Page 1

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

1

Page 2

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

RECEIVING INSPECTION

Before removing unit from its packaging, check for visual damage, especially if crate, skid, or carton has been

damaged in transit. Any damage caused by shipping should be immediately reported to the carrier. If unit appears in

satisfactory condition, remove all packing and wipe rust preventive from rollers with mild solvent.

TABLE OF CONTENTS

DESCRIPTION PAGE

RECEIVING INSPECTION...........................................................................................................................2

1 INTRODUCTION.............................................................................................................................3

2 HOW A SERVO FEED OPERATES..............................................................................................3

3 INSTALLING YOUR “MINI” SERVO FEED..............................................................................4

3.1 MECHANICAL INSTALLATION....................................................................................................4

3.2 ELECTRICAL INSTALLATION......................................................................................................4

3.3 ELECTRICAL CONNECTIONS.......................................................................................................4

4 PROGRAMMING THE “MINI”....................................................................................................6

4.1 ENTER FEED LENGTH....................................................................................................................7

4.2 ENTER FEED SPEED........................................................................................................................8

4.3 ENTER FEED ACCEL.......................................................................................................................8

4.4 SET-UP PARAMETERS....................................................................................................................9

5 OPERATING THE FEED .............................................................................................................10

5.1 LOADING THE FEED.....................................................................................................................10

5.2 AUTO/MANUAL MODE................................................................................................................10

5.3 FEED SIGNAL.................................................................................................................................12

5.4 CONTROL FAULT CONDITIONS.................................................Error! Bookmark not defined.

5.5 SERVO DRIVE FAULT TABLE.....................................................................................................12

5.6 SPEED PERFORMANCE GRAPH .................................................................................................19

6 PNEUMATIC PILOT RELEASE.................................................................................................19

6.1 PILOT RELEASE PARTS LIST AND DIAGRAM.......................................................................19

7 MAINTENANCE............................................................................................................................20

8 ROLL FEED PARTS LIST & DIAGRAM..................................................................................21

WARRANTY...................................................................................................................................23

2

Page 3

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

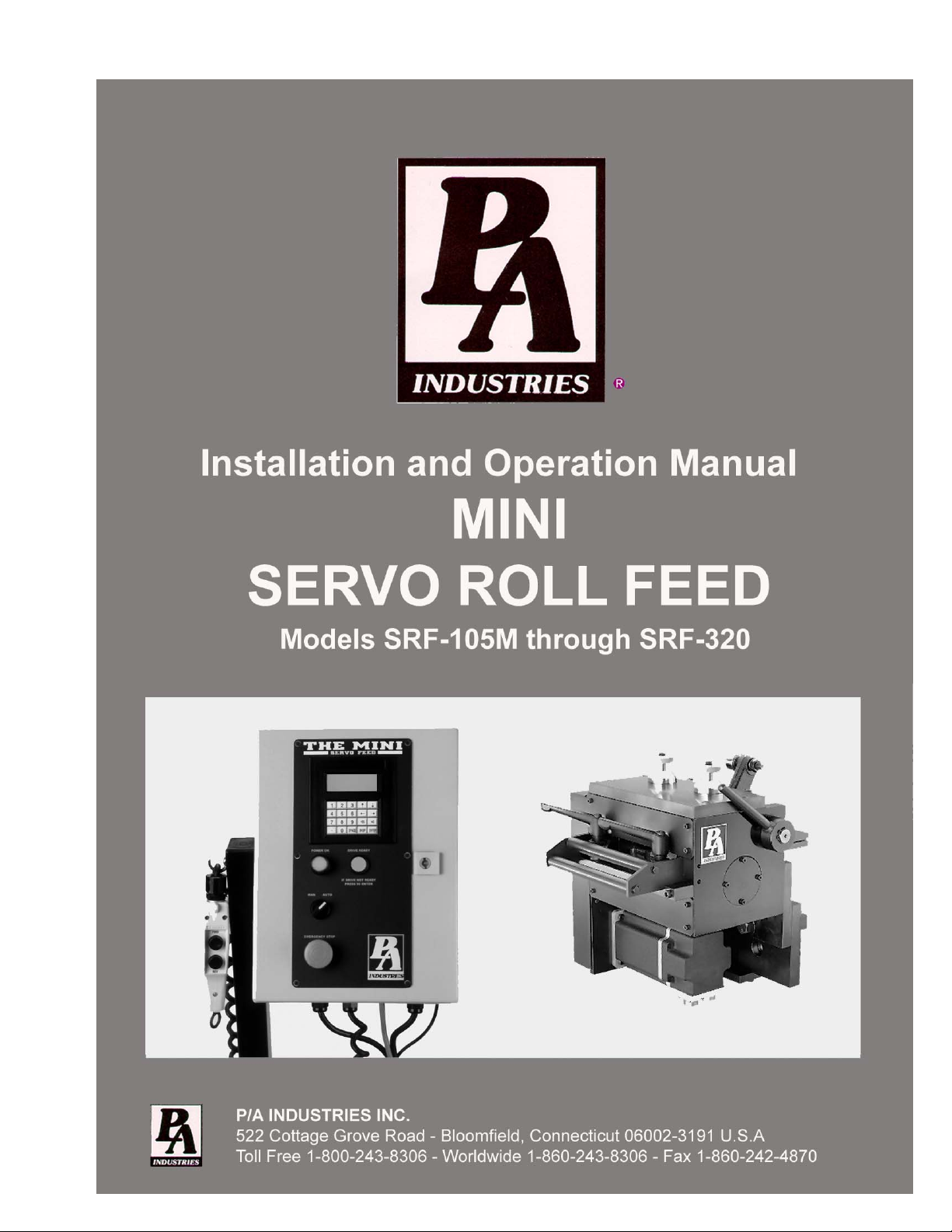

1. INTRODUCTION

The P/A Industries Mini Servo Roll Feed is a state of the art AC Servo feed, which eases operator adjustments to feed

pitch, speed, and acceleration. These operator adjustments are entered into the control memory by keypad input. With

the use of a positional limit switch, the press signals the feeder when to begin moving the strip. The operating speed of

the press should be set to provide adequate time for the index to be completed while the die is open.

The mechanical simplicity, accuracy, and ease of use of the Mini Servo Roll Feed should help to improve your quality

and production for years to come.

2. HOW A SERVO FEED OPERATES

The Mini Servo Roll Feed consists of:

1) Mechanical assembly

2) Servomotor

3) Servo Control

MECHANICAL PILOT

RELEASE ACTUATOR

CONTROL

ENCLOSURE

ADJUSTABLE

MOUNTING

BRACKET

DATA

TERMINAL

CABLES

Figure 1

The servo control acts as the central processor for the Mini Servo Roll Feed. Feed parameters entered into the servo

control are processed to position the servomotor. Calibration of the motor encoder to the feed roll circumference

allows accurate positioning of the feed roll. Each revolution of the servomotor produces 8000 encoder pulses. Every

2.857 revolutions of the servo motor shaft produce 1 revolution of the feed rollers. The circumference of the lower roll

is approximately 5.566 inches.

