEW SPEED

FOR THE FEED

STEP#1:

Position the ‘UNDERLINE’ type cursor under

PEED with the

S

☞

STEP #2:

Enter a new speed value, 70 (or 54 for HD) inches

per second is the maximum speed setting. 1 inch

per second is the minimum speed setting.

◗ key.

LENGTH 00001.253

COUNT 001000

S

PEED 0062/SEC

☞

LENGTH 00001.253

COUNT 100000

SPEED 0062/SEC

We will use 50/inches per second as our

example... Press the ‘

The control clears the existing value and inserts

50/seconds into its memory.

6

5’, ‘0’, and ‘ENTER’ buttons.

Page 7

The display should now show the new setting:

LENGTH 00001.253

COUNT 001000

S

☞

PEED 0050/SEC

These (3) parameters may be changed when the

running batch is stopped. All other feeder

parameters are locked out of the editing mode via

‘RUN/PROGRAM’ switch located inside the

electrical enclosure on the panel.

5. OPERATING THE FEED

NOTE:

It is very important to remember that the motor

on the Advantage Servo Roll Feed is only for

feeding material. It is not intended to be the

power source for a pull-through straightening

device, or the like. An adequate free loop must

be provided at all times. This will assure

consistent and accurate feeding.

5.1 PRIORITY MODE

The Advantage Servo Roll Feed has (2) modes

of automatic cycle starting. The Operator can

choose between ‘

and ‘

FEED-BEFORE-PRESS’ (FBP) operating

mode.

PRESS-BEFORE-FEED’ (PBF)

LENGTH’ is reached, then either the ‘JOG FORWARD

work. The ‘

strip to go backwards beyond the initial ‘

LENGTH’

’, or ‘JOG REVERSE’ operator buttons will

JOG REVERSE’ will not allow the

FEED

starting point. The ‘JOG FORWARD’

operator button will function until the end of the

‘

FEED LENGTH’ is reached.

During ‘SET-UP MODE’, the bottom line on the

display will show ‘

‘

FEED LENGTH’ is reached, the jog buttons become

WAITING FOR JOG’. When the

inactive and the message on the display will show

‘

WAITING FOR PRESS’. The jog buttons will not

become active again until after the press has made a

cycle.

5.3 AUTO/MANUAL MODE

‘AUTO MODE’ is used for production running of

the Advantage Servo Roll Feed. When ‘

selected via the 2-position selector switch, the

control is put into ‘

‘

CYCLE START’ button is pressed. During manual

MANUAL MODE’ until the

mode the feeder may be jogged infinitely in either

direction. After the ‘

CYCLE START’ button is

pushed, the jog buttons are inactive, and the feeding

of the strip follows the cam signals from the press.

During ‘

AUTO MODE’, the control keeps check on

synchronization of the feeder and press. If the

Feeder does not complete the index within the feed

cam window, the message ‘

SYNC FAULT’ displays.

AUTO’ is

When ‘PBF’ mode is selected and the ‘CYCLE

START

feeder causes the ‘

’ button is pressed on the control panel, the

AUTO’ and ‘PERMIT PRESS’

relays to turn on thus enabling the start of

continuous cycling on the press.

When ‘

FBP’ is selected and the ‘CYCLE START’

button is pressed on the feed control, the material/

strip will be fed forward the programmed pitch

before the press is started. The Operator may verify

that the strip is in position before starting the press.

The Advantage Servo Roll Feed will now follow the

press until it is stopped by the Operator, counter,

emergency stop, or feed error.

5.2 SET-UP MODE

‘SET-UP MODE’ is used primarily during the threading

of the strip through the die. This mode allows the

‘

JOG-TO-FEED’ Length operations to be performed.

While in ‘SET-UP MODE’, the strip may be moved

using the ‘

the ‘

JOG FORWARD’ operator button. If

JOG FORWARD’ is stopped before the ‘FEED

The Advantage Servo Roll Feed has (2) modes of

automatic cycling. The Feeder can operate with

‘

SINGLE STROKE’ or ‘CONTINUOUS PRESS

MODE

’. The mode is selected through an input

to the feed controller. The press single

‘

STROKE/CONTINUOUS MODE’ switch should be

interfaced to this input for proper operation.

During ‘

‘

PERMIT PRESS’ output relay is activated upon

the completion of each feed index. The ‘

PRESS OUTPUT RELAY

continue cam signal turns on. The ‘

PRESS OUTPUT RELAY

SINGLE STROKE MODE’ operation, the

PERMIT

’ remains active until the

PERMIT

’ may be used to signal

the press when to initiate the single stroke cycle.

