Page 1

PRECISION

AIR FEED

®

INSTALLATION

& OPERATING

INSTRUCTION

MANUAL

Page 2

P/A INDUSTRIES INC.

OVER FORTY YEARS EXPERIENCE

Since 1954, P/A engineers have been designing

and building equipment for the Metalforming Industry.

Our commitment to provide innovative production

equipment of the highest quality is second to none.

CUP SEAL DESIGN

P/A is the only air feed manufacturer that provides

low maintenance, high-cycle life cup wiper seals on

the main cylinder. Every quality-built air cylinder uses

the same technology as P/A. Cup seals reduce

friction and heat which increases cycle life and

performance by a conservative factor of 50 times.

U.S. PATENTS

The leader in pneumatic press feed patents in the

world is unquestionably P/A Industries. Todays design

is covered by a combination of the following patents:

3,329,327; 3,462,056; 3,485,430; 3,561,657;

3,583,268; 3,561,309; 3,847,320; 4,051,987;

4,195,161; 4,310,114; 4,160,518; 4,076,161;

4,095,733; 4,140,261; 4,175,688; 4,290,541;

4,261,238; 4,277,997; 4,207,999; 4,267,950;

4,329,897; 4,351,462; 4,399,937; 4,444,346;

4,531,662; 4,619,390.

Other patents pending and foreign patents are not

included above.

Page 3

CONTENTS

P/A believes in providing the best production

performance air feed available anywhere in the world

today. To prove that we are the BEST, a serialized

Repair Certificate is

enclosed with each

air feed. This can

be used at any

time for a

“no-charge” repair.

Please keep this

valuable

Certificate with

your records

and return to

P/A with the

feed for our

FREE REPAIR

SERVICE.

AIR FEED FEATURES .................................................... 2

MOUNTING THE AIR FEED ........................................... 4

AIR POWER SUPPLY CONNECTION

TO THE FEED ............................................................ 5

FEED LUBRICATION ...................................................... 5

PRESS FEED TIMING .................................................... 6

AIR FEED SEQUENCE ...................................................7

CONTROLLING THE FEED

Mechanical Actuation .................................................. 8

Remote Pneumatic Actuation ..................................... 9

Remote Electric Actuation .........................................10

Repeater Control System .........................................11

FEED LENGTH ADJUSTMENT .................................... 11

MATERIAL ADJUSTMENT ............................................12

SPEED CONTROL ........................................................13

THREE PILOT RELEASE METHODS .......................... 14

FEEDING SHAPED MATERIAL .................................... 15

PROTECTIVE COVERS ...............................................15

MODEL AX PARTS LIST ...............................................16

MODEL AX EXPLODED VIEW ..................................... 17

MODELS CX, DX PARTS LIST ..................................... 18

MODELS CX, DX EXPLODED VIEW ........................... 19

MODELS FX, HX, LX PARTS LIST ...............................20

MODELS FX, HX, LX EXPLODED VIEW ..................... 21

ACTUATION METHODS ............................................... 22

PILOT RELEASE ACTUATION METHODS .................. 23

TROUBLE SHOOTING CHART .................................... 24

1

Page 4

AIR FEED FEATURES

FASTER SPEEDS

Our patented system sequences

high speed models up to 400 cycles

per minute at full two inch pitch.

VERSATILE

Coil stock can be fed in any direction

or angle at any time during the

machine cycle. A single feed can

push or pull through long or short

progressions. A variety of stock

widths and thicknesses can be fed at

different speeds and feed lengths.

Two or more strips can be

simultaneously fed by the same feed.

INEXPENSIVE

The cost of P/A feeds are 65% to 90%

less than conventional roll or slide

feeds. With savings like that you

should consider leaving the feed

permanently mounted on the tool

to decrease set up time and increase

productivity.

Surveys show that Contract Job

Shop Stampers prefer P/A air feeds

because they are the easiest and most

economical way to change from one

job to another.

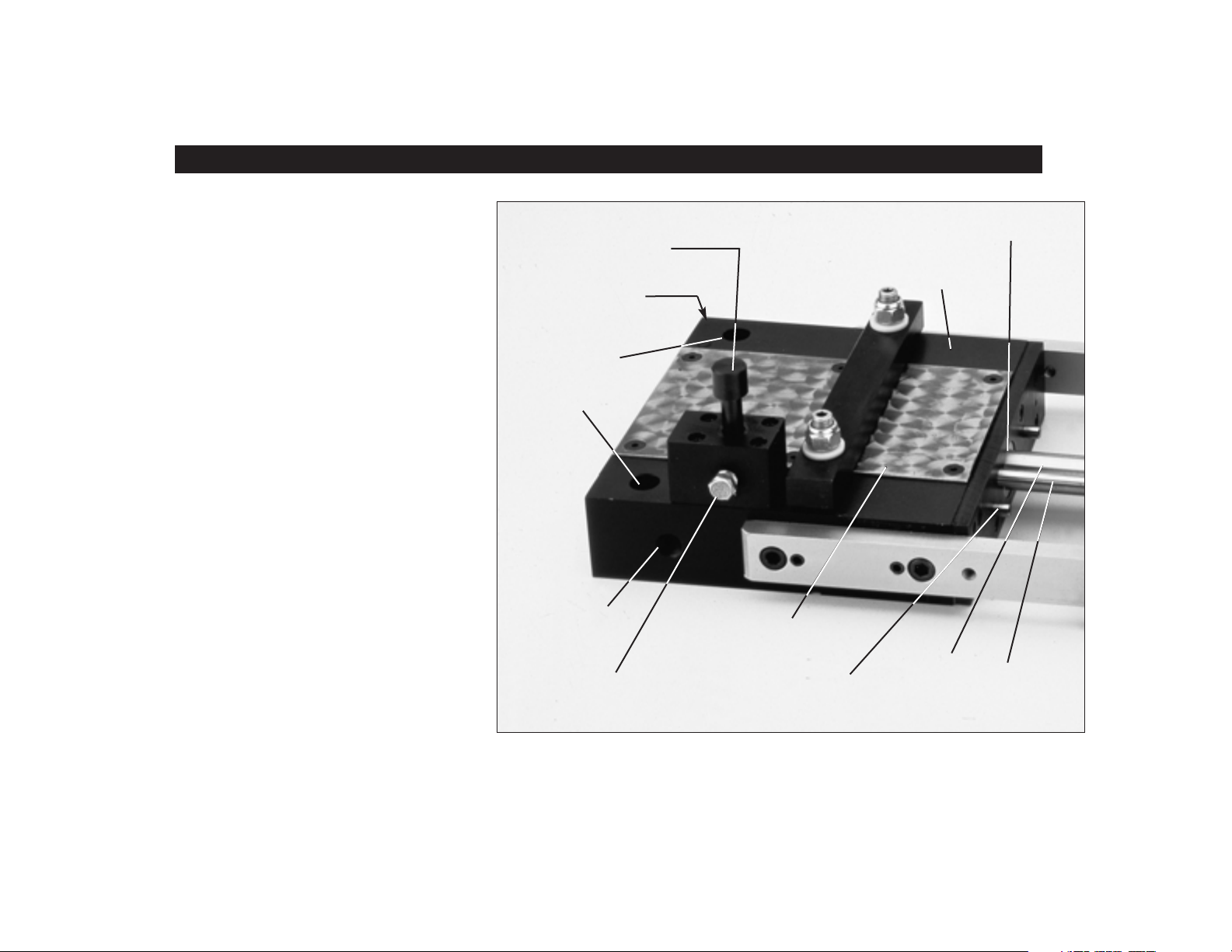

Actuating valve or optional

remote actuation controls feed

motion and clamp sequencing

Speed adjustment screw

controls feed head velocity

and material inertia

Two (or four) drilled

holes provide easy

mounting to die shoe,

bolster, or mounting

bracket

Oversized air inlet

eliminates air pressure

volume problems

Air silencers greatly

reduce noise to enhance

the operator’s environment

Modern Cup Wiper Seal (instead of “O” Rings) maintains

clean piston assembly and significantly increases cycle life

Body constructed of hard-coat

anodized, aircraft aluminum for weight

reduction and minimal wear characteristics

Replaceable steel wear

plates protect feed surface

from material edges

Two shock absorbers

automatically control feed

head and material inertia

Main piston

rod is hard

chrome plated

and ground

Twin

external air

tubes are

stainless steel.

