Page 1

Page 2

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

INTRODUCING

PACE ST SYSTEMS

HEAT TECHNOLOGY

TIP HEATER CARTRIDGE & SENSATEMP TECHNOLOGY

IN TODAY’S ENVIRONMENT

FLEXIBILITY ISN’T JUST

IMPORTANT, IT’S THE KEY

TO SUCCESS...

Component foot-prints are shrinking, through-put requirements are

increasing, and thermally massive power management components

(connectors, heat sinks, RF shields, and SMDs) on heavy ground

planes are not going away anytime soon. Oh yes, let’s not forget

about the challenges of incorporating Lead Free solders into your

process! Being locked into one heat control technology on your

Soldering/Desoldering system isn’t going to open the door to your

success...

The ability to have multiple heating technologies available within

a single system directly affects your bottom line. Until now, most

systems only offer one type of heating technology which will never

fit every application efficiently. The time has come for soldering

and desoldering systems to evolve.

....FLEXIBILITY DRIVES THROUGH-PUT!

PACE is proud to introduce your key to future success...The

INTELLIHEATTM Control System. IntelliHeat is the only thermal control

system capable of managing multiple types of heating technologies

within a single Power Source. There is no longer a need to have

multiple Power Sources on your work bench or to force operators

to use only one heating technology. Simply plug in any compatible

handpiece and IntelliHeat does the rest.

The IntelliHeat Control System allows either SENSATEMP® or TipHeater Cartridge based technology handpieces to be plugged into

a single Power Source. Finally, the benefits of SENSATEMP® and

Tip-Heater Cartridge based technology can be found in a single

system, without restriction.

PACE’s legendary SENSATEMP® technology is renowned for its

temperature stability and ability to handle high mass applications.

For smaller components and when through-put is important, there

is Tip-Heater Cartridge based technology. Tip-Heater Cartridge

based technology is a patented technology that boasts the best

response time for high volume applications and easily keeps up in

a fast paced environment.

Upgrade your equipment, clear off your work bench and unlock

your success with INTELLIHEATTM!

With over 50 years of experience and industry leadership in

rework and repair technology and techniques, PACE provides

much more than simply equipment. When you purchase PACE

products, you receive access to one of the most valuable resources

in the industry; PACE’s applications and technical support services.

Over the years, our applications support services have been the

cornerstone of quality assurance and repair reliability for countless

customers. Whenever you encounter a new component, a new PCB,

Lead Free Solder, or if you just want reassurance that your process

is safe and effective, simply contact PACE and we will create a

procedure for you that not only identifies the equipment required to

do the job correctly, but also every step in the process!

TABLE OF CONTENTS

PAGE

2 INTRODUCTION & TABLE OF CONTENTS

3 PACE HEATING TECHNOLOGY

4 INTELLIHEAT COMPATIBLE HANDPIECES

6 HANDPIECE AND POWER SOURCE CHARTS

7 ST 30, ST 50 AND ST 70 SYSTEMS

8 ST 100 SYSTEM

9 INSTANT SETBACK CUBBY & LEAD FREE ACCESSORIES

10 ST 65, ST 75 AND ST 115 POWER SUPPLIES

11 ST SYSTEMS SPECIFICATIONS

12 MBT 301

13 MBT 350

14 ST 25, MBT 250 AND PRC 2000

15 LEAD FREE SOLDERING

16 SOLDERING WITH NITROGEN

17 NITROGEN ASSISTED SOLDERING ACCESSORIES

18 TD-100 STANDARD TIPS

20 TD-100 DIAMOND SERIES TIPS

21 TD-100 SMT REMOVAL TIPS

22 MT-100 & TP-100 SMT REMOVAL TIPS

23 PS-90 SOLDERING TIPS

24 PS-90 SMT REMOVAL TIPS

25 SX-90 DESOLDERING/SOLDER REMOVAL TIPS

26 TT-65 SMT TIPS AND TJ-85 NOZZLES

27 PRODUCT PAGE

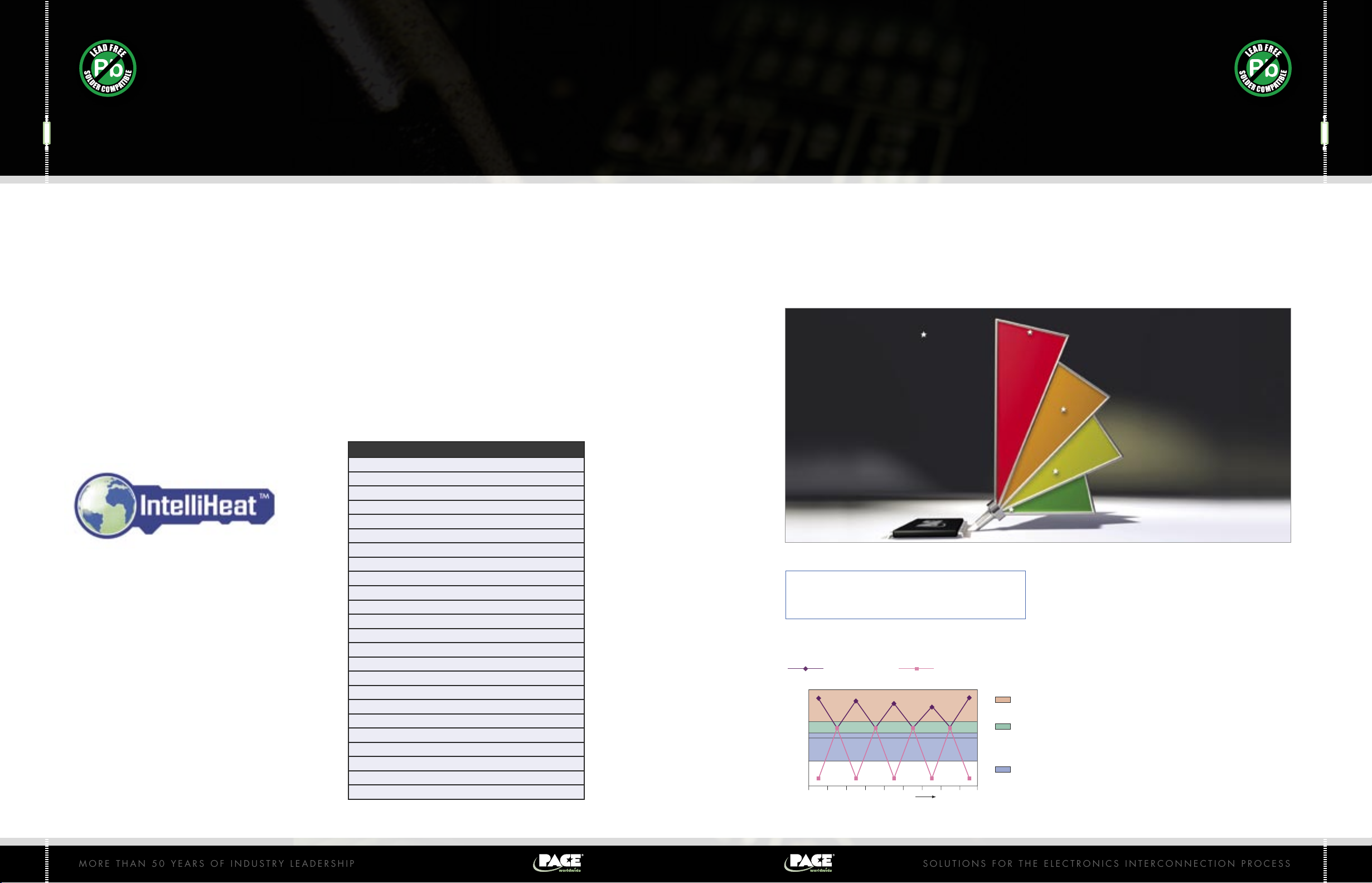

TIP-HEATER CARTRIDGE TECHNOLOGY

The key advantage of Tip-Heater Cartridge based technology is that its advanced

electronics provide instantaneous load sensing and on-demand power to quickly reflow solder joints, regardless of the mass of the application.

Further, the position of the control sensor is as far forward as possible to immediately respond to the thermal demand of the work. The tip and

heater are permanently coupled, ensuring all the heat generated by the heater is available for use by the tip. For applications where the work

cycle is high and for micro-miniature applications the direct power approach is ideal as the thermal demand is continuously monitored and the

heater responds immediately by providing adequate power to meet the demand from the work, without overshoot.

Control Sensor Position

Relative to Tip

For efficient heating, accurate

control and for forming the

best solder joint, use an iron

with the shortest sensor

Poor Position,

Inefficient

Heater “Printed” on Ceramic Heater - Standard resistance

Heating Element, (40-60 W)

Curie-Point Heating Systems - High frequency emission

creating heat in ferromagnetic slug using its Curiepoint

to control temperature (30-40 W)

Fair Position,

Fairly Efficient

PACE SensaTemp Precision Control System. High

mass resevoir heater with platinum RTD sensor.

(52 W)

pathway!

Good Position,

MAINTAINING PERFORMANCE IN THE

“GREEN” ZONE IS MORE LIKELY AS

SENSOR PATHWAY BECOMES SMALLER

IDEAL IRON PERFOMANCE

Tip Temperature Solder Joint Temperature

350 OC

Too Hot

200 OC

0 OC

Workflow Increasing

Ideal Process

Control

Window

Too Cold

Efficient

Best Position, Highly Efficient

SENSATEMP® TECHNOLOGY

is a laser trimmed, platinum RTD sensor that is more than 5 times

more accurate than conventional thermo-couples. This level of

accuracy allows for safe, productive soldering at the lowest possible

temperatures. As a result, the amount of time spent reflowing each

joint is reduced, minimizing the possibility of damage. Additionally,

SensaTemp allows you to change tips, heaters and handpieces at

will, without ever having to re-calibrate! SensaTemp’s unique heater

design acts as a thermal dampener that minimizes tip temperature

overshoot, ensures temperature stability and creates a “thermal

reservoir” that can be accessed instantaneously when high mass

applications are being performed.

SensaTemp delivers consistent, repeatable results regardless of the

thermal demand of the work. Its ability to respond quickly is ideal

for light work, while its amazing thermal capacity can meet the

challenges of the heaviest thermal loads, providing the operator with

the flexibility that is essential in today’s ever changing environment.

Regardless of your application, SensaTemp delivers unsurpassed

thermal performance, productivity and “bottom line” savings.