The automatic cycling of the press and feeder will

continue until the batch is completed, or the cycle is

stopped by the Operator, or an error occurs.

During ‘

‘

PERMIT PRESS RELAY OUTPUT’ turns on at the

beginning of the indexing. The ‘

RELAY

is stopped by either ‘

COMPLETE’,

CONTINUOUS PRESS MODE’, the

PERMIT PRESS

’ remains active until the automatic cycling

CYCLE STOP’, ‘BATCH

‘SYNC FAULT’, or any other drive

7

Page 8

related error. Under ‘CYCLE STOP’ or ‘BATCH

COMPLETE’

the beginning of the ‘

stopping, the output will turn off at

FEED CAM SIGNAL’. This

should allow the press to stop near the top of the

stroke. Under ‘

conditions, the ‘

SYNC FAULT’ or other drive fault

PERMIT PRESS RELAY’ will turn

off immediately upon detection of the error.

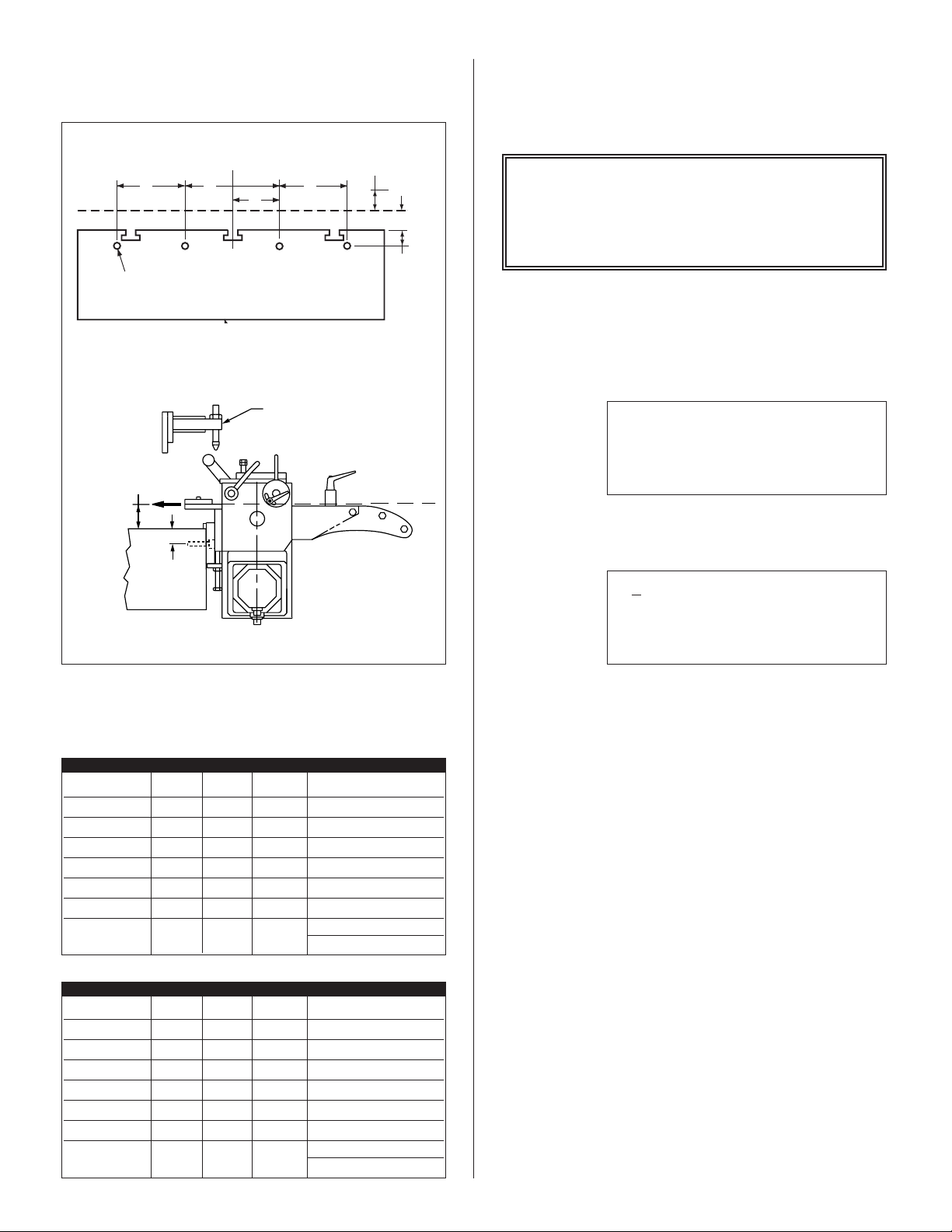

8. Jog the press down slowly observing when the

longest pilot would engage the pilot hole in the

material if the material were there. (Refer to

Figure 4.) Note the press positional readout and

put this setting into your Programmable Limit

Switch (PLS) for the ‘PILOT RELEASE TURN ON’

setting. The ‘PILOT RELEASE TURN ON’ setting

should be 180. (See Figure 5.)