When a new feed pitch is entered into the system, the built-in computer calculates the correct number of electronic

“pulses” it must receive from the motor mounted encoder in order to rotate the feed rolls the correct distance.

Example: If a feed pitch/length of 5.566 inches is entered into the feeder, this will result in exactly one revolution of

the feed rolls. The motor will accelerate and turn 2.857 turns. This will produce (2.857 x 8000 = 22,856) pulses of

the encoder. The feeder will decelerate and stop when 22,856 pulses are detected. The feeder is now on position. The

3

Page 4

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

end result is an accurately positioned strip exactly 5.566 inches from its starting point. This entire process happens in

milliseconds.

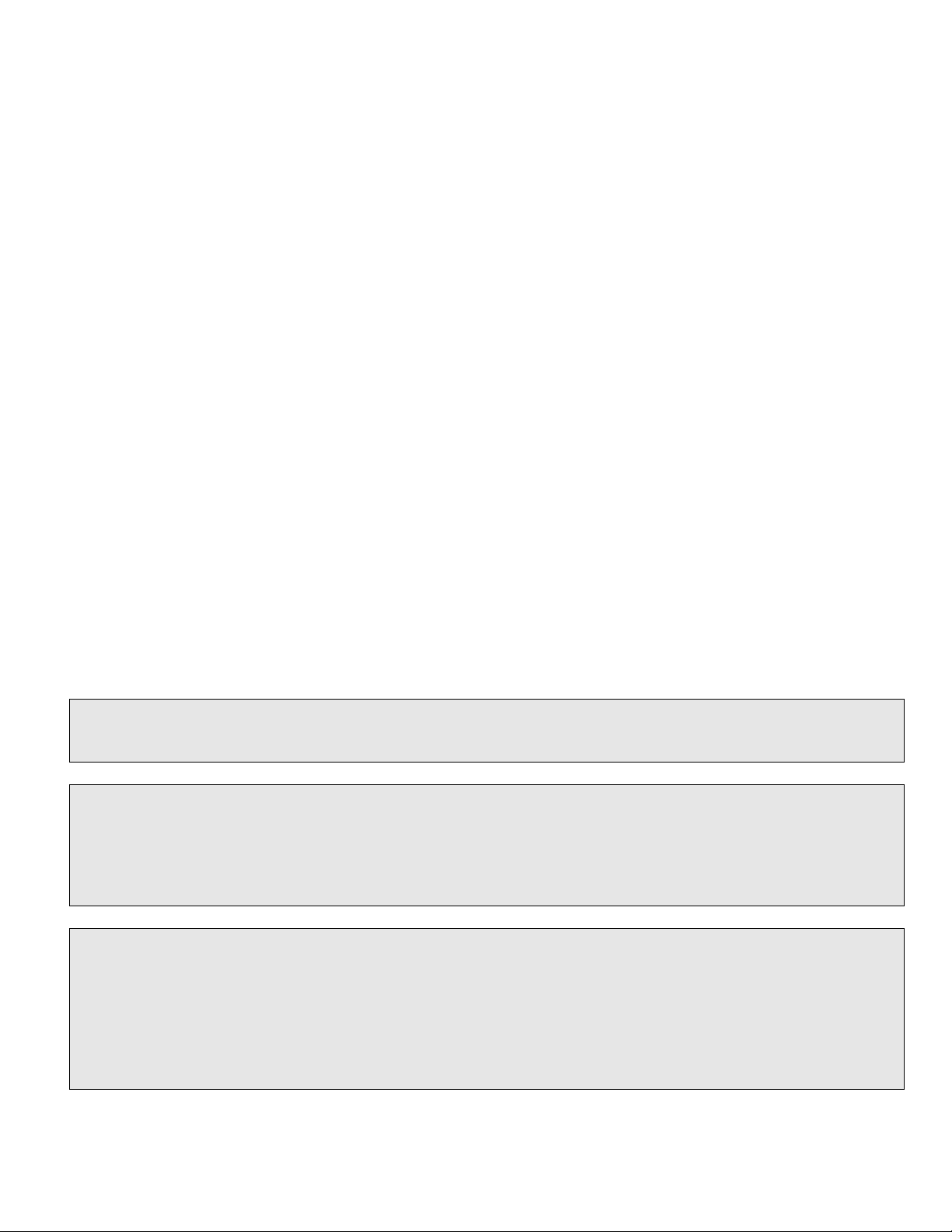

3.INSTALLING YOUR “MINI” SERVO FEED

3.1 MECHANICAL INSTALLATION

The Mini Servo Roll Feed is supplied with an adjustable mounting bracket. The feed should be securely mounted to

the press frame. (A transition bracket is sometimes required in certain applications.) The feed should be centered,

square, and perpendicular to the pass line of the press. It should be mounted at a height that will accommodate the

appropriate die sets. The feed has a pass line height adjustment of ±1.2 inches (Note: The centerline of the Feeder is

NOT the centerline of the rolls.) Refer to Figure 2 on Page 4 for dimensioning.

The feeder may be used to push or pull strip stock through the die.

If pilot locating pins are used in your die sets, the optional mechanical roll release bracket should be attached to the

press ram. It must be mounted in such a way as to provide roll release at the proper time and be adjustable for different

die sets.

If the optional electro-pneumatic piloting is used, another cam switch will be necessary for controlling feed roll

opening and closing.

3.2 ELECTRICAL INSTALLATION

The Mini Servo Roll Feed has been designed to make electrical connections quickly and easily. Simply connect the

power plug to a "clean" 115 VAC, single phase, 10-Ampere source (15-Ampere for SRF-320 model). Avoid having

other equipment share the same circuit as the feeder. The inputs and outputs to your press control (i.e. Emergency

Stop, Feed Cam Contact, Pilot Release Cam Contact) must also be connected for proper operation. The motor connects

by factory installed "Amphenol" (Military Specifications) Quick connectors.

3.3 ELECTRICAL CONNECTIONS

For more detailed wiring information refer to Electrical Schematic A-17647-11.

NOTE:

All connections should be made in accordance with National Electrical Code (NEC) requirements and must comply

with all local ordinances.

NOTE:

A word about electrical “noise”. Most pressroom environments contain considerable electrical noise. It is emitted from

electro-mechanical press relays, contacts, and solenoids. While the Mini Servo Roll Feed has been designed to

minimize “self generated” electrical noise, it is difficult to provide protection for all applications. If erratic system

behavior is experienced, then the source of the “noise” must be suppressed with either a resistive/capacitive type of

suppressor on AC coils, or “Avalanche” type diodes on DC coils.

