Page 1

TP-65

TP-65 THERMOPIK HANDPIECE

OPERATION & MAINTENANCE INSTRUCTIONS

Page 2

PACE Incorporated retains the right to make changes to specifications

contained herein at any time, without notice.

Contact your local authorized PACE Distributor or PACE Incorporated to obtain

the latest specifications.

The following are registered trademarks and/or servicemarks of PACE

Incorporated, Laurel Maryland U.S.A. and may only be used to identify genuine

PACE products or services:

Arm-Evac, Mini-Wave, PACE, SensaTemp, Snap-Vac, Sodrtek, Sodr-XTractor, ThermoFlo, ThermoJet, ThermoTweez, ToolNet, VisiFilter

Since 1958, PACE Incorporated has provided advanced

technology training in all aspects of hand soldering, rework and

repair.

For any questions regarding the following instructions, contact your local

authorized PACE dealer or contact PACE directly at:

Toll Free: 1-888-535-7223, Fax : (301) 604-8782

PACE Incorporated

9893 Brewers Court

Laurel MD 20723-1990

© 2000 PACE Incorporated, Laurel MD. All rights reserved. Printed in the U.S.A.

Page 3

variety of FlatPacks (FPs) and Plastic Quad Flat Packs (PQFPs) in a matter of

The TP-65 uses a conductive heat transfer process which is very efficient and

which typically allows component removal at temperatures in the 316 - 343°C

temperature setting for initial use in most applications. You should determine

TP-65

THERMOPIK HANDPIECE

PACE P/N 7024-0001

OPERATION & MAINTENANCE

INSTRUCTIONS

MANUAL NUMBER 5050-0335

REV. C

INTRODUCTION

The TP-65 ThermoPik handpiece provides safe, one-handed removal of a wide

seconds. The ThermoPik is a member of the PACE SensaTemp family of

advanced SMT/Thru-Hole handpieces.

(600 - 650°F) range. PACE recommends the use of a 316°C (600°F) tip

the lowest possible removal temperature to work with on your board and

component types. A low temperature extends tip life.

NOTE

Always use this handpiece in a well ventilated area to avoid the inhalation

of fumes created by the heating of solder flux.

Remember that the ThermoPik is a component removal tool and is not

intended for installation of components. Other SensaTemp handpieces

are designed for component installation.

Page 4

HANDPIECE SETUP

Use the following procedures to set up your handpiece.