PACE Tip Heater Cartridge System - High thermo

delivery, Sensor controlled ceramic heater/tip cartridge

(62 W)

At the heart of SensaTemp

2 3

Page 3

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

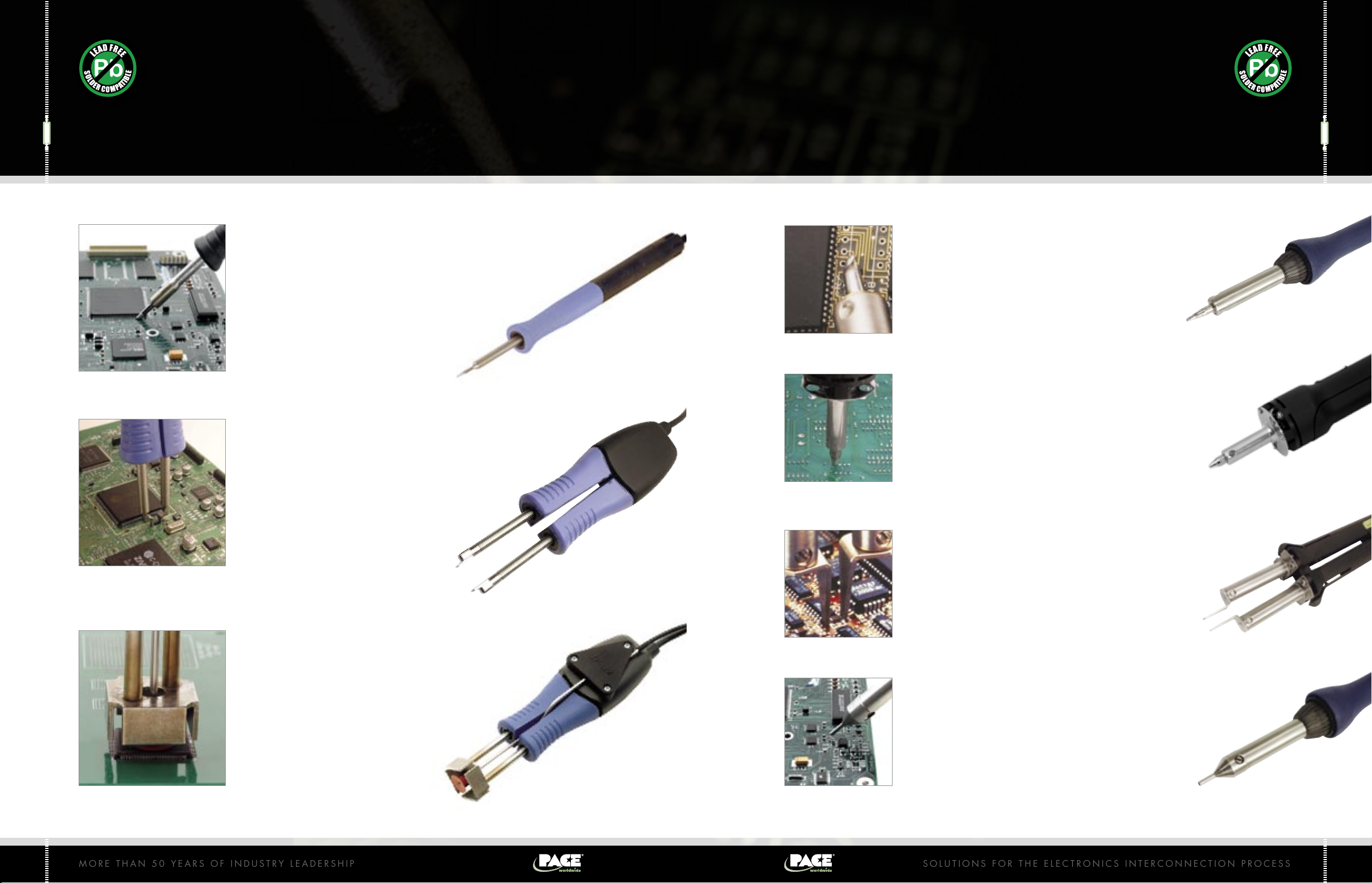

INTELLIHEAT COMPATIBLE HANDPIECES

TIP-HEATER CARTRIDGE HANDPIECES PERFECT FOR LEAD FREE

INTELLIHEAT COMPATIBLE HANDPIECES

VERSATILITY, PERFORMANCE AND VALUE SENSATEMP HANDPIECES

TD-100 THERMO-DRIVE® SOLDERING IRON

The TD-100 Thermo-Drive® Soldering Iron is the only iron

crafted by a team of surgical instrument engineers and is

uniquely designed to eliminate operator fatigue, improve control

and enhance productivity in demanding soldering applications.

The TD-100 uses a patented Tip-Heater Cartridge that is the

best performing and lowest priced Tip-Heater Cartridge on

the market today! Almost 100 soldering tip geometries are

available as well as over 30 surface mount removal tips.

See Pages 18-21 for tip selection.

Shown with optional comfort grip 6993-0241-P1

MT-100 MINITWEEZ™

The only high capacity, micro tweezer (MT-100 MiniTweez™)

on the market today features soft comfort grips, the smallest

stroke available, and its tweezing action mimics the natural

motion of the human hand to eliminate hand fatigue. With 10

styles of component removal tips available, the MT-100 is one

of the most versatile component removal tweezers and our tips

cost less than half of our competitors!

See Page 22 for tip selection.

THERMOPIK® 100

The newest tool for SMT component removal the ThermoPik®

100. The TP-100 is designed to reflow and remove QFPs in

seconds. The integrated vacuum pik lifts the component from

the PCB upon reflow. Based on our unique MT-100 handpiece,

there isn’t another SMT removal tool that is more comfortable in

your hand. Over 10 styles of tips are available.

See Page 22 for tip selection.

PS-90 UNIVERSAL SOLDERING IRON

The Universal Soldering Iron (PS-90) is ideal for most soldering

applications and SMT rework operations where high thermal capacity

and flexibility are required. The PS-90 features a rugged plug in heater

with gold contacts. There are 15 single point soldering tips and over

10 surface mount removal tips available for the PS-90.

See Pages 23-24 for tip selection

SX-90 SODR-X-TRACTOR®

The best performing, in-line, vacuum desoldering tool (SX-90 SodrX-Tractor®) is ideal for Thru-Hole desoldering when fitted with SX-90

Desoldering tips and for SMT land clean-up when fitted with SX-90

Flo-D-Sodr® tips. SX-90 Desoldering tips are the longest lasting, best

performing desoldering tips on the market! The SX-90 features a unique

solder collection system that can utilize disposable Flux/Solder traps or

a reusable glass collection chamber. An operator replaceable plug-in

heater cartridge that can be changed in seconds is standard. There is a

wide range of standard and precision SX-90 Desoldering tips for when

access is tight! See Page 25 for tip selection.

TT-65 THERMOTWEEZ®

The most versatile and only patented SMT removal tool (TT-65

ThermoTweez®) provides safe, one-handed, rapid reflow and

component removal of PLCCs and other 4 or 2 sided SMT components.

Unlike other methods, its high thermal capacity and targeted heat

delivery remove even the largest SMDs in just seconds without

damaging the PCB or risking of adjacent component reflow; even on

heavy assemblies. The patented vertically oriented handpiece and a

wide variety of quick-change, slim-line tips easily reach into the tightest

spaces for fast, safe component removal. The TT-65 also features a

patented “stroke” adjustment to reduce hand fatigue for repetitive

operations. See Page 26 for tip selection.

TJ-85 THERMOJET®

When the precise application of hot air is required, our slim line

air pencil (TJ-85 ThermoJet®) is ideal for delivering heat for the

installation and removal of chip components, SOTs, and SOICs.

Multiple quick-change nozzle sizes are available. The handpiece’s

slim line, pencil grip design maximizes operator comfort and control.

The TJ-85’s airflow is actuated with a foot pedal. Ideal for the precise

application of hot air for large SMDs down to 0201s.

See Page 26 for nozzle selection.

4 5

Page 4

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

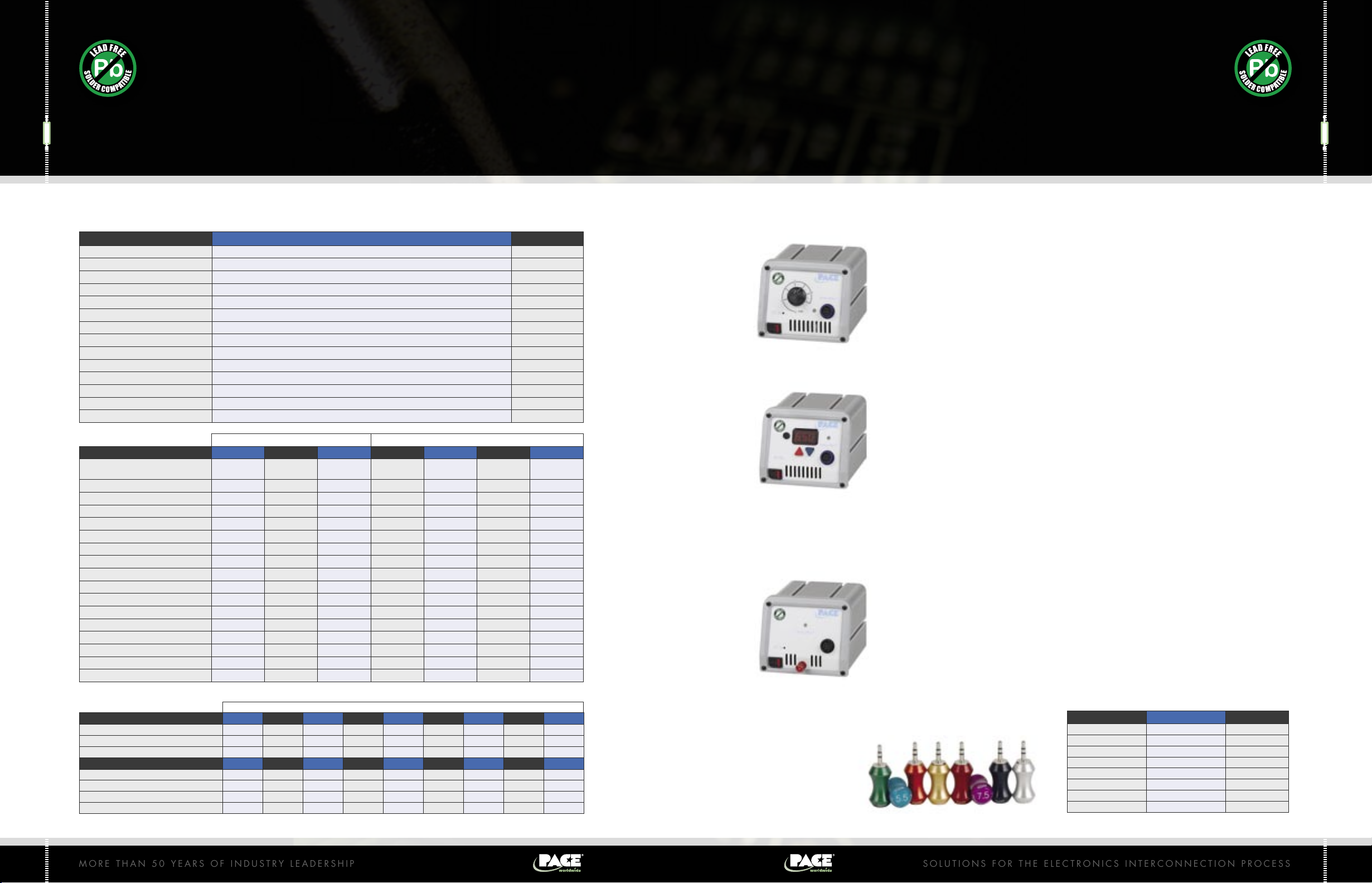

HANDPIECE & POWER SOURCE CHARTS

CHOOSE THE RIGHT INTELLIHEAT HANDPIECE FOR YOUR APPLICATION

ST SYSTEMS

PRODUCTION SOLDERING STATIONS ST30, ST 50 & ST 70 POWER SUPPLIES

HANDPIECES

HANDPIECE DESCRIPTION PART NUMBERS

TD-100 Thermo-Drive Iron The most responsive soldering iron available. Uses tip-heater cartridges. 6993-0263-P1

