Page 1

Page 2

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

TABLE OF CONTENTS

DESCRIPTION PAGE

1 INSTALLATION .............................................................................................................................................. 3

1.1 MECHANICAL INSTALLATION............................................................................................................ 3

1.2 ELECTRICAL INSTALLATION ............................................................................................................. 5

1.3 PLS ENCODER INSTALLATION ......................................................................................................... 6

1.4 LOADING THE FEED............................................................................................................................. 7

1.5 THREADING THE TOOL....................................................................................................................... 8

1.6 RUNNING THE FEED ............................................................................................................................ 9

3 MAINTENANCE........................................................................................................................................... 11

4 ROLL FEED PARTS LIST........................................................................................................................... 12

WARNING......................................................................................................................................................... 16

SAFETY PROGRAM....................................................................................................................................... 16

WARRANTY ..................................................................................................................................................... 16

2

Page 3

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

1 INSTALLATION

1.1 MECHANICAL INSTALLATION

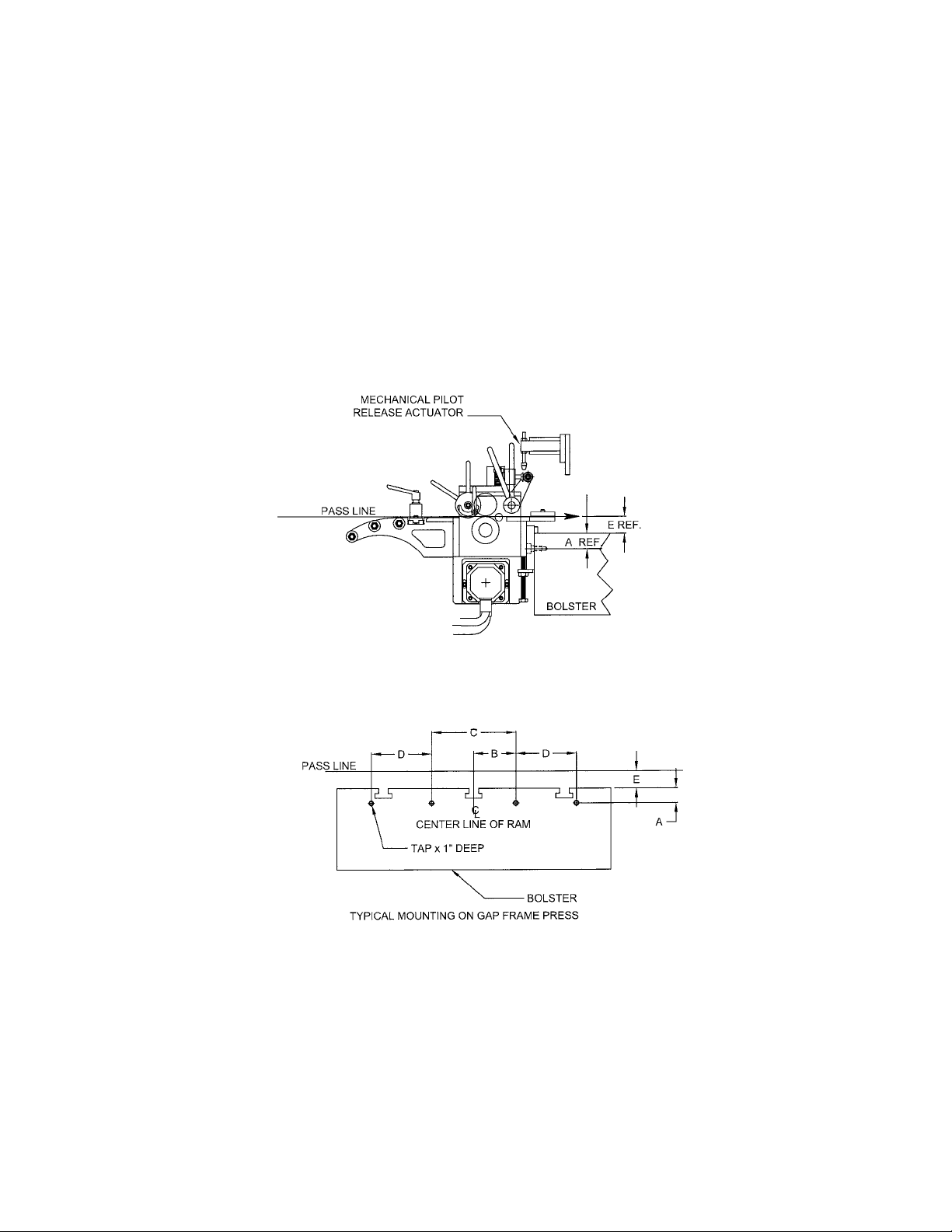

The Servo Pilot Release assembly comes fully installed on the Servo Roll Feed so that no installation tasks are

required. The Ultra Advantage Servo Roll Feed is supplied with an adjustable mounting bracket. The feed should be

securely mounted to the press frame. (A transition bracket is sometimes required in certain applications.) The feed

should be centered, square, and perpendicular to the pass line of the press. It should be mounted at a height that will

accommodate the appropriate die sets. The feed has a pass line height adjustment of ±1.2 inches. (Note: The centerline