5.4 LOADING THE FEED

ADJUST CAM

WITH MAT’L. IN

FEEDER. SET

FOR MINIMAL

PLAY

IN PILOT

LEVER

PILOT

LEVER

Figure 3.

Use the following steps to load the feeder:

(Refer to Figure 3.)

1. Record the present settings of the feed advance

cam, continue cam, and pilot release cam into a job

set-up record sheet for future reference to the job

(see Programmable Limit Switch Job Set-Up Sheet).

2. Open the feed rolls by pulling on the Roll

Release Lever. Insert the material through the feed

rolls and close the feed rolls by releasing the Roll

Release Lever.

ROLL RELEASE LEVER

MATERIAL THICKNESS ADJUSTMENT CAM

ADJUSTABLE

LOCK

SCREW

DRAWING 17415-02

PILOT PIN

STRIP

Figure 4. PILOT PIN

9. Continue to jog the press slowly until the

longest pilot just comes above the material. Note

the press positional readout and put this setting into

your PLS for the ‘

FEED ADVANCE TURN ON’

setting. Set the ‘FEED ADVANCE TURN OFF’

point approximately 30 degrees less than the pilot

release turn on point. (See Figure 5.)

10. Set the continue cam to turn on at 180 degrees

and to turn off at 200 degrees. This setting should

never need changing. (See Figure 5.)

5.5 RUNNING THE FEED

3. Adjust for the material thickness using the

Material Thickness Adjustment Cam and Adjustable

Lock Screw. Refer to the figure above for proper

setting.

4. Adjust the roll clamping force by pre-loading

the two die springs located on top of the feed

housing. Normal setting for the roll force spring

pre-load is two full turns clockwise from finger

tight. Be sure to use the jam nut to lock the setting.

5. Using the ‘

JOG FORWARD’ button on the jog

pendant, advance the material up to the entrance of

the die (but not too far, where the punches would

pierce the material).

6. Check the vertical alignment of the strip. If

necessary, adjust the pass line of the feeder so that

the material is at the proper height.

7. Assuming that the press shut height and the

tool are set up properly, jog the press one or two

strokes without the feed working.

NOTE ABOUT CAMS:

The Feed Advance Cam (open tool): The

feed system uses this press cam for timing

the feeder to the press crankshaft. Although

no shafting or belts actually connect the

press to the feeder, the feed must be “told”

when it is safe to move the strip and when

the feed move must be completed.

• This “connection” is an electrical one,

and not a mechanical one. This gives the

operator/set-up personnel total flexibility in

deciding when the feed progression should

take place.

• Each die set can have a unique ‘Feed

Angle’. This ‘Feed Angle’ is dependent

upon many variables; pilot and punch

length, press stroke, strip forming in

the die, etc.

8

Page 9

TYPICAL 180 DEGREE FEED ANGLE (FROM 260 DEGREES TO 80 DEGREES)

FEED ADVANCE CAM

180° FEED ANGLE

FEEDER STARTS FEEDING AT 260°

AND MUST BE IN POSITION AT 80°

WITH MECHANICAL PILOT RELEASE:

TDC

0°

80°

FEED CAM “OFF”

FEED MUST BE

“IN POSITION”

260°

FEED CAM “ON”

ROLL CLOSING

ZONE;

FEED ROLLS

MUST FULLY CLOSE

IN THIS ZONE

TO PREVENT ROLL

SLIPPAGE AT START

OF FEEDING

WORKING ANGLE

(PUNCHES IN STRIP)

(ROLLS RELEASED WITH

MECHANICAL RELEASE)

Figure 5. FEED ANGLE

235°

SAFETY ANGLE;

PRESS RAM MUST

STOP IN THIS ZONE

IN EVENT OF A

FEED ERROR

125°

ROLL OPENING

ZONE FOR

PILOT RELEASE

(PNEUMATIC OR

MECHANICAL)

200°

180°

BDC

CONTINUE CAM SIGNAL

CONTINUE CAM “ON” AT 180°

CONTINUE CAM “OFF” AT 200°

DRAWING 17141-02

All the adjustments to the feed system and press

have now been made. The press is at Top Dead

Center (

TDC) and ready for automatic cycling.

Proceed by inching the press thru another stroke,

verifying that things are happening at the correct

time (pilot release, feed advance). If the system is

operating properly, you can make a few more “hits”,

check your parts, and then put the press into

continuous mode.