2

Page 5

AIR FEED FEATURES

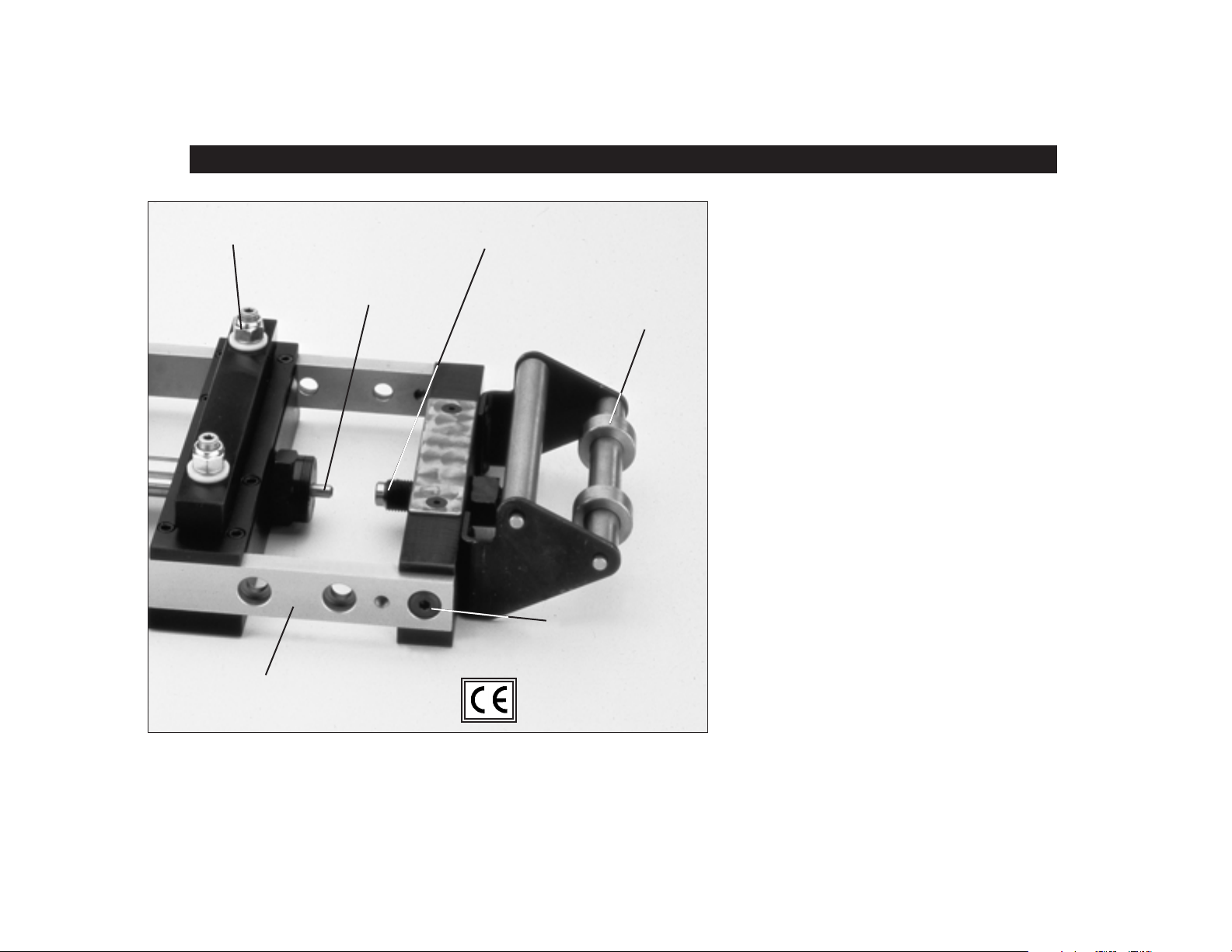

Nylock hex nut used in aircraft engines

to absorb vibration and eliminate loosening

Shock absorber stops

slamming and reduces noise

High strength, chrome plated, steel

guide rails maintain feed head alignment

throughout its stroke

Large adjusting screw and lock nut

provide vernier feed length control

Combination stock dampener and

adjustable guide rollers provide

vibration free material to the feed

Counterbored holes and

precision ground shoulder

screws provide coarse feed

length adjustment and secure

rigid alignment

SIMPLE INSTALLATION

Our feeds are extremely easy to mount.

Two (or four) mounting bolts and a single

air line connection are all that’s necessary.

A compact, clean design permits the P/A

Air Feed to be mounted right on the die set.

QUICK SET-UP

Adjustments are quick, simple and positive.

To change feed length, turn the adjustment

screw to the desired pitch between positive

stops and tighten the locknut.

PATENTED DESIGN

Technologically the BEST air feed on the

market today! U.S. Patent No. 4,444,346.

REPEATABILITY

Consistently holds ±.001" (.025mm) stroke

after stroke. The most precise press feed

available at a reasonable cost.

HANDLES VARIETY OF MATERIALS

Paper, plastic, foil, fabric, wire, tubing

...you name it and P/A will feed it. Highly

polished materials or extrusions, preformed

or irregularly shaped materials – all can

easily be adapted with special clamps.

3

Page 6

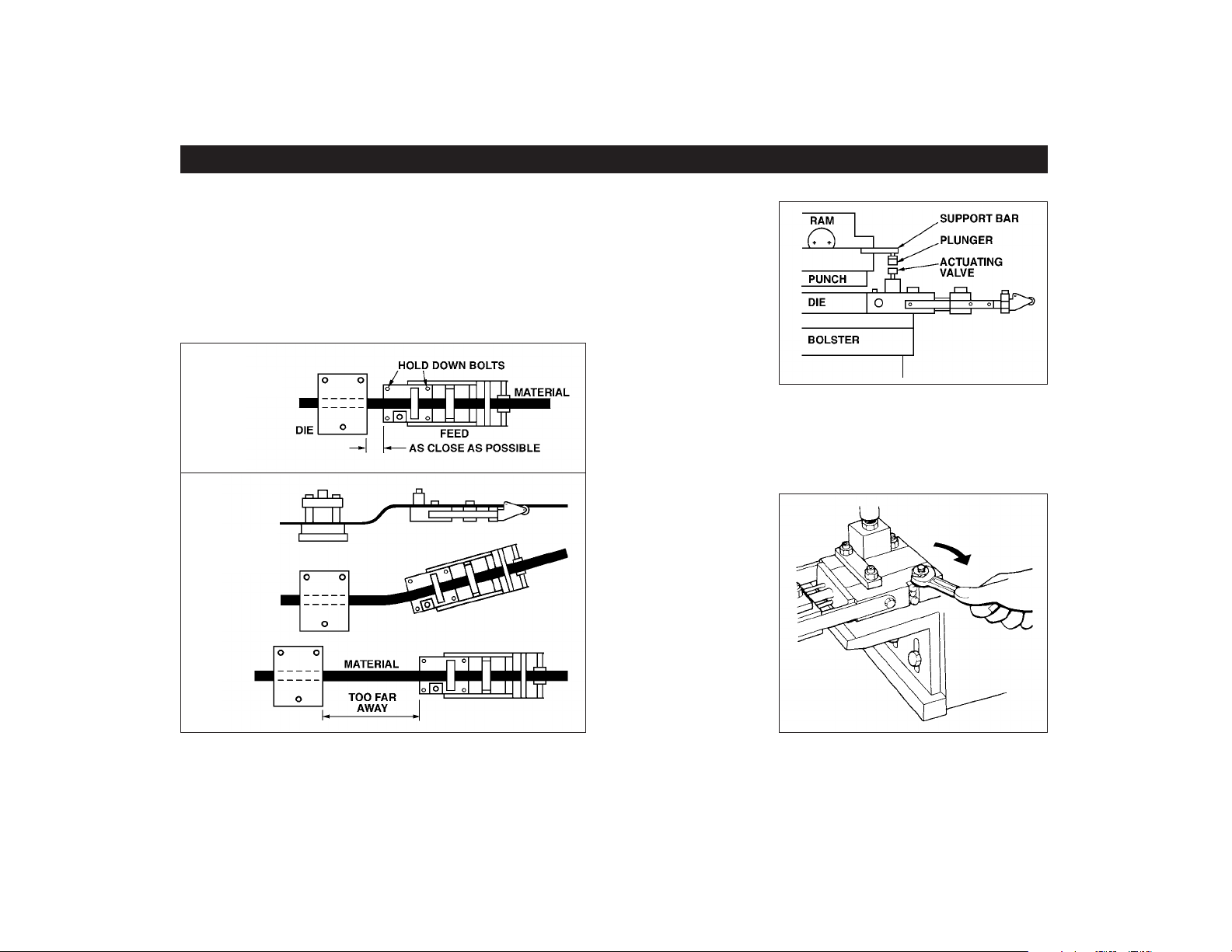

MOUNTING THE AIR FEED

Its compact design will allow this Feed to be installed

on the Die or Press Bolster, or on many types of

machines, at any angle, including upside down or

vertical. Use two (or four) minimal clearance HoldDown Bolts to solidly fasten the Feed as close to the

Work Station as possible. NEVER use ‘C’ clamps as

the Feed may move or shift position.

CORRECT

NOT

CORRECT

Mounting directly

on the Die is

recommended

for “Just-In-Time”

production and

to reduce set-up

time.