of the Feeder is NOT the centerline of the rolls.) Refer to FIGURE 1 for dimensions.

The feeder may be used to push or pull strip stock through the die.

FIGURE 1

3

Page 4

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

MOUNTING HOLE DIMENSIONS

ENGLISH-INCHES

DIMENSION SRF-5 SRF-8 SRF-12 SRF-16/20/24/28/32/36

A

B 3.15 3.94 3.94 3.94

C 6.30 7.87 7.87 7.87

D - - - 5.91

TAP M16 M16 M16 M16

E MIN. 2.4 2.4 2.4 2.4

1.97 1.97 1.97 1.97

PASS LINE

ADJUSTMENT

WIDTH OF

MTG. PLATE

+2.4

-0.0

+2.4

-0.0

+2.4

-0.0

+2.4

-0.0

12.13 14.88 18.82 22.76 / 26.69 / 30.63

34.57 / 38.50 / 43.19

METRIC- ( MM )

DIMENSION SRF-5 SRF-8 SRF-12 SRF-16/20/24/28/32/36

A

50 50 50 50

B 80 100 100 100

C 160 200 200 200

D - - - 150

TAP M16 M16 M16 M16

E MIN. 60 60 60 60

PASS LINE

ADJUSTMENT

WIDTH OF

+60

-0.0

+60

-0.0

+60

-0.0

+60

-00.0

308 378 478 578 / 678 / 778

MTG. PLATE

FIGURE 2

878 / 978 / 1097

4

Page 5

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

1.2 ELECTRICAL INSTALLATION

The Ultra Advantage Servo Roll Feed has been designed to make electrical connections quickly and easily. All that is

required is a "clean" 220 VAC single-phase 32-ampere source that must be connected to the main disconnect switch.

(Three phase 400 Volt power source can be used if 220 Volt single phase is not available). It is recommended that #12

MTW (Machine Tool Wire) be used for the primary power supply input.

The inputs and outputs to your press control (i.e. Emergency Stop) must also be connected for proper operation.

The Feed motor connects by factory installed "Amphenol" (Military Specifications) Quick connectors.

The Release motor connects by factory installed "ITT Industries, Cannon ®" (Twist Lock) Quick connectors.

For more detailed wiring information, refer to Electrical Schematic:

A-18164-15 UltraAdv-SPR US;

A-18164-16 UltraAdv-SPR CE;

IMPORTANT!

A #12 MTW GROUNDING CONDUCTOR MUST BE INSTALLED FOR PROPER MACHINE GROUNDING.

NOTE:

All connections should be made in accordance with National Electrical Code (NEC) requirements and must

comply with all local ordinances.

NOTE:

A word about electrical “noise” - Most pressroom environments contain considerable electrical noise. It is

emitted from electro-mechanical press relays, contacts, and solenoids. While the Ultra Advantage Servo Roll

Feed has been designed to minimize “self generated” electrical noise, it is difficult to provide protection for all

applications. If erratic system behavior is experienced, then the source of the "noise" must be suppressed with

either a resistive/capacitive type of suppressor on AC coils, or “Avalanche” type diodes on DC coils.