NOTE:

The Mini Servo Roll Feed is fully protected by line circuit breakers. If it becomes necessary to replace the fuses, use

only exact equivalent fuse types to prevent serious damage to the system.

NOTE:

The electrical control enclosure is supplied with a stand-support, which may be placed in any convenient location. The

enclosure may also be mounted in any fixed location as long as the cabling is adequate to reach the feed. It is not

recommended that the electrical enclosure be mounted directly to the press. The vibrations caused by the punch press

can result in damage to the control system.

4

Page 5

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

PASS LINE

DF

K - PASS LINE

ADJUSTMENT

J

BOLSTER

∅0.551’’

(∅14MM)

THRU

MOUNTING

HOLES

C

A

B

PASS LINE

E

D

F

H

G

Figure 2

MOUNTING DIMENSIONS

SRF-105M SRF220M SRF-320M

DIMENSION INCHES MILLIMETERS INCHES MILLIMETERS INCHES MILLIMETERS

A 4.63 117.50 6.89 175.00 8.86 225.00

B 1.77 45.00 1.77 45.00 1.77 45.00

C 9.25 235.00 13.78 350.00 17.72 450.00

D 1.97 50.00 3.94 100.00 3.94 100.00

E 3.94 100.00 7.87 200.00 7.87 200.00

F 1.58 40.00 1.58 40.00 1.58 40.00

G 1.58 40.00 1.58 40.00 1.57 40.00

H 4.72 120.00 4.72 120.00 4.72 120.00

J 0.79 20.00 0.79 20.00 0.79 20.00

K - PASS LINE MAX 4.37 MAX 111 MAX 4.37 MAX 111 MAX 4.37 MAX 111

ADJUSTMENT MIN 2.O1 MIN 51 MIN 2.O1 MIN 51 MIN 2.O1 MIN 51

5

Page 6

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

4. PROGRAMMING THE “MINI”

IMPORTANT!

Before turning the system on for the first time, verify that the main input voltage is correct (115 VAC single phase)

and inspect all connections for tightness, shorts, etc.

Plug the 115 VAC plug into a clean 10 Amp supply (15 Amp for SRF-320 model. Press the amber ‘POWER ON’

push button. The button will illuminate and the data input display will be visible. If pressing the ‘POWER ON’ push

button has no effect, then check the ‘TWIST-TO-UNLOCK’ Emergency Stop button for the ‘UP’ or ‘RELEASED’

position.

Start up screen is displayed for about 5 seconds.

P/A Industries Inc

MINI

Servo Roll Fe e d

V 2.1 Copyright 2004

Provided no fault is present, the following screens will appear sequentially:

Checking

servo drive

No faults found!

Communications

with servo drive

established

In case of a fault condition present in the servo drive, the following flashing screen will display all present faults by

their numbers. Fault numbers and their descriptions are listed in the fault table on page 13 of this manual.

Fault code: 30

S ee fault code table

Any fault problem must be solved before further operating.

Normally, there are no faults and the keypad reads values of Length, Speed and Accel, stored in the servo drive.

Getting Length

6

Page 7

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

Getting Speed

Getting Accel

At this point a servo feed ready for normal operation.

Units of measure are displayed in inches or meters/millimeters, depending on the value of the scale parameter.

Standard Scale values are: 4106.7 counts/inch and 161.7 counts/mm.

1 Length:2.54 in

2 Speed: 100 in/s

3 Accel:400 in/s ^2

E nter choice:

1 Length:25.4 mm

2 Speed: 2.5 m/s

3 Accel:10 m/s ^2

E nter choice:

To Change:

> Length press ‘1’ then ‘ENTER’

> Speed press ‘2’ then ‘ENTER’

> Accel press ‘3’ then ‘ENTER’

4.1 ENTER FEED LENGTH

Enter in ‘1’ and press ‘ENTER’.

1 Length:2.54 in

2 Speed: 100 in/s

3 Accel:400 in/s^2

E nter choice:

Enter in the new feed Length and press ‘ENTER’ or to cancel, press ‘ENTER’ (leave the Length field blank).

L ength:2.54 in

N ew Length:

P ress ENTER to exit

L ength:2.54 in

N ew Length:3.00

P resS ENTER to exit

7

Page 8

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

L engTh:3.00 in

N ew Length:

P resS ENTER to exit

To exit, press ‘ENTER’ (leave the Length field blank).

1 Length:3.00 in

2 Speed:100.00 in/s

3 Accel:400.0 i n / s ^ 2

E nter choice:

The maximum feed Length that may be entered is 999999 inch or mm.

4.2 ENTER FEED SPEED

Enter in ‘2’ and press ‘ENTER’

1 Length:3.00 in

2 Speed:100.00 in/s

3 Accel:400.0 i n / s ^ 2

E nter choice:

Enter in the new Speed and ‘ENTER’ or to cancel, press ‘ENTER’ (leave the Speed field blank).

S peed:100.0 0 in/s

N ew Speed:

P ress ENTER to exit

S peed:100.0 0 in/s

N ew Speed:1 20

P ress ENTER to exit

S peed:120.0 0 in/s

N ew Speed:

P ress ENTER to exit

To exit, press ‘ENTER’ (leave the Speed field blank).

1 Length:3.00 in

2 Speed:120.00 in/s

3 Accel:400.0 i n / s ^ 2

E nter choice:

The maximum Speed that may be entered is 160 in/sec or 4 m/sec.

4.3 ENTER FEED ACCEL

Enter in ‘3’ and press ‘ENTER’

1 Length:3.00 in

2 Speed:120.00 in/s

3 Accel:400.0 i n / s ^ 2

E nter choice:3

8

Page 9

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

A ccel:400.0 i n / s ^ 2

N ew Accel:

P ress ENTER to exit

Enter in the new Accel and press ‘ENTER’ or to cancel, press ‘ENTER’ (leave the Accel field blank).

A ccel:400.0

N ew Accel:600

P ress ENTER to exit

A ccel:600.0 i n / s ^ 2

N ew Accel:

P ress ENTER to exit

To exit, press ‘ENTER’ (leave the Accel field blank).

1 Length:3.00 in

2 Speed:120.00 in/s

3 Accel:600.0 i n / s ^ 2

E nter choice:

The maximum Accel that may be entered is 1200 in/sec^2 or 30 m/sec^2.

4.4 SET-UP PARAMETERS

The set-up parameters are set at P/A Industries factory and normally don’t need adjustment. To access these

parameters:

Press ‘99’ then ‘ENTER’ to check servo drive fault status.

Press ‘100’ then ‘ENTER’ for Jog Speed.

Press ‘102’ then ‘ENTER’ for KP Gain.