The top of the Feed Wear Plate should be level with

the lower Die Face and the front of the Feed square

and centered with the tool.

A mounting

bracket provides

easy vertical

adjustment for

tools with different

stock line

heights.

The Feed can be

moved from

press to press, or

die to die, in a

matter of minutes.

4

Page 7

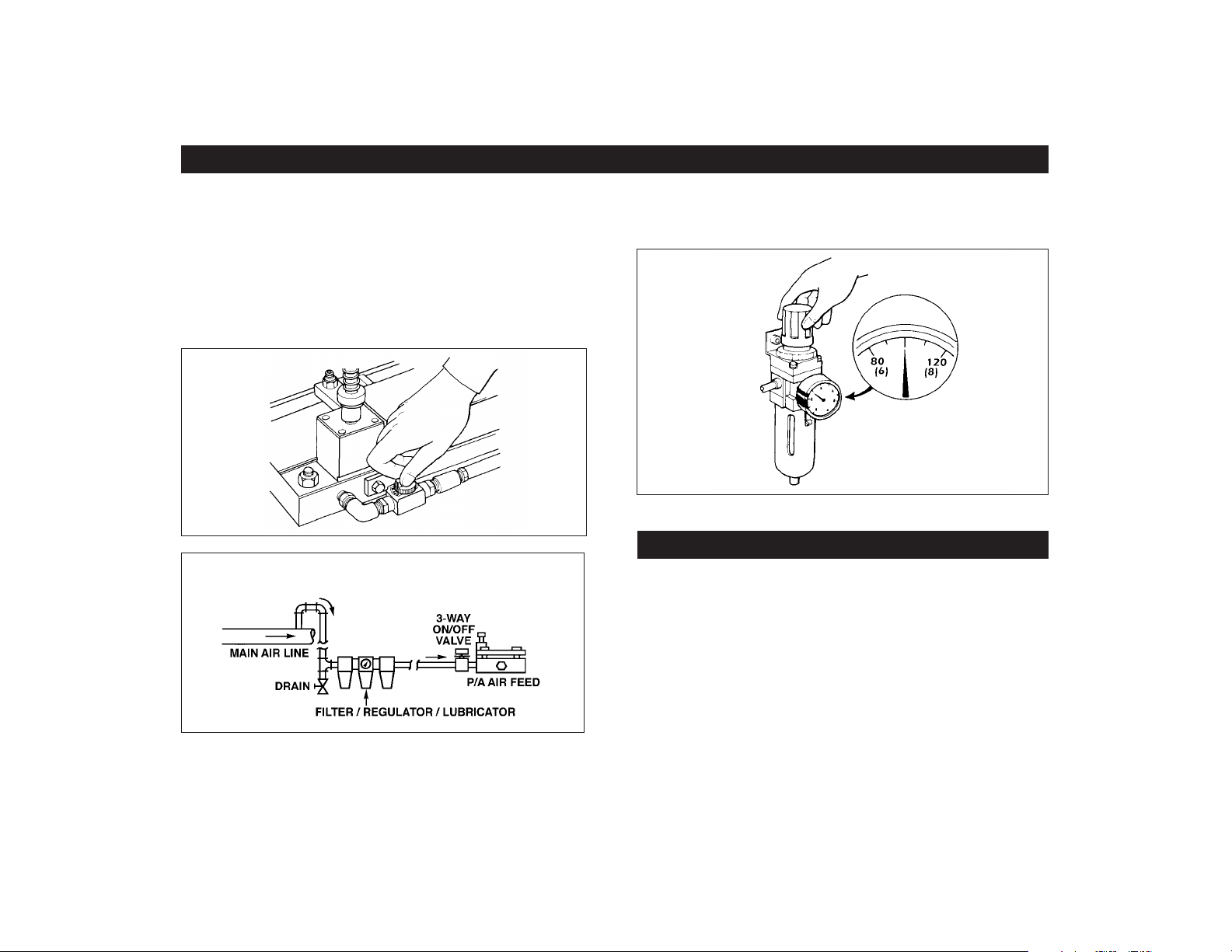

AIR POWER SUPPLY CONNECTION TO THE FEED

A single air line connection is all that is needed for

maximum power with minimum air consumption. We

strongly recommend that an oversized air hose be

connected to the Feed with a water separator type

filter and air line oiler.

The use of a 3-Way On/Off Exhaust Valve will make

minor adjustments and strip insertion easier.

RECOMMENDED AIR LINE CONNECTION

TO ELIMINATE MOISTURE AND PARTICLES FROM MAIN LINE

Set the Air Pressure Regulator between 80 and

120 PSI (6 to 8 Bar).

FEED LUBRICATION

Fill the air line lubricator with a good grade of

hydraulic cylinder oil, like Shell Tellus 32. Set for one

drop per minute to properly clean and lubricate all

internal parts.

NEVER use Spindle Oils, Motor Oils, Solvents,

WD-40, or Stock Lubricating Oils. Use of these types

of oils will cause Feed performance to deteriorate, as

well as premature wear.

5

Page 8

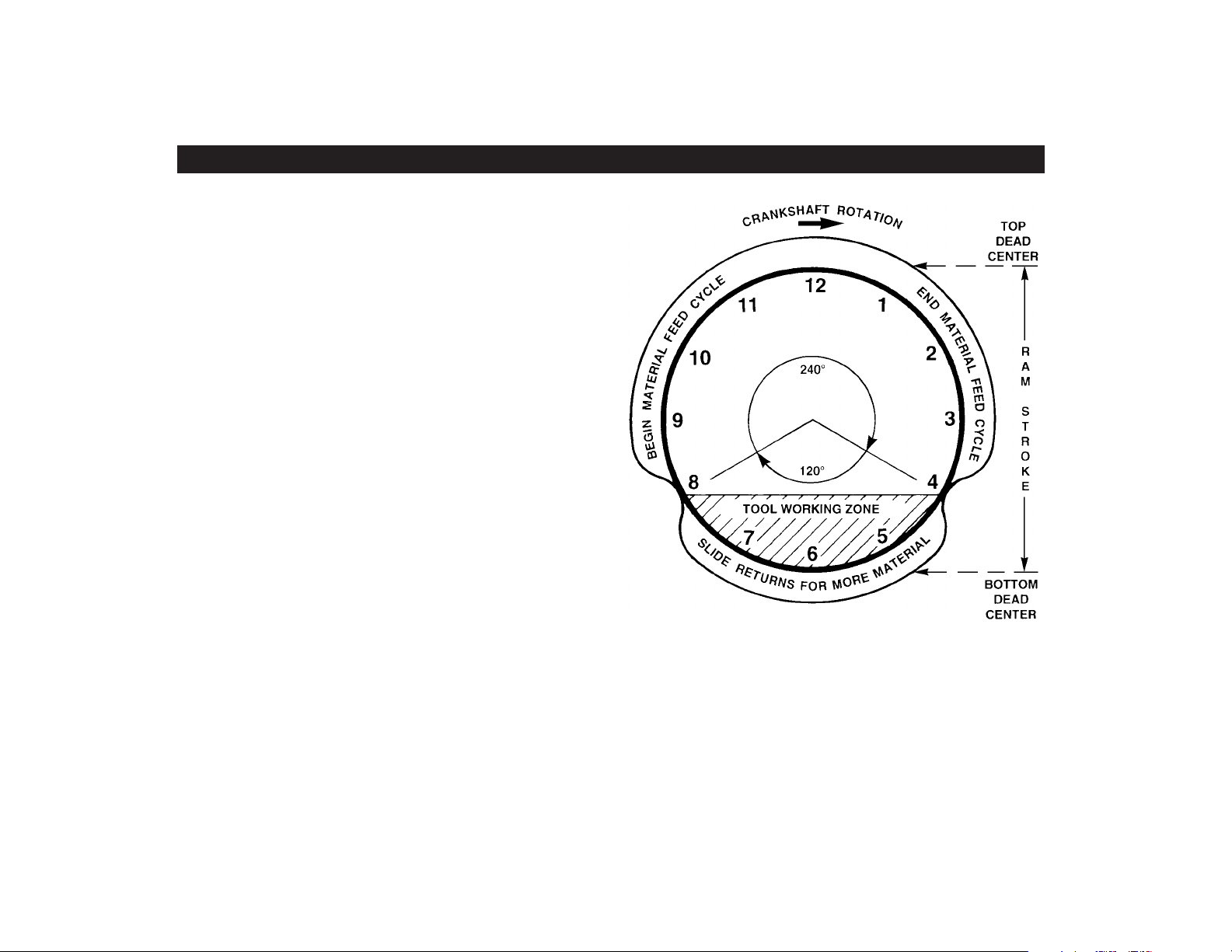

PRESS FEED TIMING

The Reciprocating Linear Motion of the Feed Slide must

be timed to the press crankshaft rotation for optimum

performance. The Actuating Valve’s vertical motion

controls the sequencing of the Stock Clamp, Feed

Clamp, and the Feed Slide.