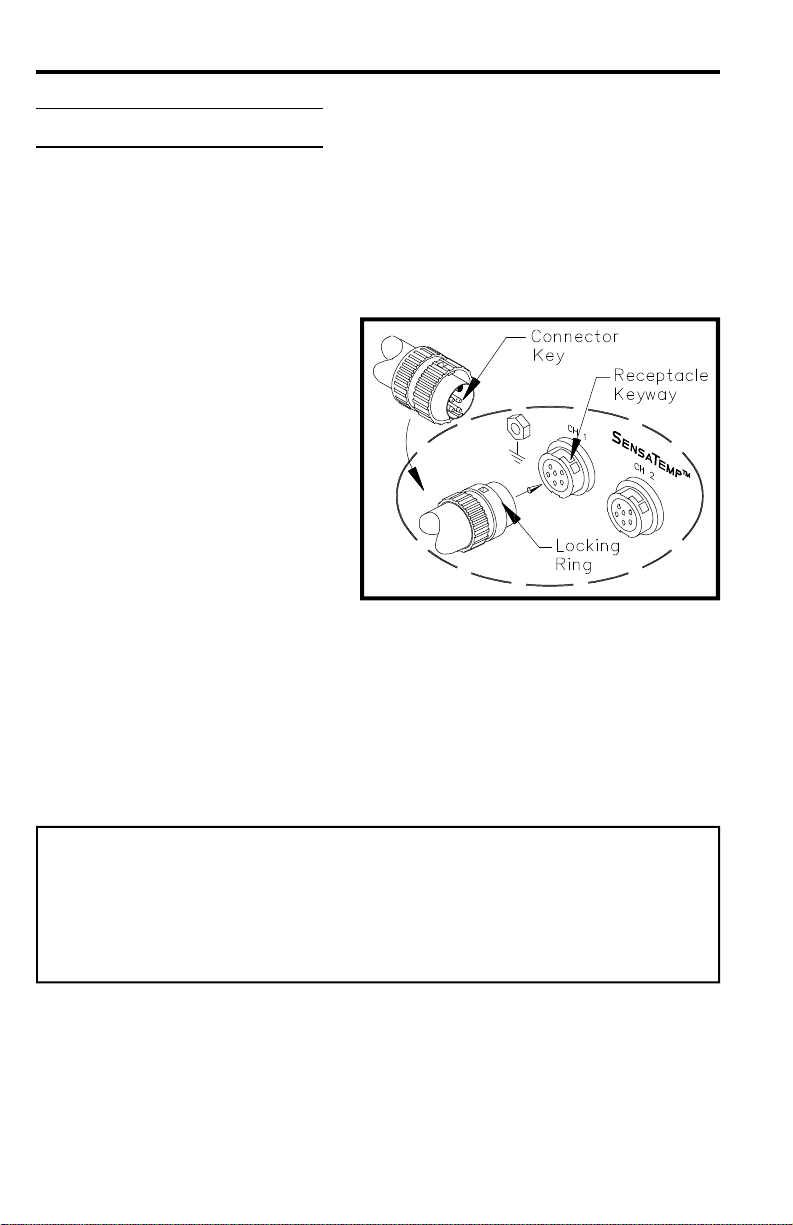

Power Receptacle Connection

Connect the handpiece power

cable plug to one of the power

receptacles on your PACE power

source. PACE recommends that

air handpieces utilize the power

receptacles closest to the AUTO

SNAP-VAC (or SNAP-VAC) and

Controllable PRESSURE Ports

to minimize cord tangles. Refer

to the Operation & Maintenance

Manual included with your power

source for details.