Press ‘103’ then ‘ENTER’ for Scale Factor.

Press ‘104’ then ‘ENTER’ for Direction.

Press ‘105’ then ‘ENTER’ for Dwell.

Press ‘106’ then ‘ENTER’ for Kff gain.

Press ‘107’ then ‘ENTER’ for P gain.

Press ‘108’ then ‘ENTER’ for I gain.

Press ‘109’ then ‘ENTER’ to reset faults.

NOTE:

Before changing the “Direction” parameter, the servo drive must be disabled by pressing and holding “Power

On/Reset” button.

9

Page 10

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

5. OPERATING THE FEED

NOTE:

It is very important to remember that the motor on The Mini Servo Roll Feed System is only for feeding material. It is

not intended to be the power source for a pull-through straightening device, or the like. An adequate free loop must be

provided at all times. This will assure consistent and accurate feeding.

5.1 LOADING THE FEED

The material should be brought from the powered pay off device to the feeder. The rolls of the feed must now be

opened to accept the material. This is done by roll release lever to lift the upper roll. The maximum thickness

capability of the Mini Servo Roll Feed is .062 inches. Do not try to operate the feeder with material that is thicker than

it was designed to feed. Damage to the feeder may result.

ROLL RELEASE LEVER

MATERIAL THICKNESS ADJUSTMENT

Figure 3

With the material inserted into the feed rolls and the upper roll resting on the material, the two socket head thickness

screws should be adjusted to provide minimum “play” in the pilot release actuator arm. Tighten the lock nuts.

We presume that the feed system has been programmed with the proper Length, Speed, and Accel for the first die set.

Also, that the press has been adjusted for the current job (i.e. shut height, tonnage monitors, lubrication, speed, etc.).

The material should be jogged into position at the die set (first station on a progressive type die). Check the “free

running” of the strip in the die.

If possible, put the strip through the entire die set, open the rolls, and make sure the material slides easily in the die set.

Once the material is aligned square into the die, then the guide rollers on the inlet of the feeder must be adjusted.

These rollers should be locked into position with approximately .010 inch gap between the edge of the strip and the

roller. If the rollers are set tightly against the strip, then servo drive overloads could result.

5.2 AUTO/MANUAL MODE

When ‘MANUAL’ is selected via the 2-position selector switch, the control is put into ‘MANUAL MODE’. During

manual mode the feeder may be jogged infinitely in either direction.

Pressing ‘Cycle Start’ button, while the 2-position selector switch is in ‘AUTO MODE’ makes a servo feed ready to

accept an index signal from the press.

10

Page 11

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

NOTES ABOUT "POSSIBLE PROBLEM TOOLING"

• A tight die, one that is not square, or has other tooling problems, will cause significant difficulty and

downtime. Accuracy in feeding is directly related to how easily the feeder can position the strip in the die. Binding,

bad part ejection, or sticking parts may cause the material to “jam” in the die.

• The Mini Servo Roll Feed will “try” to overcome the "jam-up" by applying more power to the rolls.

ONE OF THREE OUTCOMES WILL RESULT:

• The feed will apply more power to the rolls causing them to slip on the material. This produces a “short-feed”.

In reality, the feeder did not “misfeed”. The rolls positioned properly; the strip just did not keep up. The die then closes

producing a miss-hit.

• The feed applies more power to a thin strip causing the material to buckle somewhere between the feed and the

die set. The feeder positioned the strip accurately, it just did not occur in the die set.

• The feed tries to apply so much power to a heavy strip in order to move it, that excessive current is drawn by

the servo drive. This results in the drive shutting itself down to protect itself.

The press ram should now be “inched” down until the pilot pin is located just above the prepunched strip. The

mechanical pilot actuator on the feed should now be adjusted to open the rolls just after the pin is into the strip. (See

Figure 4.)

The ram can now be inched thru the bottom of the stroke and carefully inched up until the pilot pin or longest punch is

just clear of the strip.

Now look at the entire die set and see that it is "safe" to move the strip. If so, now is the time to set the ‘Feed

Index Cam’.

PILOT PIN

STRIP

Figure 4

NOTE ABOUT CAMS:

The Feed Index Cam (open tool): The feed system uses this press cam for timing the feeder to the press crankshaft.

Although no shafting or belts actually connect the press to the feeder, the feed must be “told” when it is safe to move

the strip.

• This “connection” is an electrical one, and not a mechanical one. This gives the operator/set-up personnel

total flexibility in deciding when the feed progression should take place.

• Each die set can have a unique ‘Feed Angle’. This ‘Feed Angle’ is dependent upon many variables; pilot and

punch length, press stroke, strip forming in the die, etc.

11

Page 12

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

5.3 FEED INDEX SIGNAL

The Mini Servo Roll Feed requires one signal to control the feed indexing. This signal initiates the start of feeding,

and is usually set to occur as soon as the die is open. The duration of the feed signal should be at least 30 milliseconds

(ms). The feed signal should be ‘OFF’ at the top of the press stroke to prevent double feed indexes. (See Figure 5.)

TDC

360

°

PRESS ROTATION

90°

FEED SIGNAL

(30 milliseconds

minimum)

START FEED

270°

225°

150

°

BDC

180

°

PNEUMATIC

PILOT

RELEASE

MECHANICAL

PILOT

RELEASE

Figure 5

5.4 CONTROL FAULT CONDITIONS

If a Fault Condition exists on power up, the display will be similar to the one shown below.

Fault code: 30

If a Fault Condition happens while the feed is running (the ‘DRIVE READY’ indicator goes off), enter ”99”

into the keypad, and then press “ENTER” key to display the drive Fault Numbers. Refer to the Fault

Number table (page 13) to determine the drive’s fault. Enter “109” into keypad, and then press ‘ENTER’ key

to reset faults.

12

Page 13

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

5.5 SERVO DRIVE FAULT TABLE

Fault

Number

1

2

3

4

5

Fault Name Fault Description Possible Cause(s) Suggested Action

Non-Volatile Memory

Endurance Exceeded

Position Change

Exceeds Position

Rollover

Absolute Feedback

Range Exceeded

Motor Overtemperature ON indicates the motor

IPM Fault

A section of non-volatile

memory is used to assist in

tracking absolute position

when the drive is connected

to a motor with absolute

feedback. This fault occurs

when the total number of

memory writes to this area

exceeds the maximum

value allowed.

This fault is generated if the

change in position

command or position

feedback exceeds half the

machine cycle size during a

position loop update. This

effectively limits the velocity

to half the machine cycle

size per millisecond.

This fault is generated if the

motor position exceeds +/2047 revolutions from the

home position, but can only

be generated in firmware

versions 1.00 and 1.02.

thermostat has tripped.