To understand how the rotary crankshaft and linear

Feed Slide motion work together in a Press Feed Cycle,

it might be helpful to visualize a Clock Face. The

position “Top Dead Center” of the Ram Stroke would be

12 o’clock, half way down would be 3 o’clock, “Bottom

Dead Center” is 6 o’clock, and moving half way up

would be 9 o’clock.

The optimum Feed cycle requires two thirds of the

crankshaft rotation (240 degrees) to feed the material

into position. During the remaining 120 degrees, the

Feed Slide returns to the Stop Screw for more Material.

As soon as the Stamped Part has been ejected and the

Punches are clear of the Die (approximately 8 to 8:30

on the clock), the Feed Clamp will grip the Stock and

then the Feed Slide will begin moving towards the Feed

Body.

CAUTION: To properly complete a Feed Stroke, the

Feed Slide must have enough time to contact the Feed

Body before 4 o’clock and then return to the Stop Screw

before 8 o’clock during the 360 degree crankshaft rotation

otherwise erratic short feed progressions will occur.

6

Another method of controlling the Feed Timing is

to use the Remote Electric or Pneumatic Actuation

Systems to suit the Press and Part applications.

These methods require the same 240° feed and 120°

return timing cycle.

Page 9

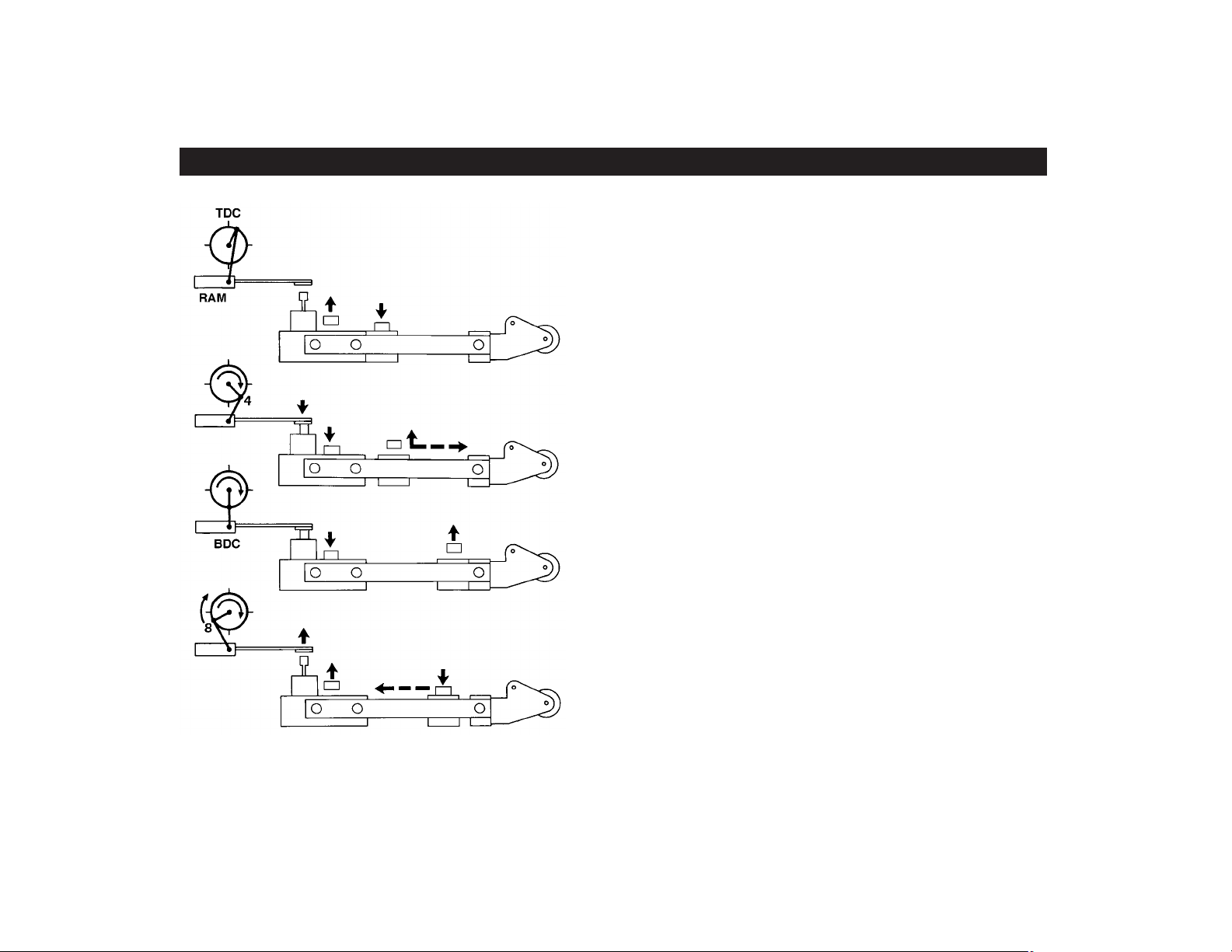

AIR FEED SEQUENCE

Actuating Valve up

•

Feed Slide forward

•

Stock Clamp open

•

Feed Clamp closed

•

Actuating Valve down

•

Stock Clamp closes

•

Feed Clamp opens

•

Feed Slide moves back

•

Feed Slide rests

•

against Stop Screw

Stock Clamp closed

•

Feed Clamp open

•

AT TOP OF

PRESS STROKE

AT BEGINNING OF

NON-FEED STROKE

AT END OF

NON-FEED STROKE

Actuating Valve up

•

Feed Clamp closes

•

Stock Clamp opens

•

Feed Slide moves forward

•

AT BEGINNING OF

FEED STROKE

7

Page 10

CONTROLLING THE FEED

MECHANICAL ACTUATION

Install a Support Bar with a Plunger on the upper Die

Block of the Tool or on the Press Ram. The vertical

Plunger should be threaded to allow vertical height

adjustments. The Plunger should contact the center

of the Feeder’s Actuating Valve Stem. After contact,

and during the first 1/4" (6mm) of downward Valve Stem

travel, nothing happens with the Feed Slide Control.

During the next 3/16" (5mm) of travel, the Mechanical

Actuation Valve opens causing the clamps to shift and

PRESS CRANKSHAFT

ROTATION

SUPPORT

BAR

RAM

RAM

MECHANICAL

ACTUATING

VALVE

PLUNGER

VALVE

STEM

AIR FEED

the non-feed stroke begins. The remaining downward stroke of the Valve Stem is over-travel.

When the Press Ram passes BDC and begins to

move upward, the Valve Stem reverses travel direction.

As the Plunger moves off the Valve Stem, the

Mechanical Actuation Valve closes causing the clamps

to shift and the Feed Slide to begin the feed stroke.

Installing a Spring on the Plunger to contact the

Actuating Valve Stem will result in a more desirable

Feed Cycle for Presses with long strokes.

CAUTION! Excess over-travel will damage the Feed

TDCTDC

RAM

SPRING

COMPRESSED

8

Page 11

CONTROLLING THE FEED

REMOTE PNEUMATIC ACTUATION

By removing the Mechanical Actuating Valve

Assembly, the timing control of the feed cycle can be

changed by installing the optional Piston Operated

Valve (POV).

LINEAR CAM OPERATION ROTARY CAM OPERATION

1/4” (6MM) POLYFLO TUBING LINEAR CAM/BRACKET

AIR CONNECTION FROM PISTON

OPERATED VALVE TO COMMON

(“CYL”) PORT OF SPOOL VALVE

MALE CONNECTOR AT

VALVE PILOT AIR PORT

PISTON OPERATED VALVE

CONNECTION

3-WAY ON/OFF

SELECTOR VALVE

RECOMMENDED

TEE FITTING AT AIR INLET

AIR SUPPLY

The Feed Cycle is then controlled by a cam operated 3-Way Spool Valve and a Linear Cam mounted

on the Press Ram, or by a Rotary Cam mounted on

the crankshaft.

CAM OPERATED 3-WAY

SPOOL VALVE

AIR CONNECTION

FROM TEE TO NORMALLY

CLOSED (“IN”)

9

Page 12

CONTROLLING THE FEED

REMOTE ELECTRIC ACTUATION

To control the timing of the Feed Slide motion

electrically, install the 3-Way Solenoid Valve on top

of the P.O.V. and wire into a Limit Switch. Mounting

a Linear Cam on the Press Ram Slide or installing a

Rotary Cam on the crankshaft are two ways to

electrically control the Feed Cycle.

Many new presses today are equipped with electronic

Programmable Controllers and/or electronic Rotary

Limit Switches. Specify 24 VDC for Solenoid Valve.

