Page 1

Vac-U-Flo 90 SMT Desoldering Station

Operation & Maintenance Manual 5050-0497

1. Packing Contents (8007-0354 or 8007-0355)

A) VF 90 SMT Desoldering Station

B) VF 90 SMT Desoldering Hand-piece fitted with Standard Tip.

C) Hand-piece cubby fitted with Micro Switch for controlling air-flow

D) Angle Bracket Kit (6800-0097-P1)

E) Cleaning tool (6800-0037-P1)

F) Tip Wrench (Open End Wrench (6.35mm (.25”) & 7.9 mm (.31”)) ) (6800-0036-P1)

G) Flux Condenser (6800-0001-P1) NOTE VACUUM FLOW DIRECTION

H) Silencer (6800-0050-P1)

I) Filter Set for Hand-piece (6800-0032-P1)

J) Felt Filters 3 Pieces (6800-0002-P1)

K) Foam Filters 5 Pieces (6800-0002-P1)

L) Mica Sheets 1 Piece (6800-0006-P1)

M) O Ring Lubricant (6900-0040-P1)

N) Adjustment Tool (6800-0054-P1)

O) Tip Cleaning Shaft (.635mm (.025”) Diameter)

P) Air Hoses (2)

Q) Power Cord

2. Specification

Power Requirements:

8007-0354

8007-0355

Weight

Power Supply

Hand-piece

Dimensions 135mm (5.3”) H x 165mm (6.5”) W x

Temperature Range:

Air Flow: 11 SLPM (22 SCFH) @ 5.5 bar (80 p.s.i.)

Voltage Leakage Tip to Ground < 2mV

Tip to Ground Resistance < 2 Ohm

120 VAC, 60 Hz, 39 - 330 W

230 VAC, 50 Hz, 39 – 330 W

3.8 kg (8.5 pounds)

383g (13.5 oz)

260mm (9.25”) D

205°C – 425°C (400°F – 800°F)

9 SLPM (19 SCFH) @ 4.5 bar (65 p.s.i.)

Page 2

VF 90 System Operations Manual, Rev B

3. Safety Information

a. Do not contact the heater or its peripheral parts during operation.

b. Once turned off, let the unit cool completely before contacting.

c. When using fluxes, use fume extraction equipment or use in a well-ventilated area to

minimize operator exposure to fumes. Testing

4. Features

Hot gas assist Effectively pre-heats area to be desoldered, reducing

N2 compatible Reduces/eliminates the need for flux and reduces bridging.

Variety of tips available Flexibility, choose the right tip to suit your application

Stainless steel tip Tip will not pit or corrode eliminating pad damage

Shop air powered vacuum Quiet operation: Ideal for high volume applications

Variable vacuum control Variable adjustment allows desired amounts of solder to be

Large capacity collection

chamber

Independent temperature

control for desoldering tip and

hot gas.