The Advantage Servo Roll Feed will now follow

the press until it is stopped by the Operator,

counter, emergency stop, or feed error.

The display will show:

LENGTH 00001.253

COUNT 001000

SPEED 0050/SEC

BATCH RUNNING

The speed performance chart (Figure 6) is to be

used as a guide only. Actual feeder/press speeds

may vary depending on factors such as material

thickness, width, rigidity, surface finish, and line

payoff/straightener conditions.

9

Page 10

NOTES ABOUT

"POSSIBLE PROBLEM TOOLING":*

•

A tight die, one that is not square, or has other

tooling problems, will cause significant difficulty

and downtime. Accuracy in feeding is directly

related to how easily the feeder can position the

strip in the die. Binding, bad part ejection, or

sticking parts may cause the material to "jam" in

the die.

• The Advantage Servo Roll Feed will "try" to

overcome the "jam-up" by applying more power

to the rolls.

ONE OF FOUR OUTCOMES WILL RESULT:

•

The feed will continue to try to move the strip

(if the rolls do not slip) until the feed advance

cam opens. A Sync Fault Error will occur and

the press will be stopped by the feeder.

• The feed will apply more power to the rolls,

causing them to slip on the material. This

produces a "short-feed". In reality the feeder

Figure 6. SPEED PERFORMANCE CHART

did not "misfeed". The rolls were positioned

properly, the strip did not keep up, causing the

die to close and a miss-hit is produced.

• The feed applies more power to a thin strip,

causing the material to buckle somewhere

between the feed and the die set. The feeder

positioned the strip accurately, it just did not

occur in the die set.

• The feed tries to apply so much power to a heavy

strip in order to move it, that excessive current is

drawn by the servo drive. This results in the

drive shutting down to protect itself and in doing

so stops the press.

NOTE: The feed detected a problem and

emergency-stopped the press before the die

closed. In using the Advantage Servo Roll Feed,

you in fact have added a "die protection" system

to your tooling.

* A tooling problem is a problem caused by tooling

and not the Feeder itself.

VELOCITY = 72 In./Sec. ACCEL = 402 In./Sec

FEED (In.) FEED (mm) FEED TIME (Sec.) 90° 180° 270°

0.25 6.35 0.085 176 353 529

0.50 12.7 0.106 142 284 426

0.75 19.05 0.122 123 247 370

1.00 25.4 0.135 111 333 333

2.00 50.8 0.176 85 170 255

3.00 76.2 0.208 72 144 216

4.00 101.6 0.235 64 128 191

5.00 127 0.259 58 116 174

6.00 152.4 0.280 54 107 161

7.00 177.8 0.300 50 100 150

8.00 203.2 0.318 47 94 142

9.00 228.6 0.335 45 90 134

10.00 254 0.351 43 85 128

11.00 279.4 0.367 41 82 123

12.00 304.8 0.381 39 79 118

14.00 355.6 0.409 37 73 110

16.00 406.4 0.435 34 69 103

18.00 457.2 0.459 33 65 98

20.00 508 0.482 31 62 93

22.00 558.8 0.504 30 60 89

24.00 609.6 0.525 29 57 86

26.00 660.4 0.545 28 55 83

28.00 711.2 0.565 27 53 80

30.00 762 0.585 26 51 77

35.00 889 0.635 24 47 71

40.00 1016 0.685 22 44 66

45.00 1143 0.735 20 41 61

50.00 1270 0.785 19 38 57

55.00 1397 0.835 18 36 54

60.00 1524 0.885 17 34 51

2

FEED CAM WINDOW DEGREES

STROKES PER MINUTE

10

Page 11

6. TROUBLESHOOTING GUIDE

The chart that follows contains the most frequently encountered issues.

SYMPTOM CAUSE or REMEDY

No power indication when • Check main power supply for proper voltage.

‘POWER ON’ button is pressed

No display on power up • Check cabling connection between display and servo drive.

Feed will not jog • Check that the Feed is in manual mode. Move selector switch to ‘AUTO’;

• Check supply fuses and circuit breakers.

• Verify that the main disconnect switch is on.

• Verify that the E-Stop is not engaged (E-Stop Loop closed.)

• Check bulb in ‘POWER ON’ push button.

• Check 5 Volt logic supply LED on motion control card on right side

of Servo Drive/Amplifier under orange connectors.

• Check fuses in drive under right side cover.

press the ‘POWER ON’ push button to reset control.

• Check if the Feed is in ‘SET-UP’ mode. Waiting for press.