LINEAR CAM OPERATION ROTARY CAM OPERATION

ELBOW CONNECTOR TO TEE AT SUPPLY PORT NO. 1

3-WAY SOLENOID VALVE

MANUAL OVERRIDE

HEX NIPPLE TO VALVE

PISTON OPERATED VALVE

CONNECTION

ROLLER LIMIT SWITCH

LINEAR CAM/BRACKET

3-WAY ON/OFF

SELECTOR VALVE

RECOMMENDED

10

AIR SUPPLY

1/4” (6MM) POLYFLO TUBING

TEE FITTING AT AIR INLET

Page 13

CONTROLLING THE FEED FEED LENGTH ADJUSTMENT

REPEATER CONTROL SYSTEM

The Air Feed can be multiple stroked for each cycle

of the Press to obtain greater feed length increments

than the Air Feed’s maximum feed stroke capacity.

The Repeater Control has a digital counter and Key

Lock Selector Control for “Feed Control Press” or

“Press Control Feed”. Used with Remote Electric

Actuation and 120 VAC, 50/60 Hz Power Supply.

Transformers for other voltages are available.

For coarse feed length adjustment there are

counter-bored holes provided in the side rails of the

Feed. Move the Stop Block, and insert and tighten

the Shoulder Screws in the holes closest to the

desired feed stroke.

➥

For fine

adjustment,

move the Feed

Slide to the

exact distance

between it and

the Main Body.

Adjust the

Stop Screw to

contact the

Feed Slide and

tighten the Hex

Nut.

11

Page 14

MATERIAL ADJUSTMENT

STEP 1. The strip material must be straight and

parallel from the Rear Stock Guides through the

Feed and into the Tool.

STEP 2. Adjust the two Roller Stock Guides with

enough lateral clearance for camber and variations

in stock width.

STEP 3. Recommended vertical clearance between

the Material and the two Clamps is .010" to .020"

(.3mm to .5mm). Adjust by holding the Clamp

Piston Stem with a Hex Key and turn the Hex Nut.

CAUTION! It is very important to have a level Clamp

condition for both the Feed Clamp and the Stock Clamp.

12

Page 15

SPEED CONTROL

The Speed Adjustment Screw is located on the side

opposite the air inlet. It provides material velocity

control during the feeding direction of the Feed Slide.

HOW TO SET

1. Cycle the Feed manually, turning the Speed

Adjustment Screw clockwise until the Feed motion

becomes erratic or incomplete.

2. Turn the Speed Adjustment Screw counter-clockwise until Feed Slide makes a complete forward motion.

3. Turn the Speed Adjustment Screw an additional

half turn counter-clockwise.

4. If the material slips forward under the Clamp upon

impact with the Main Body, turn the Speed Adjustment

Screw clockwise 1/4 turn or until slippage stops.

CAUTION!

Never open the

Speed Adjustment

Screw more than

three complete turns.

SAFE WORKING SPEEDS AT VARYING LENGTHS

MODEL

AX

MODELS

CX & DX

MODELS

FX & HX

MODEL

LX

13

Page 16

THREE PILOT RELEASE METHODS

MECHANICAL PILOT RELEASE

The Mechanical Spring-Loaded Pilot Release Clamp

is installed in place of the standard Stock Clamp.Turn

the Hex Nut to compress the Spring for the desired

clamp and material pressure. Not available on LX.

PNEUMATIC PILOT RELEASE

The Pneumatic Pilot Release can be used for those

applications that require more sensitive clamping

pressure, or that the Clamp pad be completely free

of the material. With this system, the clamping

pressure may be adjusted by regulating the air

supply to the valve. The clamp pad is fitted with a

quick-response cylinder for positive stock grip and

release. Timing is controlled by an external 4-way

Solenoid valve or spool valve.

MECHANICAL

PILOT

RELEASE

PNEUMATIC

PILOT

RELEASE

INTERNAL PILOT

RELEASE (IPR)

This internal valving system

provides up to 270 pounds

of clamping force with the

standard clamp and is

available on all FX, HX, and

LX models. The Internal Pilot

Release controls the release

ALREADY

INSTALLED

*

IN AIR FEED

of the Stock Clamp with a

timed air signal connected to

the 1/8" NPT port. This

feature gives you the option

of using pilot release, or not,without the downtime

necessary for changing clamps. One switch turns the

system on or off. The IPR requires an external 3-Way

Spool or Solenoid Valve.

CYLINDER

IN

EX

AIR SUPPLY 120 PSI MAX.(8 BAR)

S

ADJUSTMENTS

RELEASE

CLAMP

VALVE

INTERNAL PILOT RELEASEPNEUMATIC PILOT RELEASE

EXHAUST

PILOT

AIR SUPPLY

N.C. (STD)

For most pilot release applications, set the Feed Pitch

approximately .005" (.1mm) short and the Pilot

Release Stock Clamp will allow the pilot pin to pull the

material under the clamp pad into the proper position.

14

Page 17

FEEDING SHAPED MATERIAL PROTECTIVE COVERS

By machining the grip side of the Clamps to the

desired contour, any kind of material or preformed

parts like electronic contacts, terminals, or wire,

tubing, and channel can be easily handled.

STANDARD CLAMPS

MODIFIED STANDARD CLAMPS

SPECIAL CLAMPS

P/A Industries strongly recommends our rugged,

see-through Cover of Plexiglas or Expanded Metal

for operator protection. Pre-drilled holes in the Feed

Guide Rail accept the Slip-Fit Fasteners that secure

the Cover over the top and sides of the Feed. These

Protective Covers further protect the Feed from dirt,

oil, chips, and other harmful materials.

PLEXIGLAS

COVER

(Available for AX, CX,

DX, and FX Models)

EXPANDED

METAL COVER

(Available for HX

and LX Models)

15

Page 18

MODEL AX PARTS LIST

( ) Indicates quantity used if more than one

Item Description AX

1 Valve Block 14261

2 O-Ring 14208-011 (2)

3 Ring Insert 14295-01 (2)

4 Valve Stem 14260

5 Valve Disc 14263-01

6 O-Ring 14208-008

7 Hex Nut 943010ZP

8 Screw 900006-08LA (4)

9 Gasket, Valve Block 14262

11 Cartridge Valve 12110-12

12 Valve Plug 15488-01

13 O-Ring 14208-011

14 O-Ring 14208-012

15 Screw 901010-03LA (2)

16 Washer DIN-125-M5BO (2)

17 Collar, Spacer - Loctite #609 14571-06 (2)

18 O-Ring 14208-011 (2)

20 Screw 905010-02.5LA

21 Stock Clamp Piston 14287-04 (2)

22 O-Ring 14208-114 (2)

23 Spring, Compression 12442-18 (2)

24 Pilot Release Clamp 15856

25 Spring Stud 15832

26 Spring Clamp 15857

27 Spring Sleeve 15833

28 Spring, Compression 12442-36

29 Hex Nut 943031ZP

31 Hex Nut, Nylock 943031ZP (4)

32 Speed Adj. Screw 15787

33 O-Ring 14208-006

34 Silencer (Body) 12024-11

36 Spring Pin 972018-04 (2)

37 Shoulder Screw 919032-03 (4)

40 Ring 14271-01

41 Piston Seal 14245-01

42 Spacer 14272-01

43 Locknut - Loctite #242 947038ZP

45 Retaining Plate 14274

46 Guide Bushing - Loctite #324 14298

47 O-Ring 14208-113

49 O-Ring 14208-008

50 Dowel Pin 970012-03 (2)

51 Gasket, Retaining Plate 14273

52 Screw 900008-03LA (4)

53 Feed Slide 16278

56 Feed Clamp Piston 14287-08 (2)

57 O-Ring 14208-117 (2)

58 Rod Guide 16283 (2)

59 O-Ring 14208-020 (2)

61 O-Ring 14208-012 (2)

62 Cover Plate 16279

63 Screw 900008-03LA (4)

64 Spring, Compression 12442-16 (2)

65 Feed Clamp 14289-01

67 Stop Anvil - Loctite #242 14283

74 Stop Block 16311

75 Wear Strip 15874-01

Item Description AX

77 Stop Screw 16312

78 Hex Nut 941044BO

79 Roller Bracket, Left 15858-03

80 Roller Bracket, Right 15858-04

81 Screw 902025-02LA (4)

82 Roller Shaft 15859-01 (2)

84 Roller Stock Guide 12441-25 (2)

89 Cartridge Guide P.O.V. 12110-13

90 Valve Block P.O.V. 15486

91 Piston Oper. Valve Assy. 15507

92 Mechanical Valve Assy. 14304

93 P.R.S.C. Assy. 15806

94 Stock Clamp 14289-05

97 Dowel Pin - Loctite #609 970006-01 (2)

98 Flanged Bushing 12128-52 (4)

100 Air Line Tubing (10 Ft.) 15676-02

101 Fitting 12032-13

102 Cylinder 12111-23

103 Clamp Pad 16507

105 Clamp, Pneu. Release 16508

106 Screw 904006-10

107 Screw 905010-05LA

108 Spool Valve 3-Way 12110-10

109 Spool Valve 4-Way 12110-18

110 Solenoid Valve 3-Way 12039-31

111 Solenoid Valve 4-Way 12039-59

112 3-Way On/Off Exhaust 12110-02

113 Linear Cam 14170

114 Limit Switch 12031-02

116 Nut 942006ZP

117 Pneu. Pilot Release Assy. 16604

122 Fitting, Straight 12032-12

(120 VAC, 50/60 Hz)