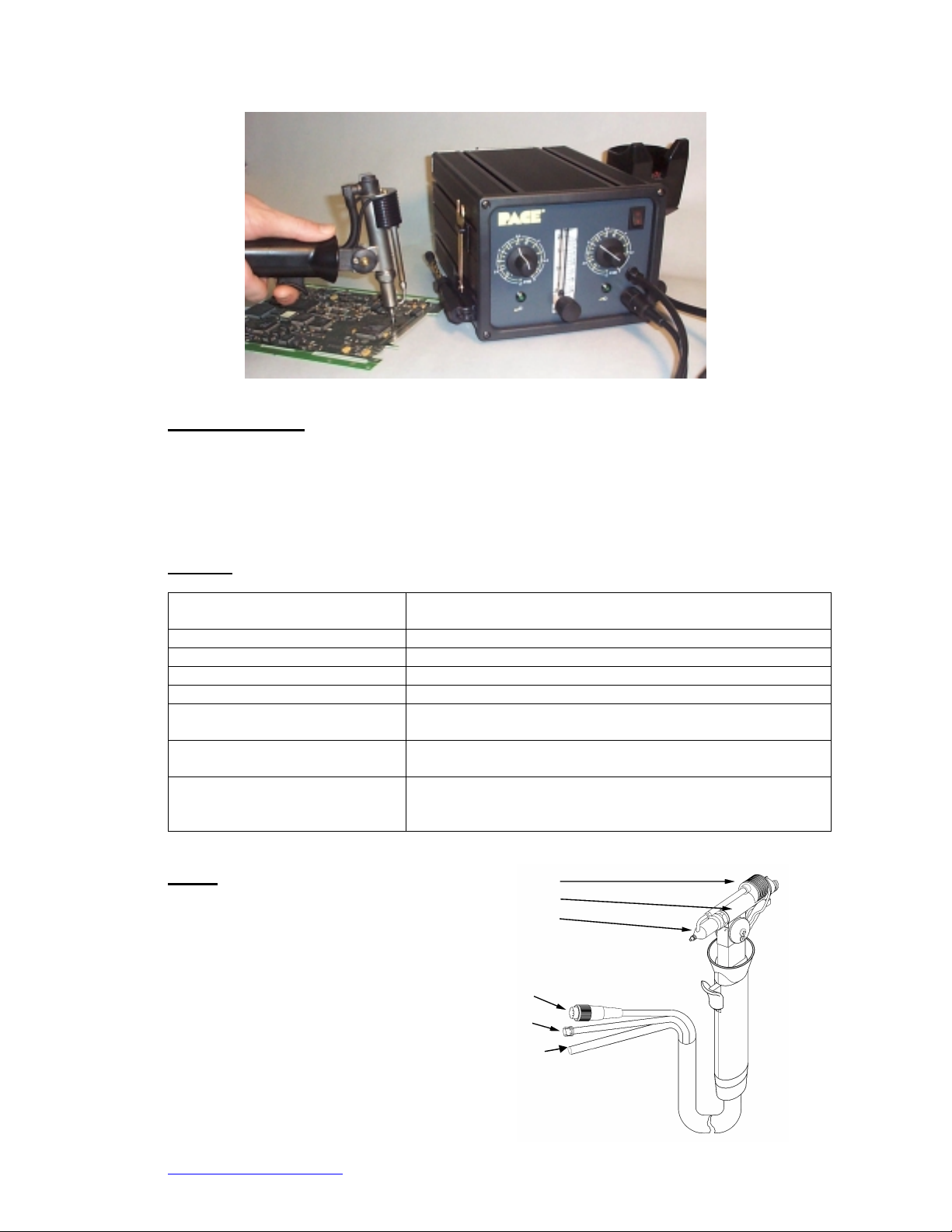

5. Set-Up

A. Hand-piece

1. Gas Heater

2. Desoldering Head Housing

3. Desoldering Tip

4. 24 Volt input, turn clockwise to engage

5. Gas connector, turn clockwise to engage

6. Vacuum Line, connect to condenser

thermal shock and contact time.

left on pads, more consistent finish.

Reduces cleaning frequency and allows for large jobs to be

completed quickly.

Easily adapts to a wide variety of jobs

1

2

3

4

5

6

www.paceworldwide.com

Page 2 of 10

Page 3

VF 90 System Operations Manual, Rev B

B. Power Supply (Front)

Hand Tool Connectors must be turned clockwise to engage.

1. 24 volt hand-piece connection

2. Air flow connection

3. Condenser and vacuum hose

connection

4. Tip temp adjust

5. Hot gas temp adjust

6. Airflow regulator

7. Power switch

8. Temperature indicating LEDs

5

6

4

7

2

1

3

8

VF 90 Hand-piece not connected to power supply VF 90 Hand-piece connected to power supply