• Check if ‘IN POSITION’ indicator is off. Check parameters. Check drive

for Error Codes.

• Check ‘FAULT’ in display. i.e. ‘SERVO AMP FAULT’. Check drive for Error

Code. See Section 6.1

‘POWER ON’ indicator is lit, • Check that the ‘IN POSITION’ indicator is lit. If not, check parameters.

Feed will not operate.

Feed will not accept new feed • Check that the Selector switch is in Set-Up mode (running Set-Up program).

length or other parameters

Inaccurate feeding • Adjust rolls for correct material thickness; roll release lever must have

Feed runs backwards • Check for negative feed length, i.e. minus sign in length (–5.125).

• Check that the Error message is in the Display. If so, check error

description in Section 6.1

• Move selector switch to Auto, press ‘POWER ON’ button (E-Stop will show

in display), release ‘POWER ON’ button, try to jog feeder.

• Check that the Selector switch is in Auto mode and ‘CYCLE START’ has

been pressed (running Auto Program). Press ‘POWER ON’ push button

to reset.

• Check that the Run/Program toggle switch is in ‘RUN’ position; this will only

allow length, speed, and count to be changed. Set the Program Position;

then the Program position will allow any parameter to be changed.

small amount of play/wobble in it.

• Adjust spring pressure (Do not bottom springs. Catastrophic damage

can occur.)

• Confirm if rolls are slipping on strip. Remove oil from feed rolls, reduce

acceleration, check tool for binding/slugs, etc.

• Adjust Upstream Equipment if Upstream equipment not providing

adequate/consistent free loop.

• Check roll release for proper settings.

• Verify that direction parameter has been reset. Check CW or CCW

direction parameter.

Servo Amp Fault This is a generic display prompt indicating a fault on the Servo Amplifier.

• Look at the diagnostic display on the Servo Amplifier. The cause of the

fault can be determined by reading the Error Code.

• Refer to Sections 6.1 and 6.2. This fault condition can be caused by any

one of the errors in the lists.

• Check for Error Code first, then reset the Servo Amplifier by turning the

power off, waiting 10 seconds, then powering back on.

• Verify that the fault will not reset. Call the factory for assistance.

11

Page 12

Some errors encountered with the Advantage Servo Roll Feed may be diagnosed by the motion controller. These

errors are typically displayed on the bottom line of the Operator Terminal Display. These errors are related to

improper motion of the servomotor. These errors are listed below. These errors may be reset by either pushing

‘

POWER ON’, which has a reset function, or by power-down and power-up.

6.1 PRO-200 MOTION CONTROL CARD ERRORS

SYMPTOM REMEDY

Encoder Feedback Error or • Simultaneous transitions on the ‘A’ and ‘B’ channels of the encoder were

Encoder Fault detected or one of the encoder signals is missing (possible broken wire).

Check Pilot Release settings for accuracy. Check Cabling.

Amplifier Fault Detected • The System Status Output from the Servo Amplifier went ‘OFF’, indicating

a problem with the Servo Amplifier. Try to reset fault by pressing

‘POWER ON’. Check Servo Amplifier for faults.

Excessive Follower Error • The follower error has exceeded the programmed maximum Follower

Error Limit (FEL) for the Programmed Follower Error time (FET).

• Check for loose or damaged encoder cable or motor cable.

• Check parameters for FEL and FET. Raise the values to see if error

diminishes.

• Check for excessively -speed setting. (I.e. above 72 Inches/Second)

• Check for binding in the tool. Check for mechanical binding or overload

caused by material or tooling.

Nonvolatile RAM Checksum Error • The process found a problem with the checksum of the parameters.

The most likely cause of this will be a power failure while entering new

data or electrical noise at power up/down.

• Loss of power while entering the parameters

• Electrical noise addection the control. Check all solenoids and relays for

surge suppression.

Parameter Error • A parameter was entered improperly. Review all parameters per legend

panel. Correct any deviant parameters.

Watchdog Time-out Fault • Check that the watchdog timer triggered, indicating that the

microprocessor was not operating properly or momentary power failure.

Frequently caused by ‘POWER OFF’ immediately followed by ‘POWER ON’

without waiting for ‘POWER ON’.

• Wait 10 seconds after power down before power on.

Limit Switch Hit • Check if the ‘FORWARD LIMIT’ or ‘REVERSE LIMIT’ switch has

been activated.

• Check Limit Switch for end of material at inlet of feeder.

• Check the inputs for 24 DC on the control.

If the problem you are having does not appear in the above chart, or does appear in the chart and you have

questions about it, call the P/A Service Department for assistance. Please have your Model Number and Serial

Number ready. However, it is advisable to check the basics before calling to be sure the problem is not

something simple that may have been overlooked.