Solenoid Valve 3-Way 12039-39

(240 VAC, 50/60 Hz)

Solenoid Valve 3-Way 12039-60

(24 VDC)

(120 VAC, 50/60 Hz)

Solenoid Valve 4-Way 12039-58

(240 VAC, 50/60 Hz)

Solenoid Valve 4-Way 12039-61

(24 VDC)

Item Description AX2 AX4 AX6

10 Main Body 15546-01 15546-02 15546-03

19 Wear Strip, Body 15841-01 15841-02 15841-03

35 Guide Rail 15733-01 (2) 15733-02 (2) 15733-03 (2)

38 Main Piston Rod 14269-01 14269-02 14269-03

55 Tubes w/Loctite #609 15844-01 (2) 15844-02 (2) 15844-03 (2)

121 Protective Cover 14222-01 14222-02 14222-03

REPAIR KITS

Model AX – P/A No. 15925

Repair Kits include these Item Numbers:

2, 5, 6, 9, 11, 13, 14, 18, 22, 23, 28, 31, 33, 34, 41, 46, 47, 49, 51, 57, 59, 61, 64, 98

REPAIR KIT includes a complete set of O-Rings, Cartridge Valve, Gaskets,

Piston Seal, Guide Bushing, Springs, Valve Disc, and Exhaust Silencers.

Note: O-Rings may be ordered from a local supplier by specifying the 3-digit number

which conforms with ARP Universal series numbers.

(Example: Model AX item 2, specify -011).

Note: Item Number 31, Nylock Hex Nut, MUST be replaced after disassembly.

Note: Assemble Guide Bushing (Item #46) with outer rim slot aligned with slot

in Gasket (Item #51)

16

Page 19

MODEL AX

17

Page 20

MODELS CX, DX PARTS LIST

( ) Indicates quantity used if more than one

Item Description CX DX

1 Valve Block 15783 15783

2 O-Ring 14208-012 (2) 14208-012 (2)

3 Ring Insert 14295-03 (2) 14295-03 (2)

4 Valve Stem 14325 14325

5 Valve Disc 14263-02 14263-02

6 O-Ring 14208-008 14208-008

7 Hex Nut 943010ZP 943010ZP

8 Screw 900008-12LA (4) 900008-12LA (4)

9 Gasket, Valve Block 14327 14327

11 Cartridge Valve 12110-12 12110-12

12 Valve Plug 15488-02 15488-03

13 O-Ring 14208-011 14208-011

14 O-Ring 14208-012 14208-012

15 Screw 901010-03LA (2) 901010-03LA (2)

16 Washer DIN-125-M5BO (2) DIN-125-M5BO (2)

17 Piston Guide 16375 (2) 16375 (2)

18 O-Ring 14208-014 (2) 14208-014 (2)

20 Screw 905010-02.5LA 905010-02.5LA

21 Stock Clamp Piston 14287-05 (2) 14287-05 (2)

22 O-Ring 14208-214 (2) 14208-214 (2)

23 Spring, Compression 13453-04 (2) 13453-04 (2)

24 Pilot Release Clamp 16177 16178

25 Spring Stud 15832 15832

26 Spring Clamp 15831 15805

27 Spring Sleeve 15833 15833

28 Spring, Compression 12442-36 12442-36

29 Hex Nut 943031ZP 943031ZP

30 Insert, Clamp 14272-05 (4) 14272-05 (4)

31 Hex Nut, Nylock 943038ZP (4) 943038ZP (4)

32 Speed Adj. Screw 15787 15787

33 O-Ring 14208-006 14208-006

34 Silencer (Body) 12024-11 12024-11

36 Spring Pin 972018-06 (4) 972025-06 (4)

37 Screw 900031-06LA (4) 900031-06LA (4)

39 O-Ring 14208-016 14208-016

40 Ring 14271-02 14271-02

41 Piston Seal 14245-02 14245-02

42 Spacer 14272-02 14272-02

43 Locknut - Loctite #242 14317-02 14317-02

45 Retaining Plate 15485 15609

46 Guide Bushing - Loctite #324 14338-01 14338-01

47 O-Ring 14208-116 14208-116

48 O-Ring 14208-010 (2) 14208-010 (2)

49 O-Ring 14208-011 (2) 14208-011 (2)

50 Dowel Pin - Loctite #609 970012-03 (2) 970012-03 (2)

51 Gasket, Retaining Plate 15794 15811

52 Screw 901010-05LA (6) 901010-05LA (6)

53 Feed Slide 15484-01 15484-02

54 Hard Disc - Loctite #324 15770 (2) 15770 (2)

56 Feed Clamp Piston 14287-06 (2) 14287-06 (2)

57 O-Ring 14208-217 (2) 14208-217 (2)

58 Rod Guide 15492 (2) 15492 (2)

59 O-Ring 14208-027 (2) 14208-027 (2)

60 O-Ring 14208-016 (2) 14208-016 (2)

61 O-Ring 14208-112 (2) 14208-112 (2)

62 Cover Plate 14330 14349

63 Screw 901010-03LA (6) 901010-03LA (6)

Item Description CX DX

64 Spring, Compression 12442-17 (2) 12442-17 (2)

65 Feed Clamp 15830 15804

68 Buffer Housing 14335 14352

69 Buffer Piston 14316-02 14316-03

70 O-Ring 14208-011 14208-110

71 Striker Plate 14333 14333

72 Screw 900006-02LA (3) 900006-02LA (3)

73 O-Ring 14208-018 14208-018

74 Stop Block 15862 15863

75 Wear Strip 15874-02 15874-03

76 Shoulder Screw 919039-04 (2) 919039-04 (2)

77 Stop Screw 14331 14331

78 Hex Nut 941062BO 941062BO

79 Roller Bracket, Left 15858-01 15858-01

80 Roller Bracket, Right 15858-02 15858-02

81 Screw 902025-04LA (4) 902025-04LA (4)

82 Roller Shaft 15859-02 (2) 15859-03 (2)

84 Roller Stock Guide 12441-25 (2) 12441-25 (2)

86 Buffer Piston 15491-01 (2) 15491-01 (2)

87 O-Ring 14208-110 (2) 14208-110 (2)

88 E-Ring 12013-20 12013-20

89 Cartridge Guide P.O.V. 12110-13 12110-13

90 Valve Block P.O.V. 15487 15487

91 Piston Oper. Valve Assy. 15508 15508

92 Mechanical Valve Assy. 14307 14307

93 P.R.S.C. Assy. 15807 15808

94 Stock Clamp 15830 15804

96 Silencer (Valve Block) 12024-11 12024-11

97 Dowel Pin - Loctite #609 970012-02 (2) 970012-02 (2)

98 Flanged Bushing 12128-52 (4) 12128-52 (4)

100 Air Line Tubing (10 Ft.) 15676-02 15676-02

101 Fitting 12032-10 12032-10

102 Cylinder 12111-24 12111-24

103 Clamp Pad 16514 16514

105 Clamp, Pneu. Release 16504 16505

106 Screw 905010-10LA 905010-10LA

107 Screw 905031-05LA 905031-05LA

108 Spool Valve 3-Way 12110-10 12110-10

109 Spool Valve 4-Way 12110-18 12110-18

110 Solenoid Valve 3-Way 12039-31 12039-31

111 Solenoid Valve 4-Way 12039-59 12039-59

112 3-Way On/Off Exhaust 12110-02 12110-02

113 Linear Cam 14170 14170

114 Limit Switch 12031-02 12031-02

116 Nut 943010ZP 943010ZP

117 Pneu. Pilot Release Assy. 16605 16606

122 Fitting, Straight 12032-12 12032-12

(120 VAC, 50/60 Hz)

Solenoid Valve 3-Way 12039-39 12039-39

(240 VAC, 50/60 Hz)

Solenoid Valve 3-Way 12039-60 12039-60

(24 VDC)

(120 VAC, 50/60 Hz)

Solenoid Valve 4-Way 12039-58 12039-58

(240 VAC, 50/60 Hz)

Solenoid Valve 4-Way 12039-61 12039-61

(24 VDC)

18

Page 21

REPAIR KITS

Model CX – P/A No. 15926

Model DX – P/A No. 15927

Repair Kits include these Item Numbers:

2, 5, 6, 9, 11, 13, 14, 18, 22, 23, 28, 30,

31, 33, 34, 39, 41, 46, 47, 48, 49, 51,

57, 59, 61, 64, 70, 73, 87, 96, 98

REPAIR KIT includes a complete set of

O-Rings, Cartridge Valve, Gaskets,

Piston Seal, Guide Bushing, Springs,

Valve Disc, and Exhaust Silencers.