TD-100 N A nitrogen compatible version of the TD-100. Requires 6993-0271-P1. 6993-0272-P1

TD-100 with Instant SetBack Cubby A kit containing the TD-100 and Instant SetBack Cubby 6993-0281-P1

MT-100 MiniTweez Tip-heater cartridge based tweezer for 2 sided SMD removal. 6993-0264-P1

TP-100 ThermoPik QFP removal tool with integrated component vacuum pick to lift reflowed component. 6993-0280-P1

PS-90 Universal Soldering Iron Our famous High Capacity Soldering Iron for the most demanding applications. 6993-0267-P1

PS-90 N A nitrogen compatible version of the PS-90. 6993-0274-P1

SX-90 Sodr-X-Tractor The latest innovation in desoldering. Features disposable or reuseable solder traps. 6993-0266-P1

TT-65 ThermoTweez High capacity tweezer for large or small SMDs. 6993-0268-P1

TJ-85 ThermoJet A foot-pedal activated precision air pencil for the installation or removal of SMDs. 6993-0270-P1

SX-90 Heat Sleeve Maintains comfortable temperature in heavy use applications. 6993-0229-P1

Instant Setback Cubby for TD-100* Reduces tip temperature when iron is not in use. 6019-0077-P1

Nitrogen Regulator Accessory Controls the flow of nitrogen to tip. 6993-0271-P1

N2 Manifold Kit Connect up to 10 N2 irons to a single N2 source. 6993-0277-P1

KITS & APPLICATIONS

KITS & APPLICATIONS TD-100 MT-100 TP-100 PS-90 SX-90 TT-65 TJ-85

Handpiece Kits

(includes handpiece and tool stand)

Handpiece Only Part Number 6010-0147-P1 6010-0148-P1 6010-0158-P1 6010-0150-P1 6010-0149-P1 6010-0151-P1 6010-0153-P1

High Cycle Soldering

Standard Soldering

High Mass Soldering

Micro Soldering

Chip Installation

Solder Wicking

Thru-Hole Desoldering

SMT Land Preparation

Solder Removal from Lands

Large SMD Removal

Standard SMD Removal

Micro SMD Removal

Large Component Installations*

Standard Component Installations*

Micro Component Installations*

Tip Heater Cartridge Technology Handpieces SensaTemp Technology Handpieces

6993-0263-P1

6993-0281-P1

✓ ✓

✓ ✓

✓

✓ ✓ ✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓

✓ ✓ ✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

✓ ✓ ✓

6993-0264-P1 6993-0280-P1 6993-0267-P1 6993-0266-P1 6993-0268-P1 6993-0270-P1

✓ ✓

INTELLIHEAT POWER SOURCE & HANDPIECE COMPATIBILITY

Power Source Options - ST and MBT Systems ✓= Optional Handpiece ★ = Standard handpiece packaged with System

TIP-HEATER CARTRIDGE HANDPIECES ST 30 ST 50 ST 65 ST 70 ST 75 ST 100 ST 115 MBT 301 MBT 350

• TD-100

• MT-100

• TP-100

SENSATEMP HANDPIECES ST 30 ST 50 ST 65 ST 70 ST 75 ST 100 ST 115 MBT 301 MBT 350

• PS-90

• SX-90

• TT-65

• TJ-85

★ ★ ✓ ★ ✓ ★ ✓ ★ ★

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ★

✓ ✓ ✓ ✓ ✓

✓ ★ ✓ ✓ ✓ ✓ ✓ ✓ ✓

★ ★ ★ ★ ★

✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Part Number includes handpiece and standard cubby *Does not include Handpiece

✓

✓

✓

*with Solder Paste

✓ ✓ ✓ ✓

FEATURES:

FEATURES:

FEATURES:

• IntelliHeat Control

Technology

• oC/oF Temperature Scales

• Temperature Adjustment

Lockout

• ESD grounding jack

• ESD Safe metal housing

• Stackable

• Can be mounted under

workbench or shelf with

optional bracket

1321-0609-P1

• IntelliHeat Control

Technology

• Digital Display & Keypad

• oC/oF display options

• Password lockout

• Temperature SetBack

• Auto-Off

• Definable operating

temperature range

• ESD grounding jack

• ESD Safe metal housing

• Stackable

• Can be mounted under

workbench or shelf with

optional bracket

1321-0609-P1

• IntelliHeat Control

Technology

• Performance level lockout

(if Power Module is

removed the system is shut

down.)

• ESD grounding jack

• ESD Safe metal housing

• Stackable

• Can be mounted under

workbench or shelf with

optional bracket

1321-0609-P1

• Supplied with 6.5, 7 and

7.5 Power Modules

The ST 30 is a single channel system with dial control featuring IntelliHeat.

The system is packaged with the TD-100 ThermoDrive Soldering Iron or can

be purchased as a Power Source only and combined with any of 4 optional

handpieces. The ST 30 improves quality, reduces costs and eliminates the

maintenance and calibration hassles associated with other systems. The

heavy-duty metal housing makes this system the ideal choice for the harshest

environments and the sloped face of the front panel is a standard feature for

ease of use. An optional mounting bracket (P/N 1321-0609-P1) is available

to mount the system under a work-bench or shelf, preserving precious bench

top space. The optional Instant-SetBack Cubby is available for the TD-100

ThermoDrive Soldering Iron to extend tip life, especially beneficial when Lead

Free solders are used.

The ST 50 is a single channel, digital power supply that is available with

the TD-100 ThermoDrive Soldering Iron or PS-90 SensaTemp Soldering Iron.

The ST 50 can also be purchased as a Power Source only and combined

with any of 4 optional handpieces. The programmable features of the ST 50

cannot be found anywhere on similarly priced systems! The ST 50 improves

quality, reduces costs and eliminates the maintenance and calibration

hassles associated with other systems. The ST 50 features IntelliHeat Control

Technology. The heavy-duty, durable metal housing ensures years of service

and the sloped face of the front panel is a standard feature for ease of use.

An optional mounting bracket (P/N 1321-0609-P1) is available to mount the

system under a work-bench or shelf, preserving precious bench top space.

The optional Instant-SetBack Cubby is available for the TD-100 ThermoDrive

Soldering Iron to extend tip life, especially beneficial when Lead Free solders

are used.

The ST 70 is a single channel system that is controlled by POWER

MODULES™ and comes with the ThermoDrive Soldering Iron (TD-100). The

system can also be purchased as a Power Source only and combined with

any of 4 optional IntelliHeat handpieces. The ST 70 is the easiest to operate.

Simply select the performance level you desire, plug in the appropriate Power

Module and the system takes care of the rest! The ST 70 improves quality,

reduces costs while protecting your process. The heavy-duty metal housing

makes this system the ideal choice for the harshest environments and the

sloped face of the front panel is a standard feature for ease of use. An

optional mounting bracket (P/N 1321-0609-P1) is available to mount the

system under a work-bench or shelf, preserving precious bench top space.

The optional Instant-SetBack Cubby is available for the TD-100 ThermoDrive

Soldering Iron to extend tip life, especially beneficial when Lead Free solders

are used.

POWER MODULE PART NUMBER COLOR

Heat Level 5 1207-0446-01-P1 Green

Heat Level 5.5 1207-0446-02-P1 Blue

Heat Level 6 1207-0446-03-P1 Orange

Heat Level 6.5 1207-0446-04-P1 Gold

Heat Level 7 1207-0446-05-P1 Red

Heat Level 7.5 1207-0446-06-P1 Purple

Heat Level 8 1207-0446-07-P1 Black

Heat Level 8.5 1207-0446-08-P1 Silver

6 7

Page 5

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

DUAL CHANNEL SOLDERING SYSTEMS

SOLDERING & REWORK SYSTEMS

LEAD FREE ACCESSORIES

CUSTOMIZE YOUR SYSTEM FOR EVEN GREATER FLEXIBILITY

ST 100 THE ANSWER FOR THE LEAD FREE

SOLDER TRANSITION...

While transitioning from lead containing solders to Lead

Free solders a very real problem is that most soldering

operations will need to utilize Lead Free AND lead containing

solders at the same time. Having only one soldering iron, or

other handpiece, on the bench will ultimately lead to crosscontamination issues and result in lower productivity and

potentially, higher costs. The ST 100 is a fully programmable

system featuring two, individually controlled, IntelliHeat

compatible handpiece channels. The system allows for 2

soldering irons, 2 MiniTweezers or one of each to co-exist on

a workbench. Color coding accessories that clearly identify

which handpiece is designated for use with Lead Free and lead

containing solders are available.

The ST 100 is loaded with features to improve quality, control

your process, increase through-put, and extend tip life. The

system is fully programmable and can be password protected

to prevent unauthorized changes. When high-mass tips are

used, an offset can be programmed into the system.

Technicians can become frustrated with being locked into a

single temperature. Additionally, a higher set temperature

is often desired when working with Lead Free solders. The

ST 100 has the solution! An approved, unique, operating

range or process window, can be programmed FOR EACH

HANDPIECE, allowing operators the flexibility to do their work,

while eliminating the risks associated with giving techs access

to the entire temperature range of the system. Also, a process

window can be defined for the handpiece using leaded

solder, and a separate process window can be defined for the

handpiece using lead containing solder. Operators can be

given a range of 5 to 450OF to operate within!

To maximize tip life and reduce operating costs, PACE’s

well recognized “SetBack” and “Auto-Off” features are

included. The system will automatically reduce the set

temperature to below solder melt temperatures, then turn

off after a user defined period of inactivity, from 10 to 90

minutes each. To really protect the more expensive tip-heater

cartridge and fine point soldering tips from oxidation, the

TD-100 iron can be used with the PACE’s “Instant-SetBack

Cubby”. The cubby puts the iron’s channel into SetBack if

it has been in the cubby for more than 45 seconds! Up to

two Instant-SetBack cubbies can be connected to the ST 100.