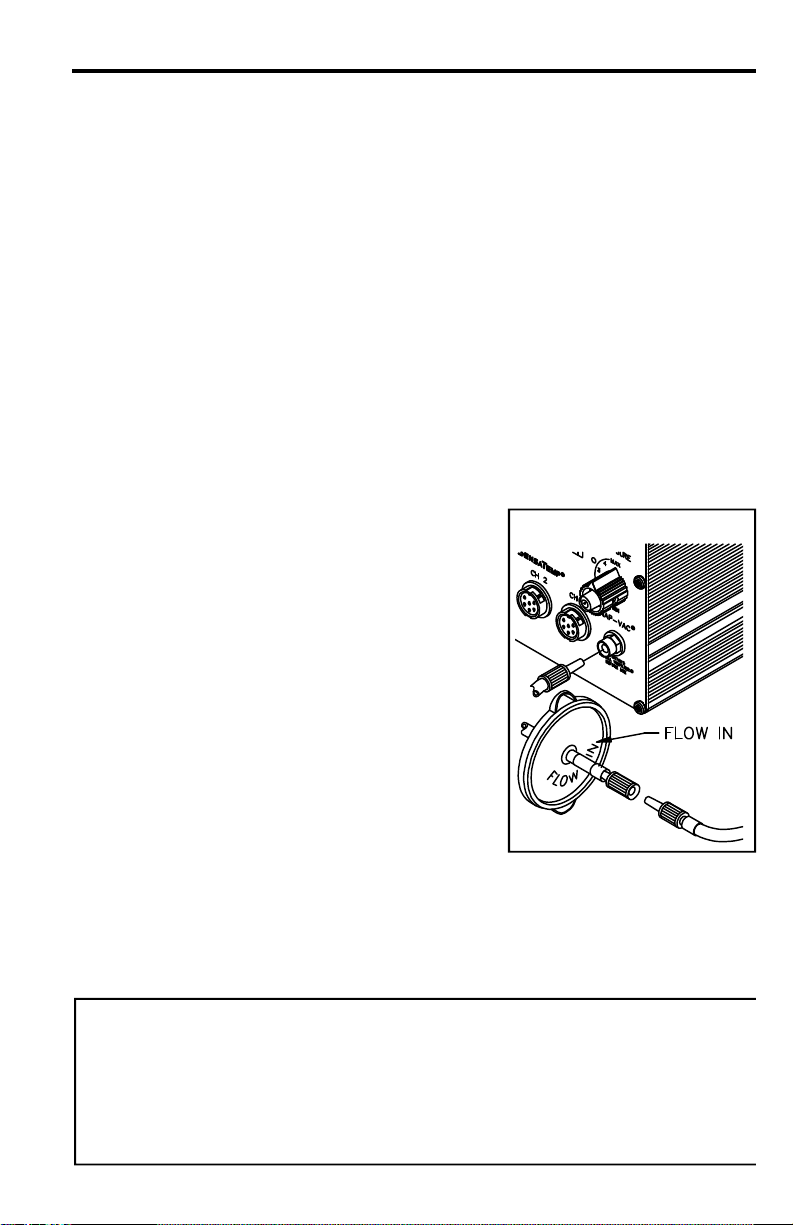

Air Hose Connection

There are two methods of attaching the air hose from the PACE power source

to the TP-65. Select the method which best suits your needs. The Quick

Connect Method is best suited for SensaTemp handpiece configurations where

multiple air handpieces may be in use. The Traditional Method is best suited

for single air handpiece configurations.

CAUTION

Regardless of connection method, ensure that only one air hose is

connected to the power source AUTO SNAP-VAC (or SNAP-VAC) or

Controllable PRESSURE Port at one time. Attachment to both ports

simultaneously will cause a deterioration of performance.

Page 5

QUICK CONNECT METHOD

To set up your TP-65 for the quick connect operation, perform the following steps.

1. Attach a 2.5cm length (1 inch) of clear pvc air hose (P/N 1325-0003-

07) to the metal tube in the back of the handpiece.

2. To the other end of the 2.5cm length (1 inch) clear pvc air hose attach

a female quick connect hose mount fitting (P/N 1259-0086).

3. Prepare a quick connect air hose by inserting a male quick connect

hose mount fitting (P/N 1259-0087) into each end of a 137cm (54 inch)

length of air hose. (You may already have this piece if you have other

quick disconnect handpieces configured.)

4. Prepare a VisiFilter in the following manner:

a) Connect a 2.5cm (1 inch) length of air hose to each side of the

VisiFilter.

b) To the free end of the 2.5cm (1 inch) air

hose connected to the FLOW IN side of

the VisiFilter, insert a female quick

connect hose mount fitting (P/N 1259-

0086).

b) To the free end of the 2.5cm (1 inch) air

hose connected to the FLOW OUT side

of the VisiFilter, insert a male quick

connect hose mount fitting (P/N 1259-

0087).

c) Insert the end of the male quick connect

hose mount fitting (on VisiFilter FLOW

OUT side) into the power source AUTO

SNAP-VAC (or SNAP-VAC) Port.

5. Connect the male fitting of the 137cm (54 inch) length of air hose to

the female quick connect hose mount fitting on 2.5cm (1 inch) air hose

(connected to VisiFilter) for desoldering, or into the Controllable

PRESSURE Port for hot air jet operation.

NOTE

When removing any air hose, turn and pull. Do not attempt to pull hose directly

off. Damage to or breakage of fitting or VisiFilter may occur. Use your TP65 ThermoPik with a clean VisiFilter element . Otherwise a deterioration in

performance or damage to the unit may occur.

Page 6

TRADITIONAL METHOD

1. Connect the 137cm (54 inch) length of air hose to the metal tube in

the back of the handpiece.