Note: O-Rings may be ordered from a

local supplier by specifying the 3-digit

number which conforms with ARP

Universal series numbers.

(Example: Model CX item 2,

specify -012).

Note: Item Number 31, Nylock Hex Nut,

MUST be replaced after disassembly.

Note: Assemble Guide Bushing (Item

#46) with outer rim slot aligned with slot

in Gasket (Item #51)

MODELS CX, DX

Item Description CX3 CX6 CX9 CX12 DX4 DX6 DX12

10 Main Body 15431-01 15431-02 15431-03 15431-04 15608-01 15608-02 15608-03

19 Wear Strip, Body 15786-01 15786-02 15786-03 15786-04 15802-01 15802-02 15802-03

35 Guide Rail 14324-01 (2) 14324-02 (2) 14324-03 (2) 14324-04 (2) 14347-01 (2) 14347-02 (2) 14347-03 (2)

38 Main Piston Rod 14318-01 14318-03 14318-04 14318-05 14318-02 14318-03 14318-05

55 Tubes w/Loctite #609 15828-01 (2) 15828-02 (2) 15828-03 (2) 15828-04 (2) 15828-05 (2) 15828-02 (2) 15828-04 (2)

121 Protective Cover 14222-04 14222-05 14222-06 14222-07 14222-08 14222-09 14222-13

19

Page 22

MODELS FX, HX, LX PARTS LIST

( ) Indicates quantity used if more than one

Item Description FX HX LX

1 Valve Block 15783 15783 15783

2 O-Ring 14208-012 (2) 14208-012 (2) 14208-012 (2)

3 Ring Insert 14295-03 (2) 14295-03 (2) 14295-03 (2)

4 Valve Stem 14325 14325 14325

5 Valve Disc 14263-02 14263-02 14263-02

6 O-Ring 14208-008 14208-008 14208-008

7 Hex Nut 943010ZP 943010ZP 943010ZP

8 Screw 900008-12LA (4) 900008-12LA (4) 900008-12LA (4)

9 Gasket, Valve Block 14327 14327 14327

11 Cartridge Valve 12110-13 12110-13 12110-13

12 Valve Plug 15769 15769 15769

13 O-Ring 14208-015 14208-015 14208-015

14 O-Ring 14208-113 (3) 14208-113 (3) 14208-113 (3)

15 Screw 901010-03LA (2) 901010-03LA (2) 901010-03LA (2)

16 Washer DIN-125-M5BO (2) 958010 (2) 958010 (2)

17 Piston Guide 16375 (2) 16375 (2) 16375 (2)

18 O-Ring 14208-014 (2) 14208-014 (2) 14208-014 (2)

20 Screw 905P010-02.5LA 905P010-02.5LA 905010-03LA

21 Stock Clamp Piston 14287-05 (2) 14287-05 (2) 14287-10 (2)

22 O-Ring 14208-214 (2) 14208-214 (2) 14208-220 (2)

23 Spring, Compression 13453-04 (2) 13453-04 (2) 12442-43 (2)

24 Pilot Release Clamp 16179 16767 N/A

25 Spring Stud 15832 (2) 15832 (2) N/A

26 Spring Clamp 15824 15824 N/A

27 Spring Sleeve 15833 (2) 15833 (2) N/A

28 Spring, Compression 12442-36 (2) 12442-36 (2) N/A

29 Hex Nut 943031ZP (2) 943031ZP (2) N/A

30 Insert, Clamp 14272-05 (4) 14272-05 (4) 14272-06 (4)

31 Hex Nut, Nylock 943038ZP (4) 943038ZP (4) 943050ZP (4)

32 Speed Adj. Screw 15787 15787 15787

33 O-Ring 14208-006 14208-006 14208-006

34 Silencer (Body) 12024-12 12024-12 12024-12

36 Spring Pin 972025-06 (4) 972025-06 (4) 972025-06 (4)

37 Screw 900031-06LA (4) 900031-06LA (4) 900031-06LA (4)

39 O-Ring 14208-016 14208-016 14208-016

40 Ring 14271-03 14271-03 14271-06

41 Piston Seal 14245-03 14245-03 14245-04

42 Spacer 14272-03 14272-03 14272-07

43 Locknut - Loctite #242 14317-02 14317-02 14317-02

44 Ring Insert N/A N/A 14295-01 (2)

45 Retaining Plate 15818 16752 16938

46 Guide Bushing - Loctite #324 14338-02 14338-02 14338-02

47 O-Ring 14208-116 14208-116 14208-116

48 O-Ring 14208-010 (2) 14208-010 (2) 14208-010 (2)

49 O-Ring 14208-011 (2) 14208-011 (2) 14208-011 (2)

50 Dowel Pin - Loctite #609 970012-03 (2) 970012-03 (2) 970012-03 (2)

51 Gasket, Rtng Plate 15819 16753 16939

52 Screw 901010-05LA (6) 901010-05LA (8) 901010-05LA (12)

53 Feed Slide 15671 16754 16940

54 Hard Disc - Loctite #324 15770 (2) 15770 (2) 15770 (2)

56 Feed Clamp Piston 14287-07 (2) 14287-07 (2) 14287-09 (2)

57 O-Ring 14208-223 (2) 14208-223 (2) 14208-228 (2)

58 Rod Guide 15771 (2) 15771 (2) 16951 (2)

59 O-Ring 14208-031 (2) 14208-031 (2) 14208-036 (2)

60 O-Ring 14208-016 (2) 14208-016 (2) 14208-016 (2)

61 O-Ring 14208-112 (2) 14208-112 (2) 14208-114 (2)

62 Cover Plate 14361 16755 16941

Item Description FX HX LX

63 Screw 900025-04LA (6) 900025-04LA (8) 900025-04LA (12)

64 Spring, Compression 12442-21 (2) 12442-21 (2) 12442-42 (2)

65 Feed Clamp 15850 16756 16942

68 Buffer Housing 14631 14631 14631

69 Buffer Piston 14316-03 14316-03 14316-03

70 O-Ring 14208-110 14208-110 14208-110

71 Striker Plate 14333 14333 14333

72 Screw 900006-02LA (3) 900006-02LA (3) 900006-02LA (3)

73 O-Ring 14208-018 14208-018 14208-018

74 Stop Block 15864 16758 16943

75 Wear Strip 15874-4 15874-5 16584

76 Shoulder Screw 919051-04 (2) 919051-04 (2) 919051-04 (2)

77 Stop Screw 14331 14331 16945

78 Hex Nut 941062BO 941062BO 947075BO

79 Roller Bracket, Left 15858-01 15858-01 15858-05

80 Roller Bracket, Right 15858-02 15858-02 15858-06

81 Screw 902025-02LA (4) 902025-02LA (4) 902025-02LA (4)

82 Roller Shaft 15859-04 (2) 15859-05 (2) 15859-06 (2)

84 Roller Stock Guide 12441-25 (2) 12441-25 (2) 12441-22 (2)

86 Buffer Piston 15491-01 (2) 15491-01 (2) 15491-01 (2)

87 O-Ring 14208-110 (2) 14208-110 (2) 14208-110 (2)

88 E-Ring 12013-20 12013-20 12013-20

89 Cartridge Guide P.O.V. 12110-13 12110-13 12110-13

90 Valve Block P.O.V. 15487 15487 15487

91 Piston Oper. Valve Assy. 15508 15508 15508

92 Mechanical Valve Assy. 14307 14307 14307

93 P.R.S.C. Assy. 15809 16762 N/A

94 Stock Clamp 15823 16761 16946

96 Silencer (Valve Block) 12024-11 12024-11 12024-11

97 Dowel Pin - Loctite #609 970012-02 (2) 970012-02 (2) N/A

98 Flanged Bushing 12128-52 (4) 12128-52 (4) 12128-60 (4)

100 Air Line Tubing (10 Ft.) 15676-02 15676-02 15676-02

101 Fitting, Elbow 12032-10 12032-10 12032-10

102 Cylinder 12111-24 12111-24 12111-24

103 Clamp Pad 16512 16512 16950

105 Clamp, Pneu. Release 16506 16763 16947

106 Screw 905010-10LA 905010-10LA 905010-10LA

107 Screw 905031-05LA 905031-05LA 905031-06LA

108 Spool Valve 3-Way 12110-10 12110-10 12110-10

109 Spool Valve 4-Way 12110-18 12110-18 12110-18

110 Solenoid Valve 3-Way 12039-31 12039-31 12039-31

111 Solenoid Valve 4-Way 12039-59 12039-59 12039-59

112 3-Way On/Off Exhaust 12110-15 12110-15 12110-21

113 Linear Cam 14170 14170 14170

114 Limit Switch 12031-02 12031-02 12031-02

115 Cap 16956 16956 16956

116 Nut 943010ZP 943010ZP 943010ZP

117 Pneu. Pilot Release Assy. 16607 16764 16948

118 Valve Plug 16955 16955 16955

119 Internal Pilot Release Kit 16957-01 16957-02 16957-03

120 Spacer N/A 16772-01 16772-02

122 Fitting, Straight 12032-12 12032-12 12032-12

(120 VAC, 50/60 Hz)