The backlit, digital, LCD screen displays the temperature of both

handpiece channels or with scan mode activated will cycle

through the handpiece channels one at a time displaying set

and actual temperatures. The backlight and character contrast

on the display can be adjusted to meet individual preferences.

Finally, the system can be programmed with the name of the

operator or company which is displayed when the system is

turned on.

The optional INSTANT-SETBACK CUBBY is available for

use with the ST 30, ST 50, ST 65, ST 70, ST 75, ST 100 and

ST 115. When connected, it automatically puts the system into

SetBack mode when the TD-100 Iron has been in the cubby for

45 seconds. SetBack mode means that the temperature is set

to just below solder melt temperature so the corrosive action

of the leaded or Lead Free solder is stopped, maximizing the

life of your tips! The system returns to normal operation when

the iron is removed from the cubby. The part number for the

Instant-SetBack Cubby is 6019-0077-P1. The Instant-SetBack

Cubby is also available for use with the TD-100 fitted with the

Green Lead-Free moulded Comfort Grip as part number 60190078-P1.

LEAD FREE IDENTIFIABLE During the transition from

leaded to Lead Free solders, it will not be uncommon to be

using both types of solders at the same time. To assist in

reducing cross contamination of soldering tools and to keep

additional tips separated on a workbench, PACE is pleased

to offer a variety of options to clearly identify handpieces and

tool stands being used with Lead Free solders. The handpieces

are identified by green comfort grips and the tool stands are

identified with green cubbies. These options are available for

the TD-100, MT-100 and PS-90 handpieces in the following

configurations.

DESCRIPTION PART NUMBER

Lead Free Cubby (Available Nov 07) with Green Insert for TD-100 6019-0079-G-P1

Green Replacement Handpiece Insert for TD-100 1140-0081-G-P1

MT-100/TP-100 Green, Lead Free Handpiece Cubby (Available Nov 07) 6019-0080-G-P1

MT-100/TP-100 Green, Lead Free Handpiece Insert (Available Nov 07) 1257-0383-G-P1

Green Comfort Grip and Green Handpiece Insert for TD-100 Tip & Tool Stand 6993-0283-P1

Replacement Green Comfort Grips for TD-100, pack of 5 1119-0176-P5

Instant SetBack Tip & Toold Stand for TD-100 with Green insert 6019-0078-P1

Green Replacement Handpiece Insert for TD-100 Tip & Tool Stand (Before Nov 07) 1140-0075-G-P1

Green Comfort Grip and Green Handpiece Insert for MT-100 Tip & Tool Stand 6993-0284-P1

Replacement Green Comfort Grips for MT-100, pack of 2 1119-0177-P2

Green Replacement Handpiece Insert for MT-100 Tip & Tool Stand (Before No 07) 1257-0323-G-P1

PS-90 Handpiece (IntelliHeat Version) with Green Comfort Grip 6010-0159-P1

PS-90 Tip & Tool Stand with Green Insert 6019-0074-P1

PS-90 Lead Free Cubby with Green Insert (Available Nov 07) 6019-0081-G-P1

Replacement Green Handpiece Insert for PS-90 1140-0083-G-P1

8 9

Page 6

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

SOLDERING & REWORK SYSTEMS

ST 65, ST 75 & ST 115 POWER SUPPLIES

PACE REWORK AND REPAIR

ST SYSTEM SPECIFICATIONS

The ST 65 is a single channel, dial control power supply that is

FEATURES:

compatible with all IntelliHeat handpieces and comes as a system

with the new SX-90 Sodr-X-Tractor or as a Power Source only.

Featuring a powerful multistage venturi that is powered by your

compressed air source, the ST 65 is ideal for application where

continuous vacuum or pressure is required. An N2 source can

be connected to create an inert gas reflow environment when

using an N2 capable soldering iron. The heavy-duty, durable

metal housing ensures years of service and the sloped face of

the front panel is a standard feature for ease of use. An optional

mounting bracket (P/N 1321-0609-P1) is available to mount the

system under a work-bench or shelf, preserving precious bench

top space. N2 capable soldering iron.

• IntelliHeat Control Technology

• Dial control

• oC/oF Temperature Scales

• Temperature lockout

• Patented Snap-Vac Technology

• ESD grounding jack

• ESD Safe metal housing

• Stackable

• Can be mounted under

workbench or shelf with

optional bracket 1321-0609-P1

The ST 75 and ST 115 are ideal for users having to deal with wide ranges of applications. With these systems, you can solder, desolder,

remove components with a variety of tweezers and thermo-piks, as well as make use of the high performance, foot pedal activated, air pencil.

The systems come standard with PACE’s patented SNAPVAC desoldering technology to ensure quick, clean removal of solder from any throughhole joint. The Hi-Flo pump is so powerful that you won’t lose vacuum in continuous use applications when removing residual/excess solder

from surface mount leads. The new, high resolution pressure control valve delivers the widest range of adjustable airflow available on the market

today. So if you’re using the new TJ-85 to reflow a PLCC or an 0201 resistor, you always have the precise level of control that you need to get

the job done right!

ST 75 A single channel, dial control power supply, the ST 75

FEATURES:

is compatible with all IntelliHeat handpieces and comes as a

system with the new SX-90 or as a Power Source only. The ST 75

improves quality, reduces costs and eliminates the maintenance

and calibration hassles associated with other systems. The

heavy-duty, durable metal housing ensures years of service and

the sloped face of the front panel is a standard feature for ease

of use.

• IntelliHeat Control Technology

• Dial control

• oC/oF Temperature Scales

• Temperature lockout

• Hi-Flo Pump

• Patented Snap-Vac Technology

• ESD grounding jack

• ESD Safe metal housing

• Stackable

ST 115 A single channel, digital display, fully programmable

FEATURES:

power supply, the ST 115 is compatible with all IntelliHeat

handpieces and comes as a system with the new SX-90 or as

a Power Source only. The programmable features of the ST

115 cannot be found anywhere on similarly priced systems!

The ST 115 improves quality, reduces costs and eliminates the

maintenance and calibration hassles associated with other

systems. The heavy-duty, durable metal housing ensures years

of service and the sloped face of the front panel is a standard

feature for ease of use.

• IntelliHeat Control Technology

• Digital Display & Keypad

• oC/oF display options

• Password lockout

• Temperature SetBack

• Auto-Off

• User defined operating

temperature range

• Hi-Flo Pump

• Patented Snap-Vac Technology

• ESD grounding jack

• ESD Safe metal housing

• Stackable

SPECIFICATIONS ST 30 ST 50 ST 70 ST 100

System with TD-100 115v 8007-0499 8007-0500 8007-0504 8007-0525

System with PS-90 115v N/A 8007-0532 N/A N/A

Power Source Only 115v 8007-0497 8007-0501 8007-0505 8007-0524

System with TD-100 230v 8007-0512 8007-0514 8007-0518 8007-0527

System with PS-90 230v N/A 8007-0533 N/A N/A

Power Source Only 230v 8007-0513 8007-0515 8007-0519 8007-0526

Power Requirements 97-127 VAC, 50/60 Hz, 90 Watts max. 197-253 VAC, 50/60 Hz, 90 Watts max.

Dimensions 104mm H x 130mm W x 152mm D

Weight 5 Kg (11 lbs.)

Control Dial LED Display Power Module LCD Display & Keypad

Control Technology IntelliHeat

Tip to Ground Resistance 2 ohms or less

Temperature Accuracy Meets or exceeds ANSI-J-STD 001 N/A Meets or exceeds ANSI-J-STD 001

Absolute Temperature Stability ± 1.1°C (± 2 °F) at idle tip temp.

Temperature Range

System Can be Calibrated Yes

SPECIFICATIONS ST 65 ST 75 ST 115

System 115v 8007-0502 8007-0506 8007-0508

Power Source Only 115v 8007-0503 8007-0507 8007-0509

System 230v 8007-0516 8007-0520 8007-0522

Power Source Only 230v 8007-0517 8007-0521 8007-0523

Power Requirements 97-127 VAC, 50/60 Hz, 90 Watts max.

197-253 VAC, 50/60 Hz, 90 Watts max.

Dimensions 104mm H x 130mm W x 152mm D

(4.1” H x 5.1” W x 6.0” D)

Weight 2.3 Kg (5 lbs.) 4 Kg (9 lbs.)

Control Dial Dial LED Display & Keypad

Control Technology IntelliHeat

Tip to Ground Resistance 2 ohms or less

Temperature Accuracy Meets or exceeds ANSI-J-STD

Absolute Temperature Stability ± 1.1°C (± 2 °F) at idle tip temp.

Temperature Range Tip Heater Cartridge Technology Handpieces = 205° to 454°C (400° to 850°F)

System Can be Calibrated Yes

Vacuum/Pressure Source Type Compressed Air Powered Venturi Self Contained Pump

Vacuum Rise Time 150 ms Average

Vacuum (Nominal) 20 in Hg max

Flow Control Valve Coarse Adjustment High Precision Needle Valve

Pressure (Nominal) 18 p.s.i. max

Air Flow (Nominal) 8 slpm max

(4.1” H x 5.1” W x 6.0” D)

Tip Heater Cartridge Technology Handpieces = 205° to 454°C (400° to 850°F)

SensaTemp Dial Control 176°C to 482°C (350°F to 900°F)

SensaTemp Digital Control 37°C to 482°C (100°F to 900°F)

97-127 VAC, 50/60 Hz, 120 Watts max.

197-253 VAC, 50/60 Hz, 120 Watts max.

88mm H x 171mm W x 254mm D

(3.5” H x 6.75” W x 10” D)

SensaTemp Dial Control 176°C to 482°C (350°F to 900°F)

SensaTemp Digital Control 37°C to 482°C (100°F to 900°F)

135mm H x 165mm W x 260mm D

(5.3” H x 6.5” W x 9.25” D)

10 11

Page 7

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

MBT 301

SIMPLE AND EASY TO USE FOR REWORK TECHNICIANS OR OPERATORS ON THE LINE

MBT 350

ADVANCED TECHNOLOGY AND PROGRAMMABILITY

The MBT 301 is a multi-technology system with

two, individually controlled, universal handpiece

channels. The system features a two-line back lit

LCD display. The programmable features include:

password protection from unauthorized changes,

a user definable temperature operating range, and

"SetBack" & "Auto-Off" functions to preserve tip life.

To protect your more expensive tip-heater cartridge

and fine point soldering tips from oxidation, the

TD-100 can be used with the optional "InstantSetBack Cubby". The cubby puts the iron's channel

into setback if it is idle in the cubby for more than

45 seconds! One Instant SetBack Cubby can be

connected to the MBT 301.

The new dual purpose vacuum/pressure pump and delivery system featuring PACE's patented SNAP-VAC Technology, provides the

most vacuum available for desoldering applications. When used with an air pencil, the high resolution, pressure control valve allows

for precise adjustment when working on the smallest components such as 0201's.