NOTE:

The Ultra Advantage Servo Roll Feed is fully protected by line circuit breakers.

NOTE:

The electrical control enclosure is supplied with a stand/support, which may be placed in any convenient location.

The enclosure may also be mounted in any fixed location as long as the cabling is adequate to reach the feed. It is

not recommended that the electrical enclosure be mounted directly to the press. The vibrations caused by the

punch press can result in damage to the control system

5

Page 6

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

1.3 PLS ENCODER INSTALLATION

The PLS encoder must be mounted on the press so its shaft is coupled or belted to the crankshaft with one to one (1:1)

ratio. It is strongly recommended to use plastic chain or timing belt and plastic or aluminum sprockets on the encoder

shaft.

When all required electrical connections are made, power up the feed control and bring up the Status screen:

T o o l # 1 P o s : 1 8 2

M a n u a l M o d e

3 0 / C o n t . R u n

P r e s s a M o d e K e y

Inch the press and watch the press position reading on the status screen. Verify that as the press is moving, the press

position reading is changing in ascending order. If it is changing in descending order, then power down the feed control

and swap the following wires:

Servo drive connector CN1B, pin 2 - orange wire;

Servo drive connector CN1B, pin 3 – red wire.

Power up the feed control and verify that the press reading is now changing in ascending order as the press moving.

NOTE:

CN1A and CN1B signal connectors on the Ultra5000 drive are spring-clamp connectors. A rectangle hole next to

each wire hole is used to unclamp the connection by inserting the miniature screwdriver provided with the servo

feed control.

6

Page 7

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

1.4 LOADING THE FEED

FIGURE 3

Prior to this step, the electrical control must be powered up and all needed parameters are loaded.

(Refer to the Ultra Advantage Servo Feed Operating Manual.)

1. Adjust the roll clamping force by pre-loading the two die springs located on top of the feed housing. Normal

setting for the roll force spring pre-load is two full turns clockwise from finger tight (factory preset). Be sure to

use the jam nut to lock the setting.

2. Open the feed rolls by pulling on the Roll Release Lever. Insert the material through the feed rolls and close the

feed rolls by releasing the Roll Release Lever.

3. Adjust for the material thickness using the Material Thickness Adjustment Cam and Adjustable Lock Screw.

Refer to the FIGURE 3 for proper setting.

0

4. The Servo Pilot Release comes with the Release Angle parameter set for 15

Open/Close switch and verify if this angle provides appropriate roll opening for material release and adjust it if

necessary. (Refer to the Ultra Advantage Servo Feed Operating Manual.) Close rolls.

5. Put the Ultra Advantage control into “MANUAL MODE”.

6. Using the Jog Forward button on the jog pendant, advance the material up to the entrance of the die (far

enough where the punches would not

7. Check the vertical alignment of the strip. If necessary, adjust the pass line of the feeder so that the material is at

the proper height.

pierce the material).

. Open rolls using jog pendant

8. Assuming that the press shut height and the tool are set up properly, jog the press one or two strokes without the

feed working.

9. Open the Pilot Release screen of your previously created Tool program. Jog the press down slowly observing

when the longest pilot would engage the pilot hole in the material if the material were there. (Refer to Figure 4.)

Note the press positional readout (on the right top corner of Pilot Release screen) and put this setting for the

‘Pilot Release On’ setting. The ‘Pilot Release Off’ setting, in most cases, should be 180º. (See Figure 5.)

Some drawing applications require the rolls to remain open past 180º.

7

Page 8

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

FIGURE 4

10. Open the Feed Cam screen. Continue to jog the press slowly until the longest pilot just comes out of the

material. Note the press positional readout and put this setting for the ‘Feed Cam On’ setting. Set the ‘Feed

Cam Off’ point so that there is enough time to complete the feed length and enough time to stop the press, if

there is a feed fault. (See Figure 5.)

11. Open the Reset Cam screen and set the ‘Reset Cam On’ for 180 degrees and ‘Reset Cam Off’ for 200 degrees.

This setting should never need changing. (See Figure 5.)