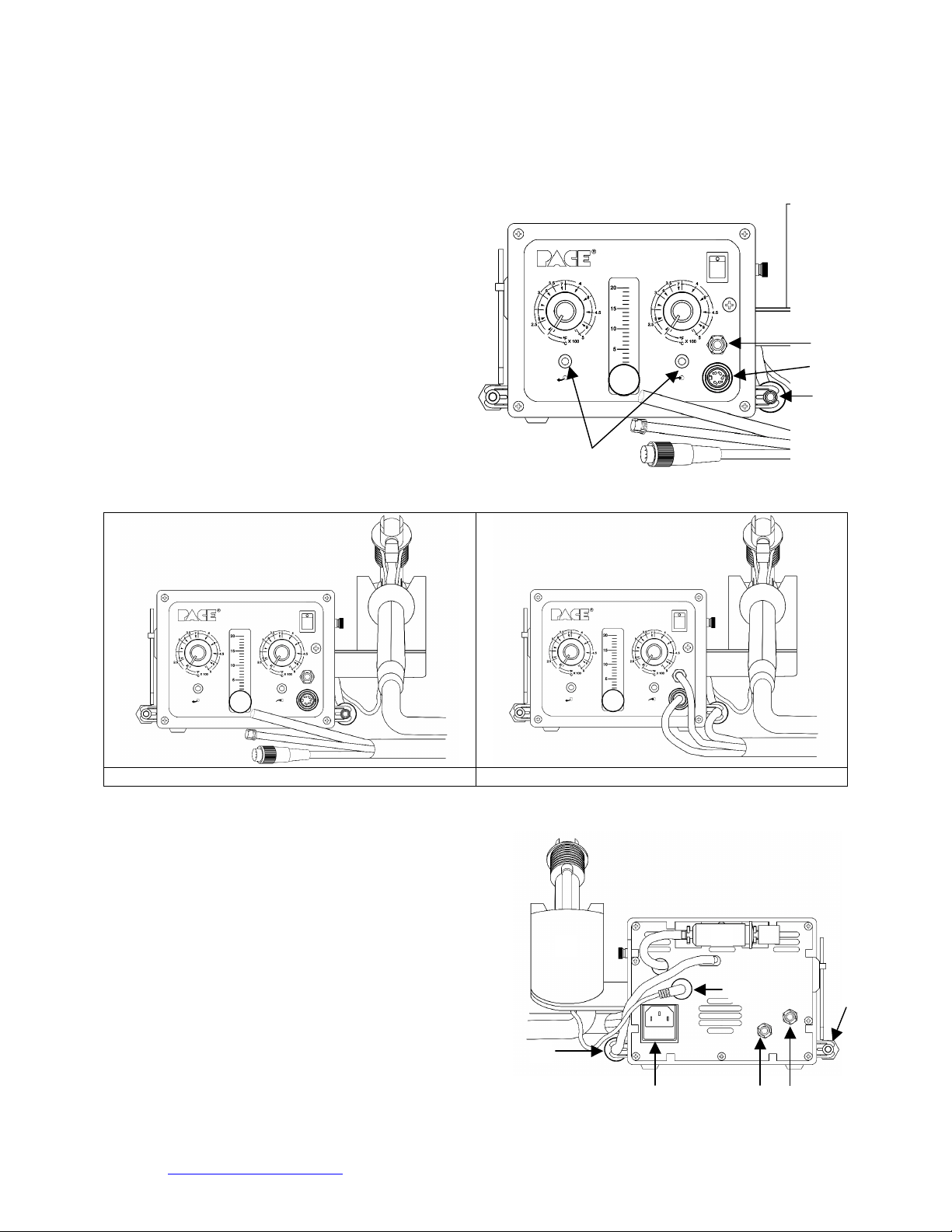

C. Power Supply (Back)

1. Condenser (Back)

2. Power input

3. Silencer

4. Cleaning tool

5. Tool stand micro switch connection

6. Hand-piece cubby

7. Airflow supply

8. Vacuum supply

6

3

5

www.paceworldwide.com

Page 3 of 10

1

2

8

7

4

Page 4

VF 90 System Operations Manual, Rev B

6. Operation

(Vacuum)

Ideal air pressure input:

60 to 90 psi 13 psi max.

413.7 – 620.5 KPA 5 SCFH

4.1 – 6.2 bar 2.4 L/min

Ideal Gas Input (Air Flow)

(color-coded sleeve):

1. Turn on power switch. The heater indicator (green LEDs) will light

up. Hot Gas & Vacuum will activate if tool is removed from the

holder.

Note: Hand-piece should always be placed in holder when not

use. Hot gas flow will stop when tool is placed in the

holder

2. Adjust temperature settings for hot gas and tip to the desired setting

325°C – 375°C (600°F - 700°F). The heater indicator will remain

on until the appropriate heater reaches the set temperature. A

blinking heater indicator means set temperature has been achieved

and is being maintained.

3. Adjust airflow regulator to desired setting.

CAUTION: If airflow is too high, molten solder may be blown off of the PCB

4. Place tip close to working area.

5. When solder melts, press trigger to remove solder.

6. If the tip clogs, use the cleaning shaft from the cleaning tool by unscrewing it as shown

below.

7. Use the cleaning shaft to remove the

obstruction. While using the cleaning shaft, activate the

vacuum pulses rather than continuous suction.

7. Hand-piece Head Adjustment

A. Adjustment of angular orientation should be done while the tool is cool.

in

1. To tilt the head assembly, loosen (2) adjustment

screws.

2. Tilt the head assembly to desired position

3. Retighten screws.

B. Head rotation should be done while the tool is cool.

1. While handpiece is in the cubby, push handle down and twist.

Adjustment Screws

www.paceworldwide.com

Page 4 of 10

Page 5

VF 90 System Operations Manual, Rev B

A

g

A

g

p

2. Twist until head locks into 1 of its 4 positions. Twisting counter-clockwise will permit a

180° turn. Twisting clockwise will permit a 90° turn.