MBT 300 SERIES SPECIFICATIONS

SPECIFICATIONS MBT 301 MBT 350 MBT 301 E MBT 350 E

Kit with Handpieces Part Numbers:

Power Source Only Part Numbers:

Power Requirements 120 VAC, 60 Hz (240 watts maximum) 230 VAC, 50 Hz (240 watts maximum)

8007-0478

(TD-100 & SX-90)

8007-0480

8007-0454

(TD-100, MT-100 &

SX-90)

8007-0452

8007-0479

(TD-100 & SX-90)

8007-0481

8007-0455

(TD-100, MT-100 &

SX-90)

8007-0453

The MBT 350 is loaded with features to improve

quality, increase through-put, extend tip life, and

protect your process. The system is fully programmable

and can be password protected from unauthorized

changes. In some cases technicians become frustrated

with being locked into a single temperature. The MBT

350 provides the solution! An approved operating

range can be programmed allowing operators the

flexibility to do their work, while eliminating the risks

associated with giving techs access to the entire

temperature range of the system. Operators can be

given a range of 5 to 450˚F (3-250˚C) to operate

within! When high-mass tips are required, an offset

can be programmed for each of the three channels,

individually.

To maximize tip life and reduce operating costs, PACE's well recognized “SetBack” and “Auto-Off” features are included. The system

will automatically reduce the set temperature by 50% then turn off after a user defined period of inactivity, from 1 to 90 minutes. To

really protect your more expensive tip-heater cartridge and fine point soldering tips from oxidation, the TD-100 can be used with the

new “Instant-SetBack Cubby”. The cubby puts the iron's channel into setback if it’s in the cubby for more than 45 seconds! Up to

two Instant SetBack cubbies can be connected to the MBT 350.

The new dual purpose vacuum/pressure pump and delivery system featuring PACE's patented SNAP-VAC Technology, provides the

most vacuum available for desoldering applications. When used with an air pencil, the high resolution, pressure control valve allows

for precise adjustment when working on the smallest components such as 0201's.

The new backlit, digital, LCD screen displays the temperature of all three handpiece channels or, with scan mode activated, will cycle

through the handpiece channels one at a time displaying set and actual temperatures. The backlight and character contrast on the

display can be adjusted to meet individual preferences. And finally, the system can be programmed with the name of the operator

or company which is displayed when the system is turned on.

Handpiece Technology Compatibilty IntelliHeat Handpieces with Tip Heater Cartridge or SensaTemp Technology

Dimensions 135mm H x 165mm W x 260mm D (5.3” x 6.5” x 9.25”)

Weight 5 Kgs (11 lbs.)

Tip to ground resistance < 2 Ohms

Temperature Stabililty ± 1.1 OC (2 OF)

Temperature Accuracy Meets or exceeds ANSI J Std 001

Set Temp Range

Vacuum Rise Time 150 ms Average as measured with PACE Process Monitor

Vacuum 20 in Hg max

Pressure 18 p.s.i. max

Air Flow 8 SLPM max

12 13

37-482 OC (100-900 OF) SensaTemp

205-454 OC (400-850 OF) tip Heater Cartridge

1. TD-100 THERMO-DRIVE IRON

2. MT-100 MINITWEEZ

3. PS-90 UNIVERSAL IRON

4. TT-65 THERMOTWEEZ

5. TJ-85 THERMOJET

6. SX-90 SODR-X-TRACTOR

7. TP-100 THERMOPIK

4.

1.

5.

2.

6.

3.

7.

Page 8

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

SENSATEMP REWORK SYSTEMS

ST 25, MBT 250 & PRC 2000

LEAD FREE SOLDERING

WORKING WITH LEAD FREE SOLDERS

The PRC 2000 Benchtop Factory is the ultimate rework

center. The PRC 2000 can tackle just about any Thru-Hole,

SMT application and is well suited for multilayer repairs on

damaged or prototype PCBs. Featuring 3 simultaneously active

SensaTemp handpiece channels, a built-in paste dispenser, MicroChine for removing conformal coatings or grinding away PCB

laminate, and pulse heat technology. The PRC 2000 comes with 9 handpieces and continuously calibrates automatically.

The ST 25 soldering system uses SensaTemp to maximize heat delivery and improves quality, reduces costs and eliminates the

maintenance and calibration hassles associated with other soldering systems. The heavy-duty metal housing makes this system the ideal

choice for the harshest environments and the sloped face of the front panel is a standard feature for ease of use. An optional mounting

bracket (P/N 1321-0609-P1) is available to mount the system under a work-bench or shelf, preserving precious bench top space.

FEATURES:

• SensaTemp Control Technology

• Analog (dial) control

• oC/oF Temperature Scales

• Temperature Adjustment Lockout

• ESD grounding jack

• ESD Safe metal housing

• Stackable

• Can be mounted under work

bench or shelf with optional bracket 1321-0609-P1

MBT 250

SD/SDTP

Still Available

SENSATEMP POWER SOURCE SPECIFICATIONS

SPECIFICATIONS ST 25 MBT 250 SD/MBT 250 SDTP PRC 2000 SMT PRC 2000 TH

System 115 V 8007-0528

Power Source Only 115 V 8007-0529 8007-0349 N/A N/A

System 230 V 8007-0510

Power Source Only 230 V 8007-0511 8007-0353 N/A N/A

Input Power Requirements 97-127 VAC, 50/60 Hz or 197-253 VAC, 50/60 Hz

Max Power Consumption 120 W 240 W 400 W

Dimensions

Weight 2.3 Kgs (5 lbs.) 5 Kgs (11 lbs.) 13 Kgs (28.6 lbs.)

Control LED Display LED Display

Control Technology SensaTemp (Black Connector HandPieces)

Tip to Ground Resistance 2 ohms or less

Temperature Accuracy Meets or exceeds ANSI-J-STD 001

Absolute Temperature Stability ± 1.1°C (± 2 °F) at idle tip temp.

Temperature Range 176° to 482°C (350° to 900°F) nominal

System Can be Calibrated Calibration not required

Pump Type N/A Self Contained Pump

Vacuum Rise Time N/A 150 ms Average

Vacuum (Nominal) N/A 20 in Hg max

Flow Control Valve N/A High Resolution Needle Valve Coarse adjustment

Pressure (Nominal) N/A 18 p.s.i. max 7 p.s.i. max

Air Flow (Nominal) N/A 8 slpm max 13 slpm max

104mm H x 130mm W x

152mm D

(4.1" H x 5.1" W x 6.0" D)

8007-0203 (SD)

8007-0206 (SDTP)

8007-0204 (SD)

8007-0207 (SDTP)

135mm H x 165mm

W x 260mm D

(5.3" H x 6.5” W x 9.25" D)

8007-0132 8007-0138

8007-0133 N/A

175mm H x 350mm W x 230mm D

(6.9" H x 13.75” W x 9.25" D)

Lead Free solders do not behave or look like their lead containing counterparts. As our industry changes over to Lead Free solders,

individual PCB assemblers will need to address several issues relating to hand soldering and rework. These issues include:

• Higher melting temperatures – which mistakenly lead to operators increasing equipment operating temperatures. Higher

operating temperatures do not make the process quicker, they can actually slow it down.

• Poor wetting and spreading properties – Additional time is required when working with lead free solders, they do not

spread or wet like lead containing solders do. Operators must slow down.

• Difficult to work with - Bridging and insufficient solder defects are common, even for experienced operators, leading to

operator frustration and poor quality.

• Dull grainy finish – makes inspection difficult.

Because Lead Free solders oxidize quickly, more aggressive

and longer lasting fluxes are required to keep surfaces clean

Tip-Brite is a high quality tip tinner that will remove stubborn

oxidation.

and free from oxidation. Working with no-clean fluxes is

challenging as their process window is often small. Once they

are burned off, oxidation immediately begins to form which

can result in a marginal or defective solder joint. Additionally,

increasing operating temperatures creates an ideal environment

for oxidation to form and will also lead to flux and solder ball

splatter on the PCB. If the flux is splattered all over the PCB, it’s

not able to do its job on the surfaces to be joined during the

The use of equipment with SetBack and Auto-Off functions

(standard on all PACE equipment), is very desirable. Additionally,

optional accessories such as PACE’s Instant SetBack Cubby

ensure that tip life is maximized. The Instant SetBack Cubby puts

the system into “SetBack” after 45 seconds of inactivity. When

the iron is removed from the cubby, it restores itself to the set

temperature almost immediately.

soldering process.

The use of nitrogen assisted soldering equipment helps to

Lead Free solders also affect soldering and rework tools and their

effect is detrimental. Lead Free solders contain high percentages

of tin, almost always over 94%. Tin is a corrosive and active

metal. When it mixes with iron (the protective layer on soldering

tips), an inter-metallic compound is formed that wears away

more quickly than the iron would either by itself or when used

with lead containing solder. This causes two problems, one is

shorter tip life as the protective iron coating is dissolved in the

tin, and the second is that oxidation forms more quickly which is

mitigate the problems associated with using Lead Free solders.

Nitrogen helps on two fronts. First, it creates an inert environment

around the soldering tip, reducing the potential for tip to oxidize.

Second, it assists in the soldering process at the PCB level by

purging oxygen from the immediate area which reduces or

eliminates the formation of oxidation on the work site. This not

only reduces the amount of flux that is required, but it also helps

to improve wetting, spreading and leaves a finish that is shinier

and less grainy.

further exacerbated by the high temperature environment the tips

work in. As a result, tin oxides form and create an inter-metallic

compound with the iron plating on the tip. Once the oxidation

begins to form, the tip will lose its ability to wet with solder and if

not cleaned off quickly, it becomes almost impossible to remove

and the tip must be replaced.

PACE’s nitrogen assisted soldering systems pass the nitrogen

through or around the heater before it is directed to the work

site. This “pre-heats” the immediate area which can also help

to reduce thermal shock to component leads and to components

themselves. Pre-heating also allows for the use of lower, safer

and more effective soldering temperatures.

When using Lead Free solders, regardless of alloy, it is absolutely

imperative that tips are properly maintained, otherwise tip life

will be reduced significantly. Tips should be cleaned frequently

to remove oxidation before it becomes impossible to remove.

Tips should always be tinned when not being used, otherwise

oxidation will quickly form on the tip. If the iron will not be used

for extended periods of time, they should be turned off. Should

oxidation form that cannot be easily cleaned by tinning or by

PACE’s soldering systems offer legendary thermal control as well

as advanced features to maintain your process. Unique PACE

features such as IntelliHeat, Power Modules and password

protection ensure consistency and quality in your process.

Economical tips and standard features such as “SetBack” and

“Auto-Off” maximize tip life to reduce operating costs and

increase your bottom line.

using a cleaning tool, PACE’s Tip-Brite is recommended.