Solenoid Valve 3-Way 12039-39 12039-39 12039-39

(240 VAC, 50/60 Hz)

Solenoid Valve 3-Way 12039-60 12039-60 12039-60

(24 VDC)

(120 VAC, 50/60 Hz)

Solenoid Valve 4-Way 12039-58 12039-58 12039-58

(240 VAC, 50/60 Hz)

Solenoid Valve 4-Way 12039-61 12039-61 12039-61

(24 VDC)

20

Page 23

REPAIR KITS

Model FX – P/A No. 15928

Model HX – P/A No. 16751

Model LX – P/A No. 16935

Repair Kits include these Item Numbers:

2, 5, 6, 9, 11, 13, 14, 18, 22, 23, 28, 30,

31, 33, 34, 39, 41, 46, 47, 48, 49, 51, 57,

59, 61, 64, 70, 73, 87, 96, 98

REPAIR KIT includes a complete set of

O-Rings, Cartridge Valve, Gaskets,

Piston Seal, Guide Bushing, Springs,

Valve Disc, and Exhaust Silencers.

Note: O-Rings may be ordered from a

local supplier by specifying the 3-digit

number which conforms with ARP

Universal series numbers.

(Example: Model FX item 2,

specify -012).

Note: Item Number 31, Nylock Hex Nut,

MUST be replaced after disassembly.

Note: Assemble Guide Bushing (Item

#46) with outer rim slot aligned with slot

in Gasket (Item #51)

MODELS FX, HX, LX

Item Description FX4 FX6 FX9 FX12

10 Main Body 15630-01 15630-01 15630-02 15630-03

19 Wear Strip, Body 15821-01 15821-01 15821-02 15821-03

35 Guide Rail 15958-04 (2) 15958-01 (2) 15958-02 (2) 15958-03 (2)

38 Main Piston Rod 14356-01 14356-01 14356-02 14356-03

55 Tubes w/Loctite #609 15828-02 (2) 15828-02 (2) 15828-03 (2) 15828-04 (2)

121 Protective Cover 14222-14 14222-10 14222-11 14222-12

Item Description HX4 HX6 HX9 HX12 LX6 LX12

10 Main Body 16759-01 16759-01 16759-02 16759-03 16937-01 16937-02

19 Wear Strip, Body 16760-01 16760-01 16760-02 16760-03 16944-01 16944-02

35 Guide Rail 15958-04 (2) 15958-01 (2) 15958-02 (2) 15958-03 (2) 16949-01(2) 16949-02(2)

38 Main Piston Rod 14356-01 14356-01 14356-02 14356-03 14356-04 14356-05

55 Tubes w/Loctite #609 15828-02 (2) 15828-02 (2) 15828-03 (2) 15828-04 (2) 15828-06(2) 15828-07(2)

121 Protective Cover 16765-01 16765-02 16765-03 16765-04 16954-01 16954-02

21

Page 24

FEED ACTUATION METHODS ACCESSORIES

See pages 9 and 10 for schematics

MECHANICAL

ACTUATION

22

92

PNEUMATIC

SIGNAL

ACTUATION

ELECTRIC

SIGNAL

REMOTE

MODEL

AX

92

MECHANICAL

ACTUATION

PNEUMATIC

SIGNAL

ACTUATION

MODELS

CX, DX, FX, HX, LX

ELECTRIC

SIGNAL

9191

REMOTE

Page 25

PILOT RELEASE ACTUATION METHODS

See page14 for schematics

PNEUMATIC

SIGNAL

93

MECHANICAL

PILOT RELEASE

PILOT RELEASE

MODEL

AX

ELECTRIC

SIGNAL

REMOTE

93

MECHANICAL

PILOT RELEASE

MODELS

CX, DX, FX, HX

PNEUMATIC

SIGNAL

117117

REMOTE

PILOT RELEASE

MODELS

CX, DX, FX, HX, LX

ELECTRIC

SIGNAL

PNEUMATIC

SIGNAL

PILOT RELEASE

INTERNAL

MODELS

LX

ELECTRIC

SIGNAL

ALREADY

*

INSTALLED

IN AIR FEED

23

Page 26

FEEDS

FEEDS FEEDS AND FEED AIR

TROUBLE

SHOOTING

CHART

SET-UP & OPERATION

Air Pressure or Volume Too Low ✔✔✔ ✔ ✔

Feed Mounted Loose or Misaligned ✔✔ ✔ ✔

Obstruction within Die: Slugs, Scrap ✔✔ ✔

Camber, Burrs, Unstraightened Coil ✔✔ ✔

Oily, Slippery Strip ✔✔✔

Stock Reel Drag or Tight Loop ✔✔✔ ✔

Feed Timing Incorrect ✔✔ ✔✔✔

Forming Die Pulls Strip Forward ✔✔

Shearing Die Pushes Strip Backward ✔✔

Speed Adjust Screw Set Wrong ✔✔✔✔

Clamp Clearance Set Wrong ✔✔ ✔ ✔✔

MAINTENANCE

Water or Dirt in Air Line ✔✔✔ ✔ ✔✔ ✔ ✔

Cartridge Valve Malfunction ✔✔✔ ✔ ✔✔ ✔✔✔ ✔

Clamp Pistons O-Rings Leaking ✔✔ ✔✔✔ ✔

Main Piston Cup Seals Leaking ✔ ✔

Air Tube O-Rings Leaking ✔✔ ✔

Valve Disc Broken ✔✔

Gasket Failure Under Valve ✔✔

Worn or Broken Clamp Springs ✔✔

Feed or Stock Clamp Springs Reversed ✔✔✔

Not Enough Air Line Oil ✔✔

Retaining Plate Gasket Leaking ✔✔✔

Cushions Filled with Oil or Dirt ✔✔ ✔✔

Strip Strip Slide Moves Strip Strip

Moves Moves Not Before Moves Moves Moves Exhaust

Under Under Making Feed Under Under To Port

Feed Stock Full Clamp Feed Stock Stock Stop No Valve Main Air

Clamp Clamp Stroke Closes Clamp Clamp Buckles Screw Motion Block Body Tubes

SHORT LONG SHORT SLIDE LEAKAGE

Feed

Feed Slide

LONG

24

Page 27

WARRANTY

We warrant our new parts against defects under normal use and service for a period of 2 years after

date of shipment. Our obligation under this warranty is limited to replacing or repairing (at our option) the

defective part without charge, F.O.B. our plant in Bloomfield, Connecticut. The defective part must be

forwarded to our plant, freight-prepaid, for our inspection prior to replacement or repair. EXCEPT AS

EXPRESSLY PROVIDED HEREIN, THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING A WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

WARNING !

This equipment offers various means of operating metal forming machines, delivers material or parts to

the machine, or removes material, parts, or scrap from the machine. The operator

in or near the point-of-operation of the machine, or the operating parts of any equipment installed on the

machine, or bodily injury could result. The EMPLOYER must post adequate warning signs on the press

with proper warnings for his machine and the specific application to which the machine and equipment

are being applied. If the EMPLOYER requires help in preparing wording for his application after he has

determined the details of that application, he is invited to contact P/A Industries for such help.

The EMPLOYER must meet all OSHA regulations including, but not limited to, 1910.211, 1910.212,

1910.217 and all applicable state laws. All equipment manufactured by P/A Industries is designed to

meet the construction standards of OSHA in effect at the time of sale, but the EMPLOYER installs the

equipment, and therefore the EMPLOYER is responsible for installation, use, application, training, and

maintenance, as well as adequate signs on the press or other machine onto which this equipment will be

installed.

All P/A products are sold for use only in accordance with our installation and operating instructions

which accompany the products. P/A accepts no responsibility for any use or application not in accordance with our instructions, or for any modification or alteration of the product.

Accident-free press operation will result from a well developed, management-sponsored and enforced

press safety program. P/A Industries is not responsible for notifying the user of this equipment of further

changes in State or Federal laws, construction standards, or changes in P/A designed and built products.

’s hands must NOT be

Page 28

P/A INDUSTRIES INC.

P/A Technology Park

522 Cottage Grove Road

Bloomfield, CT 06002 USA

Toll Free: 1-800-243-8306

Worldwide: 1-860-243-8306

Fax: 1-860-242-4870

E-Mail: sales@pa.com

Webpage: http.//www.pa.com

FORM 996 12-00

®

Loading...

Loading...