1.5 THREADING THE TOOL

For a comprehensive description, refer to the Ultra Advantage Servo Roll Feed Operation Manual.

NOTE ABOUT CAMS:

The Feed Cam (open tool): The feed system uses this press cam for timing the feeder to the press crankshaft.

Although no shafting or belts actually connect the press to the feeder, the feed must be “told” when it is safe to

move the strip and when the feed move must be completed.

• This “connection” is an electrical one, and not a mechanical one. This gives the Operator/set-up personnel

total flexibility in deciding when the feed progression should take place.

• Each die set can have a unique ‘Feed Angle’. This ‘Feed Angle’ is dependent upon many variables; pilot and

punch length, press stroke, strip forming in the die, etc.

Put the Ultra Advantage control into “JTL” mode. All the adjustments to the feed system and press have now

been made. The press is at Top Dead Center (TDC) and ready for automatic cycling. Proceed by advancing the

material using Jog Forward button on the jog pendant until WAITING FOR PRESS is seen in the display and

inch the press through another stroke, verifying that things are happening at the correct time (Roll Release, etc.).

If the system is operating properly, you can make a few more “hits”, checking your parts.

8

Page 9

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

1.6 RUNNING THE FEED

Put the Ultra Advantage into “Auto” mode and press the Cycle Start button. The Ultra

Advantage Servo Roll Feed will now follow the press until it is stopped by the Operator,

counter, emergency stop, or feed error.

TYPICAL 180 DEGREE FEED ANGLE (FROM 260 DEGREES TO 80

DEGREES) WITH MECHANICAL PILOT RELEASE:

9

Page 10

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

NOTES ABOUT ‘POSSIBLE PROBLEM TOOLING’: *

o A tight die, one that is not square, or has other tooling problems, will cause

significant difficulty and downtime. Accuracy in feeding is directly related to how

easily the feeder can position the strip in the die. Binding, bad part ejection, or

sticking parts may cause the material to "jam" in the die.

o The Ultra Advantage Servo Roll Feed will "try" to overcome the "jam-up" by

applying more power to the rolls.

ONE OF FOUR OUTCOMES WILL RESULT:

1. The feed will continue to try to move the strip (if the rolls do not slip) until the Feed

Cam opens. A SYNC FAULT Error will occur and the press will be stopped by the

feeder.

2. The feed will apply more power to the rolls, causing them to slip on the material.

This produces a "short-feed". In reality the feeder did not "miss-feed". The rolls

were positioned properly, the strip did not keep up, causing the die to close and a

miss-hit is produced.

3. The feed applies more power to a thin strip, causing the material to buckle

somewhere between the feed and the die set. The feeder positioned the strip

accurately, it just did not occur in the die set.

4. The feed tries to apply so much power to a heavy strip in order to move it, that

excessive current is drawn by the servo drive. This results in the drive shutting down

to protect itself and in doing so stops the press.

NOTE: The feed detected a problem and emergency-stopped the press before the die

closed. In using the Ultra Advantage Servo Roll Feed, you in fact have added a "die

protection" system to your tooling.

* A tooling problem is a problem caused by tooling and not the Feeder itself.

.

10

Page 11

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

3 MAINTENANCE

The Ultra Advantage Servo Roll Feed needs very little maintenance to keep the system operating at its optimum

performance.

o This precision equipment must be kept as clean as possible. This is especially important if

large amounts of air suspended oil mists in combination with “dirty metals” are used. The

resulting abrasive dust can attach itself to the feed rolls and other surfaces, leading to

premature wear on many parts.

o Some bearings used on the feeder are fully sealed and maintenance-free roller ball bearings.

The exceptions are provided with standard “zerk” type grease fittings. They should be

lubricated with a good grade of high pressure bearing grease. The frequency of lubrication will

depend on the overall usage of the system. A small “shot” once a day is a good starting point.