The servo drive module has built in diagnostics in the form of LED Status Display. You can also display errors

on a PC (Personal Computer) terminal using special software available on request. See the following pages for

more detailed information.

12

Page 13

6.2 DDM DRIVE ERROR MESSAGES

If there is a fault, the drive provides specific error

messages. Faults are detected by the drive in two

ways: power-up hardware and run-time faults. A

power-up fault usually requires servicing of the

hardware. A run-time fault can be cleared by

resetting the drive.

6.4 POWER-UP ERROR CODES

A power-up error indicates in almost all cases that

the drive should be returned to the factory for

service. In general, any occurrence of a Power-up

error should be treated with extreme caution. It may

indicate the hardware is marginal. (Refer to the

following table for Power-Up Error Codes).

The Status display, located on the front of the servo

drive module, indicates faults by flashing the letter

‘

E’, followed by additional digits to indicate the

error. The error display repeats until the drive is

reset or powered down.

For example, ‘

E..0..9..E..0..9..E..0..9..’ indicates

a Bus Under voltage fault. When an error occurs,

the error code and the service time of the error are

logged into a Fault History record stored in EPROM.

(Refer to Section 6.3)

6.3 RUN TIME ERROR CODES

STATUS ERROR FAULT

DISPLAY CODE DESCRIPTION

E....0....1 01 +24 VDC Fuse blown

E....0....2 02 +5 VDC Fuse blown

E....0....3 03 Encoder Power Fuse blown

E....0....4 04 Motor Over temperature,

Thermostat

E....0....5 05 IPM Fault (Over temperature/

Over current/Short Circuit)

E....0....6 06 Channel IM Line Break

E....0....7 07 Channel BM Line Break

E....0....8 08 Channel AM Line Break

E....0....9 09 Bus Under voltage

E....1....0 10 Bus Over voltage

E....1....1 11 Illegal Hall State

E....1....2 12 Unused interrupt - sub

processor

E....1....3 13 Unused interrupt - main

processor

E....1....4 14 Reserved

E....1....5 15 Reserved

E....1....6 16 Reserved

E....1....7 17 Excessive Average Current

E....1....8 18 Motor Over speed

E....1....9 19 Excessive Following Error

E....2....0 20 Motor Encoder State Error

E....2....1 21 Auxiliary Encoder State Error

E....2....2 22 Motor Thermal Protection

E....2....3 23 IPM Thermal Protection

24 - 27 Reserved

E....2....8 28 No Motor Selected

E....2....9 29 Motor Selection not in Table

E....3....0 30 Personality Write Error

E....3....1 31 Service Write Error

E....3....2 32 CPU Communications Error

STATUS ERROR FAULT

DISPLAY CODE DESCRIPTION

E....5....1 51 Program Memory Boot Block Error

E....5....2 52 Program Memory Main Block

Error

E....5....3 53 Uninitialized Personality EPROM

Error

E....5....4 54 Personality EPROM Read Error

E....5....5 55 Personality EPROM Data

Corruption

E....5....6 56 Main Processor Watchdog Error

E....5....7 57 Sub Processor Watchdog Error

E....5....8 58 Main Processor RAM Error

E....5....9 59 Sub Processor RAM Error

E....6....0 60 Uninitialized Service EPROM

Error

E....6....1 61 Service EPROM Read Error

E....6....2 62 Service EPROM Data Corruption

Error

E....6....3 63 Main Processor AID Converter

Error

E....6....4 64 Sub Processor A/D Converter

Error

E....6....5 65 ANALOG 1 Output Error

E....6....6 66 Gate Array Error

E....6....7 67 ANALOG2 Output Error

E....6....8 68 Inter-Processor Communication

Error

E....6....9 69 Sub Processor Initialization Error

E....7....0 70 Sub Processor SRAM Error

E....7....1 71 Sub Processor Code Loading

Error

E....7....2 72 Sub Processor Start-up Error

E....7....3 73 Sub Processor Checklist Error

E....7....4 74 Personality EPROM Write Error

E....7....5 75 Service EPROM Write Error

E....7....6 76 Software Clock Error

E....7....7 77 Sub Processor Communication

Checklist Error

E....7....8 78 Sine Table Generation Error

E....7....9 79 Personality Data Out of Range

E....8....1 80 Service Data Out of Range

E....8....2 81 Motor Block Checksum Error

7. MAINTENANCE

The Advantage Servo Roll Feed needs very little

maintenance to keep the system operating at its

optimum performance.

13

Page 14

• This precision equipment must be kept as clean

as possible. This is especially important if large

amounts of air suspended oil mists in combination

with “dirty metals” are used. The resulting abrasive

dust can attach itself to the feed rolls and other

surfaces, leading to premature wear on many

parts.