ON indicates that a fault

was detected in the

Integrated Power Module

which resides in the

Ultra3000 drive.

Range of motion and number

of home position definitions

during the product life exceeds

the maximum allowed.

The velocity command or

feedback exceeds half the

machine cycle length per

millisecond.

The motor position exceeds

+/- 2047 revolutions from the

home position.

Motor thermostat trips due to

high motor ambient

temperature and/or excessive

current.

Motor wiring error

Incorrect motor selection

Motor cables shorted.

Motor winding shorted

internally.

Ultra3000 temperature too

high.

Operation above continuous

power rating.

This is an unrecoverable fault,

the drive must be sent back to

the factory

Increase machine cycle size

or reduce velocity profile.

Note: This error only applies to

firmware versions prior to

1.10.

Decrease application range of

motion.

Upgrade firmware.

Operate within (not above) the

continuous torque rating for

the ambient temperature

(40ºC maximum).

Lower ambient temperature,

increase motor cooling.

Check motor wiring.

Verify the proper motor has

been selected.

Disconnect motor power

cables from the drive. If faults

stop, then either replace cable

or try to find the short.

Verify by disconnecting motor

from drive and then try to turn

by hand. If difficult to turn by

hand, the motor needs to be

repaired or replaced.

Check for clogged vents or

defective fan.

Ensure cooling is not

restricted by insufficient space

around the unit.

Verify ambient temperature is

not too high. Operate within

13

Page 14

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

SERCOS overtravel ON indicates the SERCOS

6

Encoder channel

7

line B break

Encoder channel

8

line A break

Bus Undervoltage

9

Bus Overvoltage

10

Limit indicator is lit.

ON indicates a wiring error

with channel line B.

ON indicates a wiring error

with channel line A.

ON indicates the DC Bus is

below normal operating

voltage.

ON indicates the DC Bus is

above normal operating

voltage.

Ultra3000 has a bad IPM

output, short circuit, or

overcurrent,

Dedicated overtravel input is

inactive.

Motor wiring error.

Motor wiring error.

Low AC line/AC power input.

100 VAC minimum for safe

Ultra3000 operation.

Excessive regeneration of

power. When the drive is

driven by an external

mechanical power source, it

may regenerate too much

peak energy through the

drive's power supply. The

system faults to save itself

from an overload.

Excessive AC input voltage.

Output short circuit.

Motor cabling wires shorted

together.

Internal motor winding short

circuit.

the continuous power rating.

Increase Motion Time or allow

dwell periods.

Reduce acceleration rates.

Remove all power and motor

connections, and then check

continuity from the DC bus to

U, V, and W outputs. If

continuity exists, check for

conductive materials between

terminals.

Replace the Ultra3000 drive.

Troubleshoot SERCOS by

checking wiring and verifying

motion profile

Check motor encoder channel

line B wiring.

Check motor encoder channel

line A wiring.

Verify voltage level of the DC

Bus. The Bus should be

1.414*VAC level.

Check AC power source for

glitches or line drop.

Install an uninterruptible power

supply (UPS) on your AC

input.

Change the deceleration or

motion profile.

Use a larger system (motor

and Ultra3000).

Use an Active Shunt.

Verify input is below 264 VAC.

Disconnect the power line

from the drive and then do

continuity check from the

positive and negative poles of

the DC Bus to each of the

motor output phases U,V, and

W. If a continuity exists, check

for wire fibers between

terminals, or send drive in for

repair.

Disconnect motor power

cables from the drive. If faults

stop, then either replace cable

or try to find the short.

Verify by disconnecting motor

from drive and then try to turn

14

Page 15

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

Illegal Hall State

11

Home Search Failed ON indicates that the home

12

Home Position Outside

13

Limits

Net communication

14

Electrical Cycle

15

SERCOS Overtravel ON indicates SERCOS

16

User Current

17

Overspeed

18

Following Error

19

Motor Encoder State ON indicates the motor

20

ON indicates there is a

problem with the motor's

Hall Effect sensors.

position was not found.

ON indicates that the home

position exceeds a

hardware overtravel limit

value.

ON indicates DeviceNet

communications network is

broken.

(For linear motors only) ON

indicates there is a problem

with the motor's maximum

line count.

overtravel limit exceeded.

ON indicates the User

Current Fault level, input

above, has been exceeded.

ON indicates the motor

speed has exceeded 125%

of maximum rated speed.

ON indicates the Following

Error Limit, set above, has

been exceeded.

encoder encountered an

illegal transition.

Incorrect phasing

Bad connections

Home sensor or marker is

outside the overtravel limit.

Home sensor, marker or final

home position exceeds a

hardware overtravel limit.

DeviceNet communications

network is broken.

Electrical cycle length exceeds

maximum lines per electrical

cycle.

Programmed overtravel limit

has been exceeded.

User-specified average

current level exceeded.

Motor exceeded 125% of thespecified maximum rated

speed.

Position error limit exceeded. Retune the drive, start by

Motor encoder encountered

an illegal transition

by hand. If difficult to turn by

hand, the motor needs to be

repaired or replaced.

Check the Hall phasing.

Verify the Hall wiring.

Verify power supply to

encoder.

Check wiring

Reposition the overtravel limits

or home sensor.

Reposition the overtravel limits

or home sensor.

Adjust the final home position.

Troubleshoot DeviceNet.

Replace the linear

motor/encoder.

Verify motion profile.

Verify overtravel settings are

appropriate.

Increase User Current Level

and Time to a less restrictive

setting.

Increase time allowed for

motion

Check cables for noise.

Check Motor wiring.

Retune drive & motor

combination.

Use an actual oscilloscope to

check Encoder phasing.

setting the feedforward gain to

100%.

Increase the Following Error

Limit and Time.

If in Follower Mode, increase

the Slew Limit (in the Follower

window).

Check position loop tuning.

Replace the motor/encoder.

Use shielded cables with

twisted pair wires.

Route the feedback away from

potential noise sources.

Check the system grounds.

Ensure digital filtering of

encoder signals is enabled.

15

Page 16

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

Bad encoder

Auxiliary Encoder State ON indicates the auxiliary

21

Motor Filter

22

Thermal Protect Filter ON indicates the internal

23

Velocity Error

24

Sensor not assigned ON indicates that homing or

25

User Velocity

26

Axis Not Homed

27

Motor Parameter

28

Error

encoder encountered an

illegal transition.

ON indicates the internal

filter protecting the motor

from overheating has

tripped.

filter protecting the drive

from overheating has

tripped.

ON indicates that the

velocity error exceeds the

Velocity Error Fault Limit for

a length of time greater than

the Velocity Error Fault

Time value.

registration motion was

attempted without a sensor

assigned.

ON indicates the User

Velocity Fault level, above,

has been exceeded.