The feed roll gears set should be coated with a small amount of open gear grease.

o The main drive belt should be checked periodically for tightness. It can be adjusted by

loosening the two fasteners on the motor adjuster plate, applying downward pressure on the

motor adapter plate, and retightening. ERRATIC MOTOR BEHAVIOR WILL BE

EXPERIENCED IF THE DRIVE BELT IS LOOSE!

o All fasteners should be checked for tightness at regular intervals.

o The electrical system also requires very little maintenance. Keep the enclosure clean and

replace any burned indicator bulbs. Do not expose the electrical enclosure to constant high

temperatures. Possible system failure could result.

o The Feeder’s electrical enclosure door is sealed to prevent oil and contaminants from entering

inside. However, small gaps can be found around some sealing surfaces and faceplates. It is a

good idea, therefore, to keep the console free of stamping oils and fluids, which could "seep

into" the enclosure. Most often, these oils are carried by the Operator’s hands or by air mist

lubrication etc.

o All of the above guidelines should be added to your existing pressroom Preventive

Maintenance (PM) Program.

11

Page 12

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

4 ROLL FEED PARTS LIST

FIGURE 7

12

Page 13

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

ITEM QTY DESCRIPTION

1 1 BEARING HOUSING - LEFT SIDE PLATE

2 1 BEARING HOUSING - RIGHT SIDE PLATE

3 1 PLATE- CASCADE MTG.

4 1 PLATE - FEED MTG.