• The roll release system requires clean, dry air supply.

• Some bearings used on the feeder are fully sealed

and maintenance-free roller ball bearings. The

exceptions are provided with standard “zerk” type

grease fittings. They should be lubricated with a

good grade of high pressure bearing grease. The

frequency of lubrication will depend on the overall

usage of the system. A small “shot” once a day is a

good starting point. The cluster gear set should be

coated with a small amount of open gear grease.

• The main drive belt should be checked

periodically for tightness. It can be adjusted by

loosening the two fasteners on the motor adjuster

plate, applying downward pressure on the

motor adapter plate, and retightening.

ERRATIC MOTOR BEHAVIOR WILL BE

EXPERIENCED IF THE DRIVE BELT IS

LOOSE!

• All fasteners should be checked for tightness at

regular intervals. The electrical system also requires

very little maintenance. Keep the enclosure clean

and replace any burned indicator bulbs. Do not

expose the electrical enclosure to constant high

temperatures. Possible system failure could result.

• The Feeder’s electrical enclosure door is sealed

to prevent oil and contaminants from entering

inside. However, small gaps can be found around

some sealing surfaces and faceplates. It is a good

idea, therefore, to keep the console free of

stamping oils and fluids, which could "seep into"

the enclosure. Most often, these oils are carried by

the operator’s hands or by air mist lubrication etc.

• All of the above guidelines should be added to

your existing pressroom Preventive Maintenance

(PM) Program.

8. ROLL FEED PARTS LIST & DIAGRAM

ITEM QTY DESCRIPTION

1 1 BEARING HOUSING - LEFT SIDE PLATE

2 1 BEARING HOUSING - RIGHT SIDE PLATE

3 1 PLATE- CASCADE MTG.

4 1 PLATE - FEED MTG.

5 1 PLATE - EXIT

6 1 PLATE - MATERIAL HOLD DOWN

7 1 BRACKET - UPPER ROLL, LEFT

8 1 BRACKET - UPPER ROLL, RIGHT

9 1 PLATE - UPPER ROLL

10 1 GUARD - ENTRY

11 1 ROLL - LOWER

12 2 DUST SHIELD - LOWER

13 1 SPACER - LOWER

14 2 BEARING - LOWER

15 1 GEAR - LOWER

16 1 ROLL - UPPER

17 2 DUST SHIELD - UPPER

18 2 RETAINING RING

19 2 BEARING - UPPER

20 1 GEAR - UPPER

21 1 SHAFT - THICKNESS ADJUSTMENT

22 1 LEVER - THICKNESS ADJUSTMENT

23 1 CAM ECCENTRIC BUSHING

24 1 BUSHING - TAPER LOCK - INNER

25 1 BUSHING - TAPER LOCK - OUTER

26 1 SHAFT - ROLL RELEASE

27 2 BEARING, NEEDLE

28 2 WEAR PAD

29 1 RELEASE LEVER - MANUAL

30 1 RELEASE LEVER - MECHANICAL

31 1 BEARING - ROLL RELEASE

32 1 SPACER - RELEASE BEARING

33 2 RETAINER, SPRING ROD

ITEM QTY DESCRIPTION

34 2 ROD, ROLL TENSION

35 2 SPRING, ROLL TENSION

36 1 SET SCREW M6 X 16

37 2 BRACKET - CASCADE

38 1 BLOCK - CASCADE MTG., LEFT

39 1 BLOCK - CASCADE MTG., RIGHT

40 1 PLATE - ENTRY

41 2 BAR - GUIDE ROLLER

42 2 CLAMP - GUIDE BAR

43 2 GUIDE ROLLER

44 4 SPACER - GUIDE ROLLER

45 2 NUT - T SLOT

46 3 ROLL - CASCADE, ENTRY

47 3 SHAFT - ROLL

48 10 BEARING - GUIDE & ENTRY ROLL

49 1 TRANSITION PLATE

50 1 ADJUSTMENT TAB

51 1 SCREW - HEX HD

52 1 NUT - HEX, JAM

53 1 KEY 22mm x 5mm x 110mm

54 2 KEY 22mm x 12mm x 40mm

55 1 STRIKER - RELEASE ACTUATOR

56 1 ARM - ADJUST

57 1 ARM - FIXED

58 1 BLOCK - MOUNTING

59 1 BRACKET - MOUNTING

60 1 NUT, STRIKER ADJUST

63 1 KEY 7mm SQ x 35mm

64 1 KEY 5mm SQ x 15mm

65 4 GREASE FITTING

67 4 NUT, M14, ROLL TENSION

69 2 HANDLE, WIDTH GUIDE ADJUSTMENT

70 1 HANDLE, THICKNESS ADJUSTMENT

71 6 NUT, HEX

14

Page 15

ADVANTAGE MECHANICAL PARTS DIAGRAM

DRAWING A17135-01

PNEUMATIC PILOT RELEASE

Item Description Part No.