14 15

Page 9

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

LEAD FREE SOLDERING

LEAD FREE SOLDERING COMPATIBLE AND RoHS COMPLIANT

LEAD FREE SOLDERING

NITROGEN ASSISTED SOLDERING ACCESSORIES

PACE’s soldering systems offer legendary thermal control as well as advanced features to maintain your process. Unique PACE features

such as IntelliHeat, Power Modules and password protection ensure consistency and quality in your process. Economical tips and

standard features such as “SetBack” and “Auto-Off” maximize tip life to reduce operating costs and increase your bottom line.

All ST & MBT systems, handpieces and tips are Lead Free soldering compatible and RoHS compliant.

They can be used with any Lead Free alloys without modification. PACE’s soldering systems, handpieces and tips are fully compatible

with your Lead Free process. PACE’s TD-100 soldering iron boasts one of the most efficient heat transfer capabilities and is clearly one of

the most responsive irons on the market today. This means that the TD-100’s ability to recover from thermal loading and maintain its heat

output is far superior to other conventional irons, eliminating the need for higher, unsafe temperatures when using Lead Free solders.

Quick and consistent heat transfer also ensures that flux is fully activated and burned off, leaving the work site properly prepared for

the formation of highly reliable solder joints. Our PS-90 soldering iron has been the staple of the industry for years and is known for its

amazing thermal capacity and ability to deliver the heat at safe, low temperatures. Both the TD-100 and PS-90 are available for use

with nitrogen.

HANDPIECE KIT HANDPIECE ONLY

TD-100 N 6993-0272-P1 6010-0156-P1

PS-90 N 6993-0274-P1 6010-0157-P1

All ST products are compatible with either the PS-90 N and/

or the TD-100 N handpieces. The benefits of nitrogen assisted

soldering are available for all of PACE’s soldering stations with

the N2 Regulator Accessory which can be easily mounted to any

ST system.

All of PACE’s soldering, desoldering and component removal tips are tinned with Lead Free solder

NF 50 & NF 100

The compact highperformance single

station N2 generator

(NF 100) will generate

Nitrogen Gas at a

maximum concentration

level of 99.9%. This

system should be used

in conjunction with NF

50 N2 Flow Control

Unit.

NF 500 & NF 1000

PACE is also pleased to offer

the NF Series Nitrogen farms.

Nitrogen farms harvest N2 from

a compressed air supply that is

passed through a specialized

filter. The other atoms that

make up “air” are forced

through the filter, leaving

a pure stream of N2 as the

product of filtering. Nitrogen

farms are passive collection

devices which means that there

are no electrical or moving

parts, little or no maintenance,

low running costs, and they

maintain the balance of air/N2

in a confined space (as long

as the compressed air is pulled

from the same space).

NF 100 PERFORMANCE TABLE

N2 Concentration %

99.9 99.5 99.0 98.0 97.0 96.0 95.0 90.0

0.3 0.15 0.37 0.48 0.66 0.88 1.1 1.3 2.6

0.4 0.24 0.57 0.77 1.1 1.4 1.7 2.0 4.4

0.5 0.35 0.75 1.1 1.5 1.9 2.2 2.9 5.9

0.6 0.48 0.97 1.3 1.8 2.4 3.1 3.5 7.5

Input compression

air pressure (MPa)

0.7 0.55 1.2 1.6 2.2 3.1 3.7 4.2 9.2

NF SYSTEMS DESCRIPTION PART NUMBERS

NF 50 Single station N2 regulator with shut off 8110-0500

NF 100 For a single station 8110-0100

NF 500 For up to 2 stations 8110-0001

NF 1000 For up to 10 stations 8110-0002

(L/min)

Output amount

Due to the corrosive nature of the high tin content in Lead Free

alloys and because more aggressive fluxes are commonly

required when using Lead Free solders, we have also optimized

the iron plating on our tips to maximize thermal transfer while

When reworking area array components with Lead Free solder,

the greatest enhancement to existing equipment is the use of

nitrogen for reflow. All of PACE’s Area Array equipment comes

fitted for nitrogen use as standard.

Air tube O/D 6mmAir tube O/D 6mm

AIR INN2 OUT

Regulator

Compressed, dry, filtered air

providing for the longest life possible.

Additionally, PACE manufactures Fume Extraction Systems to

PACE is leading the way in soldering technology with our

patented “Diamond Series” tips. “Diamond Series” tips are

manufactured with an iron matrix that is impregnated with sub

micron sized diamond particles. The diamond-impregnated

surface is harder and more corrosion resistant than iron alone.

16 17

reduce exposure to harmful particulates and gases created

from hand soldering operations. PACE Fume Extraction Systems

effectively remove these contaminants from the workers breathing

zone thereby reducing or eliminating health risks and improving

productivity.

NF 100

N2 Gas

Generator

NF 50 N2 Flow Control Unit

NF 100/50 CONNECTION METHOD

N2 Soldering Iron

• PS-90N

• TD-100N

Page 10

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

TD-100 STANDARD SOLDERING TIPS

TIP SPECIFICATIONS

TIP SPECIFICATIONS TIP SPECIFICATIONS

TD-100 STANDARD SOLDERING TIPS

TIP SPECIFICATIONS

TIPS DESCRIPTION TIP SIZE - L SIZE - D PART NUMBER

1/32" Conical Sharp Extended 13.4mm (0.530") 0.80mm (0.031")

1/64" Conical Sharp 7.8mm (0.310") 0.40mm (0.016")

1/64" Conical Sharp Bent 30 Degrees 7.8mm (0.310") 0.40mm (0.016")

1/64" Conical Sharp Extended 13.5mm (0.535") 0.40mm (0.016")

13/64" Conical Sharp Extended 4.7mm (0.188") 0.80mm (0.031")

3/128" Conical 4.6mm (0.184") 0.58mm (0.023")

1/16" 90 Degree Chisel 10.9mm (0.430") 2.03mm (0.080")

3/64" 30 Degree Chisel 9.7mm (0.380") 1.20mm (0.047")

3/64" 30 Degree Bevel 3.6mm (0.140") 1.20mm (0.047")

13/64" Extra Large Chisel 7.62mm (0.300") 5.15mm (0.203")

1/64" 60 Degree Bevel 14.7mm (0.580") 0.40mm (0.016")

1/32" 30 Degree Chisel 9.1mm (0.360") 0.80mm (0.031")

3/32" 30 Degree Chisel 9.9mm (0.390") 2.40mm (0.094")

5/64" 60 Degree Chisel 4.7mm (0.185") 2.00mm (0.078")

1/64" Conical, Sharp, Bent 30 Degrees, Extended 15.1mm (0.595") 0.40mm (0.016")

3/64" Chisel Bent 30 Degrees 11.7mm (0.460") 1.20mm (0.047")

1/16" 60 Degree Chisel 15.8mm (0.620") 1.60mm (0.063")

1/32" Conical Sharp Extended 16.7mm (0.660") 0.80mm (0.031")

1/16" 30 Degree Chisel 9.9mm (0.390") 1.60mm (0.063")

1/8" 90 Degree Chisel 4.8mm (0.190") 3.20mm (0.125")

1124-0001-P1

1124-0002-P1

1124-0003-P1

1124-0004-P1

1124-0005-P1

1124-0006-P1

1124-0007-P1

1124-0008-P1

1124-0009-P1

1124-0010-P1

1124-0011-P1

1124-0012-P1

1124-0013-P1

1124-0014-P1

1124-0015-P1

1124-0016-P1

1124-0017-P1

1124-0018-P1

1124-0019-P1

1124-0020-P1

MAXIMIZING TIP LIFE PACE recommends the following practices to maximize tip life.

1. Always use the lowest possible temperatures while soldering. High temperatures cause tips to oxidize faster, which

reduces heat transfer and damages the protective iron plating.

2. Avoid aggressive fluxes whenever possible. Aggressive fluxes erode tips faster; shortening their useful life.

3. Always use a properly sized tip for the work. Tips, that are too small, will wear out faster and tips that are too large

will wear unevenly which, in turn, will change the tip geometry rendering it useless, possibly damaging pads.

4. Always tin tips when not in use and after cleaning on a damp sponge. A coating of solder will prevent oxidation

from forming which causes tips to lose their tinning or wetting capability.

5. Always feed solder wire into the heated work, not the tip. Feeding solder directly into the tip will cause pin-holes in

the tip and will cause the flux in the solder wire to be burned off before it can activate and prepare the surfaces being soldered.

Should tips lose their tinning or wetting capability, a tip cleaner such as PACE’s Tip-Brite may be used to restore them.

TIPS DESCRIPTION TIP SIZE - L SIZE - D PART NUMBER

3/128" Conical Sharp Bent 30 Degrees 14.4mm (0.570") 0.58mm (0.023")

1/16" Conical Sharp 9.9mm (0.390") 1.60mm (0.063")

1/8" 90 Degree Chisel Extended 8.6mm (0.340") 3.20mm (0.125")

1/16" 30 Degree Bevel 9.9mm (0.390") 1.60mm (0.063")

1/16" Conical Sharp Extended 12.1mm (0.478") 1.60mm (0.063")

1/16" Chisel Bent 30 Degrees 9.7mm (0.385") 1.60mm (0.063")

3/128" Conical Sharp 15.2mm (0.600") 0.58mm (0.023")

3/64" Chisel, Bent 30 Degrees, Extended 15.2mm (0.600") 0.91mm (0.36")

1/32" 30 Degree Bevel 9.1mm (0.360") 1.91mm (0.75")

1/32" Conical Sharp 9.9mm (0.390") 0.80mm (0.031")

Heat Staking N/A 4.04mm (0.159")

MiniWave N/A 3.05mm (.120")

Angled MiniWave N/A 3.05mm (.120")

Single Sided Chisel N/A 3.05mm (.120")

Angled MiniWave N/A 2.11mm (.083")

1/128" Conical N/A 0.20mm (0.008")

1/4 Flat Blade N/A 4.57mm (0.180")

Single Sided Chisel, Fine Pitch N/A 1.5mm (.06")

Angled MiniWave, Fine Pitch N/A 1.6mm (.064")

MicroFine Single Sided Chisel N/A 0.9mm (.035”)

MicroFine Single Sided Chisel N/A 1.1mm (.045”)

MicroFine Conical N/A 0.25mm (.01”)

MicroFine Bent Conical N/A 0.76mm (.03”)

MicroFine Bent Conical N/A 0.5mm (.02”)

Angled Micro-Wave N/A 1.1mm (.045")

Micro-Wave N/A 1.1mm (.045")

Angled Chisel 8.4mm (0.33") 1.33mm (0.051")

Single Sided Chisel 17.00mm (0.693") 4.55mm (0.178")