ON indicates that a absolute

move was tried, before

Home position was defined.

ON indicates a parameter

loaded from a smart

encoder or a SERCOS blob

is incompatible with the

drive.

Auxiliary encoder encountered

an illegal transition

Setup time violation for

Step/Direction or CW/CCW

input.

Motor overheated

Drive overheated

Velocity error limit exceeded. Increase Velocity Error Fault

Homing or registration motion

attempted without a sensor

assigned.

User-specified velocity level

exceeded.

Absolute positioning

attempted without homing.

Connection to an improperly

programmed or incompatible

smart encoder. An attempt to

load a SERCOS blob for a

motor that is not supported by

the drive.

16

Replace motor/encoder.

Use shielded cables with

twisted pair wires.

Route the encoder cable away

from potential noise sources.

Bad encoder - replace

encoder.

Check the ground

connections.

Check timing of inputs to

determine if setup time

requirements are met.

Reduce acceleration rates.

Reduce duty cycle (ON/OFF)

of commanded motion.

Increase time permitted for

motion.

Check system tuning.

Use larger Ultra3000 and

motor.

Reduce acceleration rates.

Reduce duty cycle (ON/OFF)

of commanded motion.

Increase time permitted for

motion.

Check system tuning.

Use larger Ultra3000 and

motor.

Limit or Velocity Error Fault

Time value or both.

Reduce Acceleration.

Assign a sensor to a digital

input.

Increase User Velocity Fault

Level and Time to a less

restrictive setting.

Verify homing position.

Select a different SERCOS

motor blob.

Install a different motor.

Page 17

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

Excessive Output

29

Frequency

Encoder Communication ON indicates loss of

30

Encoder Data

31

Excessive Interpolated

32

Feedback Frequency

Absolute Position

33

Exceeds Position

Rollover

Ground Short Circuit ON indicates the motor

34

ON indicates the motor

encoder output frequency

exceeds the maximum

value.

Note: This fault can only be

generated when the

encoder output is

synthesized by the

Ultra3000.

communication with an

intelligent encoder.

ON indicates encoder data

is corrupted.

ON indicates Sine/Cosine

frequency of encoder

exceeds specified value.

Note: This fault can only be

generated when the

encoder output is

synthesized by the

Ultra3000.

ON indicates motion is

commanded to a position

outside the position rollover

range. The position rollover

range is [0 .. machine cycle

size - 1].

Note: This fault can only be

generated when the

machine cycle position

rollover is enabled.

ground is shorted.

Encoder output frequency

exceeds the maximum value.

Communication was not

established with an intelligent

encoder.

Encoder data is corrupted. Replace the motor/encoder.

Encoder output frequency

exceeds the maximum user

specified value.

An absolute index is initiated

that specifies a position

outside the position rollover

range.

A homing cycle is initiated with

the home position outside the

position rollover range.

A define home is initiated with

the home position outside the

position rollover range.

A preset position is initiated

that specifies a position

outside the position rollover

range.

The home position parameter

is changed to a value outside

the position rollover range, the

system has absolute feedback

and the drive is reset or power

cycled.

Wiring error

Motor internal ground short

17

Increase the encoder output

maximum frequency

parameter.

Decrease the encoder

interpolation parameter.

Increase the encoder output

divider parameter.

Reduce motor speed.

Verify motor selection.

Verify the motor supports

automatic identification.

Verify motor encoder wiring.

Reduce motor speed.

Use encoder with lower

resolution (before

interpolation).

Set motion command to a

position within the position

rollover range.

Check motor power wiring.

Replace motor.

Page 18

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

Soft-Starting Fault

35

Power Module

36

Overtemperature

AC Input Phase Loss ON indicates incorrect

37

Self-sensing

39

Commutation Startup

Error

ON indicates a soft fault at

startup.

ON indicates an

overtemperature condition

in the power module.

power phasing.

ON indicates a self-sensing

commutation error was

encountered during startup

Internal malfunction

Low AC input voltage

Internal malfunction

Excessive heat in power

circuitry.

Loss of one or more phases of

power.

Motion required for selfsensing startup commutation

was obstructed.

Disconnect motor power cable

from drive and enable drive

with current limit set to 0. If

fault remains, call your A-B

representative. If fault clears,

a wiring error or an error

internal to the motor exists.

Check AC input voltage on all

phases.

Call your A-B representative.

Reduce acceleration rates.

Reduce duty cycle (ON/OFF)

of commanded motion.

Increase time permitted for

motion.

Use large Ultra3000 and

motor.

Check motor tuning.

Check AC input voltage on all

phases.

Verify that there are no

impediments to motion at

startup, such as hard limits.

Increase self-sensing current if

high friction or load conditions

exist.

Verify the line count, pole

count, or electrical cycle

length motor parameters.

Swap any two motor

connections and verify the

motor feedback counts in the

correct direction during

positive motor movement.