1 Solenoid Valve 12039-62 (120V)

Solenoid Valve 12039-67 (220V)

Solenoid Valve 12039-68 (24VDC)

Solenoid Valve 12039-69 (24VAC)

2 Cylinder 12111-27

3 Bracket 16730

4 Suppressor 16286-02 (120V)

4 Suppressor 16286-03 (220V)

4 Suppressor 16286-04 (24VDC & 24VAC)

15

Page 16

WARNING

This equipment offers various means of operating or

controlling machines. The operator must not be in or

near the point-of-operation of the machine, or the

operating parts of any equipment installed on the

machine, or bodily injury could result. The EMPLOYER

must post adequate warning signs onto the machine with

proper warnings for his machine and the specific

application to which the machine and equipment are

being applied.

Occupational Safety and Health Act (OSHA) Sections

1910.211, 1910.212, and 1910.217 contain installation

information on the distance between danger points and

point-of-operation guards and devices. No specific

references have been made to which paragraph

of OSHA 1910.211, 1910.212, 1910.217, or any other

applicable sections because the paragraphs may change

with each edition of the publication of OSHA

provisions.

All equipment manufactured by us is designed to meet

the construction standards of OSHA in effect at the

time of sale, but the EMPLOYER installs the equipment

so the EMPLOYER is responsible for installation, use,

application, training, and maintenance, as well as

adequate signs on the machine onto which this

equipment will be installed.

Remember, OSHA says that the EMPLOYER must use

operating methods designed to control or

eliminate hazards to operating personnel.

It shall be the responsibility of the EMPLOYER to

establish and follow a program of periodic and regular

inspections of his machine to insure that all their parts,

auxiliary equipment, and safeguards are in a safe

operating condition and adjustment. Each machine

should be inspected and tested no less than weekly to

determine the condition of the machine. Necessary

maintenance or repair of both shall be performed and

completed before the machine is operated. The

EMPLOYER shall maintain records of these inspections

and the maintenance work performed.

Our Company is not responsible to notify the user of

this equipment of future changes in State or Federal

laws, or construction standards.

SAFETY PROGRAM

Accident free operation will result from a well developed,

management sponsored and enforced safety program.

Of vital importance to any successful program is the

proper selection of guards and devices. However, there is

no safety device that will bring "automatic" safety to

your operation.

Of equal importance to this proper selection of the guard

and the device is the training of your personnel. Each

person must be trained as to the operation of the guard

or safety device, highlighting why they have been

provided on the equipment. Rules for safe operating

should be written and enforced at all times. A final

major concern of an effective safety program is regularly

scheduled inspection and maintenance of all of the

equipment.

To ensure continued safety at all times, top management,

line supervision, safety engineers and all employees must

assume their proper share of the responsibility in the

program. Only as a group, one that knows your own

operation and its problems, can you carry out an

effective safety program.

To assist you in the development of and continued use

of safety programs, many safety minded groups have

made guidelines available to you. However, you must

know when and how to apply these guidelines. The

manufacturer provides information to assist you in

properly adjusting and maintaining your equipment.

There is no shortcut to proper safety; therefore, it is

recommended that you comply with their

recommendations at all times.

WARRANTY

We warrant our new parts against defects under normal

use and service for a period of 12 months after date of

shipment. Our obligation under this warranty is limited

to replacing or repairing (at our option) the defective

part without charge, Freight On Board (FOB) our plant

in Bloomfield, Connecticut. The defective part must be

forwarded to our plant, freight prepaid, for our inspection

prior to replacement or repair. EXCEPT AS EXPRESSLY

PROVIDED HEREIN, THIS WARRANTY IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING A WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Furthermore, the seller does

not warrant or represent that the equipment complies

with the provisions of any law, particularly including the

Occupational Safety and Health Act of 1970, and

regulations promulgated thereunder. In no event shall we

be liable for special, indirect incidental or consequential

damages, however rising.

P/A INDUSTRIES INC. 522 Cottage Grove Road • Bloomfield, Connecticut 06002-3191 U.S.A.

Toll Free 1-800-243-8306 • Worldwide 1-860-243-8306 • Fax 1-860-242-4870

Website http://www.pa.com • E-Mail service@pa.com

FORM 1036 12-00

16

Loading...

Loading...