1124-0021-P1

1124-0022-P1

1124-0023-P1

1124-0024-P1

1124-0025-P1

1124-0026-P1

1124-0027-P1

1124-0028-P1

1124-0029-P1

1124-0030-P1

1124-0031-P1

1124-0032-P1

1124-0033-P1

1124-0034-P1

1124-0035-P1

1124-0036-P1

1124-0037-P1

1124-0038-P1

1124-0039-P1

1124-0040-P1

1124-0041-P1

1124-0042-P1

1124-0043-P1

1124-0044-P1

1124-0045-P1

1124-0046-P1

1124-0047-P1

1124-0048-P1

18 19

Page 11

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

UNIQUE TO PACE... PATENTED DIAMOND/IRON PLATING PROCESS USING

REAL DIAMONDS THAT PROVIDES IMPROVED THERMAL PERFORMANCE AND

LONG LIFE WHEN WORKING WITH LEAD FREE SOLDER

DIAMOND SERIES EXTENDED LIFE SOLDERING TIPS

FOR USE WITH THE TD-100

PROFILE DESCRIPTION PART NUMBER

.016 Conical 1126-0601-P1

.039 Conical 1126-0602-P1

.055 Conical, Blunt 1126-0603-P1

.031 Conical, Blunt 1126-0604-P1

.016 Conical, Long 1126-0605-P1

.016 Conical 1126-0606-P1

.016 Conical, Extended 1126-0607-P1

.024 Conical 1126-0608-P1

.039 Conical 1126-0609-P1

.031 Conical 1126-0610-P1

.047 Conical 1126-0611-P1

.016 Conical Bent 1126-0612-P1

.016 Conical, Blunt, Bent 1126-0613-P1

.016 Conical, Blunt 1126-0614-P1

.016 Conical Extended, Bent 1126-0615-P1

.157 Bevel, 45 Degree 1126-0616-P1

.078 Bevel, 60 Degree 1126-0617-P1

.118 Bevel, 60 Degree 1126-0618-P1

.157 Bevel, 45 Degree Tinned on

edge/face

.039 Bevel, 60 Degree, Extended 1126-0620-P1

.039 Bevel, 45 Degree

Tinned on edge / face

.078 Bevel, 45 Degree

Tinned on edge / face

.118 Bevel, 45 Degree

Tinned on edge / face

.039 Bevel, 45 Degree 1126-0624-P1

* Drawings are representative of tips actual shape. Actual tips may differ somewhat, other than front end geometry.

1126-0619-P1

1126-0621-P1

1126-0622-P1

1126-0623-P1

PROFILE DESCRIPTION PART NUMBER

.06 Wide, Bevel 60 Degrees,

.12x.06 Oval Face

.07 Bevel, 60 Degree 1126-0626-P1

.078 Bevel, 45 Degree 1126-0627-P1

.13 Bevel, 60 Degree 1126-0628-P1

.118 Bevel, 45 Degree 1126-0629-P1

.023 Bevel, Special 1126-0630-P1

.031 Chisel Standard 1126-0631-P1

.047 Chisel Standard 1126-0632-P1

.062 Chisel Standard 1126-0633-P1

.094 Chisel Standard 1126-0634-P1

.157 Chisel Standard 1126-0635-P1

.205 Chisel Standard 1126-0636-P1

.157 Chisel Long Reach 1126-0637-P1

.205 Chisel Long Reach 1126-0638-P1

.078 Chisel Blunt 1126-0639-P1

.125 Chisel Blunt 1126-0640-P1

.055 Chisel, Bent 30 Degrees 1126-0641-P1

.062 Chisel, Bent 30

Degrees

.055 Chisel, Bent, Extended 1126-0643-P1

.185 Knife, 45 Degree 1126-0644-P1

.181 Knife, 45 Degree 1126-0645-P1

.185 Knife, 45 Degree,

Blunt

.118 Knife, 45 Degree 1126-0647-P1

Single Sided Chisel .08

Wide

1126-0625-P1

1126-0642-P1

1126-0646-P1

1126-0648-P1

TD-100 SMT REMOVAL TIPS

TIP SPECIFICATIONS

TIP - CHIP/SOT REMOVAL COMPONENT TYPE SIZE - A SIZE - B PART NUMBER

Chip 0402 Angle (fig. A) 2.2mm (.085”) - 1124-0581-P1

(fig. A)

(fig. B)

(fig. C)

(fig. D)

TIP - SOIC/SOP/TSOP REMOVAL COMPONENT TYPE SIZE - A SIZE - B PART NUMBER

TIP - SOIC/SOP/TSOP REMOVAL COMPONENT TYPE SIZE - A SIZE - B PART NUMBER

TIP - SOIC/SOP/TSOP REMOVAL COMPONENT TYPE SIZE - A SIZE - B PART NUMBER

(fig. E)

(fig. F)

(fig. G)

Chip 0201 Angle (fig. A) 0.5mm (.02”) - 1124-0533-P1

Chip 1808 (fig. B) 5.0mm (.195”) - 1124-0520-P1

Chip 0402 (fig. C) 1.0mm (.40”) - 1124-0521-P1

Chip 0201 (fig. C) 0.5mm (0.2”) - 1124-0534-P1

SOT 23 (fig. D) 1.8mm (.070”) - 1124-0522-P1

SOT 89 (fig. E) 2.8mm (.110”) - 1124-0523-P1

Chip 1206 (fig. F) 3.6mm (.142”) - 1124-0524-P1

Chip 0805 (fig. G) 2.4mm (.095”) - 1124-0525-P1

SOIC 14/16 5.2mm (.205”) 10.5mm (.415”) 1124-0504-P1

SOIC 20 9.6mm (.377”) 13.6mm (.535”) 1124-0505-P1

SOP 28 10.8mm (.426”) 18.6mm (.734”) 1124-0506-P1

SOP 40 11.9mm (.467”) 25.7mm (1.011”) 1124-0507-P1

SOP 44 13.1mm (.516”) 28.4mm (1.120”) 1124-0508-P1

TSOP 56 18.8mm (.739”) 14.1mm (.557”) 1124-0509-P1

TSOP 28 12.0mm (.471”) 8.5mm (.333”) 1124-0510-P1

SOIC 8 5.1mm (.202”) 4.65mm (.183”) 1124-0519-P1

TSOP 40 18.8mm (.740”) 10.4mm (.410”) 1124-0526-P1

PLCC 28 Socket 9.3mm (.365”) 9.3mm (.365”) 1124-0511-P1

PLCC 32 14.2mm (.561”) 11.7mm (.459”) 1124-0512-P1

PLCC 44 16.8mm (.622”) 16.8mm (.622”) 1124-0513-P1

QFP 144 20.6mm (.810”) 20.6mm (.810”) 1124-0514-P1

PLCC 28 11.8mm (.465”) 11.8mm (.465”) 1124-0515-P1

QFP 100/128 22.0mm (.865”) 16.0mm (.628”) 1124-0516-P1

PLCC 18 7.6mm (.300”) 12.8mm (.505”) 1124-0528-P1

TQFP 80 12.5mm (.491”) 12.5mm (.491”) 1124-0529-P1

PLCC 52 19.4mm (.762”) 19.4mm (.762”) 1124-0530-P1

QFP 100 26.6mm (1.048”) 26.6mm (1.048”) 1124-0531-P1

VQFP 100 15.5mm (.610”) 15.5mm (.610”) 1124-0535-P1

TQFP 64 15.3mm (.602”) 15.3mm (.602”) 1124-0537-P1

Blade 6mm (.236”) - 1124-0536-P1

Blade 10.8mm (.425”) - 1124-0501-P1

Blade 16.0mm (.630”) - 1124-0502-P1

Blade 21.2mm (.835”) - 1124-0503-P1

Blade 25.0mm (.984”) - 1124-0532-P1

20 21

Page 12

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

MT-100 AND TP-100 SMT REMOVAL TIPS

TIP SPECIFICATIONS

PS-90 SOLDERING TIPS

TIP SPECIFICATIONS

MT-100 TIPS

TIP - CHIP/SOT REMOVAL COMPONENT TYPE SIZE - A SIZE - B PART NUMBER

Chip (fig. A) 0.2mm (.008”) 0.2mm (.008”) 1124-1001-P1

(fig. A) (fig. B)

(fig. C)

Chip, SOT (fig. B) 0.7mm (.03”) 0.5mm (.03”) 1124-1002-P1

Chip, SOT (fig. B) 0.7mm (.03”) 1mm (.04”) 1124-1003-P1

Chip, SOT (fig. B) 0.7mm (.03”) 2mm (.08”) 1124-1004-P1

Chip, SOT, TSOPS (fig. C) 0.7mm (.03”) 6mm (.24”) 1124-1005-P1

Chip, SOT, TSOPS (fig. C) 0.7mm (.03”) 8mm (.31”) 1124-1006-P1

Chip, SOT, TSOPS (fig. C) 0.7mm (.03”) 10mm (.39”) 1124-1007-P1

Chip, SOT, TSOPS (fig. C) 0.7mm (.03”) 13mm (.51”) 1124-1008-P1

Chip, SOT, TSOPS (fig. C) 0.7mm (.03”) 18mm (.74”) 1124-1009-P1

Chip, SOT, TSOPS (fig. C) 0.7mm (.03”) 28mm (1.09”) 1124-1010-P1

TP-100 TIPS

TIP TYPE LEAD COUNT SIZE - A SIZE - B

LQFP/TQFP 80 12mm (.472”) 12mm (.472”) 1.4mm 2.0mm 1124-2001-P1

A

B

LQFP/TQFP

LQFP/TQFP

LQFP/TQFP 176, 216 24mm (.945”) 24mm (.945”) 1.4mm 2.0mm 1224-2004-P1

64, 80,100,

120, 128, 168

128, 144,

160, 176

14mm (.551”) 14mm (.551”) 1.4mm 2.0mm 1124-2002-P1

20mm (.788”) 20mm (.788”) 1.4mm 2.0mm 1124-2003-P1

COMPONENT

HEIGHT

COMPONENT

FOOTPRINT

PART NUMBER

TIPS DESCRIPTION TIP SIZE PART NUMBER

1/16" Chisel 1.60mm (0.063")

1/32" Conical 0.80mm (0.031")

1/8" Chisel 3.20mm (0.125")

1/16" Chisel (MicroFine) 1.60mm (0.063")

1/32" Chisel 0.80mm (0.031")

3/32" Chisel 2.40mm (0.094")

1/32" Bent Chisel 0.80mm (0.031")

Single-Sided Chisel 3.30mm (0.13")

1/16" Chisel (High Capacity) 1.60mm (0.063")

Mini-Wave 3.30mm (0.13")

1/16" Chisel, Long Reach 1.60mm (0.063")