18

Page 19

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

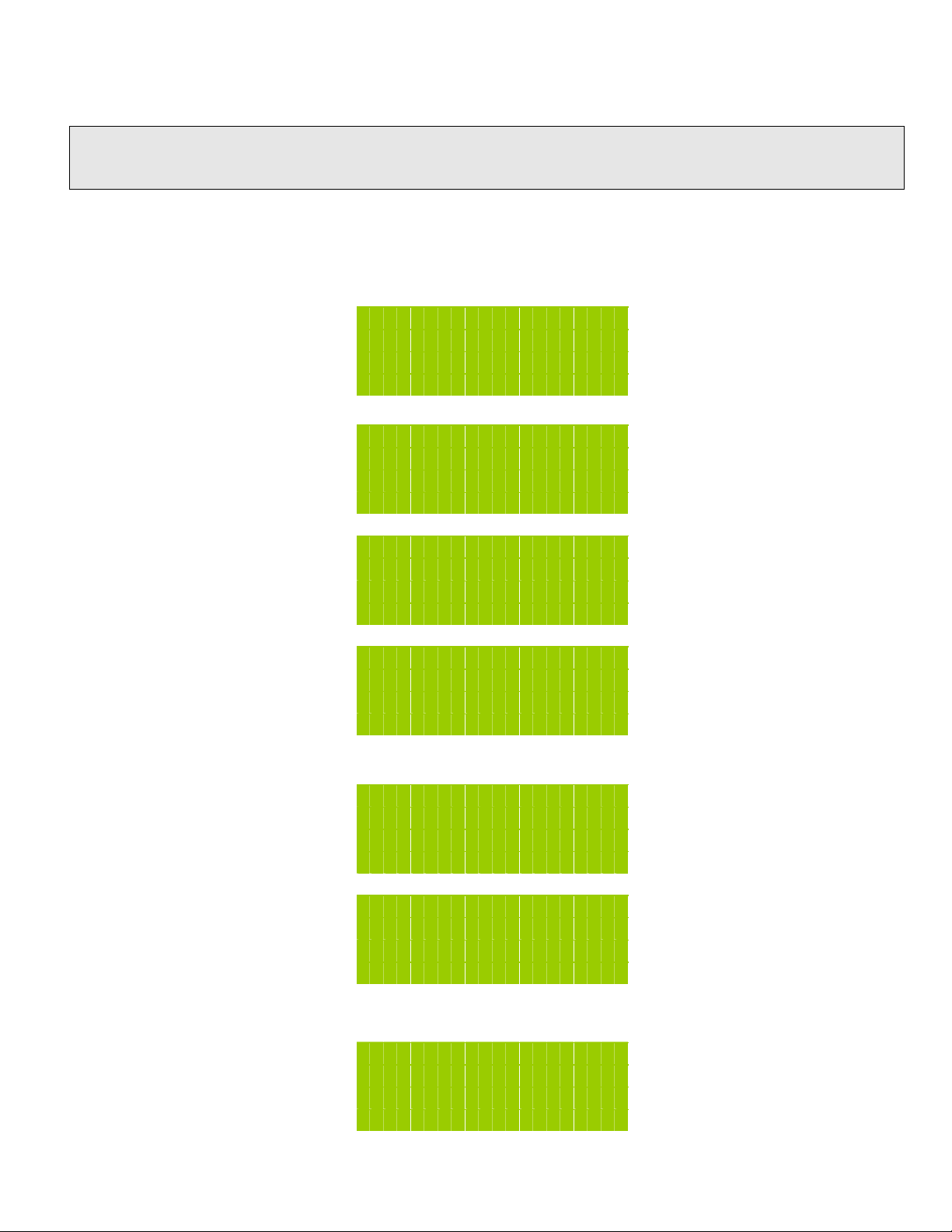

5.6 SPEED PERFORMANCE GRAPH

The speed performance graph shown below is to be used as a guide only. Actual feeder/press speeds may vary

depending on factors such as material thickness, width, rigidity, surface finish, and free loop.

700

600

500

400

300

200

Strokes Per Minute

100

0

012468101418222630405060

Figure 6.

Feed Angle (degrees) :

Feed Length, Inches

270 180 90

19

Page 20

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

6. PNEUMATIC PILOT RELEASE

During operations such as forming or using pilots, the purpose of the Pneumatic Pilot Release is to release the strip

from being held by the feeder rolls. This allows the material to be adjusted slightly any time during the press cycle.

The pneumatic release mechanism is mounted centrally on the top of the feeder using (4) M8 screws and washers in

slotted holes. The slots are to allow proper alignment and adjustment with the release arm and roller.

Open the rolls allowing clearance between the upper roll and the material approximately 0.010”/0.25 mm.

(Use a shim on top of the material, if needed.)

Position the Pilot Release mechanism so that with the cylinder piston fully extended against the roller.

The SRF Pilot Release mechanism is pre-assembled, only needing outside air and electrical connections. For air

connections, refer to Figure 6.

The release is operated through the 3-way solenoid valve when the appropriate voltage signal is applied. This power

signal can come from a source such as a rotary cam switch.

The solenoid valve, located on the side of the feeder body, is provided with a cable attached to the solenoid valve for

connecting the power signal leads.

Air pressure of 80-100 PSI is required for proper operation of the release. A 1/4” tubing fitting is provided

for the air supply connection.

6.1 PILOT RELEASE PARTS LIST AND DIAGRAM

Item Q-ty Description Item Q-ty Description

01 01 Bracket 12 01 Straight fitting

02 01 Silencer 13 01 Elbow fitting

05 02 Screw, M6x20 14 01 Elbow fitting

06 01 ScrewM8x25, flat head 15 01 Pneumatic cylinder

07 02 Flat washer, M6 16 01 Straight fitting

08 01 Hex nut, M8 17 04 Tubing

09 04 Screw, M8x25 18 03 Screw, M3x20

10 01 3 way valve, 24VDC 19 01 Silencer

11 01 Valve solenoid cable

20

Page 21

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

7. MAINTENANCE

The Mini Servo Roll Feed needs very little maintenance to keep the system operating at its optimum performance.

• This precision equipment must be kept as clean as possible. This is especially important if large amounts of

air suspended oil mists in combination with “dirty metals” are used. The resulting abrasive dust can attach itself to the

feed rolls and other surfaces, leading to premature wear on many parts.

• The roll release system requires a clean, dry air supply.

• Some bearings used on the feeder are fully sealed and maintenance-free roller ball bearings. The exceptions

are provided with standard “zerk” type grease fittings. They should be lubricated with a good grade of high pressure

bearing grease. The frequency of lubrication will depend on the overall usage of the system. A small “shot” once a

day is a good starting point. The cluster gear set should be coated with a small amount of open gear grease.

• The main drive belt should be checked periodically for tightness. It can be adjusted by loosening the three

fasteners on the motor adjuster plate, applying downward pressure on the plate, and retightening. ERRATIC MOTOR

BEHAVIOR WILL BE EXPERIENCED IF THE DRIVE BELT IS LOOSE!

• All fasteners should be checked for tightness at regular intervals. The electrical system also requires very little

maintenance. Keep the enclosure clean and replace any burned indicator bulbs. Do not expose the electrical enclosure

to constant high temperatures. Possible system failure could result.

• The Feeder’s electrical enclosure door is sealed to prevent oil and contaminants from entering inside.

However, small gaps can be found around some sealing surfaces and faceplates. It is a good idea, therefore, to keep the

console free of stamping oils and fluids, which could "seep into" the enclosure. Most often these oils are carried by the

operator’s hands or by air mist lubrication etc.

• All of the above guidelines should be added to your existing pressroom Preventive Maintenance

(PM) Program.