2. Insert a male quick connect hose mount fitting (P/N 1259-0087) to

the free end of the 137cm (54 inch) length of air hose.

3. Secure the air hose to the handpiece power cable with cable clips

(P/N 1321-0085-01).

4. Prepare a VisiFilter in the same manner as in steps 4 & 5 of the

"Quick Connect Method".

TIP SELECTION

Selection of the proper tip is essential for effective operation. Attempts to use

an improperly sized tip will result in unsatisfactory handpiece operation and

may result in lifted lands or board damage.

Table I details a partial listing of available tips. Contact your local authorized

PACE dealer for the latest Tips & Accessories Catalogue which details all

available tips.

TIP INSTALLATION

1. Carefully remove any installed vacuum cup from the TP-65 using the

tip tool and set aside.

2. Select the proper tip for your application. Refer to Table I.

3. Insert the tip shaft fully into the heater bore.

4. Using the tip tool, tighten the heater assembly set screw for a snug

fit. Do not over tighten.

5. Install the vacuum cup set aside in step #1 onto the vacuum pickup

rod. Utilize the tip tool to install the vacuum cup if the tip is hot.

NOTE

The TP-65 tips must be kept properly tinned and free of oxidation to ensure

that optimum heat transfer will take place. Refer to the "Tip Preparation"

portion of this manual.

Page 7

TIP

TIP DESCRIPTION

TIPTIP

B

A

APPLICATION

DESCRIPTION

DESCRIPTIONDESCRIPTION

FlatPack Tip

FlatPack Tip

PQFP-68 Tip

(bumper pack)

PQFP-64/80 Tip

(non-bumper pack)

PQFP-84 Tip

PQFP-100 Tip

PQFP-132 Tip

PQFP-160 Tip

PQFP-208 Tip

PQFP-196 Tip

All dimensions are nominal, inside diameters. Consult

your authorized PACE Distributor for sizes not listed

PQFP-144

PQFP-208

TIP SIZE

TIP SIZE

TIP SIZETIP SIZE

A X B

A X B

A X BA X B

15.5 x 21.6mm

(0.61 x 0.85")

16.8 x 22.9 mm)

(0.66 x 0.90")

15.7 x 15.7mm

(0.62 x 0.62")

15.7 x 15.7mm

(0.62 x 0.62")

18.3 x 18.3mm

(0.72 x 0.72")

20.8 x 20.8mm

(0.82 x 0.82")

25.9 x 25.9mm

(1.02 x 1.02")

29.2 x 29.2mm

(1.15 x 1.15")

30.0 x 30.0mm

(1.18 x 1.18")

31.0 x 31.0mm

(1.22 x 1.22")

36.3 x 36.3mm

(1.43 x 1.43")

NOTE:

PART

PART

PARTPART

NUMBER

NUMBER

NUMBERNUMBER

1121-0322-001

1121-0322-002

1121-0323

1121-0484

1121-0324

1121-0325

1121-0326

1121-0456

1121-0544

1121-0351

1121-0483

Table I. ThermoPik Tip Selection Guide

7

Page 8

TIP AND PICK ALIGNMENT

For the TP-65 to operate at its maximum efficiency (maximum heater to tip

heat transfer), the tip must be fully inserted into the heater bore and properly

secured. Due to large physical size and tip mass, the TP-65 has Tip Offset

Constants that range from 34°C (62°F) to 112°C

(201°F).

The vacuum pick assembly within the TP-65

handpiece comes factory adjusted for most

QFP components. A vacuum pick setting where

the vacuum cup makes contact with the

component body as the tip makes contact with

the component leads is the recommended

starting point. A good vacuum must be

maintained to quickly remove the component.

Use the following procedure and accompanying

illustrations if adjustment is necessary.

NOTE

The factory setting of the collars on the vacuum pick is 74mm (2.9inches)

from the end of the pick rod to the front edge of the first collar. This setting

is correct for removal of most components.