1121-0335-P5

1121-0336-P5

1121-0337-P5

1121-0349-P5

1121-0359-P5

1121-0360-P5

1121-0361-P5

1121-0406-P5

1121-0414-P5

1121-0490-P5

1121-0499-P5

LQFP/TQFP 208, 256 28mm (1.10”) 28mm (1.10”) 1.4mm 2.0mm 1224-2005-P1

QFP

QFP

QFP

QFP

QFP

QFP 160 28mm (1.10”) 28mm (1.10”) 3.4mm 3.9mm 1124-2011-P1

22 23

52, 64, 80,

100

52, 64, 80,

100

64, 80, 100,

128

64, 80, 100,

128

120, 128,

144, 160, 208

14mm (.551”) 14mm (.551”) 2.7mm 3.2mm 1124-2006-P1

14mm (.551”) 14mm (.551”) 2.7mm 3.9mm 1124-2007-P1

14mm (.551”) 20mm (.788”) 2.7mm 3.2mm 1124-2008-P1

14mm (.551”) 20mm (.788”) 2.7mm 3.9mm 1124-2009-P1

28mm (1.10”) 28mm (1.10”) 3.4mm 3.9mm 1124-2010-P1

1/16" Bent Chisel, Long Reach 1.60mm (0.063")

1/16" Chisel, Extended Reach 1.60mm (0.063")

Angled Mini-Wave 2.40mm (0.09")

1/64" Sharp Bent Conical 0.40mm (0.016")

1121-0500-P5

1121-0533-P5

1121-0610-P5

1121-0830-P5

Page 13

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

PS-90 SMT REMOVAL TIPS

TIP SPECIFICATIONS

SX-90 DESOLDERING TIPS & SOLDER REMOVAL TIPS

TIP SPECIFICATIONS

TIPS DESCRIPTION TIP SIZE PART NUMBER

(fig. B)

(fig. A)

(fig. C)

SOIC - 8 (JEDEC) (fig.A)

SOIC - 14 (JEDEC) (fig.A)

SOIC - 16 (JEDEC) (fig.A)

Chip Component (fig.B)

TSOP (fig.C)

Flat Blade Tip A = 7.6mm (0.3")

Flat Blade Tip A = 10.2mm (0.4")

Flat Blade Tip A = 12.7mm (0.5")

Flat Blade Tip A = 17.8mm (0.7")

5.05mm x 5.08mm

(0.199" x 0.200")

5.05mm x 8.99mm

(0.199" x 0.354")

5.05mm x 10.2mm

(0.199" x 0.404")

3.56mm x 2.03mm

(0.14" x 0.08")

19.333mm x 8.1mm

(0.76" x 0.32")

1121-0390-P1

1121-0391-P1

1121-0392-P1

1121-0303-P1

1121-0403-P1

1121-0512-P1

1121-0514-P1

1121-0473-P1

1121-0416-P1

TIPS SELECTION One of the most important aspects for successful solder removal is the selection of the proper size tip. There are

several points to keep in mind.

1. The Inside Diameter (I.D.) of the tip must be large enough to

fit over the lead, while providing sufficient room so that air and

solder can be drawn through the tip.

TIPS DESCRIPTION DIAMETER PART NUMBER

Thermo-Drive 0.76mm (0.030”) I.D. x 2.03mm (0.080”) O.D. 1121-0930-P5

Thermo-Drive 1.02mm (0.040”) I.D. x 2.29mm (0.090”) O.D. 1121-0931-P5

Thermo-Drive 1.52mm (0.060”) I.D. x 3.05mm (0.120”) O.D. 1121-0932-P5

Thermo-Drive 2.29mm (0.090”) I.D. x 5.1mm (0.200”) O.D. 1121-0933-P5

Thermo-Drive 4mm (0.16”) I.D. x 5.1mm (0.200”) O.D. 1121-0951-P5

Thermo-Drive, Flathead (0.050”) x (0.090”) I.D. x (0.110”) x (0.190”) O.D. 1121-0934-P5

Extended Reach Thermo-Drive 0.78mm (0.030”) I.D. x 2.29mm (0.090”) O.D. 1121-0935-P5

Extended Reach Thermo-Drive 1.02mm (0.040”) I.D. x 2.54mm (0.10”) O.D. 1121-0936-P5

Extended Reach Thermo-Drive 1.52mm (0.060”) I.D. x 3.05mm (0.120”) O.D. 1121-0937-P5

ThermoMax 0.76mm (0.030”) I.D. x 1.91mm (0.075”) O.D. 1121-0938-P5

ThermoMax 1.02mm (0.040”) I.D. x 2.20mm (0.085”) O.D. 1121-0939-P5

2. The Outside Diameter (O.D.) of the tip must be slightly

smaller than the diameter of the pad to prevent tip contact to the

board laminate and minimize the possibility of damage.

ThermoMax 1.52mm (0.060”) I.D. x 2.69mm (0.106”) O.D. 1121-0940-P5

Flat Blade Tip A = 20.3mm (0.8")

Flat Blade Tip A = 25.4mm (1.0")

24 25

1121-0497-P1

1121-0448-P1

Precision 0.50mm (0.020”) I.D. x 1.79mm (0.070”) O.D. 1121-0941-P5

Precision 0.76mm (0.030”) I.D. x 2.03mm (0.080”) O.D. 1121-0942-P5

Precision 1.02mm (0.040”) I.D. x 2.29mm (0.090”) O.D. 1121-0943-P5

Precision 1.52mm (0.060”) I.D. x 2.79mm (0.110”) O.D. 1121-0944-P5

Precision 0.635mm (0.025”) I.D. x 1.39mm (0.055”) O.D. 1121-0949-P5

Precision 0.635mm (0.025”) I.D. x 1.14mm (0.045”) O.D. 1121-0950-P5

Flo-D-Sodr 1.52mm (0.060") I.D. X 4.78mm (0.188") O.D. 1121-0945-P5

Flo-D-Sodr, Precision 0.50mm (0.020") I.D. X 1.78mm (0.070") O.D. 1121-0946-P5

Flo-D-Sodr, Precision 0.50mm (0.020") I.D. X 1.78mm (0.070") O.D. 1121-0947-P5

Flo-D-Sodr, Precision 1.02mm (0.040") I.D. X 2.29mm (0.090") O.D. 1121-0948-P5

Not suitable for use with SX-70 or SX-80

Page 14

M O R E T H A N 5 0 Y E A R S O F I N D U S T R Y L E A D E R S H I P

S O L U T I O N S F O R T H E E L E C T R O N I C S I N T E R C O N N E C T I O N P R O C E S S

TT-65 SMT REMOVAL TIPS & HOT JET NOZZLES

TIP SPECIFICATIONS

PRODUCT PAGE

FOR A COMPLETE PRODUCT LISTING CONTACT PACE OR VISIT www.paceworldwide.com

TT-65 SMT REMOVAL TIPS

CHIP REMOVAL TIPS DESCRIPTION TIP SIZE PART NUMBER

SOIC, SOJ, SIMMs A=10.2mm (0.4")

SOIC, SOJ, SIMMs A=12.7mm (0.5")

SOIC, SOJ, SIMMs A=17.8mm (0.7")

SOIC, SOJ, SIMMs A=20.3mm (0.8")

SOIC, SOJ, SIMMs A=25.4mm (1.0")

Chip Component A=0.76mm (0.03")

Chip Component A=2.0mm (0.08")

Chip Component A=4.1mm (0.16")

Chip Component, Small SOIC A=6.4mm (0.25")

Thin-Walled Chip Component A=0.76mm (0.03")

Thin-Walled Chip Component A=2.0mm (0.08")

1121-0514-P1

1121-0473-P1

1121-0416-P1

1121-0497-P1

1121-0448-P1

1121-0398-P1

1121-0313-P1

1121-0399-P1

1121-0401-P1

1121-0520-P1

1121-0521-P1

1/64" Angled Fine Point Conical A=0.43mm (0.017") 1121-0517-P1

PLCC REMOVAL TIPS DESCRIPTION TIP SIZE A x B PART NUMBER

PLCC-20 6.86mm x 6.86mm (0.27" x 0.27")

PLCC-28 9.4mm x 9.4mm (0.37" x 0.37")

PLCC-32 12.2mm x 9.65mm (0.48" x 0.38")

PLCC-44, PQFP-84 14.5mm x 14.5mm (0.57" x 0.57")

PLCC-52, PQFP-100 17.0mm x 17.0mm (0.67" x 0.67")

PLCC-68, PQFP-132 21.9mm x 21.9mm (0.86" x 0.86")

PLCC-84, PQFP-160 26.9mm x 26.9mm (1.06" x 1.06")

1121-0316-P1

1121-0317-P1

1121-0352-P1

1121-0318-P1

1121-0319-P1

1121-0320-P1

1121-0321-P1

TT-85 HOT JET NOZZLES

TIPS DESCRIPTION TIP SIZE PART NUMBER

PACE provides innovative solutions, products and training for the assembly, rework, repair and testing of printed circuit boards.

PACE’s unique capabilities and evolving vision have provided universal solutions to thru-hole and surface-mount assembly and rework

problems for the most advanced electronics. Our strong commitment and history of achievement has resulted in an unparalleled range

of Assembly, Repair and Fume Extraction systems to meet your company’s needs whether working to ISO-9000, industrial, military or

your own internal specifications. Whatever the challenge, PACE stands ready to provide the best, cost-effective solution for you.

ST SYSTEMS ST 30 ST 50 ST 70 ST 115

PACE’s new ST systems offer the most

innovative control technology ever

developed - IntelliHeat. ST systems are

capable of providing the widest range

of applications and flexibility by

simply adding additional handpieces.

Regardless if you are a small or

large shop, ST systems are the right

answer for you!

FUME EXTRACTION ARM-EVAC 105 ARM-EVAC 250 FUMEFLO WORKTABLE ARM-EVAC 50

PACE’s Fume Extraction Systems

feature the latest advancements in

filter condition monitoring and process

control as well as cost effective

solutions. A variety of collection

accessories are available.

MBT/PRC SYSTEMS MBT 350 PRC 2000

PACE offers a broad range of rework

and repair products to meet all your

repair needs. Whether you are

replacing a surface mount component,

repairing a multi-layer printed circuit

board, or making a plated thru-hole

repair.

THERMOFLO SYSTEMS TF 1700 TF 2700 XR 3000

PACE’s family of ThermoFlo products

offer complete solutions from simple

surface mount removal and installation

to delicate BGA and CSP rework.

PACE’s new inspection systems feature

X-Ray and endoscopic technology

to really “SEE” the results of your

processes.

ST 30 ST 50 ST 70 ST 100 ST 115

TF 1700 TF 2700 XR 3000

Round Nozzle 1.5mm (.06”) Inner diameter

Round Nozzle, Bent 60 degrees 1.5mm (0.6”) Inner diameter

Flat Jet Nozzle

6.1mm x 1.9mm (.24” x .074”)

Inner flow dimensions

1259-0129-P1

1259-0130-P1

1259-0131-P1

CONVECTIVE & PRE-HEAT

PACE’s new family of hot air

rework systems are ideal for all

SMT applications. A wide range of

product features are available to

meet your specific needs. They can

be easily upgraded by adding one

of our powerful preheaters and/or

PCB holders.

ST 300 ST 350 ST 525 ST 450

26 27

Page 15

Loading...

Loading...