8. ROLL FEED PARTS LIST & DIAGRAM

List of parts that are common for 105M through 320M models

Item Q-ty Part # Description Item Q-ty Description Part #

01 01 R-SRF-MINI-01 Left housing bearing 35 01 Hex head cap screw DIN-912-M14x120

02 01 R-SRF-MINI-02 Lower front dust shield 36 01 Nut DIN-934xM14

03 01 R-SRF-MINI-03 Right housing bearing 37 01 Adjustment tab R-SRF-MINI-37

04 01 R-SRF-MINI-04 Lower rear dust shield 39 02 Key 18144

02 02 R-SRF-MINI-06 Spring 43 02 Manual release lever R-SRF-MINI-43

07 02 R-SRF-MINI-07 Spring housing 45 02 Needle bearing R-SRF-MINI-45

08 02 R-SRF-MINI-08 Adjust screw 46 04 Thrust race R-SRF-MINI-46

09 02 DIN-916-M12x12 Set screw 47 01 Key 15104-24

10 01 DIN-7991-M5x16 Flat head screw 48 02 Ball point screw R-SRF-MINI-48

11 04 R-SRF-MINI-11 Bearing 49 02 Cam follower R-SRF-MINI-49

12 01 R-SRF-MINI-12 Lower gear 51 02 Set screw

13 01 15104-22 Key 52 02 Needle bearing R-SRF-MINI-52

14 01 15104-23 Key 53 02 Lower roll spacer R-SRF-MINI-53

16 01 R-SRF-MINI-16 Upper gear 54 01 Hex head cap screw DIN-912-M10x60

21 01 R-SRF-MINI-21 Upper roll spacer 55 03 Roll release bearing R-SRF-MINI-55

22 01 R-SRF-MINI-22 Upper roll fixed plate 56 01 Release bearing spacer R-SRF-MINI-56

23 02 R-SRF-MINI-23 Cascade bracket 57 01 Mechanical release lever R-SRF-MINI-57

26 04 R-SRF-MINI-26 Dry bearing 58 01 Washer DIN-1278-M10

27 02 R-SRF-MINI-27 Adjustable hand lever 59 01 Nut DIN-934-M10

28 01 R-SRF-MINI-28 Guide roll spacer 60 01 Upper front dust shield R-SRF-MINI-60

29 01 R-SRF-MINI-29 Bearing 61 01 Upper rear dust shield R-SRF-MINI-61

30 02 DIN-934-M10 Hex nut 62 01 Key 15104-25

34 01 R-SRF-MINI-34 Motor bracket

21

Page 22

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

List of parts that are different between 105M through 320M models

Item Q-ty 105M Part # 220M Part # 320M Part # Description

05 01 R-SRF-105M-05 R-SRF-220M-05 R-SRF-320M-05 Upper plate

15 01 R-SRF-105M-15 R-SRF-220M-15 R-SRF-320M-15 Upper roll bracket

19 01 R-SRF-105M-19 R-SRF-220M-19 R-SRF-320M-19 Textured Upper roll

20 01 R-SRF-105M-20 R-SRF-220M-20 R-SRF-320M-20 Textured lower roll

24 01 R-SRF-105M-24 R-SRF-220M-24 R-SRF-320M-24 Entry roll cascade

25 02 R-SRF-105M-25 R-SRF-220M-25 R-SRF-320M-25 Shaft

31 01 R-SRF-105M-31 R-SRF-220M-31 R-SRF-320M-31 Roll guide bar

32 01 R-SRF-105M-32 R-SRF-220M-32 R-SRF-320M-32 Lower cover

33 01 R-SRF-105M-33 R-SRF-220M-33 R-SRF-320M-33 Upper cover

38 01 R-SRF-105M-38 R-SRF-220M-38 R-SRF-320M-38 Transition plate

40 01 R-SRF-105M-40 R-SRF-220M-40 R-SRF-320M-40 Mounting plate

41 01 R-SRF-105M-41 R-SRF-220M-41 R-SRF-320M-41 Exit plate

42 01 R-SRF-105M-42 R-SRF-220M-42 R-SRF-320M-42 Material hold down plate

44 01 R-SRF-105M-44 R-SRF-220M-44 R-SRF-320M-44 Roll release shaft

50 01 R-SRF-105M-50 R-SRF-220M-50 R-SRF-320M-50 Fixed shaft

22

Page 23

Form 1145 Mini Installation Form and Operation Manual 02/02/2006

WARNING

This equipment offers various means of operating or controlling machines. The operator must not be in or near the point-ofoperation of the machine, or the operating parts of any equipment installed on the machine, or bodily injury could result. The

EMPLOYER must post adequate warning signs onto the machine with proper warnings for his machine and the specific

application to which the machine and equipment are being applied.

Occupational Safety and Health Act (OSHA) Sections 1910.211, 1910.212, and 1910.217 contain installation information on the

distance between danger points and point-of -o perat io n g uar ds a n d devices. No specific references have been made to which

paragraph of OSHA 1910.211, 1910.212, 1910.217 or any other applicable section s because the paragraphs may change with each

edition of the publication of OSHA provisions.

All equipment manufactured by us is designed to meet the construction standards of OSHA in effect at the time of sale, but the

EMPLOYER installs the equipment so the EMPLOYER is responsible for installation, use, application, training, and maintenance,

as well as adequate signs on the machine onto which this equipment will be installed.

Remember, OSHA says that the EMPLOYER must use operating methods designed to control or eliminate

hazards to operating personnel.

It shall be the responsibility of the EMPLOYER to establish and follow a program of periodic and regular inspections of his

machine to insure that all their parts, auxiliary equipment, and safeguards are in a safe operating condition and adjustment. Each

machine should be inspected and tested no less than weekly to determine the condition of the machine. Necessary maintenance or

repair of both shall be performed and completed before the machine is operated. The EMPLOYER shall maintain records of these

inspections and the maintenance work performed.

Our Company is not responsible to notify the user of this equipment of future changes in State or Federal laws, or construction

standards.

SAFETY PROGRAM

Accident free operation will result from a well developed, management sponsored and enforced safety program. Of vital

importance to any successful program is the proper select i on of gu ards and devices. However, there is no safety device that will

bring “automatic” safety to your operation.

Of equal importance to this proper selection of the guard and the device is the training of your personnel. Each person must be

trained as to the operation of the guard or safety device, highlighting why they have been provided on the equipment. Rules for

safe operating should be written and enforced at all times. A final major concern of an effective safety program is regularly

scheduled inspection and maintenance of all of the equipment.

To ensure continued safety at all times, top management, line supervision, safety engineers and all employees must assume their

proper share of the responsibility in the program. Only as a group, one that knows your own operation and its problems, can you

carry out an effective safety program.

To assist you in the development of and continued use of safety programs, many safety minded groups have made guidelines

available to you. However, you must know when and how to apply these guidelines. The manufacturer provides information to

assist you in properly adjusting and maintaining your equipment. There is no short cut to proper safety; therefore, it is

recommended that you comply with their recommendations at all times.

WARRANTY

We warrant our new parts against defects under normal use and service for a period of 12 months after date of shipment. Our

obligation under this warranty is limited to replacing or repairing (at our option) the defective part without charge, F.O.B. our plant

in Bloomfield, Connecticut. The defective part m ust be forwarded to our plant, freight prepaid, for our inspect i o n prior to

replacement or repair. EXCEPT AS EXPRESSLY PROVIDED HEREIN, THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING A WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Furthermore, the seller does not warrant or represent that the equipment complies with the provisions

of any law, particularly including the Occupational Safety and Health Act of 1970, and regulations promulgated thereunder. In no

event shall we be liable for special, indirect incidental or consequential damages, however rising.

23

Loading...

Loading...