Note: The head assembly does not make a full 360°°°° turn.

8 Tip/Accessory Replacement

It is recommended for the operator to remove and inspect the tip daily. Replace the tip if there is

any sign of wear. Doing this will also prevent the tip from seizing onto the heater.

CAUTION: ONLY REMOVE THE TIP WHEN THE HAND-PIECE IS COOL

A Removing the Tip

4. To remove the tip, loosen air flow tube nut (A), then the retaining sleeve nut (B).

5. Remove retaining sleeve.

6. Remove tip.

B. Installing a new Tip

1. Insert tip into heater

2. Replace retaining sleeve over tip/heater

3. Check the alignment of retaining sleeve by inserting the end of the cleaning shaft

4. Tighten the retaining sleeve nut (B).

5. Tighten air flow tube nut (A)

Cleaning Shaft Handle

Use this wrench to

loosen nuts A & B

handle inside the tip

Tip

Retaining Sleeve

B

Retainin

Sleeve

Sleeve

B

Ti

Retainin

www.paceworldwide.com

Page 5 of 10

Page 6

Hole Diameter Length Part Number

2.3mm (.09”) 14mm (.55”) Focus Nozzle 6800-0028-P1

1.3mm (.05”) 10.9mm (.43”) Standard Nozzle 6800-0027-P1

9. Cleaning & Maintenance

Proper maintenance and regular cleaning are required to keep your VF 90 operating properly.

Please refer to the replacement parts table in Section 10 of this manual when ordering

replacement parts.

A. The following items should be

inspected and cleaned or replaced on

a regular basis:

•= Replace Felt Filter (6800-0032)

•= Clean Solder Cone (6800-0011)

•= Replace Mica Sheet (6800-0006).

•= Check O Rings on End Cap

Assembly and Elbow Connector.

Part numbers 6800-0053 for End

Cap and 6800-0051 for Elbow

Connector.

•= Replace worn-out Tip.

B. Flux Condenser Maintenance (6800-0001)

1. Replace felt filter (6800-0002) and foam filters (8000-0003)

2. Clean barrel housing (6800-0052) and condenser (6800-0019) with alcohol.

3. Tip wrench can be used to remove 6800-0015 filter cap.

6800-0002

6800-0015

4. If flux gets in the venturi, disconnect the flux condenser and the silencer. Flush the

venturi with alcohol. You may need to pump the alcohol through the venturi.

CAUTION: Disconnect power before opening back panel to access venturi!

VF 90 System Operations Manual, Rev B

Optional Tips

.5mm (.02”) 20.3 mm (.8”) Round Needle Tip P/N 6800-0029-P1

.3mm (.01”) 16mm (.63”) Small Oval Needle 6800-0030-P1

.5mm (.02”) 20mm (.80”) Medium Oval Needle 6800-0031-P1

6800-0049-P1

6800-0032-P1

6800-0011-P1

6800-0051-P1

Not Used

6800-0006-P1

6800-0003

6800-0003

6800-0052

6800-0019

6800-0015

www.paceworldwide.com

Page 6 of 10

Page 7

VF 90 System Operations Manual, Rev B

C. Silencer Maintenance

1. Disconnect air hose.

2. Open plastic housing (6800-0047).

3. Replace foam filters (6800-0002).

4. Close plastic housing.

5. Reattach air hose and install on back of power supply.

D. Cleaning the desoldering collection chamber and replacing the heater tube and silicon

washer in collection chamber

Always dispose of old solder in accordance with local environmental regulations.

To clean the collection chamber, remove the

end cap and dump out old solder. Using the

cleaning tool, remove the mica sheet and

clean. Replace if worn.

To clean the solder pathway, first remove the

retaining sleeve and Tip. Next, insert the

cleaning tool all the way into the opening to

remove any obstruction

To remove the heater tube, push the cleaning

tool in all the way, the heater tube will come out

of the front end and can be removed.

Remove the silicon washer using the hook on

the cleaning tool.

Replace the heater tube, flanged end out.

Insert new silicon washer into chamber. Using

the handle of the cleaning tool, with the tip

cleaner removed, press the silicon washer in to

place.

www.paceworldwide.com

Page 7 of 10

Page 8

VF 90 System Operations Manual, Rev B

E. O-Rings Replacement inside valve assembly

1. Unscrew lock nut at the end of the tool handle.

2. Remove handle cover.

3. Slide out valve assembl y while placi ng your

finger over the spring seat. BE CAREFULL

NOT TO LET THE SPRING SEAT SHOOT

OUT FROM THE HOUSING.