1. Using the tip tool, remove the vacuum cup and set aside.

2. Remove the handpiece rear seal and compression spring and set

aside.

3. Slide out the vacuum tube assembly and locate the two Collars.

4. Adjust the Collars in the following manner:

a) Loosen the set screw in the Collar closest to point "A" to adjust

for increased component height or the Collar closest to point "B"

for decreased component height. Adjust the Pick position for

your component. Tighten set screw to secure in position.

b) Loosen the set screw of the second Collar and adjust collar so

that the Washer is snug between the two collars yet free to

rotate. Tighten set screw to secure in position.

5. Reassemble the vacuum pick in reverse order.

Page 9

A

74mm

(2.9")

B

Page 10

TIP PREPARATION

The TP-65 tips must be kept properly tinned and free of oxidation to ensure

that optimum heat transfer will take place at all times. Tips must be kept

properly tinned and free of oxidation to ensure that optimum heat transfer will

take place.

Tin the tip using the following procedure.

1. Clean all bottom edges of the installed

tip using the P ACE fiber cleaning tool.

2. Shock the bottom edges of the installed

tip using a moist P ACE sponge tool.

3. Apply a continuous bead of solder along

the bottom edges of the installed tip.

TIP TEMPERATURE

P ACE recommends the use of a 316°C (600°F) tip temperature setting for

initial use in most applications. A low temperature extends tip life. You

should determine the lowest removal temperature to work with on your board

and component types.

Refer to the Tip & T emperature Selection System Chart (P/N 5050-0251

booklet) for your particular handpiece/tip combination. For all Dial/Display

systems, the booklet will indicate the correct Dial/Display setting for the True

Tip Temperature desired. On systems incorporating a Digital Readout, set the

desired operating temperature and Tip Offset Constant for the TP-65

handpiece/tip combination.

PCB/COMPONENT PREPARATION

Proper preparation is the key to successful component removal. Use the

following procedure to obtain optimum results.

PCB Preparation

1. Clean the component leads and PCB land areas using an approved

solvent or cleaner.

2. Ensure that the PCB is free of moisture.

3. Preheat the PCB as necessary. PCBs consisting of heat sinking

materials (e.g., ceramic, polyamide, etc.) or those with an

exceptionally heavy ground or power planes may require the use of a

preheater such as the P ACE Heat Wave.

10

Page 11

Component Preparation

1. Remove any protective coatings and clean the component leads

and land areas using an approved solvent or cleaner.

2. Ensure that the PCB is free of moisture.

3. Preheat the PCB as necessary . PCBs consisting of heat sinking

materials (e.g., ceramic, polyamide, etc.) or those with an

exceptionally heavy ground or power planes may require the use of

a preheating system such as the P ACE Heat W ave.

4. In order to maximize heat transfer from the handpiece tip to PQFP

component lead/land connections, P ACE recommends adding

bridgefill ..............

solder wrap ..........

or

flux ......................

to maximize heat transfer across

all connections.

11

Page 12

COMPONENT REMOVAL

Use the following procedure to remove the component. Ensure that the

component and board have been properly prepared (see "Board/Component

Preparation") before removing component. The technique shown is the

Bridgefill Method.

PROCEDURE

1. Ensure that all Board/

Component Preparation has

been performed.

2. St art with a tip temperature of

315°C (600°F) and adjust as

necessary.

3. Enter Tip Offset Constant for the

selected tip.

4. Install QFP Removal Tip into

ThermoPik using Tip T ool.

5. Install vacuum cup onto vacuum

pick tube using Tip Tool.

6. Remove old solder from tip with

sponge. Tin inside and bottom

edges of tip with solder.

7. Lower tip over component

contacting ALL leads with tip

(see &).

8. Confirm solder melt of ALL

joints, apply vacuum and lift

component from PCB (see

&).