5 1 PLATE - EXIT

6 1 PLATE - MATERIAL HOLD DOWN

7 1 BRACKET - UPPER ROLL, LEFT

8 1 BRACKET - UPPER ROLL, RIGHT

9 1 PLATE - UPPER ROLL

10 1 GUARD - ENTRY

11 1 ROLL - LOWER

12 2 DUST SHIELD - LOWER

13 1 SPACER - LOWER

14 2 BEARING - LOWER

15 1 GEAR - LOWER

16 1 ROLL - UPPER

17 2 DUST SHIELD - UPPER

18 2 RETAINING RING

19 2 BEARING - UPPER

20 1 GEAR - UPPER

21 1 SHAFT - THICKNESS ADJUSTMENT

22 1 LEVER - THICKNESS ADJUSTMENT

23 1 CAM ECCENTRIC BUSHING

24 1 BUSHING - TAPER LOCK - INNER

25 1 BUSHING - TAPER LOCK - OUTER

26 1 SHAFT - ROLL RELEASE

27 2 BEARING, NEEDLE

28 2 WEAR PAD

29 1 RELEASE LEVER - MANUAL

30 1 RELEASE LEVER - MECHANICAL

31 1 BEARING - ROLL RELEASE

32 1 SPACER - RELEASE BEARING

33 2 RETAINER, SPRING ROD

34 2 ROD, ROLL TENSION

35 2 SPRING, ROLL TENSION

36 1 SET SCREW M6 X 16

37 2 BRACKET - CASCADE

38 1 BLOCK - CASCADE MTG., LEFT

13

Page 14

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

39 1 BLOCK - CASCADE MTG., RIGHT

40 1 PLATE - ENTRY

41 2 BAR - GUIDE ROLLER

42 2 CLAMP - GUIDE BAR

43 2 GUIDE ROLLER

44 4 SPACER - GUIDE ROLLER

45 2 NUT - T SLOT

46 3 ROLL - CASCADE, ENTRY

47 3 SHAFT - ROLL

48 10 BEARING - GUIDE & ENTRY ROLL

49 1 TRANSITION PLATE

50 1 ADJUSTMENT TAB

51 1 SCREW - HEX HD

52 1 NUT - HEX, JAM

53 1 KEY 22 mm x 5 mm x 110 mm

54 2 KEY 22 mm x 12 mm x 40 mm

55 1 STRIKER - RELEASE ACTUATOR

56 1 ARM - ADJUST

57 1 ARM - FIXED

58 1 BLOCK - MOUNTING

59 1 BRACKET - MOUNTING

60 1 NUT, STRIKER ADJUST

63 1 KEY 7 mm SQ x 35 mm

64 1 KEY 5 mm SQ x 15 mm

65 4 GREASE FITTING

67 4 NUT, M14, ROLL TENSION

68 1 PLANETARY GEAR REDUCER

69 2 HANDLE, WIDTH GUIDE ADJUSTMENT

70 1 HANDLE, THICKNESS ADJUSTMENT

71 6 NUT, HEX

72 1 TIMING SHEAVE

73 1 BUSHING

74 1 MOTOR BRACKET

75 1 TIMING BELT

76 1 MOTOR ADAPTER

77 1 TIMING SHEAVE

78 1 GUARD

79 1 SERVO MOTOR

14

Page 15

ITEM QTY DESCRIPTION

1 1 MOUNTING PLATE

2 1 MOTOR MOUNTING PLATE

8 1 COUPLING

9 1 PLANETARY REDUCER, 4:1

10 1 SERVO MOTOR

11 1 WEAR PAD

13 1 SHAFT SEAL

Page 16

ULTRA ADVANTAGE SERVO ROLL FEED 6/ 3/2002

WARNING

This equipment offers various means of operating or controlling machines. The operator must not be in or near the point-ofoperation of the machine, or the operating parts of any equipment installed on the machine, or bodily injury could result. The

EMPLOYER must post adequate warning signs onto the machine with proper warnings for his machine and the specific application

to which the machine and equipment are being applied.

Occupational Safety and Health Act (OSHA) Sections 1910.211, 1910.212, and 1910.217 contain installation information on the

distance between danger points and point-of-operation guards and devices. No specific references have been made to which

paragraph of OSHA 1910.211, 1910.212, 1910.217 or any other applicable sections because the paragraphs may change with each

edition of the publication of OSHA provisions.

All equipment manufactured by us is designed to meet the construction standards of OSHA in effect at the time of sale, but the

EMPLOYER installs the equipment so the EMPLOYER is responsible for installation, use, application, training, and maintenance,

as well as adequate signs on the machine onto which this equipment will be installed.

Remember, OSHA says that the EMPLOYER must use operating methods designed to control or eliminate hazards to operating

personnel.

It shall be the responsibility of the EMPLOYER to establish and follow a program of periodic and regular inspections of his machine

to insure that all their parts, auxiliary equipment, and safeguards are in a safe operating condition and adjustment. Each machine

should be inspected and tested no less than weekly to determine the condition of the machine. Necessary maintenance or repair of

both shall be performed and completed before the machine is operated. The EMPLOYER shall maintain records of these

inspections and the maintenance work performed.

Our Company is not responsible to notify the user of this equipment of future changes in State or Federal laws, or construction

standards.

SAFETY PROGRAM

Accident free operation will result from a well developed, management sponsored and enforced safety program. Of vital importance

to any successful program is the proper selection of guards and devices. However, there is no safety device that will bring

“automatic” safety to your operation.

Of equal importance to this proper selection of the guard and the device is the training of your personnel. Each person must be

trained as to the operation of the guard or safety device, highlighting why they have been provided on the equipment. Rules for safe

operating should be written and enforced at all times. A final major concern of an effective safety program is regularly scheduled

inspection and maintenance of all of the equipment.

To ensure continued safety at all times, top management, line supervision, safety engineers and all employees must assume their

proper share of the responsibility in the program. Only as a group, one that knows your own operation and its problems, can you

carry out an effective safety program.

To assist you in the development of and continued use of safety programs, many safety minded groups have made guidelines

available to you. However, you must know when and how to apply these guidelines. The manufacturer provides information to

assist you in properly adjusting and maintaining your equipment. There is no short cut to proper safety; therefore, it is

recommended that you comply with their recommendations at all times.

WARRANTY

We warrant our new parts against defects under normal use and service for a period of 12 months after date of shipment. Our

obligation under this warranty is limited to replacing or repairing (at our option) the defective part without charge, F.O.B. our plant

in Bloomfield, Connecticut. The defective part must be forwarded to our plant, freight prepaid, for our inspection prior to

replacement or repair. EXCEPT AS EXPRESSLY PROVIDED HEREIN, THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING A WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Furthermore, the seller does not warrant or represent that the equipment complies with the provisions of

any law, particularly including the Occupational Safety and Health Act of 1970, and regulations promulgated thereunder. In no

event shall we be liable for special, indirect incidental or consequential damages, however rising.

16

Loading...

Loading...