4. Clean all parts with alcohol only.

5. Replace the O-Ring Set, set of 3 (6800-0007).

6. Lubricate new O-Rings with 6800-0040 O-Ring

lubricant.

7. Make sure wires and hoses are not pinched or

kinked.

8. Reassemble hand-piece.

www.paceworldwide.com

Page 8 of 10

Page 9

10. Major Replacement Parts

Part Name Part Number

Felt Filter (Set of 10) 6800-0002-P1 Medium Oval

Foam Filter (Set of

10)

End Cap Assembly

(Standard)

High Performance

Filter Assembl y

Mica-Sheets (set of

12)

O-Ring set of Valve

Assembly

O-Ring for Heater

Bushing Eend Cap

Retaining Sleeve 6800-0009-P1 Silicone Washer 6800-0038-P1

Solder Cone 6800-0011-P1 O-Ring Lube 6800-0040-P1

Heating Element for

Tip Heater

Poppet and o-ring 6800- 001 3-P1 Meter 6800-0042-P1

Spring 6800-0014-P1 Thermocouple 1 6800-0043-P1

End Cap for Filter 6800-0015-P1 Thermocouple 2 6800-0044-P1

Valve Assembly 6800-0016-P1 Thermoprobe 1 6800-0045-P1

Transformer 6800-0017-P1 Thermoprobe 2 6800-0046-P1

Flux Condenser for

cooling fan

Heating Element for

Hot Gas

Circuit Board for

Cooling Fan

Soldenoid Valve 6800-0022-P1 Silencer 6800-0050-P1

Fan Assembly 6800-0023-P1 O-Ring for Elbow

Circuit Board for Left

(hot-gas) Side

Circuit Board for

Right (tip) Side

Handpiece Tool (VF-

90)

Standard Tip 6800-0027-P1 Tip Cleaning Shaft 6800-0057-P1

Focus Nozzle 6800-0028-P1 Air Hoses 6800-0058-P1

Long Reach Needle

Nozzle

Small Oval Nozzle 6800-0030-P1

VF 90 System Operations Manual, Rev B

6800-0003-P1 Filter Set for

6800-0004-P1 Vacuum Generator 6800-0033-P1

6800-0005-P1 Fuse Domestic,

6800-0006-P1 Fuse Export, 1.6A

6800-0007-P1 Tip Wrench 6800-0036-P1

6800-0008-P1 Cleaning Tool 6800-0037-P1

6800-0012-P1 Hot Tube 6800-0041-P1

6800-0019-P1 Plastic Housing 6800-0047-P1

6800-0020-P1 Foam Cylinder 6800-0048-P1

6800-0021-P1 End Cap Assembly 6800-0049-P1

6800-0024-P1 Barrel Filter

6800-0025-P1 Adjustment Tool 6800-0054-P1

6800-0026-P1 Wrench 6800-0056-P1

6800-0029-P1 End Cap O-Ring 6800-0059-P1

Part Name Part Number

6800-0031-P1

Nozzle

6800-0032-P1

handtool

6800-0034-P1

3.15A Fast Acting

6800-0035-P1

Fast Acting

6800-0051-P1

Connector Cap

6800-0052-P1

Housing

www.paceworldwide.com

Page 9 of 10

Page 10

VF 90 System Operations Manual, Rev B

11. Compliance

PACE Incorporated retains the right to make changes to specifications contained herein at any

time, without notice.

PACE products meet or exceed all applicable military and civilian EOS/ESD, temperature

stability and other specific a tions , inc lud ing MIL-Std-2000, ANSI/J- Std-0 01, and IPC-A-610.

Complies with MIL-S-45743E, MIL-STD-2000, DOD-STD-2000-1B, WS6536E and ESD SPEC,

DOD-STD-1686, DOD-HDBK-263

12. Service

For any questions regarding this Operation & Maintenance Manual, contact your local

authorized PACE distributor or contact PACE directly at the appropriate address listed below.

Please contact PACE or your Local Representative for service and repair.

www.paceworldwide.com

PACE USA PACE Europe

9893 Brewers Court Sherbourne House

Laurel, MD 20723 Sherbourne Drive

USA Tilbrook, Milton Keynes

MK7 8HX

United Kingdom

Tel: (301) 490-9860 (44) 1908-277666

Fax: (301) 498-3252 (44) 1908-277777

1-888-535-PACE

www.paceworldwide.com

Page 10 of 10

Loading...

Loading...