12

Page 13

9. Release component onto a heat resistant surface.

10. Re-tin tip with solder and return ThermoPik to its Tip & Tool Stand.

11. Prepare lands for component replacement.

Use the SX-80 Sodr-X-Tractor handpiece to remove the old solder from the

PCB and to prepare the lands for accepting a new part. Refer to one of the

SX-80 Sodr-X-Tractor manuals for suggested solder removal techniques.

SPECIAL APPLICATIONS

If you require assistance in the use of this handpiece or require assistance

with a special application, contact PACE Product Management at:

Telephone: (301) 490 - 9860

Fax: (301) 604 - 8782

Page 14

CORRECTIVE MAINTENANCE

Your TP-65 requires no special maintenance other than being kept clean. The

heater bore and the heater assembly set screw which secures the tip must be

kept free of oxidation and debris in order to maintain the proper tip to ground

resistance. Periodically inspect the power cable, connector and handpiece

itself for evidence of physical damage. Do not use a handpiece with a

damaged power cable. Refer to Table II and the illustration following for

information on troubleshooting most handpiece problems. Table III lists the

common handpiece parts.

Use Table II and the Connector Plug illustration to determine the condition of

your TP-65 ThermoPik handpiece. Disconnect the handpiece from the PACE

power source. Use a voltmeter to check the resistance across the handpiece

Connector Plug pins as outlined in the “Checkout Procedure” column.

NOTE

The handpiece Heater Assembly must be at room temperature (22° C or

72°F) before performing "Heater Assembly Checkout Procedures".

SYMPTOM

No heat Check resistance - Pin 2 to

Handpiece

overheating

Fuse blows

when unit is

turned on

No Ground

on Tip

Pin 5. Resistance should

be 10 ohms.

If not - -

Check resistance - Pin 3 to

Pin 6.

If circuit reads open - -

Check resistance - Pin 3 to

Pin 6. Resistance should

be 110 ohms. If circuit

reads less than 105 ohms - -

Check resistance - Pin 2 to

Pin 5. Resistance should

be 10 ohms.

If not - -

Check resistance - Pin 4 to

a NEW Tip. Resistance

should be less than 2 ohms.

If not - -

CHECKOUT

PROCEDURE

CAUSE SOLUTION

Open

Heater

Open

Sensor

Shorted

Sensor

Shorted

Heater

Oxidation

buildup in

Heater Bore

Defective

Heater

Replace

Heater

Assembly

Replace

Heater

Assembly

Replace

Heater

Assembly

Replace

Heater

Assembly

Clean Heater

Bore using

appropriate

wire brush

Replace

Heater

Assembly

Page 15

Connector Plug Pin Locator

REPLACEMENT P ARTS

PART

DESCRIPTION

Replacement Handle 6993-0140

Heater Assembly 6010-0081-P1

Cord/Switch Assembly 4010-0098-P1

Rear Seal Assembly 4010-0101-P1

Tip (and Vacuum Cup) Tool 1100-0239

NUMBER

Heater Set Screw 1348-0547-P10

Vacuum Cups - - - - - - - -

4.4 mm (0.175") O.D. 1121-0382-P5

7.6mm (0.300") O.D. 1121-0383-P5

12.7mm(0.500") O.D. 1121-0384-P5

Kit (with 3 cups, 1 each size) 6993-0153-P1

SX Tip & Tool Stand 6019-0044-P1

Tip Redi-Rak 6021-0007-P1

Tip Maintenance Station 6993-0138

Table III. TP-65 Replacement Parts

Page 16

PACE USA

9893 Brewers Court

Laurel, MD 20723

U.S.A.

Tel: (301) 490-9860

1-888-535-PACE (7223)

Fax: (301) 498-3252

PACE EUROPE

Sherbourne House,

Sherbourne Drive

Tilbrook, Milton Keynes

MK7 8HX

United Kingdm

Tel: (44) 1908-277666

Fax: (44) 1908-277777

www.paceworldwide.com

Loading...

Loading...